#mining equipment industry

Explore tagged Tumblr posts

Text

𝕿𝖍𝖊 𝖊𝖆𝖗𝖙𝖍 𝖜𝖎𝖑𝖑 𝖙𝖆𝖐𝖊 𝖇𝖆𝖈𝖐 𝖜𝖍𝖆𝖙'𝖘 𝖍𝖊𝖗𝖘 𓂍

#abandoned#urbex#pnw gothic#pnw photography#junkyard#vines#brambles#crane#industrial#exploration#fog#foggy#pully#equipment#americana#american gothic#industrial gothic#creepy#deserted#decay#decaying#urban decay#post apocalyptic#post apocalypse#mine#my pics#my photos#photography

18 notes

·

View notes

Text

Liebherr 966 crawler excavator

#heavy industry#heavy equipment#excavator#machines#machinery#vehicle#construction#mining#bucket excavator

18 notes

·

View notes

Text

#business#branding#industrial pumps#pumps#oil & gas industry#food industry#mining equipment#chemical industry#biogas#beverage industry

2 notes

·

View notes

Text

Mining is a highly complex and heavy-duty process that requires reliable and high-performance equipment. Component suppliers specialize in delivering the essential machinery and tools required in various stages of the mining process.

We are reliable Mining Spare Parts Suppliers, offering high-quality, durable components to ensure efficient mining operations. Our extensive range includes wear-resistant and precision-engineered parts, tailored to meet industry standards and enhance the performance of your mining equipment.

Visit:- https://www.rpalloys.com/lq-project/mining-minerals/

#Mining Minerals Industry Component Suppliers#Mining Spare Parts Suppliers#Rpalloys#Mining Equipment Spare Parts#Construction Machinery Parts

0 notes

Text

Exploring Essential Tools and Services Provided by Construction and Mining Equipment Manufacturers

The leading construction and mining equipment manufacturers offer specialised mining and engineering services, which form the basis of the mining and diverse engineering sectors. The best 2D or 3D design solution may be offered by the leading manufacturers of components for various machines with engineering design expertise. The design of mechanical components involves several elements, such as both static and dynamic analysis. The best companies in this industry are adept at producing the best 2D and 3D models utilising CAD software and other technologies.

Examples of extremely important engineering services that are needed in practically any industry that is engaged in manufacturing, etc. include welding and fabrication and similarly important products like industrial pin bushes are also manufactured by leading brands. The top businesses are capable of structural welding as well as welding other machine parts. The top businesses are capable of performing a wide range of welding processes, including arc, TIG, and MIG. Precise quality control is necessary because industrial welding tasks require precision.

The leading companies provide mining and engineering equipment, such as manifold blocks, concrete pumps, and heavy fabrication, in addition to software. Bespoke components are often requested by engineering-related enterprises, necessitating the involvement of specialised organisations with the necessary design and development capabilities. Complex mechanical assembly or production lines are also necessary for many modern enterprises, and leading engineering firms are able to create such products effectively. Similar to this, hydraulics is another essential component of engineering solutions, and the top firms providing engineering solutions are capable of doing bespoke hydraulic power unit installation, hydraulic engineer design, etc.

No matter how big or little, electrical systems are present in every industry. The best firms with electrical engineering expertise not only design electrical systems but also offer installation, maintenance, and troubleshooting—all essential services. Well-established businesses employ trained and qualified workers who follow safety protocols.

Contact the leading suppliers of engineering services, buy products from their catalogues, or request specialised engineering services to develop the right tools or capabilities for your company.

Source

0 notes

Text

Karflo Corporation G2-GE Industrial Beamdrill

Source: The Essential Guide to Weapons and Technology (Del Rey, 1997)

#star wars#general equipment#mining technology#karflo#g2-ge#g2-ge industrial beamdrill#industrial beamdrill#beamdrill#essential guide to weapons and technology#essential guides

1 note

·

View note

Text

Commodity Trading Software

Robo-Soft provides advanced Commodity Trading Software designed to streamline trade management, enhance market analysis, and improve decision-making. With real-time data, risk management tools, and seamless integration, our software helps traders optimize their strategies and boost profitability in the commodity markets.

Visit us for more details: https://www.scribd.com/document/799240729/Best-Software-for-Commodity-Trading

#Oil and Gas Industry#Robo-Soft Trading#Metal Trading#Agro Commodities#Energy Sector#Solutions#Petroleum Products#Oil Trading#Gas Supply Chain#Metal and Mining#gricultural Products Trading#Oilfield Equipment#Natural Resources#Energy Commodities#Metal Distribution#Agro Industry Trading

0 notes

Text

Streamlining Your Workflow with Advanced Stone Crusher Plants

A stone crusher plant is more than just an arrangement of crushing machines; it’s a highly efficient system designed to process raw materials like rocks and gravel into usable aggregates. For businesses in construction, road building, or mining, streamlining workflows with advanced stone crusher plants can significantly enhance productivity and cost efficiency. This article explores how modern stone crusher plants(plantas chancadoras de piedra), including gravel crusher solutions, optimize operations and boost overall efficiency.

The Role of Stone Crusher Plants in Workflow Optimization

Understanding Stone Crusher Plants

A stone crusher plant is a facility that uses crushers and supporting equipment to break down large rocks into smaller, usable materials. These materials, such as gravel, are essential for infrastructure projects, including road construction, building foundations, and landscaping.

Why Streamline Workflows?

Streamlined workflows reduce downtime, improve efficiency, and ensure higher productivity. By investing in advanced equipment and adopting smart systems, businesses can save time and resources while meeting project deadlines.

Key Features of Advanced Stone Crusher Plants

Integrated Crushing Systems

Modern stone crusher plants combine multiple crushing stages into one streamlined system.

Primary Crushers: Handle large rocks and break them into smaller pieces.

Secondary and Tertiary Crushers: Refine materials into desired sizes for specific applications.

Automation and Smart Controls

Advanced plants often feature automated systems that monitor and control operations in real time.

IoT Sensors: Provide live updates on machine performance and material flow.

Automated Adjustments: Allow the plant to adapt to changing requirements without manual intervention.

High-Efficiency Gravel Crushers

Specialized gravel crushers(trituradoras de piedra para grava) enhance the ability to process and shape materials for road construction, landscaping, and other applications.

Impact Crushers: Ideal for creating uniformly sized gravel.

Cone Crushers: Ensure high throughput with precision.

How Advanced Stone Crusher Plants Streamline Workflows

Reduced Material Handling

By integrating conveyors and screens, modern plants minimize manual material handling.

Conveyors: Transport materials seamlessly between crushing stages.

Screens: Sort materials by size, reducing unnecessary processing steps.

Faster Processing Times

Automated systems ensure consistent material flow and faster processing, allowing businesses to meet tight deadlines without compromising quality.

Energy Efficiency

Innovative designs and energy-efficient motors reduce power consumption, lowering operational costs while maintaining high productivity.

Customization and Scalability

Tailored Plant Designs

Every project has unique requirements, and advanced stone crusher plants can be customized accordingly.

Capacity Adjustments: Scale operations up or down based on project demands.

Material-Specific Crushers: Choose equipment that best suits the type of rock or gravel being processed.

Modular Components

Modular designs allow businesses to expand or modify their plants as needed, ensuring long-term flexibility.

Maintenance and Long-Term Efficiency

Simplified Maintenance

Advanced plants are designed for easier maintenance, reducing downtime and repair costs.

Accessible Components: Ensure quicker replacements for wear parts.

Predictive Maintenance Systems: Use IoT to detect potential issues before they lead to breakdowns.

Long-Term Benefits

Investing in advanced stone crusher plants pays off with consistent performance, reduced operational costs, and higher ROI.

youtube

Applications of Stone Crusher Plants and Gravel Crushers

Road Construction

Crushed gravel is essential for creating durable road bases, and gravel crushers in a stone crusher plant ensure a steady supply of high-quality materials.

Building Foundations

Aggregates produced by stone crusher plants are critical for strong and stable building foundations.

Landscaping and Decorative Projects

Gravel and other crushed materials are used in landscaping to create pathways, driveways, and aesthetic outdoor spaces.

Conclusion

Streamlining your workflow with an advanced stone crusher plant, including specialized gravel crushers, can transform how you manage material processing. From faster processing and reduced material handling to energy efficiency and scalability, modern plants offer numerous advantages that boost productivity and profitability. By adopting these advanced systems, businesses can achieve more efficient operations and deliver higher-quality results for a wide range of projects.

