#nx cad software

Explore tagged Tumblr posts

Text

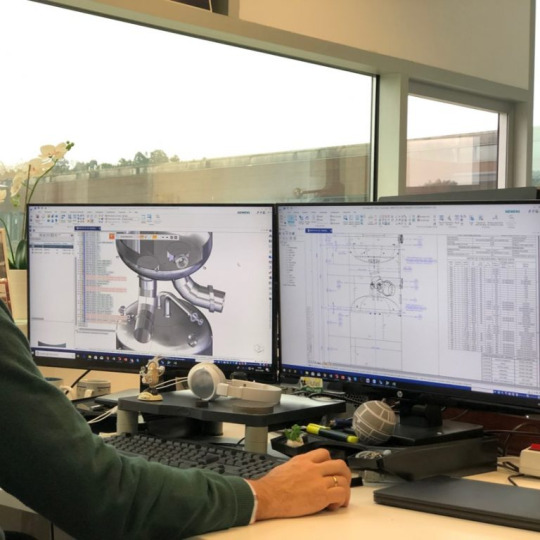

Siemens NX is a cutting-edge, high-end CAD/CAM/CAE software package widely used for mechanical product design, engineering, and manufacturing. The NX CAD designing tools set industry benchmarks for speed, performance, and ease of use. CAD DESK’s NX CAD Training course is meticulously designed to offer in-depth learning, providing a flexible solution for product development.

NX CAD stands out for its seamless data integration compared to other CAD systems, enabling designers to achieve quick results by maximizing the use of virtual product models and minimizing the need for physical prototypes. CAD DESK delivers top-notch NX CAD CAM training and encourages students to participate in internships during their NX Training to gain practical experience. All training sessions are conducted on the latest version of NX CAD Training Institute in Maharashtra.

0 notes

Text

i hope whoever made siemens nx the way it is has a horrible day forever

#FUCK this software#anyone who has ever done cad before understands this. the displeasure of working with nx is a shared experience#ell shut up

2 notes

·

View notes

Text

NX CAD Design Software: Career, Benefits, Uses

In today's rapidly evolving technological landscape, proficiency in Computer-Aided Design (CAD) software has become a cornerstone skill for aspiring engineers, designers, and architects. Among the plethora of CAD tools available, NX CAD stands out as a comprehensive and powerful solution that not only facilitates efficient design but also opens doors to diverse career opportunities. In this blog, we'll delve into the world of NX CAD, exploring its myriad benefits, versatile applications, and its pivotal role in shaping careers across various industries.

The Power of NX CAD

NX CAD, developed by Siemens Digital Industries Software, is a leading-edge CAD software renowned for its robust capabilities and advanced features. It offers a wide array of tools for 3D modeling, simulation, and manufacturing, making it indispensable in industries ranging from automotive and aerospace to consumer goods and electronics.

One of the key strengths of NX CAD lies in its parametric modeling capabilities, which allow designers to create complex geometries while maintaining associativity between different design elements. This enables seamless design modifications and iterations, significantly enhancing productivity and reducing time-to-market.

Career Opportunities

Proficiency in NX CAD opens doors to a plethora of career opportunities across various industries. Companies in automotive, aerospace, defense, and manufacturing sectors actively seek professionals with expertise in NX CAD for roles such as CAD designer, product engineer, mechanical engineer, and design analyst.

Moreover, as the demand for product customization and innovation continues to rise, so does the need for skilled CAD professionals who can leverage tools like NX CAD to bring creative ideas to life. This presents exciting career prospects for individuals with a passion for design and engineering.

Benefits of NX CAD

Streamlined Design Process: NX CAD streamlines the design process through intuitive tools and workflows, enabling designers to translate concepts into tangible products efficiently.

Collaborative Environment: With features like synchronous technology and multi-CAD data integration, NX CAD facilitates collaboration among cross-functional teams, fostering innovation and accelerating time-to-market.

High-Fidelity Simulation: NX CAD's integrated simulation capabilities enable engineers to validate designs virtually, identify potential issues, and optimize product performance before physical prototyping, saving time and resources.

Manufacturing Integration: Seamless integration with manufacturing tools allows designers to generate production-ready documentation and NC programs directly from the CAD model, ensuring manufacturability and consistency.

Scalability and Customization: NX CAD's scalability and extensibility make it suitable for organizations of all sizes, while its open architecture allows for customization to meet specific industry requirements and workflows.

Versatile Applications

The versatility of NX CAD extends across a wide range of applications, including:

Product Design: From conceptualization to detailed design, NX CAD empowers designers to create innovative products across various industries.

Engineering Analysis: Engineers can perform structural, thermal, and fluid flow analysis within the NX CAD environment, enabling comprehensive design validation.

Manufacturing Planning: NX CAD facilitates manufacturing process planning, tooling design, and NC programming, ensuring seamless transition from design to production.

Digital Twin Creation: By integrating CAD with simulation and IoT data, NX enables the creation of digital twins for virtual prototyping and predictive maintenance.

Conclusion

In conclusion, NX CAD emerges as a game-changer in the realm of computer-aided design, offering a potent combination of advanced features, versatility, and scalability. For aspiring professionals, mastering NX CAD not only opens doors to exciting career opportunities but also equips them with the skills needed to thrive in today's competitive marketplace. Whether you're a seasoned engineer looking to enhance your skill set or a student embarking on a career in design, investing in NX CAD proficiency is sure to yield substantial returns in terms of career advancement and personal growth.

0 notes

Note

Are there any primitives or operations you wished parametric CAD software had?

This is tricky, because parametric CAD is what I learned to design on so its feature set feels "natural".

