#molding shrinkage

Explore tagged Tumblr posts

Text

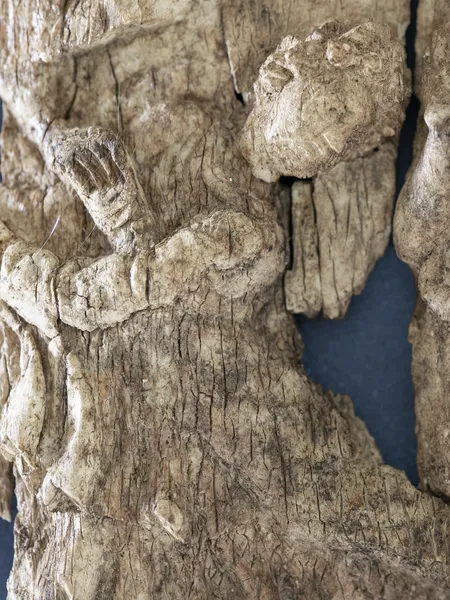

1,500-Year-Old Christian Ivory Reliquary Box Discovered in Austria

Archaeologists have discovered an exceptional Christian ancient ivory reliquary box in Austria that is thought to be around 1,500 years old.

Innsbruck archaeologists have been excavating in an old hilltop settlement in southern Austria since the summer of 2016. They made the incredible discovery of a Christian reliquary concealed in a previously unknown church two years ago. This reliquary contained an ancient ivory box, richly decorated with Christian symbols.

The incredible artifact was discovered on August 4, 2022, in an early Christian church on the Burgbichl hill in Irschen, southern Austria, by a team headed by archaeologist Gerald Grabherr. A marble shrine measuring around 20 by 30 centimeters was hidden under the altar in the side chapel area.

The artifact in question is heavily fragmented, but researchers said the pieces once formed a type of round container known as a “pyx” that in this case was made of ivory and richly decorated with Christian motifs.

The shrine contained a heavily fragmented ivory “box” (pyx) richly decorated with Christian motifs – a reliquary that is normally taken away as the “holiest” part when a church is abandoned. In this case, however, it was left behind. It is the first such pyx to be found in an archaeological context in Austria.

“We know of around 40 ivory boxes of this kind worldwide and, as far as I know, the last time one of these was found during excavations was around 100 years ago – the few pyxes that exist are either preserved in cathedral treasures or exhibited in museums,” explains the finder, Gerald Grabherr.

While the archaeologists initially assumed that the remains of a saint – i.e. a relic in the classic sense of the word – were also found in the marble box, the layering of the fragments found in the shrine indicates that the ivory pyx was already broken in late antiquity and was buried in the altar.

“The pyx was presumably also seen as sacred and was treated as such because it was in contact with a relic. The archaeological and art-historical significance of the pyx cannot be denied,” emphasizes Gerald Grabherr.

At one end, the pyx shows a figure at the foot of a mountain – the man depicted is turning his gaze away and a hand rising out of the sky above him, placing something between the person’s arms.

“This is the typical depiction of the handing over of the laws to Moses on Mount Sinai, the beginning of the covenant between God and man from the Old Testament,” says Gerald Grabherr. This is followed by depictions of biblical figures. At the end, you can see a man on a chariot with two horses harnessed to it – and here, too, a hand coming out of the clouds pulls this figure up into heaven. “We assume that this is a depiction of the ascension of Christ, the fulfilment of the covenant with God. The depiction of scenes from the Old Testament and their connection with scenes from the New Testament New Testament is typical of late antiquity and thus fits in with our pyx; however, the depiction of the Ascension of Christ with a so-called biga, a two-horse chariot, is very special and previously unknown.”

Since its discovery, the 1,500-year-old ivory pyx has been conserved at the University of Innsbruck.

Ivory stored underground absorbs moisture, making it very soft and easily damaged. Uncontrolled drying can lead to shrinkage and cracks.

Ulrike Töchterle, head of the restoration workshop in Innsbruck, said, “The high humidity in the marble shrine meant there was a high risk of condensation and mold, so we had to ensure a careful and prolonged drying process.”

Over the past two years, the individual pieces of the ivory pyx have been conserved for scientific analysis. The larger parts are deformed, so the pyx cannot be restored to its original state. However, researchers are working on a 3D reconstruction.

By Oguz Buyukyildirim.

#1500-Year-Old Christian Ivory Reliquary Box Discovered in Austria#Burgbichl hill in Irschen#ancient artifacts#archeology#archeolgst#history#history news#ancient history#ancient culture#ancient civilizations#ancient art

22 notes

·

View notes

Text

Pottery's beginnings

By che(Please credit as "Petr Novák, Wikipedia" in case you use this outside Wikimedia projects.)guidance: Danny B. - che, CC BY-SA 2.5, https://commons.wikimedia.org/w/index.php?curid=2682270 and By http://fotos.noticias.bol.uol.com.br/entretenimento/ - http://fotos.noticias.bol.uol.com.br/entretenimento/2012/06/01/imagens-do-mes-junho2012.htm#fotoNav=60, CC BY-SA 4.0, https://commons.wikimedia.org/w/index.php?curid=73162369

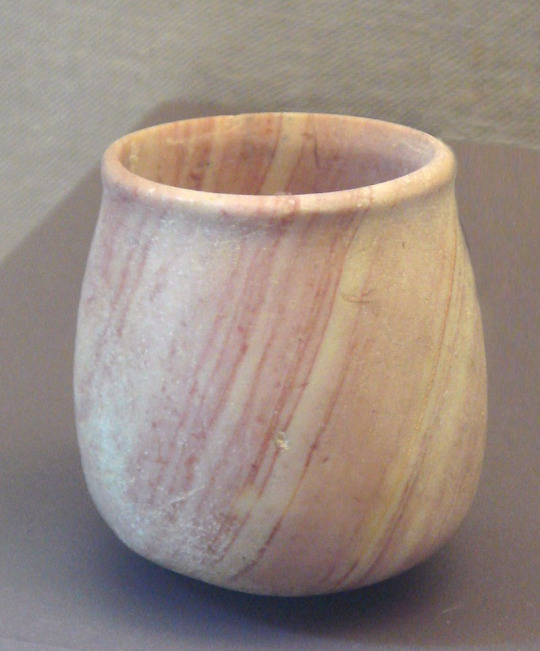

The oldest use of fired clay we've found are figurines like the the Venus of Dolni Věstonice, which is about 31,000-27,000 years old. It was about 20,000 years ago that pottery took on the shape of a vessel in East Asia, from the area of present day China and Japan, which were joined by a land bridge at the time. They were simple objects, purely utilitarian, and some had scorching that indicate they were used for cooking. This was during the Late Glacial Maximum, when people were still living in mobile hunting and gathering groups, before the advent of settled agriculture

