#Stainless Steel Welding

Explore tagged Tumblr posts

Text

Stainless steel welding is a specialized service offered by experienced fabricators and welders. It involves joining stainless steel components using various welding techniques like TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), or stick welding.

0 notes

Text

Revolutionizing Pipe Spool Fabrication with Nikit Engineers: The Future of Welding Automation and Robotic Solutions

In the dynamic landscape of industrial fabrication, the quest for efficiency, precision, and cost-effectiveness has led to significant advancements. Among these, pipe spool fabrication stands out as a vital process in industries ranging from oil and gas to pharmaceuticals and beyond. At the forefront of this evolution is Nikit Engineers Welding Automation and Robotic Solutions, pioneering innovative approaches to enhance the pipe spool fabrication process in India.

Key Takeaways about Pipe Spool Fabrication:

Off-Site Precision: Pipe spool fabrication entails the assembly of pre-cut pipe sections and fittings in a controlled off-site environment. This controlled setting allows for meticulous attention to detail, ensuring precise measurements and welds.

Reduced Construction Time: By fabricating pipe spools off-site, construction time at the installation site is significantly reduced. This streamlined process minimizes downtime, accelerating project completion timelines.

Enhanced Quality Control: Fabricating pipe spools in dedicated facilities enables easier quality management. Rigorous inspection protocols can be implemented, ensuring compliance with industry standards and specifications.

Mitigated Production Delays: Fabrication in specialized facilities mitigates the risk of production delays caused by adverse weather conditions or site-specific challenges. This resilience to external factors enhances project reliability and on-time delivery.

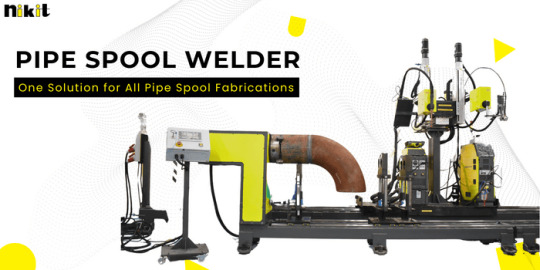

What Is Pipe Spool Fabrication?

Pipe spool fabrication involves the prefabrication of interconnected pipe sections, valves, and fittings into modular units known as spools. These spools are then transported to the installation site for final assembly, significantly simplifying on-site construction.

Pipe Spooling Application

The versatility of pipe spooling extends across various industrial sectors, including:

Oil and Gas: Pipeline networks for transportation and distribution.

Chemical Processing: Complex piping systems for chemical production.

Power Generation: Steam and water piping for thermal and nuclear power plants.

Pharmaceutical: Hygienic piping for pharmaceutical manufacturing facilities.

HVAC: Heating, ventilation, and air conditioning systems in commercial and industrial buildings.

Why Are Pipe Spools Prefabricated?

The prefabrication of pipe spools offers several advantages:

Precision Engineering: Off-site fabrication ensures consistent quality and adherence to design specifications.

Cost Efficiency: Reduced labor and material costs associated with on-site assembly.

Enhanced Safety: Controlled environments minimize the risk of accidents and injuries.

Flexibility: Modular spools allow for easy customization and adaptation to project requirements.

Cost Savings in Pre-Fabrication, Inspection, and Testing

Nikit Engineers leverages cutting-edge welding automation and robotic solutions to optimize the pipe spool fabrication process. By integrating advanced technologies, they deliver unparalleled efficiency, accuracy, and cost savings throughout the fabrication journey. From automated welding systems to robotic inspection and testing, Nikit Engineers ensures that every spool meets the highest standards of quality and performance.

Contact Nikit Engineers for Your Next Industrial Pipe Spool Fabrication Project

With a proven track record of excellence and innovation, Nikit Engineers is your trusted partner for all your industrial pipe fabrication needs. Whether you’re embarking on a new construction project or seeking to optimize existing processes, our team of experts is ready to deliver tailor-made solutions that exceed your expectations.

Experience the future of pipe spool fabrication with Nikit Engineers Welding Automation and Robotic Solutions. Contact us today to discuss your project requirements and discover how we can transform your vision into reality.