I don't really think so! Most of the obvious innovations are already covered, SolidWorks can take a model back and forth between parametric and primitives modelling in its own weird way, Inventor has really great design for manufacture features, from what I've seen SolidEdge has done some clever stuff with the solver to help you design parts that are customizable as you go down the chain. Who knows what's going on in NX these days, not me. There's definitely some holes in the sense of individual packages lacking features, but almost anything you can ask has been implemented somewhere, by someone.

Good quality design for manufacture tools really do help, I remember doing sheet metal stuff in Inventor back before they cut off free Inventor access and being able to see your generated sheet and bend allowances so clearly was great, and now even OnShape has pretty solid design helpers.

A thing small shops and hobbyists would probably like is better handling of point clouds and photogrammetry for matching parts, since you're much more likely to be working with parts and projects where you didn't do all the design, I've spent many hours trying to accurately model a mating feature, but even that's like. Pretty good these days, importing 3D scans into an editor is pretty standard and the good CAD packages will even let you pick up holes and clean up point clouds directly from the scan.

I'm not that much of a mech eng, and never really was, my CAD is mostly self taught for simple tasks, real mechanical designers no doubt have better opinions on this, @literallymechanical probably has thoughts on T-splines.

38 notes

·

View notes

Text

NX Cad Training program for Mechanical Engineers.

The best professional training from professionals.

This software training will allow mechanical engineers to boost their career in Manufacturing and Produce design industry.

The course is project based training and follows industrial curriculum which will make you field ready.

Contact us now and book your free demo session.

#nxcad#mechanicalengineering#mechanical#mechanicalengineer#productdesign#productmanufacturing#manufacturing#productdesigner#mechanicaldesign#mechanicaldrawing#mechanicalmodmechanicals#mechanicalanimation#mechanicalstudent#delhi#rohini#pitampura#gurugram#noida

2 notes

·

View notes

Text

Mechanical drafter here!

While we nowdays never really do full on blueprints by hand bc thats waaaay too much work (and most apprentices/trainees dont even really learn how to do that anymore, although I did), we need to be able to do rough sketches to get the idea across. We use CAD software (like CATIA or NX) to make a 3D model first and then generate the blueprints off of said model, Tails would likely do that, too!

Basically he would probaply do a (rough) first draft by hand to get an idea for the mechanism he wants to create, and then move on to his CAD software of choice (probaply custom made by yours truely, to really accomodate all the features HE needs for HIS work). First creating LOTS of models for all the parts and then the drafts. Given that Tails is an inventor first and a drafter second, his drafts would most likely be a nightmare that I do NOT want to have to decipher let alone use for production....

But back to the topic at hand! Lil guy can probaply draw some banger straight lines, elipsis and circles, but art in the traditional sense.... uhhh not so much... Most drafters I know are very 'I can do a stick figure?', while being able to do some real impressive rough drafts in the matter of minutes or even seconds. Although there are some artists among us, too, it's just an exception

Tails must be a real good artist, since he needs to sketch out his blueprints to his inventions all the time. Like? He would at least have a good grip on the anatomy of machines and infrastructure, in order to repair and build it accurately.

I love this idea, it's canon now.

#i love yapping abt my work#knowing he is self taught and works alone AND does ooak machinery makes me shudder just thinking abt the hellish drafts he throws together#that one drafter at the office that everyone hates i am so sorry tails

662 notes

·

View notes

Text

Are You Searching for NX training in tambaram?

CADD Centre Tambaram apart is its dedication to equipping learners with industry-relevant skills. The courses are designed by experts who have in-depth knowledge of the latest technological advancements in design and drafting. The centre offers specialized programs in software like AutoCAD, Solid Works, Revit, STAAD Pro, and many others, ensuring that students gain proficiency in tools that are widely used across industries. Additionally, the course content is frequently updated to reflect new developments and innovations in CAD technology, keeping the curriculum fresh, advanced, and aligned with current industry standards.

One of the unique aspects of CADD Centre Tambaram is its approach to training. The programs here are not just theoretical; they focus heavily on practical, hands-on learning. Students get the opportunity to work on real-world projects, which helps them develop a deeper understanding of how CAD principles are applied in professional scenarios. This kind of immersive learning ensures that graduates are job-ready and equipped with the skills that employers look for.

The faculty at CADD Centre Tambaram is another highlight. With extensive experience in their respective domains, the trainers guide students through every aspect of the learning process, offering personalized attention and mentoring. They help bridge the gap between academic knowledge and practical skills, making the learning process smooth and effective. The centre also boasts state-of-the-art facilities, ensuring that students have access to the latest tools and technologies to hone their skills.

CADD Centre Tambaram has a strong track record of successful placements, with many students finding rewarding careers in top companies. The institution's commitment to excellence in education, coupled with a focus on industry-specific training, makes it one of the best CADD centres in Tambaram. NX training in tambaram Whether you're a beginner looking to start a career in CAD or a professional seeking to upgrade your skills, CADD Centre Tambaram provides a comprehensive learning environment that sets you up for success in the competitive design and drafting industry. Placement Assistance: CADD Centre Tambaram takes pride in its robust placement assistance program.

The institute has established strong ties with leading companies in the engineering, architectural, and design sectors, enabling it to offer excellent placement opportunities to its students. The dedicated placement cell provides support with resume building, interview preparation, and job search strategies, ensuring that students are well-prepared to enter the job market. This comprehensive support system has helped numerous graduates secure lucrative positions in top companies, further solidifying CADD Centre Tambaram’s reputation as a leading CAD training provider.

Flexibility and Accessibility: Understanding the diverse needs of its students, CADD Centre Tambaram offers flexible learning options, including part-time and full-time courses, as well as online training programs. This flexibility allows students to learn at their own pace and convenience, making quality education accessible to all. Whether you are a working professional looking to upskill or a fresh graduate seeking to start a career in CAD, CADD Centre Tambaram has a program that fits your schedule and learning preferences.