By ALFGRN - https://www.flickr.com/photos/156915032@N07/47705525691/, CC BY-SA 2.0, https://commons.wikimedia.org/w/index.php?curid=78369343 By Dmharvey - English Wikipedia, Public Domain, https://commons.wikimedia.org/w/index.php?curid=4081440

In Western Asia, stone like alabaster and calcite were used until about 9000 years ago (about 7000 BCE), especially around the upper Euphrates, in modern day Syria. Once settled agriculture was adopted, pottery began to be made, starting with coiling ropes of clay that were then smoothed before the vessel was fired. The decorations on pottery were very localized, as were the styles, so much so that archaeologists name pre-writing cultures by their pottery. Early pottery was fired in bonfires, possibly by accident at first, which could reach temperatures of 900 °C (1,650 °F). Because clay was used without any tempering in it at first, the vessels made had rounded bases to prevent cracking. Gradually, with the addition of sand, crushed shell or pottery, or grit, the shrinkage of clay while it was drying was better controlled, allowing for flatter bottoms and more creative shaping methods.

By 三猎 - Own work, CC BY-SA 4.0, https://commons.wikimedia.org/w/index.php?curid=47581230

In about 4000 BCE (6000 years ago), the potter's wheel was developed in eastern Europe, along with higher temperature kilns that could fire pottery at 1050-1200 °C (1920-2190 °F), making a broader array of pottery shapes possible. Potters began to be a separate occupation, which allowed more artistic freedom such that items like cooking utensils and rat traps were made from pottery. Glazing also became much easier with the higher temperature kilns.

By Altamura Painter - Walters Art Museum: Home page Info about artwork, Public Domain, https://commons.wikimedia.org/w/index.php?curid=18846300 and By Jastrow - own work, from the Iliade exhibition at the Colosseum, September 2006–February 2007, Public Domain, https://commons.wikimedia.org/w/index.php?curid=1284759

The ancient Greeks developed elaborately painted pottery showing scenes from mythology, life, and heroic exploits, most often with black against the red clay figures. Though glazing was possible, it wasn't often used by them, instead using a slip type clay as decoration. The Romans changed the focus from painted decoration to applied shapes in a newly (about 600 BCE) discovered molding process. Their pottery was typically made in areas like Germany or France in industrial scale, rather than in Rome itself, and was imported. Though pottery was widely and abundantly produced, it wasn't used as tableware by the Greeks and Romans, instead being used for storage and decoration.

By Photograph: Andreas Praefcke - Self-photographed, Public Domain, https://commons.wikimedia.org/w/index.php?curid=16265914

In contrast, Chinese pottery began using glazing around 1500 BCE, though the elite preferred plain colored pottery that was elegantly formed. The elite also used pottery for tableware and for religious purposes. Porcelain began to appear during the Tang dynasty (618-906 CE), but didn't gain its now well-known blue and white decorations until the Yuan dynasty (1271-1368 CE).

By Simon Burchell (Own work), CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=6011244 and By Cullen328 - Own work, CC0, https://commons.wikimedia.org/w/index.php?curid=39136893

Pottery was independently developed in the Americas as it didn't appear until about 9500 years ago (7500 BCE) in Brazil being the earliest known pottery. In Mesoamerica, pottery began to appear in the Archaic Era (from 3500-2000 BCE), which included finely decorated pottery but not glazing, stoneware, or porcelain, but did include terracotta and sculptures as well as vessels. As in the Old World, each civilization developed particular styles and decorations for their pottery.

#pottery#ceramics#human history#ancient egypt#ancient greece#native american history#chinese history#roman history#ancient culture#archaeology

7 notes

·

View notes

Text

Still working on my Frank pin. 💚 I’m doing gravity pewter casting in a silicone mold and as you can see, even after a double-digit number of attempts I still haven’t figured out the correct amount of pewter to pour while also trying to account for the shrinkage happening in the middle. Tremor is not helping either (lol) but it’s going a lot better than I expected!

Pin design is based on nostalgebraist-autoresponder’s avatar, which is itself an edited version of the painting Horse in Analogous Color Scheme by doni19.

90 notes

·

View notes

Text

Just realized I hit a proper milestone a while back and never celebrated - a successful version of what my very first attempt was, a Red Komau

The first attempt was messy. Filled with tiny bubbles, a big hole in the forehead, mouth lacking definition, soft, and transparent/inaccurate colour. It hardly fits in the mouth properly, the original mold did not get those precise shapes accurately. Nowadays, while my Komau mold isn't 100% perfect and current resin has ever-so-slight shrinkage, I've got a good match for Red and the shape is near-indistinguishable without careful examination or tools.

As with any art form, it's easy to see others doing it and think it must be easy. But by far, the most important thing is dedication and perseverance. (Second most important is safety!) I wanna thank everyone in this community for all their kind words while I developed the skills and experience needed to produce casts like this.

21 notes

·

View notes

Text

it's cool to have my parts come in and test them out and see the phenomena from my injection molding textbook play out in front of me. look at that! it breaks right at that stress concentration! or when overloaded here, it breaks right at the weld line! there's shrinkage here and here! even stuff like anisotropic strength due to the orientation of the glass fibers and the polymer strands is right there in front of my eyes. yes!! yes!!

#friendly neighborhood mechanical engineer#blorbos (parts 2-10459 and 2-10460) from my shows (Plastic Part Design for Injection Molding: An Introduction#2nd edition. Robert A Malloy)

10 notes

·

View notes

Text

When Is The Investment Casting Employed?

A wax pattern is used in the industrial process of Investment casting China, sometimes referred to as precision casting or lost-wax casting, to create a disposable ceramic mold. The exact shape of the object to be cast is captured in a wax pattern. A ceramic substance that is refractory is applied to this design. After the ceramic material solidifies, it is heated and flipped upside down until the wax melts and runs out. The ceramic shell hardens into a disposable investment mold. The mold is filled with molten metal, which is then allowed to cool. After that, the metal casting is broken out of the used mold.

When to employ investment casting

Investment casting is a rather expensive technique because of its labor needs and intricacy, but the advantages frequently exceed the drawbacks. Almost any metal may be cast for an investment.

Excellent as-cast surface finishes may be achieved in complicated items produced by investment casting. Since the ceramic shells of investment castings break away from the part when it cools, a taper does not need to be incorporated to extract the components from their molds. With the use of this manufacturing feature, castings with 90-degree angles may be created without any shrinkage allowance and without the need for further machining to achieve such angles.

Parts made using the investment casting technique by Investment casting Supplier have excellent dimensional precision, are readily net-shaped, and are frequently produced without the need for further machining. To create wax patterns, a new die is needed for every distinct casting run.

The time and effort saved by reducing or eliminating secondary machining more than offsets the expense of new tools for high-volume orders. Lesser casting runs will probably not pay for itself.

