#motor torque

Explore tagged Tumblr posts

Text

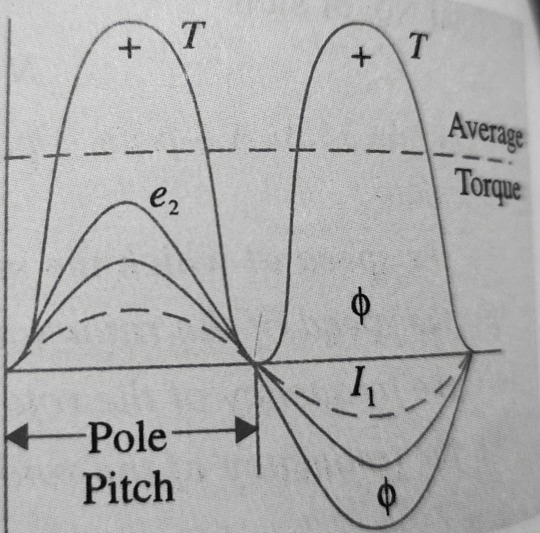

Torque in induction motor and relationship with power factor.

the torque in induction motor is proportional to the product of flux per stator pole and the rotor current one more term we will take in account is power factor of the rotor.

T → φ * I₂ * cos∅₂

Where φ - flux per status pole

I₂ - rotor current

cos∅₂ - rotor power factor

The induced rotor EMF E2 is proportional to flux per status φ.

Therefore T = K1 * E₂ * I₂ * cos∅₂

Where K1 is another constant.

∅₂ phase angle rotor current and rotorEMF.

From the above equation it is clear that when φ2 increases cos∅₂ decreases and vice versa.

due to the revolving stator flux EMF is induced in rotor conductor, and this EMI is also sinusoidal.

When rotor is non inductive.

φ₂=0

in this case rotor current is in phase with rotor EMF. So the instantaneous value of torque is product of instantaneous value of flux and current. It is seen that torque is always positive.

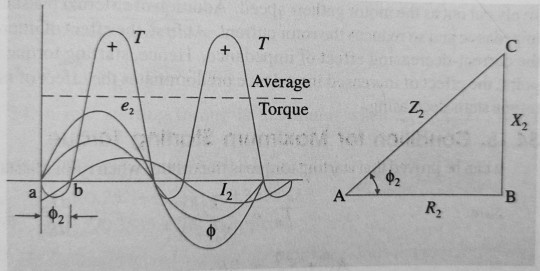

When rotor is inductive load.

in inductive load I₂ lags behind E₂ bY an angle φ2.

φ2 = tan-¹(X₂/R₂ )

R2 = rotor resistance per phase

X2 = rota reactance per phase at standstill.

Its clear from diagram that portion of torque is reverse direction and hence the total torque is difference of forward torque and reverse torque. When φ2 = 90 degree then reverse torque equals to forward torque and total torque is equals to zero so the motor will not run.

