#mould base manufacturers

Explore tagged Tumblr posts

Text

VMC Machine Manufacturing in India

See the quality of our products. we at Precious Enterprises are best manufacturer of Finish Core and cavity 3D Machining, VMC Machine, high precision inserts machining in Pune and India.

#Finish Core and cavity 3D Machining Pune#VMC Machine Manufacturer in Pune#high precision inserts machining#Pressure Die Casting Mould Base Manufacturer in Pune#Pressure Die Casting Mould Base Supplier in Pune#Pressure Die Casting Dies in Pune

0 notes

Text

Manufacturing Microfluidic Devices: Materials, Processes, and Challenges

Explore the materials, fabrication techniques, and challenges of manufacturing microfluidic devices. Learn how PDMS, glass, thermoplastics, and silicon shape Lab-on-Chip technology. Discover the latest advancements in microfluidics for diagnostics, drug delivery, and chemical analysis. Contact us for expert solutions.

#microfluidic device manufacturing#Lab-on-Chip fabrication#injection moulded microfluidics#photolithography microfluidics#soft lithography process#microfluidic material selection#biomedical microfluidics#microfluidic sealing techniques#UK microfluidic industry#high-resolution microfluidics#polymer-based microfluidics#A-Gas Electronic Materials

0 notes

Note

Hello,

You've probably encountered this issue before, but I just wanted to amplify what Electrolux/Frigidaire is doing with their front-loading washing machine door gaskets. I got a new washer, and discovered too late that the company is soaking these big rubber seals in smelly oil-based deodorizer, or just baking it into the rubber during the manufacturing process - who knows. This is presumably an attempt to counteract the smell of mildew and mould that will grow on the seal if you don't take care of it. (Electrolux, probably not coincidentally, is facing a class-action lawsuit for bad door gasket and internal drainage design that lets their washing machines and door gaskets fill with black mould very quickly.) The deodorizer Electrolux is using is from that horrible new family of long-lasting, oil-based fragrances that never go away and can't be removed with anything short of a flamethrower. I don't know if other washing machine companies are also doing this, but I'll find out soon enough when I return this evil contraption that has me wheezing like a chimney, with kleenex stuffed up my nose, regardless of inhalers and antihistamines. This deodorizer doesn't actually have a very strong smell, but the potency of the allergens that it's off-gassing is unbelievable. It also gets into your clothes...I still don't know if I'm going to be able to get the smell out of the first load I did, before I realized what was going on.

I don't have the audience to get the word out to people with allergies and fragrance sensitivities that these machines can harm them, never mind what it will cost in both time and money to replace, should they buy one.

Electrolux being bastards strikes again. Ugh, thanks for letting me know. We had SO many problems with our old machine and the door gaskets. And I am zealous about cleaning the machines, so it wasn't just a lack of cleaning that was making them moldy.

I am so sorry you ended up being exposed to that. Hopefully you'll be able to get the smell out of your clothing :/

536 notes

·

View notes

Text

NEW to Not S&P Approved on Etsy: The Mystery Marseilles No.1 and 2: Le Bateleur and L'Hermite

A 3” recycled acrylic keyring, with gun metal keychain and lobster clasp - inspired by the legendary Marseilles Tarot. This particular pair features with Grunkle Stan as Le Bateleur - The Magician, or Grunkle Ford as L'Hermite - The Hermit, with artwork based upon the Nicholas Conver pattern of the legendary Marseilles Tarot.

Grunkle Stan as Le Bateleur The Magician is one of the most symbolic cards of the tarot; an exercise in inner strength and sheer, stubborn will. Via the power of the elements around him and the strength of the suits, he takes the unseen potential in The Fool and moulds it into his own dogged sense of purpose. He, above all else, proves that we have the strength to manipulate our environment, using sheer wit and stubborn dedication…

Grunkle Ford as L'Hermite The Hermit is easily misunderstood. He may appear lonely, but he walks a journey of self-discovery to find his own strength, even if the isolation is sparked by an unexpected happenstance or conflict. The Hermit may take the form of an unexpected mentor, but will always remind you that you author your own fate. And that you should never be afraid to reflect upon your successes and mistakes…

Complete with a holographic sticker, miniature card, and a metal charm - all packaged together in a miniature ‘Star & Moon’ organza bag.

"I found these freaky doo-dads when piling through my mom’s old junk. She loved all of her tarot cards and all that crud, even if she was a total sham. Sayin’ that, them magical markets in New Jersey were no joke. She picked up this pack back in the 50s, and …is it me or is this kinda uncanny?

I can’t complain. Easy merch, right? Perfect for you nerds. Especially you Tarot nerds. I kinda feel like a Venn diagram of Gravity Falls fans and Tarot fans should be a circle.

Now you can pick up a keychain dedicated to me, in a weird…heraldry-printery sorta style. Whatever floats your boat. I’ve even fitted a big ol’ lobster clasp, got some stickers made, printed out some cards, and stuck ‘em all in a little organza bag. Don’t say Grunkle Stan doesn’t do anythin’ for ya!

These keychains are manufactured using 100% recycled and recyclable acrylics, that have reached the end of their life-cycle and are destined for landfill or incineration. It's just as good as new plastic, whilst being completely VOC and HFC free and way better for the fish and stuff. Any offcuts are recycled too. Basically, it’s great stuff. Top-shelf stuff, and double-layered too, so it’s pretty chunky. Could be a weapon? Who knows. The world’s your oyster!"

