#monel metal

Explore tagged Tumblr posts

Photo

"Monel Alloy 400 Manufacturer."

Monel Alloy 400 is almost immune to chloride associated ion pressure corrosion cracking in ordinary environments. Although, its corrosion resistance is very good in reductive environments, it’s far taken into consideration to be bad in oxidative conditions. Monel Alloy 400 Rod is known to have great mechanical properties at even at subzero temperatures. The alloy can be used in temperatures up that go to 1000° F. Monel 400 has a high melting point, it melts between the temperature range of 2370° F – 2460° F. Since alloy 400 has low strength in an annealed condition , a variety of tempering techniques may be used to increase the tensile strength.

#stainless steel round bar#manufacturer of stainless steel in india#stainless steel round bar manufacturer in india#ss round bar#monel metal composition#monel 400#monel metal#polished stainless steel#stainless steel manufacturers in india#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor

0 notes

Text

"Vardhman Ferro Alloys is your go-to destination for high-quality Monel 400 scrap. As a trusted importer and exporter, we provide top-grade materials at competitive prices. Contact us for all your metal scrap needs in Mumbai."

0 notes

Text

Inconel 600 or Monel Fasteners: Choosing the Best Alloy for Your Application

Choosing the right fastener material is crucial for ensuring longevity and affects your project's overall performance. When it comes to high-performance applications that demand resistance to corrosion, high temperatures, and harsh environments, two alloys stand out: Inconel 600 and Monel.

With This blog let’s help you make the right decision for your project: Inconel 600 or Monel fasteners

Let’s begin with understanding both these alloy types and their ideal industry applications:

Inconel 600

Inconel 600 is a nickel-chromium-iron superalloy known for its exceptional strength and resistance to oxidation, creep rupture, and carburization. Its high nickel content makes it highly resistant to corrosion in a wide range of environments, including oxidizing, reducing, and acidic conditions. Here at Online Fittings, we offer a variety of Inconel 600 fasteners, including bolts, nuts, washers, and screws, in various sizes and thread types to meet your specific needs.

Inconel 600 is the ideal choice for applications requiring exceptional high-temperature strength, oxidation resistance, and resistance to creep rupture. Its ability to withstand harsh environments makes it suitable for use in:

1. Jet engines 2. Nuclear reactors 3. Chemical processing equipment 4. Gas turbines 5. Heat exchangers 6. Furnace components 7. Cryogenic applications (at limited temperatures)

Monel

Monel is a nickel-copper alloy that offers excellent resistance to various corrosive media, including seawater, sulfuric acid, and hydrofluoric acid. It also boasts superior mechanical properties at both high and cryogenic temperatures. You have the liberty to choose from our online vast selection of Monel fasteners, including hex cap screws, square neck bolts, U-bolts, and coupling nuts, ensuring you have the right fastener for your application.

Monel is ideally used in industries that demand superior resistance to saltwater corrosion, sulfuric acid, and hydrofluoric acid. Its good strength at both high and low temperatures makes it a versatile option for:

1. Marine equipment 2. Offshore oil and gas rigs 3. Chemical processing plants 4. Pulp and paper mills 5. Pickling tanks 6. Desalination plants

Key Factors to Consider When Choosing Between Inconel 600 and Monel Fasteners

Here’s a breakdown of key factors to consider whilst deciding between Inconel 600 and Monel fasteners:

Property Inconel 600 Monel

Maximum Service Temperature, 1600°F (871°C), 800°F (427°C)

Strength

Higher, Lower

Oxidation Resistance

Excellent, Excellent

Chloride Stress Cracking

Good, Excellent

Cost

Higher, Lower

Additional pointers to consider:

1. Size and thread type: Ensure the fasteners are the correct size and thread type for your application. Look for an alloy fastener manufacturer who can customize each inch for your requirements.

2. Head style: The head style of the fastener (e.g., hex head, socket head) should be compatible with the installation tools and space constraints of your application.

3. Surface finish: Consider the desired surface finish (e.g., plain, zinc-plated) for factors like corrosion resistance and aesthetics.

Why Choose Online Fittings for Your Inconel 600 and Monel Fastener Needs?

At Online Fittings, we are committed to providing our customers with the highest quality Inconel 600 and Monel fasteners. We offer a comprehensive selection of fasteners in various sizes, thread types, and head styles to meet the demands of your project.

The experts at Online Fittings are always here to help you select the right fasteners to ensure the success of your project.

Let Online Fittings be your one-stop shop for all your Inconel 600 and Monel fastener needs. Contact us today to discuss your project requirements and receive a custom quote quote.

0 notes

Text

https://www.vardhmanferroalloys.com/metal-scrap/monel-400-importer-supplier/

"At Vardhman Ferro Alloys, we are the top importer and supplier of premium Monel 400 metal scrap. Our superior quality and competitive prices make us the go-to source for all your Monel 400 needs. Trust us for reliable and efficient delivery of the best metal scrap in the market.