2 notes

·

View notes

Text

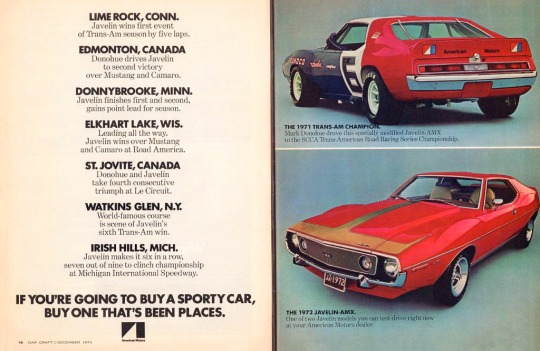

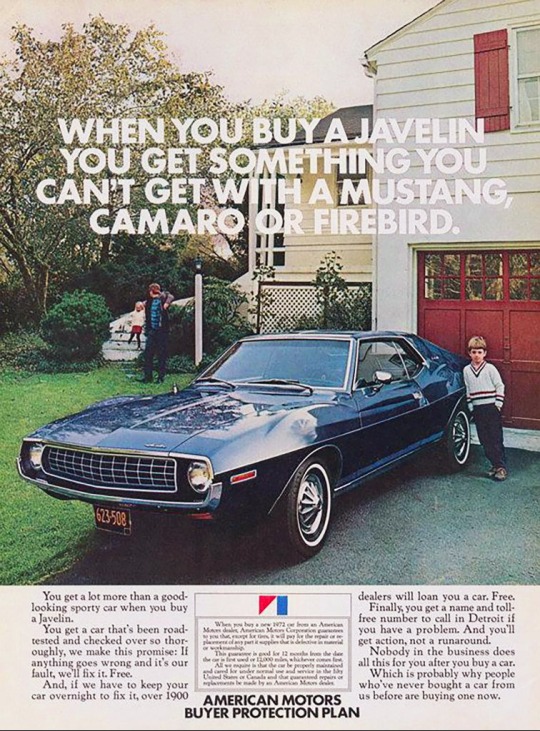

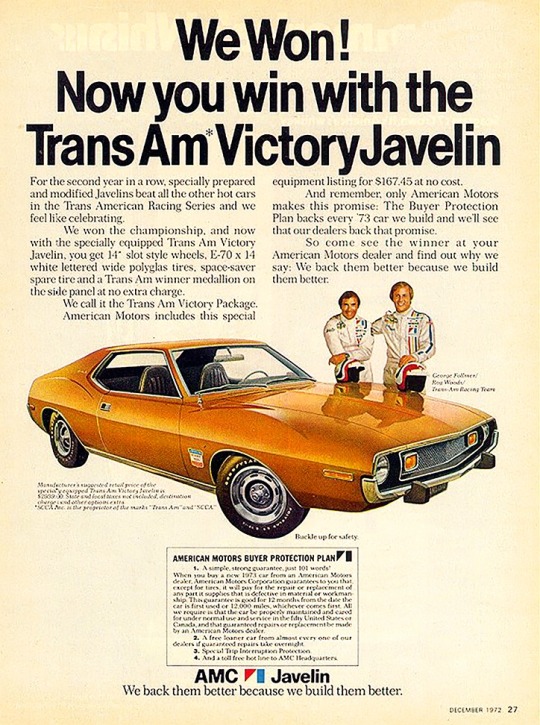

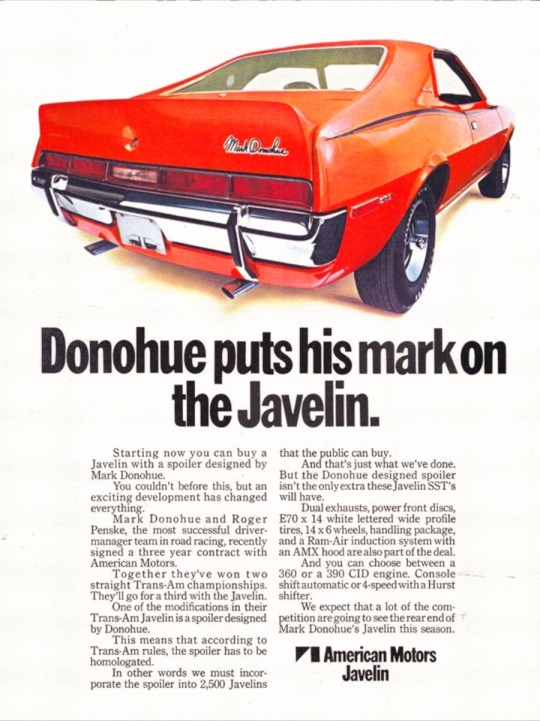

🇺🇲 Step back in time and experience the roar of the iconic AMC Javelin, a true legend of American muscle cars! Introduced in 1967 by American Motors Corporation (AMC), the Javelin was a front-engine, rear-wheel-drive, two-door hardtop automobile manufactured across two generations, spanning from 1968 through 1970 and then from 1971 through 1974 model years. It was designed to compete in the pony car market segment against rivals like the Ford Mustang and Chevrolet Camaro.

🚗💨 The AMC Javelin burst onto the scene in 1968, showcasing a sleek design and powerful engines. Styled by Dick Teague, the Javelin offered a range of trim and engine levels, from economical pony car variants to high-performance muscle car models. Its distinctive appearance, featuring a long hood and aggressive stance, turned heads on the streets and racetracks alike.

🏭 Besides being manufactured in Kenosha, Wisconsin, Javelins were also assembled under license in Germany, Mexico, the Philippines, Venezuela, and Australia, showcasing its global reach. American Motors even offered discounts to U.S. military personnel, leading to many Javelins being exported overseas.

