#metalindustrial

Explore tagged Tumblr posts

Text

youtube

We have finished recording a new track, we present our version of the song 'Blinded by Fear' by the Swedish masters of melodic death metal. The track is available on our YouTube, Instagram, Vimeo, SoundCloud, and as a free download on our Bandcamp profile.

#melodic death metal#melodeath#cyber metal#melodic metal#melodicdeathmetalmusic#industrialdeathmetal#melodeathmusic#melodeathmetal#atthegates#metalcover#symphonicdeathmetal#symphonicmelodicdeathmetal#epicmelodicdeathmetal#deathmetalmelodico#atthegatesband#atmosphericdeathmetal#metalcovers#melodicdeathmetal#melodicdeath#symphonicdeath#deathmetalindustrial#newmetalrelease#newmetalmusic#gothicdeathmetal#epicmetal#deathmetalmelodic#industrialmetal#metalindustrial#Youtube

5 notes

·

View notes

Text

#tumblr cannot stop me from posting the entire photoshoot#digital art#fashion#fashion illustration#illustration#calligraphy#design#artwork#sketchbook#sewing#metalindustry

4 notes

·

View notes

Text

Are you looking to secure your investment with top-quality tools, die, and mold steel?

Look no further! We offer a wide selection of imported and highest quality steel to meet your needs. Get in touch with us today to place your requirement!

Our commitment to maintaining a high level of inventory from world-renowned manufacturers, such as Swiss Steel Group (DEW), Nippon Koshuha Steels Co. Ltd, Hyundai Steel, SeAH Besteel Corp and many more. This ensures that our customers receive only the best quality products that meet international standards.

VIRAT SPECIAL STEELS PVT. LIMITED , INDIA is one of India’s top Tool Steel, Die Steel suppliers, and Mold Steel Stuckists. This company provides special steel of every kind in sizes and shapes (flat, round, or bars) per customer requirements. Based in Gurgaon (Haryana) & Ludhiana (Punjab) India.

Product List

DIE STEEL ( HH 370 - 410 BHN ) DIN-1.2714 / AISI L6 )

HOT WORK STEELS (DIN 2343, 2344 / AISI H11, H13)

PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

ALLOY STEELS, EN-SERIES ETC.

Choose VIRAT SPECIAL STEELS for a seamless blend of quality, variety, and reliability in every steel grade.

Contact us today to buy the best quality DB6 / DIN 2714 steel for your tooling needs! https://www.viratsteels.com/din-2714.html

Virat Special Steels is the largest Supplier, Stockiest, Trader, Dealer, Importer and Exporter of Din 1.2714 Hot Work Tool Steels.

Any further queries feel free to contact us : 🌐https://www.viratsteels.com 📩[email protected] 📲+91-98140-21775

#2714steel#L6steel#DB6Steel#DIN2714#SteelTrades#SpecialSteel#viratspecialsteels#toolsteelsupplier#viratsteels#gurgaon#gurugram#pune#ludhiana#viral trends#viratsteelindia#viratsteelsindia#MetalIndustry

3 notes

·

View notes

Text

Jindal GI ERW Pipes: Durable and Reliable at the Best Prices

One of the significant advantages of Jindal GI ERW pipes is their compliance with industry standards. The company’s commitment to quality ensures that each pipe meets or exceeds national and international specifications. This attention to detail results in a product that not only performs well but also provides long-term reliability. Whether for construction, plumbing, or industrial applications, Jindal pipes are recognized for their strength and resistance to corrosion, making them a trustworthy choice for both small and large-scale projects.

For purchasing Jindal GI ERW pipes at competitive prices, check out Jindal GI ERW Pipe from Udhhyog.

Applications of GI ERW Pipes

GI ERW pipes have diverse applications across various sectors. In construction, these pipes are widely used for structural applications, such as scaffolding and support systems. Their strength and lightweight nature make them a preferred choice in building frameworks, where reliability is essential.

Additionally, GI ERW pipes are commonly employed in water transportation systems. They are used for both potable and non-potable water supply lines, ensuring that water is transported safely and efficiently. Their resistance to corrosion further enhances their longevity in such applications, making them a cost-effective solution.

In industrial settings, these pipes are often utilized for transporting various fluids, gases, and materials, highlighting their versatility and reliability in meeting the demands of different industries.

Udhhyog: The Best Supplier for Jindal GI ERW Pipes

Udhhyog is recognized as the go-to supplier for Jindal GI ERW pipes in India, thanks to its commitment to providing high-quality products at competitive prices. Udhhyog understands the unique needs of its customers, offering a streamlined procurement process that simplifies the buying experience.

With an extensive inventory of Jindal GI ERW pipes, Udhhyog ensures availability for projects of all sizes. Their focus on customer satisfaction means that clients can expect timely delivery and excellent service. Whether you're sourcing pipes for a large construction project or smaller installations, Udhhyog is dedicated to meeting your needs effectively.

By choosing Udhhyog, customers benefit from not only affordable pricing but also expert guidance in selecting the right products for their specific applications.

How to Ensure Correct Installation and Maintenance

Proper installation and maintenance of GI ERW pipes are crucial for ensuring their longevity and performance. Here are some practical tips:

Installation: Ensure that the pipes are installed by qualified professionals familiar with local building codes and regulations. Proper alignment and support are vital to prevent unnecessary stress on the pipes.

Handling: During installation, handle the pipes carefully to avoid damaging the protective coating. Scratches or dents can expose the underlying metal to corrosion.

Maintenance: Regular inspections should be conducted to check for signs of corrosion or damage. Keeping the pipes clean and free of debris helps maintain their integrity.

Protective Coating: Ensure that the protective coating is intact. If any damage occurs, reapply protective paint or coatings to prevent rust and corrosion.

By following these guidelines, you can help maintain the quality and performance of your Jindal GI ERW pipes, ensuring they serve your needs for years to come.

The Best MS ERW Pipe Supplier in India: Why Udhhyog Stands Out

What are MS ERW Pipes?

Mild Steel (MS) Electric Resistance Welded (ERW) pipes are a type of welded steel pipe that is manufactured using an electrical resistance welding process. During this process, steel strips are rolled into pipes and welded longitudinally using heat generated by the resistance to the electric current. This method results in strong, continuous welds, making MS ERW pipes a cost-effective and durable option for various applications.

The primary benefit of MS ERW pipes lies in their strength and affordability. Because they are made from mild steel, they offer excellent mechanical properties while being lightweight. Their versatility makes them suitable for numerous applications, including construction, water transportation, and industrial projects. With their cost-effective manufacturing process, MS ERW pipes provide a reliable solution for both small-scale and large-scale projects.

Applications of MS ERW Pipes

MS ERW pipes have a wide range of applications in various industries. In construction, they are commonly used for structural purposes, including scaffolding, support systems, and structural frameworks. Their strength and lightweight nature make them a popular choice among engineers and builders.

In the oil and gas sector, MS ERW pipes are often used for transporting fluids and gases. They provide an efficient means of transportation while ensuring safety and reliability in potentially hazardous environments. Additionally, these pipes are widely utilized in water transportation systems, providing a cost-effective solution for delivering potable and non-potable water.

The adaptability and strength of MS ERW pipes make them suitable for various applications, ensuring they meet the diverse needs of different industries.

Why Udhhyog is the Top MS ERW Pipe Supplier in India

When it comes to sourcing MS ERW pipes in India, Udhhyog stands out for several reasons. First and foremost, Udhhyog offers competitive pricing, making it an attractive option for businesses looking to manage costs without compromising on quality. Their extensive inventory of MS ERW pipes ensures that customers can find the right products for their specific needs.

Udhhyog is also known for its exceptional customer service. Their team is dedicated to helping customers navigate their purchasing decisions, providing expert advice and guidance on product selection. Additionally, Udhhyog supports bulk purchasing options, making it easier for businesses to acquire the quantities they need for larger projects.

With a focus on reliability and convenience, Udhhyog is committed to providing a seamless procurement experience for all customers.

#SteelPrices#Flanges#Pipes#PipeFittings#SteelSuppliers#SteelManufacturers#MetalIndustry#IndustrialSupplies#SteelMarket#SteelProducts#SteelTrade#SteelInfo#PipeIndustry#SteelUpdates

2 notes

·

View notes

Text

Procura LIGA DE AÇO, BARRAS BRILHANTES, EN-SERIES em na #europa #portugal e #espanha?

As ligas de aço são produzidas pela combinação de aço carbono com um ou mais elementos de liga, como manganês, silício, níquel, titânio, cobre, cromo e alumínio.Esses metais são adicionados para produzir propriedades específicas não encontradas no aço carbono comum.

Aplicativo : Indústria elétrica e de aparelhagem, indústria de fundição sob pressão, indústria aeroespacial etc…

Modo de Fornecimento: EDELSTAHL VIRAT IBÉRICA é o maior estoque e fornecedor de AÇO LIGA, BARRAS BRILHANTES, AÇO EN-SERIES para ferramentas de barra plana, quadrada e redonda. Nós fornecemos aço em todos os tamanhos de acordo com suas necessidades. Consulte nossa equipe que irá auxiliá-lo na consulta de LIGAS DE AÇO, BARRAS BRILHANTES.

PARA SABER MAIS >> https://moldsteel.eu/steel-products/alloy-and-en-series/

Bate-papo WhatsApp: +351-920016150 E-mail: [email protected]

#europe#porto#portugal#din2738#edelstashlviratibrica#viratsteels#oportunidades#empresas#agricultura#b2b#ENSeries#MetalTraders#AlloySteels#PlasticMouldSteels#MetalIndustry#espanha#ukraine#turkiye#turkish

2 notes

·

View notes

Text

2 notes

·

View notes

Text

Unlocking the Power of Silicon Manganese: Sarda Metals

Silicon manganese is a critical alloy used in various industries, each benefiting from its unique properties and versatility. Sarda Metals, a renowned producer and leading metals manufacturer in India, has been at the forefront of supplying high-quality silicon manganese for countless applications. In this article, we explore the diverse areas where silicon manganese makes a significant impact.

Electronics: Powering the Digital World

Silicon manganese is a key ingredient in the world of electronics. Its exceptional conductivity and durability make it an ideal component for semiconductors, transistors, and integrated circuits. These tiny yet powerful devices are the backbone of our digital world, driving everything from smartphones to computers.

Solar Panels: Harnessing Clean Energy

The renewable energy sector relies on silicon manganese for the production of solar panels. These panels use silicon as a semiconductor to convert sunlight into electricity efficiently. As the world shifts toward sustainable energy sources, silicon manganese plays a pivotal role in supporting this transition.

Construction: Building for the Future

In the construction industry, silicon manganese is used in high-strength materials such as silicones and sealants. These materials provide durability and weather resistance, making them invaluable for sealing structures against the elements.

Medical Devices: Precision and Biocompatibility

Silicon manganese-derived silicones find applications in the medical field. They are used in the production of biocompatible medical implants, such as breast implants and catheters, due to their non-reactive nature and flexibility.

Automotive Industry: Driving Innovation

The automotive sector benefits from silicon manganese in various components, including sensors, engine control units (ECUs), and tire pressure monitoring systems (TPMS). These components enhance vehicle performance, safety, and efficiency.

Aerospace: Soaring to New Heights

Silicon manganese-based materials are essential in aerospace applications, thanks to their lightweight and high-temperature resistance. They contribute to the construction of aircraft components and spacecraft, ensuring safe and efficient travel beyond our atmosphere.

Kitchenware: Enhancing Culinary Experiences

In the kitchen, silicon manganese-derived silicones are used to create non-stick cookware, baking molds, and kitchen utensils. Their heat resistance and non-reactive properties make cooking a breeze.

Glass Industry: A Clear Choice

Silicon dioxide (silica), derived from silicon, is a fundamental component in the glass manufacturing process. It enhances the transparency, strength, and heat resistance of glass products.

Chemical Industry: Catalyzing Innovation

Silicon compounds play a pivotal role in various chemical processes, acting as catalysts that drive the production of a wide array of products, ranging from plastics to pharmaceuticals.

But let's delve deeper into the world of silicon manganese, expertly manufactured by the industry leader, Sarda Metals, a renowned metals manufacturer in India. It's more than just an alloy; it stands as a catalyst for progress and innovation across a multitude of sectors. As we forge ahead in the realms of technology and environmental sustainability, silicon manganese emerges as a critical player in shaping our future.

Silicon manganese isn't merely an alloy—it's the very foundation upon which countless innovations are built. Join us in recognizing its profound significance as we strive to construct a brighter and more sustainable future together.

🏠 Address: 50-96-4/1, 2nd & 3rd Floor, Sri Gowri Nilayam, Seethammadhara NE, Visakhapatnam, Andhra Pradesh, 530013 - India.

📞 Phone: 9493549632

📧 Email: [email protected]

#SiliconManganese#SardaMetals#Metallurgy#Alloys#SteelProduction#IndustrialMaterials#Mining#MetalIndustry#RawMaterials#Manufacturing#Steel#Metals#Production#ManganeseAlloy#QualityMaterials#SustainableIndustry

3 notes

·

View notes

Text

Shim Manufacturers in India: A Growing Global Presence in Precision Engineering

India has emerged as a significant player in the global shim manufacturing industry. With advanced technology, a skilled workforce, and a commitment to innovation, shim manufacturers in India are producing high-quality products that cater to the diverse needs of industries worldwide. Whether it’s stainless steel shims, brass shim sheets, or shim sheet metal, India’s manufacturing sector is driving global growth and meeting increasing demand for precision components.

India’s Role in Shim ManufacturingIndian manufacturers are recognized for their competitive pricing, innovative solutions, and commitment to high standards. As global demand for precision components grows, Indian shim manufacturers cater to industries such as automotive, aerospace, and construction, providing essential components like stainless steel shims, brass shim sheet, and shim sheet metal.

Why Choose Shim Manufacturers in India?

Global Reach: Indian shim manufacturers export their products globally, ensuring that businesses across different regions have access to high-quality precut shims and other shim variants.

Innovative Solutions: Manufacturers in India are known for their continuous innovation in shim production. This includes the development of specialized products like SS shim plate and custom stainless steel shims to meet the specific needs of various industries.

Cost-Effective: India’s lower manufacturing costs provide a cost-effective solution for businesses worldwide. Despite the competitive pricing, Indian shim manufacturers maintain a high level of quality in their products, ensuring that brass shim sheets, precut shims, and other components are produced to international standards.

The Rise of Custom ShimsAlongside standard products like stainless steel shims, there has been a surge in demand for custom shim sheet metal products. These are made to meet precise specifications for industries requiring specialized materials, thicknesses, and sizes.ConclusionIndian shim manufacturers are at the forefront of providing high-quality, cost-effective solutions for industries globally. With a strong focus on innovation and precision, Indian manufacturers are shaping the future of shim production. By offering a range of products such as brass shim sheets, precut shims, and SS shim plates, they continue to meet the growing needs of industries around the world. Whether you require standard shims or customized solutions, shim manufacturers in India provide the expertise and quality you need.

0 notes

Text

We don’t just make the alloys we shape the perfection with every alloy. Contact us today and find the alloys as per your requirements.

See product details: https://snehmetals.com/our-products/

#Snehmetal#snehmetalalloys#brassrods#brassroundbars#metalindustry#jamnagar#brasspipes#metalproducts#manufacturers#suppliers#exporters#ingots#brassbillets#brassfittings#brassparts#brassproducts#brasscomponents#brasshollowrods#brassroundrod#Gujarat#india#extrusion

0 notes

Text

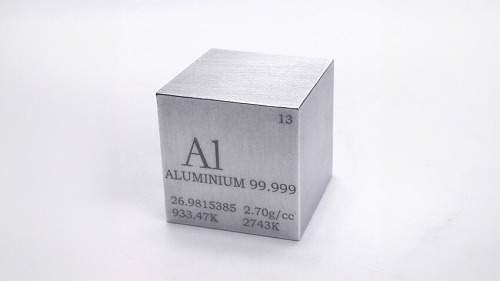

Comprehensive Aluminium Testing Solutions for the Metal Industry

Explore Aluminium testing solutions tailored for the metal industry's diverse needs across sectors like automotive, aerospace, and packaging. Learn about the role of Optical Emission Spectrometers (OES) in precise elemental analysis, quality control for alloys, and real-time feedback for melt compositions. Discover Metal Power's specialized OES models for fine wire, foil, and master alloy analysis, ensuring accuracy, cost efficiency, and enhanced productivity in Aluminium manufacturing and recycling.

If you want to get complete information related to this topic click HERE.

0 notes

Text

We are working on a new song, more info coming soon!

#melodic metal#gothic black metal#metal#dark metal#symphonic metal#gothic metal#industrial metal#industrial black metal#cyber metal#guitareffects#guitargear#guitarpedals#effectspedals#metalunderground#metalmusic#metalband#undergroundmetal#metalindustrial#melodeath#epic metal#heavymetal#heavymetalmusic#extremegothicmetal#atmosphericmetal#melancholic metal#underground music#industrial#dark#heavymusic#distortionpedal

3 notes

·

View notes

Text

Unlock the power of precision with our End Mill Grinder! Designed for cutting operations at various angles, it delivers smooth, accurate milling with enhanced performance. A cost-effective alternative to conventional mills, it enables the creation of intricate shapes and sharp edges on different materials, making it a must-have tool for industrial applications. Boost your productivity and take your milling process to the next level with this versatile and reliable device!

For more details, visit - https://www.yashmachine.com/product/drill-point-grinder/end-mill-grinder

0 notes

Text

Did you know about the Steel Facts? Steel is one of the most widely used materials in the world, found in everything from buildings and bridges to cars and household appliances. Steel is 100% recyclable without any loss of quality.

But what happens when steel products reach the end of their life cycle in all these applications?

Actually, it’s not the end. Indeed, for steel there is no end, as steel is 100% and infinitely recyclable without any loss of quality. The steel in end-of-life products can be melted down to be reused in the production of new steel.

This involves several stages:

Collection:

Sorting:

Shredding:

Melting and refining:

Casting and rolling:

The study delves into the value of reestablishing compositional information for steel recycling and sheds light on the dynamic nature of steel grades.

VIRAT SPECIAL STEELS PVT. LIMITED , INDIA, Your Trusted Partner in Special Steels. Explore a vast inventory of Die Blocks and Tool Steels sourced from renowned manufacturers worldwide…

Our Steel Yards boast a comprehensive inventory, including:

DIE STEEL ( HH 370 – 410 BHN ) (DB6 / DIN-1.2714 / AISI L6 )

HOT WORK STEELS (DIN 2343, 2344 / AISI H11, H13)

PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

COLD WORK STEELS – HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

ALLOY STEELS, EN-SERIES ETC.

Choose Virat Special Steels for your steel needs and experience the difference quality makes. Contact us today to learn more about our products and services!

Learn more : https://www.viratsteels.com/

Any further queries feel free to contact us : 📩[email protected] 📲+91-98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#SteelFacts#ToolSteel#DieSteels#MetalIndustry#HCHCr

2 notes

·

View notes

Text

Learn all about ferrous and non-ferrous metals, their properties, and common applications in this essential guide.