Double-layered acrylic with a double-sided design

Inspired by the Nicholas Conver pattern of the Marseilles Tarot, published in 1760

Presented with a holographic sticker, definition card and a metal charm

Presented in a ‘Star and Moon’ Organza bag

100% recycled acrylic from renewable manufacturers

Manufactured in the UK

#gravity falls#gravity falls fandom#gravity falls fanart#not s&p approved#stan pines#grunkle stan#gravity falls merch#etsy#ford pines#grunkle ford#gravity falls keychain#acrylic keychain#keyring

29 notes

·

View notes

Text

Another concept for tiny moshi-monsters style collectible figures, this time considering the method of manufacture;

the base would be made through twin shot injection moulding, then the bowtie, face and suspenders would be printed on.

The glasses could be a separate piece of plastic with the eyes printed on, attached by a rod to the centre of the face, though this would increase the price of the toy, so they could just be printed on.

(Similar concept with Harry Anderson)

#tavvy crocker#homestuck beyond canon#tavros crocker#homestuck: beyond canon#harry anderson egbert#I liked this version of the Tavvy hair when I made it#but now I’m a bit off on it#I gave Harry two hair spikes by accident#but I kept them because it was funny

28 notes

·

View notes

Note

So, your sex doll au triggered some Thoughts ™️ based on what I've learned from my courses on business law....

Typically, manufacturers have strict liability for defects or design problems that may cause injury/harm. A part of this is that, if a consumer could foreseeably modify a product in a manner that makes it unsafe or causes harm, the manufacturer is held liable for not implementing effective safeguards, etc. Hence why manufacturers often will safeguard against altering a product or warn against it, and why product design has to consider elements of safety and risk.

What if Teyvat's reaction to this was to implement some deeply hidden code encouraging their robots to, uh, hide the evidence of anything that could hold Teyvat liable? Basically a "past the point of no return" policy where, if the safeguards have failed, yandere behavior is instead encouraged as a means of reducing business risk in a highly dystopian way. This could also be triggered more easily if the technician isn't an official Teyvat technician (hence the recommendation to do all repairs through Teyvat) because they don't know how to step around this hidden last resort code. Basically, second-hand bots are highly liable to be triggered for this behavior when they're refurbished by any non-Teyvat technician for resale. Anything you find beat up on the side of the road and fix up yourself is at especially high risk.

(If Teyvat weren't a suspicious dystopian tech corporation they'd just hire lawyers and take the defense that there's an assumed risk to modifying bots, or that there was shared responsibility on behalf of the user for moulding the ai's natural learning in a manner that is dangerous. But yanderes are cheaper than lawyers. 🤡)

Hope you don't mind my HC dump 🙏

no no no cuz i can totally see a ""safeguard"" being put in place that, when an android is modified, makes them behave more affectionately to ensure that their user is too attached to them to, y'know, report the issue and send them back to the factory when their beloved companion gets a little glitchy and locks them in their own apartment for the better part of a month. obviously, giving androids with exponentially increased chances of malfunctioning a permanent dose of 'love your partner and don't stop unless you want to literally die' medicine makes for some, uh, less-than-breathing customers, but by the time they noticed the correlation between their special line of code and the sky-rocketing rates of people being maimed by their companion droids, they've done the math and realized that dead users are cheaper than all the lawsuits they'd have to weather if their bots weren't quite so fatal. it's not exactly the most ethical approach to business, but hey, that's life under capitalism, baby!

#i actually have an idea for something like this as a diluc/reader oneshot#where the reader is sorta like teyvat's fixer and diluc's their rouge-android assistant fljsdfkjskl it's a lot i know#you'll see tho#you'll all see#personal#insidieus-beez#sex doll au

149 notes

·

View notes

Text

I don’t know, I can’t swallow the arguments posed by some amateur ‘class conscious’ and marxist critics of shows like Arcane have where “the villain made good points and the writers were too cowardly to put their all in revolution so they wrote in some stuff that made him evil to show that revolution is bad.’

Like what moment did you think that Silco was a good guy, and what point did you think that the revolution was being portrayed as bad? Ekko is RIGHT there not disagreeing with the need for change but very much disagreeing with how Silco is literally poisoning Zaun in his efforts to make weapons and scary super soldiers. Silco reluctantly and cynically understands that ‘base violence’, or the threat of it, is necessary to force change but where Silco gets it wrong is that he’s willing to sacrifice the well-being of his own people to achieve it. You can have a militant revolution and not poison your people. You can have a violent uprising and not force children to work in dangerous toxic factories, but for Silco, such exploitation is all he knows, because that exploitation is what got Piltover their prosperity and results, so in Silco’s mind the same exploitation is alright because it will be for Zaun’s benefit.

The writers of Arcane didn’t just randomly tack on some evil moments to Silco’s character to undermine his cause. The man’s final form is from the ground up a complex character sketch of how the violence of poverty can turn you down several different paths. You become a Silco, a Vander, an Ekko, a Powder, a Vi.

Do you think that gangs in real life are some knights in shining serving their communities? No, they’re terrorizing it same as the police. They’re poisoning their neighborhoods with drugs and weapons and intimidating shops and luring kids with no future prospects into violent lives. The only difference between them and Silco is that Silco is a Thomas Shelby/Don Corleone type, an echo of the early 20th century organized crime boss who has the business acumen and political savoire faire to match and mirror any of their ‘legitimate’ oligarch counterparts.

