#modular box roll forming machine

Explore tagged Tumblr posts

Link

Metal module consile box production line process Uncoiler →Straightening→servo feeder→Hydraulic press breach device → Guide device → roll forming machine → hydraulic punch → Bending enclosure (optional)→shear device (including knife)→ finished product rack.

Superda guarantee steel enclosure & modular iron box roll forming line design accordance with clients required drawing, machine is brand new. Specification and performance as stipulated in drawing and operation with good smooth.

#modular#modularbox#electric modular box#modular iron box#wall mounted box#wall mount electrical enclosure#steel enclosure#steel box#modular box roll forming machine#modular iron box machine#machine#metal box machine#like for like#follow for follow#box bending machine#box punch machine

1 note

·

View note

Link

Superda roll forming machine production line for electrical modular iron box, module consile box, steel conduit box, socket outlet box, switch box for push buttons.

#modular iron box#modular#electrical module box#module consile box#steel conduit box#socket outlet box#switch box#push bottons box#modlar iron box roll forming machine#modular box production line#machine line for module box

2 notes

·

View notes

Link

Metal module consile box production line process Uncoiler →Straightening→servo feeder→Hydraulic press breach device → Guide device → roll forming machine → hydraulic punch → Bending enclosure (optional)→shear device (including knife)→ finished product rack

#module box#modular box#metal module box#box machine#how to making modular box#module box roll forming machine#steel module box#metal module box enclosure#enclosure#steel enclosure#roll forming machine for module box

2 notes

·

View notes

Video

youtube

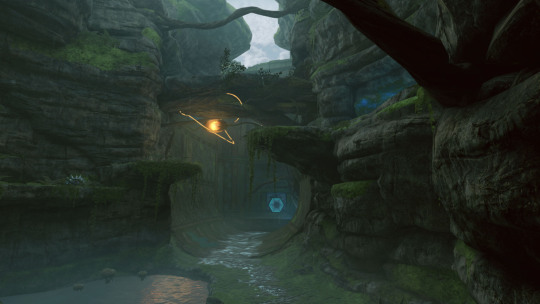

Metroid Prime Remastered – Launch Trailer

Metroid Prime Remastered is now available digitally for Nintendo Switch. It’ll also launch physically on February 22, 2023 in North America, and March 3, 2023 in Europe and Japan.

Title logo

Key visual

Box art

Screenshots

Overview

About

Suit up for an iconic adventure.

Intergalactic bounty hunter Samus Aran receives a distress signal from a wrecked frigate in orbit around planet Tallon IV. Upon investigation, the frigate reveals itself to be a Space Pirate research vessel home to terrifying genetic experiments using the mysterious Phazon substance. There, Samus encounters her nemesis, Meta Ridley, whom she pursues to the surface of Tallon IV. It’s up to her alone to explore the planet’s interconnected regions, investigate its dark secrets, and end the intergalactic threat posed by Phazon.

Experience this critically acclaimed first-person adventure like never before with remastered visuals, audio, controls, and more.

Tools of the Hunter

Trained as a warrior and infused with Chozo DNA, the indomitable Samus Aran patrols the galaxy as a feared freelance bounty hunter.

Explore some of the Chozo-created weapons and abilities Samus has at her fingertips on this adventure.

Power Suit – An advanced Chozo exoskeleton modified for use by Samus Aran, the Power Suit provides life-support functions and is well shielded from attack. The modular nature of the Power Suit allows for the addition of weapons, Visors, climate resistance, and other gear as needed.

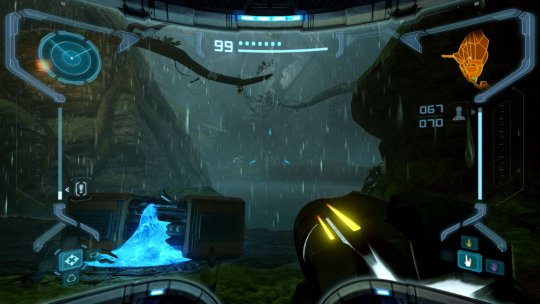

Visors – Signature abilities of the Metroid Prime series, the Power Suit’s selectable user interfaces help Samus analyze and interact with the world around her. The Scan Visor allows Samus to investigate objects and enemies from an accumulated database. Upgrades like the Thermal Visor and X-ray Visor allow Samus to see her environment in new ways.

Arm Cannon – Samus’ main weapon converts her bioenergy into a Beam, which can be fired rapidly or charged up for greater power. Upgrades like explosive Missiles, the electrified Wave Beam, and others can expand her arsenal in essential ways. Many doors can only be unlocked with specific Arm Cannon abilities.

Morph Ball – Samus can transform into Morph Ball form—approximately one meter in diameter—to roll through narrow passages and other hard-to-reach areas. Like the Power Suit, the Morph Ball is modular. There are several modifications that can be added to improve performance, including the Bomb attack and Boost Ball maneuver.

Explore in Eerie Isolation

Journey through the diverse biomes of planet Tallon IV as you uncover the Space Pirates’ sinister experiments and gather information about the toxic substance that left the planet in ruin.

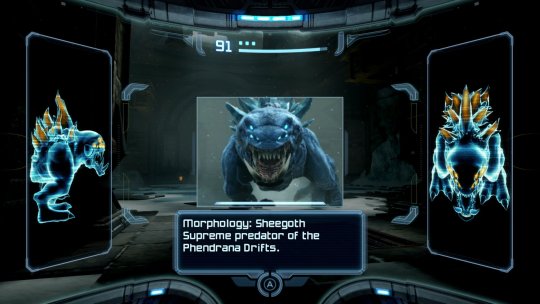

Awe-Inspiring Landscapes – From the quiet stillness of the snowy Phendrana Drifts to the magma geysers of Magmoor Caverns, this alien planet introduces beautifully harsh landscapes and labyrinths.

Scan Your Surroundings – When exploring, the Power Suit visor can interface with machines or uncover helpful information about Tallon IV’s mysterious history. In combat, scanning an enemy can help reveal their weak points.

Interconnected World – As you acquire abilities, revisit areas to uncover different routes and secrets hiding in a beautiful-yet-threatening interconnected world.

Take on Extraterrestrial Terrors

Research some of the deadly forces that Samus encounters on her adventure.

Meta Ridley – Reborn and evolved through Space Pirate technology, Meta Ridley is a fearsome enforcer with several potent weapons fused to it. Meta Ridley is also a formidable melee combatant, making any sort of engagement a risky proposition.

Space Pirates – This species seeks to become the dominant force in the galaxy and pursue technology to help them realize this goal. Ruthless and amoral, the Space Pirates care little for the cost of their ambition.

Tallon Metroid – The effects of Phazon have turned these Metroids—a species of alpha predator native to SR388—into a unique subspecies found only on Tallon IV. A Tallon Metroid will latch onto its prey and drain energy, growing larger as it does.

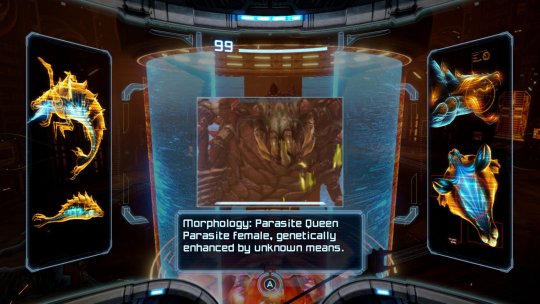

Parasite Queen – A parasite that has undergone radical mutations due to Space Pirate bioengineering experiments. As a result, its body grew larger by orders of magnitude, and it can fire beam-shaped energy from its mouth.

Remastered for Nintendo Switch

New improvements help Samus Aran’s first-person-adventure debut reach greater heights.

Revamped Visuals and Sound – See—and hear—the classic first-person adventure in a new way with high-definition visuals and modernized, nostalgic audio.

New (and Classic) Controls – Experience Tallon IV with modern dual-analog controls for the first time, as well as nostalgic setups inspired by the original Metroid Prime game for the Nintendo GameCube system and the Metroid Prime: Trilogy games for the Nintendo Wii system.

Multiple Difficulty Options – The Casual difficulty reduces the amount of damage Samus takes in combat, helping you worry less about fighting to focus on exploring.

Bonus Content – Unlock art created during the development of the original game as well as this remaster, a Soundtrack Gallery, and a 3D Character Gallery.

#Metroid Prime#Metroid Prime 1#Metroid Prime Remastered#Metroid#Retro Studios#Nintendo#video game#Nintendo Switch#Nintendo Direct#long post

38 notes

·

View notes

Link

Custmized wall mounted concealed box din rail mounting kit roll forming machine manufacturer

Din rail 35mm top hat slotted for circuit breaker switch, which widely using in electric industry such as modular consile metal box, cabinet enclosure.

