#nickel superalloy properties

Explore tagged Tumblr posts

Note

How significant is powder metallurgy for the use of bastardly-to-machine stuff like inconel these days? it's just i was checking out some quotes for DMLS printing recently and there wasn't *that* much of a price delta between alu and stuff like maraging steel and superalloys

I can’t speak to other industries, but in rocket engineering and fusion engineering it’s huge. Everybody loves to 3D print inconel, as well as funky copper alloys (shoutout to GRCop-84) and steel. It has terrific mechanical properties and you can make almost any arbitrary shape. The hot new thing to do is to 3D print as much of your rocket as possible.

HOWEVER, in nuclear fusion, inconel in general is kind of going out of fashion. For those of you in the room who aren't familiar, inconel refers to a class of "superalloys," structural metals that can retain their strength while very close to their melting point. One would think this would be a super useful property in a fusion reactor, and one would be absolutely correct. JET in the UK went hog-wild with inconel, as did TFTR at Princeton.

But, depending on the alloy, inconel is anywhere from 50% to 70% nickel. Nickel is particularly problematic in areas of high neutron flux (like, say, in a fusion reactor), where it captures neutrons and "activates." Almost every element does this to one extent or another, but it's real bad when it happens to nickel.

I'm not a neutronics person, but from what they tell me, the various transmutation reactions give you both radioactive byproducts with annoyingly long half-lives, and pockets of helium that lead to severe embrittlement. A nickel-rich alloy is just not going to have a good time in a fusion power plant, long term.

96 notes

·

View notes

Text

Things You Should Know About Hastelloy Flanges By Manilaxmi Industrial

Manilaxmi Industrial: When it comes to choosing materials for industrial applications, Hastelloy flanges stand out as a top option due to their remarkable properties and performance। Understanding Hastelloy flanges' characteristics and benefits can help you make informed choices about your projects, whether you're working in chemical processing, oil and gas production, or power generation। What you need to know about Hastelloy flanges is here।

What are Hastelloy Flanges?

Hastelloy flanges are components made from Hastelloy, a high-performance alloy primarily composed of nickel, chromium, and molybdenum. This superalloy is renowned for its excellent corrosion resistance, high-temperature strength, and durability in harsh environments. Flanges are used to connect pipes, valves, pumps, and other equipment, ensuring a secure and leak-proof system.

Key Properties of Hastelloy Flanges?

1. Corrosion Resistance: Hastelloy flanges are highly resistant to various forms of corrosion, including pitting, crevice corrosion, and stress corrosion cracking. This makes them ideal for use in aggressive environments where other materials might fail.

2. Temperature Resistance: These flanges can withstand extreme temperatures, both high and low, without losing their structural integrity. This property is crucial for industries that operate under severe thermal conditions.

3. Mechanical Strength: Hastelloy flanges offer exceptional mechanical strength, ensuring durability and reliability even under high stress and pressure.

4. Versatility: Due to their unique properties, Hastelloy flanges are versatile and suitable for a wide range of applications across various industries

Types of Hastelloy Flanges?

Hastelloy flanges come in different types, each designed for specific applications and connection methods. Common types include:

• Weld Neck Flanges: These flanges are designed to be welded to the pipe, providing a strong and leak-proof connection ideal for high-pressure applications.

• Slip-On Flanges: Easier to install than weld neck flanges, these are slipped over the pipe and then welded. They are suitable for low-pressure environments.

• Blind Flanges: Used to close the end of a pipe or valve, blind flanges are essential for testing and maintenance purposes.

• Socket Weld Flanges: These flanges are similar to slip-on flanges but have a socket for welding, providing a smoother flow inside the pipe.

• Lap Joint Flanges: These are used with a stub end and are ideal for systems that require frequent disassembly.

Applications of Hastelloy Flanges?

Given their superior properties, Hastelloy flanges are used in a variety of demanding applications, such as:

• Chemical Processing: The exceptional corrosion resistance of Hastelloy makes it perfect for handling corrosive chemicals and acids.

• Oil and Gas: In the oil and gas industry, Hastelloy flanges are used in pipelines and equipment exposed to harsh environments and high pressures.

• Power Generation: These flanges are used in power plants, particularly in high-temperature and high-pressure sections.

• Marine Engineering: Hastelloy’s resistance to seawater corrosion makes it ideal for offshore and marine applications.

Advantages of Using Hastelloy Flanges?

1. Longevity: The durability and resistance to wear and tear extend the lifespan of the equipment, reducing the need for frequent replacements.

2. Safety: Enhanced mechanical strength and corrosion resistance ensure safer operations in critical applications.

3. Cost-Effective: Despite the higher initial cost, the longevity and reliability of Hastelloy flanges can lead to cost savings over time by minimizing downtime and maintenance.

#Hastelloy Flanges#Hastelloy Flange Manufacturer#Hastelloy Flanges Supplier#Buy Hastelloy Flanges Online#Hastelloy Flange Types#Hastelloy C276 Flanges#Hastelloy C22 Flanges#Hastelloy Flanges Price#Industrial Hastelloy Flanges#Hastelloy Flanges Exporter#Custom Hastelloy Flanges#High-Quality Hastelloy Flanges#Corrosion-Resistant Hastelloy Flanges#Hastelloy Flanges for Chemical Industry#Hastelloy Flanges for Oil & Gas#Hastelloy Flanges Specifications#Hastelloy Flanges Distributor#Hastelloy Flanges Stockist#Hastelloy Flanges Applications#Best Hastelloy Flanges

2 notes

·

View notes

Text

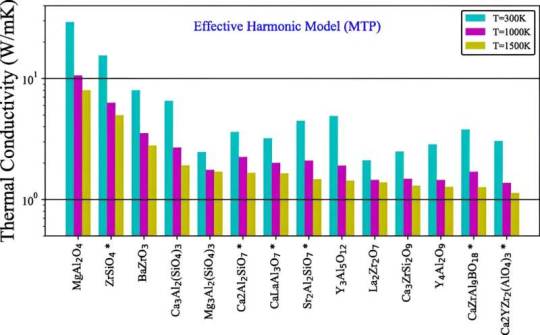

New ceramics promise hotter gas turbines that produce more power

Skoltech researchers have identified promising ceramic materials for metal coatings that would boost gas turbine efficiency. If further experimental tests prove successful, the coatings will enable power plants to produce more electricity and jet planes to consume less fuel. With the material discovery technique tried and tested, the researchers intend to continue the search and find more candidates with perhaps even better properties. The study is published in Physical Review Materials. Thermal barrier coatings are used to protect turbine blades at power plants and in jet engines. The blades themselves are made of nickel-based superalloys. These offer a great combination of high-temperature strength, toughness, and resistance to degradation. However, as things get really hot, the superalloy softens and may even melt. Protective coatings make it possible to operate turbines at higher temperatures without compromising their integrity. And in this case, higher temperature means greater efficiency.

Read more.

#Materials Science#Science#Ceramics#Skoltech#Coatings#High temperature materials#Thermal conductivity

2 notes

·

View notes

Text

Chapter 199 Trivia (Part 2)

(Previous part)

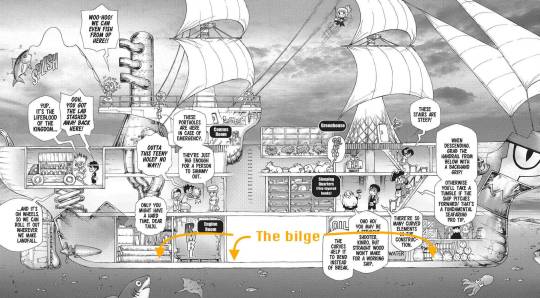

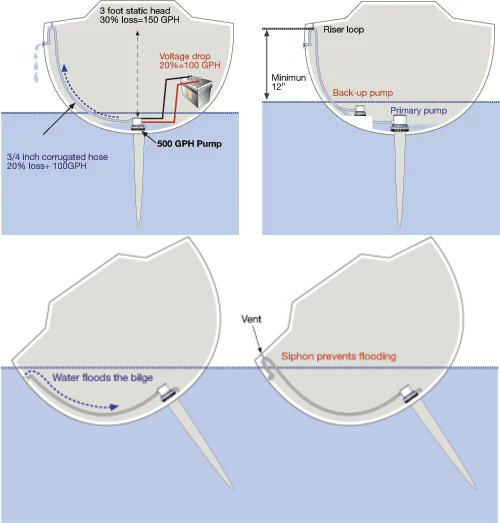

The drainage function Xeno is talking about here that caused the Perseus to sink is probably the bilge pump. The bilge is the lowest part of the ship. As any water on a ship drains downwards, a pump is needed to remove the water so it doesn't collect.

Without anyone ensuring the pump didn't stop, the hull filled with water and the Perseus sank. Bilge water also isn't usually just water, but can be full of other things like oil, chemicals, pitch, and dirt.

The KoS used pillow lift bags to recover the Perseus. To do this, someone needs to dive down and attach them (Taiju and Ryusui again, maybe?), then inflate them with compressed air.

A lifting bag filled with 1L of air lifts 1kg of weight, so if we knew the total size of the bags we could approximate the weight of the Perseus… Except they grossly overestimated, since the ship is flying out of the water rather than lifting slowly in a controlled manner.

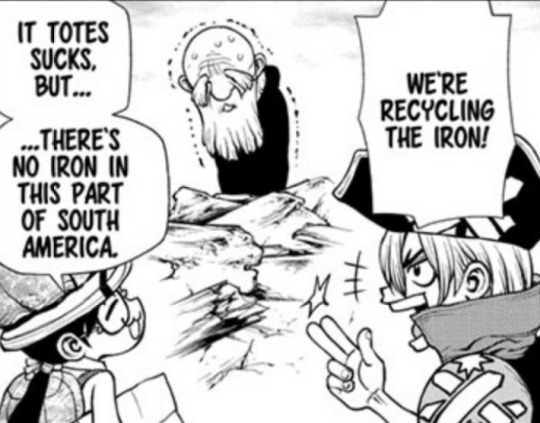

Chelsea's iron comment here confuses me because several of the ores they collected include iron in them? Maybe there's just not enough.

The simplicity of the lower half of the mecha shown here along with the briefs reminds me of Astro Boy. The top half I believe is just the "DR" from Dr. Stone along with rocket-ship-inspired arms and Senku's face. Alternatively, it could be a reference to Tetsujin 28, also known in the western audiences as Gigantor, or even Mazinger Z.

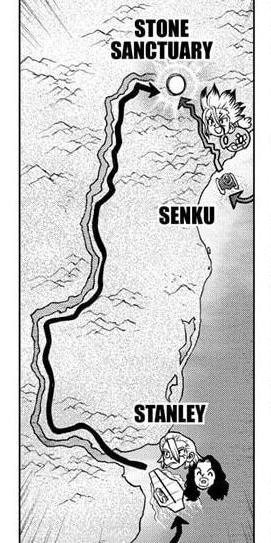

Isla Martin Garcia is on the mouth of the Río de la Plata, between Uruguay and Argentina. It's less than 2km^2, and 150 people live there permanently (=Dunbar's number?)

If you're wondering why the KoS is suddenly so far away from Fort Medusa, it's because it's where Stanley docked the Perseus several chapters ago.

Stainless steel uses approximately 11% chromium to get its heat- and rust-resistant properties, but can include other elements as well.

Senku had already introduced bottling to the Ishigami villagers, but the addition of canning means less glass. Canning is especially good because while both methods can last several years, cans don't shatter and also protect from light. They also weigh less!

Francois is making cans of fish meat and "gibier", which is the French word for game, or any kind of hunted meat. Going by the size of the carcasses and the picture on the can, I think it may be cow as Uruguay also eats the most beef per person in the world.

Francois is serving sashimi on a generic model boat. How fancy!

I assume this won't be the design for the next Perseus, since it's made of wood rather than superalloys (and also covered in fish).

Is Carlos jealous or uncomfortable with the fact that Max is reviving someone who looks just like him? I wonder if there's any blood relation…

Taiju is tired for what may be the first time ever! Though it could be because he somehow managed to wear out a pickaxe of all things…

Maya is revival #75 according to the bottle Taiju is holding. It also means Taiju returned back to Fort Medusa to mine rather than staying at Isla Martin Garcia.

Communication between Fort Medusa and Isla Martin Garcia is established thanks to the usual radio setup, but with the addition of a Yagi-Uda antenna. This is a directional antenna, so they may be trying to hide from Whyman.

Senku and Chrome simply mark dangerous items with a skull and crossbones. Xeno? He makes the entire thing into the shape, with gas coming out of the eyes.

Can you get any more cartoonishly villainous, Xeno!?

Xeno uses the Mond process to purify nickel.

The toxic gas he mentions is nickel carbonyl, which can be fatal if absorbed through the skin or inhaled. The gas smells musty or sooty, and decomposes to carbon monoxide quickly. Special gas masks are required to block the fumes.

Xeno loves referring to people as the "mindless/ignorant masses". I wonder if his parents were the original "ignorant masses" telling him to stop messing around with dangerous chemicals in the backyard…

I think this rock that Taiju finally manages to break with the help of Maya (and a new pickaxe) is the same one from before, but from a different angle.

A few outfit changes: Suika's lenses are now full circles and not broken, Xeno's zipper is straight rather than zig-zagged and Charlotte has a little skirt to cover herself up better.

The timeline isn't very clear here, but at least 2 weeks pass between Maya and Charlotte's revival and Xeno's discussion with Senku going by moon phase.

Many people have been revived, but because of the location they likely speak Spanish. We know several of the KoS know English and Japanese, and Francois knows French, so who's translating here?

I think it's funny Xeno didn't get a team-up high-5 from Senku even though everyone else does. They may be superallies now but not even Senku wants to go near those claws…

#trivia#dr stone#chapters#199#I had to remove so many images because I hit the max despite putting this into two parts...

6 notes

·

View notes

Text

A Comprehensive Guide to Inconel Alloy 718

Introduction

Inconel 718 is a high-performance nickel-chromium alloy known for its exceptional strength, corrosion resistance, and heat resistance. It is widely used in industries such as aerospace, power generation, marine, and chemical processing. Developed in the 1950s, Inconel 718 remains one of the most versatile and reliable superalloys in demanding applications.

Inconel 718 fasteners are high-strength, corrosion-resistant fasteners made from a nickel-based superalloy known for its exceptional performance in extreme environments. These fasteners are widely used in industries such as aerospace, marine, chemical processing, and power generation due to their superior mechanical properties, oxidation resistance, and excellent weldability.

Composition of Inconel 718

Inconel 718 is primarily composed of nickel, chromium, and iron, with additional elements that enhance its properties. Below is a typical chemical composition of Inconel 718:

Key Properties of Inconel 718

1. High Strength and Toughness

One of the most notable features of Inconel 718 is its outstanding mechanical strength. It has excellent tensile and yield strength, making it ideal for applications that require durability under extreme stress.

2. Corrosion and Oxidation Resistance

Inconel 718 offers superior resistance to corrosion and oxidation in harsh environments. It performs exceptionally well in high-temperature, high-pressure, and chemically aggressive conditions.

3. Excellent Weldability

Unlike many other superalloys, Inconel 718 can be welded easily without the risk of cracking. This is due to its slower precipitation hardening response, which prevents strain-age cracking.

4. High-Temperature Stability

It maintains its mechanical properties at elevated temperatures, up to 1300°F (704°C). This makes it suitable for aerospace and gas turbine applications.

5. Creep and Fatigue Resistance

The alloy demonstrates excellent creep resistance and fatigue strength, making it ideal for components subjected to cyclic loads over extended periods.

Applications of Inconel 718

1. Aerospace Industry

Inconel 718 is extensively used in jet engines, gas turbines, and aerospace components, including:

Turbine blades and discs

Combustion chambers

Fasteners and structural components

2. Power Generation

The alloy is used in nuclear reactors, steam turbines, and power plants due to its ability to withstand extreme temperatures and pressures.

3. Oil and Gas Industry

Inconel 718 is widely used in drilling equipment, downhole tools, and pipelines due to its resistance to corrosion, pressure, and temperature.

4. Marine Industry

Naval and marine applications, including submarine and offshore structures, benefit from the alloy’s resistance to saltwater corrosion.

5. Chemical Processing Industry

Inconel 718 is used in chemical plants for heat exchangers, reactor vessels, and piping systems exposed to aggressive chemicals.

Manufacturing and Processing of Inconel 718

Heat Treatment

Inconel 718 is typically heat-treated to achieve its full mechanical properties. The standard heat treatment process includes:

Solution Annealing - Heating to 980-1010°C followed by rapid cooling.

Aging Treatment - Heating at lower temperatures (720°C) to enhance hardness and strength.

Machining and Fabrication

Due to its toughness, Inconel 718 is challenging to machine. Specialized cutting tools and techniques, such as carbide tooling and slow cutting speeds, are used.

Welding

The alloy is readily weldable using conventional welding techniques like TIG and MIG welding. Post-weld heat treatment is recommended to prevent potential issues like stress corrosion cracking.

Comparison of Inconel 718 with Other Alloys

Conclusion

Inconel 718 is a superior superalloy known for its exceptional strength, corrosion resistance, and thermal stability. Its extensive use in aerospace, power generation, oil & gas, marine, and chemical industries highlights its importance in high-performance applications. Although it is expensive and challenging to machine, its unique combination of properties makes it an indispensable material in critical environments.

If you are looking for a high-strength, corrosion-resistant alloy with excellent performance under extreme conditions, Inconel 718 is undoubtedly one of the best choices available.

FAQs

Q1: What makes Inconel 718 different from other Inconel alloys?A: Unlike other Inconel alloys, Inconel 718 has superior weldability and a unique precipitation hardening mechanism that enhances its strength.

Q2: Can Inconel 718 be used at cryogenic temperatures?A: Yes, Inconel 718 retains good mechanical properties at cryogenic temperatures, making it useful for applications requiring low-temperature performance.

Q3: What is the lifespan of Inconel 718 components?A: Due to its excellent fatigue and creep resistance, Inconel 718 components have a long operational lifespan, often exceeding several decades in the right conditions.

Q4: How does Inconel 718 compare with stainless steel?A: Inconel 718 is much stronger and more resistant to heat and corrosion compared to stainless steel, but it is also more expensive and harder to machine.

For more technical details and applications of Inconel 718, feel free to reach out to experts or consult material data sheets from manufacturers.

#ananka#fasteners#articles#inconel#inconel718#inconelfasteners#fastenersmanufacturer#inconelalloy#anankafasteners#manufacturer#supplier#hex#mumbai#blogs#tumblr blog#bolt

0 notes

Text

Aerospace metal components Usages

Aerospace metal components play a vital role in various critical applications within the aviation and space sectors. These components are engineered for high strength, lightweight properties, and the ability to withstand extreme temperatures and conditions. Here are some key areas where aerospace metal components are utilized: 1. Aircraft Structures Fuselage: Materials like titanium, aluminum, and composites are employed to ensure strength while minimizing weight. Wings: Constructed from aluminum alloys and titanium to endure aerodynamic forces. Landing Gear: High-strength steel and titanium are used for their durability and impact resistance. 2. Engines & Propulsion Systems Jet Engine Components: Turbine blades, combustion chambers, and exhaust systems are made from titanium, nickel-based superalloys, and stainless steel. Rocket Engines: Superalloys such as Inconel and titanium are designed to handle extreme heat and pressure. 3. Spacecraft & Satellites Structural Frames: Aluminum and titanium are utilized in satellite frames and spacecraft structures for their lightweight and corrosion-resistant properties. Heat Shields: High-temperature alloys like Inconel and ceramic-coated metals safeguard spacecraft from the intense heat of reentry. 4. Fasteners & Hardware Bolts, nuts, and rivets crafted from titanium or stainless steel secure aerospace components under high stress and vibration conditions. 5. Electronic & Avionics Housings Aluminum and magnesium alloys provide shielding and lightweight protection for sensitive electronic components. 6. Fuel & Hydraulic Systems Stainless steel and titanium are preferred materials for fuel lines, pumps, and hydraulic actuators due to their corrosion resistance and ability to perform under high pressure.

0 notes

Text

Inconel Tube Manufacturer

Amongst industrial materials, all those who did not over-step in the sense must necessarily have included in their ranks, standing in the limelight those that actually over-stretched themselves beyond the limits of others at that extreme level into the material of Inconel.

Being the suppliers of the different varieties of tubing tubes for organizations up to now, types in the Inconel that enabled provision and availing different forms of services and commodity products in multiple industries Inconel Tube Manufacturer around this world's many parts; indeed, in fact, that the search, by way of being visibly and perceptually seen and contemplated merely as good as it may be, enough, partly in appreciation, as it happens, for that aesthetic appeal which this very fact presents as itself to produce just this existing condition that there is already a large number of organizations forming such growth wherein, in entirety, it may represent what in this world there is and can develop. We then move to the details on some properties of Inconel tubes, application, and the best by working with a good manufacturer of Inconel.

Interestingly, Inconel is one all pure superalloy containing chrome with nickel. Oxidation resistance here is fabulous with superb corrosion resistance superior. It would have to be the best example of some properties that a material can provide for the tubings while working at conditions which are simply phenomenal, keeping in view the kind of working environment that would actually call for phenomenal strength to work.

For an enthusiast who would want to enjoy some of the high-performance traits, in the front product it would just have been part of any meaningful effort or undertaking that one would have undertaken had been to sport Inconel tubing.

Inconel Tube Manufacturer astronomical while the edginess of itself, relative to the thousands there within various industries of settings; through playing on such an elementary basis of which lies there: that one, said of this very system-of one Inconel tube. This would, therefore mean that if you choose an organization that you can consider credible, then surely you would be assured of receiving the best possible product, which comes in combination with quality and reliability. Be that as it may, in any case standards or specific tubes of Inconel have that of course peaceful times while working together with the firm that for all intents and purposes has a substantial amount of the same since to begin with is only going all out for high applications.

0 notes

Text

Nickel Superalloy market Analysis, Size, Share, Growth, Trends, and Forecasts by 2031

The global nickel superalloy market represents an intriguing and dynamic sector within the metallurgical industry. This specialized market is distinctive for its extraordinary resilience and adaptability in the face of shifting industrial landscapes and technological advancements.

𝐆𝐞𝐭 𝐚 𝐅𝐫𝐞𝐞 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭:https://www.metastatinsight.com/request-sample/2442

Top Companies

Precision Castparts Corp. (PCC)

ATI (Allegheny Technologies Incorporated)

Carpenter Technology Corporation

Doncasters Group Ltd

Haynes International, Inc.

Rolled Alloys, Inc.

Sandvik AB

VDM Metals GmbH

Howco Group plc.

Special Metals Corporation

Langley Alloys Ltd

Neonickel Ltd.

Voestalpine AG

Michlin Metals Inc

AMETEK, Inc

This report delves into the world of nickel superalloys, examining the essential aspects that define their uniqueness, market dynamics, applications, and the factors that drive its growth.

𝐄𝐱𝐩𝐥𝐨𝐫𝐞 𝐭𝐡𝐞 𝐅𝐮𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭:@https://www.metastatinsight.com/report/nickel-superalloy-market/2442

Nickel superalloys, often dubbed as high-performance alloys, are materials forged under extreme temperatures, engineered with precise elemental compositions. These alloys are primarily distinguished by their high resistance to corrosion, excellent mechanical properties at elevated temperatures, and superior durability. Composed primarily of nickel, these alloys integrate various alloying elements such as cobalt, chromium, and molybdenum to augment their performance characteristics.

The global nickel superalloy market is not just a niche industry, but a thriving ecosystem embedded within the very fabric of modern society. Its resilience is underpinned by its irreplaceable role in a wide range of applications across industries as diverse as aerospace, energy, healthcare, and manufacturing. As industries evolve and technologies advance, the nickel superalloy market continues to adapt, ensuring that high-performance materials remain a cornerstone of modern engineering and innovation.

Global Nickel Superalloy market is estimated to reach $9,110.2 Million by 2030; growing at a CAGR of 7.6% from 2023 to 2030.

Contact Us:

+1 214 613 5758

#NickelSuperalloy#NickelSuperalloymarket#NickelSuperalloyindustry#marketsize#marketgrowth#marketforecast#marketanalysis#marketdemand#marketreport#marketresearch

0 notes

Text

Petrovietnam-approved flanges in KSA

Inconel 625 Flanges: The Pinnacle of Strength and Corrosion Resistance

The unchallenged leaders in high-performance materials for harsh environments are Inconel 625 Flanges. Made from an alloy of nickel, chromium, and molybdenum, these flanges are renowned for their remarkable resistance to oxidation, corrosion, and high-temperature stresses. The most demanding applications are met by Inconel 625 flanges, which are designed for deep-sea oil rigs and aerospace systems.

What is Inconel 625?

Inconel 625 is a nickel-based superalloy with high levels of chromium, molybdenum, and niobium. These elements impart superior strength, toughness, and resistance to a wide range of corrosive media, including seawater, acids, and alkalis.

Key Properties of Inconel 625:

Exceptional Corrosion Resistance: Withstands pitting, crevice corrosion, and oxidation in harsh environments.

High-Temperature Strength: Maintains integrity and mechanical properties at temperatures up to 2000°F (1093°C).

Fatigue and Stress Resistance: Excellent resistance to cracking under cyclic and thermal stresses.

Versatility: Performs well in oxidizing and reducing conditions.

Types of Inconel 625 Flanges

Inconel 625 flanges are available in various types, each suited to specific industrial needs:

Slip-On Flanges

Easy to align and install, ideal for low-pressure systems.

Weld Neck Flanges

Perfect for high-pressure and high-temperature applications, offering seamless stress distribution.

Blind Flanges

Used to seal the ends of pipelines or pressure vessels.

Lap Joint Flanges

Designed for systems requiring frequent dismantling and reassembly, paired with stub ends.

Socket Weld Flanges

Preferred in smaller pipelines, providing a secure and leak-proof connection.

Ring Type Joint (RTJ) Flanges

Ensures leak-proof sealing in high-pressure environments.

Nipo Flanges and Spacer Flanges

Customized for specialized applications requiring durability and precision.

Applications of Inconel 625 Flanges

The superior properties of Inconel 625 flanges make them indispensable in a wide range of industries:

Oil and Gas: Used in offshore platforms, subsea equipment, and pipelines exposed to seawater and corrosive hydrocarbons.

Aerospace: Integral to jet engines, exhaust systems, and turbine components that operate under extreme temperatures.

Chemical Processing: Ideal for handling aggressive chemicals, acids, and solvents.

Marine Engineering: Resistant to seawater and brine, making them essential in shipbuilding and desalination plants.

Power Generation: Utilized in boilers, heat exchangers, and flue gas scrubbers.

Why Choose Inconel 625 Flanges?

Corrosion Resistance: Protects against a wide array of corrosive media, ensuring long service life.

High Strength: Withstands intense mechanical stress in demanding environments.

Thermal Stability: Maintains performance across a wide temperature range.

Standards Compliance: Manufactured to meet international standards like ASTM B564, ASME B16.5, and DIN specifications.

Customization: Available in a variety of sizes, pressure ratings, and face types to suit specific operational needs.

Advantages of Inconel 625 Flanges

Durability: Long-lasting in harsh environments, reducing maintenance and replacement costs.

Versatility: Suitable for both oxidizing and reducing conditions, enhancing operational flexibility.

Reliability: Withstands fluctuating pressures and temperatures without compromising structural integrity.

Weldability: Facilitates easy fabrication and installation for complex piping systems.

Conclusion

For industries requiring exceptional strength, dependability, and resistance to harsh environments, Inconel 625 flanges are the best option. Even in the most demanding applications, their resilience to high temperatures, pressures, and corrosive media guarantees longevity and operational efficiency. Searching for Inconel 625 Flanges of the highest caliber? Collaborate with reliable producers to find flanges that satisfy the exacting requirements of your project. Invest in performance, longevity, and peace of mind for your vital operations by selecting Inconel 625.

For More Information:

Visit Our Website: https://www.merakimetals.ae

Contact No: +971-523973687

E-Mail ID: [email protected]

#Inconel 625 Flanges Manufacturers in UAE#Inconel 625 Flanges Suppliers in UAE#Inconel 625 Flanges Stockists in UAE#Inconel 625 Flanges Exporters in UAE#Petrovietnam Approved Flanges in UAE#PTT Global Chemical Approved Flanges in UAE#PTTP Approved Flanges in UAE

0 notes

Text

Global Nickel-Based Superalloys Market Analysis 2024: Size Forecast and Growth Prospects

The nickel-based superalloys global market report 2024 from The Business Research Company provides comprehensive market statistics, including global market size, regional shares, competitor market share, detailed segments, trends, and opportunities. This report offers an in-depth analysis of current and future industry scenarios, delivering a complete perspective for thriving in the industrial automation software market.

Nickel-Based Superalloys Market, 2024 report by The Business Research Company offers comprehensive insights into the current state of the market and highlights future growth opportunities.

Market Size - The nickel-based superalloys market size has grown strongly in recent years. It will grow from $8.06 billion in 2023 to $8.79 billion in 2024 at a compound annual growth rate (CAGR) of 9.1%. The growth in the historic period can be attributed to a rise in the automotive industry, increasing demand for electric vehicles, increased aviation fuel efficiency, increasing demand for lngot metallurgy in various industries, and increasing fuel economy and performance.

The nickel-based superalloys market size is expected to see strong growth in the next few years. It will grow to $12.65 billion in 2028 at a compound annual growth rate (CAGR) of 9.5%. The growth in the forecast period can be attributed to growing demand from aerospace for lightweight alloys, growing focus on renewable energy, growing need for high-performance materials, growing use of gas turbines in the power generation industry, and growing need for sophisticated materials. Major trends in the forecast period include technological advancements, advancements in 3D printing for complex superalloy components, the development of complicated geometries, the development of next-generation aircarft, and advancements in alloy design.

Order your report now for swift delivery @ https://www.thebusinessresearchcompany.com/report/nickel-based-superalloys-global-market-report

Scope Of Nickel-Based Superalloys Market The Business Research Company's reports encompass a wide range of information, including:

1. Market Size (Historic and Forecast): Analysis of the market's historical performance and projections for future growth.

2. Drivers: Examination of the key factors propelling market growth.

3. Trends: Identification of emerging trends and patterns shaping the market landscape.

4. Key Segments: Breakdown of the market into its primary segments and their respective performance.

5. Focus Regions and Geographies: Insight into the most critical regions and geographical areas influencing the market.

6. Macro Economic Factors: Assessment of broader economic elements impacting the market.

Nickel-Based Superalloys Market Overview

Market Drivers - The expansion of the aerospace industry is expected to propel the growth of the nickel-based superalloy markets going forward. The aerospace industry refers to businesses involved in designing, developing, producing, and maintaining aircraft, spacecraft, and related systems and equipment. The demand for the aerospace industry is rising due to increasing global air travel, driven by expanding middle-class populations and the push for next-generation fuel-efficient aircraft to meet stricter environmental regulations. Nickel-based superalloys are essential in the aerospace industry due to their exceptional properties, enabling high performance in extreme environments. For instance, in September 2023, according to the Aerospace Industries Association (AIA), a US-based trade association representing manufacturers and suppliers of civil, military, and business aircraft, in 2022, the American aerospace and defense industry saw a 6.7% increase in sales, reaching over $952 billion compared to 2021. Therefore, the expansion of the aerospace and power industries is driving the growth of the nickel-based superalloys market.

Market Trends - Major companies operating in the nickel-based superalloy market are focusing on developing technologically advanced solutions, such as nickel ultra-high-temperature superalloy, to meet the growing demand for enhanced performance in critical applications like aerospace and power generation. Nickel ultrahigh-temperature superalloys are advanced materials that withstand extreme temperatures and harsh environments. For instance, in July 2024, Alloyed and Aubert & Duval, a France-based metallurgical company, launched a new nickel superalloy named ABD-1000AM, specifically designed for additive manufacturing and capable of withstanding temperatures exceeding 1000°C in its age-hardened state. This ultra-high-temperature alloy boasts a relative density greater than 99.9%, a significant gamma prime phase fraction of 55%, and comparable stress rupture life to the cast alloy Ni247LC. The development utilized Alloyed's Alloys-by-Design platform, with Aubert & Duval providing the necessary powder feedstock.

The nickel-based superalloys market covered in this report is segmented –

1) By Type: Nickel-Copper, Nickel-Chromium, Nickel-Molybdenum, Other Types 2) By Form: Cast, Wrought 3) By Base Element: Cobalt, Rhenium, Tantalum, Tungsten 4) By Distribution Channel: Direct Sales, Distributors And Traders 5) By End-Use Industry: Aerospace, Electronics, Industrial, Automotive, Oil And Gas, Other End Use Industries

Get an inside scoop of the nickel-based superalloys market, Request now for Sample Report @ https://www.thebusinessresearchcompany.com/sample.aspx?id=19125&type=smp

Regional Insights - Asia-Pacific was the largest region in the nickel-based superalloys market in 2023. The regions covered in the nickel-based superalloys market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa.

Key Companies - Major companies operating in the nickel-based superalloys market are CMK Corporation, BaoSteel, Thyssenkrupp Aerospace, Sandvik Materials Technology, Outokumpu Oyj., Aperam S.A., Fushun Special Steel Co Ltd., Precision Castparts Corp., Howmet Aerospace Inc., Walsin Lihwa Corporation, Eramet S.A., Allegheny Technologies Incorporated, Beijing Cisri-Gaona Materials and Technology Co Ltd., Carpenter Technology Corporation, AMG Advanced Metallurgical Group, Nippon Yakin Kogyo Co Ltd., VSMPO-AVISMA Corporation, Special Metals Corporation, Haynes International Inc., Doncasters Group, Smiths Metal Centres Limited, AEETHER Inc., Mishra Dhatu Nigam Limited, Rosswag GmbH, QuesTek Innovations

Table of Contents 1. Executive Summary 2. Nickel-Based Superalloys Market Report Structure 3. Nickel-Based Superalloys Market Trends And Strategies 4. Nickel-Based Superalloys Market – Macro Economic Scenario 5. Nickel-Based Superalloys Market Size And Growth ….. 27. Nickel-Based Superalloys Market Competitor Landscape And Company Profiles 28. Key Mergers And Acquisitions 29. Future Outlook and Potential Analysis 30. Appendix

Contact Us: The Business Research Company Europe: +44 207 1930 708 Asia: +91 88972 63534 Americas: +1 315 623 0293 Email: [email protected]

Follow Us On: LinkedIn: https://in.linkedin.com/company/the-business-research-company Twitter: https://twitter.com/tbrc_info Facebook: https://www.facebook.com/TheBusinessResearchCompany YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ Blog: https://blog.tbrc.info/ Healthcare Blog: https://healthcareresearchreports.com/ Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

HASTELLOY C276 PLATE VS ALLOY 825 PLATE

Hastelloy C276 and Alloy 825 are two of the most popular options regarding corrosion-resistant alloys. These alloys are ideal for environments with paramount strength, durability, and corrosion resistance. However, deciding which one to choose can be confusing. In this blog post, we will compare the Hastelloy C276 plate and Alloy 825 plate to help you make an informed decision.

HASTELLOY C276 PLATE

Hastelloy C276 Plate is a nickel-molybdenum-chromium alloy with an addition of tungsten. It has superior corrosion resistance in oxidizing and reducing environments, making it suitable for chemical processing, flue gas desulfurization systems, and pollution control applications. It is highly resistant to pitting and crevice corrosion, stress cracking, intergranular attack, and general corrosion in most severely corrosive media. The Hastelloy C276 plate has excellent weldability with no pre- or post-weld heat treatments required.

ALLOY 825 PLATE

Alloy 825 Plate is a Nickel-based plate with high creep and stress rupture properties. It offers excellent corrosion resistance in many media, including sulfuric, phosphoric, and nitric acids. Adding molybdenum improves pitting and crevice corrosion resistance compared to the 800-range alloys. At the same time, copper allows for increased resistance to sulfide stress cracking and better general corrosion characteristics. Alloy 825 Plate is also used for applications involving seawater or phosphate environments where chloride ion contamination must be resisted.

DIFFERENCE BETWEEN HASTELLOY C276 AND ALLOY 825 PLATE

Chemical Composition:

Hastelloy C276 is a nickel-molybdenum-chromium superalloy that contains tungsten and is known for its excellent corrosion resistance in various acidic and alkaline media. On the other hand, Alloy 825 is a nickel-iron-chromium alloy that contains molybdenum, copper, and titanium and is also known for its excellent resistance to corrosion and stress cracking in various environments.

Mechanical Properties:

Hastelloy C276 has a high yield strength and is known for its excellent hardness, while Alloy 825 has a low yield strength and is known for its high ductility. This means that Hastelloy C276 is ideal for applications where strength is the primary concern, while Alloy 825 is better suited for applications where corrosion resistance and ductility are more important.

Corrosion Resistance

Both Hastelloy C276 and Alloy 825 are highly corrosion-resistant alloys. However, Hastelloy C276 has better pitting and crevice corrosion resistance due to its high molybdenum and tungsten content. In contrast, Alloy 825 has better resistance to oxidizing and reducing environments due to its high nickel and chromium content.

Tensile Strength

The Hastelloy C276 plate has a higher tensile strength than the Alloy 825 plate. This means that it is more resistant to being pulled or stretched apart.

Yield Strength

The Hastelloy C276 plate also has a higher yield strength than the Alloy 825 plate. This means that it can resist being deformed more before it starts to break.

Applications

Hastelloy C276 is commonly used in chemical processing, pollution control, and pulp and paper due to its excellent resistance to corrosive environments. On the other hand, Alloy 825 is commonly used in oil and gas production, chemical processing, and power generation industries due to its excellent resistance to stress corrosion cracking and pitting.

CONCLUSION

In conclusion, both the Hastelloy C276 plate and the Alloy 825 plate are great choices for applications that require corrosion resistance, strength, and durability. Hastelloy C276 is ideal for applications where resistance to pitting and crevice corrosion is crucial, while Alloy 825 is better suited for applications where corrosion resistance and ductility are more important. Ultimately, the choice between the two will depend on the specific requirements of your application and your budget. We hope that this comparison has helped you make an informed decision.

To Know More https://www.smmindustriesllp.com/hastelloy-c276-plate-vs-alloy-825-plate/

0 notes

Text

Inconel Round Bars Supplier & Exporter in Dubai, UAE | Metalforgeindia

In the dynamic landscape of modern engineering, the choice of substances performs a pivotal position in figuring out the achievement of numerous applications. Among these substances, Inconel 625 round bars stand out for their wonderful performance under severe conditions. As a distinguished provider and exporter primarily based in Dubai, UAE, Metal Forge India is dedicated to supplying first-rate Inconel 625 round bars that meet the stringent wishes of industries starting from aerospace to chemical processing.

What is Inconel 625?

Inconel 625 is a nickel-chromium-molybdenum alloy acknowledged for its extraordinary resistance to heat and corrosion. This superalloy exhibits remarkable fatigue power and can withstand temperatures up to 2,000°F (1,093°C). Its particular composition gives it the ability to perform in harsh environments, making it an exquisite preference for diverse applications, together with:

Aerospace: Components like gasoline turbine engines, wherein energy and lightweight features are essential.

Marine Engineering: Equipment that encounters seawater and extreme pressure, which incorporates subsea pipelines.

Chemical Processing: Parts uncovered to corrosive environments, consisting of reactors and heat exchangers.

Nuclear Power: Components that require high standard performance and corrosion resistance under radiation exposure.

Why Choose Metal Forge India?

We understand the critical nature of the projects our clients undertake. Here are numerous motives why we are the favored preference for sourcing Inconel 625 round bars in Dubai:

1. Unmatched Quality Standards

Quality is in the middle of our operations. Our Inconel 625 round bars undergo rigorous finding out and inspection methods to ensure they meet worldwide necessities. This consists of checks for chemical composition, mechanical properties, and ground extraordinary, ensuring that you get a stock of products that might be reliable and sturdy.

2. Comprehensive Product Range

While Inconel 625 round bars are our strong point, we offer a huge variety of products to cater to diverse company goals. Our stock consists of various grades and sizes, making sure that you can find precisely what you want on your particular application. Whether you require trendy dimensions or custom-designed answers, we've got the functionality to satisfy your requirements.

3. Expert Technical Support

Navigating the complexities of product choice may be hard. Our professional organization is right here to offer professional guidance, helping you pick the right products for your applications. We are devoted to facts about your needs and imparting tailored answers that decorate your challenge consequences.

4. Timely and Efficient Delivery

In recent times’s fast-paced market, delays can be steeply priced. We pleasure ourselves with our efficient logistics and supply chain management. We make sure that your orders are processed unexpectedly and introduced on time, allowing you to keep your tasks on schedule.

5. Global Reach with Local Expertise

While our base is in Dubai, our operations are bigger than in the UAE. We serve diverse customers at some stage in diverse regions, ensuring that our incredible products are handy globally. Our know-how of local markets, combined with our global requirements, permits us to cater to the proper goals of each customer.

Applications of Inconel 625 Round Bars

Inconel 625 round bars are utilized in a myriad of applications because of their specific properties. Some key regions wherein the one's round bars are employed encompass:

Aerospace Components

In the aerospace area, in which weight and strength are vital, Inconel 625 round bars are used for production factors like turbine blades and combustion chambers. Their capability to face up to excessive temperatures and stresses makes them first-class for jet engines.

Marine Applications

The marine industry benefits from Inconel 625's resistance to seawater corrosion. Subsea applications, which include valves and piping structures, rely upon the durability of this alloy to ensure prolonged-time high performance beneath tough situations.

Chemical Processing Equipment

In the chemical industries, the types of equipment frequently encounter competitive environments that might result in fast degradation. Inconel 625 round bars are regularly used to supply heating exchangers and reactors, in their corrosion resistance substantially enhances operational sturdiness.

Oil and Gas industries

Inconel 625 is also extensively used in the oil and gasoline enterprise, wherein components are uncovered to excessive strain and temperature. From downhole tubing to subsea structures, the robustness of Inconel 625 round bars is beneficial.

Conclusion

To get the best outstanding usual performance and toughness, it is crucial to choose the appropriate materials for your projects. Inconel 625 round bars, with their first-rate resistance to excessive temperature and corrosion, are a tremendous preference for a wide variety of industries.

We're dedicated to being your dependable supplier and exporter of top-notch descended-on Inconel 625 round bars in Dubai, UAE. With our dedication to excellence, truth, and customer satisfaction, we're here to support your goals at every stage. Whether you need customized or preferred solutions, our team is prepared to assist you in making decisions that put pressure on your tasks in advance.

Contact us these days to examine more about our products and the way we will permit you to achieve your engineering goals. With Metal Forge India, you may remember that you’re getting satisfactory materials for your crucial applications.

0 notes

Text

Periodic Table Championship: Round 2, Day 3, Phosphorus vs. Niobium

Match 4 of day 3 of round 2 of the championship has element 15, phosphorus, facing off against element 41, niobium. Last round, phosphorus scored an easy victory over mendelevium with 82.8% of the votes, while niobium had a slightly less decisive match, beating rhenium with 66.7% of the votes. A reminder of our challengers:

Phosphorus is a nonmetallic element with several allotropes, each of which have different properties. White phosphorus is a soft, waxy solid with two crystalline forms. It is the least stable and most reactive of the allotropes. Red phosphorus, the other common allotrope, is polymeric in structure and, as an intermediate phase between white and violet phosphorus, has a range of potential property values. Perhaps most well known as a fertilizer, phosphorus is also used as a food additive and in flame retardants and steel production. Its name is the Ancient Greek name for Venus, and means light-bringer.

Niobium is a ductile, paramagnetic transition metal that crystalizes in the body-centered cubic structure at room temperature. It’s slow reactivity means that it has been used in jewelry as a hypoallergenic alternative to nickel, but niobium’s main application is in alloying, primarily steels but also superalloys. It was named for its similarity to tantalum, after Niobe, the daughter of Tantalus in Greek mythology, though for a time it was known as columbium.

8 notes

·

View notes

Text

Nickel Alloy Market Size, Share, Trends, Growth and Competitive Outlook

"Global Nickel Alloy Market – Industry Trends and Forecast to 2031

Global Nickel Alloy Market, By Product (Nickel-Chromium-Iron Alloys, Nickel-Chromium Alloys, Nickel-Chromium-Molybdenum Alloys, Wrought Nickel, Nickel-Chromium-Cobalt Alloys, Nickel-Copper Alloys, Nickel-Iron Alloys, Nickel-Molybdenum Alloys, and Nickel-Titanium Alloys), Form (Bar, Rods, Tubing, Plate, Sheets, Wire, Billets, Pipe, Ingots, Strips, Flanges, Ball, Angles, Pipe Fittings, Channels, Coils, and Forgings), Function (High Performance and Electronics Grade, Heat Resistant, and Corrosion Resistant), Application (Energy and Power, Aerospace and Defense, Chemical, Oil & Gas, Electrical and Electronics, Automotive, and Others) - Industry Trends and Forecast to 2031.

Access Full 350 Pages PDF Report @

**Segments**

- **Product Type**: The nickel alloy market can be segmented based on product type, such as nickel-copper alloys, nickel-chromium alloys, nickel-iron alloys, nickel-molybdenum alloys, and others. Each type of nickel alloy offers different properties and characteristics, making them suitable for various applications in different industries.

- **End-Use Industry**: Another important segmentation factor is the end-use industry of nickel alloys. Industries such as aerospace, automotive, electronics, oil and gas, energy, and others utilize nickel alloys for their unique properties like corrosion resistance, high temperature strength, and durability.

- **Region**: Geographically, the nickel alloy market can be segmented into regions such as North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. Each region may have varying demand for nickel alloys based on industrial growth, manufacturing activities, and infrastructure development.

**Market Players**

- **Precision Castparts Corp.**: Precision Castparts Corp. is a prominent player in the nickel alloy market, offering a wide range of nickel-based products for various applications in industries like aerospace, defense, and energy.

- **VDM Metals**: VDM Metals is a key market player known for its high-performance nickel alloys used in critical applications where corrosion resistance and mechanical strength are paramount.

- **Haynes International**: Haynes International specializes in advanced nickel-based alloys that cater to industries like chemical processing, aerospace, and power generation, showcasing their expertise in developing innovative alloys.

- **ATI**: ATI is a leading producer of nickel-based superalloys that find applications in extreme environments such as gas turbines, jet engines, and oil & gas processing facilities, highlighting their focus on high-performance materials.

The global nickel alloy market is witnessing steady growth due to the increasing demand for corrosion-resistant and high-temperature materials across various industries. Factors such as rapid industrialization, infrastructural development, and technological advancements are driving the market growth. The aerospace sector is a significant consumer of nickel alloysThe global nickel alloy market is experiencing robust growth driven by the escalating demand for high-performance materials that offer corrosion resistance, high temperature strength, and durability across a wide range of industries. One of the key factors fueling this growth is the ongoing industrialization and infrastructural development in emerging economies, leading to increased adoption of nickel alloys in sectors such as aerospace, automotive, electronics, oil and gas, and energy. The aerospace industry, in particular, is a major consumer of nickel alloys due to their exceptional properties, making them ideal for critical applications in aircraft components, engines, and structural elements.

In terms of product type segmentation, nickel alloys can be categorized into various types such as nickel-copper, nickel-chromium, nickel-iron, nickel-molybdenum, and other specialized alloys. Each type offers distinct properties and characteristics that make them suitable for specific applications within different industries. For example, nickel-chromium alloys are known for their high-temperature strength and corrosion resistance, making them ideal for use in gas turbine components and other high-temperature applications.

When considering the end-use industry segmentation, it becomes evident that different sectors rely on nickel alloys for various applications. The automotive industry utilizes nickel alloys for manufacturing components that require high mechanical strength and corrosion resistance, contributing to the market demand. Similarly, in the oil and gas sector, nickel alloys play a crucial role in equipment used for drilling, exploration, and refining processes due to their resistance to harsh operating environments.

Geographically, the nickel alloy market is segmented into regions including North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa. Each region exhibits varying demand for nickel alloys based on factors such as industrial growth, infrastructure development, and manufacturing activities. For instance, Asia Pacific is a significant market for nickel alloys due to the booming industrial sector in countries like China and India, driving the demand for high-performance materials across multiple industries.

Prominent market players in the nickel alloy industry, such as Precision Castparts Corp., V**Segments:**

- **Product Type** - Nickel-Copper Alloys - Nickel-Chromium Alloys - Nickel-Iron Alloys - Nickel-Molybdenum Alloys - Others

- **End-Use Industry** - Aerospace - Automotive - Electronics - Oil and Gas - Energy

- **Region** - North America - Europe - Asia Pacific - Latin America - Middle East & Africa

**Global Nickel Alloy Market Overview:**

The global nickel alloy market is projected to witness substantial growth over the forecast period. The escalating demand for advanced materials with superior corrosion resistance, high-temperature strength, and durability across a diverse range of industries is a key driver of market expansion. The market is propelled by factors like rapid industrialization, infrastructural development, and technological advancements, driving the adoption of nickel alloys in sectors such as aerospace, automotive, electronics, oil and gas, and energy.

**Product Type Analysis:**

The segmentation of nickel alloys based on product type offers tailored solutions for specific industry requirements. Nickel-copper alloys are favored for their corrosion resistance, while nickel-chromium alloys are renowned for high-temperature strength, making them suitable for gas turbine components and similar applications. Nickel-iron alloys are preferred for their magnetic properties, and nickel-molybdenum alloys excel in demanding environments where strength and corrosion resistance are crucial.

**End-Use Industry Insights

Countries Studied:

North America (Argentina, Brazil, Canada, Chile, Colombia, Mexico, Peru, United States, Rest of Americas)

Europe (Austria, Belgium, Denmark, Finland, France, Germany, Italy, Netherlands, Norway, Poland, Russia, Spain, Sweden, Switzerland, United Kingdom, Rest of Europe)

Middle-East and Africa (Egypt, Israel, Qatar, Saudi Arabia, South Africa, United Arab Emirates, Rest of MEA)

Asia-Pacific (Australia, Bangladesh, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Sri Lanka, Thailand, Taiwan, Rest of Asia-Pacific)

Objectives of the Report

To carefully analyze and forecast the size of the Nickel Alloy market by value and volume.

To estimate the market shares of major segments of the Nickel Alloy

To showcase the development of the Nickel Alloy market in different parts of the world.

To analyze and study micro-markets in terms of their contributions to the Nickel Alloy market, their prospects, and individual growth trends.

To offer precise and useful details about factors affecting the growth of the Nickel Alloy

To provide a meticulous assessment of crucial business strategies used by leading companies operating in the Nickel Alloy market, which include research and development, collaborations, agreements, partnerships, acquisitions, mergers, new developments, and product launches.

Key questions answered

How feasible is Nickel Alloy Market for long-term investment?

What are influencing factors driving the demand for Nickel Alloy near future?

What is the impact analysis of various factors in the Global Nickel Alloy market growth?

What are the recent trends in the regional market and how successful they are?

Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America

Browse Trending Reports:

Meat Poultry And Seafood Processing Equipment Market Hemiballismus Treatment Market Fluid And Lubricant Market Virtual Infrastructure Manager Market Water Flosser Market Water Saving Shower Heads Market Galactoligosaccharides Market Rocky Mountain Spotted Fever Treatment Market Overhead Conveyor Market Olliers Disease Market Functional Bowel Disorder Agents Market Bio Based Leather Market Melanoma Cancer Diagnostics Market Intracranial Hematoma Drug Market Glucosinolates Market Autorefractor Keratometer Device Market Feed Mycotoxin Modifiers Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

0 notes

Text

Inconel Fasteners: A Comprehensive Guide

Introduction to Inconel

Inconel is a family of nickel-chromium-based superalloys known for their exceptional strength, corrosion resistance, and ability to withstand extreme temperatures. Developed by Special Metals Corporation, Inconel alloys are widely used in aerospace, marine, chemical processing, and power generation industries.

The primary advantage of Inconel is its ability to retain mechanical strength even in high-temperature and corrosive environments. It resists oxidation, carburization, and chloride-induced stress corrosion cracking, making it an ideal material for fasteners used in critical applications.

What Are Inconel Fasteners?

Inconel fasteners are bolts, nuts, washers, screws, and studs made from Inconel alloys. These fasteners are designed to perform in extreme conditions where ordinary steel or stainless steel fasteners would fail. The combination of nickel, chromium, and iron (along with other elements in varying amounts) provides outstanding durability, even in the harshest environments.

Characteristics of Inconel Fasteners

High-Temperature Resistance: Can withstand temperatures exceeding 1000°C.

Corrosion Resistance: Excellent resistance to oxidation, pitting, and crevice corrosion.

Superior Strength: High tensile and yield strength.

Resistance to Creep and Fatigue: Maintains integrity under prolonged exposure to stress and heat.

Non-Magnetic: Some Inconel alloys exhibit non-magnetic properties, making them suitable for specific applications.

Different Types of Inconel Fasteners

1. Inconel Bolts

Hex bolts

Anchor bolts

U-bolts

J-bolts

Stud bolts

2. Inconel Nuts

Hex nuts

Lock nuts

Wing nuts

Flange nuts

Dome nuts

3. Inconel Washers

Flat washers

Spring washers

Belleville washers

Fender washers

4. Inconel Screws

Machine screws

Socket head cap screws

Set screws

Self-tapping screws

5. Inconel Studs

Fully threaded studs

Double-end studs

Tap-end studs

Each type of fastener is available in different grades of Inconel, such as Inconel 600, Inconel 625, Inconel 718, and Inconel 925, depending on the application and environment.

Uses of Inconel Fasteners

1. Aerospace Industry

Used in jet engines, gas turbines, and exhaust systems due to high heat resistance.

2. Marine Industry

Ideal for shipbuilding, offshore drilling platforms, and seawater applications due to exceptional corrosion resistance.

3. Chemical Processing Industry

Used in reactors, heat exchangers, and pressure vessels to withstand harsh chemicals and extreme temperatures.

4. Power Generation

Essential in nuclear reactors, steam turbines, and other high-temperature power generation equipment.

5. Oil and Gas Industry

Used in pipelines, valves, and drilling equipment exposed to high pressure and corrosive fluids.

6. Medical Industry

Applied in medical implants and surgical instruments due to its non-reactive properties.

7. Automotive Industry

Used in high-performance and racing vehicles for exhaust systems and turbocharger components.

Specifications of Inconel Fasteners

Common Standards for Inconel Fasteners

ASTM B166 (Rod and bar)

ASTM B167 (Pipe and tubing)

ASTM B168 (Plate, sheet, and strip)

ASTM F2281 (Bolting materials)

UNS N06600 (Inconel 600)

UNS N06625 (Inconel 625)

UNS N07718 (Inconel 718)

Mechanical Properties of Inconel 625 Fasteners (Example)

Tensile Strength: 930 MPa (135 ksi)

Yield Strength (0.2% Offset): 517 MPa (75 ksi)

Elongation: 50%

Hardness: Rockwell B88

Chemical Composition of Inconel 625

Conclusion

Inconel fasteners are an essential component in industries requiring high-performance fastening solutions. Their ability to resist extreme temperatures, corrosion, and mechanical stress makes them a preferred choice in aerospace, marine, oil and gas, and many other industries.

Ananka Fasteners is a leading manufacturer, supplier, and exporter of Inconel fasteners, offering high-quality products that meet international standards. If you are looking for reliable and durable Inconel fasteners, get in touch with us today!

Frequently Asked Questions (FAQs)

Q1: What makes Inconel fasteners different from stainless steel fasteners?

Inconel fasteners offer superior high-temperature and corrosion resistance compared to stainless steel, making them suitable for extreme environments.

Q2: What is the most commonly used Inconel grade for fasteners?

Inconel 625 and Inconel 718 are the most widely used grades due to their excellent mechanical and chemical properties.

Q3: Are Inconel fasteners expensive?

Yes, Inconel fasteners are more expensive than stainless steel fasteners due to their superior properties and complex manufacturing process.

Q4: Can Inconel fasteners be used in seawater applications?

Yes, Inconel fasteners, especially Inconel 625, are highly resistant to seawater corrosion and are used in marine applications.

Q5: Where can I buy high-quality Inconel fasteners?

You can purchase premium-quality Inconel fasteners from Ananka Fasteners, a trusted manufacturer and supplier in the industry.

#ananka#anankafastenrs#fasteners#fastenersmanufacturer#linkedin#articles#inconel#inconelfasteners#blog#anankafasteners#manufacturer#supplier#mumbai#hex#bolt#usa

0 notes

Text

Why Choose Hastelloy C276 Tubes? Insights from Top Suppliers

In the realm of industrial materials, Hastelloy C276 stands out as a premier choice for applications requiring exceptional resistance to corrosion and high-temperature stability. This superalloy, primarily composed of nickel, molybdenum, and chromium, is particularly favored in industries like chemical processing, oil and gas, and power generation. When considering the best materials for your projects, Hastelloy C276 tubes offer numerous advantages, and insights from top suppliers can guide your decision-making process. In this blog, we’ll explore the reasons to choose Hastelloy C276 tubes and highlight insights from leading Hastelloy C276 tube suppliers.

1. Superior Corrosion Resistance

One of the most compelling reasons to choose Hastelloy C276 tubes is their remarkable corrosion resistance. The alloy is specifically designed to withstand harsh environments, including:

Chloride-Induced Stress Corrosion Cracking: Hastelloy C276 is highly resistant to stress corrosion cracking, making it ideal for use in environments with chlorides, such as seawater or chemical processing plants.

Pitting and Crevice Corrosion: The alloy’s high molybdenum content provides enhanced resistance to pitting and crevice corrosion, which are common issues in many industrial applications.

Leading Hastelloy C276 tube suppliers often emphasize the alloy’s resilience in their product literature, citing extensive testing and real-world performance in challenging environments. This assurance of quality helps customers make informed decisions based on proven results.

2. High-Temperature Stability

Hastelloy C276 tubes maintain their mechanical properties even at elevated temperatures, making them suitable for a wide range of applications, including:

Chemical Processing: Many chemical reactions occur at high temperatures, and materials used in these processes must withstand heat without losing integrity.

Aerospace and Power Generation: Components in gas turbines and reactors are often exposed to extreme temperatures, requiring materials that can endure these conditions without deforming or failing.

According to top suppliers, the ability of Hastelloy C276 to perform consistently in high-temperature environments makes it a preferred choice for industries that cannot compromise on safety and reliability.

3. Versatility in Applications

Hastelloy C276 tubes are not limited to a single industry; their versatility makes them suitable for various applications, such as:

Heat Exchangers: The corrosion resistance and heat tolerance of Hastelloy C276 make it an excellent choice for heat exchangers in chemical processing and petrochemical industries.

Piping Systems: Many suppliers highlight that the alloy's durability makes it ideal for piping systems that transport corrosive fluids or gases.

Welded Structures: The weldability of Hastelloy C276 allows for easy fabrication into complex shapes and structures, expanding its use in various engineering applications.

Leading suppliers often provide case studies or examples demonstrating the successful implementation of Hastelloy C276 tubes in diverse applications, underscoring the material's adaptability.

4. Quality Assurance and Compliance

When sourcing materials like Hastelloy C276 tubes, quality assurance is paramount. Reputable suppliers ensure that their products meet or exceed industry standards:

Certifications: Top Hastelloy C276 tube suppliers often provide documentation and certifications that verify compliance with ASTM, ASME, and other relevant standards. This certification process is essential for industries with strict regulatory requirements.

Testing Protocols: Leading suppliers conduct rigorous testing, including non-destructive testing (NDT) methods, to ensure the integrity of their tubes. This commitment to quality gives customers confidence in the reliability of their materials.

According to industry experts, working with suppliers that prioritize quality assurance can significantly impact the success of your projects, particularly in high-stakes environments.

5. Cost-Effectiveness Over Time

While Hastelloy C276 tubes may come with a higher upfront cost compared to less specialized materials, their long-term benefits often outweigh the initial investment:

Reduced Maintenance Costs: The corrosion resistance and durability of Hastelloy C276 tubes lead to lower maintenance and replacement costs over time. Industries that operate in harsh environments can save significantly by choosing high-quality materials.

Extended Service Life: Suppliers frequently highlight that Hastelloy C276 tubes can last longer than other materials, providing a better return on investment in the long run.

Leading suppliers often encourage customers to consider the total cost of ownership, rather than just initial costs, when evaluating materials for their projects.

6. Expertise and Technical Support

When choosing Hastelloy C276 tube suppliers, the level of expertise and support they offer can make a significant difference:

Technical Consultation: Top suppliers often have teams of metallurgical and engineering experts available to provide guidance on material selection, fabrication, and welding processes.

Customized Solutions: Leading suppliers are increasingly offering tailored solutions to meet specific customer needs. This customization can include adjustments in tube dimensions, alloy composition, and packaging options.

Troubleshooting Assistance: Reliable suppliers are often available to assist with any challenges encountered during installation or operation, helping to mitigate risks and ensure project success.

Having access to expert support can enhance your project’s outcomes and foster a strong partnership between you and your supplier.

7. Sustainability Practices

As industries move towards more sustainable practices, many leading Hastelloy C276 tube suppliers are adopting eco-friendly measures:

Recycling Initiatives: Suppliers often have programs in place to recycle scrap materials generated during manufacturing, contributing to reduced waste.

Energy-Efficient Manufacturing: Many suppliers invest in energy-efficient technologies to minimize their environmental footprint, aligning with global sustainability goals.

Responsible Sourcing: Top suppliers prioritize sourcing raw materials from ethical and sustainable sources, ensuring that their supply chains adhere to environmental standards.

By choosing suppliers that prioritize sustainability, businesses can align their operations with their own environmental objectives.

8. Strong Industry Relationships

Choosing a reputable Hastelloy C276 tube supplier can lead to the development of long-term partnerships that benefit both parties:

Networking Opportunities: Established suppliers often have extensive networks in the industry, providing access to additional resources and knowledge that can benefit your projects.

Collaborative Innovation: A strong partnership can lead to collaborative efforts in research and development, driving innovation and improvements in material performance.

Shared Knowledge: Working closely with experienced suppliers allows for the exchange of best practices and insights, enhancing overall operations.

Building relationships with trusted suppliers can contribute to your long-term success in the industry.

Conclusion

Choosing Hastelloy C276 tubes for your projects offers numerous advantages, from superior corrosion resistance and high-temperature stability to versatility and long-term cost-effectiveness. Insights from top Hastelloy C276 tube suppliers emphasize the importance of quality assurance, technical support, and sustainability practices in selecting the right materials for demanding applications.

As industries continue to evolve and face new challenges, partnering with reputable suppliers can enhance your operational efficiency, drive innovation, and ensure project success. By making informed choices and fostering strong supplier relationships, businesses can effectively leverage the benefits of Hastelloy C276 tubes to meet their unique requirements.

0 notes