Silco is not a political leader who happens to do ‘counterproductive criminal things’ that are then supposed to be intended by the writers as ‘see? Revolution bad’. He was an aggrieved socioeconomically marginalized man who threw himself into the gray-black world of unregulated drug and weapon manufacturing because those avenues granted a modicum of power and money back to the community (see the tweet about Vander and Silco setting up the Lanes with smuggling. That was to take back some economic power denied to them by Piltover). Silco distinguished himself by wanting to go further. He wanted to use what resources Zaun had to fight for its independence. Of course he was a criminal and did criminal things. Being poor in Zaun is a crime and a punishment in the eyes of Piltover. When fighting for the right to exist is a crime, when basic luxuries and staples of decent living are inaccessible except through illegal channels, do you honestly not expect or understand why men like Silco might want to push the envelope further? Why the exploitation and violence (inherent to scarcely fettered capitalism) inflicted upon them might not then be internalized and reflected back onto the world in retaliation? Do you not expect men like Silco to be moulded from these circumstances, to be a bit wayward and skewed in their morals and values? Like what the hell are we even doing here.

38 notes

·

View notes

Photo

Abarth 1300OT Periscopica Coupé

In 1958, the American Chrysler Corporation pursued an entry into the European motor manufacturing market by buying 15 per cent of the French Simca company's stock from Ford. At that time, however, the dominant shareholder remained Fiat of Turin, and their influence remained distinctively apparent in the engineering and design of Simca cars for several years into the early 1960s. However, in 1963 Chrysler increased its Simca stake to a controlling 64 per cent by purchasing stock from Fiat, subsequently extending that holding to 77 per cent.

Chrysler had no interest in any continuation of the previously successful Simca Abarth and Abarth Simca high-performance car collaboration, which came to a juddering halt. In Turin Carlo Abarth found himself left more or less high and dry, but the supply of basically Simca 1000 chassis floor pans, upon which the sleek and superfast Abarth Simca 1600s and 2000s had been based, left quite a number in stock, as yet unused. The popular legend is that it was upon these unused Simca platforms that Abarth then founded his 1300cc class Gran Turismo design for 1965 – the OT 1300. Abarth's technical team under Mario Colucci had developed a boxed pressed-steel chassis structure on the modified Simca 1000 floor pan to which allindependent suspension was attached with componentry drawn from the Fiat 850 shelves. The Abarth OT 1300 then emerged, to race for the first time as a prototype in the September, 1965, Nurburgring 500-Kilometre classic.

Driver Klaus Steinmetz hammered the new Coupé home to a fine third-place finish overall and the OT 1300 was up and running into the record books, becoming one of the most successful – and also one of the most distinctive – models that Abarth & C ever produced. The OT 1300's rear-mounted all-Abarth engine was overhung – in best Carlo Abarth-approved style. It was a 4-cylinder unit with twin overhead camshaft cylinder head, using a block with cylinder bore and stroke dimensions of 86mm x 55.5mm to displace 1289cc.

With two valves per cylinder and a 10.5:1 compression ratio, the engine breathed through two twin-choke Weber 45DCOE9 carburettors. Ignition was by two plugs per cylinder, fired by single distributor. Dry-sump lubrication was adopted and the power unit produced a reliable 147bhp at 8,800rpm. This lusty engine, perfected by Abarth's power-unit specialist Luciano Fochi with five main-bearing crankshaft, drove via a five-speed and reverse Abarth transaxle.

Wheelbase length of the OT 1300 was nominally 2015mm, front track 1296mm and rear track 1340mm. It featured moulded glassfibre clamshell-style opening front and rear body sections moulded by Sibona & Basano in Turin, and this pert-nosed Coupé became a familiar sight dominating its class for three consecutive years. Production of the OT 1300 began on May 15 1966 and ended on March 30, 1966, by which time the minimum production number of 50 required by the FIA for homologation as a Gran Turismo model had (allegedly) been achieved. The most distinctive single characteristic of the OT 1300 Coupé, apart from its huge International success within its class, was its adoption of the Periscopica air-cooling intake on the rear of the cabin roof. Casual onlookers would assume that the periscopelike intake fed intake air into the rear-mounted engine, but this is absolutely not the case. Instead, the water and oil-cooling pipe runs through the cockpit area heated-up the cabin to what was generally considered to be an unacceptable level for endurance racing, and the periscope intake merely blasted cold air down into the cabin to cool the driver himself...

From the OT 1300 Mario Colucci developed the OT 2000 Coupé using the 1946cc 4-cylinder power unit perfected by his colleague Luciano Fochi and with some 215bhp at 7,600rpm that largerengined model was capable of exceeding 165mph in a straight line. In fact all these Abarths with their sleek aerodynamic bodies and light weight really were exceedingly rapid by the standards of the time and within their respective capacity classes.

103 notes

·

View notes

Text

Are you looking to secure your investment with top-quality tools, die, and mold steel?

Look no further! We offer a wide selection of imported and highest quality steel to meet your needs.

Get in touch with us today to place your requirement! Our commitment to maintaining a high level of inventory from world-renowned manufacturers, such as Swiss Steel DEW, NLMK Verona, Vitkovice, Somers Forge, and Villares Metals and many more. This ensures that our customers receive only the best quality products that meet international standards.

VIRAT SPECIAL STEELS PVT. LIMITED , INDIA is one of India’s top Tool Steel, Die Steel suppliers, and Mold Steel Stuckists. This company provides special steel of every kind in sizes and shapes (flat, round, or bars) per customer requirements. Based in Gurgaon (Haryana) & Ludhiana (Punjab) India.

Product List

DIE STEEL ( HH 370 - 410 BHN ) DIN-1.2714 / AISI L6 )

HOT WORK STEELS (DIN 2343, 2344 / AISI H11, H13)

PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

ALLOY STEELS, EN-SERIES ETC.

Choose VIRAT SPECIAL STEELS for a seamless blend of quality, variety, and reliability in every steel grade.

Contact us today to buy the best quality of #Din2714Steel | #DIN2714 | #L6steel | #DB6Steel | 1.2714 Steel Hot Work Tool Steel for your tooling needs! https://www.viratsteels.com/din-2714.html

Any further queries feel free to contact us : 🌐https://www.viratsteels.com 📩[email protected] 📲+91-98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#diesteel#db6 steel#h13steel#h11steel#din 2714#din2344#p20steels#d2steel#m2steels

3 notes

·

View notes

Text

#mould base supplier in pune#mold base manufacturer pune#best molding companies india#gun drilling machine pune#plastic moulds manufacturer in pune#mould bases#mould base supplier in india#mould base manufacturer in india#mould bases in pune#plastic injection molding pune

0 notes

Text

Effervescent tubes have revolutionised the pharmaceutical and nutraceutical industries, becoming the go-to solution for packaging effervescent tablets. As a prominent name in the sector, NBZ Healthcare, located in Mumbai, stands at the forefront of exceptionally effervescent tube manufacturing, ensuring quality and innovation.

In this article, we delve deep into the manufacturing of effervescent tubes, their applications, benefits, and the unparalleled expertise of NBZ Healthcare in this domain.

Understanding Effervescent Tubes

Effervescent tubes are specialised containers designed to store and preserve effervescent tablets. These tablets, when exposed to moisture or air, tend to lose their potency, necessitating robust, moisture-resistant packaging. Effervescent tubes, often crafted with airtight and tamper-proof caps, provide the ideal solution to ensure the longevity and effectiveness of these tablets.

Importance of Effervescent Tubes

Effervescent tubes are more than just packaging; they play a crucial role in the pharmaceutical and nutraceutical industries by:

1. Protecting Product Integrity:

- Shielding tablets from moisture and air.

- Preventing degradation of active ingredients.

2. Enhancing Consumer Experience:

- Easy to open and reseal.

- Portable and convenient for on-the-go consumption.

3. Ensuring Regulatory Compliance:

- Meeting stringent health and safety standards for pharmaceutical products.

4. Sustainability:

- With increasing focus on eco-friendly materials, many effervescent tubes are now designed to be recyclable or biodegradable.

Effervescent Tube Manufacturing Process

Effervescent tube manufacturing is a precise and technologically driven process. At NBZ Healthcare, we combine state-of-the-art machinery with strict quality control measures to produce exceptional effervescent tubes. Here’s an overview of the key stages:

1. Material Selection

- High-grade plastic materials such as polypropylene (PP) or polyethylene (PE) are used.

- Materials are selected based on moisture resistance, durability, and eco-friendliness.

2. Tube Extrusion

- Plastic granules are melted and extruded into tube-like shapes using extrusion machines.

- The dimensions and thickness are carefully controlled to meet industry standards.

3. Moulding

- Injection moulding is used to form the caps and closures of the tubes.

- Caps are designed to ensure an airtight seal and tamper resistance.

4. Printing and Branding

- Tubes are labelled or printed with product details, branding, and regulatory information.

- Advanced printing techniques ensure durability and clarity.

5. Quality Control

- Rigorous testing for moisture resistance, durability, and compatibility with effervescent tablets.

- Each tube undergoes inspection to ensure zero defects.

NBZ Healthcare: Redefining Effervescent Tube Manufacturing

As a leader in exceptionally effervescent tube manufacturing, NBZ Healthcare sets the benchmark for quality and innovation. Based in Mumbai, our facility is equipped with cutting-edge machinery and a dedicated team of professionals who prioritise precision and excellence.

What Sets NBZ Healthcare Apart?

1. Advanced Manufacturing Capabilities

- NBZ Healthcare utilises the latest extrusion and moulding technologies to produce high-quality tubes.

2. Customisation Options

- We offer custom designs, sizes, and branding options to cater to the unique needs of our clients.

3. Sustainable Practices

- Focused on reducing environmental impact, we incorporate eco-friendly materials and processes wherever possible.

4. Regulatory Compliance

- Our manufacturing processes comply with international standards, including ISO and FDA regulations.

5. Global Reach

- While based in Mumbai, NBZ Healthcare serves clients across India and internationally, ensuring timely delivery and exceptional service.

Applications of Effervescent Tubes

Effervescent tubes find applications in various sectors, including:

1. Pharmaceuticals:

- Storage of vitamins, supplements, and medications in effervescent tablet form.

2. Nutraceuticals:

- Packaging for dietary supplements and health-boosting effervescent tablets.

3. Food and Beverage:

- Containment of flavour-enhancing or health-focused effervescent powders and tablets.

4. Personal Care:

- Packaging for effervescent bath tablets or other similar products.

Innovations in Effervescent Tube Manufacturing

At NBZ Healthcare, innovation is at the heart of our operations. Here are some of the cutting-edge advancements we incorporate:

1. Smart Packaging Solutions

- Tubes embedded with QR codes or NFC tags for enhanced consumer engagement and traceability.

2. Enhanced Moisture Resistance

- Using desiccant-lined caps and advanced sealing technologies to further improve moisture protection.

3. Eco-Friendly Materials

- Transitioning to biodegradable plastics and exploring sustainable alternatives like biopolymers.

4. Automation and AI Integration

- Automated production lines ensure consistency and reduce manufacturing errors.

- AI systems monitor quality in real-time for enhanced accuracy.

Challenges in Effervescent Tube Manufacturing

While effervescent tube manufacturing offers immense potential, it comes with its own set of challenges, such as:

1. Material Costs:

- Balancing quality and affordability when sourcing raw materials.