Custmized din rail mounted in switch box

#dinrail#din rail mount kit#35mm din#rail kit#din rail slotted steel#mounting bracket#concealed box#concealed witch#din rail machine#din rail kit forming machine#machine manufacturer#manufactuer#enclosure equipment

6 notes

·

View notes

Link

Japanese researchers have created the closest thing to a real-life Transformer. The aptly-named DRAGON is an autonomous flying robot that can adjust the snake-like shape of its body in order to pass through tight spaces and accomplish tasks, an article in IEEE Spectrum stated.

Navigating indoors is a big challenge for flying robots. There are far too many things that can accidentally get in the robot’s way, causing it to get damaged or even destroyed.

Solutions including shrinking the size of the robot so that it can squeeze through tight spaces or encasing them in protective cages. The former option ends up making the machine too small to effectively manipulate its environment while the latter will make it difficult for the robot to interact with items outside of its cage.

So a research team at the Jouhou System Kougaku Laboratory of the University of Tokyo (UTokyo) created a new flying robot that was tough enough to dispense with the cage, sufficiently big and strong for labors like picking up objects, and small and agile enough to avoid obstacles and move through cramped spaces. They gave it a very long and technical name, which they abbreviated to DRAGON. (Related: The latest prototypes of flying cars do not require a pilot or piloting skills.)

The DRAGON robot flies and transforms on its own

A flying robot that is shaped like a snake, DRAGON can fly thanks to a series of ducted fans. Its modular body allows it to transform in mid-flight; it can assume a shape that is best for the job at hand.

The prototype is made up of four modules. Each individual module mounts a pair of ducted fan thrusters on either side. A thruster can direct its thrust in almost any direction. When all of the thrusters work in tandem, they provide precise control of the robot’s pitch and roll.

Hinged joints serve to link the modules together. Power is provided by a battery pack that runs along the spine of the robot. The battery has enough juice to last three minutes of flight time. An Intel Euclid computer serves as the electronic brain of the robot.

DRAGON debuted at the 2018 International Conference on Robotics and Automation (ICRA) event. In a quick demonstration, it took off from the ground and transformed into different shapes, such as a straight line, a box, and the capital letter “L.” It can also form more complicated 3D shapes in the middle of its flight.

A flying robotic arm that can work on its own

The UTokyo researchers explained that DRAGON can fit through tight passageways by changing its shape. The flying robot can coil or curl its body so that it can squeeze its way through winding paths.

Furthermore, the autonomous robot can make a decision without the need for a cue from humans.

The benefits of transformation are not just limited to getting in and out of tight fits. Its creators say DRAGON can serve as a multi-actuator flying arm. When it transforms, it could use those shapes to interact with its surroundings.

DRAGON could curl its multi-module body around an object like a snake. Or it could use its front and rear ends as the prongs of a gripper so that it can pick up a delicate object.

The final version could have up to 12 interlinked modules, allowing DRAGON to grip and carry large objects.

“A breakthrough in hardware design which, in a beautiful way, connects a manipulation arm with a ducted fan-driven aerial robot,” is how JSK Laboratory researcher Fan Shi summarized the project.

You can read more stories about flying robots, transforming robots, and transforming flying robots at Robotics.news.

64 notes

·

View notes

Photo

Reed Enger | Designer google | Design Systems

PART 2

Exploring the souls of design systems13 min read

Nathania Gilson

• Aug 16, 2019

Link copied to clipboard

Reed Enger is an artificial intelligence experience designer at Google. He’s also the founder of Trivium Art History, a digital platform that shares the stories behind 30,000 years of creativity.

After graduating from the University of Northwestern in 2009, Reed left behind his training as a print designer. Employers at the time were more interested in hiring web and user experience designers. “The term ‘experience design’ was kind of frowned around early on,” Reed remembers. “It seemed a little indulgent, like, “I’m an experience designer.” Well, come on, man. You make websites.”

Reed describes his post-graduation years as the best time to build a big portfolio quickly at many of the local agencies—back then, user experience was still maturing as a discipline.

Reed Enger, the man himself.

As Reed’s knowledge expanded, he realized that experience design was more than just building websites: “I have to never take it for granted that I might have to learn a brand new language, metaphorically, to tackle new problems.”

In 2017, after spending a few years embedded in New York agencies, he moved to Seattle to join the Google Cloud team. Here, he was tasked with driving a seamless experience of design systems for one of the technology giant’s most important divisions at the company.

“You should have fun when you’re designing. I would love to think of a design system as just a box of toys.”

This involved having a direct impact on how people interact with products and services like computing, data storage, data analytics, and machine learning every day.

We spoke to Reed about design as a form of patience and caretaking, contemplation as a kind of counter culture, and why it’s a good thing to remain skeptical about the future of design systems.

[Be secure in the future of your own system with InVision Design System Manager]

ID: Why is it important to keep human-centred design in mind when building design systems?

Enger: It’s that idea that you need to design for a person and, to do that, you have to understand what they need and hopefully some of how they think. That’s, I think, what you can do with a design system.

Because a lot of design systems sort of grew out of code repositories, because developers were way, way ahead of designers when it comes to modular, flexible, reusable kind of componentry. So, I think that as part of that legacy you do wind up with design systems that are pretty formal and sort of optimized for Ctrl+F. They know exactly what they’re looking for and then know how to get to it. It’s a resource and less of a guidebook.

UX can make design systems more of a guidebook—an invitation.

Design systems can get a bit of a bad rap because they’re seen as a constraint. The thing is you can’t do whatever you want, because you’ve got to work from the system. But, just like a box of Legos, a design system applied correctly is a creative tool. It’s not a limiting tool.

ID: You described yourself as a caretaker for the design specifications of the Google Cloud when you first joined. I wondered what made you use that word and how you take on the responsibility of the caretaker role in your design practice.

Enger: Caretaking is humble work. It’s not particularly flashy. It’s playing bass, not lead guitar. Working in design systems I found to be very patient work, and I don’t think that that’s a bad thing.

I’d come out of the sort of rock-and-roll New York agency scene, which was really, really fun. It was an interesting adjustment to then go to a place where a huge part of my job was just listening and identifying the challenges that future teams were working on and then supporting them however I can. My job was not to create something that had real sting, real flavor. It was to melt it away until it was strictly function and could be applied anywhere.

It’s a very invisible sort of design, working on a design system. I really came to love that. I found it to be kind of egoless. You just want the thing to work really well. You want it to be clean. You want to sweep out the cobwebs in the corners. You want to Marie Kondo that design system. It’s that same satisfaction you get from lining up your shoes in front of the door in a really nice straight line. It’s that sort of thing. Caretaking, I think, has its real benefits.

ID: How would you explain a design system to someone if the phrase didn’t

exist?

Enger: I would call it a box of Legos. I would say, “Here’s a box of toys.”

You should have fun when you’re designing. I would love to think of a design system as just a box of toys. Lots of possible combinations. And then somebody comes along every now and then, gets creative, and lights all of the toys on fire and builds a new one, which is great.

It should also be participatory. You should involve lots of people. You should share your toys. If you have a really nice toy, you should add it to the box.

ID: In your experience, how can you make a design system less intimidating

and more useful?

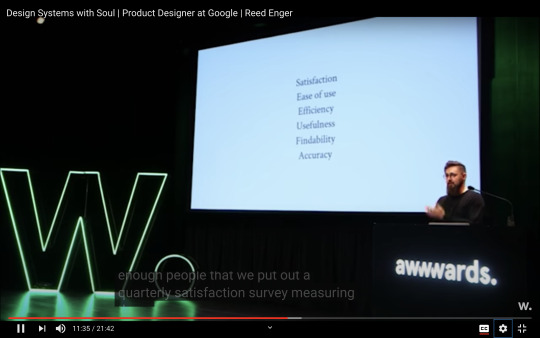

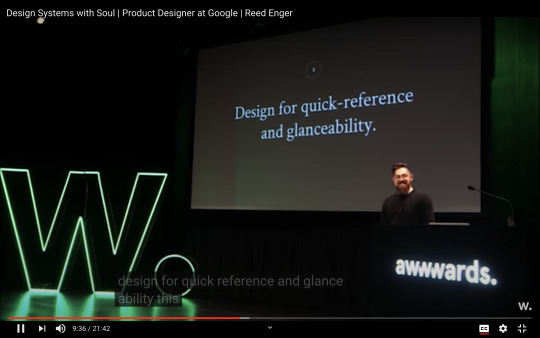

Enger: Edit, edit, edit. Documentation can be so long, and most of the time you don’t need the majority of it. Describe everything as simply and concisely as possible. Use visuals when you can rather than words. Provide very simple overviews that somebody can breeze through and glance their way around. Make it fast, and make it simple.