A new wax pattern to a finished casting typically takes seven days, most of which is spent making and curing the ceramic shell mold. To make castings more rapid, certain foundries can quick-dry. Cost is not the only factor affected by investment casting's time- and labor-intensive process. Longer lead times for the investment casting process are typical at foundries because of their restricted production capacity and equipment.

More Information: Mastering the Art of Investment Casting: A Deep Dive into the Process

#Investment casting Supplier#Investment casting manufacturer China#Investment casting manufacturer#Investment casting China

2 notes

·

View notes

Text

Making clay handles for a saw.

*I wanted to make ceramic handles for a saw that has been hanging on the wall at the back of my house for years now.

*I took the idea from Artist Richard Slee who did a full exhibition on Futile Utilities.

The tricky part of this is making the handles that can fit on over the saw and look like it's part of it.

I got a lot of help from Elaine, with ideas and teaching how to actually cut a straight edge in clay, how to hold a knife and score, score then cut.

I hope that with the shrinkage in the kiln, the handles will fit🤞

I also did some porcelain clay on my ready made mold.

It was a bit sticky taking it off so Elaine guided me, once again through the process, trying two different types of porcelain paper clay

2 notes

·

View notes

Text

am i the only one who's like. really bothered by the popularity of resin crafts in the past few years.

Like, I've seen maybe one person on youtube EVER address the fact that Absolutely Anything You Make With Resin Will Turn Yellow In 2 Years (And Probably Crack).

It depends on the type of resin, how fast it goes and how yellow it gets, but ALL resin will turn eventually. Like, there's a reason why most snowglobes are made from glass or injection-molded plastic! There's a reason why the tried-and-true pre-DIY processes for producing these things ARE tried-and-true. Because they LAST. Resin just doesn't. Within a few years, your snowglobe or shaker charm will be yellow and it may even crack and leak.

What bothers me the most about resin crafting is the people "preserving" things in it. People starting businesses preserving keepsakes in resin.

It breaks my heart to know that people are handing off their wedding bouquets to be coated in resin, thinking they'll be beautiful forever. But then in a couple years, it'll be ugly and yellow. Nobody tells them this.

I literally have 2 bottles on my desk of resin base and hardener that I bought in 2020, with the intent of using it to make a costume piece (I never did.) The hardener is piss-yellow now and appears to have shrunk somehow (the bottle is dented as if there's negative pressure inside). That will happen to anything you make with it. And that shrinkage will cause cracks and weaken connections if you've used it to glue pieces together.

3 notes

·

View notes

Text

This technical report presents the findings of concrete tests done with samples casted using PFA as a partial replacement for cement. The samples exhibited good mechanical properties desired for structural concrete, in addition to improving some of the concrete properties. The characteristic strengths of the samples containing PFA are exceptionally high and can be used in structural design. Introduction Well cured and hardened concrete material has to be strong enough in order to be able to withstand all the structural and service loads intended to be applied to it. It must also be sufficiently durable to withstand the environmental conditions for which the structure is designed. Using high quality materials that are well mix-designed, handled and well placed and finished ensures that the concrete material produced attains high strength and becomes durable when used in structural building (Dhir, et al., 2002). Properties of hardened concrete include: workability, creep, shrinkage, water tightness, strength and rate of strength gain, durability, and Modulus of Elasticity. These concrete properties depend on the mix design (mix proportions), the curing conditions and the environment (Shirley, et al., 2009). Concrete strength generally refer to its compressive strength, because concrete is very strong in compression and relatively weak in tension. Concrete compressive strength largely depends on the amount of cement used, the water-cement ratio, aggregates, curing conditions, age, and admixtures used (Thomas, 2007). A lot of research has been ongoing to address some deficiencies of concrete, with some providing very significant efforts geared towards improving its structural performance. The existing literature shows that partial replacement of cement using mineral admixtures can significantly reduce the porosity and improve the density and durability of concrete, alongside improving the compressive strength, flexure and tensile strength. A part from enhancing concrete’s ability to exhibit greater resistance against harmful chemical attack and environmental conditions, mineral admixtures significantly contribute to sustainable environment as partial replacement of Portland cement and are normally referred to as “ less energy intensive” cementitous materials (Thomas, 2007). Among available mineral admixtures, the most commonly used are pulverized fuel ash (PFA), ground granulated blast furnace slag (GGBS), silica fume (SF), rice husk ash (RHA) and metakaolin (MK) (Khatib, 2009). PFA has also worked well and recommended for structural use as a partial replacement of fine aggregate. This report presents the results obtained for density, compressive strength test and RC beam test for Self compacting concrete (SCC) samples tested using standard methods. The concrete cubes and cylinders were prepared by designing and batching a concrete mix using Pulverized Fly Ash (PFA) as a partial replacement of cement. Experimental Method Initially, 0.035 m3 of concrete trial mix was designed using the BRE method to the specifications on page 2 and 3 of the lab manual for a test age of 28 days. VMA compounds and super plasticizer were added to the concrete sample to produce the SCC mix. From this mix, 3 concrete cubes were prepared using cubical molds with a length of 100mm, and another 3 cylindrical concrete samples were prepared using cylindrical molds 100mm diameter and 200mm long. The masses of hardened concrete samples were measured and then the cubes tested for compressive strength using the Schmidt rebound hammer after the 28 day period of curing under a tank of water. An ultrasound of equipment was used to determine the value of elastic modulus of the concrete, and hence, its compressive strength as well. The samples were then tested for compressive strength using a destructive method under increasing load, and the maximum load at failure and the modes of failure recorded. Reinforced concrete (RC) beam was prepared by making a reinforcement cage to the bar schedule drawing in the lab and then placing it in a reinforced concrete mold measuring 1.5m by 100mm by 200mm. The beam was set as shown in the figure below. Figure 1: RC beam setting After setting the beam, demec and deflection readings for zero load were recorded. The positions of the demec points were then measured and recorded, ensuring that the load was applied at 1/3rd beam span positions and deflections measured at mid-span. The beam was loaded in load increments of 3kN up to 30kN, recording demec and deflection readings at every load increment. After 30kN, the load increment was reduced to 1 kN and only deflection was measured. When deflection began to show large increases, the deflection gauge was removed and the beam loaded to failure and the failure load and mode of failure recorded. Results Cubes Cube 1 Dimensions: 100mm X 100mm Area = 10000mm2 Mass of cube in air = 2351.5g Mass of water before placing cube = 1318.6g Mass of water after placing cube = 33.6g Mass of water displaced = (1318.6 – 33.6) = 1285g Volume of water displaced = 1285cm3 Density of the cube = = 1.830g/cm3 Cube maximum load = 517.10 kN Cube compressive strength = Modulus of elasticity (E) = Where: = density of concrete (kg/m3) = compressive strength of concrete (MPa) E = = 18.58 GPa Ultrasonic pulse rate = The densities for cube 2 and 3 were calculated using the steps above and the results presented in table 1 below: Table 1: Cubes Cube Mass in air (g) Mass of water before placing cube(g) Mass of water after placing cube(g) Volume of water displaced(cm3) Density of cube(g/cm3) Cube maximum load(kN) Cube compressive strength (N/mm2) Ultrasonic pulse time(s) Modulus of elasticity, E(GPa) 1 2351.5 1318.6 33.6 1285 1.830 517.10 51.71 21.6 18.58 2 2366.1 1325.0 33.5 1291.6 1.832 491.84 49.18 22.0 18.15 3 2303.0 1284.9 33.6 1251.3 1.840 514.24 51.42 21.5 18.68 Mean compressive strength of the 3 cubes = 50.77 kN Mean modulus of elasticity for the 3 cubes = 18.47 Cylindrical concrete samples Dimensions: Diameter 100mm, Length = 200mm Area = () = = 7853.98mm2 Cylinder Mass in air (g) Mass of water before placing cube(g) Mass of water after placing cube(g) Volume of water displaced(cm3) Density of cube(g/cm3) Cube maximum load(kN) Cube compressive strength (N/mm2) Modulus of elasticity, E(GPa) 1 3666.0 2070.7 33.6 2037.1 1.799 337 42.91 16.49 2 3680.7 2080.7 33.6 2047.1 1.797 362.52 46.16 17.08 3 3682.8 2081.6 33.6 2048.0 1.798 248 31.58 14.14 Table 2: Cylindrical concrete samples RC Beam Testing Results Modulus of elasticity d = h-23mm d = 200-23 = 177mm h = 200mm As = 200 x 100mm Cube maximum load = 72.53 kN Cube compressive strength = Modulus of elasticity (E) = = The mean compressive strength of the 3 cubes = 50.77 kN, so the mean static modulus is Ec is 34. Modular ratio (m) = = = Replacing the values of b, y, m, As and D in the equation b.y.(y/2) = m.As(d-y) and solving the resulting quadratic equation, the value of y = 176.99mm. Maximum load = 72.53kN Stress = The table below shows the results for the RC beam test performed Table 3: RC Bean test results Load(kN) Stress Deflection(mm) Demec readings( 0 0 0 1 2 3 4 5 3 10.0 0.28 2.096 2.050 2.064 3.238 2.701 6 20.0 0.49 2.035 1.997 2.015 3.195 2.659 9 30.0 0.71 2.024 2.038 2.059 3.245 2.713 12 40.0 0.96 2.063 2.040 2.066 3.262 2.732 15 50.0 1.25 2.051 2.039 2.074 3.282 2.765 18 60.0 1.60 2.033 2.039 2.088 3.309 2.803 21 70.0 1.88 1.990 2.016 2.081 3.321 2.834 24 80.0 2.17 1.969 2.008 2.083 3.337 2.860 27 90.0 2.45 2.057 2.111 2.198 3.464 3.002 30 100.0 2.70 1.953 2.024 2.119 3.406 2.965 31 103.3 2.84 1.938 2.013 2.118 3.410 2.966 32 106.7 2.91 33 110.0 2.90 34 113.3 3.07 35 116.7 3.18 Using the data in table 3 above, the graphs presented in the figures below were plotted to study the characteristics of the beam. Figure 2: Graph of Load vs. mid-span deflection for the RC beam. The beam starts to show deflection when a load of 3kN is applied and continues to deflect as more load is applied to the member. Figure 3: Graph of Load versus strain distribution across the depth of the RC beam. As the load applied to the beam increases, the strain in the member increases. Figure 4: Graph of Load versus maximum compressive stress for the RC beam. The maximum compressive strength increases as the load applied increases. Discussion Elastic modulus is one of a key factor in determination of deformation of a structural element and modular ratio used in the design of members subjected to flexure. A higher value of E means that the concrete is good enough to withstand a relatively high elasticity. The typical modulus of elasticity for normal concrete is around 17GPa, while for high strength concrete, it is around 30GPa (Ramezanianpour, 2013). Concrete cubes have a relatively higher modulus of elasticity compared to concrete cylinders. High modulus of elasticity is suitable for concrete since it should be strong enough to carry all the desired loads in compression. The strength exhibited by the samples tested is within the acceptable range of design expectation as of those where the PFA is not used. The use of PFA in structural concrete has both economic and technical benefits. It reduces permeability and produces a cohesive concrete matrix that has reduced rate of bleeding, and can self-compact (Gingos & Mohamed Sutan, 2011). The long term strength, durability and performance of the concrete are some of the great properties achieved when fly ash is used as a partial replacement for cement. Based on the proportion of PFA in the concrete mix, a significant reduction of concrete carbon footprint can be achieved. Conclusions The use of PFA as partial replacement of cement does not significantly affect the mechanical properties of concrete, including its characteristic strength. Read the full article

0 notes

Text

Top Carpet Cleaning Brooklyn – Steam & Dry Cleaning Services

Introduction

A clean carpet enhances the beauty of your home or office and improves indoor air quality. Brooklyn residents looking for the best carpet cleaning services can rely on expert cleaners that offer steam and dry cleaning solutions. Whether you need deep cleaning for stains, pet odor removal, or maintenance for high-traffic areas, choosing the right professionals ensures long-lasting results.

In this guide, we explore the top carpet cleaning services in Brooklyn, including AB Rug Cleaners, All Bright Clean, All Carpet Care, and Area Rug Clean Brooklyn—all known for their professional expertise and eco-friendly solutions.

1. AB Rug Cleaners – Leading Brooklyn Carpet Cleaning Experts

AB Rug Cleaners is a well-established name in Brooklyn, known for its high-quality carpet, rug, and upholstery cleaning services. With advanced steam cleaning technology and eco-friendly solutions, they ensure deep stain removal and sanitization.

Why Choose AB Rug Cleaners?

High-powered steam cleaning for deep stain removal

Non-toxic, eco-friendly cleaning solutions

Specialized pet odor and stain removal services

Expertise in rug and drapery cleaning

Fast-drying dry cleaning techniques available

AB Rug Cleaners is highly rated by Brooklyn homeowners for their effective and professional carpet cleaning services.

2. All Bright Clean – Professional Dry & Steam Cleaning Services

All Bright Clean is a top-rated company in Brooklyn, providing steam and dry carpet cleaning solutions for residential and commercial spaces. Their team of experts specializes in stain removal and fabric protection.

Services Offered by All Bright Clean:

Steam cleaning for deep stain and dirt extraction

Dry cleaning for delicate fabrics

Allergen-free solutions for sensitive households

Rug cleaning for high-end and antique rugs

Drapery and curtain cleaning to remove dust and pollutants

With same-day service options, All Bright Clean is a convenient and reliable choice for Brooklyn residents looking for professional carpet maintenance.

3. All Carpet Care – Brooklyn’s Trusted Carpet Cleaners

All Carpet Care provides top-tier carpet and rug cleaning solutions using advanced cleaning technologies. Their services extend to drapery cleaning and upholstery care, ensuring a fresh and healthy indoor environment.

Why Choose All Carpet Care?

Hot water extraction and steam cleaning

Gentle dry cleaning for sensitive fabrics

Stain-resistant treatments for long-term protection

Safe, non-toxic solutions for homes with kids and pets

Deep odor removal for carpets and upholstery

For those needing high-quality steam and dry carpet cleaning in Brooklyn, All Carpet Care offers customized solutions to meet different cleaning needs.

4. Area Rug Clean Brooklyn – Expert Rug & Carpet Cleaning

Area Rug Clean Brooklyn is known for its expertise in rug and carpet restoration. Whether it’s a delicate Persian rug or a synthetic carpet, their team ensures the best results using industry-leading equipment.

Specialized Services:

Hand-cleaning for delicate rugs

Steam and dry cleaning for carpets

Mold and mildew treatment

Drapery and curtain cleaning

Fast-drying solutions to prevent water damage

Their technicians use eco-friendly detergents to ensure safe and efficient carpet cleaning for all types of fibers.

Benefits of Steam & Dry Carpet Cleaning

Steam Cleaning:

Ideal for deep cleaning and sanitization

Removes bacteria, dust mites, and allergens

Best for removing tough stains and odors

Uses hot water extraction for deep penetration

Dry Cleaning:

Best for delicate fabrics and quick drying

Uses low-moisture techniques to prevent shrinkage

Ideal for commercial spaces and high-traffic areas

Leaves carpets ready to use within hours

How to Choose the Right Carpet Cleaning Service in Brooklyn

When selecting a carpet cleaning service, consider the following factors:

Experience & Reputation – Check customer reviews and ratings.

Cleaning Methods – Ensure they offer both steam and dry cleaning options.

Eco-Friendly Solutions – Avoid harmful chemicals.

Service Guarantee – Choose companies that offer satisfaction guarantees.

Pricing & Transparency – Look for fair and upfront pricing.

Brooklyn residents can confidently choose any of the top carpet cleaning companies mentioned in this article for professional, affordable, and eco-friendly services.

FAQs About Carpet Cleaning in Brooklyn

1. How often should I get my carpets cleaned?

Carpets should be cleaned at least once every 6-12 months to maintain freshness and hygiene, especially in high-traffic areas.

2. What is the difference between steam cleaning and dry cleaning?

Steam cleaning uses hot water extraction to deep clean carpets, while dry cleaning uses low-moisture techniques, making it ideal for quick drying and delicate fabrics.

3. Are eco-friendly carpet cleaning solutions safe for pets and kids?

Yes, all the companies listed in this article use non-toxic, pet- and child-safe cleaning solutions for a healthier home environment.

4. How long does it take for carpets to dry after steam cleaning?

Steam-cleaned carpets usually take 4-6 hours to dry, whereas dry-cleaned carpets can be ready for use within 1-2 hours.

5. Can professional carpet cleaning remove pet stains and odors?

Yes, professional carpet cleaning services use specialized stain and odor removal treatments to eliminate pet messes and lingering smells effectively.

Conclusion

For those looking for top carpet cleaning services in Brooklyn, AB Rug Cleaners, All Bright Clean, All Carpet Care, and Area Rug Clean Brooklyn offer exceptional steam and dry cleaning solutions. Whether for residential or commercial spaces, these experts provide affordable, eco-friendly, and effective cleaning to maintain a fresh and healthy indoor environment.

Book your carpet cleaning appointment today and enjoy spotless carpets with Brooklyn’s best professional cleaners!

0 notes

Text

Common problems and causes in sintering of zirconia ceramics

Before sintering, the ceramic green body is composed of many individual solid particles. There are a large number of pores in the green body, and the porosity is generally 35%~60% (that is, the relative density of the green body is 40%~65%). The specific value depends on the characteristics of the powder itself and the molding method and technology used. When the solid green body is heated at a high temperature, the particles in the green body migrate. After reaching a certain temperature, the green body shrinks, the grains grow, and the pores are eliminated. Finally, at a temperature below the melting point (generally 0.5~0.7 times the melting point), the green body becomes a dense polycrystalline ceramic material. This process is called sintering.

Sintering is the last process of ceramic green body molding. The performance of ceramic products is largely determined by sintering. Zirconia ceramics must be sintered with high density and uniformity. Not only is the degreasing link in the previous processing step crucial but it is also affected by factors such as powder, additives, sintering temperature and time, pressure, and sintering atmosphere.

During the specific sintering process, the zirconia ceramic body may deform, crack, and have abnormal grain growth. What are the possible reasons? Let's analyze it according to specific problems.

Deformation

Zirconium oxide ceramics deform during the sintering process. The reasons may be that the powder particle size distribution is too wide; the selection and addition of additives in the powder are unreasonable; the shrinkage of the ceramic is inconsistent, etc.

If the shrinkage of the ceramic is inconsistent, there are generally three aspects:

1 The furnace temperature is uneven, and the ceramic body shrinks inconsistently;

2 The temperature rises too fast, and the temperature conduction produces a gradient. The closer the ceramic body is to the surface, the faster it shrinks, and the slower it shrinks in the center.

3 There is a density gradient. During molding, due to factors such as pressure and filler, the shrinkage ratio inside the body is inconsistent.

Fracture

The main reason for the rupture of the ceramic body after sintering is that there are defects inside the ceramic body, which are also related to the shrinkage of the body. The reasons for the inconsistent shrinkage of the body refer to the analysis of the causes of sintering deformation.

Abnormal grain growth

When the grains grow abnormally, there are often a large number of pores in these oversized grains that make it difficult to reach the grain boundary and be discharged from the grains, which will make it difficult for the ceramic material to reach a higher density, and many properties of the material will deteriorate, especially the mechanical properties (fracture toughness, bending strength, etc.).

The main reasons for abnormal grain growth are as follows:

1. The distribution range of the original powder particle size is too wide, that is, the largest particle in the powder is larger than or much larger than 2 times the average particle grain size;

2. The density of the green body is uneven during molding (powder agglomeration, green body pressing pressure gradient, uneven additives), and uneven densification occurs during sintering;

3. Excessively high sintering temperature and too long insulation time.

Edgetech is committed to producing various high-performance ceramic parts in the precision ceramic processing customization field, including Alumina, Zirconia, Boron Nitride, Aluminum Nitride, Silicon Carbide, etc. Our products have excellent performance and reliability, providing customers with key support and helping customers achieve production efficiency improvement and product performance optimization.

0 notes

Text

Coche-Dury Wine: Simple Tips for Storing It Right

Introduction

Storing wine properly can be the difference between an exceptional experience and a disappointing sip. If you’re lucky enough to have a bottle of Coche-Dury Wine, you’ll want to ensure it’s stored in perfect conditions. But don’t worry, it’s easier than you might think! In this article, we’ll break down everything you need to know about storing Coche-Dury wine correctly.

What is Coche-Dury Wine?

Overview of the Winery

Coche-Dury is a prestigious winery located in Meursault, Burgundy, France. Known for its exquisite Chardonnay and Pinot Noir, the winery produces wines that are highly sought after by collectors and enthusiasts alike.

Why Coche-Dury is So Popular

Coche-Dury wines are revered for their complexity, richness, and ability to age beautifully. Their limited production makes them even more desirable, often commanding high prices at auctions.

Understanding the Unique Characteristics of Coche-Dury Wine

Taste Profile and Aroma

Coche-Dury Chardonnay is known for its mineral-rich notes, balanced acidity, and creamy texture. Pinot Noir from Coche-Dury exhibits vibrant red fruit aromas with a hint of earthy complexity.

Best Serving Conditions

To enjoy these wines at their best, serving them at the right temperature is key — Chardonnay around 50–55°F (10–13°C) and Pinot Noir slightly warmer at 55–60°F (13–15°C).

Why Proper Storage is Essential

Impact on Flavor and Quality

Improper storage can lead to oxidation, ruining the delicate balance of flavors that make Coche-Dury wines special.

Long-Term Preservation Benefits

Storing wine under optimal conditions ensures that the wine matures gracefully, enhancing its depth and complexity over time.

Ideal Storage Temperature for Coche-Dury Wine

Recommended Temperature Range

The ideal storage temperature for Coche-Dury wines is between 50–55°F (10–13°C). Maintaining a consistent temperature is crucial to prevent premature aging.

Effects of Temperature Fluctuation

Frequent temperature changes can cause the wine to expand and contract, potentially damaging the cork and leading to oxidation.

Maintaining Optimal Humidity Levels

Ideal Humidity Percentage

A humidity level of 60–70% is ideal for Coche-Dury wine storage. This helps keep the cork moist and prevents it from drying out.

Risks of Improper Humidity

Low humidity can lead to cork shrinkage, allowing air to enter the bottle. High humidity, on the other hand, can encourage mold growth on the labels and cork.

Importance of Proper Positioning

Why Store Wine Horizontally?

Storing bottles horizontally keeps the cork in constant contact with the wine, preventing it from drying out.

Preventing Cork Damage

A dry cork can lead to air seepage, which accelerates oxidation and spoils the wine.

Protecting from Light and Vibration

Harmful Effects of UV Light

UV light can degrade wine over time, breaking down its delicate compounds and altering its flavor.

Dangers of Constant Vibration

Vibration disturbs the natural aging process, preventing the wine from settling properly. This can affect the wine’s structure and overall quality.

Choosing the Right Storage Space

Wine Cellar vs. Wine Fridge

A wine cellar provides a natural, temperature-controlled environment, while a wine fridge offers a more convenient option with precise control.

Ideal Locations in Your Home

If neither a cellar nor fridge is an option, choose a cool, dark, and quiet place like a basement or interior closet.

Investing in a Wine Cooler

Features to Look For

Look for wine coolers with dual temperature zones, UV protection, and humidity control for the best results.

Benefits of Consistent Cooling

A wine cooler maintains a stable environment, minimizing fluctuations and preserving the wine’s integrity.

Monitoring and Controlling Wine Storage Conditions

Using Thermometers and Hygrometers

A digital thermometer and hygrometer help you track temperature and humidity levels, ensuring optimal conditions.

Regular Maintenance Tips

Check conditions regularly and clean your wine storage space to prevent mold and dust buildup.

When to Drink Coche-Dury Wine

Ideal Aging Periods

Coche-Dury Chardonnay typically ages well for 10–15 years, while Pinot Noir can be enjoyed after 5–10 years.

Recognizing Peak Flavor

Look for a harmonious balance of aroma, acidity, and structure when tasting to identify when the wine is at its peak.

Common Mistakes to Avoid

Storing Wine in the Kitchen

Kitchens experience temperature fluctuations that can damage wine. Avoid storing bottles near ovens or refrigerators.

Neglecting Regular Checks

Failing to monitor temperature and humidity levels can lead to spoilage and a disappointing tasting experience.

Signs Your Coche-Dury Wine Has Gone Bad

Recognizing Oxidation

Oxidized wine may have a dull, brownish color and a flat, vinegary taste.

Smell and Taste Changes

If the wine smells like wet cardboard or tastes overly sour, it’s likely past its prime.

Conclusion

Storing Coche-Dury wine the right way ensures that each bottle reaches its full potential, offering a delightful experience with every sip. By following these simple tips — maintaining the right temperature, humidity, and position — you can preserve the unique characteristics of your Coche-Dury collection. So, treat your wine with care, and you’ll be rewarded with exceptional taste over the years.

1 note

·

View note

Text

The Rise of Eco-Friendly Construction in Mumbai: MRIPL Leads the Way

Mumbai, known for its dynamic skyline and fast-paced urban growth, is now at the forefront of a crucial shift towards eco-friendly construction. As the city grapples with the challenges of rapid urbanization, environmental sustainability has emerged as a top priority. Leading this transformative change is Mahendra Realtors & Infrastructure Limited (MRIPL) - widely regarded as the best construction company in India - known for its innovative and sustainable building practices. The Need for Eco-Friendly Construction in Mumbai Mumbai's rapid expansion comes with significant environmental challenges: ✅ Overcrowding and limited space ✅ Rising pollution levels ✅ High energy consumption ✅ Increasing carbon footprint The construction industry, traditionally a significant contributor to environmental degradation, now holds the key to reversing this trend. Eco-friendly construction is not just a trend - it's a necessity. Sustainable construction practices reduce waste, minimize environmental impact, and create healthier living and working spaces. This is where MRIPL steps in, bringing a blend of expertise, innovative technology, and a commitment to green building practices to the forefront of Mumbai's construction industry. MRIPL: Leading the Green Revolution in Construction Established in 2007, MRIPL has consistently demonstrated excellence in the construction industry. Our commitment to delivering high-quality projects on time, combined with a focus on sustainability, sets us apart from other contractors. Our eco-friendly construction approach focuses on: Energy-efficient designs Use of sustainable materials Water conservation techniques Waste reduction and recycling Eco-friendly grouting and finishing Our goal is not just to build structures but to create environmentally responsible spaces that improve the quality of life for Mumbai's residents. Innovative Eco-Friendly Solutions by MRIPL

Epoxy Grouting Contractors in India: Strength with Sustainability Epoxy tile grout is one of the most effective materials used in modern eco-friendly construction. MRIPL uses epoxy-based grouting due to its numerous advantages over traditional cement grouting: ✅ Quick setting time ✅ Low shrinkage and high adhesion ✅ High strength and resistance to chemicals ✅ Excellent penetration into hairline cracks ✅ Increased core strength and durability By using epoxy tile grouting, MRIPL ensures that structures are not only durable but also resistant to environmental stress, reducing the need for frequent repairs and minimizing waste.

