#nickel 200 suppliers

Explore tagged Tumblr posts

Text

The Benefits of using nickel 200 round bar

Nickel 200, a commercially pure wrought nickel, is renowned for nickel 200 material properties that make it a preferred choice in various industrial applications. Among its versatile forms, Nickel 200 Round Bars stand out for their unique set of benefits. As the leading Nickel 200 Round Bar Suppliers in India, MV Super Alloys takes pride in offering a comprehensive range of Nickel 200 products like nickel 200 pipes, nickel 200 pipes, and nickel 200 sheets, with a particular emphasis on the round bars types like Square Bar, Hex Bar, Rectangular Bar, Flat Bar, Bright Bar, and Forged Bar so that our customers can choose the one that will perfectly suit their project requirements!

In this blog post, we'll delve into the advantages of using Nickel 200 Round Bars, shedding light on why they are a reliable choice across industries.

Benefits of Using Nickel 200 Round Bar

Exceptional Corrosion Resistance:

One of the standout features of Nickel 200 Round Bars is their unparalleled corrosion resistance. In harsh environments, where exposure to corrosive elements is inevitable, these round bars demonstrate remarkable durability. This property makes them ideal for applications in chemical processing, marine engineering, and other industries where corrosion poses a significant challenge.

High Thermal and Electrical Conductivity:

Nickel 200 is celebrated for its excellent thermal and electrical conductivity. When shaped into round bars, this material becomes an asset in applications that require efficient heat transfer or reliable electrical conductivity. Industries such as electronics, telecommunications, and power generation benefit significantly from N02200 Round Bars in their manufacturing processes.

Temperature Stability:

Nickel 200 Round Bars exhibit impressive stability in extreme temperature conditions. Whether subjected to high temperatures or extreme cold, these bars maintain their structural integrity. This feature is particularly crucial in industries like aerospace, where materials must withstand varying temperatures without compromising performance.

Ease of Fabrication:

Manufacturers appreciate the ease with which 2.4066 Round Bars can be fabricated and machined. This characteristic not only streamlines the production process but also allows for the creation of intricate designs and precise components. This versatility makes Nickel 200 Round Bars a top choice for industries that demand precision and intricate detailing, such as the automotive and aerospace sectors.

Low Gas Content:

Nickel 200 boasts low gas content, which enhances its suitability for applications where purity is paramount. In sectors like pharmaceuticals and electronics, where even minimal impurities can have significant consequences, 2.4066 Round Bars offer a reliable solution.

Cost-Effective Long-Term Investment:

While the initial cost of N02200 Round Bars might be slightly higher than some alternatives, their longevity and resistance to corrosion contribute to a cost-effective, long-term investment. The reduced need for maintenance and replacements makes them an economically viable choice for industries looking to optimize operational costs over time.

Nickel 200 Round Bar Equivalent Grades

Standard - Nickel 200

UNS - N02200

WNR - 2.4066

JIS - NW 2200

EN - Ni 99.2

Chemical Composition of Nickel 200-Round Bars

Grade - Nickel 200

C - 0.15 max

Mn - 0.35 max

Si - 0.35 max

S - 0.01 max

Cu - 0.25 max

Fe -0.40 max

Ni - 99.0 min

Mechanical Properties of Nickel 200-Round Bars

Grade - Nickel 200

Density - 8.9 g/cm3

Melting Point - 1446 °C (2635 °F)

Tensile Strength - Psi – 67000 , MPa – 462

Yield Strength (0.2%Offset) - Psi – 21500 , MPa – 148

Elongations - 45 %

Applications of Nickel 200-Round Bars

Petrochemical Industry

Oil and Gas Industry

Chemical Industry

Power Plant Industry

Energy Industry

Pharmaceuticals Industry

Pulp & Paper Industry

Food Processing Industry

Aerospace Industry

Refining Industry

Other Applications

Final Words! Experience the unmatched advantages of Nickel 200 round bars, pipes, and sheets, featuring exceptional corrosion resistance and heightened thermal and electrical conductivity. As the leading industry supplier, MV Super Alloys ensures top-tier quality, complemented by Material Test Certificates (MTC) confirming adherence to specified nickel 200 material properties and standards. Serving as prominent nickel 200 suppliers, we extend our reach to major cities across India, including Hyderabad, Gujarat, Chennai, Bangalore, Mumbai, Telangana, Rajasthan, Delhi, Punjab, and Himachal Pradesh, guaranteeing nationwide accessibility at competitive nickel 200 prices. Elevate your projects with the reliability and superior performance of Nickel 200 products from MV Super Alloys, your trusted source for nickel 200 round bars, pipes, and sheets.