0 notes

Text

Buy best quality Monel 400 Flanges at Metal Forge India

Looking for pinnacle-notch Monel 400 Flanges? Look no further than Metal Forge India! Our enterprise gives the finest high-quality Monel 400 Flanges that assure sturdiness and reliability. With a commitment to excellence, Metal Forge India ensures that every flange meets the very best industry requirements, promising unrivaled performance and toughness. Whether you are in want of flanges for industrial, marine, or every other utility, our tremendous range caters to diverse wishes. Backed by using years of knowledge and a dedicated group, we satisfaction ourselves on handing over products that exceed expectations. Trust Metal Forge India in your Monel 400 Flanges necessities and revel in remarkable exceptional and carrier.

0 notes

Text

Exploring the Diversity of Nickel Alloys: A Guide by Apex Metal India

Nickel alloys are the unsung heroes of the materials world, offering a unique blend of strength, corrosion resistance, and versatility. At Apex Metal India, we take pride in being a Leading Importer, Supplier, and Stockist of these diverse nickel alloys, sourced from reputable European mills with valid certificates. In this guide, we'll delve into the different types of nickel alloys and their unique characteristics, shedding light on how they empower various industries.

1. Inconel Alloys - Inconel alloys are the high-temperature champions. They offer superb resistance to extreme temperatures and corrosion, making them indispensable in aerospace and gas turbine components. Apex Metal India provides various grades, including Inconel 600 and Inconel 718,and many more ensuring top-notch quality for your projects.

2. Hastelloy Alloys- Hastelloy alloys are renowned for their exceptional corrosion resistance, especially in highly aggressive chemical environments. Industries such as chemical processing and oil and gas rely on Hastelloy alloys like Hastelloy C4, C-276, etc for their critical applications.

3. Incoloy Alloys- Incoloy alloys are valued for their unique combination of strength and corrosion resistance. They find use in diverse applications, ranging from marine environments to nuclear reactors. Apex Metal India offers a range of Incoloy alloys, ensuring that you have access to materials tailored to your specific requirements.

4. Monel Alloys- Monel alloys are celebrated for their exceptional corrosion resistance, making them ideal for applications in marine and acidic environments. One of the most widely used grades is Monel 400, but Apex Metal India goes further by providing options like Monel K-500 and Monel R405, ensuring you have the right Monel alloy for your specific needs.

5. Nickel-Copper Alloys Nickel-copper alloys offer a balanced blend of strength and corrosion resistance, making them highly suitable for applications in chemical processing and marine industries. Apex Metal India provides Nickel-Copper alloys like Alloy 825 and Alloy 925, ensuring that you have access to materials that can withstand the toughest challenges.

Your Partner for Nickel Alloys

With our extensive range of nickel alloys, you gain the power to choose the perfect material tailored to your specific needs. Whether you're soaring in the Aerospace Industry, working in corrosive Chemical Environments, or Power and Energy Generation, Apex Metal India is here to provide you with the finest nickel alloys available.

Reach out today and unlock the potential of nickel alloys for your projects. Contact us now for expert guidance and top-notch materials!

0 notes

Text

#avoidplastics#FollowTrafficRules#ourbestqualityproduct#ontimematerialdispatch#bestproducts#goodwillenginnering

#DrugFreeSociety#metalgasket

Metallic Gaskets are used for sealing higher temperature and pressure applications, where non-asbestos materials will fail. Typical applications are for heat exchangers, compressors, condensers, pumps, and valves.

Metal gaskets are manufactured from a material such as Soft iron, Low Carbon steel, Stainless Steel, Monel, and Inconel. These gaskets are also known as ring gaskets or RTJ gaskets

here are 3 main classifications of gasket: metallic, semi-metallic and non-metallic.

Metallic Gaskets. These gaskets are made from one metal or a combination of several metals. ...

Semi-metallic Gaskets. These gaskets are made from a combination of metallic and non-metallic components.

Gaskets are mechanical seals that inhibit leakage by filling the gaps between static mating surfaces. Both polished and unpolished surfaces, particularly metal surfaces, have an inherent roughness or microscopic asperity that creates spaces where fluids can pass through.

A gasket is a seal that is manufactured to fit between two or more surfaces, such as two lengths of piping. The gasket is designed prevent leakage whilst being subjected to varying levels of compression.

Metal Gasket Materials – The manufacturing of metal gaskets can be done using multiple materials including Stainless Steel, Copper, Cast Steel, Monel, Inconel, Brass, Bronze, 17-4, among many others. They also can be combined with various rubber products.

Gaskets are normally made from a flat material, a sheet such as paper, rubber, silicone, metal, cork, felt, neoprene, nitrile rubber, fiberglass, polytetrafluoroethylene (otherwise known as PTFE or Teflon) or a plastic polymer (such as polychlorotrifluoroethylene).