🛞 Under the hood, the Javelin packed serious power. It was available with inline-six engines or potent V8s, delivering thrilling acceleration and speed. The AMX variant, equipped with a 6.4-liter V8, boasted over 300 horsepower!

🏆 The AMC Javelin wasn't just about looks—it excelled on the track too. It competed in Trans-Am racing, demonstrating its speed and agility. In fact, the second-generation AMX variant was the first pony car used as a standard vehicle for highway police car duties by an American law enforcement agency. Today, the Javelin's unique style and racing heritage make it a sought-after classic among collectors.

💔 By 1974, the automobile landscape had shifted. While other manufacturers downsized engines in response to changing market demands and fuel shortages, the Javelin's big engine option continued until production ceased in November 1974 amidst the Arab oil embargo and declining interest in high-performance vehicles.

🦅 The AMC Javelin embodies the spirit of American muscle cars, blending style, performance, and affordability. It's a timeless classic that continues to capture the hearts of car enthusiasts everywhere. Get ready to hit the road and experience the thrill of the AMC Javelin!

#brits and yanks on wheels#retro cars#transatlantic torque#vehicle#cars#old cars#brands#companies#automobile#american cars#amc#american motors#american muscle#amc javelin#javelin#muscle car#pony car#race car#trans am#old car#classic cars#car#american auto#automotive#chevrolet camaro#chrysler#wisconsin#kenosha#made in usa#ford mustang

306 notes

·

View notes

Text

History of the Worlds First Hybrid Logging Truck

youtube

3 notes

·

View notes

Text

The engine is shaking on a Toyota Avalon.

A side motor mount is worn, causing excessive movement. The car also has a worn transmission mount and torn torque strut mount.

We noticed the problem when performing an oil change.

#engine shaking#toyota avalon#motor mount#transmission mount#torque strut mount#steve's auto repair and tire#prince william county virginia

0 notes

Text

The Exciting World of Electric Skateboard Motors

The electric skateboard industry is rapidly evolving, and one of the standout brands making waves is MEEPO. Known for their innovative designs and high-quality performance, MEEPO has become a favorite among skateboard enthusiasts.

One of the key components that sets MEEPO apart is their electric skateboard motor technology. These motors are engineered for efficiency and power, providing riders with a smooth and exhilarating experience. With advancements in battery life and motor performance, MEEPO electric skateboards are perfect for both beginners and experienced riders alike.

Not only do these motors deliver impressive speeds, but they also offer excellent torque, making it easier to tackle hills and rough terrain. MEEPO's commitment to quality ensures that every ride is not just enjoyable but also safe.

As the electric skateboard industry continues to grow, MEEPO is at the forefront, pushing the boundaries of what electric skateboards can achieve. Whether you are commuting or just having fun, MEEPO's electric skateboard motors are designed to enhance your riding experience.

0 notes

Text

Maximizing Energy Efficiency with Variable Frequency Drives

Discover how VFDs can revolutionize your operations

Variable Frequency Drives (VFDs) revolutionize energy efficiency for AC motors, offering unmatched control and optimization for modern industrial systems. They control motor speed and torque, optimizing operations in applications ranging from HVAC fans to quarry and mining stone crushers. With easy setup and robust performance, VFDs can reduce your energy costs up to 50%. Choose us for your advanced motor control solutions.

The VFD Exchange

#vfd#variablefrequencydrive#torque#speed#voltage#amperage#phase#frequency#electrical#motor#controls#automation#industrial

0 notes

Text

Innovative Solutions in Hydraulic Filtration Tanks: Advancing Efficiency and Durability

Hydraulic filtration tanks play a pivotal role in ensuring the optimal performance and longevity of hydraulic systems across industries. These systems, commonly found in construction, manufacturing, agriculture, and automotive applications, rely on clean, contaminant-free hydraulic fluid to function efficiently. The hydraulic filtration tank acts as the backbone of this process, filtering debris, moisture, and other contaminants that can compromise system performance. Check their site to know more details hydraulic filtration tanks

Understanding Hydraulic Filtration Tanks

At their core, hydraulic filtration tanks are designed to house and maintain filters that clean hydraulic fluids. They come in various shapes, sizes, and configurations depending on the application and system requirements. The tanks not only store hydraulic fluid but also provide a pathway for it to pass through high-performance filters.

Hydraulic fluid contamination is one of the leading causes of system failure, often resulting in equipment downtime, costly repairs, and reduced operational efficiency. The filtration tank ensures the hydraulic fluid remains clean by trapping particles, preventing corrosion, and minimizing wear and tear on critical components.

Key Components of Hydraulic Filtration Tanks

Filter Media: The heart of the filtration tank, responsible for capturing contaminants. Advanced filter media, such as microglass fibers and multi-layered synthetic materials, offer superior performance and durability.

Tank Reservoir: Holds the hydraulic fluid and allows proper circulation through the system. Reservoirs are often designed with baffles or flow control mechanisms to prevent turbulence and ensure uniform filtration.

Pressure Indicators and Sensors: Modern tanks are equipped with sensors that monitor fluid pressure and contamination levels, alerting operators when maintenance or filter replacement is required.

Valves and Connections: Properly designed inlet and outlet valves ensure smooth fluid transfer and seamless integration into hydraulic systems.

Technological Advancements in Hydraulic Filtration Tanks

The evolution of hydraulic filtration tanks has been driven by the need for enhanced efficiency, reduced downtime, and better adaptability to challenging environments.

Smart Filtration Systems: Integration of IoT-enabled sensors and real-time monitoring has revolutionized hydraulic filtration tanks. These systems provide data on fluid cleanliness, pressure levels, and operational health, allowing predictive maintenance and reducing unexpected failures.

Eco-Friendly Designs: Manufacturers are increasingly adopting sustainable materials and designs that minimize waste. Reusable filter elements and recyclable tank components are gaining popularity.

Compact and Modular Tanks: As hydraulic systems become more compact, so too have filtration tanks. Modular designs allow for easier customization and installation in space-constrained environments.

Applications Across Industries

Hydraulic filtration tanks are indispensable in industries such as:

Construction: Ensuring the smooth operation of heavy equipment like excavators and loaders.

Agriculture: Maintaining hydraulic systems in tractors and harvesters.

Manufacturing: Supporting automation and robotic systems with precise fluid control.

Best Practices for Maintenance

To maximize the performance of hydraulic filtration tanks, regular maintenance is crucial:

Monitor Filter Condition: Replace filters as needed to prevent clogging and fluid contamination.

Check Fluid Levels: Ensure the reservoir is adequately filled with the recommended hydraulic fluid.

Inspect for Leaks: Regularly check seals and connections for signs of leakage.

Conclusion

Hydraulic filtration tanks are critical to the efficiency and reliability of hydraulic systems. As technology advances, these tanks are becoming smarter, more durable, and eco-friendlier. For industries reliant on hydraulic machinery, investing in high-quality filtration tanks and adhering to maintenance best practices ensures smoother operations and cost savings in the long run.

#hydraulic valves#hydraulic pumps#hydraulic motors#hydraulic filtration tanks#hydraulic parts#hydraulic control#hydraulic drive technology#hydraulic systems#hydraulic spare parts#Low speed high torque hydraulic motor

1 note

·

View note

Text

Temperature Condition for Brushless Motor Magnets

Temperature Condition for Brushless Motor Magnets Brushless motors use permanent magnet as one of their key components. These magnets usually use high-performance permanent magnet materials, such as rare earth neodymium strong magnets, mainly arc-shaped, fan-shaped, wedge-shaped, and rectangular. Today, this article mainly introduces the temperature requirements of brushless (DC) motor…

#AC motors#bonding neodymium iron boron#Brushless motor magnets#DC motors#Embedded Permanent Magnets#Ferrite magnet#high-performance permanent magnet motors#interior permanent magnet motors#IPM motors#magnet working temperature#Magnetic alloy#magnetic field#magnetic fields#magnetic flux density#magnetic forces#magnetic parameters#magnetic properties#Magnetic stators#Magnetic torque#magnetization direction#Magnets Temperature#motor magnets#permanent magnet motors#Permanent Magnets#PM Motors#rotor and stator#SPM motors#surface permanent magnet motors#Surface Permanent Magnets

0 notes

Text

The Rise of HVLS Fans in Industrial Applications

In the rapidly evolving industrial sector, maintaining optimal working conditions is crucial for productivity, employee well-being, and energy efficiency. High-Volume Low-Speed (HVLS) fans have emerged as a revolutionary solution, providing significant benefits across various industries. This article delves into the world of HVLS fans in Bangalore, exploring their advantages, applications, and the leading manufacturers driving this innovative market.