2. Environmental Concerns:

- Reducing the carbon footprint of manufacturing processes.

3. Regulatory Compliance:

- Adhering to diverse regulatory standards across different markets.

4. Consumer Expectations:

- Meeting the growing demand for sustainable and innovative packaging solutions.

The Future of Effervescent Tube Manufacturing

The demand for effervescent tubes is expected to rise significantly as more consumers turn to effervescent products for their convenience and efficiency. NBZ Healthcare is well-positioned to lead this growth, with a focus on:

1. Sustainability Initiatives

- Introducing greener manufacturing processes and materials.

2. Global Expansion

- Reaching untapped markets to provide high-quality effervescent tubes worldwide.

3. Product Diversification

- Expanding into new applications and industries beyond pharmaceuticals and nutraceuticals.

4. Technological Upgrades

- Adopting emerging technologies to enhance efficiency and product quality.

Why Choose NBZ Healthcare for Effervescent Tubes?

At NBZ Healthcare, we combine years of expertise with a commitment to innovation and customer satisfaction. When you partner with us, you’re choosing:

- Unmatched Quality: Every tube is crafted with precision and care.

- Custom Solutions: Tailored to your product’s specific needs.

- Reliable Service: Consistent and timely delivery of all orders.

- Sustainable Values: Supporting environmentally responsible practices.

Conclusion

Effervescent tubes play a pivotal role in preserving the efficacy and quality of effervescent tablets. With NBZ Healthcare’s expertise in exceptionally effervescent tube manufacturing, businesses can rely on robust, high-quality packaging solutions tailored to their needs.

As a Mumbai-based pioneer in the industry, NBZ Healthcare continues to set the standard for excellence, innovation, and sustainability. Whether you’re in the pharmaceutical, nutraceutical, or any related industry, NBZ Healthcare is your trusted partner for exceptional effervescent tube solutions.

Reach out to us today and experience the difference in quality and service!

2 notes

·

View notes

Text

The Commonly Used Metal 3D Printing Materials

Metal 3D printing uses a variety of metal powders, wires, and even liquid resins infused with metal. Almost any metal can be 3D printed, from stainless steel to nickel-based alloys, and in practice, about 8 are most commonly used. The most common question about metal 3D printing is: Will the final part have the same mechanical properties as a machined, moulded or forged metal part? The answer is yes, and sometimes even better mechanical quality, but it depends a lot on the metal 3D printing technology you use, the type of feedstock used, post-processing and the shape of the part. In addition, the comparison depends on the aspects you are concerned about: for example, tensile strength, static load strength, high cycle fatigue, and so on.

In general, the material properties of metal parts made by metal bond jetting are equivalent to those of metal parts produced by metal injection moulding, and it is one of the most widely used manufacturing methods for the mass production of metal parts. These 8 metal alloys below are just the beginning of what is possible today as metal material producers continue to push the boundaries and customize metal alloys for specific needs using specific metal 3D printing technologies.

1.Stainless Steel Feature: All-round Stainless steel is not the material most commonly used in 3D printing, but many alloy varieties. The first two are 316L and 17-4 PH, but also 304L, 15-5 PH, 420, 254, PH1, GP1, 630, and 410 can be printed, as well as custom blends produced by material manufacturer. These steels are specifically designed to resist corrosion. They are a lightweight and affordable metal that is ideal for 3D printing. This is because it is faster and cheaper than traditional methods and can print small batches and complex parts. 3D printing is the preferred option for companies that need a single tool or several replacement parts. Stainless steel can be used in almost any type of 3D printing, from economical wire for extruded 3D printing on benchtop machines to powder for binder jetting and laser powder bed fusion, and even resin.

2.Tool Steel Feature: High hardness, good wear resistance Tool steels, like stainless steels, come in different varieties with different tensile strengths, ductility, hardness and other properties. Tool steels are a variety of alloy steels designed specifically for the manufacture of tools. They are known for their hardness, wear resistance and ability to hold a cutting edge at high temperatures. This 3D printing steel is commonly used in the manufacture of injection mould inserts, aerospace components, military applications, manufacturing tools, as well as construction and architecture. The main advantage of 3D printed tool steel is not only its strength, but also its unique ability to create parts with internal channels (e.g. cooling channels in moulding tools) and lattice fillings that cannot be manufactured by traditional methods.

3.Low-Alloy Steel All 3D printing steels are alloys, but this category includes steels with low or less than 5 per cent of other elements. These low alloy steels are designed to have higher mechanical properties and greater resistance to wear and corrosion than other steels which are commonly used in automotive, aerospace and structural applications.

4.Aluminum Feature: Lightweight and corrosion resistant For aerospace, automotive and industry, the design freedom and cost efficiency of 3D printing further enhances the lightweight and chemical resistance of aluminum components. The use of aluminum and aluminum alloys in 3D printing is surging because the metal is economical and easy to 3D print. Like most metals, aluminum can be used as wire or powder for a variety of 3D printing techniques. Aluminium has good chemical resistance, is very light and has one of the best strength-to-weight ratios of any metal. Combined with silicon and magnesium, it is the choice of many in the aerospace and automotive industries because of its ability to withstand harsh conditions.

5.Titanium Feature: Lightweight and biocompatible As strong as steel but half the weight, titanium is a complex metal that is practically made for 3D printing. Titanium has become one of the most commonly used metals in additive manufacturing, with a wide range of applications in aerospace, joint replacement and surgical tools, racing car and bicycle frames, electronics and other high-performance products. Titanium and titanium-based alloys offer high mechanical strength, high strength-to-weight ratios and better corrosion resistance than stainless steel. It makes rockets and aircraft lighter, thus saving fuel and increasing payload capacity. In the medical industry, 3D printed titanium implants have been successfully used in the spine, hips, knees and extremities due to the inherent biocompatibility and good mechanical properties of the metal, coupled with the ability to customize porous structures with 3D printing, allowing for osseointegration and mass customization for better patient outcomes.