A combination of cork and rubber, for example neoprene or nitrile, yields a gasket resistant to solvents, oils, and fuels. Some of the materials used in the formulations and grades include: Cork & Neoprene Blend. Cork & Viton Blend.

#avoidplastics#FollowTrafficRules#ourbestqualityproduct#ontimematerialdispatch#bestproducts#goodwillenginnering#DrugFreeSociety#metalgasket#Metallic Gaskets are used for sealing higher temperature and pressure applications#where non-asbestos materials will fail. Typical applications are for heat exchangers#compressors#condensers#pumps#and valves.#Metal gaskets are manufactured from a material such as Soft iron#Low Carbon steel#Stainless Steel#Monel#and Inconel. These gaskets are also known as ring gaskets or RTJ gaskets#here are 3 main classifications of gasket: metallic#semi-metallic and non-metallic.#Metallic Gaskets. These gaskets are made from one metal or a combination of several metals. ...#Semi-metallic Gaskets. These gaskets are made from a combination of metallic and non-metallic components.#Gaskets are mechanical seals that inhibit leakage by filling the gaps between static mating surfaces. Both polished and unpolished surfaces#particularly metal surfaces#have an inherent roughness or microscopic asperity that creates spaces where fluids can pass through.#A gasket is a seal that is manufactured to fit between two or more surfaces#such as two lengths of piping. The gasket is designed prevent leakage whilst being subjected to varying levels of compression.#Metal Gasket Materials – The manufacturing of metal gaskets can be done using multiple materials including Stainless Steel#Copper

0 notes

Text

@bishop-percival

(Previous) [text] Would there happen to be anything generally considered rare or expensive?

[text] Ah.

[text] You’re only interested in selling it.

[text] A Xoq Beefuzz shawl, which causes 78% of watchdogs to shed due to pollen dust getting in their eyes. The non-eyeclops test subjects loved it.

[text] Torribington Silk uniform. Close contender, not puncture resistant, don't wear near flames.

[text] Monel-GWE coat. It was intended to be a three layer labcoat with softened Monel bands in the second layer. Coworkers compared it to plate armor. Nice striped pattern. Never added metal to the torso.

4 notes

·

View notes

Text

Humming a tune, walking into the empty Stark Laboratory, whistling a tune as I settle down...

'J.A.R.V.I.S, come in, it's playtime...'

Monitor system buzzing, activating processing units...

Evening Ma'am. Feeling Creative, I see. How would you like your ambience, Miss Grace?

'What can I say, J, I'm in the mood for work tonight, Aren't you too? Smiles...Just play whatever Mister Stark has on his playlist...'

Noted. Now Playing- Paint it Black by The Rolling Stones

Going into Creative, Miss Grace...

'Restore all of the last few browsings and display into list, please.'

LAST BROWSINGS:

What are the fundamental principles for designing high-entropy alloys with superior strength, ductility, and corrosion resistance for specific applications?

How can we optimize the microstructure of metallic materials to achieve a balance between strength, toughness, and fatigue resistance for specific applications, such as aerospace and automotive?

How can we ensure the long-term durability and safety of nuclear power plant components, considering the harsh radiation and temperature environments?

What are the environmental impacts of metal extraction, processing, and recycling, and how can we develop sustainable strategies to minimize these impacts?

How can we effectively integrate advanced characterization techniques to understand the degradation mechanisms of metallic components in service, and use this knowledge to improve component life and reliability?

Smiles...

'Thank you, I'll be needing that next...Now give me....sustainable microfibre alloy proportions...'

Very Well. You will now need narrowing down from your records.

Iron-based alloys: Often used in machinery due to abundance and cost-effectiveness.

Nickel-based alloys: Known for high-temperature strength and corrosion resistance, suitable for nuclear components.

Titanium alloys: Lightweight and corrosion-resistant, but expensive. High-entropy alloys: Emerging class of alloys with potential for unique properties.

'Now give the proportions we've considered the last time we looked into our simulators, Only for....the Nickel Based Alloys, make a list...'

Looks over thoughtfully as the list is being formulated...scrolls down the list, switching screens on the holograms...

Monel: A nickel-copper alloy known for corrosion resistance. 63% nickel, between 29% and 34% copper, between 2% and 2.5% iron, and between 1.5% and 2% manganese.