What Are HVLS Fans?

HVLS fans are large ceiling fans with diameters ranging from 7 to 24 feet. Unlike traditional fans that operate at high speeds, HVLS fans move a large volume of air at a low speed. This unique design enables them to create a gentle breeze that can cover expansive areas, making them ideal for large industrial spaces.

Benefits of HVLS Fans

Energy Efficiency: HVLS fans consume significantly less energy compared to conventional air conditioning systems. By improving air circulation, they help regulate temperature and reduce the load on HVAC systems, leading to substantial energy savings.

Enhanced Comfort: By distributing air evenly throughout a facility, HVLS fans eliminate hot and cold spots. This consistent airflow improves overall comfort for employees, contributing to increased productivity and morale.

Energy Efficiency: HVLS fans are designed to reduce energy consumption by improving air circulation, which helps to regulate temperatures and reduce the load on HVAC systems. This can lead to significant cost savings on energy bills, particularly in large spaces.

Improved Comfort: By creating a gentle breeze, HVLS fans enhance thermal comfort for employees, reducing heat stress and improving productivity. The consistent air movement helps to maintain a more uniform temperature throughout the facility.

Versatility: These fans are suitable for various industrial settings, including warehouses, manufacturing plants, ventilation HVLS fans suppliers in Bangalore centers, and agricultural facilities. Their adaptability makes them a valuable addition to any large space requiring effective air movement.

Leading HVLS Fan Manufacturers

Several companies stand out in the HVLS fan manufacturing industry, each offering innovative solutions tailored to meet diverse industrial needs.

Big Ass Fans

Overview: Known for their high-quality and durable products, Big Ass Fans is a leading name in the HVLS fan market. Their fans are designed to provide superior airflow and energy efficiency.

As the industrial sector continues to prioritize energy efficiency, employee comfort, and cost savings, high torque low speed fan motors in Hyderabad have become an indispensable asset. Leading manufacturers like Big Ass Fans are at the forefront of this market, delivering cutting-edge solutions that transform large industrial spaces. Investing in HVLS fans is not just a step towards a more comfortable work environment but also a move towards sustainability and operational efficiency.

#high torque low speed fan motors in hyderabad#large industrial hvls ceiling fans in bangalore#large industrial hvls ceiling fans manufacturers in bangalore#large industrial hvls ceiling fans suppliers in bangalore#large industrial hvls ceiling fans in nellore#ventilation hvls fans suppliers in bangalore#large industrial hvls ceiling fans in vijayawada#large industrial hvls ceiling fans manufacturers in vijayawada#high torque low rpm electric motors in bangalore#hvls fans in bangalore#high volume low speed fans in bangalore#hvls ceiling fan price in bangalore#industrial hvls ceiling fans in bangalore

0 notes

Text

🇺🇸 September 23, 1991: on this day, the production of the Ford Falcon came to an end at the General Pacheco plant in Buenos Aires, Argentina.

🏭 The Ford Motor Argentina company began assembling Ford Falcon units on January 10, 1962, at their La Boca plant in Buenos Aires. National manufacturing of the Ford Falcon began on July 15, 1963, with the first Argentine body built on April 30 of the same year.

🎉 The final unit produced was a platinum gray Ford Falcon GL, which was raffled among the 6,000 workers of Autolatina Argentina. The lucky winner was Emilio Félix Pogliotto, an employee at the Transax Puente Box Plant in Córdoba. This last unit marked the end of an era, with a total of 494,209 units manufactured.

🔧 By 1982, only 46 of the 3,500 parts that made up the Ford Falcon were common to the original 1962 model, showcasing the extensive nationalization and transformation the car underwent over 29 years of production.

#transatlantic torque#brits and yanks on wheels#retro cars#vehicle#cars#old cars#brands#companies#automobile#american cars#ford motor co#ford#ford falcon#detroit#michigan#automotive#argentina#buenos aires#manufacturing#plant#old car#classic cars#cool cars#vintage cars#retro aesthetic#history#automobiles#british automotive#automotive history#1990s

25 notes

·

View notes

Text

Battle Droids Flee the Explosion

STAR WARS EPISODE I: The Phantom Menace 02:02:54

#Star Wars#Episode I#The Phantom Menace#Battle of Naboo#N-1 starfighter#Bravo Seven#Vuutun Palaa#Droid Control Ship#Lucrehulk-class LH-3210#starboard main hangar#inner hangar#Zone 3#unidentified battle droid#OOM security battle droid#receiver assembly casing#waste energy conduit#E-5 blaster rifle#blaster gas cartridge#high-torque motors#starboard main reactor

0 notes

Text

Direct Drive Linear Torque Motor

A linear direct drive motor, also known as a torque motor or a direct drive rotary motor, is a type of electric motor that provides direct and high-torque rotary motion without the need for mechanical transmission elements such as gears or belts. It operates on the principle of electromagnetic induction and is designed for applications that require precise and smooth rotary motion.

Types of Direct Drive Torque Motor

Direct Drive Torque Motors offer high torque, precision, and efficiency in rotary motion applications, making them suitable for a wide range of industries, especially in situations where accuracy, smoothness, and reliability are critical.

Advantages of Direct Drive Torque Motor

High Torque: Direct Drive Torque Motors can deliver high torque at low speeds, making them ideal for applications requiring high power output.

Precision and Accuracy: They offer precise and accurate positioning due to the absence of mechanical transmission components, reducing backlash and hysteresis.

Smooth Operation: Direct Drive Motors provide smooth and cogging-free motion, improving overall system performance.

Energy Efficiency: With no mechanical losses from gearboxes or belts, they exhibit high energy efficiency.

Low Maintenance: Their simple design with fewer moving parts results in reduced maintenance requirements.

Advantages of Direct Drive Torque Motor

Working Principle of Direct Drive Torque Motor

A Direct Drive Torque Motor operates using the principle of electromagnetic induction. It consists of a stator and a rotor. The stator contains windings that generate a magnetic field, and the rotor consists of permanent magnets or soft magnetic materials. When electrical current is supplied to the stator windings, a magnetic field is created, which interacts with the magnetic field of the rotor, resulting in rotational motion.

Applications of Direct Drive Torque Motor

Robotics: Direct Drive Torque Motors are used in robotic joints and manipulators to provide precise and dynamic motion control.

Machine Tools: They are employed in CNC machines for accurate positioning and spindle rotation.

Semiconductor Manufacturing: Used in wafer handling and scanning applications.

Aerospace: Direct Drive Motors are utilized in motion control systems for aircraft control surfaces.

Medical Devices: In applications such as medical imaging equipment and robotic surgery systems.

0 notes

Text

I think in the future, or at least the ideal future, software should be written so that the user interface has a very distinct and memorable musical identity. It definitely should have a distinct visual one too, but music is where I think a lot of software is lacking. Now obviously, this could get annoying, especially if it increases the size of the software, but I’m not talking about giving task manager a soundtrack or something. Mostly i just want a few more things in my computer to look and feel like the Wii or the Playstation 2.

#high torque motor: destruction of god#i also wanted to gush about the DS but it would make the post too long

1 note

·

View note

Text

Variable Frequency Drive (VFD)

Optidrive E3 General Purpose series

NEMA 4X Outdoor Rated Enclosure

#invertek#drives#optidrive#variablefrequency#speed#controls#ac#drive#vfds#motor#torque#voltage#current#phase#nema4x#outdoor#electrical

0 notes

Text

The sensorless BLDC motor controller works without a sensor; it detects the rotor's position by estimating back electromotive force (back EMF).

0 notes

Text

BYD eMAX 7 Superior: The Ultimate Electric MUV for Families

₹29.9 Lakh Overview and General Features The BYD eMAX 7 Superior is an all-electric Multi-Utility Vehicle (MUV) that offers a spacious 7-seater configuration, making it suitable for larger families or anyone requiring a high level of interior space. The model comes in four attractive colors: Quartz Blue, Cosmos Black, Crystal White, and Harbour Grey. It features a 6-year/1.5 lakh kilometers…

#201.15 bhp#310 Nm torque#530 km range#7-seater#AC Permanent Magnet Synchronous Motor#Adaptive cruise control#Advanced Driver Assistance Systems#airbags#automotive technology#BYD eMAX 7 Superior#driving dynamics#eco-friendly#Electric Mobility#Electric Power Steering#Electric Powertrain#Electric vehicle#family vehicle#Fast charging#forward collision warning#high-speed performance#Infotainment System#lane departure warning#Lithium-Ion Battery#Luxury SUV#MUV#Panoramic Sunroof#Performance#regenerative braking#safety features#suspension

0 notes