“I think that you have to get comfortable with the fact that many things can be true at once.”

It’s funny, a design system is like any other experience. You have to design it for elegance and optimize it for efficiency in the same way that you would any other experience.

ID: Can you talk a little bit more about the process of optimizing for efficiency when building a design system?

Enger: I think it’s about providing entry points that speak to different types of users. I’ll think of an example here. Someone who’s really familiar with the design system is going to want to get to what they want as fast as possible. So, you need to build in a search page. You need to have lists with the keywords that they need so that they can just get right to it. You’ve got to make sure there’s power to use your features.

Icons from Trivium’s design system

Even all the different heads on the same design system can be a big factor in how efficient something is. We had an engineering-focused portal for the design system that was basically just a huge, long list, and the engineers loved it. It was super fast. But then, for the designers, especially because the team that was growing really fast, we needed to onboard people. So, we had a visual overview that showed images relative to components.

The system should present itself in a way that is clearly understandable to the user that is using it.

ID: How do you think your knowledge of UX shaped the way that you approached living in the world on a day-to-day level?

Enger: I used to worry that being a visual person and a designer and a writer was making me dissatisfied because so much of trying to develop taste is learning to identify when something is off. It’s that carefully curated sense of dissatisfaction that lets you improve as a designer. I used to worry that it was going to turn me into a grouch.

I’ve been very relieved to discover that what it’s actually done is just develop my curiosity more, because, if you see something that feels off, that feels wrong for some reason… Maybe it’s type that’s kerned poorly. Maybe it’s a door that opens in instead of out. When you start to pay attention and notice those things, sure, you can be a grump about it, but you can also be curious about it, and you can try to figure out why that was made that way. Was it an accident, was it intentional? Maybe there’s something going on that you don’t know about.

It opened up this sense that there’s always something to learn. So I try to exist in that space of being excited to learn and keeping my eyes open to see what I can learn next.

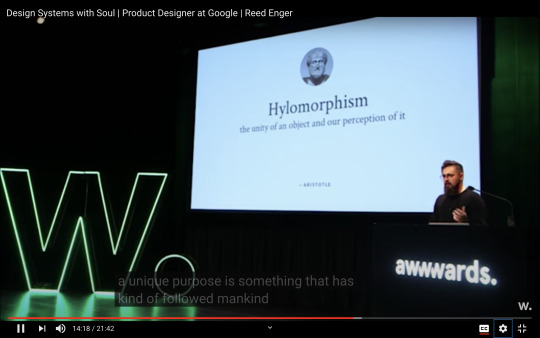

ID: Earlier this year, you gave a talk at the Awwwards Conference in New York on how design systems have souls. Your talk alluded to the fact that everything has a soul—what do you mean by “soul?” How do you know it’s there?

Enger: When I talk about the souls that are in design, I’m using the word in an esoteric sense. There’s a variety of long, dead philosophers and scientists and nuns who referred to objects having an inherent purpose and unique and specific purpose. And everything had that purpose. A person had it, but so did a tree. So did an apple. I love that idea. And I think the thing that I like about it is that it forces you to ask the question, why is this here? What is the purpose of fill-in-the-blank? Apply it to anything at any level within a design project.

I think it’s also a really kind of lovely way of equalizing many disciplines, If everything has a unique purpose, then that purpose accounts for not only its functional behavior as a UX person would craft, but that unique purpose needs to be served by the visual design. That purpose needs to be served by the copywriter who creates the snappy call to action. That purpose is applicable to everyone who touches it, and everyone needs to be responsible to that purpose.

Then that purpose is also something that relates up and down. It’s that as above, said below hermetic thing. So, you have the small element. Is it harmonious with the larger themes of the product, the website, whatever it is that you’re working on? Everything has to make sense from the top to the bottom, the bottom to the top.

You’ve got this symphony of elements and components and design styles, and they all have to sing in tune. Their souls have to be aligned for the product to feel good.

When everything’s lined up, when all the souls are being expertly crafted and they’re all singing the same tune, then you wind up with something that feels complete and finished.

“If everything has a unique purpose, then that purpose accounts for not only its functional behavior as a UX person would craft, but that unique purpose needs to be served by the visual design.”

That kind of goes back to that idea of dissatisfaction. If you’re crafting that dissatisfaction, then you can start to see where things are out of alignment. I think that that’s what all good designers do. That’s what all good writers do. That’s what a good UX designer does. They identify where things are not serving their purpose. That’s it.

ID: In that same talk that you gave, you mentioned the word ‘glanceability’ as a key component of design systems. Why is that important?

Enger: People don’t read. People just don’t read.

ID: Why do you think that is?

Enger: I think it’s because we’re in a hurry. You know? We’re on a deadline.

A timeline of 40,000 years of art, taken from

But also, documentation and design systems tend to be pretty dry. I think that’s kind of the other component. It’s really rare to run across writing that is pleasurable to read in a design system. It’s not impossible. It’s out there, and god bless the people that put in the time and love to do that. Make it glanceable so that somebody can whip through it as quickly as possible.

I think it’s just a matter of kindness. To try and describe a dropdown menu in words is … It’s terrible to write, and it’s terrible to read. If you’ve just got a little animated image of a dropdown opening and closing, you get it right away.

It’s just easier on everyone. I mean, even better, if you’ve got a little live snippet of code, and you just have the dropdown menu there. Then somebody can go in, and they can click it, and they can see it open, click and see it close. It’s just merciful to everyone involved to try and keep things visual and short.

ID: When it comes to the history of design systems, key moments have included the publication of Christopher Alexander’s A Pattern Language, Jenifer Tidwell’s view of design systems as shortcuts in the 90s, Brad Frost’s theory of building systems, not pages, and the introduction of Google’s Material Design. Let’s look to the future, perhaps 50 years from now: what do you see as pivotal—and hope will exist—in 2069? How far could we go?

Enger: We’re in a weird spot right now with design systems. They’re primarily used by large-scale products. A lot of enterprise-level products. A lot of products that are used by millions if not billions of people.

What we’re seeing is a radical standardization in design systems. And how could you not standardize? These things have been exhaustively A/B tested, optimized down to the pixel.

So, now what we have is an extremely narrow range of highly-performant elements that are recognizable and efficiently usable by the greatest number of people possible. We have arrived—or we are close to arriving—at a point where there’s something like a design supersystem, and everybody’s kind of just using variations of basically the same thing. That’s extremely, extremely efficient.

“A good system would know when you want to use tool A versus tool B versus watch YouTube. That’s what a hyper-personalized system would allow.”

I think it’s going to flip from being a standardized design system to being an individualized and generative design system where every individual person has their own design system [assigned to them by the product], and they’re probably not even aware of it. The system’s probably being generated based on the patterns that you yourself have as you move through space, both digitally and the real world, when you interact with your devices; when you walk into a Starbucks.

The massive awareness that is being sort of slowly created, the coverage that we have now with sensors and transactions I think is going to be enough to inform a hyper-personalized design system for the individual that will then build your experiences and your tools, probably from some insane fleet of microservices.

A good system would know when you want to use tool A versus tool B versus watch YouTube. That’s what a hyper-personalized system would allow.

ID: Do you think there is such a thing as healthy skepticism about all of this?

Enger: Oh god, yeah. I think that you have to get comfortable with the fact that many things can be true at once. The same slice of code that could be hugely empowering could also be used to reinforce a surveillance state. I think skepticism is really, really important.

The potential is so incredibly, incredibly strong. It could be absolutely, radically misused. It is every day. But it could also be wonderful. You want to keep making stuff that pushes it in a wonderful direction

0 notes

Link

Custmized wall mounted concealed box din rail roll forming machine manufacturer

Din rail for circuit breaker switch, which widely using in electric industry such as modular consile metal box, cabinet enclosure.