Experience the Future with Nikit Engineers: Free Weld Trial Services

Embark on the journey of enhanced efficiency and precision with Nikit Engineers. To showcase the transformative power of our automation solutions, we are proud to offer Free Weld Trial Services. Experience firsthand how our profile welding automation systems can elevate your welding processes.

Book Free Weld Trial Services

At Nikit Engineers, we believe that the future of welding lies in automation. Our commitment to excellence, precision, and efficiency sets us apart as leaders in the field. Elevate your profile welding processes with Nikit Engineers Welding Automation and Robotic Solutions – where innovation meets craftsmanship.

Contact us today to schedule your Free Weld Trial Services and unlock the potential of automation in profile welding.

Nikit Engineers’ Robotic Welding Automation Solutions proudly declare that all our products are #MADEININDIA

Check out our other industrial ventures www.thewelder.in and www.civilautomation.com

Don’t forget to subscribe to our YouTube Channel for the latest videos and updates – www.youtube.com/@Nikitengineers

#robotics solutions#welding automation#orbital welding#circular welding#linear welding#Profile Wedling#Stainless Steel Welding

0 notes

Text

Phased Array Ultrasonic Testing services in India

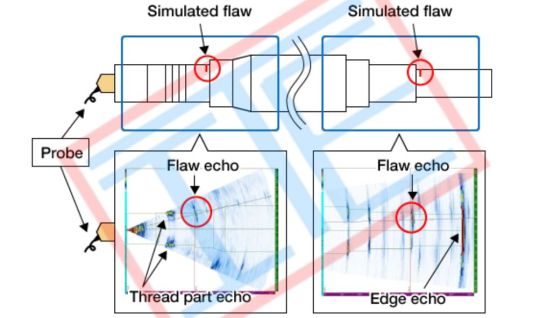

Phased Array Ultrasonic Testing (PAUT) services in India have gained significant popularity in recent years. PAUT is a non-destructive testing technique that uses ultrasonic waves to inspect materials for defects or flaws. It offers several advantages over traditional methods, making it a preferred choice for material testing in various industries.

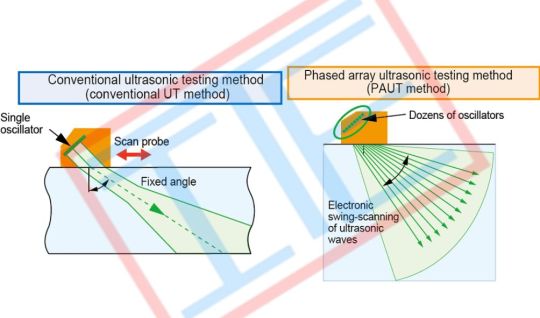

PAUT inspection involves the use of an array of ultrasonic transducers that can be electronically controlled to emit and receive ultrasonic waves at different angles. This allows for the creation of a detailed and accurate image of the material being tested. The ability to control the angle and focus of the ultrasonic waves makes PAUT testing highly versatile and effective in detecting both surface and subsurface defects.

One of the major benefits of PAUT testing is its speed and efficiency. With traditional ultrasonic testing methods, multiple scans are required to cover the entire area being inspected. However, with PAUT, multiple beams can be emitted simultaneously, covering a larger area in a single scan. This not only reduces the inspection time but also increases productivity and cost-effectiveness.

Another advantage of PAUT inspection is its ability to provide real-time imaging. The data collected from the ultrasonic waves can be displayed as a visual image, allowing for immediate analysis and interpretation. This real-time imaging feature enables faster decision-making and reduces the need for additional testing or re-inspection.

PAUT testing is widely used in various industries such as aerospace, oil and gas, power generation, manufacturing, and infrastructure. In the aerospace industry, PAUT is used for inspecting critical components such as aircraft wings, turbine blades, and engine parts. In the oil and gas industry, it is used for inspecting pipelines, storage tanks, and pressure vessels. In power generation, PAUT is used for inspecting boilers, turbines, and heat exchangers.

India has witnessed a significant growth in the demand for PAUT services due to its numerous advantages and applications. Several testing service providers in India offer PAUT inspection services to cater to the growing needs of industries. These service providers use advanced PAUT equipment and employ trained technicians who are proficient in operating and interpreting the results from PAUT systems.

When selecting a PAUT testing service provider in India, it is important to consider factors such as experience, expertise, and certifications. The service provider should have a proven track record in performing PAUT inspections and should be equipped with state-of-the-art equipment. Additionally, they should have a team of qualified technicians who are trained in conducting PAUT inspections and interpreting the results accurately.

In conclusion, PAUT inspection services in India have gained immense popularity due to their speed, efficiency, and accuracy. The ability to detect both surface and subsurface defects makes PAUT an ideal choice for material testing in various industries. With the growing demand for reliable non-destructive testing methods, PAUT is expected to continue being widely used in India's industrial sectors.

If you are looking for testing service in Delhi/NCR, India worldwide. Look no further now, contact us : +91-9810059715, +91-9953489999 . Our Address is F 22-23, Site C, Surajpur Industrial Area, UPSIDC, Greater Noida, 201306.

#paut inspection#paut testing#non destructive testing#ultrasonic testing equipment#material testing#stainless steel welding#steel welding

0 notes

Text

At Advance Tube Engineering, our material capabilities include bending aluminum, stainless steel, and mild steel, in addition to square tube bending services to customer specification. In addition to bending, we also offer beading, flaring, swaging, and other services.

We are capable of meeting your tube bending needs with a variety of applications including: beading, flaring and welding.

2 notes

·

View notes

Text

Leading Distributor of Pipes for Solar System Works - tubetrading

Discover the future of energy with Tube Trading, your go-to source for top-quality pipes for solar system works in Vadodara. We are your trusted partner in harnessing the power of the sun. Our wide range of pipes and expert guidance will ensure your solar projects shine bright. Find the perfect pipes for your solar projects, from the most reliable brands. Our knowledgeable team is here to guide you in choosing the right solutions. We deliver pipes that meet the highest industry standards. With Tube Trading, you get more than pipes; you get innovation, quality, and sustainability.

Join us in creating a cleaner, greener planet through solar energy.

#Pipes for solar system works distributors in Vadodara#Pipes for solar system works#Stainless steel pipes#spiral welded pipes#IBR pipes#ERW pipes#Steel industry#Gujarat#Vadodara#tubetrading#Jindal pipes#business

6 notes

·

View notes

Text

DUPLEX STEEL & ENGINEERING -

Duplex steel and engg. Co. Pvt. Ltd is one of the leading manufacturer of Duplex Steel 2205, Super duplex 2507, pipe, Tube, sheet, plates, flanges, fasteners in India.

DUPLEX STEEL 2205 / UNS S31803PLATES / SHEETS / COIL Request the latest Duplex Steel 2205 Plates / Sheets / Coil Price List. Please Call +91 98691 88888 or Send an Email to [email protected] for Duplex Steel UNS S31803, 1.4462 Pipe Plates / Sheets / Coil Ready stock information and updated price list.

https://www.unisteelsengg.com

#Duplex Steel 2205 Sheet#Super duplex 2507 Plate#Stainless Steel Pipe#SS Tubes#duplex 2205 pipe#duplex 2205 tube#316 Stainless steel Sheet#Inconel 200 Flanges#Monel 400 Tube Fittings#Nickel Alloy 20 Sheet#Titanium Grade 2 Round Bar#Hastelloy C22 Angle Bar Supplier#Alloy 20 Butt weld Fittings Dealer#Inconel 600 Flanges Exporter in India

2 notes

·

View notes

Text

interview at welding job on tuesday :3c

#emord rambles#not fr#i'm used to strike start tig on carbon steel but they do pulse welding on stainless steel so that's gonna be... an adjustment#the interview includes a welding test and im like. gimme a barebones explanation and i'll get it#if it's anything like the other tig stuff i'll be fine at it immediately but oh lord unfamiliarity under pressure is insane

6 notes

·

View notes

Text

The Importance of Stainless Steel Pipes and Seamless Pipes in Singapore’s Industrial Landscape

Explore the significance of stainless steel pipes and seamless pipes in Singapore’s industrial growth. Find high-quality piping solutions.