Conclusion : In conclusion, CADD Centre Tambaram is not just a training institute; it is a launching pad for successful careers in the world of CAD. With its comprehensive curriculum, expert instructors, state-of-the-art facilities, industry-relevant projects, and robust placement assistance, it offers an unparalleled learning experience. For anyone looking to excel in the fields of engineering, architecture, or design, CADD Centre Tambaram is the place to be.

0 notes

Text

How to Choose the Best AutoCAD Course in Trivandrum for Your Career?

AutoCAD has become one of the most widely used software in industries such as architecture, engineering, construction, and manufacturing. As the demand for skilled professionals continues to rise, it's essential to choose the right AutoCAD course to give your career the boost it needs. If you're looking for the best AutoCAD course in Trivandrum, this blog will help guide you through the key factors to consider.

1. Understand Your Career Goals

Before you begin your search for an AutoCAD course, it's important to define your career goals. Are you interested in architecture, civil engineering, electrical designing, or mechanical design? AutoCAD is a versatile software, and different industries use it for various purposes. Some courses may focus on specific modules such as architectural drafting, civil CADD, or mechanical CAD, while others offer a more comprehensive approach. By understanding which industry aligns with your career aspirations, you can select the course that offers specialized training for your desired field.

2. Accreditation and Certification

When choosing an AutoCAD course, ensure that the institute offers accredited and recognized certification. Look for courses that are associated with reputable organizations and industry standards. A valid certification not only boosts your credibility but also enhances your chances of getting hired by top companies. Institutes that partner with well-known educational bodies or offer authorized programs tend to provide the best quality training.

At SreeCadd, we offer over 100+ authorized courses, including architecture, building designing courses, civil CADD courses, and more. By enrolling in our Certificate of Association program, you can gain access to subsidized pricing and receive a globally recognized certification, making it a solid choice for aspiring professionals.

3. Experienced and Qualified Trainers

The expertise of the trainers is a crucial factor when choosing the right course. It's important to ensure that the trainers have in-depth knowledge and practical experience in the field. Experienced trainers can provide insights and real-world examples, helping you understand complex AutoCAD tools and techniques.

Check if the trainers are certified professionals themselves and have a proven track record of working in industries where AutoCAD is used. At SreeCadd, we pride ourselves on having a team of qualified trainers who bring years of industry experience to the table. Our trainers offer a hands-on approach to teaching, ensuring you gain practical skills that can be directly applied to your career.

4. Course Content and Curriculum

The curriculum should cover all essential topics, from the basics to advanced techniques in AutoCAD. Look for a course that provides in-depth knowledge of 2D and 3D drawing, dimensioning, annotation, plotting, and other key features of AutoCAD.

A well-structured course should also include practical assignments, projects, and assessments to help you build a portfolio that showcases your skills. If you're looking for specialized training, ensure that the course offers tailored modules in your area of interest, such as civil engineering, electrical designing, or mechanical CAD.

SreeCadd offers a wide range of courses, including civil CADD, electrical & electronics CAD courses, mechanical CAD, and NX CAD courses in Tamil Nadu. Our curriculum is designed to meet the industry standards and provides in-depth knowledge and practical skills to make you job-ready.

5. Training Mode and Flexibility

Consider the mode of training that works best for you. Many institutes offer both online and offline courses, giving you the flexibility to choose based on your schedule and preferences. Online courses can be more convenient for individuals who are working or have other commitments, while offline courses may provide more interaction and hands-on experience.

At SreeCadd, we understand that students have different learning preferences. Therefore, we offer both online and offline training programs to cater to a diverse range of learners. Whether you're looking for a flexible schedule or want in-person guidance, we ensure you get the training that fits your needs.

6. Pricing and Affordability

Pricing is an important consideration when selecting an AutoCAD course. While you don’t want to compromise on the quality of training, it’s essential to find an option that fits your budget. Some institutes may offer discounts or subsidized pricing, which can be a great opportunity for students looking for affordable courses.

At SreeCadd, we believe in making education accessible. We offer subsidized pricing for our courses through the Certificate of Association program. This makes it easier for students in Trivandrum and Tamil Nadu to access top-quality AutoCAD training without breaking the bank.

7. Student Reviews and Testimonials

Before enrolling, take the time to read reviews and testimonials from previous students. This will give you a clearer idea of the quality of training, the support provided by the institute, and the overall learning experience. Institutes with positive reviews and high success rates in placements are usually a reliable choice.

SreeCadd has built a reputation for delivering excellent training in various CADD fields. Our students have gone on to achieve success in top firms, and their testimonials are a testament to our commitment to quality education.

Conclusion

Choosing the right AutoCAD course is a critical step toward building a successful career in architecture, engineering, or design. By considering factors such as career goals, accreditation, trainer expertise, course content, flexibility, pricing, and student feedback, you can make an informed decision.

At SreeCadd, we offer a wide array of authorized and industry-recognized courses at affordable prices. Our hands-on training, experienced trainers, and specialized programs make us one of the best AutoCAD couses in Trivandrum. Enroll in our Certificate of Association program today and take your career to new heights!

#AutoCAD training centre in Trivandrum#AutoCAD courses in Trivandrum#AutoCAD training centre in Nagercoil#AutoCAD courses in Nagercoil#CAD CAM CAE courses in Nagercoil

0 notes

Text

Why Mechanical Engineering is a Great Career Path: Courses to Get Started

Mechanical engineering has long been regarded as one of the most versatile and rewarding fields of study. Whether you’re fascinated by robotics, automotive design, or aerospace engineering, this discipline opens doors to an array of exciting career opportunities. If you’re considering a career in mechanical engineering, it’s essential to start with the right foundation. In this blog, we’ll explore why mechanical engineering is a fantastic career choice and highlight some of the best courses available in cities like Pune to help you kickstart your journey.

The Appeal of Mechanical Engineering

Mechanical engineering is the backbone of technological innovation, contributing to the design, analysis, and manufacturing of products across various industries, from automotive to energy. As industries evolve, mechanical engineers are increasingly sought after for their expertise in problem-solving and innovation. This field offers a robust career with excellent job security, competitive salaries, and opportunities for growth and specialization.

Furthermore, mechanical engineering is ideal for those who enjoy hands-on work, critical thinking, and tackling complex challenges. If you’re someone who thrives in dynamic, ever-changing environments, this could be the perfect career path for you.

Popular Mechanical Engineering Courses in Pune

Pune has become a major educational hub for engineering students, with numerous institutes offering high-quality mechanical engineering courses. If you are planning to pursue a mechanical engineering degree or diploma, Pune is home to top-tier colleges and training centers that provide both theoretical knowledge and practical skills.

Mechanical Engineering courses in Pune cover various aspects of the field, including thermodynamics, fluid mechanics, mechanics of materials, and robotics. These programs prepare you for a wide range of careers in industries such as manufacturing, automotive, aerospace, and energy.

Specialized Training Programs: NX Classes in Pune

As technology advances, the demand for engineers with specialized skills continues to rise. NX (Siemens NX) is one of the most widely used software programs in mechanical engineering for computer-aided design (CAD), computer-aided engineering (CAE), and computer-aided manufacturing (CAM). Taking NX classes in Pune can significantly enhance your career prospects, as NX software is used by some of the world’s leading engineering firms.

By enrolling in NX classes, you will learn how to design complex mechanical systems, perform advanced simulations, and optimize product development cycles. These skills are highly valued in industries like automotive, aerospace, and manufacturing. If you want to stay ahead in the competitive job market, mastering NX will give you a significant edge.

HyperMesh Training in Pune: A Must for Simulation Experts

Another specialized skill that can set you apart in mechanical engineering is proficiency in simulation software. HyperMesh training in Pune offers you the tools to perform finite element analysis (FEA), structural simulations, and meshing for complex engineering problems. This training is crucial for engineers involved in designing and testing components in real-world conditions.

HyperMesh is widely used in automotive, aerospace, and defense industries, where simulations are essential for ensuring safety, performance, and reliability. By gaining expertise in HyperMesh, you’ll be well-equipped to tackle the challenges faced by engineers working with intricate mechanical systems.

The Growing Demand for Skilled Mechanical Engineers

Mechanical engineers are in high demand, and the need for skilled professionals is only growing. With the rise of new technologies such as automation, artificial intelligence, and sustainable energy solutions, there are more career opportunities than ever before. Whether you want to work as a design engineer, a project manager, or a researcher, the career options are vast.

Additionally, mechanical engineers often find themselves working in leadership roles, making strategic decisions that affect product development and company growth. The field also offers a diverse range of industries to work in, from automotive manufacturing to energy production, ensuring job stability and long-term career prospects.

Why Choose G2G Innovation for Mechanical Engineering Training

For those serious about kickstarting their career in mechanical engineering, G2G Innovation is a standout choice. G2G Innovation provides a comprehensive range of engineering courses, including NX classes in Pune and HyperMesh training in Pune, designed to equip you with the latest industry skills. With experienced instructors and state-of-the-art facilities, G2G Innovation offers a hands-on learning experience that prepares students for real-world challenges.

By enrolling at G2G Innovation, you’ll not only gain technical expertise but also practical insights into the demands of the mechanical engineering industry. Whether you’re looking to specialize in CAD software, simulation tools, or general mechanical engineering principles, G2G Innovation has the right courses to help you succeed.

Conclusion

Mechanical engineering is an exciting and fulfilling career path that opens up a world of opportunities. By enrolling in relevant mechanical engineering courses in Pune, along with specialized programs like NX classes in Pune and HyperMesh training in Pune, you can ensure that you’re well-prepared to meet the demands of this dynamic field. The right education and training can make all the difference, and with institutions like G2G Innovation, you’ll receive the best education and practical skills needed to thrive in your career.

To know more about G2G Innovation,

Contact details,

Visit website: https://g2ginnovation.com/

Address: IT Space, Unit 101 A, 1st Floor, AG Trade Centre, S. No 7 & 8 Pl №18, Bavdhan Kh, Bavdhan, Haveli, Pune, 411021, Maharashtra, India

Email: [email protected]

Get directions: https://maps.app.goo.gl/QLkg23uWaojh4SCh6

0 notes

Text

Curious About NX X Essentials?

What makes NX X Essentials the go-to SaaS CAD solution for businesses of all sizes?

NX X Essentials is redefining how businesses design, collaborate, and innovate with its lightweight, browser-based #CADsolution. Whether you're a startup, SMB, or large enterprise, there's something in #NXX Essentials for you.

0 notes

Text

Unlock Your Career Potential with CAD Training Courses in Pune

Why Choose CAD Training in Pune?

Pune has emerged as a prime destination for technical education and professional skill enhancement. The city boasts several reputed institutes that offer comprehensive CAD training in Pune. These courses are designed to equip students and professionals with the necessary skills to excel in their respective industries.

Mechanical CAD Course in Pune

A Mechanical CAD Course in Pune is perfect for aspiring mechanical engineers and designers who aim to master tools like AutoCAD, SolidWorks, and CATIA. The course covers essential design principles, 2D drafting, 3D modeling, and assembly design, ensuring a holistic understanding of mechanical components and their functionalities. With hands-on training and real-world projects, this course prepares you for diverse roles in the mechanical design industry.