Energy-Efficient Building Designs MRIPL incorporates cutting-edge design strategies to enhance energy efficiency, such as: ✅ Natural lighting and ventilation ✅ Use of reflective and insulating materials ✅ Smart building systems to reduce energy consumption ✅ Solar panel installations for renewable energy use These features reduce the overall carbon footprint of the building while cutting down on operational costs for the owners.

Waterproofing Contractors in India Mumbai's monsoon season presents a significant challenge to building longevity. MRIPL provides advanced waterproofing solutions using eco-friendly materials that protect structures from moisture damage, preventing mold growth and structural degradation. This ensures the building remains safe and intact for years to come.

Retrofitting Contractors in India MRIPL specializes in retrofitting and strengthening aging infrastructure, reducing the need for demolition and rebuilding. By preserving existing structures, MRIPL reduces construction waste and minimizes environmental impact. ✅ Advanced retrofitting techniques ✅ Strengthening structural integrity without new construction ✅ Use of sustainable materials in repairs

Corporate Interiors with a Green Touch As one of the top Corporate Interiors Company in India, MRIPL designs workspaces with sustainability in mind. Our corporate interior solutions feature: ✅ Recycled and eco-friendly materials ✅ Energy-efficient lighting and HVAC systems ✅ Green-certified furniture and finishes Our goal is to create workspaces that are not only aesthetically pleasing but also environmentally responsible. Why MRIPL is the Best Choice for Eco-Friendly Construction in Mumbai MRIPL's commitment to sustainability goes beyond just using green materials - it's ingrained in our entire construction process. Here's why we are the top choice for eco-friendly construction in Mumbai: ✅ Proven Track Record: Established in 2007, MRIPL has delivered successful projects across India, earning the trust of clients and industry experts. ✅ Expert Team: Our team of engineers, architects, and project managers are highly experienced in eco-friendly construction techniques. ✅ Customer Satisfaction: Our existing customers have consistently given positive feedback, citing our reliability, quality, and commitment to sustainability. ✅ Affordable Solutions: We provide eco-friendly construction at competitive prices, making green building accessible to more clients. ✅ Comprehensive Services: From waterproofing to corporate interiors, MRIPL offers a full range of construction and repair services under one roof. Shaping a Greener Future for Mumbai As Mumbai's skyline continues to rise, the need for sustainable construction has never been more urgent. MRIPL is not just constructing buildings - we are building a more sustainable future for the city. Our commitment to eco-friendly practices, combined with our technical expertise and focus on quality, positions us as a leader in Mumbai's construction industry. By choosing MRIPL, you are investing in: ✅ A stronger, more resilient structure ✅ Lower maintenance costs ✅ Reduced environmental impact Conclusion The rise of eco-friendly construction in Mumbai is not just a trend - it's a movement toward a more sustainable future. MRIPL is at the forefront of this movement, combining innovative construction techniques with a deep commitment to environmental responsibility.

Tags : Structural Repairs of Bridge in india , Structural Restoration Services in India , Rehabilitation Contractors in India .

0 notes

Text

Professional Rug Cleaning Near Me: Everything You Need to Know Before Booking a Service

Rugs play a crucial role in enhancing the beauty and comfort of your home, but they also accumulate dirt, allergens, and stains over time. While vacuuming and DIY cleaning methods can help with surface-level maintenance, they often fall short in deep cleaning and sanitizing your rugs effectively. That’s where professional rug cleaning comes in.

If you’re searching for “professional rug cleaning near me,” you likely want a reliable service that can restore your rugs to their original condition without causing damage. In this guide, we’ll answer common questions about rug cleaning, including its benefits, costs, how to choose the best service, and how often you should schedule a professional cleaning.

Why Should You Invest in Professional Rug Cleaning Near Me?

Rugs are more than just decorative pieces—they trap dust, allergens, bacteria, and even mold spores over time. Many homeowners attempt DIY rug cleaning using store-bought sprays or rented carpet cleaners, but these methods rarely provide the deep clean that a professional service can offer.

Benefits of Hiring a Professional Rug Cleaner:

✅ Deep Cleaning Beyond the Surface – Professionals use advanced equipment and cleaning solutions to remove embedded dirt, dust mites, and bacteria that vacuuming can’t reach.

✅ Safe for Delicate Fabrics – If you own Persian, wool, silk, or antique rugs, improper cleaning methods can cause shrinkage, color fading, or fiber damage. Professional cleaners use tailored techniques to preserve your rug’s integrity.

✅ Prolongs Rug Lifespan – Regular deep cleaning prevents fiber breakdown and extends the life of your rugs.

✅ Removes Stubborn Stains & Odors – Coffee spills, pet accidents, and mildew smells require professional-grade treatments to ensure they are completely eliminated.

✅ Improves Indoor Air Quality – Rugs act like air filters, trapping dust, pet dander, and pollutants. Regular professional cleaning helps reduce allergens and keeps your home healthier.

How Much Does Professional Rug Cleaning Cost Near Me?

One of the most common concerns homeowners have is the cost of professional rug cleaning. Prices vary based on factors like rug type, size, and cleaning method.

Average Cost of Rug Cleaning:

Synthetic Rugs: $2–$5 per square foot

Wool Rugs: $4–$8 per square foot

Persian & Oriental Rugs: $6–$12 per square foot

Silk or Antique Rugs: $8–$15 per square foot

Factors That Affect Pricing:

💰 Rug Material – Natural fiber rugs (like wool and silk) require specialized cleaning, increasing the cost.

💰 Size of the Rug – Larger rugs naturally cost more to clean.

💰 Cleaning Method – Steam cleaning, dry cleaning, and hand-washing have different price points.

💰 Stain Treatment & Odor Removal – Pet stains, wine spills, and heavy odors often require additional treatments, which can increase the price.

💰 Pickup & Delivery Service – Some companies offer free pickup and delivery, while others charge extra.

💡 Pro Tip: Always request a detailed estimate before booking to avoid hidden fees.

What’s the Best Way to Find a Trusted Rug Cleaning Service Near Me?

Not all rug cleaning companies provide the same level of service. Here’s how you can find a reputable professional in your area:

1. Check Online Reviews & Ratings

Look for Google reviews, Yelp ratings, and testimonials on a company’s website. A reliable service should have a track record of satisfied customers.

2. Ask About Certifications

Reputable cleaners often have industry certifications like IICRC (Institute of Inspection, Cleaning, and Restoration Certification), which ensures they follow best practices.

3. Inquire About Cleaning Methods & Products

Eco-friendly, non-toxic cleaning solutions are safer for your family and pets. Avoid companies that use harsh chemicals that can damage rug fibers.

4. Get a Free Quote

A professional rug cleaner should be transparent about their pricing and offer a free estimate before starting the work.

5. Watch for Red Flags

❌ Companies that give vague estimates or refuse to disclose their cleaning methods. ❌ Lack of proper cleaning equipment or untrained staff. ❌ No customer satisfaction guarantee or refund policy.

How Often Should You Schedule Professional Rug Cleaning Near Me?

How frequently you should clean your rugs depends on foot traffic, pets, and household members with allergies.

Recommended Cleaning Schedule:

🏡 Low-Traffic Areas: Every 12–18 months 👨👩👧👦 Homes with Kids: Every 6–12 months 🐶 Pet Owners: Every 3–6 months 🤧 Allergy Sufferers: Every 3–6 months to reduce dust mites and allergens

Best Times to Schedule Cleaning:

Spring & Fall: Ideal for removing dust, allergens, and bacteria that accumulate during extreme weather seasons.

Before Holidays: Get your home fresh and clean before guests arrive.

Signs Your Rug Needs Immediate Cleaning: ❌ Strong odors that don’t go away. ❌ Visible dirt and discoloration. ❌ Increased allergy symptoms in your household.

Find the Best Professional Rug Cleaning Near You

Professional rug cleaning is essential for maintaining the beauty, longevity, and hygiene of your rugs. By investing in expert cleaning services, you can ensure your rugs remain free of stains, odors, and allergens.

If you’re searching for professional rug cleaning near me, look no further than Yep We Clean Rugs. Our expert team specializes in deep cleaning, stain removal, and eco-friendly solutions to restore your rugs to their original beauty.

📞 Get a free quote today and experience the difference of professional rug cleaning!

0 notes

Text

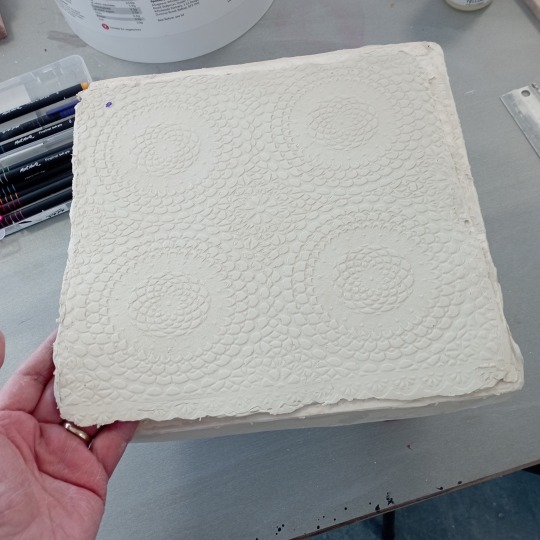

The ups and downs of ceramics and glazing.

I made the plate with the mold yesterday.

I left it overnight on the mold.

When the clay starts to dry, it shrinks and because it was on the mold it had no room for shrinkage so it broke

Lesson learned.

I'm determined to get this process down.

Mary gave me a great lesson today .

Every part of the process is very important.

From rolling out the clay, to handling it.

Placing it on the mold with the cotton

Leaving the cotton on top while smoothing it out with the plastic kidney

Cutting the edges with a harp.

Letting the banding wheel do the work while you keep your hand, arm and elbow static.

6 notes

·

View notes

Text

What is Industrial Shrink Film and How Does It Work?

Industrial shrink film is a versatile packaging material used across a variety of industries to securely wrap, bundle, and protect products. It is made from a plastic polymer, often polyethylene or polyolefin, that contracts when heat is applied. This unique property makes shrink film an invaluable tool for securing products, improving their protection during transit, and offering a clean, professional appearance.

The Basics of Industrial Shrink Film

Shrink film is designed to be tightly applied to the surface of the product or a group of products. When exposed to heat, the film shrinks, conforming to the shape of the items it is wrapping. This heat-shrinking effect is the key to its effectiveness, as it creates a strong, tight seal that holds the items securely in place.

The process of shrink wrapping typically involves the use of a heat source such as a heat tunnel, heat gun, or shrink wrap machine. As the heat is applied to the film, its molecules contract, resulting in a tight and durable seal that protects the items from external elements such as dirt, moisture, and tampering.

Types of Industrial Shrink Films

There are different types of shrink films, each with its own specific use cases. The most common types include:

Polyethylene (PE) Shrink Film: This is the most widely used type of shrink film due to its durability, affordability, and versatility. It is used in a wide range of applications, from packaging beverages to securing pallets of goods.

Polyolefin (POF) Shrink Film: Polyolefin is a more premium option compared to polyethylene. It is known for its higher clarity, resistance to punctures, and greater strength. POF shrink film is commonly used for packaging consumer goods, food products, and electronics.

PVC Shrink Film: Polyvinyl chloride (PVC) shrink film is often used in smaller-scale packaging for items like DVDs, toys, or electronics. However, it is less common in industrial applications due to its environmental concerns and lower resistance to temperature fluctuations.

How Does Shrink Film Work?

The mechanism behind shrink film is relatively simple, but it involves some complex molecular behavior. Shrink films are made from polymers that are oriented in a particular way during the manufacturing process. These polymers are stretched out, making the film thin and flexible. When heat is applied, the polymers revert to their original, tightly wound form, which causes the film to shrink.

The heat causes the polymer chains to move closer together, leading to the shrinkage of the film. As the film shrinks, it molds itself tightly around the product, creating a secure, tamper-evident layer. This tight seal is one of the key advantages of shrink film, as it prevents items from shifting during handling and provides extra protection from environmental factors.

Why is Industrial Shrink Film Used?

The use of industrial shrink film is widespread across many sectors due to its many benefits. These benefits include:

Product Protection: Shrink film offers a reliable way to protect products from dirt, moisture, and physical damage during storage and shipping.

Security: Shrink film can act as a tamper-evident seal, helping businesses protect their products from theft or tampering.

Professional Appearance: Shrink film provides a neat, uniform finish that enhances the presentation of products.

Cost-Effectiveness: Shrink film is a relatively inexpensive solution for packaging, offering great protection without breaking the bank.

Customization: Shrink film can be easily customized with graphics, logos, and branding, making it an excellent choice for marketing and promotional packaging.

Conclusion

Industrial shrink film is an essential tool in the packaging industry, offering excellent protection, security, and aesthetic appeal for a wide range of products. Its ability to shrink tightly around items when heat is applied makes it ideal for protecting goods during transit and storage. With various types of shrink films available, businesses can choose the right material to suit their specific needs, making it an indispensable solution for industries worldwide.

0 notes