#stainless steel seamless pipes#steel pipe singapore#stainless steel pipe supplier#engineering#weldedpipes#stainless steel pipe singapore#apecmetal#welded pipes#seamless pipes#apec metal

0 notes

Text

Best forged tee fitting online

Buy the best forged tee fitting online! High-quality, durable, and precision-engineered fittings for industrial and plumbing applications. Order now!

#Best steel cross tee in india#Carbon Steel Threadolet online#Stainless Steel Pipe Nipple online#Carbon Steel Blind Flanges Online#Steel Flanges Online in India#Steel Flanges online#Pipe Bends online#Socket weld flanges online in India

0 notes

Text

#stainlesssteel#suppliers#industrial#manufacturers#pipesupplier#Stainless Steel 316L Welded Pipes#Stainless Steel 316L Welded Pipes Manufacturers#Stainless Steel 316L Welded Pipes Suppliers#Stainless Steel 316L Welded Pipes Stockists#Stainless Steel 316L Welded Pipes Exporters#Welded Pipes#Welded

0 notes

Text

Enhancing Industrial Efficiency: Welding Components on Nikit Engineers’ Mini Profile Welder

n the realm of industrial automation, precision and efficiency are paramount. Nikit Engineers Welding Automation and Robotics Solutions India have been at the forefront of revolutionizing industrial processes with their cutting-edge technologies. Among their impressive array of offerings, the Mini Profile Welder stands out as a versatile solution for welding various industrial components with utmost precision. Let’s delve into the diverse components welded on this remarkable machine and explore how they contribute to enhancing industrial efficiency.

Stellite Welding

Stellite, known for its exceptional wear resistance and durability, is a vital component in many industrial applications, particularly in high-temperature and corrosive environments. Welding Stellite requires precision and expertise to ensure a strong bond without compromising its properties. The Mini Profile Welder, equipped with advanced welding capabilities, ensures seamless welding of Stellite components, guaranteeing optimal performance and longevity in industrial settings.

youtube

Bellow with Flange

Bellow assemblies find widespread use in various industries for their ability to absorb thermal expansion, vibration, and misalignment. Welding bellows with flanges demands meticulous attention to detail to maintain structural integrity and sealing effectiveness. With its precise control and customizable welding parameters, the Mini Profile Welder ensures flawless welding of bellows with flanges, meeting the stringent quality standards required in industrial applications.

youtube

Spin Tube

Spin tubes play a crucial role in diverse industrial machinery, facilitating smooth rotational motion and power transmission. Welding spin tubes demands high precision to achieve uniformity and strength along the weld joints. The Mini Profile Welder’s advanced welding technology, coupled with its automated processes, enables consistent and reliable welding of spin tubes, contributing to the seamless operation of industrial equipment.

youtube

Copper Busbar

Copper busbars are essential components in electrical power distribution systems, requiring robust welding techniques to ensure efficient current flow and conductivity. Welding copper demands specialized expertise due to its high thermal conductivity and susceptibility to oxidation. The Mini Profile Welder’s advanced welding capabilities, including precise heat control and shielding gas management, facilitate accurate and reliable welding of copper busbars, ensuring optimal electrical performance in industrial applications.

youtube

Castor Wheel Brackets

Castor wheel brackets play a critical role in facilitating mobility and maneuverability in various industrial setups. Welding these brackets demands structural integrity and stability to withstand dynamic loads and harsh operating conditions. The Mini Profile Welder’s precision welding technology ensures strong and durable welds on castor wheel brackets, providing reliable support for equipment mobility in industrial environments.

youtube

Bellow Nut Assembly

Bellow nut assemblies are integral components in mechanical systems, providing adjustable support and sealing capabilities. Welding bellow nut assemblies requires precision to maintain dimensional accuracy and thread integrity. With its advanced welding features and customizable parameters, the Mini Profile Welder enables seamless welding of bellow nut assemblies, ensuring optimal functionality and performance in industrial applications.

youtube

In conclusion, the Mini Profile Welder by Nikit Engineers Welding Automation and Robotics Solutions India offers a comprehensive solution for welding a diverse range of industrial components with precision and efficiency. By seamlessly welding components such as Stellite, bellows, spin tubes, copper busbars, castor wheel brackets, and bellow nut assemblies, this innovative machine enhances industrial productivity and reliability, setting new standards in welding automation technology. With its advanced features and robust performance, the Mini Profile Welder continues to revolutionize industrial welding processes, driving progress and innovation across various sectors.