CAD Interior Design Courses

For those with a creative flair for designing living spaces, CAD Interior Design Courses offer specialized training in software tools like SketchUp, 3ds Max, and Revit. These courses focus on space planning, material selection, lighting design, and virtual walkthroughs, enabling you to create stunning interior visuals. Whether you are an aspiring interior designer or a professional looking to upgrade your skills, these courses provide the right platform.

Plastic Domain Training Institute in Pune

The plastic industry requires highly specialized design expertise due to the complex nature of mold designs and material behavior. A Plastic Domain Training Institute in Pune offers advanced training in mold design, plastic part design, and analysis tools like Moldflow and NX CAD. This training ensures you are well-prepared for roles in industries like automotive, consumer goods, and packaging.

Key Benefits of CAD Training in Pune

Experienced Faculty: Learn from industry experts with years of practical experience.

State-of-the-Art Infrastructure: Access modern labs equipped with the latest CAD software.

Hands-On Projects: Work on live projects and real-world simulations to build practical skills.

Placement Assistance: Benefit from placement support and job interview preparation sessions.

Who Can Enroll in CAD Training Courses?

CAD training courses in Pune are suitable for:

Engineering students and graduates

Architects and interior designers

Working professionals seeking skill enhancement

Entrepreneurs in the design industry

0 notes

Text

Precision in Every Pixel: Exploring the Power of 3D CAD Software

The global 3D CAD software market report provides an in-depth analysis of market segments and sub-segments across multiple regions, covering the period from 2015 to 2023. This comprehensive report evaluates the market trends, growth factors, and projections for the global and regional markets. According to updated forecasts, the global 3D CAD software market is anticipated to grow at a compound annual growth rate (CAGR) of 7.1% during the forecast period from 2023 to 2030, with the market size expected to reach approximately USD 12.4 billion by 2030, up from USD 7.5 billion in 2023.

What is 3D CAD Software?

3D CAD (Computer-Aided Design) software enables engineers, designers, and architects to create, visualize, and modify digital models of physical objects. This software is widely used across various industries—including automotive, aerospace, construction, and consumer goods—for tasks such as product design, prototyping, and structural analysis. The ability to create precise 3D models facilitates enhanced design accuracy, reduces manufacturing errors, and supports efficient product development cycles.

Get Sample pages of Report: https://www.infiniumglobalresearch.com/reports/sample-request/809

Market Drivers and Growth Factors

Several factors are driving the expansion of the 3D CAD software market:

Increasing Demand in Product Design and Manufacturing: The need for precision in product design and the push towards digital transformation in manufacturing processes have heightened the demand for 3D CAD software. Industries like automotive and aerospace rely on 3D CAD for prototyping, testing, and customization.

Technological Advancements in CAD Tools: Modern CAD tools offer features like cloud integration, augmented reality (AR) support, and artificial intelligence (AI) enhancements, making them more accessible, scalable, and useful in diverse applications.

Rising Adoption in Architecture and Construction: 3D CAD software plays a critical role in building design, structural analysis, and project planning in architecture and construction, supporting intricate designs and efficient planning.

Digital Twin Technology: As industries adopt digital twins for real-time simulations and predictive analytics, demand for advanced 3D CAD software for creating digital replicas of physical assets has increased.

Regional Analysis

North America: North America is a leading market for 3D CAD software due to the high adoption rate in sectors like automotive, aerospace, and construction, with the U.S. playing a dominant role in driving growth.

Europe: Europe holds a significant share in the global market, supported by industries like automotive and industrial machinery. Germany, the UK, and France are notable contributors to this region’s growth.

Asia-Pacific: Asia-Pacific is projected to experience the highest growth rate, driven by rapid industrialization in countries like China, Japan, and India. Increasing adoption in manufacturing and rising demand for automotive and construction applications fuel market expansion.

Rest of the World: Gradual adoption of 3D CAD software in Latin America, the Middle East, and Africa is observed as these regions increase their focus on industrial and architectural development.

Competitive Landscape

The 3D CAD software market is competitive, with major players concentrating on technology innovations, product development, and strategic partnerships:

Autodesk, Inc.: Known for its wide range of CAD solutions, Autodesk offers user-friendly software tools suitable for multiple industries.

Dassault Systèmes: Dassault’s SOLIDWORKS and CATIA platforms are widely used across various industries for high-precision 3D modeling and design.

PTC Inc.: PTC’s CREO platform supports high-performance 3D CAD and offers advanced simulation and augmented reality capabilities.

Siemens PLM Software: Siemens provides NX and Solid Edge software, known for their efficiency in complex design tasks and industrial applications.

Bentley Systems: Bentley specializes in software for infrastructure, catering to construction, transportation, and energy sectors.

Report Overview : https://www.infiniumglobalresearch.com/reports/3d-cad-software-market

Challenges and Opportunities

Challenges: Despite the growth prospects, the 3D CAD software market faces some challenges. High initial costs and ongoing licensing fees can be prohibitive for small and mid-sized enterprises, limiting adoption rates. Additionally, the complexity of some advanced CAD tools often necessitates specialized training, which can increase operational costs and create a learning curve barrier. Compatibility issues among various CAD platforms may also hinder seamless collaboration across projects that involve multiple software systems.

Opportunities: The 3D CAD software market has substantial opportunities for growth through the integration of emerging technologies. For example, the incorporation of AI and machine learning enables CAD tools to suggest design improvements and automate certain processes, enhancing productivity. Cloud-based CAD solutions also present new opportunities by making sophisticated software accessible to remote teams and reducing infrastructure costs.