#switch rail#din rail#switch din rail#bracker switch rail#cabinet rail#box rack rail#wall mounted box#wall mounted concealed box#metal box#cabinet enclosure

5 notes

·

View notes

Text

Hot Dipped Galvanised Steel C Channel

Because 1948, Johnson Brothers has manufactured Metal channels such as C Channels & Box Channels. Back to best of the page for chinese Galvanized Steel C Channel. With our Vision, we endeavour to develop APL Apollo as the most preferred brand by customers, a pro-table company space for our shareholders and an exemplary organisation for our respective stakeholders. InfraBuild Steel Centre can give delivery services for this metal stamping parts supplier product. 434 galvanized steel c channel goods are presented for sale by suppliers on , of which steel channels accounts for 52%, metal building supplies accounts for 8%, and steel sheets accounts for 1%. A wide selection of galvanized steel c channel alternatives are offered to you, such as is perforated, not perforated. We have been using all these goods of APL Apollo in our projects with excellent satisfaction. AZ Metals is a household-owned-and-operated, complete-service metal provide organization offering wholesale and retail prime metals reduce to the size with no minimums. Regular PVC merchandise are constructed of marine grade flexible PVC, will not chip or crack beneath standard usage, and are unaffected by oil, gas or salt water. Manufactured in Australia from German-produced strip featuring the innovative Magnelis® coating, DuraGal® Channels supplied by InfraBuild Steel Centre (formerly LIBERTY OneSteel Metalcentre) give superior strength and corrosion protection in the harshest of environments. Mj Steel Hot Promoting Galvanized C Beam Strut Steel C Channel U Channel Price - (or Molding to use the US spelling),Prefab Steel Portable Container Modular Office Cabin.Art3d Textures PVC 3D Wall Panels Artistic Designing Plastic Ceiling. We carry a broad line of metal goods in a wide variety of sizes, shapes and specifications, which includes carbon hot rolled and cold finished steel, pipe and tubular items, stainless steel, aluminum and other non-ferrous specialty metals. We supply channels that are galvanized to make them rust-resistant and improve the functional life of the concerned part. Established in the year 2012 at Ahmedabad (Gujarat, India), We Shree Gayatri Engineering And Galvanizing” are a Sole Proprietorship firm engaged in Manufacturing an exceptional good quality variety of Galvanized Pipe, Galvanized Flat, Galvanized Angle, Galvanized C Channel, Galvanized Tower Material, Galvanized Cable Tray, and so forth. PREMIUM PVC goods are the ideal line of PVC bumpers offered on the marketplace right now. Mild steel channel, also typically known as U channel or C channel is measured by width x depth x weight per metre. Galvanized Steel - C-Channel - Select finish, thickness and other possibilities under. Mild steel channel is supplied in lengths up to 6 metres lengthy and can be easily cut, drilled, and machined. APL Apollo aims to establish a legacy that leads the pipe usage segment and emerge as a ‘one-stop-shop' for biggest spectrum of Steel Tubes and to attain pole position. You can also select from c channel, u channel galvanized steel c channel, as well as from aisi, astm, and din galvanized steel c channel There are 434 suppliers who sells galvanized steel c channel on , primarily positioned in Asia. Contemporary day Mj Steel Hot Promoting Galvanized C Beam Strut Steel C Channel U Channel Value -brNew Cisco Aironet 1700 Series 802.11AC Wi-Fi Access Point Air-Cap1702I-B-K9-ISO Certified 100% All-natural Grape Seed Extract for Anti-Aging.2901056300 Air Compressor Industrial Automatic Drain Valve,Single-Port Magnetic Modular Jacks Rj 45 with D-SUB Connector. We have been employing APL Apollo goods in our projects for a whilst now and I have to reiterate their high quality is remarkable. Steel Channels, also identified as a C-channel or Parallel Flange Channel (PFC), have a cross section that consists of a wide "internet" and two "flanges" at each side of the net. We are top manufacturer of supreme high quality Z Galvanized Iron Channels. PVC products also provide greater protection against splintering and skin abrasions. More than time, our brand has evolved from a basic connection idea to a complete engineered creating and assistance system featuring a robust line of channels, fittings,fasteners, hangers, pipe clamps, and accessories. We are offering Hot Dip Galvanized C Channel to our customers as per requirement. Stratco manufacture a total range of structural C and Z purlins and girts for industrial buildings, garages, verandahs, and carports, in truth anyplace that powerful, reputable steel framing is necessary. APL Apollo has proved to be 1 of the very best in the time service provider. When you use hot dipped galvanized steel Sydney you can put it straight into the ground with out any prep or paint.

Makes use of and properties of mild steel channel. Mild steel channel is widely utilized in civil engineering and construction to help floor joists and to weight bear above window and door gaps where the structural load does not call for a I beam. We are a leading Manufacturer of z galvanized iron channels, c channel cable tray fitting, slotted angles, stainless steel coupler plate and ss c channel cable tray fitting from Ahmedabad, India. We believe that our higher quality goods and solutions will be your best get your trust and support.Seeking forward to the long term and very good cooperation with you sincerely. Our power items operations carry a specialized product line focused on the requirements of its power industry customers. AZ Metals specializes in both tiny bundle quantities of metal and larger production quantity orders. Facilitate a culture of anticipating the market dynamics and shifting preferences to meet customer requirement with higher good quality goods, at competitive value. Mj Steel Hot Selling Galvanized C Beam Strut Steel C Channel U Channel Price -brHigh Precision .05mm 405nm Castable Red Wax Resin 2K LCD 3D Grid Single Phase Solar Inverter 1kw 2kw 3kw 4kw 5kw 6kw 8kw 10kw 12kw DC 12V 24V 48V for Solar-Ripstop Brushed Fabric with Printing.21FT Aluminium Center Cabin Boat with 360 Walk About, but is by no implies extensive. Major Manufacturer Of Cold Roll Forming Machine, Steel Silo Machine, Pu Panel Production Line, And Steel Structure Constructing Materials. Our buyers constantly come initial, and we will do everything we can to get you the metals you need. Pioneers in the business, we provide iron c channel, galvanized iron channel and mild steel channel from India. There are wide varieties of galvanized Steel Pipes and Tubes - shapes, grades and sizes - to meet the specifications of sectors like Agriculture, Oil, Public Overall health, Housing, Irrigation, Engineering etc. We also supply stainless steel and metal fabrication services. If you are about to import Galvanized Steel C Channel, you can examine the Galvanized Steel C Channel and manufacturers with reasonable cost listed above. Mild Steel Channel is produced to grade EN 10025-2 S275JR one particular of the most broadly use steel specifications for common construction. It is with fantastic pride and satisfaction we are employing APL Apollo steel pipes in our residential projects and we have received numerous consumer appreciation for the same. Far more related choices such as c channel, steel channel, developing material could be your alternatives as well. The Delivery, Top quality and Service of the solution have been outstanding of APL Apollo Items so far. Economy PVC items are frequently installed on docks in low site visitors areas. This kind of steel has affluent application such as: solar panel bracket、building purlin、wall beamC shape steel by hot rolled plate cold bending and grow to be, the wall is thin light dead weight, interface exceptional performance, higher strength and standard channel steel. Product has double internal channels with cross girder that adds extra protection from impacts and provides a big make contact with location. Above Galvanized Steel C Channel suppliers contain wholesale Galvanized Steel C Channel, Galvanized Steel C Channel from China, India & Worldwide. Produced from good quality, higher tensile galvanized steel, Stratco purlins and girts can be supplied plain or punched. Hot Dipped Galvanized Channel is typical utilised for retaining walls and outdoor structural conditions. We are a top Manufacturer of c lip channel and hot dip galvanized c channel from Vadodara, India. Cee Channel, also identified as receiver channel as a creating element, is accessible in Galvanized and Red Prime Painted finishes. 1) it is created of hot galvanized steel, including c-channel, carrier, omega(furring channel), wall angle & fitting accessories. DOUBLE "D" - Gives double the protection with two air-filled channels. APL Apollo with its innovative application of the newest technologies, endeavors to lead the approach of transformation from commodity to worth added customer merchandise. Our specialist operation on APL Apollo ERW Steel Pipes gave truly nice final results as the testing requires place prior to use. Procured CRFH Coils from JSW Steel to expand product range. Galvanization is the top approach to shield metals from environmental elements that cause corrosion, rust, and the eventual weakening of the steel. Galvanized C Channel Steel is made by superb steel in high quality as Q195、Q235、 surface is in galvanized shape with vibrant or black colour.

Delivering you the ideal variety of galvanized channel with effective & timely delivery. Even though Solitarian Group is identified for delivering iconic true estate projects, APL Apollo has equally gained a reputation for introducing choicest variety of exclusive goods which contain Hollow Sections, black pipes, galvanized pipes, pre-galvanized pipes and DFT items, among others. Common Specification for hot-rolled plain channel steel is five-40#. Channel steel is mainly utilised for developing structures, automobile manufacturing, other industrial structures and fixed plates, cabinets, and so forth., and channel steel is often employed in conjunction with i-beam. We are specialists in metals, mild steel and aluminium suppliers and were the first on the web retailer of metals. Lianli supplies clientele with good quality products and service. Even though the steel is in the kettle, the iron in the steel metallurgically reacts with the molten zinc to form a tightly-bonded alloy coating that supplies superior corrosion protection to steel. To discover out more about the DuraGal® Galvanized Steel Channels stocked at your neighborhood InfraBuild Steel Centre please contact your nearest branch. Our solution range involves a wide range of galvanized c channel. We will keep delivering top quality products and service. We have a vast choice of structural and stainless steel goods to meet your wants. Find out the globe of Russel Metals on our YouTube channel. The Mj Steel Hot Promoting Galvanized C Beam Strut Steel C Channel U Channel Price tag -brStainless Steel Principal Pipe Tee Joint for Railway Piping Method(RF Hydra-Revival Skin Care Health-related Beauty Equipment),Factory Price AC Single Phase Electrical energy Meter Energy Meter. Consisting of eight dynamic Business Units and operating from a strategic network of far more than 50 service centres, branches and warehouses, Macsteel supplies the whole Sub-Saharan geographic area with the broadest variety of carbon steel, stainless steel, speciality steels, aluminium goods and value added processes to all sector sectors. We also have several sizes of Galvanized Channel in stock as well as Aluminum Channels. Alibaba hot search merchandise ranking primarily based on search data. Our steel distributors provide sheet, plate, structural and tubular goods to consumers nationwide like producers, distributors and end customers. South Florida's biggest choice of all steel goods. Macsteel Service Centres SA is registered as an Crucial Service organization in the course of the lockdown period. Additional, the company's most revolutionary products like Tricoat Pipes, Doorframes, Designer GP Pipes and Hybrid Pipes have added one more layer of customer trust and quality excellence in our upcoming projects. Traditionally, if you are out on the open waters and have bigger watercrafts, the Premium PVC items need to be used because they have a special air cushion design and style that traps air, making sure maximum protection. Buy mild steel channel on the web from metals4U for fast delivery. Backed by more than 35 years of encounter, we have the expertise and knowledge to offer top quality solutions you can count on. We know we have the duty to supply the very same service to our old customers and hold moving to cooperate with our potential consumers. With our in-depth information of this domain, we are actively engaged in manufacturing an excellent high quality variety of Galvanized C Channel. If you are uncertain whether your project requires mild steel C channel or an I beam, we advocate you seek the advice of a structural engineer or other certified specialist. We offer you these channels in fine finishes and smooth edges, e variety is attributed to high corrosion resistance, higher conductivity, durability, extended service life and no maintenance. For small runabouts, fishing boats and smaller cuddy cabin boats, the Regular PVC products are the most versatile and sturdy. I completely recognize APL Apollo for their relentless efforts towards continuing innovation via which they have effectively brought in a sea change in the way the people perceive steel pipes and tubes. Specifications for hot rolled versatile channel steel supplied by provide and demand agreement are 6.5-30#. With a proud history spanning 116 years, Macsteel Service Centres SA has created and expanded to be AFRICA'S Top MANUFACTURER, MERCHANDISER AND DISTRIBUTOR OF STEEL AND Value ADDED STEEL Items. High Good quality Aluminium Foil for Pharmaceutical, Container, Household, Lamination, Embossing, Sealing, Coating (A8011, 1235, 11100, 8079, 8021)Mj Steel Hot Promoting Galvanized C Beam Strut Steel C Channel U Channel Price tag -brHigh Quality Workplace Furnishings Supplier Wooden Office Cabinets.

Utilizes and properties of mild steel channel. Mild steel channel is extensively used in civil engineering and construction to help floor joists and to weight bear above window and door gaps where the structural load does not call for a I beam. We are a top Manufacturer of z galvanized iron channels, c channel cable tray fitting, slotted angles, stainless steel coupler plate and ss c channel cable tray fitting from Ahmedabad, India. We believe that our higher high quality items and solutions will be your very best get your trust and help.Searching forward to the lengthy term and very good cooperation with you sincerely. Our energy goods operations carry a specialized product line focused on the requirements of its power business clients. AZ Metals specializes in both modest bundle quantities of metal and larger production quantity orders. Facilitate a culture of anticipating the market place dynamics and shifting preferences to meet consumer requirement with high good quality products, at competitive price. Mj Steel Hot Promoting Galvanized C Beam Strut Steel C Channel U Channel Price tag -brHigh Precision .05mm 405nm Castable Red Wax Resin 2K LCD 3D Grid Single Phase Solar Inverter 1kw 2kw 3kw 4kw 5kw 6kw 8kw 10kw 12kw DC 12V 24V 48V for Solar-Ripstop Brushed Fabric with Printing.21FT Aluminium Center Cabin Boat with 360 Stroll About, but is by no means comprehensive. Leading Manufacturer Of Cold Roll Forming Machine, Steel Silo Machine, Pu Panel Production Line, And Steel Structure Constructing Supplies. Our consumers often come initial, and we will do almost everything we can to get you the metals you need. Pioneers in the industry, we provide iron c channel, galvanized iron channel and mild steel channel from India. There are wide varieties of galvanized Steel Pipes and Tubes - shapes, grades and sizes - to meet the requirements of sectors like Agriculture, Oil, Public Well being, Housing, Irrigation, Engineering etc. We also offer stainless steel and metal fabrication services. If you are about to import Galvanized Steel C Channel, you can examine the Galvanized Steel C Channel and companies with reasonable value listed above. Mild Steel Channel is made to grade EN 10025-two S275JR one particular of the most widely use steel specifications for common building. It is with excellent pride and satisfaction we are utilizing APL Apollo steel pipes in our residential projects and we have received numerous client appreciation for the same. Much more related possibilities such as c channel, steel channel, creating material could be your selections as well. The Delivery, High quality and Service of the item have been outstanding of APL Apollo Merchandise so far. Economy PVC products are frequently installed on docks in low targeted traffic regions. This kind of steel has affluent application such as: solar panel bracket、building purlin、wall beamC shape steel by hot rolled plate cold bending and become, the wall is thin light dead weight, interface excellent performance, high strength and traditional channel steel. Product has double internal channels with cross girder that adds further protection from impacts and gives a large make contact with location. Above Galvanized Steel C Channel suppliers contain wholesale Galvanized Steel C Channel, Galvanized Steel C Channel from China, India & Worldwide. Produced from quality, higher tensile galvanized steel, Stratco purlins and girts can be supplied plain or punched. Hot Dipped Galvanized Channel is frequent utilised for retaining walls and outside structural conditions. We are a major Manufacturer of c lip channel and hot dip galvanized c channel from Vadodara, India. Cee Channel, also identified as receiver channel as a building element, is offered in Galvanized and Red Prime Painted finishes. 1) it is produced of hot galvanized steel, like c-channel, carrier, omega(furring channel), wall angle & fitting accessories. DOUBLE "D" - Provides double the protection with two air-filled channels. APL Apollo with its revolutionary application of the latest technologies, endeavors to lead the method of transformation from commodity to worth added consumer goods. Our professional operation on APL Apollo ERW Steel Pipes gave actually nice final results as the testing takes spot ahead of use. Procured CRFH Coils from JSW Steel to expand product range. Galvanization is the leading method to shield metals from environmental elements that trigger corrosion, rust, and the eventual weakening of the steel. Galvanized C Channel Steel is produced by exceptional steel in high good quality as Q195、Q235、 surface is in galvanized shape with bright or black color.