Inconel: A family of nickel-chromium-based alloys, often used in high-temperature applications. 61% nickel, 22% chromium, and 9% molybdenum

Hastelloy: A group of nickel-based alloys with exceptional corrosion resistance in various media. Hastelloy C276, also known as UNS N10276, has the following chemical composition: Nickel (Ni): 57%, Molybdenum (Mo): 15–17%, Chromium (Cr): 14.5–16.5%, Iron (Fe): 4–7%, Tungsten (W): 3–4.5%, Manganese (Mn): 1% maximum, Cobalt (Co): 2.5% maximum, Vanadium (V): 0.35% maximum and Silicon (Si): 0.08 maximum

Incoloy: Nickel-iron-chromium alloys designed for high-temperature applications and resistance to oxidation. Nickel: 38–46%, Chromium: 18–22%, Iron: Balance, Aluminum: 0.3–0.7%, Titanium: 0.15–0.6%, Manganese: 1.5% max, Silicon: 1% max, Carbon: 0.05% max, Sulfur: 0.015% max and Phosphorus: 0.02% max

Smirks, clapping my hands twice, the data reducing to 17 little fragments of hologram, flicking away the unnecessary bits that remain of the non highlighted data...

Data Compiled, Miss.

'Yeah, good... you've been writting down what I've been saying while I was in the simulation unit the other day and today, haven't you...?'

Yes Ma'am.

'Turn all of that, into that research booklet we were asked for, so we can give him what....roughly, an estimated idea of the whole entire suit, merits and demerits, budgeting and assemblance...give him the blueprints too, at the end of it...I have a feeling this one will not... disappoint...'

Working on it, Ma'am.

Runs hands on my face tiredly, waiting for it to compile, drumming fingers onto the table, cracks neck, shifts head...

Report Compiled, Ma'am.

'Good boy, J. You've been a darling, tonight, great help, I can never thank you enough... sometime when you're human, or if...Imma owe you big time.'

No worries, Ma'am. You've been quite amazing to work with as well.

Smiles...

'Let's call it a night, J.A.R.V.I.S...Thank you...Good Night...'

Hologram goes off...

Goodnight Ma'am.

______________________________________

( @tony-starkinator @the-loss-of-my-life )

2 notes

·

View notes

Photo

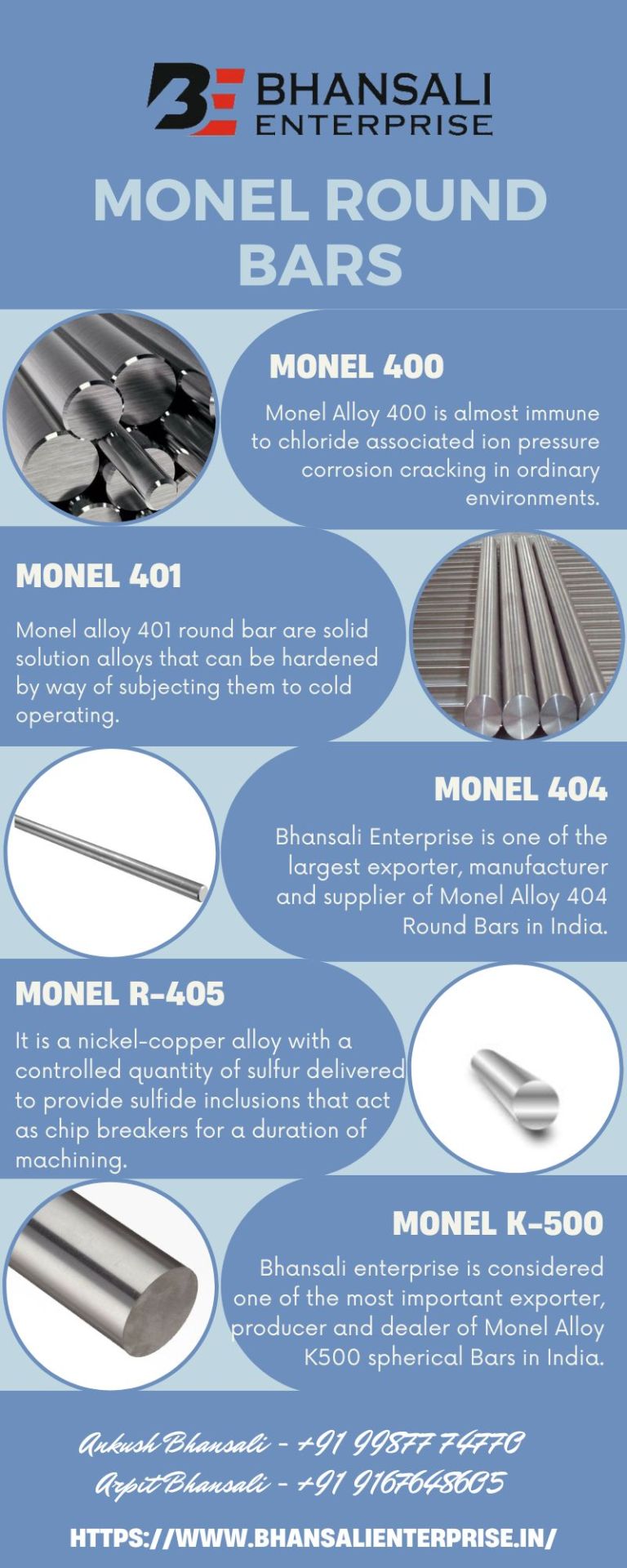

"Monel Round Bars."