#machinery#machinelearning#construction#mining#equipments#aimix#aimixgroup#industries#manufacturer#Youtube

0 notes

Text

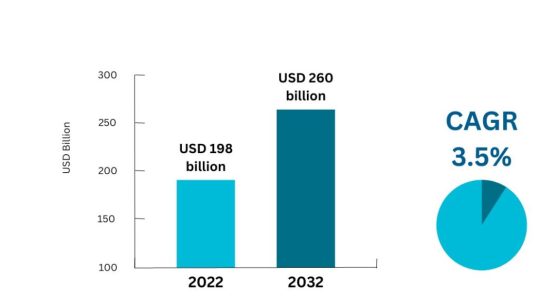

Innovative Approaches to Heavy Mining Equipment Procurement Intelligence

The heavy mining equipment category is anticipated to grow at a CAGR of 3.5% from 2023 to 2030. The category accounts for around 50% to 60% of the overall mining equipment industry. The constantly expanding mining activities in the Asia Pacific region dominates the category. The region is benefiting from high demand for metals and minerals across a range of sectors globally. The mining industry, being one of the foundational sectors of the economy, supports the category growth. Power and cement industries helped the category to thrive due to the rapid expansion of infrastructure. Other major demand drivers are an increase in the rising need for mineral fertilizers to improve agricultural yield, road construction projects, and the use of technology and automation in road construction and mining.

Larger projects require complex, efficient machinery for better efficiency and safety, which is driving the category's expansion. The demand is increasing as a result of the government's significant investments in infrastructural improvements and mining industry reforms. For instance, in the first half of 2023, Chinese investments and fresh agreements in the mining and metals industry reached more than USD 10 billion, representing a 131% increase over the same time in 2022. India, another major country, amended the Mines and Minerals (Regulation and Development) Amendment Act with the goal of streamlining regulations to boost industry participation, freeing up 500 potential mining sites, and encouraging the use of cutting-edge technologies to improve sustainability.

The rise in the development of autonomous heavy mining vehicles is driving the need to organize numerous amounts of cables and wires within the vehicles. Each vehicle contains sensors, cameras, and other connectors. As a result, such wiring needs a heavy equipment cable harness that ensures that electronic circuits perform as designed. Moreover, advancements in technology have led to the development of automatic power crushers. These crushers include hydraulic clamping machinery and spring release system designs. Spring release systems, particularly in cone crushers, establish a protective barrier between the machinery and residual materials. Advancements in clamping technology now enable increased crush-down capacity, facilitating the smooth transition of medium-grade feed from the primary to the secondary crusher.

Order your copy of the Heavy Mining Equipment Procurement Intelligence Report, 2023 - 2030, published by Grand View Research, to get more details regarding day one, quick wins, portfolio analysis, key negotiation strategies of key suppliers, and low-cost/best-cost sourcing analysis

Tools and equipment that are both technologically advanced and environmentally conscious are in higher demand as a result of rising pressure from sustainability goals. Prospects for industry participants to expand and become more efficient are being presented by the increasing adoption and implementation of artificial intelligence (AI) and machine learning (ML) in mining processes. In order to embrace sustainability, a number of developing nations are integrating hybrid technology into the production of mining equipment. In addition, to increase operational efficiency, the industry has also witnessed a large uptake of other technology clusters such as robotics & automation, smart sensors, and 3D printing. A contract for a fleet of zero-emission vehicles was signed between Nouveau Monde Graphite (NMG), a Canadian battery and auto manufacturer, and Caterpillar in April 2023. For NMG's Matawinie Mine, the latter would create an integrated solution that includes a fleet, infrastructure, and services with zero exhaust emissions. The partnership was anticipated to aid NMG's switch from conventional models to Cat machines with zero exhaust emissions.

The category is highly fragmented, given the ongoing growth of digitalization and automation, technology has become a key differentiator for the firms operating in this category. The primary players are concentrating on lowering the extraction and heavy equipment maintenance costs by using cost-reducing innovations. Other large-scale industries are acquiring new technologies embedded in the heavy machinery and equipment that they use regularly to increase efficiency and reduce costs in production, processing, and delivery. As mining operations expand globally, companies compete to establish a strong presence in various regions by tailoring their equipment to suit specific geographic and geological conditions. Some companies collaborate or form partnerships to combine expertise and resources, aiming to develop more comprehensive and advanced mining solutions.