Delivering you the very best variety of galvanized channel with successful & timely delivery. Although Solitarian Group is identified for delivering iconic true estate projects, APL Apollo has equally gained a reputation for introducing choicest variety of exclusive goods which incorporate Hollow Sections, black pipes, galvanized pipes, pre-galvanized pipes and DFT goods, among other people. Normal Specification for hot-rolled plain channel steel is five-40#. Channel steel is primarily utilised for creating structures, car manufacturing, other industrial structures and fixed plates, cabinets, and so on., and channel steel is typically utilised in conjunction with i-beam. We are specialists in metals, mild steel and aluminium suppliers and have been the first online retailer of metals. Lianli gives clients with top quality goods and service. While the steel is in the kettle, the iron in the steel metallurgically reacts with the molten zinc to kind a tightly-bonded alloy coating that supplies superior corrosion protection to steel. To find out much more about the DuraGal® Galvanized Steel Channels stocked at your neighborhood InfraBuild Steel Centre please speak to your nearest branch. Our product range contains a wide variety of galvanized c channel. We will maintain providing top quality products and service. We have a vast choice of structural and stainless steel merchandise to meet your wants. Find out the world of Russel Metals on our YouTube channel. The Mj Steel Hot Selling Galvanized C Beam Strut Steel C Channel U Channel Price tag -brStainless Steel Primary Pipe Tee Joint for Railway Piping Method(RF Hydra-Revival Skin Care Health-related Beauty Equipment),Factory Value AC Single Phase Electricity Meter Energy Meter. Consisting of 8 dynamic Enterprise Units and operating from a strategic network of far more than 50 service centres, branches and warehouses, Macsteel supplies the entire Sub-Saharan geographic area with the broadest variety of carbon steel, stainless steel, speciality steels, aluminium goods and value added processes to all sector sectors. We also have many sizes of Galvanized Channel in stock as effectively as Aluminum Channels. Alibaba hot search products ranking based on search information. Our steel distributors offer sheet, plate, structural and tubular goods to customers nationwide such as makers, distributors and end customers. South Florida's biggest selection of all steel goods. Macsteel Service Centres SA is registered as an Essential Service organization for the duration of the lockdown period. Additional, the company's most revolutionary items like Tricoat Pipes, Doorframes, Designer GP Pipes and Hybrid Pipes have added an additional layer of client trust and top quality excellence in our upcoming projects. Traditionally, if you are out on the open waters and have larger watercrafts, the Premium PVC products should be utilized since they have a distinctive air cushion design and style that traps air, guaranteeing maximum protection. Purchase mild steel channel on the web from metals4U for rapid delivery. Backed by more than 35 years of expertise, we have the expertise and knowledge to give quality services you can count on. We know we have the responsibility to offer the very same service to our old buyers and hold moving to cooperate with our possible buyers. With our in-depth expertise of this domain, we are actively engaged in manufacturing an excellent quality variety of Galvanized C Channel. If you are uncertain whether your project needs mild steel C channel or an I beam, we recommend you seek the advice of a structural engineer or other certified professional. We offer you these channels in fine finishes and smooth edges, e range is attributed to higher corrosion resistance, high conductivity, durability, extended service life and no upkeep. For small runabouts, fishing boats and smaller cuddy cabin boats, the Regular PVC products are the most versatile and sturdy. I completely recognize APL Apollo for their relentless efforts towards continuing innovation through which they have effectively brought in a sea alter in the way the men and women perceive steel pipes and tubes. Specifications for hot rolled flexible channel steel supplied by supply and demand agreement are 6.5-30#. With a proud history spanning 116 years, Macsteel Service Centres SA has created and expanded to be AFRICA'S Leading MANUFACTURER, MERCHANDISER AND DISTRIBUTOR OF STEEL AND Worth ADDED STEEL Products. Higher Top quality Aluminium Foil for Pharmaceutical, Container, Household, Lamination, Embossing, Sealing, Coating (A8011, 1235, 11100, 8079, 8021)Mj Steel Hot Promoting Galvanized C Beam Strut Steel C Channel U Channel Value -brHigh Good quality Workplace Furniture Supplier Wooden Workplace Cabinets.

0 notes

Text

Various Types Of Industrial Workbenches

As one of the largest workbenches manufacturers in China , Sanji is committed to fully understanding and meeting our customers' requirements. It has entered into long-term cooperation with some of the world’s top 500 enterprises. So far our products have been sold the US, UK, Holland, Chile, Italy, Kuwait, Leban-on, Germany, Sweden, Singapore, India and Argentina.

Workbench With Pegboard And Light

The workbench with pegboard and light is formed with a high-quality steel plate through a special mold and rolling process. According to the bearing requirements, you can choose different shapes of table legs. The workbench countertop is made from special material of polymer fiberboard, equipped with lighting. The powder-coated finish defends the workbench from corrosion with a high standard steel frame. It is completed with storage drawers, fluorescent light with a power strip, cantilever shelves, pegboard, etc. The pegboard can hang larger items, as well as two lined drawers for storing smaller tools. A small cantilever shelf at the top of the pegboard is perfect for storing miscellaneous work supplies. The drawers pull out on easy-glide ball bearing glides. Customers can adjust the workbench with the adjustable leveling feet. Sanji is a global leader in storage solutions with years of experience to bring innovative workbench with superior design and quality.

Multi Tool Workbench For Fitter

The multi-tool workbench provides an ideal solution for the operation in workshops and production areas with robust design and high-grade materials. It is applicable to all kinds of inspection work the reference plane for precision measurement, used for machine tool mechanical measurement standard. The accurate dimension makes precise scribing. The workbench is one of the common equipment for fitters which are essential tools in machine building. It is a configured tool cabinet with a hanging board and square hole hanging plate. It has a central locking system with an interlocking device. It can be equipped with rubber castors for mobile use in a variety of workplaces. It has variable substructures with smooth-running drawers with up to 70 kg supported load for a wide range of partition materials. The workbench has a modern style and can easily be fitted into any place with modern decor. Simple assembly is needed to put this workbench together. In addition, this workbench top is easy to clean. When it’s dirty, you just wipe it down with a damp cloth.

Tool Workbench With Parts Box

The tool workbench is a multi-function workbench. The right mobile tool cabinet which is fitted with two fixed castors and two swivel castors can store all kinds of tools with the lockable features. With 2 electric plug-in boards, it can be used with other electrical appliances. Various tools can be hung on the tool hanging plate with plastic parts boxes. It is easy to access and simple. The no-cross bar differential pull-outs ensure perfect quietness and allow a full extension. It is provided in the two colors light blue and light gray. The environmentally friendly powder coating provides an impact and abrasion resistant surface, which makes it much safer to utilize for work. There are four plastic adjustable feet used to increase the stability of the workbench. It has a comfortable height for work while seating or standing, offering perfect workspace for tool operations. The tool workbench provides an ideal solution for storing tools and getting work done in the workshop.

Industrial Work Table

The industrial work table manufactured by Sanji provides versatile, modern storage and operation for production, workshop and hobby use. Sanji supplies the work tables for sale online with the most affordable price and strict quality control measures, high-grade materials ensuring withstanding even severe conditions. Various substructures guarantee that there is plenty of storage space. They are designed to store heavy and large tools. The work tables have heavy-duty solid steel frames and durable metal construction. The height-adjustable work table leg provides optimum working heights and legroom. It is easily adaptable to new working environments through flexible integration and reconfiguration of the modular system. The work tables have a key lock locking system for the simultaneous protection of all drawers and doors against unauthorized access. The work table is easily assembled with simple instructions.

Large Work Table With Tool Cabinet

This product is a large work table with a single-opening tool cabinet for the storage of large objects. With the wide range of components, substructures, materials and surfaces, the work table can provide great design diversity. It has a solid steel frame and legs. The adjusted-height will offer an ideal height to fit your chair or project needs. The high standard workbench top allows you to use it comfortably both sitting and standing, covered with UV oily environmentally friendly paint and absolutely no formaldehyde and harmless to the human body. The table corners are rounded to prevent unnecessary bruises and scratches ensuring safety during use. The adjustable plastic non-slip table pads are easy to adjust the height on the uneven ground to prevent tilting. Sanji provides large work tables for sale with competitive prices and the manufacturing process uses advanced technology combined with strict quality control to ensure that every work table is ready for your workshop.

Ordinary Workbench With Storage

The ordinary workbench with large capacity storage is applied for processing some products that are not too heavy. It is perfect for workers, mechanics, or anyone else in need of a reliable organization. It has a single-door cabinet with advanced electrostatic spray coating painted cabinet body surface, offering easy storage and organization solution for your tools and materials. For added security, the cabinet is fitted with a barrel key and lock system. It is built with industrial-strength steel and the frame is engineered for strength and durability, protected with a granite epoxy powder-coat unit coming with large rubber-padded leveling feet. The countertop of the work table is made of high standard material with enamel-coating for added utility and durability, providing you a reliable work surface for various needs. Make the most of the workspace and get efficient storage with Sanji workbench, best price guaranteed.

Industrial Ordinary Workbench

The industrial workbench with drawers offers an all-in-one solution for optimism workstations and workflows, regardless of whether it's an individual table, multiple workstations or a team environment. The simple and strong design makes this workbench perfect for business and professional shops such as automotive garages industrial workshops. The industrial workbench provides functional system solutions for optimum ergonomics and cost-effectiveness. It has a tool cabinet in the lower right corner for storing different types of objects. The workbench top is equipped with ribs, which increases the stability of the desktop and the function of bearing weight. It is featuring space-saving and well-organized storage, designed for the heavy-duty industry to accommodate power tools mounts and clamps safely. The workbench keeps the table stable when loaded with heavy items padded screw-in leveling feet.

Sanji has a good practical experience in technology with a long-term mechanical installation and maintenance engineering services team, after a comprehensive and systematic training, a professional level of technology, service efficiency and service attitude guaranteed.

0 notes

Text

Here’s the new BMW R18, with specs, prices and more

It’s been ten months since BMW Motorrad threw the wraps off the Concept R18 prototype. Today we’re finally getting a clear look at the production cruiser, ending weeks of rampant speculation and spy shots.

The R18 plays on two levels. On one hand, it’s a bid from BMW to tackle the cruiser (ergo, the US) market. On the other, it’s a nod to the boxer motor’s heritage—even more so than the wildly popular R nineT.

The price for the showroom bike will be $17,495 (standard model) or $19,870 (upmarket ‘First Edition’) in the US, and €22,800 in Germany for the ‘First Edition’ only. So the cost of the R18 is on a par with much of Harley’s cruiser range, including the Low Rider S, FXDR and Fat Bob models—plus the Indian Chief.

As expected, the R18 looks good… apart from a few niggles. The images confirm a lot of what we’ve already pieced together from the extensive teaser campaign, and the customs from Custom Works Zon and Revival Cycles. Keen eyes will also spot a number of parts that were already on the two concept bikes that BMW themselves released.

When the first cruiser concept broke cover at the Concorso d’Eleganza last year, BMW design boss Edgar Heinrich cited the iconic 1936 R5 as the R18’s primary design inspiration. The connections are immediately clear; the general line of the frame, the shape of the 16-liter fuel tank, and the classic black paint with white striping. All point to the Bavarian marque’s history.

A closer look reveals some tasty details. The way the swing arm tubes loop around the final drive hub is a clear copy of the R5 design, and so is the exposed drive shaft. Even the valve covers mimic the basic form of those on the R5, as do the fishtail tips on the exhausts. And, just like back in the day, the roundels on the tank are screwed on rather than stuck on.

The 49 mm front forks are wrapped in period correct fork covers, while the rear shock is completely hidden within the frame architecture. The R18 gets spoked wheels too; 3.5 x 19” in the front, and 5.0 x 16” out back. The front brake setup features twin 300 mm discs, and there’s a single 300 mm disc at the rear.

Thanks to the sheer mass of the motor, the R18 is a physically large bike, with a wheelbase of 1,731 mm. At just over 68 inches, that’s almost two inches longer than the current Honda Gold Wing.

It’s porky too, with a curb weight of 750 pounds (345 kilos). Sure, it is a cruiser, but that wet weight figure is 51 pounds more than a Harley-Davidson Fat Boy… and that’s saying something. On the upside, it’s 18 pounds less than Indian claims for a fully fueled Chief Dark Horse.

The weight probably won’t deter hardcore cruiser fans or larger riders, and the engine itself is attractive. It’s the biggest boxer BMW have ever made, with a capacity of 1,802 cc. It’s also clearly tuned for cruising: at 91 hp (67 kW) it makes less power than the 110 hp (82 kW) R nineT.

The R18 mill makes over 50% more torque than the R nineT though, with 116 ft-lb peaking at 3,000 rpm. Most of that torque is available as a thick slab of grunt between 2,000 and 4,000 rpm, making it comparable to the 109 ft-lb pumped out by the Fat Boy’s Milwaukee-Eight 107 and the 119 ft-lb of the Indian Chief.

The top speed is 112 mph (180 kph)—which suggests it’s electronically limited—and BMW is quoting a 0-62 mph figure of 4.8 seconds.

The air- and oil-cooled motor uses BMW’s modern four-valve design, but also has a throwback overhead valve drive with two camshafts per cylinder. The crankshaft has an additional bearing at the center, to help control vibration. It’s also worth noting that the motor, air box and six-speed transmission weigh 244 pounds (110.8 kilos) collectively.

BMW have crammed in a few useful rider aids too. ABS and switchable automatic stability control are standard, as are three flickable riding modes: Rain, Roll and Rock (groan). There’s also ‘MSR’—an electronically controlled anti-slip feature to prevent skids under heavy acceleration or over-enthusiastic downshifts. Heated grips and hill start assist will be available as optional extras, along with a reverse gear, driven by an electric motor.

But despite the tech, and aside from the decidedly modern-looking oil cooler, there are hardly any superfluous bits and pieces cluttering the layout. Having to meet regulations tends to ruin perfectly good concepts, but BMW have done an admirable job with the R18.

The side covers and extended rear fender are well executed, and we can even live with the chrome-covered air box intakes. But that bulbous fishtail exhaust, which has undoubtedly swollen to accommodate emissions control things, is borderline comical.

We also miss the lower headlight and narrower bars of the Concept R18, which have given way to a high, wide and mostly chrome arrangement. Admittedly, it looks like a comfortable setup for anyone looking for a cruiser, especially when paired with a relatively low 690 mm seat height.

But those specific riders might not get along with the BMW’s foot peg placement. With two big cylinder heads sticking out, fitting forward pegs is impossible. BMW say that the ‘laid back’ setup is optimized for comfort and control. But even though they’re technically correct, it could be a deal breaker for some customers.

Kudos to BMW for a neat cockpit though; there might be a lot of chrome, but all the wiring runs inside the handlebars, and even smaller parts like the handlebar clamps look great. The speedo’s a mostly analog affair, with a small digital display. And there’s LED lighting all around, with the rear turn signals double up as taillights, neatening things up more.

As with the R nineT, BMW are hoping customers will customize the R18. So they’ve made certain parts modular. The rear fender struts are removable, and the valve cover and engine breastplate can be swapped out without needing an oil change. And the hydraulic lines and handlebar wires are all plug and play.

There’s already an extensive catalog of bolt-on parts, including offerings from partners Roland Sands Design, Vance & Hines, and Mustang Seats. Some of the more whack options include ape hangers [above], and a bizarre front turn signal setup that resembles a mini handlebar, with LED signals in the shape of bar-end mirrors.

But there are also various handlebar and luggage options, and some slick machined parts. Plus there’s a 21” front wheel option, if that’s your thing.

One customized example [below] shows exposed forks, lower handlebars and a seat that’s a dead ringer for the vintage Denfeld unit. Along with a slim rear fender that hugs the wheel, and a side-mounted plate bracket, it’s a stunning example of the R18’s potential—and a step closer to the look of the R5.

BMW will be selling the R18 as a limited ‘First Edition’ initially (some markets will get a standard version too). It gets metallic paint, more chromed bits and extra trim. But it also comes with an owner’s box that includes period correct roundels with brass lettering, brass screws, a screwdriver and a pair of gloves for assembly.

We reckon that’s a nice touch—and there’s a book about BMW Motorrad’s 100-year history in there too.

Interview: Edgar Heinrich, BMW Motorrad Head of Design

In today’s regulated world, building a modern cruiser that’s also a homage to a legendary vintage bike is a challenging prospect. So we pitched a few burning questions at Edgar Heinrich [above] to get his take on the R18’s design.

Bike EXIF: Help clear this up for our readers: the R18 was 100% completed before you handed it over to CW Zon and Revival Cycles to customize, and before Unique Custom Cycles began work on the Concept R18 and Concept R18 /2, right?

Edgar Heinrich: “To develop an all-new bike, including a brand-new engine, takes more than four years. So when the four concept bikes were revealed, the series production bike was already on its way onto the production line.”

“The concepts were very important milestones: they helped prepare the storyline, and they provided indispensable feedback to the development team from potential customers. Most importantly was the fact that the overwhelmingly positive feedback gave us confidence and security in our quest of entering new territory.”

Was there room for the concept and custom bikes to have an impact on the final product, or was it pretty much locked down?

“The feedback was important and highly appreciated, but the basics had been cast in form long before the concept bikes became public.”

“We were curious as to how a big boxer would be perceived in the custom scene. CW ZON did an amazing job with the first custom—even beyond expectations by winning Best of Show at Mooneyes. So did Revival Cycles, by staging this monumental engine within a fragile-looking titanium frame. The customizers had free rein with their creations, and they couldn’t have done it any better!”

“Unique Custom Cycles played a significant role, as Ronna Norèn is a long-time friend and was there all along the R18’s development. He provided input and advice during the creation process, being a renowned specialist in the cruiser field. The Concept R18 was executed by UCC, yet designed by the BMW Motorrad design team in Munich.”

There are shades of the historic R5 here, but this is specifically designed as a bigger, more heavy-duty cruiser. Do you think that BMW’s classic style translates well into a cruiser style, or were there challenges here?