Monel Alloy 400 Rod is known to have great mechanical properties at even at subzero temperatures. The alloy can be used in temperatures up that go to 1000° F. Monel 400 has a high melting point, it melts between the temperature range of 2370° F – 2460° F. Since alloy 400 has low strength in an annealed condition , a variety of tempering techniques may be used to increase the tensile strength. MONEL 401 is designed to be used in unique electric powered and digital applications. The common kinds of MONEL 401 alloy are strip and wire. This datasheet will look at the chemical composition, properties and applications of MONEL 401 alloy. Bhansali Enterprise is one of the largest exporter, manufacturer and supplier of Monel Alloy 404 Round Bars in India. Monel 404 Round Bars is more resistant to nickel under reducing environments and more resistant than copper under oxidizing environments, where it does exhibit however improved resistance to reducing media than oxidizing. Monel Alloy 404 Rods is a Nickel-Copper alloy, resistant to sea water and steam at elevated temperatures, in addition to caustic and salt solutions. Monel Alloy R-405 is the unfastened machining model of Monel 400. It is a nickel-copper alloy with a controlled quantity of sulfur delivered to provide sulfide inclusions that act as chip breakers for the duration of machining. Bhansali enterprise is considered one of the most important exporter, producer and dealer of Monel Alloy K500 spherical Bars in India.

#stainless steel round bar#manufacturer of stainless steel in india#stainless steel round bar manufacturer in india#ss round bar#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#monel metal composition#monel metal#stainless steel manufacturers in india#polished stainless steel

0 notes

Text

Choosing the Right Metal Sheet for Your Industry

When selecting a metal sheet for your project, choosing the right material is crucial for performance, durability, and cost-efficiency. Different industries, such as aerospace, marine, and industrial manufacturing, require specific metals to meet unique demands. This guide will help you compare stainless steel, titanium, aluminum, and exotic alloys to determine the best fit for your needs.

Stainless Steel Sheets: Strength and Corrosion Resistance

Best for: Food processing, medical, architecture, and marine applications.

High corrosion resistance, ideal for environments with moisture exposure.

Strong and durable, making it perfect for heavy-duty applications.

Available in various grades, including 304 and 316 stainless steel sheets for enhanced resistance.

Titanium Sheets: Lightweight and High-Strength

Best for: Aerospace, medical implants, and high-performance industrial equipment.

Exceptional strength-to-weight ratio, reducing overall structural weight.

Excellent heat and corrosion resistance, even in extreme environments.

Preferred for aerospace metal sheets due to its durability and efficiency.

Aluminum Sheets: Lightweight and Cost-Effective

Best for: Automotive, construction, packaging, and electrical applications.

Lightweight yet strong, making it easy to work with.

High conductivity, ideal for electrical and heat transfer applications.

Aircraft aluminum sheets are widely used in aviation for fuel efficiency.

Exotic Alloys: Extreme Durability for Harsh Environments

Best for: Chemical processing, power plants, and marine engineering.

Includes materials like Inconel, Hastelloy, and Monel, known for superior performance.

High resistance to oxidation, extreme temperatures, and chemical corrosion.

Used in specialized applications where standard metals fail.

FAQs About Choosing the Right Metal Sheet

Q1: What is the most corrosion-resistant metal sheet? A: Stainless steel and titanium offer the highest corrosion resistance, with 316 stainless steel being the best choice for marine applications.

Q2: Which metal sheet is the most lightweight? A: Aluminum sheets are the lightest among commonly used metals, making them ideal for transportation and aerospace applications.

Q3: Are exotic metal sheets worth the investment? A: If your industry requires extreme temperature and corrosion resistance, exotic alloys provide long-term cost savings and durability.

Q4: How do I choose the right thickness for my metal sheet? A: The required gauge thickness depends on your industry and application. Consult with Accromet for expert guidance.

Find the Perfect Metal Sheet for Your Application

At Accromet, we specialize in high-quality stainless steel, titanium, aluminum, and exotic metal sheets tailored to your industry’s needs. Contact us today to get expert recommendations and competitive pricing.

0 notes

Text

Monel Screws vs. Stainless Steel Screws

Introduction

At Fasteners & Fixtures LLP, an ISO-certified manufacturer, we are interested in splendid fasteners that include Monel screws and Stainless Steel screws. With our long time of experience, we impart solutions for a wide range of sectors, collectively with marine, chemical, and aerospace.

As one of the leading Screw Manufacturers and Monel suppliers, we are devoted to providing products that meet worldwide necessities, ensuring strength, sturdiness, and corrosion resistance. This blog allows us to compare stainless steel (SS) and Monel alloy screws, describing their specific advantages and helping you in selecting the first-rate fastener for your requirements.