When determining the category cost, there are a number of factors to take into consideration such as ownership costs, fixed expenses, machine costs, insurance, and taxes. Additional expenses that occasionally fall under the fixed category include the cost of a spare parts inventory, special tools required for operation or maintenance, and structures required to house the machine. Another expense is variable cost, which only appears while a machine is in use. Some of these are consumables, routine maintenance supplies (such as engine oil and filters), energy (such as fuel or electricity), and repair charges. An essential expense is the time value of maintenance and repairs. Maintenance costs of heavy mining machinery are significantly high. Most machines' total maintenance and repair expenses during their lifetimes are likely to be equal to 75% of the new machine's cost. For instance, heavy-duty hydraulic mining can price around anywhere between USD 950,000 - USD 1,650,000. Another important tool - a multipurpose dredger for sand pumping, prices for which, can range between USD 360,000 - 450,000.

Selecting the appropriate heavy mining machinery is necessary for significantly improving production quality, project efficiency, cost savings, profitability, and safety at any job site. When sourcing the category, it is important to seek for quality of the machinery, horsepower, weight handling capacity, the cost of the equipment, and the experience of the suppliers. Asia Pacific (APAC) is the region with the biggest revenue in the market for heavy construction and mining equipment due to the region's expanding population and the resulting need for considerable building expenditure.

Heavy Mining Equipment Procurement Intelligence Report Scope

• Heavy Mining Equipment Category Growth Rate: CAGR 3.5% from 2023 to 2030

• Pricing growth Outlook: 4% - 5% (annual)

• Pricing Models: Spot pricing, Fixed pricing, Contract Pricing, Competition based pricing

• Supplier Selection Scope: Cost and pricing, Past engagements, Vendor evaluation, Supply chain and Logistics

• Supplier selection criteria: Service Support, Cost & Pricing, Project Efficiency, Transportation and Handling, Technical Specifications, Operational Capabilities, Regulatory Standards and Mandates, Innovations, and Others.

• Report Coverage: Revenue forecast, supplier ranking, supplier matrix, emerging technology, pricing models, cost structure, competitive landscape, growth factors, trends, engagement, and operating model

Browse through Grand View Research’s collection of procurement intelligence studies:

• Drilling Equipment & Consumables Procurement Intelligence Report, 2023 - 2030 (Revenue Forecast, Supplier Ranking & Matrix, Emerging Technologies, Pricing Models, Cost Structure, Engagement & Operating Model, Competitive Landscape)

• Industrial Motor Procurement Intelligence Report, 2023 - 2030 (Revenue Forecast, Supplier Ranking & Matrix, Emerging Technologies, Pricing Models, Cost Structure, Engagement & Operating Model, Competitive Landscape)

Key companies profiled

• Epiroc, Boart Long year Ltd

• Caterpillar Inc

• China Coal Energy Group Co. Ltd

• Vipeak Mining Machinery Co. Ltd

• Guangdong Leimeng Intelligent Equipment Group Co. Ltd

• Henan Baichy Machinery Equipment Co. Ltd

• Komatsu Ltd

• Liebherr

• Metso Qutotec

Brief about Pipeline by Grand View Research:

A smart and effective supply chain is essential for growth in any organization. Pipeline division at Grand View Research provides detailed insights on every aspect of supply chain, which helps in efficient procurement decisions.

Our services include (not limited to):

• Market Intelligence involving – market size and forecast, growth factors, and driving trends

• Price and Cost Intelligence – pricing models adopted for the category, total cost of ownerships

• Supplier Intelligence – rich insight on supplier landscape, and identifies suppliers who are dominating, emerging, lounging, and specializing

• Sourcing / Procurement Intelligence – best practices followed in the industry, identifying standard KPIs and SLAs, peer analysis, negotiation strategies to be utilized with the suppliers, and best suited countries for sourcing to minimize supply chain disruptions

#Heavy Mining Equipment Procurement Intelligence#Heavy Mining Equipment Procurement#Heavy Procurement Intelligence#Heavy Mining Equipment Market#Heavy Mining Equipment Industry

0 notes

Text

#mining industry pump manufacturer india#mining pump supplier india#mining pump exporter india#pumps for mining industry#mining equipment pump solutions india#industrial pumps for mining india#high-performance mining pumps#mining pump supplier and exporter india#bulk pumps for mining industry india#custom mining pumps india#mining industry pump exporter

0 notes

Text

The Smart Way to Source Surplus Materials for Oil & Mining Projects

Unlock cost savings on oil & mining projects! Find premium surplus materials easily with our smart sourcing solutions. Maximize efficiency now!