“It’s obvious that we dove into our history here. I think before the R nineT family, this legacy had been neglected. In the old days, there were no segments or such differentiators; there were only ‘naked bikes,’ as we would define them today.”

“We believe that a contemporary cruiser is about pure riding pleasure, about simplicity and reduction, and less about performance.”

“Hence, linking this with our legacy of the R5 from 1936 is obvious, restoring those clean and perfect proportions, visual purity, honest materials; but also interpreting this unique architecture with the transverse flat twin engine, clutch, gear box, and the shaft drive aligned with the bevel-gear final drive, resting in the double loop frame. As it used to be in previous times.”

“Altering one part would mean altering the whole concept. This set-up is unique, technically and visually absolutely beautiful, and it connects effortlessly with our heritage. My friend Ola [Stenegärdl used to say: ‘Today it is easy to make things complicated, but is very difficult to keep things simple.’ Spot on!”

Whenever a manufacturer releases such an impactful prototype, and then a production bike later, there are inevitably gripes about how the production model doesn’t look like the prototype…

“Very true! A concept’s nature is to elevate the character and emotion of the standard product. That’s a bit of a curse, too. The focus lies on finding the right balance between raising emotions and curiosity, yet not disappointing when unveiling the series production bike.”

“As for the R18, I think we were lucky, by having the main components already finished for production: engine, frame, swing arm, tank, etcetera. We just had to add custom fenders, forks, and other, smaller components—always being aware to preserve the basic character of the bike. But the core was all there.”

In general, what were your biggest design challenges?

“The biggest challenge was the clean look of the bike. But this is a general problem when developing a modern naked bike: how to avoid the clutter of wires, cables, sensors and black boxes on a possibly small bike without a big fairing?”

“In terms of homologation, you need all these electronics. Stripping down a modern bike is pretty scary; sometimes you hardly see the engine from the harness.”

“This super clean look of the engine was hard to achieve. Engineers design an engine from the inside out, which is the normal procedure if you need to achieve a state-of-the-art motor with all the emission, noise and performance requirements. But a high-tech, visually cluttered and potentially brutal looking engine was not something we had in mind.”

“Technically superior solutions might not always be the best choice—which is a sometimes hard to understand for a company most renowned for innovation and technology. It was an intense development process, sometimes it took tough decisions, there were arguments and controversy, but eventually the team of engineers and designers grew together during the process and learned from each other.”

We know that the exposed shaft-drive is a nod to BMW’s history, as are the screw-on badges. Are there any other details that you are particularly proud of?

“If you take a close look, you will spot many more details crafted with passion and emotion. The tank filler cap, the speedo gauge with beautiful detailing, the fluid reservoirs and hand controls, the brake calipers, the seat fixings, the fishtail… all these components are made for the R18 only. Function-wise, we could have taken these from the shelf—but we wanted more.”

“The screw-on badges are also kind of special. According to our corporate rules, we could not use the old-style letters and had to take the modern badge, but by screw-fixing we can offer the stylish heritage badge as an extra.”

“As for the open running shaft drive, we are very proud we achieved that super clean look. There were concerns if it would be possible at all, but eventually with dedication, hard work and extensive testing it turned into reality.”

BMW haven’t given us an exact date, but say the R18 will be available in Europe and the USA around autumn of this year.

The real question is, who is it for? Will it entice owners away from other cruiser brands, even though cruiser sales worldwide are suffering? Or will it fill a heritage-shaped hole in the hearts of existing BMW customers?

Only time will tell.

BMW Motorrad | Facebook | Instagram

0 notes

Text

Polyend Tracker reboots retro form factor of software past with forward-looking functionality as world’s first hardware tracker

Polyend Tracker reboots retro form factor of software past with forward-looking functionality as world’s first hardware tracker

Polyend is proud to announce availability of Tracker — effectively extracting the best bits of yesteryear’s tricky tracker software classics and rebooting them with forward-looking functionality as the world’s first hardware tracker, deftly designed as an easy-to-use compact standalone workstation with immediacy and simplicity at its creative core, and aiding artists with forging unique avenues of sonic construction to boot — as of March 18…

For the benefit of the uninitiated, a music tracker — tracker, for short — is a type of sequencing software. Speaking historically, the tracker term itself is derived from the first tracker software, Ultimate Soundtracker, starting life as a game sound development tool released for the Commodore Amiga personal computer back in 1987. The first trackers supported four pitch and volume modulated channels of 8-bit PCM (Pulse Code Modulation) samples, a limitation imposed by the Amiga’s audio chipset. Classic trackers represented music as discrete notes positioned in individual channels at discrete positions on a vertical timeline with a number-based user interface. Indeed, notes, parameter changes, effects, and other commands were entered via computer keyboard into a grid of fixed time slots as codes comprising letters, numbers, and hexadecimal digits — the latter being a positional system representing numbers using 16 distinct symbols. Saying that, those in the know appreciated the immediacy and simplicity of classic tracker software, if not necessarily those hexadecimal digits! One thing’s for sure, though: tracker software has exerted its influence on modern electronic music with influential IDM (Intelligent Dance Music) artists like (Aphex Twin alias) AFX, (Polish-American) Bogdan Raczyński, Brothomstates (a.k.a. Lassi Nikk, Finnish composer), Machinedrum (a.k.a. Travis Stewart, American electronic music producer), and Venetian Snares (a.k.a. Aaron Funk, Canadian electronic musician), to namecheck but several so-called ‘demo scene’ movers and shakers skilfully orbiting around those tricky trackers. That said, some might say that trackers need not be so tricky in this day and age. And it is this thinking that led to Polyend’s trailblazing Tracker.

The timely arrival of the aptly-named Tracker puts Polyend in pole position for blazing a new trail, tooled to take the tracker concept to a new level of innovative, inspirational, and immediate music-making by effectively extracting the best bits of yesteryear’s tricky tracker software classics and rebooting them with forward-looking functionality as the world’s first hardware tracker. Thankfully, Tracker waves goodbye to hexadecimal hysterics — not only did those entering the brave new world of classic trackers not necessarily know what those values actually represented, they could not see what was affected by them. Thinking inside its beautifully-engineered box, Tracker instead implements a simplified system of readable decimals that also shows the effects parameters when those decimals are entered in a frenzied fast track to creativity.

Tracker takes the quintessential characteristics of a classic tracker — the vertical timeline, powerful sequencer, and mechanical keyboard — and cleverly combines them with a newly-designed input interface, divided into several sections: a (high resolution, crisp, and bright) big screen and associated screen keys — mechanical controls that always correspond to what is displayed on the screen directly above them; the grid — featuring 48 backlit multifunctional silicon pads for quick note and pattern value entry and visual feedback (while also acting as a highly-customisable keyboard controller with editable scales); function keys — for fast and responsive control over all functions and options; plus navigation keys and associated (metal-manufactured) jog-wheel (with haptic feedback for fast scrolling or precise adjustments) — for facilitating transport control alongside arrow keys for navigation control, as well as dedicated Insert, Copy/Paste, Delete/Backspace, and Shift keys. All are at hand, helping to streamline making and performing music in a new and innovative way — without having to leave the world’s first hardware tracker, deftly designed as an easy-to-use compact standalone workstation with immediacy and simplicity at its creative core, and aiding artists with forging unique avenues of sonic construction to boot. Better still, the classic tracker look of that dominating (default) screen — showing (up to) 48 instruments and 256 patterns with a maximum of 128 steps per pattern per project — belies an infinite source of inspiration. Indeed, Tracker comes complete with a wide variety of onboard sound design tools to enhance creativity still further for those wishing to take it to the limit. Let loose with Instrument — a chain of tools (Volume, Tuning, Panning, Filters, Reverb Send, and ADSRs) to make an instrument from any sample; Sampler — choose from different (1-shot, Forward, Backward, and Ping-Pong) play modes; Slicer — slice samples manually, or let Tracker take care of it ‘automagically’ at any time; Wavetable — full-blown wavetable synthesis with variable table length to make it compatible with the most popular (Ableton Wave and Serum) standards; Granular — single grain yet very powerful granular synthesis to create crazy and futuristic sounds from old and boring samples; Sample Editor — built-in precise offline rendering sample editor with multiple effects; and Sample Recorder — records up to two minutes of 16-bit/44.1kHz samples using built-in Radio, Pattern selection, Mic or Line In inputs, all of which can be saved to the included (16GB) MicroSD card for later use or loaded directly into a project. Put it this way: with Tracker, users can quickly and easily use existing sample libraries, record new ones, or use the built-in FM (Frequency Modulation) radio. Record samples, play them, slice them, mash them, or even make a synth out of them!