Why Choose Nikit Engineers for Mini Profile Welding Automation?

Tailored Solutions: At Nikit Engineers, we understand that every welding project is unique. Our automation solutions are customized to suit the specific needs and intricacies of profile welding applications. From simple profiles to complex geometries, our systems adapt to the nuances of each project.

Expertise that Matters: Backed by years of experience, our team of engineers is well-versed in the intricacies of profile welding. We provide comprehensive support from the initial consultation to the implementation phase, ensuring a seamless transition to automated welding processes.

Robust Training Programs: Transitioning to automation can be daunting, but not with Nikit Engineers. We offer robust training programs to empower your workforce with the skills needed to operate and maintain our automated welding systems. Our goal is to make the adoption of automation a smooth and positive experience for your team.

Experience the Future with Nikit Engineers: Free Weld Trial Services

Embark on the journey of enhanced efficiency and precision with Nikit Engineers. To showcase the transformative power of our automation solutions, we are proud to offer Free Weld Trial Services. Experience firsthand how our profile welding automation systems can elevate your welding processes.

Book Free Weld Trial Services

At Nikit Engineers, we believe that the future of welding lies in automation. Our commitment to excellence, precision, and efficiency sets us apart as leaders in the field. Elevate your profile welding processes with Nikit Engineers Welding Automation and Robotic Solutions – where innovation meets craftsmanship.

Contact us today to schedule your Free Weld Trial Services and unlock the potential of automation in profile welding.

Nikit Engineers’ Robotic Welding Automation Solutions proudly declare that all our products are #MADEININDIA

Check out our other industrial ventures www.thewelder.in and www.civilautomation.com

Don’t forget to subscribe to our YouTube Channel for the latest videos and updates – www.youtube.com/@Nikitengineers

#robotics solutions#welding automation#orbital welding#circular welding#Stainless Steel Welding#Profile Wedling#Youtube

0 notes

Text

Stainless Steel Welded pipes manufacturers

Mangalam Worldwide is a leading manufacturer of premium quality stainless steel welded pipes and seamless pipes. Our pipes are available in different sizes and grades, tailored to meet the requirements of different industries

Mangalam Worldwide is a leading manufacturer and supplier of stainless steel welded pipes, delivering premium-quality solutions for diverse industries. With a robust manufacturing program and adherence to international standards, our welded pipes are designed to meet the most demanding industrial requirements, offering exceptional strength, durability, and corrosion resistance.

#mangalamworldwide#welded pipes#Stainless Steel#Stainless Steel Welded pipes#Welded pipes manufacturers

0 notes

Text

Stainless Steel Fasteners & Hardware Accessories in Ernakulam: Discover MARTHILO TRADEX INDIA PVT LTD

When it comes to stainless steel fasteners and hardware accessories in Ernakulam, MARTHILO TRADEX INDIA PVT LTD stands out as a trusted name. Known for delivering quality, durability, and reliability, the company has established itself as a leading supplier for industries and individual clients across the region.

Why Choose Stainless Steel Fasteners?

stainless steel fastener manufacturers ernakulam are essential components in modern construction, manufacturing, and engineering. Here are some key advantages:

Corrosion Resistance: Perfect for use in harsh environments, including coastal areas like Ernakulam.

Strength & Durability: Designed to withstand heavy loads and maintain structural integrity over time.

Aesthetic Appeal: Ideal for projects requiring a clean and polished look.

Eco-Friendly: Stainless steel is recyclable, making it a sustainable choice for environmentally conscious projects.

What MARTHILO TRADEX Offers

At MARTHILO TRADEX INDIA PVT LTD, you’ll find a wide range of stainless steel fasteners and hardware accessories tailored to meet diverse needs:

Bolts, Nuts, and Washers: Available in various sizes and grades for different applications.