Monel Screws: An introduction

A nickel-copper alloy that is renowned for its excellent corrosion resistance is used to make monel alloy screws. It is apparent and also successfully evident that corrosion due to chemicals, seawater, and high temperatures may be efficaciously prevented by employing it. This makes it more labile for manufacturing fasteners of quality for sectors like aerospace, marine, chemical, and others. The fasteners of Monel meet the requirements of ASTM B164, ensuring superior durability.

Stainless Steel Screws: An Overview

Screws Stainless steel is made from an alloy of iron, chromium, and super metals. While they provide good resistance to rust, they will usually be more appropriate for large applications. SS fasteners can be classified into several grades (e.g., 304 or 316 SS), each presenting numerous degrees of corrosion resistance. Sometimes, in highly severe and tough industries, these SS screws are not as durable as monel.

Comparing Monel and Stainless Steel Screws in a Marine Application

Background: A global offshore oil and gasoline commercial enterprise company running inside the North Sea confronted normal failure with stainless-steel screws on their drilling systems. These screws had been exposed to intensifying marine environments, essential to rusting and deterioration, which introduced delays and safety problems.

Challenge: The agency required fasteners that could face up to the difficult situations of seawater, immoderate humidity, and salt exposure. The stainless-steel screws they used have been failing earlier, primarily to progress protection and downtime.

Solution: After consulting with Fasteners & Fixtures LLP, the commercial enterprise employer switched to Monel screws, which can be stated for their corrosion resistance in marine situations, as high-quality with the useful aid of ASTM B164 necessities. These screws were decided on for his or her confirmed overall performance in seawater environments, and they have been sourced immediately from a relied-on Monel business employer.

Outcome

Monel Screws: After installation, the Monel alloy screws showed no symptoms of corrosion even after numerous months of publicity to difficult marine situations. Maintenance costs had been extensively reduced, and the tool remained in operation longer, minimizing downtime.

Screws Stainless Steel: In evaluation, the SS screws failed internal weeks, requiring replacements and inflicting useless operational interruptions.

Key Takeaway: Monel alloy screws are the superior choice for marine applications where intense corrosion is a difficulty, as examined through the outcomes within the case study.

When to Choose Monel Screws?

If your challenge consists of exposure to intense corrosion or harsh environments like marine, chemical, or offshore applications, Monel alloy screws should be your first choice. Their high strength, corrosion resistance, and long-term durability lead them to tremendously challenging conditions.

When to Choose Stainless Steel Screws?

For excellent applications in which corrosion isn't always a top problem, stainless-steel screws are a more cost-effective solution. They perform well in manufacturing, car, and family programs and are a less steeply priced opportunity for a lot of much less demanding environments.

Fasteners & Fixtures LLP: Your Trusted Screws Manufacturer and Supplier

With over a long term of experience, we are a primary Monel screw manufacturer. We provide Monel alloy screws and stainless-steel screws that meet standards, ensuring reliability and common performance to your obligations. Contact us in recent times for customized fasteners designed to fit your precise needs.

Conclusion

Finally, the selection among Monel screws and stainless steel screws depends on the conditions and challenging situations in which they will be used. Monel alloy screws are first-rate for corrosive environments and excessive situations, at the same time as stainless-steel screws are first-rate for trendy applications. Fasteners & Fixtures LLP offers each solution, ensuring you get the proper fastener to your desires.

Reach out to us nowadays to know more!

0 notes

Text

Are you looking for UNS N04400 Nickel Alloys Seamless Pipes

Seminox Pipes & Tubes PVT. LTD is a leading manufacturer and supplier of UNS N04400 nickel alloys seamless pipes, known for their superior strength, corrosion resistance, and durability. With a commitment to excellence and precision engineering, the company provides high-quality piping solutions that meet international industry standards. UNS N04400, commonly referred to as Monel 400, is a nickel-copper alloy offering outstanding resistance to seawater, acids, and alkaline environments. These seamless pipes are widely used in marine engineering, chemical processing, power plants, oil and gas, and heat exchangers, where high performance under extreme conditions is essential. Seminox ensures that its Monel 400 seamless pipes are manufactured with strict quality control, meeting standards like ASTM B165 and ASME SB165. The seamless construction eliminates weak points, ensuring leak-proof performance, high mechanical strength, and excellent thermal conductivity. These properties make UNS N04400 pipes ideal for applications requiring high corrosion resistance and pressure handling. With an advanced manufacturing facility and a dedicated team of experts, Seminox Pipes & Tubes PVT. LTD delivers top-tier UNS N04400 nickel alloy seamless pipes worldwide. The company’s focus on innovation, reliability, and customer satisfaction has made it a trusted name in the metal industry.

0 notes

Text

Nickel scrap is an essential resource used in industries like stainless steel manufacturing, battery production, aerospace, and chemical processing. With sustainability becoming a priority, recycling nickel helps reduce mining dependency, minimize industrial waste, and lower carbon emissions.