Conclusion

The global 3D CAD software market is set for steady growth, driven by increasing industrial applications, technological advancements, and expanding adoption in sectors like automotive, aerospace, and construction. The market outlook remains strong with significant growth expected in Asia-Pacific, backed by rapid industrialization and demand for digital solutions across various industries.

0 notes

Text

CADD Centre Tambaram: "Turn Ideas into Reality – Learn from the Best at CADD Centre Tambaram!"

NX training in tambaram

CADD Centre Tambaram is one of the leading institutions in Tambaram for learning computer-aided design (CAD) and drafting. Renowned for its commitment to providing high-quality training in CAD, CADD Centre Tambaram offers a wide range of advanced courses tailored to meet the needs of both students and professionals in fields such as engineering, architecture, and project management.

What sets CADD Centre Tambaram apart is its dedication to equipping learners with industry-relevant skills. The courses are designed by experts who have in-depth knowledge of the latest technological advancements in design and drafting. The centre offers specialized programs in software like AutoCAD, Solid Works, Revit, STAAD Pro, and many others, ensuring that students gain proficiency in tools that are widely used across industries. Additionally, the course content is frequently updated to reflect new developments and innovations in CAD technology, keeping the curriculum fresh, advanced, and aligned with current industry standards.

One of the unique aspects of CADD Centre Tambaram is its approach to training. The programs here are not just theoretical; they focus heavily on practical, hands-on learning. Students get the opportunity to work on real-world projects, which helps them develop a deeper understanding of how CAD principles are applied in professional scenarios. This kind of immersive learning ensures that graduates are job-ready and equipped with the skills that employers look for.

The faculty at CADD Centre Tambaram is another highlight. With extensive experience in their respective domains, the trainers guide students through every aspect of the learning process, offering personalized attention and mentoring. They help bridge the gap between academic knowledge and practical skills, making the learning process smooth and effective. The centre also boasts state-of-the-art facilities, ensuring that students have access to the latest tools and technologies to hone their skills.

CADD Centre Tambaram has a strong track record of successful placements, with many students finding rewarding careers in top companies. The institution's commitment to excellence in education, coupled with a focus on industry-specific training, makes it one of the best CADD centres in Tambaram. Whether you're a beginner looking to start a career in CAD or a professional seeking to upgrade your skills, CADD Centre Tambaram provides a comprehensive learning environment that sets you up for success in the competitive design and drafting industry. Placement Assistance: CADD Centre Tambaram takes pride in its robust placement assistance program.

The institute has established strong ties with leading companies in the engineering, architectural, and design sectors, enabling it to offer excellent placement opportunities to its students. The dedicated placement cell provides support with resume building, interview preparation, and job search strategies, ensuring that students are well-prepared to enter the job market. This comprehensive support system has helped numerous graduates secure lucrative positions in top companies, further solidifying CADD Centre Tambaram’s reputation as a leading CAD training provider.

Flexibility and Accessibility: Understanding the diverse needs of its students, CADD Centre Tambaram offers flexible learning options, including part-time and full-time courses, as well as online training programs. This flexibility allows students to learn at their own pace and convenience, making quality education accessible to all. Whether you are a working professional looking to upskill or a fresh graduate seeking to start a career in CAD, CADD Centre Tambaram has a program that fits your schedule and learning preferences.

Conclusion : In conclusion, CADD Centre Tambaram is not just a training institute; it is a launching pad for successful careers in the world of CAD. With its comprehensive curriculum, expert instructors, state-of-the-art facilities, industry-relevant projects, and robust placement assistance, it offers an unparalleled learning experience. For anyone looking to excel in the fields of engineering, architecture, or design, CADD Centre Tambaram is the place to be.

0 notes

Text

CAD in India: Where Creative Length and Economic Efficiency Meet

The world of design has undergone a dramatic transformation. Gone are the days of painstaking manual drafting; computer-aided design (CAD) has revolutionized the way products are conceptualized, engineered, and brought to life. Today, 3D CAD services offer unparalleled freedom and flexibility, allowing designers to visualize and refine their creations with unprecedented detail and accuracy. However, the demands of CAD projects can be significant, especially for small and medium-sized businesses. Here’s where outsourcing CAD services to India emerges as a strategic and cost-effective solution. Consystent Info, a leading provider of CAD services, explores the benefits of this approach and highlights the potential of 3D CAD solutions for design projects of all sizes.

The Power of 3D CAD: Design Unleashed

3D CAD services empower designers to create realistic 3D models of products, buildings, and other physical objects. These models are far more than mere visuals — they are virtual prototypes that can be manipulated, tested, and analyzed in a virtual environment. This allows for:

Enhanced Design Visualization: 3D models offer a clear and comprehensive understanding of the design, facilitating collaboration and feedback from stakeholders at every stage of the project.

Improved Design Iteration: The ability to modify and refine a 3D model virtually allows for faster and more efficient design iterations, leading to a more optimized final product.

Streamlined Engineering Analysis: 3D models can be used for stress analysis, thermal analysis, and other engineering simulations, ensuring the product is functional and meets design specifications.

Reduced Prototyping Costs: Virtual prototyping through 3D CAD eliminates the need for expensive physical prototypes, resulting in significant cost savings.

Enhanced Communication: 3D models provide a common language for designers, engineers, and manufacturers, facilitating effective communication and minimizing misinterpretations.

The Case for Outsourcing CAD Services to India

While the benefits of 3D CAD are undeniable, the technology’s potential can often be underutilized by businesses due to resource limitations. Enter outsourcing CAD services to India. Here’s why this approach is gaining traction:

Cost Savings: Highly skilled and experienced CAD professionals in India offer competitive rates, allowing businesses to access high-quality CAD services at a fraction of the cost of in-house resources.

Scalability: Outsourcing CAD services provides access to a skilled workforce that can be scaled up or down depending on project requirements.