0 notes

Text

— Tunnels

view along the Ohio River

1 note

·

View note

Text

Geosight makes borehole deviation measurement easy in mining

In the world of underground mining, accuracy is paramount. That's why we at Geosight are proud to offer advanced borehole deviation measurement solutions tailored to the mining industry. Our cutting-edge technology enables precise and detailed measurements of borehole trajectories, allowing mining professionals to navigate the underground landscape with confidence and precision. Geosight's drilling deviation meters help you optimize drilling operations, minimize waste and maximize resource extraction. Backed by experience and expertise, Geosight is a trusted partner to mining companies looking to improve the efficiency and safety of their operations. Our commitment to innovation and reliability ensures that our downhole displacement measurement solutions meet the highest standards of quality and performance. Don't leave accuracy to chance - trust Geosight for all your borehole deviation measurement needs in underground mining. Contact us today to learn more about our innovative solutions and how they can benefit your mining operations.

#borehole deviation measurement#borehole deviation#industrial equipment#mining equipment#mining#canada#drill hole deviation

0 notes

Text

Because of Bitcoin ‘Halving’, Outdated Mining PCs from US Migrate Abroad - Technology Org

New Post has been published on https://thedigitalinsider.com/because-of-bitcoin-halving-outdated-mining-pcs-from-us-migrate-abroad-technology-org/

Because of Bitcoin ‘Halving’, Outdated Mining PCs from US Migrate Abroad - Technology Org

The Bitcoin “halving” event is driving the relocation of outdated US mining computers overseas.

The process of ‘mining’ new bitcoins requires a lot of computational power and needs energy. Image credit: BenjaminNelan via Pixabay, free license

In Bitcoin mining, specialized machines are utilized to validate transactions on the blockchain and earn operators fixed token rewards. Approximately 6,000 older Bitcoin mining machines in the US are slated to be decommissioned and transported to a warehouse in Colorado Springs. There, they will undergo refurbishment and be sold to buyers abroad seeking to capitalize on mining opportunities in more cost-effective environments.

These machines, among several hundred thousand expected, are being refurbished in anticipation of a significant quadrennial update in the Bitcoin blockchain, known as the halving event. Scheduled for late April, this event will reduce the reward that serves as the primary revenue source for miners. To mitigate the impact, miners are upgrading to the latest and most efficient technology.

Given that electricity constitutes the largest expense in mining operations, companies are compelled to seek lower-cost alternatives to maintain profitability. While older computers may still yield profits, they are unlikely to do so within the US market. Experts note that this trend represents a natural migration, with buyers of older machines situated in regions where power costs are minimal.

The concept of halving, integrated by the anonymous Bitcoin creator Satoshi Nakamoto, occurs once every four years to uphold the hard cap of 21 million tokens. The upcoming halving event, the fourth since 2012, will reduce the reward from 6.25 Bitcoin to 3.125 Bitcoin. Despite Bitcoin’s remarkable 50% surge this year to approximately $63,500, the impending halving has heightened the urgency to bring more efficient machines online.

As the halving approaches, the continued use of older equipment poses a risk of electricity costs surpassing mining revenue. While models like the S19 series may no longer be profitable to operate in the US post-halving, they can still yield substantial profits and enjoy an extended operational lifespan when hosted in regions such as Africa.

Some buyers are delaying their purchase of older computers until after the halving event, anticipating further price drops. For example, the cost of used S19 models was approximately $7,030 in March 2022. However, a year later, amidst declining Bitcoin prices, the price plummeted to about $900, further decreasing to approximately $427 this month. The price is projected to drop to around $356 in May, following the halving event.

In response to these price fluctuations, some miners in the US have opted not to sell their hardware but instead, plan to relocate the equipment to regions with lower electricity costs and third-party data centers.

However, not all mining equipment from the US is relocated abroad. Publicly traded companies face challenges in this regard due to the need to consider risk-averse shareholders and concerns regarding transportation costs, equipment breakage, and security.

These machines remain inactive for extended periods, collecting dust, yet companies retain them because they can still yield profits when Bitcoin prices surge, underscoring the cyclical nature of profitability in the mining industry.

Written by Alius Noreika

#000#2022#Africa#Authored post#bitcoin#Blockchain#Companies#computers#cryptocurrency#data#Data Centers#dust#electricity#energy#equipment#Fintech news#Hardware#Hardware & gadgets#impact#Industry#mining#natural#nature#plan#power#price#process#refurbished#relocation#Revenue

0 notes

Text

Mining Spare Parts Suppliers

The mining industry operates in challenging environments, requiring durable and reliable equipment to ensure smooth and efficient operations. Suppliers of mining spare parts play a vital role in maintaining the productivity and safety of mining operations. These suppliers provide high-quality components and solutions tailored to the needs of the mining minerals industry.

Importance of Mining Spare Parts

Mining equipment often operates under extreme conditions, including high pressure, heavy loads, and harsh weather environments. The wear and tear on machinery is inevitable, making regular maintenance and timely replacement of parts crucial. Spare parts suppliers ensure the availability of critical components such as drill bits, conveyor belts, crushers, pumps, and more. Their role is essential to minimize downtime and reduce operational costs, which is critical for achieving optimal profitability in mining operations.

Key Offerings by Mining Spare Parts Suppliers

Suppliers provide a wide range of components designed to meet the needs of various mining applications. These parts are sourced or manufactured to adhere to industry standards and ensure compatibility with major equipment brands. Key products include:

Crushing and Screening Components: Parts like jaw plates, liners, and hammers are vital for breaking down raw materials efficiently.

Conveyor System Parts: Conveyor belts, rollers, and drive systems ensure smooth material transport within the mine.

Hydraulic Components: Hoses, pumps, and valves are critical for maintaining equipment functionality.

Wear-Resistant Parts: Specialized parts with wear-resistant properties, such as alloy steel or ceramic coatings, enhance the lifespan of machinery operating in abrasive conditions.

Benefits of Reliable Spare Parts Suppliers

Partnering with trusted suppliers brings several advantages. First, high-quality spare parts enhance the performance and reliability of mining equipment, reducing the risk of unexpected failures. Second, efficient supply chains ensure timely delivery, avoiding costly downtime. Additionally, many suppliers offer tailored solutions, including custom manufacturing, to meet specific operational requirements.

Future Trends in Mining Spare Parts

As the mining industry evolves, the demand for innovative spare parts is increasing. Technological advancements, such as 3D printing, are enabling faster production of custom components. Additionally, the focus on sustainability is driving the development of eco-friendly materials and energy-efficient equipment components.

In conclusion, mining spare parts suppliers are indispensable to the mining minerals industry, providing the essential components needed to sustain productivity and operational efficiency. Their expertise and commitment to quality contribute significantly to the success of mining operations worldwide.

#Mining Minerals Industry Component Suppliers#Mining Spare Parts Suppliers#Rpalloys#Mining Equipment Spare Parts#Construction Machinery Parts

0 notes

Text

Unveiling The Gold Mining Market: Trends, Insights, And Key Players

Introduction

Gold mining is a critical sector in the global economy, driven by the enduring value and demand for gold as a precious metal. This article delves into the dynamics of the Gold Mining Market, exploring its trends, growth drivers, challenges, and key players shaping the industry landscape.

Understanding the Gold Mining Market

Gold mining involves the extraction of gold from the earth's crust through various methods, including surface mining, underground mining, and placer mining. Gold has been prized for centuries for its intrinsic value, serving as a store of wealth, a hedge against economic uncertainty, and a component of luxury goods and jewelry.

Gold Mining Market Research Reports

Market research reports provide valuable insights into the gold mining industry, offering analyses of market trends, production statistics, exploration activities, and regulatory developments. These reports assist investors, mining companies, and policymakers in making informed decisions regarding investment, expansion, and policy formulation.

Gold Mining Market Size

The global gold mining market is substantial, with billions of dollars invested annually in exploration, development, and production. According to recent data, The global gold mining industry was valued at approximately USD 353 billion in 2020. Gold production totaled over 3,000 metric tons in the same year, with major gold-producing countries including China, Australia, Russia, and the United States.

The market size is expected to grow steadily in the coming years, driven by factors such as increasing demand for gold in jewelry, investment, and technology sectors.

Gold Mining Market Trends

Several trends are shaping the gold mining market, including:

Technological Innovation: Advances in mining technologies, such as automation, artificial intelligence, and data analytics, are enhancing efficiency, safety, and productivity in gold mining operations. Innovative extraction methods and processing techniques are also improving recovery rates and reducing environmental impacts.

Sustainable Practices: There is a growing emphasis on sustainable mining practices in the gold mining industry. Companies are increasingly adopting eco-friendly technologies, implementing biodiversity conservation measures, and engaging with local communities to ensure responsible mining operations.

Exploration and Discovery: Despite being a mature industry, gold mining continues to benefit from ongoing exploration efforts aimed at discovering new gold deposits. Remote sensing technologies, geological modeling, and geochemical analysis are facilitating the identification of prospective areas for gold exploration.

Gold Mining Market Growth

The gold mining market is experiencing steady growth, driven by factors such as:

Safe-Haven Demand: Gold is often perceived as a safe-haven asset during times of economic uncertainty, geopolitical tensions, and currency fluctuations. As a result, demand for gold tends to increase during periods of market volatility, supporting the growth of the gold mining industry.

Investment Demand: Gold serves as an attractive investment option, offering diversification benefits and hedging against inflation and currency devaluation. Institutional investors, central banks, and retail investors allocate significant capital to gold-backed exchange-traded funds (ETFs), physical gold holdings, and gold mining equities, driving demand for gold and stimulating mining activities.

Gold Mining Market Challenges

Despite its growth prospects, the gold mining industry faces several challenges, including:

Environmental Regulations: Gold mining operations have significant environmental impacts, including habitat destruction, water pollution, and land degradation. Regulatory requirements related to environmental protection, biodiversity conservation, and mine closure are becoming increasingly stringent, posing compliance challenges and increasing operational costs for mining companies.

Cost Pressures: Rising production costs, labor shortages, and fluctuations in energy and commodity prices can exert pressure on the profitability of gold mining operations. Companies must optimize their operations, implement cost-saving measures, and invest in technological innovation to remain competitive in a challenging operating environment.

Social License to Operate: Community relations and stakeholder engagement are critical for obtaining and maintaining a social license to operate in the gold mining industry. Companies must address social and cultural concerns, respect indigenous rights, and mitigate social and environmental impacts to secure community support and regulatory approvals for their mining projects.

Key Players in the Gold Mining Market

The Gold Mining Market is dominated by several major players, including:

Newmont Corporation: Newmont is one of the world's largest gold mining companies, with operations in multiple countries and a diverse portfolio of gold assets.

Barrick Gold Corporation: Barrick Gold is a leading gold producer, with mines located in North and South America, Africa, and the Asia-Pacific region.

AngloGold Ashanti Limited: AngloGold Ashanti is a global gold mining company, with operations in Africa, the Americas, and Australia.

Polyus PJSC: Polyus is the largest gold producer in Russia and one of the top gold mining companies globally, with significant reserves and production capacity.

Kinross Gold Corporation: Kinross Gold operates mines in North and South America, West Africa, and Russia, producing gold and silver.

These key players leverage their operational expertise, financial resources, and exploration capabilities to maintain their competitive positions in the global gold mining market.

Conclusion

The gold mining market remains a vital component of the global economy, driven by enduring demand for gold across various sectors. Despite facing challenges such as environmental regulations and cost pressures, the industry continues to grow, supported by technological innovation, investment demand, and exploration efforts. As the industry evolves, collaboration, sustainability, and responsible mining practices will be essential for ensuring the long-term viability and success of the gold mining sector.

#Gold Mining Industry#Global Gold Mining Market#Gold Mining Market Analysis#Gold Mining Market Growth#Gold Mining Market Share#Gold Mining Market Size#Gold Mining Companies in India#Gold Mining Companies#Gold Mining in Alaska#Gold Mining Equipment#Gold Mining Tools#Gold Mining Industry Research Reports#Gold Mining Market Challenges#Gold Mining Market Research Reports#Gold Mining Market Emerging Trends#Gold Mining Market Outlook#Gold Mining Market Major Players

0 notes