6.Copper Feature: Electrical and thermal conductivity 3D printing using pure copper and space-age copper alloys is available with a range of metal 3D printers and services. You can create rapid copper prototypes using copper filament on an FDM 3D printer and large copper rocket boosters using copper alloys on a laser powder bed fusion 3D printer. There is also copper wire and copper resin for micro 3D printing. In fact, copper plays a huge role in the global sustainable development goals as a key component of electric motors, charging infrastructure, solar energy and batteries.

7.Nickel Alloy Feature: Extreme environments resistant Nickel-based alloys and "high-temperature alloys" are known for their excellent high-temperature strength, corrosion and oxidation resistance. These alloys retain their strength and mechanical properties at high temperatures. They are commonly used in demanding applications such as aerospace, gas turbines, chemical processing and marine environments. In recent years, these alloys have also become increasingly popular in 3D printing, especially in the aerospace and automotive industries. When referring to nickel alloys, you may hear the term inconel. Inconel is the trade name for a range of nickel-chromium-based high-temperature alloys, including IN625, IN718 and IN939. Nickel alloys are generally more expensive than other materials such as steel and aluminium and may not be suitable for low temperature applications.

8.Cobalt Chrome Feature: High temperature and corrosion resistance 3D printed cobalt chrome has a high strength-to-weight ratio and excellent corrosion resistance, making it a good material choice for aerospace components and industrial machinery. It is also biocompatible and is often used in orthopaedic implants, dental prosthetics and medical devices that require long-term contact with biological tissue. Cobalt-chromium alloys can be processed using additive manufacturing techniques such as selective laser melting (SLM) or electron beam melting (EBM). This allows complex geometries and customized parts to be produced with minimal material waste, making it attractive to industries adopting advanced manufacturing techniques.

To sum up, metal 3D printing uses a wide range of metal powders and wires, including stainless steel, tool steel, etc. to print complex parts with superior mechanical properties. Commonly used metals in 3D printing include aluminum, titanium, copper, nickel alloys, tool steel, cobalt-chromium alloys, stainless steel for aerospace, medical and jewellery applications and more.

#design#business#autos#prototype#prototyping#prototype machining#rapid prototyping#3d printed#3d printing#3d printing services#sls#slm

2 notes

·

View notes

Text

*click link to watch video*

The Women’s World Cup is just over three weeks away and there’s been plenty of media coverage about the bespoke items that players will be wearing in Australia and New Zealand – including the Phantom Luna, Nike’s first boot designed for female players.

Unfortunately, there has also been much written about the players who will be missing this tournament because of ACL injuries, such as England’s Leah Williamson and Beth Mead.

The worry for many players I know is that a connection exists between the boots they’ve been wearing – which are designed for a male foot – and the greater risk of serious knee injuries faced by women footballers.

For this reason, I sat down in a cafe in Kingston with Dr Katrine Okholm Kryger, an associate professor in sports rehabilitation at St Mary’s University, Twickenham, who I first met when she came to Chelsea for a study into women footballers’ feet.

She sits on the Uefa Women’s Health Panel and the findings of her study, commissioned by the European Club Association (ECA), involved nearly 350 players.

Here she tells me about the scale and findings of a study never before done on footballers, male or female – and explains why boot manufacturers now have no excuse when it comes to producing better boots for women players at all levels.

Magda Eriksson [ME]: Kat, can you tell me about the research you were doing and your findings?

Katrine Kryger [KK]: We scanned players from top clubs from Europe, travelling around with a scanner and speaking to some of the best players in the world.

We know men and women have different foot shapes so we scanned these to quantify exactly what a woman’s foot shape is like, so we can pass that on to the manufacturers so they have a model to base a women’s boot design on.

I’ve done groupings of different ethnicities, different playing positions, different foot types and all of that is going to be in a database that manufacturers will be offered access to.

ME: What are the potential problems for women from wearing boots designed for a man’s foot?

KK: There are three main areas of concern. The first is the fit. Football boots are really tightly fitted – or should be because you need to be able to move and change direction without sliding inside the shoe – but that means you’re wearing something that’s fitted around a man’s foot, and a white man’s foot to be more specific. And with a female foot being differently shaped, that’s going to cause squeezing and aching and blisters.

When I asked if they had pain or discomfort with football boots, just 18 per cent left it blank. So 82 per cent had an issue somewhere with boots and one in three women highlighted the heel. They’re so stiff and if the shape isn’t perfect, they’re going to rub on the heel.

ME: I had a team-mate who had to cut a hole in her boot just so her heel can stick out. I’ve also had that problem when the bone starts to grow because of constant rubbing and had to have my Nike Tiempo boots custom-made. My heel cap is really soft and they’ve had to stretch it bigger as well just to get more space.

KK: The second big concern is that a football boot will only bend in between the stud lines. It cannot just bend anywhere and if it bends over bone, bones don’t like to be bent and you are going to end up irritating both the bones and the tissues. We’ve been measuring exactly where that is for women and we’ll offer that to the manufacturers.

ME: On studs, before games I always hear players asking: ‘Should we wear the studs or the moulds?’ I know certain girls who’ve done ACL injuries when wearing studs and are afraid to wear them again. On a slippery pitch they’ll sacrifice playing well and risk slipping because they’re afraid of getting injured. They might slip but at least they’ll stay injury-free.