Access to Expertise: Businesses can tap into a pool of highly trained and experienced CAD professionals, gaining access to specialized skills and expertise that may not be readily available in-house.

Faster Turnarounds: With a dedicated team working on your project, outsourcing can significantly reduce turnaround times compared to in-house development.

Focus on Core Competencies: By outsourcing CAD tasks, businesses can free up internal resources to focus on core competencies and strategic initiatives.

Consystent Info: Your Trusted Partner for Outsource CAD Services India

Consystent Info is a leading provider of outsource CAD services India. We understand the specific needs of businesses seeking high-quality and affordable CAD solutions. Our team of experienced CAD professionals are proficient in a wide range of 3D CAD software platforms, including:

SolidWorks

Autodesk Inventor

CATIA

Siemens NX

Creo Parametric

We offer a comprehensive suite of 3D CAD services, including:

3D Modeling: Creating highly detailed and accurate 3D models of your designs.

2D Drafting: Generating high-quality 2D drawings from your 3D models for manufacturing and fabrication purposes.

Engineering Analysis: Utilizing 3D models to perform stress analysis, thermal analysis, and other engineering simulations.

Design for Manufacturing (DFM): Optimizing your design for efficient and cost-effective manufacturing.

3D Rendering: Creating photorealistic images and animations of your designs for marketing and presentation purposes.

The Future of Design: Embrace the Power of Outsourcing

By partnering with a reputable provider of outsource CAD services India like Consystent Info , you gain access to world-class talent, industry-leading technology, and cost-effective solutions. This empowers you to unlock the full potential of 3D CAD services and transform your design vision into reality. Contact Consystent Info today to discuss your project requirements and discover how we can help you design with freedom, efficiency, and success. Let us be your partner in bringing your innovative ideas to life.

0 notes

Text

Decoding Digital Twin Concept For Mobile Entrepreneurs

Imagine there exists an e-clone, a digital doppelgänger of yourself, in the virtual world.. Someone who can match your real-world capabilities & skills, and provide a replica of your own self, in a virtual world?

Someone who can never be impacted with pain or injury or embarrassment, and accomplish any and every task that you ask you to, with perfection?

It’s no more a fantasy, but a reality.

Welcome to the concept of Digital Twin, which is often declared as the flagbearer of the Industry 4.0 wave.

But what is it exactly and why should you, an entrepreneur and a decision-maker, care? Let's dive in and explore this revolutionary concept that's reshaping how we interact with the physical world.

Digital Twin: A Replica Of A Real-World Entity

A digital twin is a virtual replica of a physical object, process, or system.

It's like having a digital doppelgänger that mirrors its real-world counterpart in real-time.

For example, let’s say a wind turbine: It is equipped with powerful sensors that record data related to temperature, weather impact, energy output and more.

We take this data, send it to a processing system, and create a digital version of that wind turbine that resides inside a computer. This digital copy of the wind turbine can be used to create high level simulations, analyze performance, output and induce enhancements to find out the results, in real-time.

This data can be then used to optimize the real-world wind turbine, and not only save on costs of expensive experiments, but generate more energy, reduce production issues, and eventually, generate more ROI.

Magical, isn't it!

Brief History Of Digital Twin

The very concept of Digital Twin isn't new – NASA has been using similar concepts since the 1960s for space missions. In a research report, it was revealed that NASA has been using Digital Twin, known as Virtual Twin, to enable physical-model simulation of spacecraft, right inside computers and simulators placed on Earth.

That way, NASA was able to find out the exact outcomes of the spacecraft, without investing millions, ensuring high quality results on a consistent basis.

Recent advancements in IoT, ML, AI, and cloud computing have launched the idea of digital twin (earlier called virtual twin by NASA), into the spotlight across various sectors, including mobile apps and digital platforms.

The digital twin market is booming. According to a report, it's expected to grow from $10 billion in 2023-24 to more than $100 billion by 2028, at a CAGR of 64%. This explosive growth showcases how much businesses are betting on digital twin technology to drive innovation and efficiency.

Understanding Digital Twin: From Concept to Implementation

So, how do digital twins work in practice? At its core, a digital twin consists of three main components:

Sensors on the physical object collect data, which is then fed into the digital model. This model uses this data to simulate the physical object's behavior, allowing for real-time monitoring, analysis, and optimization. The connection and the channel between the physical entity and the digital replica is done via Digital Thread.

Let's look at a few real-world digital twin examples, as shared at the beginning of this blog.

Siemens Gamesa, a leader in the wind power industry, uses digital twins to optimize wind farm performance. They create virtual replicas of entire wind farms, allowing them to predict maintenance needs, optimize energy production, and even test new designs before implementation.

This approach has led to a 4000X increase in simulating computational fluid dynamics, which enables the company to enable rapid and accurate simulation of wake effects, thereby boosting productivity and output.

Similarly, Siemens' NX CAD software and Simcenter simulation tools are used to create digital twins of vehicles, enabling engineers to test and optimize designs before physical prototypes are built.

Another very good example is smart cities.

Civil engineers and urban planners are aided by digital twins that show 3D and 4D spatial data in real-time and incorporate augmented reality systems into built environments. This allows city officials to monitor infrastructure, manage traffic flow, and respond to emergencies more effectively.

The Business Value Proposition: Why Digital Twin Matter for Decision Makers

As a decision-maker, you might be wondering, "What's in it for me?" The answer is plenty. Digital twin offers three primary benefits: cost reduction, enhanced decision-making, and innovation.

Let’s find out how, with real-life examples:

This Is How GE Reduced Costs With Digital Twin

By simulating processes and predicting issues before they occur, digital twins can significantly cut down on maintenance costs and downtime.