Screws: From wood screws to machine screws, ensuring secure fittings.

Anchors: High-performance options for construction and installation.

Customized Solutions: Tailored products designed to match specific project requirements.

Industries We Serve

Our stainless steel fasteners are trusted by professionals across various industries:

Construction & Infrastructure

Marine & Coastal Projects

Automotive & Machinery

Electrical & Electronics

Furniture & Interior Design

Why MARTHILO TRADEX is the Best in Ernakulam

Premium Quality: All products are manufactured to meet international standards.

Competitive Pricing: Affordable rates without compromising quality.

Wide Inventory: A broad selection ensures quick delivery for urgent needs.

Expert Support: A team of professionals ready to guide you through product selection and application.

Contact Us

Ready to experience the best in stainless steel fasteners and hardware accessories dealers in ernakulam? Visit our showroom in Ernakulam or reach out to us for inquiries and orders.

MARTHILO TRADEX INDIA PVT LTD

Phone: +91-6282664465

Email: [email protected]

Website: https://mtiindia.com/

Choose MARTHILO TRADEX INDIA PVT LTD for unparalleled quality and service. Let us help you build stronger, better, and more sustainable projects!

#stainless steel fastener manufacturers ernakulam#stainless steel rod dealers in Ernakulam#steel wire rope dealer in ernakulam#railing accessories manufacturers in ernakulam#hardware accessories dealers in ernakulam#stainless steel threaded rod manufacturer ernakulam#stainless steel hex bolt dealer in ernakulam#stainless steel fasteners manufacturers Ernakulam#stainless steel t profile dealers in ernakulam#steel wall to glass connector supplier in ernakulam#stainless steel weld mesh dealers in Ernakulam#stainless steel jhula kada dealers in ernakulam#stainless steel point fitting glass bracket in ernakulam#S S Perforated sheet dealer in Ernakulam#stainless steel wire Rope dealer in ernakulam#stainless steel Turnbuckle in ernakulam#6mm wire rope clamp in ernakulam#Stainless Steel fasteners dealer in Ernakulam

0 notes

Text

High-Performance Stainless Steel Welding Rods by D&H Sécheron

D&H Sécheron offers top-grade stainless steel welding rods designed for precise and durable welding applications. These rods are ideal for industries requiring corrosion resistance and high weld strength, such as construction, shipbuilding, and manufacturing. Engineered with advanced technology, D&H Sécheron’s stainless steel welding rods ensure smooth arc stability and minimal spatter. Their versatility makes them suitable for both high-heat and low-temperature environments, delivering consistent results every time. Trusted by professionals, these welding rods are crafted to meet stringent industry standards, ensuring reliability and efficiency. Choose D&H Sécheron for superior stainless steel welding rods that elevate the quality of your welding projects.

0 notes

Text

Best Threaded Pipe Fittings Near Me Online

Explore top-quality threaded pipe fittings available online in India. These fittings offer secure and easy connections for your piping systems. Shop now for a wide range of sizes and types of threaded fittings at the best prices.

#best threaded pipe fittings near you in India#Carbon Steel Threadolet online#Threaded Pipe Fittings Near Me#Stainless Steel Threaded Flange Online#Carbon Steel Threaded Pipe Fittings online#Carbon Steel Socket weld Pipe Fittings online#Socket weld pipe fittings online#Socket weld pipe fittings Online in India#Socket weld flanges near me#Socket Weld Pipe Fitting online

0 notes

Text

Stainless Steel Welding Rods For Sale

Stainless steel is renowned for its exceptional corrosion resistance, strength, and aesthetic appeal, making it a popular choice in various industries. Welding is crucial for joining stainless steel components, and the selection of the right welding rod is paramount for achieving high-quality, durable welds. Here, you will learn about the different types of Stainless Steel Welding Rods For Sale.

Types of Stainless Steel Welding Rods

Stainless steel welding rods are available in various grades, each designed for specific applications:

304 Stainless Steel Welding Rods: These are the most common type, suitable for general-purpose applications. They offer excellent corrosion resistance and good weldability.

308 Stainless Steel Welding Rods: Widely used for joining 304 and 308 stainless steel. They provide good strength and ductility.

316 Stainless Steel Welding Rods: Ideal for applications requiring high corrosion resistance, particularly in marine environments or where exposure to chlorides is prevalent.

347 Stainless Steel Welding Rods: Specifically designed for high-temperature applications, offering excellent resistance to carbide precipitation.

Moreover, reputed companies, like Castron Electrode supply the following types of stainless steel welding rods:

Super Duplex Stainless Steel Welding Electrodes

Super duplex stainless steel welding electrodes are used to join super duplex stainless steel components. They offer excellent corrosion resistance and high strength, making them suitable for demanding applications in marine environments and chemical processing.

Carbon Steel To Stainless Steel Welding Electrode

Carbon Steel To Stainless Steel Welding Electrode are specifically designed for joining carbon steel to stainless steel. They bridge the gap between dissimilar metals, preventing corrosion and ensuring a strong, durable bond.

Carbon Steel To Stainless Steel Welding Rod

Similar to the electrode, this rod is used for dissimilar metal welding between carbon steel and stainless steel. It provides a reliable fusion zone, minimizing the risk of cracking and corrosion.

Electrode For Welding Stainless Steel To Carbon Steel

This electrode is specifically designed for joining stainless steel to carbon steel. It offers excellent weldability and corrosion resistance, ensuring a strong and durable bond between the two dissimilar metals.

Mild Steel To Stainless Steel Welding Rod

This rod is used for joining mild steel to stainless steel. It provides a strong and reliable bond between the two metals, minimizing the risk of corrosion and ensuring a long service life.

Stainless Steel To Mild Steel Welding Rod

Similar to the previous description, this rod is used for joining stainless steel to mild steel. It offers excellent weldability and corrosion resistance, ensuring a strong and durable bond between the two dissimilar metals.

Stainless Steel To Stainless Steel Welding Rod

This rod is used for joining different grades of stainless steel. It ensures a strong, corrosion-resistant weld that maintains the integrity of the stainless steel components.

Factors to Consider When Choosing Stainless Steel Welding Rods

Base Metal Compatibility: The welding rod's grade should be compatible with the base metal to ensure proper fusion and prevent cracking.

Application: The intended application will dictate the required properties of the weld, such as corrosion resistance, strength, and high-temperature performance.

Welding Process: Different welding processes (TIG, MIG, Stick) may require specific types of welding rods.

Rod Diameter: The rod diameter should be chosen based on the thickness of the base metal and the desired welding speed.

Benefits of Using High-Quality Stainless Steel Welding Rods

Stronger Welds: High-quality rods ensure strong and durable welds that can withstand the stresses of the intended application.

Improved Corrosion Resistance: Properly selected rods maintain the corrosion resistance of the base metal, preventing premature failure.

Better Aesthetics: High-quality welds exhibit a smoother, more aesthetically pleasing appearance.

Increased Efficiency: The right rods can improve welding speed and reduce rework, increasing overall efficiency.

Where to Buy Stainless Steel Welding Rods

Stainless steel welding rods are available from a variety of sources, including:

Local Welding Supply Stores: Offer a wide range of welding supplies and expert advice.

Online Retailers: Provide convenient access to a variety of welding rods at competitive prices.

Industrial Distributors: Cater to the needs of industrial customers, offering bulk quantities and specialized products.

Tips for Storing and Handling Stainless Steel Welding Rods

Store rods in a dry, clean location to prevent corrosion.

Keep rods away from moisture and humidity.

Avoid contamination from dirt, grease, or other foreign materials.

Handle rods carefully to prevent damage.

Conclusion

Selecting the right Stainless Steel Welding Rods For Sale is crucial for achieving high-quality, durable welds. By considering factors such as base metal compatibility, application requirements, and welding process, you can choose the best rods for your specific needs. Investing in high-quality rods will not only improve the quality of your welds but also increase your overall welding efficiency and productivity. For more details, visit https://castonelectrode.in/product-category/welding-consumables/welding-filler-wires/tig-mig-filler-wires/carbon-steel-welding-wires/

0 notes