KK: This is tied in with the third thing we want to highlight – that the outsoles to the studs should be designed for women.

We see women have three times the risk of ACL injuries and the common feature for getting injured is planting the foot, getting stuck, and not being able to rotate the foot but instead rotating the knee.

Currently for men and women the length of studs and number of studs is the same yet when you go into the physics of it, the traction – the grip on the surface and how much you get stuck – is much higher in a women’s football boot.

Women need less than men because they weigh less and don’t have the same muscle mass so don’t generate the same power. When pushing off, they need less and so there’s an increased risk of ACL injury.

The survey we did showed that while women often change studs depending on the surface and the weather conditions, a large group actually don’t, which is quite interesting.

ME: As well as men and women, you mentioned ethnicities before. What variations have you found there?

KK: We tried to select clubs with a high level of diversity, especially in France, and we saw there’s a tendency for African or African-descended players to have a wider foot.

To give you an example from men’s football, one Premier League player signed a sponsorship agreement with a boot company and when they asked him what size he was, he said a size 14. Yet they measured his foot and he was a size 8.

So basically, there was a big gap between the end of the toe and the end of the boot. I went to one club where three black players told me the same. It’s players wearing one or two sizes too big.

Women tend to have two types of feet: a wide foot with quite flat arches and a wide Achilles tendon, and also a narrower foot with a high arch and slimmer Achilles tendon.

The big conclusion is we should be able to cover people from different ethnicities, whatever playing position, within these two types of footwear. That’s going to be our suggestion to the manufacturers – that you don’t just have one football boot but you have two that align with those two options.

ME: This is my biggest take – that you are actually doing research on women that’s not yet been done in men’s football because it’s so conservative. It’s what I love about women’s football, that maybe we can start different conversations. What good do you hope will come from this?

KK: Having an optimal football boot designed for women from a holistic perspective is the dream.

We’re going to pass on the information that we have to the manufacturers and then it’s their job to design football boots for women.

#very good read#magdalena eriksson#woso#fc bayern frauen#chelsea fcw#swewnt#magda article#swewnt article

29 notes

·

View notes

Text

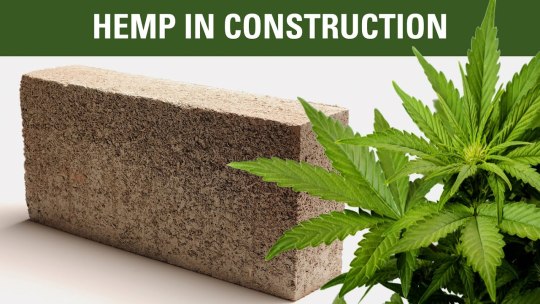

Revolutionising Construction: The Power of Hemp as a Sustainable Building Material

Introduction: A Return to Hemp

The need for sustainable building materials has never been more pressing, and the answer may lie in an ancient plant: hemp. This versatile crop, cultivated for over 10,000 years, is making a comeback in modern construction due to its exceptional properties and environmental benefits.

The Environmental and Economic Advantages of Hemp

Hemp offers a promising alternative to traditional timber-based materials. According to research conducted by Dewey & Merrill (Bulletin #404, United States Dept. of Agriculture, 1916), one acre of hemp produces as much cellulose fibre pulp as 4.1 acres of trees. This makes hemp a highly efficient source of material for pressed boards and particle boards, as well as concrete construction moulds. Moreover, hemp cultivation requires less water and fewer pesticides than traditional crops, adding to its environmental appeal.

Superior Strength and Flexibility: Hemp vs. Wood

In addition to its environmental advantages, hemp also outperforms wood in terms of strength and flexibility. Between 1991-1993, William B. Conde of Conde's Redwood Lumber, Inc., in collaboration with Washington State University, demonstrated that hemp composite building materials surpass wood fibre in these key areas, even when used in load-bearing applications like beams. The economic implications of this are significant, offering the potential for cheaper, more resilient buildings.

Isochanvre: The Mineralising Power of Hemp

One particularly intriguing application of hemp in construction is the creation of isochanvre, a material made from hemp hurds mixed with lime. This unique substance petrifies over time, turning into a mineral state that can last for centuries. A testament to its longevity, archaeologists have discovered a bridge in southern France, built during the Merovingian period (500-751 A.D.), using this process.

Hemp in Carpeting: A Strong, Healthier Choice

Hemp also has a long history in carpet manufacturing, where its strong, rot-resistant fibres provide an ideal backing material. Today, hemp carpeting offers a compelling alternative to synthetic materials, which release toxic fumes when burned and can trigger allergic reactions.

Plumbing with Hemp: A Renewable Solution

Even in areas as unexpected as plumbing, hemp presents a viable alternative. Plastic plumbing pipes, traditionally made from non-renewable coal or petroleum-based feedstocks, can be manufactured using renewable hemp cellulose. This not only reduces our dependence on fossil fuels but also contributes to a circular economy.

Envisioning a Future Built on Hemp

As we face the urgent challenges of climate change and resource scarcity, the potential of hemp as a sustainable building material is more relevant than ever. From the walls and beams of our homes to the carpets underfoot and the pipes beneath our streets, hemp offers a way to build, plumb, paint, and furnish our world sustainably. It's time to reimagine our future, built not on dwindling resources, but on the world's number-one renewable resource - hemp.

3 notes

·

View notes

Text

Summary #1

In "The Lottery of Birth," viewers are asked to question their perception of freedom and how much society impacts each individual. Four interviewees with academic backgrounds have their takes on these societal influences and how much control people don't have over their lives. It reasons this by going through topics of birth, education, employment, obedience, questioning, and creativity. Suggesting that the world moulds each individual; while schooling prepares us to fit into society, it frequently leaves out critical lessons about inequality, environmental issues, and capitalism. It speaks about how authority is in fewer hands, and overcoming these authority systems is necessary for freedom. It explains how it teaches society to accept changes and to be comfortable with their current situation, limiting their thinking and standing with their beliefs, inevitably becoming a part of their identity. The film ends by saying artistic acts connect people, and oppressive environments can force adaptation. Everyone has a responsibility to make the change they seek in this world.

At the beginning of "Do Good Design," there is a big emphasis on how often we see popular brands everywhere, such as Coca-Cola. In some poorer countries, it's not only on billboards and signs but also in front of schools and businesses. The author emphasizes that well-known brands are on a pedestal and how they create a negative/positive impact on society. The book also talks about how overly saturated our world is with advertising, giving an example of a place that outlaws billboard advertising so that people aren't as heavily influenced by it. Using Coca-Cola in another example, the author mentions that people only think it's a well-designed logo because of its imprint on everyone's head, not because of its typography or colour choices.

The point is that familiarity wins over "the best" design. The author shows how big brands are from a global standpoint, being so well circulated now with the internet because of its ease. They talk about how many symbols have been created to deceive but also inform, playing on the idea of designing a memory. One example is the Swastika that Hitler stole and is now associated with hate and war. In the last portion of the reading, the author relates this to the misuse of symbols in the modern world, showing some designers have used elements of cultural appropriation or animals wanting to be eaten. Ultimately, it states that just because you can, doesn't mean you should.

In Debbie Millman's TedTalk "How Symbols and Brands Shape Our Humanity," she starts from an evolutionary standpoint, talking about how much we've advanced as humans and how ancestors designed symbols representing their beliefs. For thousands of years, everyone has had some religion they've based their lives around, causing many wars. She explains that because of war, flags were manufactured onto uniforms to help identify each side, and brands eventually became legally recognized. She also talks about how the Nike Swoosh is one of the most recognized logos and shares identities with other logos, relating it to the Swastika and how it was a symbol of good fortune before Hitler. Millman says that these are all reasons humanity has been manufacturing language for thousands of years, and as a positive outcome, social movements have affected branding in the last ten years. Her point is that branding doesn't have to be just about capitalism, it can also be used to make the world a better place.

Key Takeaways:

Being not political still makes you political

Coca-Cola has a much bigger impact than I thought and not in the best way

Each piece of content ended off with wanting to make the world a better place

Branding is essential for a complicated world

Big corporations hold so much power, yet they don’t do much for people

2 notes

·

View notes

Text

Just got Ch.3 of All Roads Lead Back up on ao3. Here's an excerpt:

The first ‘confidential area’ Aziraphale takes them to is a vast space filled with millions upon millions of small lights appearing, streaking through the space, then fading out. Some move slow, some fast as a blink, but they never stop coming. For every one that disappears another dozen flame into existence.

“What are they?” Crowley whispers, awestruck.

“They’re prayers.” Aziraphale replies. “The Metatron sometimes sends an Angel in here to round up a few hundred and set to work granting them, with all means and methods left up to said Angel. But, um, if it turns out God does not approve of the Angel’s methods or the results, then they are swiftly punished.”

Muriel searches for the logic in this with a troubled frown. “That makes no sense. Without any boundaries or guidelines-”

“Getting it right boils down to blind dumb luck.” Crowley interjects. “Right you are, Muriel.”

Aziraphale nods in the affirmative. “Yes, the chances of failure are quite high. And it did not take me long to notice that ‘God’ only ever seems to assign prayer answering duty to those Angels who have annoyed or offended the Metatron in some way."

“Funny that.” Crowley scoffs.

The second department Aziraphale shows them is a massive factory. Conveyor belts with workers on either side quickly assembling bits and parts of who knows what as the moving belt carries those bizarre objects down the line. A huge sewing station of Angels sit hunched over machines sewing together reams and reams of shimmering, ethereal fabric. Another station where what appears to be a claylike substance made of pure light is being moulded into . . . body parts maybe? And finally a heap of feathers against the back wall, stacked floor to ceiling. Angels stand at the base of this heap miracaling feathers into the framework of a wing, loading them into a transparent vertical tube, and punching a button that sucks them up to someplace else.

“What’s-”

“An Angel production line.”

“Are you SERIOUS?!” Crowley’s snake eyes snap to Aziraphale’s. “They’re manufacturing Angels? But, but isn’t God the only one who, how can . . .” he trails off. “Oh no, no, no, they can’t possibly have permission to do this,” he flails and sputters, searching for words. “I mean on a normal day I’m all in for a spot of blasphemy but this is going too far!”

“Yes, I rather agree.” Aziraphale sighs, the weight of a troubled soul sitting heavy in his chest.

Being so tightly bound to his Angel, Crowley also feels the downward pull of said weight, and wonders if there is anything he can do to pull it in the opposite direction. Keep Aziraphale afloat in rough seas. When he speaks again it is with an uncharacteristic timidity. “But on the plus side . . . doesn’t such a clear abomination pretty much prove your theory that God has been usurped? She and I may have had our differences, but the Almighty I remember would never have outsourced the birthing of Angels.”

Bless you. Aziraphale thinks whilst allowing Crowley to pull him into a sturdy embrace. “So then . . . you do believe none of this is in accordance with her will?”

“Not a chance in hell, Angel."

**********************To start from Ch.1 go HERE

3 notes

·

View notes