For instance, GE Healthcare uses digital twins to monitor and maintain medical equipment, all across the globe.

This proactive approach has reduced unplanned downtime by up to 20%, and reduced costs by 30%, thereby saving hospitals millions in lost revenue and improving patient care.

McLaren Racing Ensures Accurate Split-Second Decisions

Digital twin provides a risk-free environment to test scenarios and make data-driven decisions, and McLaren F1 racing team is the perfect example.

They use digital twins to simulate race conditions and optimize car performance, via more than 300 sensors that are attached to the F1 racing cars.

This allows them to make split-second decisions during races, giving them a competitive edge on the track.

Unstoppable Innovations By Procter & Gamble

By providing a platform for virtual experimentation, digital twins accelerate innovation cycles, as observed in Procter & Gamble.

They use digital twins to simulate and optimize their production lines. Using Digital Twins for the assembly lines, and workflows, they know in advance, which factors can cause delays, and have the solutions beforehand.

This has allowed them to bring products to market 20-30% faster, thereby surprising their competitors, and staying ahead of the competition.

Integrating Digital Twin into Your Mobile App Strategy

This is a mobile-first world, and there exists immense possibilities on how the concept of Digital Twin can supercharge mobile applications, and empower the businesses that are built around them.

When developing digital twin-enabled mobile apps, consider these key factors:

A great example of digital twin software in action is Boeing’s AR-powered mobile app, which acts like a digital twin of their aircraft.

This digital twin of Boeing helped them to generate more than 10,000 images, which enabled them to deeply and analytically understand the issues related to maintenance and performance, and produce better planes, at a reduced research expense.

Another area where digital twins are being integrated with mobile apps and digital platforms is in the field of predictive maintenance.

By combining data from sensors on physical assets with machine learning algorithms, digital twins can predict when equipment is likely to fail and recommend preventive maintenance actions. This information can be accessed through mobile apps and digital dashboards, enabling maintenance teams to optimize their workflows and reduce downtime.

Future-Proofing Your Business: Preparing for the Digital Twin Era

As digital twin technologies continue to evolve, staying ahead of the curve is essential. Here are some emerging trends to watch:

AI and Machine Learning Integration: Digital twins are becoming smarter, using AI to predict outcomes and suggest optimizations autonomously.

Digital Thread: This concept links digital twins across an entire product lifecycle, from design to disposal, providing unprecedented insights.

Metaverse Integration: As the metaverse develops, digital twins could become our primary interface with the physical world in virtual spaces.

To start implementing digital twin in your organization:

While the benefits are clear, implementing digital twins does come with challenges. Data security, integration with legacy systems, and the need for specialized skills are common hurdles. However, with careful planning and the right partners, these obstacles can be overcome.

Conclusion: Digital Twins Is Changing The Future Of Tech & Business

Digital twin technology is not just a buzzword – it's a powerful concept that's reshaping how we interact with the physical world, and optimize experiences and outcomes.

By providing unprecedented insights, along with intelligence and enabling proactive decision-making, digital twins are helping businesses across industries to reduce costs, mitigate risks, boost productivity and drive innovation.

As we move further into the digital age, the line between the physical and digital worlds will continue to blur.

Digital twins will play a crucial role in this convergence, offering a bridge between the tangible and the virtual.

For growth-centric businesses, now is the time to explore what digital twins can do for you. After all, in the race for digital transformation, why settle for a single reality when you can leverage two?

Original Source: https://www.techaheadcorp.com/blog/what-is-digital-twin-technology-and-how-does-it-work/

0 notes

Text

How to Pick the Finest 3D Modelling Program for Your Needs in Engineering and Design

Selecting the appropriate 3D modeling software for your engineering and design projects is essential for achieving efficiency and maximizing productivity. Here’s a guide to assist you in making a well-informed choice among the leading software options available:

Scrutinize your project's needs: Start by identifying the specific requirements for your projects. Are you focused on architectural design, mechanical engineering, electrical systems, or structural analysis? Each software has its own strengths:

SketchUp: Ideal for rapid and intuitive 3D modeling in architecture, product design, and urban planning.

Spectron: Excels in advanced engineering simulations, supporting structural analysis and material science.

Rhino Software: Perfect for intricate mechanical parts and 3D printing, offering flexibility and precision.

Materialize: Specializes in 3D printing and additive manufacturing, providing tools for production-ready designs.

CSI Products (SAP2000, ETABS, SAFE): Tailored for structural analysis and design of buildings and bridges.

Siemens: Offers a variety of tools (NX, Solid Edge) for comprehensive CAD, CAM, and CAE applications in product development.

MI Power: Designed for electrical power system analysis, focusing on modeling, analyzing, and optimizing power grids.

Learning Curve Consideration: Consider how quickly your team can adapt to and use the software proficiently. Some software is straightforward, while others require more effort to master due to their complexity.

Integration and Compatibility Analysis: Evaluate how the software fits into your existing workflow and systems. Certain tools are noted for their seamless integration with a variety of platforms.

Cost and Licensing Analysis: Examine your budget and the licensing terms of each software. Many software solutions offer different pricing structures that are advantageous for smaller groups or solo practitioners.

Performance and Feature Testing: Use demo versions or trials to assess the software’s capabilities in your work environment. This hands-on experience will guide your decision-making process.

Seek Insights and Reviews: Collect feedback from colleagues and other users. Forums and discussion boards can provide in-depth insights into each software’s pros and cons.

Future-Proofing: Consider the scalability of the software and its ability to meet future project demands. Choose a solution that can grow alongside your projects.

Concerned about the ideal software for your project or in need of advice? For more assistance with similar services, get in touch with Tridax (tridaxsolutions.com), and their professionals would be pleased to help!

1 note

·

View note