1 note

·

View note

Text

Wide range of ferrous and nonferrous coils in Dass Steel service| Vaughan, ON L4H 0S8 | +19054504303

At Dass Steel Service Centre, we proudly offer a wide range of ferrous and nonferrous coils, delivering quality and precision for all your metal needs!

#MetalSolutions#FerrousCoils#NonferrousCoils#QualityMetals#SteelServiceCenter#PrecisionEngineering#MetalIndustry#ConstructionMaterials#IndustrialSupplies

1 note

·

View note

Text

Aluminum Alloys Market Report: Understanding Size, Share, and Growth Trajectories

The global aluminum alloys market is expected to reach USD 340.12 billion by 2030, expanding at a CAGR of 6.2% from 2024 to 2030, according to a new report by Grand View Research, Inc. The increasing penetration of aluminum in the automotive industry is projected to benefit the market over the coming years.

For instance, in April 2024, Steel Strips Wheels announced that the company had successfully secured an order for aluminum wheels from one of the passenger car manufacturers in India. The company is expected to supply aluminum wheels along with steel wheels to the manufacturer. The company aims to remain committed to leveraging this opportunity to improve customer satisfaction and its automotive industry footprint.

The use of aluminum in different end use industries is increasing at a rapid pace owing to its advantages and less volatility in prices compared to its counterparts. The advantages of aluminum such as flexibility, formability, strength, durability, and lightweight nature have promoted the usage of aluminum alloys in different applications. Aluminum alloys are excellent materials for recycling and thus have a low carbon footprint compared to numerous materials.

Investment in aluminum casting facilities is anticipated to drive the demand for aluminum alloys over the forecast period. In May 2024, Hydro, a leading player in the aluminum industry announced an investment of USD 85 million for a new casting line for its recycling facility in Kentucky, U.S. This line is expected to start in 2026 with the production of high-quality automotive components. This new aluminum casting production line will have a capacity of 28,000 tons.

Aluminum alloys find applications in doors, windows, ceilings, wall panels, stairs, roof sheets, and many more. Investment in the construction industry along with new residential and commercial projects is anticipated to boost the demand for aluminum products and thus aluminum alloys. For instance, in June 2024, the Government of South Korea announced an investment of USD 19 billion for the construction of semiconductor parks, infrastructure development, and financial support for the semiconductor industry.

Packaging industry is projected to provide new opportunities for market vendors over the long term. For instance, in January 2024, Novelis Inc., a leading player in the aluminum industry value chain announced that the company had secured a new contract from Ardagh Metal Packaging USA Corp. Under this contract, Novelis will supply aluminum sheets for beverage packaging application. This was the third major contract for Novelis in less than seven months in beverage packaging of North America.

For More Details or Sample Copy please visit link @: Aluminum Alloys Market Report

Aluminum Alloys Market Report Highlights

Based on end use, the automotive & transportation segment dominated the market with a share of over 26% in 2023 and is anticipated to maintain its position over the forecast period. The sluggish but positive movement of real estate in developing countries is expected to benefit the market growth.

The focus on improving the fuel efficiency of vehicles is projected to play a key role in the expansion of the market. The use of aluminum components in vehicles significantly reduced the weight of vehicles, thus improving fuel efficiency.

Packaging end use segment is poised to grow at lucrative CAGR from 2024 to 2030. Demand for 3xxx series aluminum alloys for packaging of products such as food, beverages, cosmetics, and medicines is projected to benefit the market growth.

The market is fragmented in nature, as there are a large number of small and medium companies engaged in the production of aluminum alloys.

Gain deeper insights on the market and receive your free copy with TOC now @: Aluminum Alloys Market Report

Grand View Research has segmented the global aluminum alloys market based on the end use, and region.

#AluminumAlloys#MetalIndustry#LightweightMaterials#Manufacturing#AutomotiveIndustry#AerospaceIndustry#ConstructionMaterials#IndustrialMetals#AluminumMarket#Recycling#SustainableMaterials#MarketTrends#EngineeringMaterials#AlloyDevelopment#Metallurgy

0 notes