Types of Nickel Scrap:

Pure Nickel Scrap: Sourced from high-purity industrial waste.

Nickel Alloy Scrap: Includes Inconel, Monel, and Hastelloy used in high-temperature environments.

Stainless Steel Scrap: Contains 8-12% nickel, widely used in steel production.

Battery Scrap: Recovered from lithium-ion and nickel-cadmium batteries, crucial for EVs and energy storage.

Benefits & Market Trends: Recycled nickel is cost-effective for small industries, supports sustainability, and meets rising global demand. Nickel prices fluctuate due to mining output, EV battery demand, and geopolitical factors. Government regulations and recycling technologies further enhance nickel recovery.

Sourcing & Recycling Methods: Businesses can secure nickel scrap by partnering with reliable suppliers like Metalbook, setting up internal recycling programs, and monitoring market trends.

Nickel scrap presents a profitable, sustainable alternative for businesses in metal manufacturing and trading, ensuring cost savings and environmental responsibility.

0 notes

Text

Innovative Pipe Fittings & High-quality Grades for Every Industry

Pipe fittings may seem like a small part of industrial systems, but they are pivotal to guarantee seamless operations. They connect, redirect, and seal pipelines, providing the structural and operational backbone for industries ranging from oil and gas to construction. Online Fittings specialises in delivering high-quality pipe fittings tailored to meet the most demanding applications. Understanding the science behind pipe fittings and incorporating advanced materials, we help businesses optimize their systems for efficiency, safety, and reliability.

Materials and Applications

The material used in pipe fittings directly impacts their durability and functionality. For instance, stainless steel (Grades SS 304L and SS 316L) is renowned for its corrosion resistance and tensile strength, making it indispensable in chemical and food processing. Duplex stainless steels (2205 and 2507) offer double the yield strength of standard austenitic grades, making them ideal for offshore oil rigs and marine platforms.

Carbon steel (ASTM A234 WPB) is a favourite in the construction and energy sectors for cost-effective solutions. Nickel alloys (Inconel 625, Monel 400) excel in cryogenic environments because of their exceptional oxidation resistance. Even non-metallic options like PVC-U and CPVC are popular in water distribution systems because they are lightweight and chemical-resistant.

At Online Fittings, all our materials conform to global standards such as ASTM A403, ASME B16.9, and NACE MR0175, assuring reliability in even the harshest conditions.

Innovative Technologies for Superior Performance

Advancements in material science and manufacturing have led to groundbreaking innovations in pipe fittings. Electroplated coatings, for instance, enhance corrosion resistance, while pressure-sensitive O-rings guarantee leak-proof connections under varying operating pressures.

One of the most exciting developments is the use of additive manufacturing (3D printing), allowing for custom-designed fittings that meet unique industrial needs. These innovations not only improve efficiency but also reduce downtime, giving businesses a competitive edge.

A recent example involved a chemical plant requiring fittings to handle corrosive acids at 250°C. Hastelloy C276, a nickel-molybdenum alloy, was chosen for its resistance to oxidising agents. Paired with weld neck flange fittings, it significantly improved the plant’s uptime and reduced maintenance costs by 40%.

Metal Industry Standards and Their Importance

Pipe fittings are critical components in industries where safety and precision are non-negotiable. This is why adherence to standards like ASME B16.11 (dimensions for forged fittings) and ISO 15156/NACE MR0175 (corrosion resistance in sour environments) is essential.

At Online Fittings, our products undergo rigorous testing, including hydrostatic and non-destructive tests, to warrant compliance and quality. These certifications give businesses peace of mind and confidence in the reliability of their systems.

A Unified Approach to Selection and Integration

Choosing the right pipe fittings goes beyond material selection. Factors like operating conditions, installation requirements, and future scalability should also be considered. For example:

1. High-pressure environments: Opt for forged steel fittings with seamless construction. 2. Corrosive media: Select alloys with a high chromium or molybdenum content. 3. Complex systems: Modular designs allow for easier integration and expansion.

By partnering with experts like Online Fittings, businesses can streamline the selection process and ensure their systems are equipped with the best-in-class components.

Why Online Fittings Is Your Ideal Partner

Whether it's understanding forged fittings and cast fittings and their differences in tensile strength or choosing the right material grades for specific environments, making informed decisions is the key to achieving operational excellence. Investing in innovative, high-quality fittings makes sure long-term success and safety in any application.

With a vast inventory of certified pipe fittings and a team of industry experts, Online Fittings is committed to providing solutions that exceed expectations. Our products are durable, high-performing, and customisable to suit specific industrial requirements. From advanced coatings to modular designs, we combine innovation with quality to deliver fittings that drive efficiency and safety across industries.

Whether you are upgrading an existing system or embarking on a new project, Online Fittings is your trusted partner. Contact us today to explore our range of products and discover how we can transform your operations.