#nickel 200 round bar#nickel 200 pipe#nickel 200 material properties#nickel 200 sheet#nickel 200 price#nickel 200 suppliers

0 notes

Text

Nickel 200 Wires Exporters in UAE

Meraki Star Metals Oil & Gas Equipment Trading L.L.C. is a Wires provider and exporter of Nickel 200 wires. We Manufacture them open in custom nuances, plans, lengths, thickness, widths, and that is only a brief gander at something more prominent. We are known Exporters in the general market of ferrous and nonferrous things. Our clients can intercessors for nickel wires as shown by their application necessities.

Nickel 200 Wires are made with the assistance of the different Amalgam affiliations like carbon, manganese, silicon, copper, sulfur, chromium, iron, nickel, nitrogen, etc. too. These nickel wires ought to have physical and mechanical properties like thickness, loosening up point, flexibility, yield strength, astonishing rigid nature, broadening, warm conductivity, electrical conductivity, and modulus of extension. These wires are made with different decisions like broadness, shape, size, length, width, thickness, types, structures, condition, surface, application, standard, finish, obstacles, etc. as well. These wires are accessible in many sorts, for example, reshape wire, made never-ending wire.

Nickel 200 Wires are material in various organizations, for instance, offshore oil entering undertakings, petrochemicals industry, power age plant, drug industry, substance gear, seawater equipment, drug equipment, special engineered industry, paper industry, pound industry, heat exchanger, and condenser. These wires are also significant in many general purposes like valves, shaft, shipbuilding, structure advancement, transportation equipment, range improvement, radiator parts, and various temperature-safe things.

Nickel 200 Wires are made with the best material and incredible mechanical and real properties. These wires are a good blend of formability, usefulness, welding, and resistance from the high temperatures. These wires are outrageous, hard, and made with the protected material to work at high temperatures. These wires are furthermore protected against the entire expansive disintegration like gap utilization, stress breaking, pitting block, and impact disintegration. These wires are protected in the oxidizing, decreasing and unprejudiced circumstances. These wires have the low electrical and warm conductivity that helps the wires with contradicting the electric.

Nickel 200 Wires need to go through many tests after the creation from the business, for example, erupting test, straightening test, large scale test, miniature test, hydrostatic test, ultrasonic test, pitting test, radiography test, hardness test, synthetic test, mechanical test, PMI test, etc too.

For more information : Visit our website : https://www.merakimetals.ae/ Contact us : +971-523973687, +971-48801107, +971-48240333 Email : [email protected]

#Nickel 200 Wires Manufacturers in UAE#Nickel 200 Wires Suppliers in UAE#Nickel 200 Wires Stcokists in UAE#Nickel 200 Wires Exporters in UAE

3 notes

·

View notes

Text

DUPLEX STEEL & ENGINEERING -

Duplex steel and engg. Co. Pvt. Ltd is one of the leading manufacturer of Duplex Steel 2205, Super duplex 2507, pipe, Tube, sheet, plates, flanges, fasteners in India.

DUPLEX STEEL 2205 / UNS S31803PLATES / SHEETS / COIL Request the latest Duplex Steel 2205 Plates / Sheets / Coil Price List. Please Call +91 98691 88888 or Send an Email to [email protected] for Duplex Steel UNS S31803, 1.4462 Pipe Plates / Sheets / Coil Ready stock information and updated price list.

https://www.unisteelsengg.com

#Duplex Steel 2205 Sheet#Super duplex 2507 Plate#Stainless Steel Pipe#SS Tubes#duplex 2205 pipe#duplex 2205 tube#316 Stainless steel Sheet#Inconel 200 Flanges#Monel 400 Tube Fittings#Nickel Alloy 20 Sheet#Titanium Grade 2 Round Bar#Hastelloy C22 Angle Bar Supplier#Alloy 20 Butt weld Fittings Dealer#Inconel 600 Flanges Exporter in India

2 notes

·

View notes

Text

Nickel 200 Screw Manufacturers

Nascent Pipe & Tubes offers an extensive collection of Nickel Alloy 200 Fasteners (Screws) to the respected clienteles, which has some outstanding features to offer such as durable, lightweight, dimensionally steady, and so on. Our Nickel 200 Hex Head Screws (UNS N02200) are generally used in Chemical Storage and Processing.

#Nickel 200 Screw#Nickel 200 Screw Manufacturers#Nickel 200 Screw Suppliers#Nickel 200 Screw Stockists#Nickel 200 Screw Exporters#Nickel 200 Screw Manufacturers In India#Nickel 200 Screw Suppliers In India#Nickel 200 Screw Stockists In India#Nickel 200 Screw Exporters In India

0 notes

Text

Nickel Alloy 200 Pipes Exporters

Manufacturers & Exporters of Nickel Alloy 200 Pipes & Tubes, Nickel Alloy UNS N02200 Seamless Pipes & Seamless Tubes, Nickel 200 Welded Pipes & Welded Tubes in India.Chhajed Steel Limited manufacturers & Exports premium quality Nickel 200 Pipe & Tubes. Industries such as food, paper, construction, oil extraction, food containers, medicine, maChinary, chemicals find of Nickel Alloy 200 Pipes & Tubes.

Nickel Alloy 200 is considered as pure nickel with good mechanical properties. It has excellent resistance to alkali hydroxides as well as organic compositions. Alloy 200 retain its strength despite exposure to high temperatures and is ductile at low temperature.

#Nickel Alloy 200 Pipes Manufacturers in India#Nickel Alloy 200 Pipes Suppliers in India#Nickel Alloy 200 ERW Pipes#Nickel Alloy 200 Pipes Exporters in India#Nickel Alloy 200 Pipes Importers in India.

0 notes

Text

Nickel 200 Flanges Exporters

In the world of industrial applications, where corrosion resistance and durability are key, Nickel 200 flanges are a popular choice. When it comes to sourcing top-quality Nickel 200 flanges, Sankalp Alloys Overseas stands out as a global leader in manufacturing, supplying, exporting, and stocking these flanges. Based in Mumbai, India, Sankalp Alloys Overseas is renowned for its commitment to quality, innovation, and customer satisfaction. In this article, we will explore everything you need to know about Nickel 200 flanges and why Sankalp Alloys Overseas should be your go-to supplier.

What Are Nickel 200 Flanges?

Nickel 200 flanges are made from Nickel Alloy 200, a commercially pure wrought nickel with excellent mechanical properties. The flanges serve as essential components in piping systems, connecting pipes, valves, and other equipment. Known for their high corrosion resistance, particularly in alkaline environments, Nickel 200 flanges are widely used in industries like chemical processing, food handling, and marine engineering.

Key Properties of Nickel 200 Flanges

Corrosion Resistance: Nickel 200 offers outstanding resistance to various chemicals, including caustic alkalis, making it ideal for demanding industrial environments.

High Ductility: Nickel 200 is highly ductile, allowing it to withstand extreme mechanical stress without fracturing.

Thermal and Electrical Conductivity: It provides excellent thermal and electrical conductivity, making it a versatile choice for different applications.

Magnetostrictive Properties: Nickel 200 possesses magnetostrictive properties, making it useful in certain magnetic applications.

Nickel 200 Flanges Specifications

Sankalp Alloys Overseas offers Nickel 200 flanges with the following specifications:

Dimensions: ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, and custom drawings.

Standards: ASTM, ASME, ANSI, DIN, EN, and BS Flanges.

Specifications: ASTM B564 / ASME SB 564.

Size Range: From 1/2" NB to 60" NB.

Class: 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, ASA 150#, ASA 300# DIN ND 6,10,16,25,40, etc.

Length: 100 mm to 3000 mm and above.

Grade: Nickel Alloy 200 (UNS No. N02200).

Benefits of Nickel 200 Flanges

Superior Corrosion Resistance: Nickel 200 flanges offer unmatched resistance to corrosive environments, especially in alkalis.

Longevity: These flanges have a long service life, even in harsh industrial conditions, reducing the need for frequent replacements.

Versatility: Nickel 200 is suitable for use in a wide range of temperatures, making it ideal for various applications.

High Strength: Even at extreme temperatures, Nickel 200 retains its mechanical strength, ensuring reliable performance.

Applications of Nickel 200 Flanges

Nickel 200 flanges are utilized in several industries due to their unique properties:

Chemical Processing: Highly resistant to caustic soda and other chemicals.

Food Processing: Safe for food handling and resistant to corrosion from organic acids.

Marine Engineering: Performs well in saline environments, making it ideal for shipbuilding and marine applications.

Electronics: Used in electrical and electronic components due to its high conductivity.

Pharmaceuticals: Employed in medical devices and equipment manufacturing because of its non-reactive nature.

Why Choose Sankalp Alloys Overseas?

When it comes to Nickel 200 flanges, Sankalp Alloys Overseas is a name you can trust. Here's why:

Unmatched Quality: Each product undergoes rigorous quality checks to meet international standards.

Global Reach: Sankalp Alloys Overseas serves clients worldwide, offering fast and reliable shipping.

Custom Solutions: They provide customized flanges based on your specific requirements and industry needs.

Expertise: With years of experience, Sankalp Alloys Overseas has established itself as a leading authority in nickel alloy products.

Customer-Centric Approach: The team at Sankalp Alloys Overseas is dedicated to delivering unparalleled customer service, ensuring satisfaction at every step.

Conclusion

Nickel 200 flanges are an essential component in various industrial applications, offering high durability and resistance to corrosive environments. For those seeking top-quality Nickel 200 flanges, Sankalp Alloys Overseas is the leading manufacturer, supplier, exporter, and stockist in Mumbai, India, and worldwide. With a commitment to quality, innovation, and customer satisfaction, Sankalp Alloys Overseas ensures that their Nickel 200 flanges exceed expectations in both performance and reliability.

For more information, contact Sankalp Alloys Overseas at [email protected] or +91-8828369483, or visit their website at sankalpalloys.com.

#Nickel 200 Flanges Exporters#Nickel 200 Flanges Exporters in India#Nickel 200 Flanges Manufacturers#Nickel 200 Flanges Manufacturers in India#Nickel 200 Flanges#Sankalpalloys#Sankalp Alloys Overseas#manufacturers#suppliers#exporters#stockists#innovation#flanges#nickel 200#tools

1 note

·

View note

Text

Nickel 200 Washers Stockists / Manufactures / Exporters.

Introduction

Nickel 200 washers are essential components used in various industrial applications due to their excellent mechanical properties, corrosion resistance, and durability. Whether you are in the chemical processing industry, power generation, or any other field requiring reliable fasteners, understanding the benefits and applications of Nickel 200 washers is crucial. This guide will explore the properties, applications, and highlight some of the top suppliers of Nickel 200 washers.

What is Nickel 200?

Nickel 200 is a commercially pure nickel alloy with excellent mechanical properties and resistance to various corrosive environments. This alloy is known for its high thermal and electrical conductivity, low gas content, and magnetic properties. It is highly versatile and suitable for many industrial applications.

Key Properties of Nickel 200 Washers

Corrosion Resistance: Exceptional resistance to a wide range of corrosive environments, including acids and alkalis.

Thermal Conductivity: High thermal conductivity makes it suitable for applications involving high temperatures.

Mechanical Strength: Maintains good mechanical properties over a wide temperature range.

Magnetic Properties: Exhibits magnetic properties useful in specific industrial applications.

Electrical Conductivity: High electrical conductivity for applications requiring efficient current flow.

Applications of Nickel 200 Washers

Nickel 200 washers are used in various industries due to their unique properties:

Chemical Processing: Ideal for use in equipment and machinery exposed to harsh chemicals and corrosive environments.

Power Generation: Used in power plants for components that require high strength and corrosion resistance at elevated temperatures.

Electronics: Suitable for electronic applications requiring high electrical conductivity.

Aerospace: Used in aerospace applications that demand high-performance materials with excellent thermal stability.

Marine: Provides excellent resistance to seawater corrosion, making it suitable for marine applications.

Benefits of Using Nickel 200 Washers

Durability: Long-lasting performance in harsh environments.

Versatility: Suitable for a wide range of applications across multiple industries.

Reliability: Maintains integrity under high temperatures and corrosive conditions.

Ease of Fabrication: Good machinability and weldability, facilitating easy manufacturing and installation.

How to Choose a Reliable Supplier for Nickel 200 Washers

Quality Assurance Ensure the supplier provides high-quality Nickel 200 washers that meet industry standards. Look for certifications such as ISO 9001 to verify their commitment to quality.

Range of Products A good supplier should offer a variety of washer sizes and specifications to meet your specific needs. Custom fabrication services are a plus.

Customer Reviews and Testimonials Check customer reviews and testimonials to gauge the supplier’s reputation. Positive feedback on product quality, delivery times, and customer service is a good indicator of reliability.

Technical Support Choose a supplier that offers technical support and assistance in selecting the right products for your applications.

Competitive Pricing Compare prices from different suppliers, but ensure that lower prices do not mean compromised quality. Balance cost with quality to get the best value.

Top Supplier: Nascent Group

Nascent Group is a leading supplier of Nickel 200 washers, known for their commitment to quality and customer satisfaction. They offer a wide range of high-performance washers suitable for various industrial applications.

Why Choose Nascent Group?

Quality Products: Nascent Group ensures all their Nickel 200 washers meet stringent industry standards.

Wide Selection: They offer an extensive selection of washer sizes and specifications, catering to diverse industrial needs.

Excellent Customer Service: Known for their responsive customer support and technical assistance.

Competitive Pricing: Offers high-quality products at competitive prices, ensuring good value for your investment.

Conclusion

Nickel 200 washers are essential components in many industrial applications, offering excellent corrosion resistance, high-temperature performance, and durability. When selecting a supplier, consider factors like quality assurance, product range, customer reviews, technical support, and pricing. Nascent Group stands out as a reliable supplier, providing high-quality Nickel 200 washers tailored to your needs. For more information or to place an order, contact Nascent Group today.

For more details

Email: [email protected]

Contact: 8779038854If any enquiries please contact us our support team will connect you as soon as possible

#exporters#manufacturers#metal#suppliers#steel#Nickel 200 Washers Manufacturers In India#Nickel 200 Washers Suppliers In India#Nickel 200 Washers Stockists In India#Nickel 200 Washers Exporters In India

0 notes

Text

Leading Supplier Of Nickel Alloy 200 Pipes in Bengaluru

In the industrial panorama of Bengaluru, locating a dependable dealer of top notch nickel alloy pipes is vital for various packages throughout one-of-a-kind sectors. Among the myriad of options to be had, one call sticks out: Bhagya laxmi Industrial. Renowned for its commitment to first-rate and customer pride, we have emerged as a main Nickel Alloy 200 Pipes manufacturer, Nickel Alloy 200 Pipes stockist, Nickel Alloy 200 Pipes supplier, and Nickel Alloy 200 Pipes exporter in Bengaluru.

Understanding the Significance of Nickel Alloy 200 Pipes & Tubes

Nickel Alloy 200 is a commercially natural wrought nickel alloy known for its fantastic resistance to many corrosive environments. It offers fantastic mechanical properties even at excessive temperatures and reveals appropriate electrical conductivity. These residences make Nickel Alloy 200 Pipe & Tube fantastically perfect for a huge range of applications in industries along with chemical processing, petrochemicals, marine engineering, strength technology, and greater.

Reliable Manufacturer and Supplier

As a trusted manufacturer and provider of UNS N02200 Pipes & Tubes, we guarantee that its merchandise adhere to the very best exceptional requirements. The employer makes use of advanced satisfactory uncooked substances and employs superior manufacturing techniques to produce pipes and tubes that meet the stringent requirements of various industries.

Unparalleled Quality Assurance

Quality warranty is paramount, each Nickel Alloy 200 Pipe and Tube undergoes rigorous testing strategies to make sure its integrity and performance. From dimensional accuracy to mechanical homes, each thing is thoroughly examined to assure compliance with global first-rate requirements. This unwavering commitment to pleasant has earned us the loyalty of its customers.

Customization Options

Recognizing that each assignment has particular requirements, we offer customization alternatives for Nickel Alloy 200 Pipe & Tube. Whether it is precise dimensions, tolerances, or surface finishes, the business enterprise works closely with its customers to supply tailor-made answers that precisely meet their wishes. This flexibility units from its competitors, making it the desired desire for discerning customers in Bengaluru and beyond.

Competitive Pricing

Despite offering top rate-great merchandise, we maintain aggressive pricing to make sure affordability for its clients. The organisation believes in imparting value for cash without compromising on great, making its UNS N02200 Pipes & Tubes available to a huge range of industries and organizations.

Exceptional Customer Service

The company’s dedicated group of specialists goes above and past to offer outstanding provider, from supporting with product choice to making sure timely delivery. Whether it is a small-scale mission or a massive business software, clients can depend upon Bhagyalaxmi Industrial for spark off and personalized attention

Conclusion

In conclusion, for groups in Bengaluru searching for a dependable dealer of Nickel Alloy 200 Pipes & Tubes, Bhagyalaxmi Industrial emerges as the top preference. With its unwavering dedication to high-quality, giant product variety, customization alternatives, aggressive pricing, and terrific customer support, Bhagyalaxmi Industrial sets the benchmark for excellence inside the industry. Contact us today to experience the difference firsthand and discover why it is the main provider of Nickel Alloy 200 Pipes & Tubes in Bengaluru.

Contact us for all of your UNS N02200 Pipes & Tubes necessities and experience unrivaled quality and provider.

#bhagya laxmi industrial#nickel alloy#nickel alloy 200 pipes#nickel alloy pipes supplier#nickel alloy pipes Manufacturer

0 notes

Text

Calico Metal Alloys LLP is one of the main Manufacturers, Suppliers and Exporters of top notch Duplex 2205, UNS S31803, UNS S32205, UNS S32750, UNS S32760, Duplex 2202, Duplex 2304 pipe, Tube, sheet, plates, Coil, Shim Sheet flanges, fasteners in India at low price.

#ASTM A312 TP 304/304H Stainless Steel#Titanium Grade 1 Pipes & Tubes#Nickel Alloy 200/201#Aluminium Alloy 2014#Copper and Brass Alloys#Duplex Steel 2205#Titanium Alloys#Cobalt Alloys#Silver and Gold Brazing Alloys supplier from Mumbai#India.

0 notes

Text

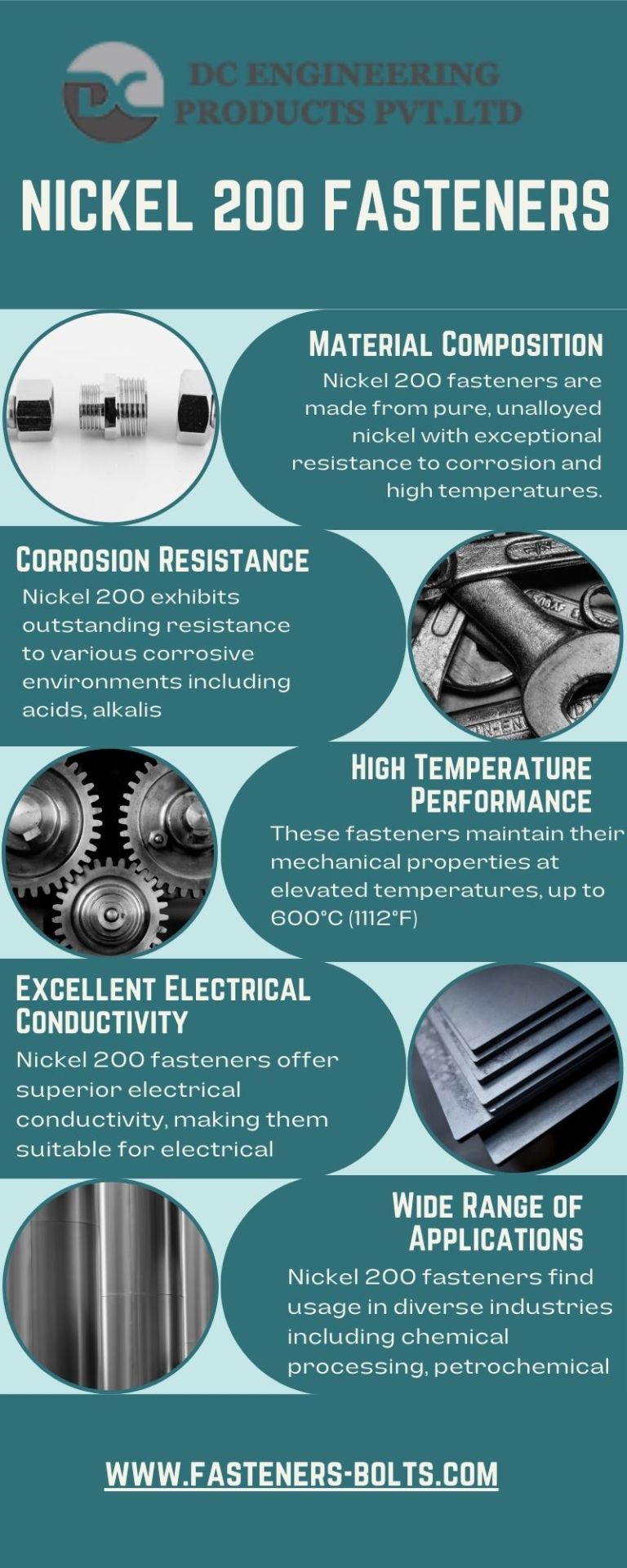

DC Engineering is leading Manufacture and Exporter of High quality of Nickel 200 Fasteners, UNS N02200 Fasteners, Alloy 200 Fasteners

#Nickel 200 Fasteners#High Nickel Alloy 200 Fastener Manufacturer#Nickel Alloy 200 Heavy Hex Nuts#Nickel 200 Hex Head Bolt#UNS N02200 Fastener#DIN 2.4066 Fasteners Supplier#Nickel 200 Spring Washer#Alloy 200 Socket Cap Screws#Nickel Alloy 200 U-bolts#Nickel Alloy 200 Hex Cap Screws#200 Nickel Alloy Hex Bolts

0 notes

Text

Nickel Strips Stockist

Technolloy Inc. is India's leading distributors, stockists, suppliers, manufacturers, and exporters of Nickel Strips. We supply Nickel strips in a variety of types, each with different properties and applications, including Nickel 200, Nickel 201, N4, N6, 18650 Pure Nickel Strips for batteries, etc.

They are typically made from pure nickel or nickel alloys, such as nickel-copper (NiCu) or nickel-iron (NiFe). These strips exhibit excellent electrical conductivity, corrosion resistance, and high melting points. The most common forms are available in various widths and thicknesses, making them adaptable for different applications.

Technolloy Inc. provides Nickel Strips in Mumbai at affordable prices while keeping up with industry standards. We have a team of professionals who make sure at all times that a strict quality assurance system is being followed in all our departments.

For more information : Contact Us : (022) 67437682 , (022) 49617682 Email : [email protected]

#Nickel Strips Manufacturers#Nickel Strips Suppliers#Nickel Strips Stockists#Nickel Strips Exporters#Nickel Strips Manufacturers in India#Nickel Strips Suppliers in India#Nickel Strips Stockists in India#Nickel Strips Exporters in India

7 notes

·

View notes

Text

Nickel 200 Coils Suppliers

Nickel 200 has splendid resistance to a substantial sort of corrosive environment, which incorporates independent and alkaline salts, fluorine, and loads of organic and inorganic compounds. MV Super Alloys is the best Nickel 200 coils suppliers in India.

0 notes

Text

#Nickel 200 Flanges Manufacturers in UAE#Nickel 200 Flanges Suppliers in UAE#Nickel 200 Flanges Stockists in UAE#Nickel 200 Flanges Exporters in UAE#Saudi Aramco approved flanges in UAE

0 notes

Text

Cobalt Alloy Haynes 188 Sheet Suppliers

Cobalt Alloy Haynes 188 Sheet in Mumbai, Cobalt Alloy Haynes 188 Sheet Importers in Mumbai, Cobalt Alloy Haynes 188 Sheet Suppliers in Mumbai, Cobalt Alloy Haynes 188 Sheet Exporters in Mumbai, Cobalt Alloy Haynes 188 Sheet Stockists in Mumbai.

Haynes 188™ is a cobalt based alloy with excellent high temperature strength and great oxidation resistance up to 2000° F. Haynes 188’s™ has good resistance to sulfidation and good metallurgical stability, therefore Haynes 188™ can be easily fabricated.

Element

Min

Max

Carbon

0.05

0.15

Manganese

--

1.25

Silicon

0.20

0.50

Phosphorus

--

0.02

Sulfur

--

0.015

Chromium

21.0

23.0

Nickel

20.0

24.0

Tungsten

13.0

15.0

Lanthanum

0.03

0.12

Boron

--

0.015

Iron

--

3.0

Cobalt

Bal.

Physical Properties

Physical Properties

°F

British Units

°C

Metric Units

Density

72

0.324 lb./in.(3)

22

8.98 g/cm(3)

Incipient Fusion Temperature

2375- 2425

1302- 1330--

Electrical Resistivity

70

39.6 microhm-in.

21

1.01 microhm-m

Mean Coefficient of Thermal Expansion

70 to -400

5.4 microin./in.-°F

21 to -200

9.7 X 10(-6)m/m-K

70 to -200

5.8 microin./in.-°F

21 to -129

10.4 X 10(-6)m/m-K

70-0

6.2 microin./in.-°F

21 to -18

11.2 X 10(-6)m/m-K

70-100

6.2 microin./in.-°F

21-38

11.5 X 10(-6)m/m-K

70-200

6.6 microin./in.-°F

21-93

11.9 X 10(-6)m/m-K

70-400

7.0 microin./in.-°F

21-204

12.6 X 10(-6)m/m-K

70-600

7.4 microin./in.-°F

21-316

13.3 X 10(-6)m/m-K

70-800

7.8 microin./in.-°F

21-427

14.0 X 10(-6)m/m-K

70-1000

8.2 microin./in.-°F

21-538

14.8 X 10(-6)m/m-K

70-1200

8.6 microin./in.-°F

21-649

15.5 X 10(-6)m/m-K

70-1400

9.0 microin./in.-°F

21-760

16.2 X 10(-6)m/m-K

70-1600

9.4 microin./in.-°F

21-871

16.9 X 10(-6)m/m-K

70-1800

9.9 microin./in.-°F

21-982

17.8 X 10(-6)m/m-K

70-2000

10.3 microin./in.-°F

21-1093

18.5 X 10(-6)m/m-K

Thermal Conductivity

100

75 Btu-in/ft²-hr-°F

38

10.8 W/m-K

400

100 Btu-in/ft²-hr-°F

204

14.4 W/m-K

600

112 Btu-in/ft²-hr-°F

316

16.1 W/m-K

800

125 Btu-in/ft²-hr-°F

427

18.0 W/m-K

1000

138 Btu-in/ft²-hr-°F

538

19.9 W/m-K

1200

152 Btu-in/ft²-hr-°F

649

21.9 W/m-K

1400

167 Btu-in/ft²-hr-°F

760

24.1 W/m-K

Thermal Diffusivity

572

0.006 in²/sec

300

3.9 x 10(-6)m²/s

752

0.006 in²/sec

400

3.9 x 10(-6)m²/s

932

0.007 in²/sec

500

4.5 x 10(-6)m²/s

1112

0.007 in²/sec

600

4.5 x 10(-6)m²/s

1409

0.008 in²/sec

765

5.2 x 10(-6)m²/s

1652

0.008 in²/sec

900

5.2 x 10(-6)m²/s

2012

0.009 in²/sec

1100

5.8 x 10(-6)m²/s

Magnetic Permeability (Room Temperature)

1.01 at 200 oersteds (15,900 A/m)

2 notes

·

View notes

Text

Top 5 Advantages of Using Super Duplex Steel S32750 Pipes & Tubes in Industrial Applications

Introduction :

Nascent Pipe & Tubes is a renowned manufacturers and suppliers of Exceptionally Super Duplex Steel Pipes & Tubes. We have been a piece of this industry for a long time and our momentous thing is being used for a surprisingly long time. We have been serving Pipes & Tubes needs of perpetual current clients with our unequaled things.

Product Overview :

These have high molybdenum and chromium content in it. Other than these SS grades offer unmatched use confirmations in its game plan. This makes these reasonable for fundamentally acidic present day work processes. Work processes that utilization acidic and formic hurting track down these Pipes & Tubes essential. They offer the overall insistence from isolating pondering inorganic acids, especially chlorides.

Specification of Super Duplex Steel S32750 Pipes & Tubes :

Super Duplex Steel S32750 is a high-performance alloy made from a combination of austenitic and ferritic stainless steel, commonly referred to as a duplex stainless steel. It is specifically designed to offer excellent resistance to corrosion, high strength, and good weldability. The typical chemical composition of S32750 includes:

Chromium (Cr): 24-26%

Nickel (Ni): 6-8%

Molybdenum (Mo): 3-5%

Manganese (Mn): 1-2%

Silicon (Si): 0.8%

Nitrogen (N): 0.24-0.32%

Iron (Fe): Balance (usually 50-60%)

Key properties include:

Yield Strength (Rp0.2): ≥ 550 MPa

Tensile Strength (Rm): ≥ 800-1000 MPa

Elongation (A5): ≥ 25% (for 50 mm gauge length)

Hardness: 250-300 HV (Vickers Hardness)

Physical Properties:

Density: ~7.8 g/cm³

Melting Point: 1300–1350°C

Thermal Conductivity: 14 W/mK at 100°C

Modulus of Elasticity: 200 GPa

Dimensional Range:

Pipe size: From ½" to 24" (varies with standards)

Wall thickness: Can range from 1mm to 40mm

Tube size: Available in various forms, including seamless, welded, and extruded.

Applications of Super Duplex Steel S32750 Pipes & Tubes :

Due to its outstanding corrosion resistance, strength, and durability, Super Duplex Steel S32750 is widely used in various industries, including:

Oil & Gas Industry:

Subsea equipment, risers, pipelines, valves, and pumps where high strength and resistance to pitting, crevice, and stress corrosion cracking are critical.

Chemical Processing:

Pipelines, heat exchangers, and reactors for handling aggressive chemicals, including acids and chlorides.

Marine & Offshore:

Construction of offshore platforms, shipbuilding, and desalination plants. S32750's high resistance to seawater corrosion makes it an ideal choice for marine environments.

Power Generation:

Used in cooling systems, heat exchangers, and other critical components where resistance to chloride stress corrosion cracking is required.

Food and Beverage Industry:

Equipment in food processing, beverage plants, and dairy industry that requires high resistance to corrosion and hygienic standards.

Pharmaceutical & Biotech Industries:

Due to its non-reactive nature, it is used in applications where high standards of cleanliness and corrosion resistance are necessary.

Conclusion :

Super Duplex Steel S32750 pipes and tubes represent a sophisticated solution for applications where both high strength and superior corrosion resistance are essential. Their unique combination of ferritic and austenitic microstructures provides them with exceptional resistance to corrosion, pitting, crevice, and stress corrosion cracking, making them a versatile material for harsh and demanding environments.

#Super Duplex Steel S32750 Pipes & Tubes#Super Duplex Steel S32750 Pipes & Tubes Manufacturers#Super Duplex Steel S32750 Pipes & Tubes Suppliers#Super Duplex Steel S32750 Pipes & Tubes Stockists#Super Duplex Steel S32750 Pipes & Tubes Exporters#Super Duplex Steel S32750 Pipes & Tubes Manufacturers In India#Super Duplex Steel S32750 Pipes & Tubes Suppliers In India#Super Duplex Steel S32750 Pipes & Tubes Stockists In India#Super Duplex Steel S32750 Pipes & Tubes Exporters In India

0 notes

Text

CHHAJED STEELS AND PIPES

It sounds like you're describing the capabilities and offerings of Chhajed Steel Limited regarding Nickel Alloy 200 Pipes & Tubes. Here's a summary of the key points from your description:

Product Offering: Chhajed Steel Limited manufactures and exports Nickel Alloy 200 Pipes & Tubes. These include UNS N02200 Seamless Pipes & Seamless Tubes, as well as Nickel 200 Welded Pipes & Welded Tubes.

Applications: Nickel Alloy 200 is used in various industries such as food, paper, construction, oil extraction, food containers, medicine, machinery, and chemicals.

Properties: Nickel Alloy 200 (UNS N02200) is known for its purity and good mechanical properties. It offers excellent resistance to alkali hydroxides and organic compositions. The alloy retains strength at high temperatures and remains ductile at low temperatures.

Quality Assurance: The pipes and tubes are designed to sustain intense pressure and are manufactured according to international and national standards.

Customization: Chhajed Steel Limited offers customization in terms of length sizes and shapes to meet client specifications.

Competitive Pricing: The company offers competitive rates for Nickel 200 Seamless Pipes & Tubes.

Product Range: Their product range includes Nickel 200 Pipes, Nickel 200 Tubes, Nickel 200 Seamless Pipes & Tubes, among others.

Warehousing: They have excellent warehousing and storage facilities for both finished and semi-finished goods.

Overall, this summary covers the key aspects of Chhajed Steel Limited's offerings of Nickel Alloy 200 Pipes & Tubes, emphasizing their quality, customization options, and application versatility across various industries.

For more information: Visit our website:https://www.chhajedpipes.com/ Email I'd:[email protected] Contact no:932-111-3630

0 notes