0 notes

Text

Monel Prices, News, Trend, Graph, Chart, Forecast and Historical

Monel a versatile nickel-copper alloy known for its corrosion resistance and strength, has consistently garnered attention in various industries, including marine, aerospace, and chemical processing. The market for Monel prices is influenced by numerous factors, ranging from raw material availability and production costs to global demand trends and economic conditions. A deeper understanding of the Monel market reveals the complex interplay of these factors, which can lead to fluctuations in pricing and availability.

The primary driver of Monel prices is the cost of its constituent metals—nickel and copper. Nickel prices, in particular, play a significant role in determining the cost of Monel, as the alloy typically contains a higher proportion of nickel. Global nickel prices are influenced by supply-demand dynamics, geopolitical events, mining output, and regulatory changes. For instance, disruptions in major nickel-producing countries such as Indonesia and the Philippines can cause supply shortages, leading to higher prices. Similarly, copper prices are subject to changes in mining activities and demand from key sectors like construction and electronics. The combined effect of these metal price fluctuations directly impacts the overall cost of Monel, making it sensitive to changes in the broader commodity markets.

Get Real time Prices for Monel : https://www.chemanalyst.com/Pricing-data/monel-1364

Another critical factor influencing Monel prices is production costs, including energy, labor, and technology used in manufacturing. The alloy's production involves sophisticated processes requiring significant energy inputs, which makes it vulnerable to shifts in energy prices. Moreover, technological advancements that improve manufacturing efficiency can help reduce costs, while labor expenses in different regions can also affect pricing. For example, producers in regions with lower labor costs may offer more competitive prices, influencing the global market dynamics of Monel.

Global demand trends play a pivotal role in shaping the Monel market. The alloy's exceptional corrosion resistance makes it a preferred choice in marine applications, such as shipbuilding and offshore oil and gas production. Additionally, Monel is widely used in the aerospace industry for manufacturing components exposed to high temperatures and corrosive environments. Demand from these sectors significantly impacts prices, particularly when large-scale projects or investments drive the need for Monel-based products. For example, increasing investments in renewable energy and offshore wind farms are expected to boost the demand for Monel in the coming years, potentially pushing prices upward.

Economic conditions and geopolitical events also influence Monel prices. Economic growth in emerging markets often leads to increased infrastructure development and industrial activities, driving demand for high-performance materials like Monel. Conversely, economic slowdowns or recessions can reduce demand, leading to price stabilization or declines. Geopolitical tensions, trade policies, and tariffs can further affect the global trade of Monel and its raw materials. For instance, restrictions on nickel or copper exports from key producing countries could tighten supply and elevate prices, while favorable trade agreements might enhance market access and stabilize costs.

Environmental regulations and sustainability initiatives are increasingly shaping the Monel market. As industries adopt more stringent environmental standards, there is a growing emphasis on sustainable and eco-friendly production practices. Recycling and the use of secondary raw materials are becoming crucial in the Monel production process, potentially reducing dependency on primary nickel and copper. This shift could influence prices by lowering production costs while meeting environmental compliance requirements. Furthermore, companies investing in greener technologies may experience initial cost increases, which could reflect in higher Monel prices in the short term.

The competitive landscape among Monel producers also impacts pricing trends. Key players in the market continually strive to optimize production, improve product quality, and enhance distribution networks to maintain a competitive edge. Price competition among manufacturers, especially in regions with lower production costs, can result in variations in Monel prices across different markets. Additionally, mergers, acquisitions, and strategic partnerships within the industry may influence supply dynamics and pricing, as consolidated entities often have greater control over production and distribution.

Currency exchange rates are another factor affecting Monel prices, particularly in the context of international trade. Since Monel is traded globally, fluctuations in currency values can impact its cost for buyers and sellers in different regions. A weaker local currency may lead to higher import costs, while a stronger currency can make exports more competitive. This dynamic is particularly relevant for countries heavily reliant on imports for their Monel requirements.

Market trends and forecasts indicate that the demand for Monel is likely to grow in the foreseeable future, driven by advancements in technology and increased adoption in critical industries. Emerging applications in areas such as hydrogen storage, fuel cells, and advanced chemical processing are expected to further bolster the market. However, uncertainties in raw material availability, geopolitical developments, and environmental regulations may continue to pose challenges to price stability.

In conclusion, the Monel market is characterized by a complex web of factors influencing pricing dynamics. The interplay between raw material costs, production expenses, global demand, economic conditions, and environmental considerations creates a highly dynamic pricing environment. As industries continue to innovate and expand, the demand for Monel is poised to grow, presenting both opportunities and challenges for market participants. Monitoring these trends closely and adopting adaptive strategies will be essential for stakeholders to navigate the evolving landscape of Monel prices effectively.

Get Real time Prices for Monel : https://www.chemanalyst.com/Pricing-data/monel-1364

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Monel#Monel Price#Monel Prices#Monel Pricing#Monel News#india#united kingdom#united states#germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes