#marine propeller shaft

Explore tagged Tumblr posts

Text

Marine Propeller Manufacturing & Repair: Precision and Reliability

In the marine industry, a well-functioning propeller is essential for optimal vessel performance. Our expert team specializes in both the manufacturing and repair of marine propellers, ensuring your vessel runs smoothly and efficiently.

Manufacturing Excellence

Precision Design: Using advanced CAD software, we create propellers tailored to your vessel’s needs.

Quality Materials: We select top-grade materials like bronze and stainless steel for durability and corrosion resistance.

CNC Machining: Our CNC machines ensure perfect symmetry and precise tolerances.

Comprehensive Repair Services

Thorough Diagnostics: We use advanced tools to identify and assess any issues with your propeller.

Expert Repairs: From minor fixes to complete overhauls, our technicians restore your propeller to peak performance.

Balancing and Testing: We balance and test every propeller post-repair for smooth operation.

Why Choose Us?

Experienced Team: Our years of industry experience ensure top-notch service.

Customer Focused: We customize our services to meet your specific needs.

Quality Guaranteed: We stand by the performance and reliability of our work.

Contact Us Enhance your vessel’s performance with our expert propeller manufacturing and repair services. Get in touch today!

0 notes

Text

A Powerful Resource: An All-Inclusive Manual on Booster Pump Systems

Efficiency Enhancement through the Use of Booster Pump Systems

Booster Pump Systems are essential instruments for fluid dynamics and effective water management. It would be impossible to exaggerate the importance of booster pump systems in various settings, including industrial applications, maritime environments, and leisure facilities such as swimming pools.

A Comprehensive Guide to Booster Pumps

Unheralded throughout its many uses, booster pump systems maintain a constant water pressure. The importance of the major components becomes clear when we examine them more closely:

Booster Pump: System Central

The booster pump is the engine that keeps the water flowing steadily through the pipes by pushing it against obstacles. The booster pump is the engine that drives water distribution systems, whether they are in tall buildings or in agricultural fields, to ensure effective irrigation.

A Lifeboat Battery Charger for Seafaring

The lifeboat battery charger is the show-stopper in underwater settings. In an emergency, this vital part keeps the lifeboat batteries charged to power the boat’s vital systems. The importance of the Lifeboat Battery Charger in ensuring the safety of mariners is highlighted by the fact that its dependability might have a fatal impact.

Control Panels for Marine Vessels: The Hub of Shipboard Operations

Shipboard Control Panels Revealed

Ships’ central nervous systems marine control panels oversee a wide range of operations critical to the ship’s navigation, security, and efficiency. These panels perfectly harmonize with Booster Pump Systems, coordinating a maritime symphony of activities.

Integrating Booster Pump Systems: A Seafaring Synergy

Marine Control Panels and Booster Pump Systems must work in perfect harmony for marine applications. Booster Pump System performance may be monitored and adjusted in real-time with the help of these panels, which optimizes efficiency and guarantees a pleasant sailing experience.

Marine Control Panels with a Lifeboat Battery Charger for Your Peace of Mind

The Marine Control Panel’s Lifeboat Battery Charger is crucial to keep life-saving machinery running. The readiness of lifeboats for deployment is ensured by a dependable charger, adding an essential safeguard for crew and passengers.

Creating a Havoc: Pool Control Panels

Immerse Yourself in Efficiency: Pool Control Panels

Regarding pools used for enjoyment, Swimming Pool Control Panels are the main attraction. Designed to make swimming fun and safe, these panels control the pool’s pumps, filtration, and other features.

Recreational Harmony: Optimizing Booster Pump Systems

Preserving pristine water quality and maximizing circulation efficiency may be achieved by optimizing booster pump systems using swimming pool control panels. Whether it’s a public or private pool, these panels are necessary for water temperature regulation and energy efficiency.

Conclusion

The most advanced devices for managing water resources are lifeboat battery chargers, control panels for ships, and panels for pools and spas. These systems guarantee uninterrupted water flow and are crucial in many areas of our lives, including industrial processes, marine safety, and recreational activities.

#Booster Pump Control Panel#Water Booster Pump Control Panel#Transfer Pump Control Panel#Pump control Panels#Marine Control Panels#Marine Switch Panels#VSD Control Panel#Star Delta Starter Panel#Customised Marine Panels#Cold Room Alarm Panel#FCU Control Panel#FCU Starter Panel#RCV Control Panel#Custom Motor Control Panel#Lifeboat Battery Charger#Lifeboat Charger#Propeller Shaft Tachometer#Emergency Engine Order Telegraph#Booster Pump System#Transfer Pump System#Fountain Control Panel#Swimming Pool Control Panel

0 notes

Text

Dreaming of You

Masterlist Here

Word Count: 1,100+, 1,700+, 1,700+, 1,400+

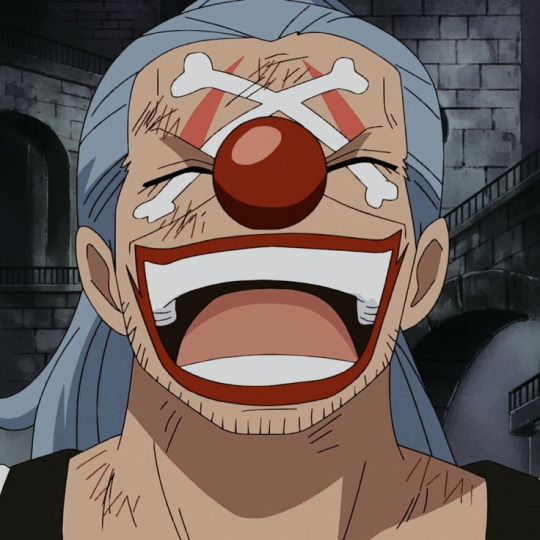

Synopsis: They couldn't help it. You looked so heavenly in their dreams. The way they had you wrapped around their body as a marionette in their minds, dancing for them as they awoke to sticky blankets when they jolted upright. Their thoughts got the better of them, and they are wracked with guilt. Sir Crocodile, Buggy, Dracule Mihawk

Warnings: wet dreams, afab!reader, swearing, masturbation, dub con (Using your image to masturbate to), suggestive content, feelings, all individual 'x reader' drabbles, same reader!insert different outcome, chop-chop fruit shenanigans, angst, romance, smut, kissing, NSFW, 18+, MDNI.

Notes: Dreaming of You Masterlist Here, Please read the warnings. I am having a lot of fun with this series, but this one got away with me. They're only meant to be silly little drabbles between larger fics. Sorry for the lengthy read! Enjoy playing the part of a marine spy for Cross-Guild!

Tag list: @sordidmusings @nerium-lil @feral-artistry @since-im-already-here @writingmysanity @indydonuts @gingernut1314 @i-am-vita @carrotsunshine @mfreedomstuff @daydreamer-in-training @lostfirefly

Hips pressed against one another, huffing pants and gasps were collected in one another's lips and skin as he pinned your back against the wooden wall behind the burgundy curtains of the tent door. Legs collected over his hips, he held your left thigh in his right hand, his forearm caging you by slotting up between your right shoulder and the cool surface.

Lusting and passionate, he drew intentional thrusts that were slow and deliberate enough to brush at your g-spot and mold your pussy to the contours of his thick cock. He slacked his jaw, his eyes swimming with emotion as he ground his pelvis against your clit with every heavy thrust.

Your voice whimpered for him, stifling your mewls of pleasure by biting down into his shoulder and crying as he bullied his cock into your needy pussy. He groaned with you, rocking his cock in slow, languid thrusts up into your body.

“Please,” you begged him, desperately clawing at his back and peppering his shoulders, neck and jaw with enthusiastic kisses, “We don't have long until the others come back.” He growled at your words, offering you a particularly mean thrust forward and a cruel bite against your neck.

“A-Aah!” you gasped in shock, biting your lip and digging your nails into his shoulders harder. He sheathed his entire length greedily into you, his shaft twitching in bliss the moment he felt his blunt tip brush your cervix. His hips stapled yours against the wall he was bullying you against.

“I don't care if they hear,” he barked against your neck, tracing his tongue over the bruise forming from his bite, “I don't care if they see.” He pulled back his hips only slightly before immediately propelling himself forward and forging his body against yours like soldering iron to a hot blade.

“Let them hear,” he admitted, huffing against your neck as he rocked his hips into yours, removing his hand from hooking around your thigh to grip your neck and bring your gaze to meet his. “Let them see.” He plastered your parted lips with his own, desperate with tongue and teeth as he released your neck to hold your thigh once more.

“I want them to hear,” he groaned into your mouth, rolling your cheek with his chin and kissing down your jaw, “I want them to see.” He trailed his needy kisses down your neck as he doubled his effort and sped up his rhythmic thrusting.

As your core sucked him in each time he retracted, his mind was lost to him and was filled with primal desire. He needed them to hear your sweet moans and whimpers. He needed them to see who was making you feel this good. He needed you to know who you belonged to.

“Say you're mine,” he growled, his lips mouthing up your neck, over your jaw and to your cheeks, “Say it.” He sped up faster, his cock hammering into you with every cruel, frenzied thrust. His hair was sticking to the dewy sheen of sweat against his forehead and neck, his brows furrowed as he glared into your eyes with an intensity he had never felt in life prior.

“Say you're mine,” he barked at you, commanding you to fulfill his desires as his cock twitched within you. Your walls beckoned him closer, the thump of your ecstasy wringing his cock as he pistoned it within you had him desperately whimper and whine your name.

“P-Please say you're mine,” he implored you in desperation, his fingers clutching your thigh in a heaping fistful as he continued to chase your mutual highs, “Tell me. Tell me your mine, and I'll be your slave.” He begged, kissing your lips and panting through his thrusts, “I'll be yours. Is that what you want?”

He chased your mutual high faster, rocking and pummeling into you with his heels digging into the floor. His belt buckle jingled atop his pants pooling at his ankles, your own pants discarded beneath you long ago. Leaning down, he took your peaked nipple into his mouth and rolled it over with his tongue.

A string of saliva attached from his lips to the puckered bud when he pulled away, huffing and panting at the lustful display of your breathing hitching. Body bouncing in sultry ripples with each thrust, he groaned as he felt his abdomen tighten with a familiar call of his imminent release.

“Yes,” you whispered his name suddenly, clutching his neck and carding your hands through his hair, “Yes, I want that. I want you-...” You whined his name as he pistoned his length deep within you, “Please, I'm yours. Only yours.”

He growled his pleasure at hearing your words into your lips, tongue lapping with yours and his hair brushing against your forehead. You hastily tugged him away from your lips by gripping the scruff of his neck and pulling hard.

“W-What? Why are you-?” He began, his words halted by the intensity of your gaze. Your lips were parted, face flushed from a higher rise of hazy temperature, and skin forming lustful bruises and mapping his treasure with his marking kisses.

“Make me yours,” you gasped at him, panting as your lust eclipsed your eyes, “Cum in me. I want it. Need it.” His eyes widened, and his jaw fell slack as his hips staggered their vicious thrusting deep inside you.

“Fuck, I-I’m gonna-...” His abdomen tightened further, his eyes glowing black with luminescent lust as his seed spilled inside you with hot spurts, “I'm cumming-... hhah-... I-I’m cumming…f-f-fuck-...” Rope after rope of translucent cum released within your walls, the rhythm of your own ecstasy milking him with squeezing grasps on his throbbing cock.

You called his name, throwing your head back as he trailed his eyes over your skin with adoration within his bliss. He couldn't get enough, reaching forward to collect your lips beneath his in a scorching mess of lips, tongue and teeth. With a desperate kiss to mold him against you completely, he forged an unspoken covenant to ensure you knew you were his and he was yours.

Opening his eyes, the image of your blissed out afterglow faded from his vision. All that he was met with was the ornate ceiling in his bedroom, his cock twitching through the final waves of untouched pleasure.

“No,” he growled, removing his duvet with his right hand and glancing at the lustful dance his swollen cock twitched with. A last spurt of cum spilled from the glossy slit and he immediately thrust the ruined blanket on top of his stomach to shield it from his sight.

“Fuck.”

Sir Crocodile

He balled his right fist, slamming it into the mattress beside his hip with a rumbling growl in his chest. Inhaling deeply, holding it for a few seconds, and exhaling slowly had him assess all that occurred to him with his night vision moments ago.

“Please say you’re mine. Say you’re mine and I’ll be your slave,” his own voice echoed in his mind, “I’ll fall to my knees and worship you in all ways. I’ll treat you like the deity I know you to be, showering you in praise and praying at your altar. Please.”

“I’m yours,” you whispered with half-hooded lessons, “I’ll only ever be yours, Sir Crocodile. Only yours.” He snapped his eyes awake, clenching his jaw impossibly tight and drawing his brows down in fury.

“I begged?” he snarled, reaching for a cigar and his flint-lock lighter, “I begged to claim you as mine?” He clicked his tongue before biting down on his cigar, lighting the end with a small flame and sucking in a sour lungful of smoke, “Utterly ridiculous.”

Pulling the duvet away from his lap, he growled at the sticky ooze pooling at his abdomen before squaring his shoulders and walking to the adjoining ensuite in his master bedroom. The Cross-Guild tent did not have many luxuries, but he refused to go without simple pleasures while working with the disgusting clown.

A bath was one such pleasure Sir Crocodile would not live without.

Running the water, he dropped each foot into the tub and sighed out at the contact of the freshwater rising to his thighs. The heat and steam eradicated his shame from his abdomen without much effort, melting it down and washing it away beneath the water. Groaning, he looked to his absent left hand and gazed down at the scarred stump.

“We don’t have long until the others come back,” he heard your voice echo within his mind, drawing himself back to the dream and causing him to grimace in annoyance. He circled his palm and fingertips over his left forearm and molded the flesh within a firm grip.

The pains on his phantom limb had returned, his mind racing and attempting to draw up distractions by any means necessary. Your midnight illusion was simply the latest commodity to preoccupy his attention with lustful desires, is how he rationalized such a shameful intrusion.

He was a fourty-six year old man, not some prepubescent teenager so consumed with the need to fuck that their minds dreamed it into an untouched and sticky reality. The pain intensified, his teeth clamping in a rough hiss as the illusionary throb of his hand caused him to shake his arm from his grip.

This was going to be a long and tiring day.

At the meeting, he was being short and harsh with anyone and everyone to cause him displeasure. His teeth snapped barks, his chest rumbling his fury and his hair was beginning to become disheveled. The clown was aggravating, and the swordsman’s silence was not as refreshing as it was under usual circumstances.

His right hand only ever left his left forearm for the chance to draw up a cigar, yet the sour smoke did very little to soothe his pain, and his hand only seemed to make the intensity of the throbbing worse. As Mihawk and Buggy stood to leave the room, he remained behind and he finally hissed out a lengthy growl behind his clenched teeth at the pain.

There was not a sound in the room, a slight ringing in his ears as the pain reached his head and dizzied his mind. Eyes scrunched tightly shut, he had no context for a gentle touch on his hand over his forearm until he snapped his purple eyes up to meet with yours.

“Allow me, Sir Crocodile,” your smile illuminated your face, gently suggesting with your touch to remove his right hand from his left forearm. He attempted to fight the urge to bark at you, snap at you and give in to his desire to have you touch him.

“And just what do you think you’re doing, Marine?” he growled, eyes narrowing and lips curling up into a deep snarl, “Who gave you the right to touch me-?”

“Oh, shut up. You've been horrendous today and I refuse to have this continue to be cause for your disgusting attitude,” you bit back, your own lips pulling back to reveal your snarl, “Let go of your arm and let me help you, damn it.” He immediately dropped his arm in favor of gripping your neck in a tight choke, bringing your face closer to his.

“You dare to give me orders, Marine?” he roared at you, your teeth gritting back the pain and glaring into his eyes. “I was a former warlord, little spy. Now I hunt and kill your kind for a living.” As Sir Crocodile monologued, he remained ignorant of your hands working to find the clamps of his prosthetic hook and releasing the golden cover from his arm.

“And now you touch me, spy? Offering me what, exactly?” he continued monologuing as you removed his hook and rolled up his embroidered sleeve. The pain in his forearm was so intense he could barely feel any relief of tension come from releasing his limb from the confines of his hook. “How are you going to help-... A-ah!” He gasped, his brows tugging up in the center of his forehead as he glared at you.

Immediately releasing your neck, he looked down at his bare forearm within both of your hands and bit back a whimper. In his own grip, his scarred forearm felt hot and throbbing beneath his cooler temperature. In your warmer hands, his arm felt encased in an encumbering embrace like hot stones sizzling on a damp surface.

Your thumbs traced the contours of his muscles, dipping between his bones and rolling his muscle between your fingers. The heel of your palm added a tight pressure to his ache, his breath coming out in rough pants the longer you held him in a tight grip. His eyes softened, his scowl loosening from anger to pain.

Hissing and panting, an uncharacteristic whimper fell from his lips as you silently focussed on working the flesh within your skilled grip. Circling your thumbs and contracting your hands, you instructed him with calming and soothing words.

“Deep breaths now,” you whispered in a slow and intentional hum, “In when I squeeze, and out when I release.” He nodded his head, feeling the soft roll of your hands over his skin. As you tightened his grip, his chest expanded with a lengthy inhale and exhaled as you withdrew.

Repeating that motion, he felt the tension in his mind begin to release him from his illusions. Focussing on your movements as your voice soothed him with each direction, he didn’t expect his emotions to overcome him at such kindness. Your hard contractions over his arm eased up, your fingertips tracing the scars on the vacant nub and causing his flesh to tingle beneath it.

“Better, sir?” halting your soft motions, you gently placed your hand on his forearm and held faint pressure over his skin. Reopening his eyes, he felt tangible relief wash its way over his face. Gazing into your eyes, you held nothing but empathy and gentleness in your twin orbs. He leaned down over your face, bringing contact between your two foreheads and offering you the slightest of smiles.

“Why would you do that?” he whispered in an uncharacteristic soft voice, “Touch me like that? Offer me such kindness after all that’s occurred between us?” He raised his right hand and cupped the back of your head in a firm grip to hold you against him.

“You didn’t kill me the moment I stepped into the red tent,” you smiled warmly at him, “Nor did you kill me any day thereafter.” Giving his arm another gentle squeeze, you glanced down at his missing limb and offered him a melancholy smile. He growled at your confession, searching your eyes for a further explanation. You huffed out a sigh, smiling further with a soft twitch up your cheeks.

“I used to do this for my friend back at the marine base,” you offered him a glimpse at your history with your explanation, “Did it all the way up until the day she died. Said something about my hands feeling warm against her skin, different to her own temperature. Soothing.”

He chuckled at that, nodding against your head and closing his eyes shut in momentary bliss. That was why you felt so good on his skin, your skilled motions causing him aid and relief. You have done this before, and were offering it freely to him.

“Oh?” he asked, his smile tugging at his cheeks and elevating the scar over his face, “And did she manage to say what she did without you by her side to aid her?” You laughed at him, breaking away your contact from his forehead and scrunching up your nose playfully.

“I was always by her side, sir,” you confessed to him, nodding as you spoke, “She and I were inseparable, even in cabin quarters.” He nodded in understanding, looking down to his limb and back up to your eyes.

“Well, if that’s the only solution for the pain I’m encountering,” he uttered, his lips curling into a wide smirk, “I would see you gather your personal effects and move into my cabin beside the tent, immediately.” You laughed at him, rising from his side and beginning to leave the meeting room.

“I hardly think that would be appropriate. Don’t you agree, sir?” you question him, collecting your bag from the circular table in the center of the room. As you moved to leave the tent, a strong forearm snaked around your chest and grasped your shoulder, tugging you firmly into a broad chest.

“Wasn’t a suggestion, Marine,” he whispered into your ear, the smooth rumble of his voice shooting tingles up your spine and causing you to gasp. “You’re mine now. Hear me?” He grazed his lips over your cheek and down your jaw in a slow motion.

“Mine.”

Buggy

“Oh, what the fuck?” his nasally voice huffed, his makeup free face flushing with a hefty sprinkle of dark blush, “You’re fucking kidding me.” He reached down to his cock and fisted it in a pistoning motion.

“Had to be you, didn't it?” he cursed your name in a pouty snarl, “The fucking spy.” He swirled his cock in his palm, growling at it before he simply detached it with his balls and brought it up to his face. He frowned in a deep scowl, drawing up his heckles as he began chastising his cock.

“C’mon, man! How could you do this to me?” He growled at his cherry-red knob, choking it in his fist, “You think this is fucking funny? You think I want to see ‘em like this?” He drew up his other hand and slapped his knob, his pelvis wincing in response.

“Out of bounds,” he berated his cock, “The spy is out of bounds. You know the spy is out of bounds.” He pinched his knob, choking it and only making his pleasure heighten. “N-Nnngh-... Not for thinking about, not for trying to fuck.”

He whimpered, his priorly ruined orgasm still gluing his duvet to his stomach. He growled, hocking a wad of spit behind his lips. He spat on his cock in an attempt to degrade himself further, only leading to lubricating his ministrations and causing him to throw his cerulean colored hair back into his plush pillows in bliss.

“Hhah-... The spy is not for you, you fucking idiot,” he gulped his confirmation, his cock thrusting itself in his fist beside his head as he frowned at it, “Think about something else,” he closed his eyes, meeting the thrusts of his cock with his hand as he tried to think about anyone else he could sheathe himself in.

“Buggy, I-I’m gonna c-cum-,” he heard your voice whimper at him, his cock twitching in his hand beside his face, “Buggy, please can I cum?” He shook his head, attempting to picture anything else. Faceless breasts bouncing, ripples of an ass jiggling, parted lips panting and huffing with eyes scrunched shut-... Your voice calling his name with adoration pouring from your lips like honey.

“Fuck, fuck, fuck,” he chanted, shaking his head and attempting to go back to the earlier images. He only pictured your hair, your skin, your perfume, and your lips behind his eyes. Those lips used to spell secrets, split in a perfect ‘O’ as he pictured you slicking his cock up in your needy cunt with your erupting ecstacy milking him of his heaping load.

“Fuck! No, no, no, no, n-oooh!” He threw his cock away from his face to not shoot himself in the eye with his release. It spattered the wall in a secondary wave of sticky cum like a grenade exploding on impact. “Nnnngh-... F-Fuck. Fu-uck-... C-cumming-.” His abdomen contracted as he rode the remaining waves of his orgasm untouched and unstimulated.

Ropes of guilt shot out of his small slit and coated the wall and floor in a sticky pile of pearlescent cum. He groaned your name, huffing and panting as his hips bucked up in an attempt to stimulate his detached cock.

“N-... No…” he whimpered, bringing his palm up to his face and clapping it over his lips. “Not the spy. I can't-... I can't have the damn spy. They're a bloody marine, you fucking idiot,” he degraded himself further, rising from his bed and wiping his abdomen of the solidifying globs of sticky cum with his duvet.

He reached his cock, staring at it as it looked like a pathetic, slobbering drunk as it lay in a pool of its own drool. He clicked his tongue at it, picking it up and dusting it off before reattaching it to his pelvis. Readjusting his balls, he found his red jumpsuit and messily thrust it over his body in one swell motion. Instead of throwing his arms through the sleeves, he tied the material around his waist and offered to remain shirtless.

“Not the spy,” he whispered to himself as he exited his ornate living quarters at the Cross-Guild base. Making his way to the kitchen, he was halted by a soft hum reverberating around the room.

A familiar somber tune painted the air with its melody, his eyes shutting and the corner of his mouth ticking up as he listened to the lyrics. Stepping into the room, he attempted to mask his nerves with his signature mischief written on his face.

As he drew his eyes over your features, your back facing away and staring out the window by the sink, he couldn't help but have the mask of protection slip away. Your lips whispered the lyrics, your heart carried the tune. You were not in your marine uniform, nor were you adorning the attire Sir Crocodile purchased for your protection.

You were dressed in simple, gray-coloured slacks that hung loosely around your hips. The top you were wearing was a cropped t-shirt with his Jolly Roger printed on the back. His lips parted in shock as he drank you in, listening to your soft singing and closing his eyes to experience it fully.

Before he could manage to say a word to reveal his presence, your hums ceased and your voice lowly uttered your apologies.

“Sorry, Captain Buggy,” you bow your head to him in greeting, “I was not assuming the three of you to be awake so early. If I bothered you with my noise, I apologize.”

“N-No bother,” he huffed your name and hastily gave his reply to you with a soft blush, “I-... I haven't heard that song since the old days. Way back when-... When Roger…” He trailed off, looking at a point just beyond your hips and against the sink beside you.

“I love the old shanties,” you chased his gaze with your own, angling your chin down and attempting to pry his eyes up to meet yours, “They're either about drinking, fucking, or grieving.” Buggy met your gaze, grinning up at you with his teal eyes beaming.

“Ah, two of my favorite pastimes,” he added his commentary, leaning in closer and a cheeky smile pulling at his cheeks, “I’m not one for fucking.” He shot you a wink, prompting you to laugh at his joke. Your laugh was music, each soft teeter was as radiant as a lilt from heavenly minstrels. After teetering off your laugh, he offered you a soft smile with his eyes wide and curious.

“Would you mind…?” Buggy trailed off again, nervously clutching the back of his neck and cringing through his smile, “...Could you perhaps tell me why you decided to join us, again?” He released his hand from his neck and darted his eyes between yours.

After taking a moment to collect your breath and mull over what it was he asked of you, shrugged and offered him a simple answer.

“The Berry is good, and it’s mutually beneficial,” you nod at him, smiling with your answer, “You were the one who offered me a choice, remember?” Crossing your arms, you leaned your hips back on the sink and glared at him, “It was either: spy for the marines as a triple agent for your Cross-Guild with a livable wage, or have Crocodile or Mihawk take my head. I chose you, Captain.”

As Buggy was reminded of his prior actions and offered you a sheepish smile in response. Stepping forward, he reached for your forearms and waited for you to flinch away or chastise him for such a soft gesture. In the wake of such a softness, he was pleasantly surprised when he felt your fingers interlace with his own and hold them beside him.

“You know, ‘m sorry ‘bout that,” he mumbled, looking to his toes and pouting his unpainted lips, “Didn’t mean t’ have it sound so bad.” You smiled in response, giving his fingers a gentle squeeze and angling your chin down to look at his uncovered fingers.

“You know, you’re actually quite handsome,” you confessed in a breathy whisper, “The infamous Captain Buggy D Clown, genius jester, king of fools, and calamity of chaos.” You named his titles with a soft smile, looking up into his rainforest-colored eyes with such gentleness.

“You-... You think I’m handsome?” He asked you, your soft laughter prompted his own to slip freely into the air. You unplaced your right hand from his left and cupped his cheek within your palm, running your fingers through his hair.

“You’re usually dressed in makeup, with your long hair tucked under your hat,” you collected a strand between your fingers and rolled your thumb over the lengthy blue locks, “And, you usually don’t have this much skin revealed.” Looking down at his chest: his messy blue hair trailed down his chest, tapered off at his stomach, and picked up again like a cerulean trail leading to the assumed treasure beneath his red jumpsuit.

“I’m not used to seeing this much of you, Captain,” you muffled, drawing your gaze back up to his with a rapidly broadening smile, “And I’m not mad about it.” Your eyes creased at the corners as you offered him a toothy grin in response to his vibrant blush.

The hue of his cheeks rivaled that of his nose and jumpsuit, his eyes almost weeping from the rapidly rising blood pooling in his face. His Adams apple bobbed at the compliment, gulping back a dry pit in his throat and swallowing it.

“Y-You know,” he stuttered, chuckling to cover his nerves and squeezing your remaining hand in his in two short motions, “I… I take back my earlier sentiment, uh-... If you’re interested?” He continued stuttering and choking on his words as he clumsily cartwheeled around his intentions.

“Oh?” you smirked at him, raking your fingers through his hair and darting your eyes between his, “And what was your earlier sentiment again, Captain?” You trailed your fingers down to the end of his lengthy locks.

He gulped his terror and humbled himself by offering you a short, huffed laugh. After taking a moment, his eyes twinkled in mischievous hope as he rejoined your eyes in a smiling gaze.

“I am one for fucking…”

Mihawk

Amber eyes stared in horror at the ceiling, wide and unblinking as he replayed the final moments over and over again in his mind. He drew his right hand down to grasp around the steel girth of his deflating cock and wield it in his firm grip.

“I want that. I want you, lord Mihawk,” You whined his name as he pistoned his length deep within you in his mind's eye, “Please, I'm yours. Only yours.” His breath hitched in his throat, his eyes twitching but remaining staring vacantly at the ceiling. Thumbing over the prior release, he hissed in agitation the moment his fingers collected his viscous eruption.

“How fatuous,” he snarled, raising his duvet once more from his waist, “So puerile.” His face remained vacant, his eyes holding only a touch more agitation than his usual persona as he walked to his ensuite shower. Turning the taps, he didn’t wait to feel the rise in water temperature.

Stepping into the freezing water, he made no reaction as the icy liquid pelted at his skin; not even blinking to dampen his rapidly drying eyes. The water began to elevate in temperature as he released his cock from the grip. Gathering his sandalwood soap bar in his hands, he began lathering himself in foamy suds and washing over his body with his shock and shame still evident on his features.

The only time he closed his amber eyes was when he washed over his face, scrubbing at his whiskered chin and massaging his cheekbones. As soon as his eyes closed, he only saw your face contorted in pleasure, your ethereal moans freely haunting him in his ears. Shaking his head beneath the water, he only saw your face and imagined your hands clawing at his back beneath the water.

Horror and shock eclipsed his eyes upon reopening, his eyes remaining that way as he concluded his shower, dried himself off, applied his cologne and skin care products, and dressed himself in his pants and greatcoat. His fingers stuttered over the lacing on his outer greatcoat, his lengthy necklace almost choking him as he placed it over his neck.

Almost stumbling into the dining space, he searched in his mind for a reason something so juvenile could occur for someone of his age, standing, and stature. He had gone for so long without taking a lover, he barely felt any lusting urges overcome him anymore. It didn’t suit his routine, his monotony, or his lifestyle as a former warlord.

His apathetic and bored stature coming from a place of loneliness in his sovereignty as World's Greatest Swordsman. His achievements were already so vast, and he had nobody to share them with - nor a desire to begin a courtship with someone akin to his title. He had no time to take a lover, no time to indulge in whoring as it took away from his duties tending his garden in Kuraigana, and his bounty collecting as Marine-Hunter for Cross-Guild.

So, why did his mind replay your pleasure over and over again in a loop of falsified memory? The marine spy, the confidant to cross-guild, the whispering oathbreaker; all the titles he sought to bestow you with. His hands reached for the bottle in front of him, clasping the green glass in his hands and uncorking the waxy tip. Pouring the rouge liquid into a crystalline glass, he felt a presence to the side of him.

“Could you spare a glass for me, my lord?” your soft susurration drew his attention back to the present, prompting his eyes to flicker to you. He witnessed your soft smile, your gaze assessing his face and shoulders.

Wordlessly, he reached for another glass and began readying it for you. The dry liquid coated the glass, a soft drop spilling from the rim and down the stem which caused you to knit your brows in concern.

“Everything okay, my lord?” you asked, reaching for a napkin and beginning to clean up the mess, “You seem out of sorts this morning. Berry for your thoughts?” You dabbed at the table with the wafer-thin paper and tidied up his spill without a second thought. His eyes followed your motions, almost viewing the dabs in slow motion the longer your hands lingered near him.

His silence seemed to perplex you further, turning your shoulders and leaning your hips back against the marble counter and staring up into his unblinking eyes in response. His shaking hands reached for his wineglass and drew it up to his lips. His mustache dipped into the liquid, messily staining his upper lip with the tart tannins.

Gazing at his shoulders, you noticed a loop of his shoulder straps seeming to bubble within the corseted lacings, your hands absentmindedly straightening the bonds without much thought. Mihawk choked on his liquid the moment your hands brushed against his shoulders.

Feeling the warmth float from your fingertips to the exposed skin beneath the weighty jacket, his eyes widened briefly and his pupils narrowed in an accusatory glare. Huffing a nervous laugh as his soft choke and shaking your head, you reached behind you to the pile of napkins and began to raise it to his face and lightly pat at his stained skin.

Reactionary, he immediately placed his glass down behind you with his right hand, his left clapped around your invasive wrist in a circled vice-grip. Your breath caught in your throat, darting your eyes around his face with your eyes wide and panicked. He immediately drew his face forward and captured your lips beneath his without restraint. He hummed into your lips, raising his right hand and carding his fingers through your hair to deepen the passion.

Lips, tongue, and teeth pulled and tugged at your mouth from the swordsman, his gentle moans and sharp breaths depicting his wanton need to join himself with you immediately. He was pent up for so long, restrained for so long, and his body betrayed him in a shameful display in his dreams as proxy to such desire. If his overnight visit from you as his midnight muse spoke for anything, it was that his needs were now becoming more insistent, prominent, and desperate to be satiated.

And you were who he wanted to aid him in such a task.

Your hands raised defensively beside you, your eyes were wide and staring at his furrowed brow and tightly clamped eyes. He continued pressing heated and passionate kisses against your lips with gusto. Not giving you time to adjust or react, he anchored himself between your legs and pinned you against the marble dining station. Lips trailing to your cheek and down your neck, he bit, nipped and sucked at your revealed skin.

His hands looped around your neck and shoulders, drawing you against him with an incessant need to depict to you his desires with his unyielding grip. You gasped as his lips traced up your skin and returned to your lips, your hands dropping to brace yourself beside you on the marble surface.

Pulling his lips away, he held your face stationary by palming at the scruff of your neck and holding your attention with his honey-colored eyes. His predatory gaze narrowed in on you as his bruise-kissed lips ticked up in his signature smirk.

“There,” he snarled at you in soft agitation, before releasing your neck. He collected his wineglass and green bottle from behind you, keeping his face in close proximity. His smirk drew up further as he turned to walk away from you.

Calling over his shoulder, he snickered his taunting remark at you before leaving through the door, “Now I can occupy your thoughts the same way you've been tormenting me in mine.”

You stood there stunned, frozen in place as your lips still tingled with the feeling of his against yours. The silky scrape of his neatly cropped beard tickling your cheeks, the way his tongue brushed with yours, and the animalistic desire to consume you with his lust had your soul ignited.

Turning to the marble bench, you claimed your wineglass and raised it to your lips, immediately gulping back the tart liquid in a heaping swig. Placing the glass in the sink, you stared at the door Mihawk just left through, your thoughts spiraling and sifting through all the possible scenarios of what his words meant, and what the kiss means for you now.

Only Mihawk knew what he intended with the kiss, and after the morning meeting, he was going to give into his desires further and offer you a place in his bed to have his dreams become reality.

#one piece#x reader#one piece smut#one piece drabble#dracule mihawk#sir crocodile#buggy the clown#crocodile x reader#mihawk x reader#buggy x reader#crocodile smut#buggy smut#mihawk smut#op crocodile#op buggy#op mihawk#opla#buggy#mihawk#crocodile#op smut#one piece x you

2K notes

·

View notes

Text

HMS Montagu aground on Shutter Rock, suffering a 91-foot (28 m) gash on her starboard side. Unable to free herself from the rocks,

At 02:00 on 30 May 1906 , Montagu ran aground on Shutter Rock, suffering a 91-foot (28 m) gash on her starboard side. Unable to free herself from the rocks, she slowly filled with water; twenty-four hours later, her starboard engine room and all of her boiler room were flooded, among others. Her crew counter-flooded the port engine room to prevent her from listing further to starboard. Divers inspected the hull to determine the extent of the damage, which proved to be more serious than initially expected. The bottom of the ship also received extensive damage, including several other holes and the port propeller shaft having been torn from the hull. The starboard bilge keel was also ripped from the hull, as was the rudder. The wreck rested on a fairly even bottom, so there was hope that the ship could be refloated

Since the Royal Navy had no dedicated salvage unit, it turned to Frederick Young, a former Royal Navy captain who now worked as the chief salvage officer of the Liverpool Salvage Association. Young was at that time the foremost expert on marine salvage in Britain, so he was hired to advise Admiral Sir Arthur Wilson the commander of the Channel Fleet, who had no experience in salvage operations. The navy initially hoped to lighten the ship by removing the medium and small-caliber guns and other equipment that could be easily taken off and then to pump out the water so that the holes in the hull could be patched. By the end of June, some twenty pumps had been assembled on the scene, with a total pumping capacity of 8,600 tonnes (8,500 long tons; 9,500 short tons) of water per hour. Difficulties with pumping, owing in part to the subdivision of the internal compartments and the need to reflood the ship during high tide to keep her from suffering more damage before the hull could be patched, led the salvors to give up the operation

Wilson next sought to remove armour plate from the sides of the ship and to erect a series of caissons , at which point a powerful air pump would be used to blow the water out of the hull. The caissons repeatedly broke free even in mild seas, and the air pump failed to have the desired effect. Her sister ship Duncan herself ran aground whilst trying to help the salvage effort, though she was successfully freed. At the end of the summer of 1906, salvage efforts were suspended for the year, with plans to resume them in 1907. However, an inspection of the ship conducted from 1 to 10 October 1906 found that the action of the sea was driving her further ashore and bending and warping her hull so that her seams were beginning to open, her deck planking was coming apart, and her boat davits had collapsed. Having failed to refloat Montagu, the navy decided to abandon the project. Further material was removed from the wreck, including her main battery guns, which were later re-used in other vessels.The Western Marine Salvage Company of Penzance completed salvage of the wreck for scrap metal over the next 15 years. The court martial convened for the affair blamed the thick fog and faulty navigation for the wreck. The trial was held aboard HMS Victory . The ship's captain, Thomas Adair and the navigation officer, Lieutenant James Dathan, were severely reprimanded, with both men being dismissed from HMS Montagu; Dathan lost two years of seniority in rank as well.The wreck site, which now amounts to little more than some armour plate on the sea floor, is a popular diving location. Divers have also located parts of her gun turrets and shells that were not recovered during the salvage operation. In September 2019 the British Government granted the wreck site—including the steps which had been chiseled out of the cliff during the salvage effort protected status

12 notes

·

View notes

Text

September 17, 2023 Update from the Battleship Texas Foundation

"DRY DOCK TOURS

Dry Dock Tours are BACK! Discount available for those who return. For more information please visit: battleshiptexas.org/drydock

Dry Dock Tour time!

SHIP REPAIRS

TORPEDO BLISTERS - The new torpedo blisters are a slightly different design and square off at the bottom below the waterline. This design change will make the new blisters easier to maintain increasing their longevity.

More thickness testing near the bow.

Access holes were cut periodically to check the tanks behind them.

Doubler plates continue being added where the torpedo blisters once tapered to the ship’s hull.

Repairs made around the propeller shaft tube. Great work Gulf Copper!

Underneath one of the torpedo blisters (starboard).

Doubler plates continue being added where the torpedo blisters once tapered to the ship’s hull.

Doubler plates continue being added where the torpedo blisters once tapered to the ship’s hull.

Doubler plates continue being added where the torpedo blisters once tapered to the ship’s hull. A seachest is visible.

COATING - The inside of the blisters, and the ship’s hull will be coated to protect against possible corrosion.

Tanks are now being cleaned and coated. This tank is near the ship’s bow (starboard).

TANK CLEANING - Tanks inside the ship are being inspected, cleaned, and repaired if need be. Some will be coated with a marine coating to help prevent corrosion.

Inside one of the torpedo blister tanks.

Corrosion on a pipe inside one of the ship’s tanks.

LEAK TESTING - All welds continue to be tested for leaks. They are done via vacuum box, dye penetrant, or magnaflux depending on the area.

Welds continue being leak tested.

Old preservative leaking from the ship’s rudder.

New torpedo blister bottoms!

The old torpedo blister framing is being removed before this section has a plate welded over it.

Holes and damage to the ship’s hull near the keel.

Underneath one of the ship’s docking keels. Note the wood that is visible.

Inside a forward tank on Battleship Texas.

Additional framing is being added inside this tank for increased structural support.

Looking aft in an outer tank on Battleship Texas.

Inside a tank of Battleship Texas.

Docking blocks were broken down just under the keel. This area will likely receive repairs soon.

Tank coating continues on Battleship Texas.

Battleship Texas!

Live, Laugh, And Flood your Torpedo Blisters.

Visit our website at: battleshiptexas.org"

Posted on the Battleship Texas Foundation Group Facebook page: link

#Battleship Texas#Battleship Texas Foundation#Update#USS Texas (BB-35)#USS Texas#New York Class#Dreadnought#Battleship#Warship#Ship#Drydock#Dry Dock#Galveston#Texas#repairs#Gulf Copper#Restoration#September#2023#my post

24 notes

·

View notes

Text

Inboard Engines Market Set for 7.8% CAGR as Hybrid & IoT Solutions Take Off by 2030

The global Inboard Engines Market has seen remarkable growth, with recent figures showing a promising trajectory. According to research from Intent Market Research, the inboard engines market was valued at USD 1.5 billion in 2023 and is projected to surpass USD 2.5 billion by 2030, experiencing a compound annual growth rate (CAGR) of 7.8% from 2024 to 2030. This anticipated growth reflects a surge in demand driven by advancements in marine engineering, increased leisure boating activities, and the expanding scope of maritime transportation. Let’s dive into the factors driving this market and what we can expect in the coming years.

What Are Inboard Engines?

Inboard engines are marine engines installed inside the hull of a boat, typically connected to a drive shaft and propeller. These engines provide the propulsion needed for a range of watercraft, from small recreational boats to larger commercial vessels. Their placement inside the hull offers benefits like better weight distribution and improved safety, especially in comparison to outboard engines, which are mounted outside the vessel.

Download Sample Report @ https://intentmarketresearch.com/request-sample/inboard-engines-market-4200.html

Why Is the Inboard Engine Market Growing?

Several factors contribute to the steady growth of the inboard engine market. Let's explore the primary drivers fueling this market expansion.

1. Rising Demand for Recreational Boating

The popularity of recreational boating has risen significantly worldwide, particularly in regions with extensive coastlines and natural waterways. With more people embracing boating as a leisure activity, there is a growing demand for reliable and efficient marine engines. Inboard engines, known for their durability and power, have become a preferred choice for recreational boaters.

2. Technological Advancements in Marine Engines

Inboard engines have seen several advancements over the past decade, particularly in terms of fuel efficiency, power output, and emissions reduction. These improvements make inboard engines more appealing to environmentally conscious consumers and those seeking cost-effective solutions for longer voyages. Enhanced durability and reduced maintenance needs are also major selling points for modern inboard engines.

3. Growth in Maritime Transportation and Shipping

The maritime transportation industry relies heavily on reliable engines to move goods across the globe. As international trade grows, so does the demand for inboard engines that power various types of commercial vessels. Inboard engines are particularly favored in commercial vessels due to their higher horsepower and ability to handle long-distance journeys without frequent breakdowns.

4. Rising Investment in Marine Infrastructure

Governments and private companies are increasingly investing in marine infrastructure, which includes the construction of new ports, marinas, and shipping facilities. These investments foster an environment conducive to growth in the marine engine market, particularly in regions like North America, Europe, and parts of Asia. With better infrastructure, the appeal of inboard engines for both commercial and recreational use continues to strengthen.

5. Adoption of Hybrid and Electric Technologies

The integration of hybrid and electric technologies in marine engines is transforming the industry, providing an option that meets both regulatory and environmental standards. Several manufacturers are now focusing on developing hybrid inboard engines that can operate on electric power in addition to conventional fuels, thereby reducing emissions and operational costs. This shift aligns with global initiatives to reduce carbon footprints and promote sustainable solutions.

Key Market Segments in Inboard Engines

The inboard engines market is segmented based on various criteria, such as application, fuel type, power range, and geographic regions. Here’s a closer look at these segments:

1. By Application

Recreational Boating: Inboard engines are widely used in yachts, speedboats, and other leisure vessels.

Commercial Shipping: Cargo ships and passenger ferries often utilize inboard engines due to their power and efficiency.

Fishing: Fishing vessels, especially those used for deep-sea fishing, favor inboard engines because of their reliability and power.

2. By Fuel Type

Diesel: Diesel engines are popular in larger vessels for their fuel efficiency and torque output.

Gasoline: Smaller boats and recreational vessels often use gasoline engines.

Electric/Hybrid: This emerging category reflects growing interest in sustainable marine technology.

3. By Power Range

Less than 500 HP: Suitable for smaller, recreational boats and small commercial vessels.

500-1000 HP: Typically used in mid-sized vessels, including passenger boats and fishing vessels.

Above 1000 HP: High-powered engines catering to large commercial and cargo vessels.

Regional Insights and Market Dynamics

1. North America

North America remains a significant player in the inboard engines market, driven largely by the United States. The popularity of recreational boating, coupled with a robust commercial shipping industry, ensures consistent demand. Government regulations on emissions have also spurred innovation, pushing manufacturers toward cleaner technologies.

2. Europe

Europe’s coastal countries have a long-standing tradition of boating and maritime activities. Countries like Norway, Germany, and the Netherlands contribute to market demand with their thriving maritime sectors. Additionally, European regulations on emissions are among the strictest globally, encouraging manufacturers to innovate in electric and hybrid engine solutions.

3. Asia-Pacific

The Asia-Pacific region is expected to see rapid growth due to expanding maritime trade and growing interest in leisure boating, particularly in countries like China, Japan, and Australia. The rise in disposable income and the expansion of tourism industries in these countries are significant contributors to the demand for inboard engines.

4. Middle East and Africa

Though smaller in comparison, the Middle East and Africa present unique opportunities, particularly in the luxury and recreational boating market. The tourism sector in countries like the UAE and South Africa continues to drive demand for premium inboard engines.

Access Full Report @ https://intentmarketresearch.com/latest-reports/inboard-engines-market-4200.html

Market Challenges

Despite the promising growth, the inboard engines market faces several challenges:

1. High Initial Costs

Inboard engines, especially advanced models with hybrid capabilities, can be quite costly. The initial investment may deter some buyers, particularly smaller boat owners or operators with tight budgets.

2. Environmental Regulations

Stringent environmental regulations pose a challenge for the inboard engine market. Meeting low-emission standards requires costly modifications, and failure to comply can limit market access in regions with strict environmental laws.

3. Competition from Outboard Engines

Outboard engines, which are easier to install and maintain, present competition in smaller vessels. Some consumers prefer outboard engines for their versatility and lower upfront costs.

Future Trends in the Inboard Engines Market

1. Increased Adoption of Hybrid and Electric Models

As global attention on sustainable practices continues, the demand for electric and hybrid inboard engines is expected to rise. These engines are well-suited for both recreational and commercial uses, offering a blend of efficiency and environmental responsibility.

2. IoT and Smart Technology Integration

The integration of Internet of Things (IoT) technology into marine engines can provide real-time monitoring and diagnostics, allowing boat owners to track performance and detect issues early. This technology could reduce maintenance costs and extend the lifespan of inboard engines.

3. Focus on Lightweight Materials

Manufacturers are exploring lightweight materials such as aluminum and composite fibers to improve engine efficiency. Lightweight engines consume less fuel and enhance a vessel's speed and performance, appealing to both recreational users and commercial operators.

FAQs

1. What is an inboard engine? An inboard engine is a marine engine installed inside the hull of a vessel, used primarily for propulsion.

2. Why is the inboard engine market growing? The market is growing due to increased recreational boating, technological advancements, and expanding maritime trade.

3. What are the main challenges facing the inboard engine market? High initial costs, strict environmental regulations, and competition from outboard engines are the primary challenges.

4. Are there electric or hybrid inboard engines available? Yes, many manufacturers are developing hybrid and electric inboard engines to meet demand for eco-friendly solutions.

5. Which region has the highest demand for inboard engines? North America has the highest demand due to a combination of recreational boating and commercial maritime activities.

About Us

Intent Market Research (IMR) is dedicated to delivering distinctive market insights, focusing on the sustainable and inclusive growth of our clients. We provide in-depth market research reports and consulting services, empowering businesses to make informed, data-driven decisions.

Our market intelligence reports are grounded in factual and relevant insights across various industries, including chemicals & materials, healthcare, food & beverage, automotive & transportation, energy & power, packaging, industrial equipment, building & construction, aerospace & defense, and semiconductor & electronics, among others.

We adopt a highly collaborative approach, partnering closely with clients to drive transformative changes that benefit all stakeholders. With a strong commitment to innovation, we aim to help businesses expand, build sustainable advantages, and create meaningful, positive impacts.

Contact Us

US: +1 463-583-2713

0 notes

Text

What is Hastelloy Round Bar and Its Uses?

In the materials engineering and production sector, the choice of uncooked materials can notably affect the overall performance and longevity of properties. Hastelloy has obtained prominence among the myriad of alloys to be had, especially in high-pressure environments. This article explores what Hastelloy round bars are, their particular characteristics, and their diverse applications across various industries.

Understanding Hastelloy Round Bars

Hastelloy is a registered trademark for a sequence of immoderate-performance alloys more regularly than not composed of nickel, with large additions of chromium and molybdenum. These factors art work together to provide amazing resistance to corrosion and oxidation. A Hastelloy bar, consequently, refers to a cylindrical bar crafted from this alloy, produced in several diameters and lengths to healthy particular applications.

Manufacturers like Piyush Steel Round Bar attention on developing Hastelloy bars that meet stringent notable necessities. These bars can be rolled, cast, or cold drawn to meet specific mechanical and structural needs in a variety of applications.

Unique Properties of Hastelloy Bars

Corrosion Resistance: One of the standout competencies of Hastelloy is its capability to resist corrosive environments, making it first-class for chemical processing industries. The combination of nickel, chromium, and molybdenum offers strong protection in competition to a massive form of corrosive entrepreneurs, collectively with acids and seawater.

High-Temperature Stability: Hastelloy bars can undergo intense temperatures without losing their structural integrity. This makes them appropriate for applications in aerospace and strength generation, wherein components are regularly exposed to immoderate heat.

Mechanical Strength: Hastelloy alloys are acknowledged for their lovely mechanical features. They can deal with heavy masses and pressure, it's important in sectors like oil and gas, wherein reliability is crucial.

Versatility: These bars may be without issues fabricated in numerous styles and sizes, enabling engineers and manufacturers to use them in numerous applications without compromising on fantastic or average performance.

Applications of Hastelloy Round Bars

1. Chemical Processing Industry

The chemical processing industry is one of the number one customers of Hastelloy bars. Their first-rate corrosion resistance makes them best for manufacturing additives like reactors, warmth exchangers, and piping structures that address harsh chemicals. Whether it's miles sulfuric acid or hydrochloric acid, Hastelloy bars can face up to the check of time.

2. Aerospace

In the aerospace area, materials want to satisfy strict safety and performance requirements. Hastelloy bars are frequently used in the creation of engine components, turbine blades, and special vital elements that require excessive electricity and resistance to high temperatures. The lightweight nature blended with advanced mechanical features makes Hastelloy a preferred preference for aerospace engineers.

3. Oil and Gas

The oil and fuel corporation regularly deals with extreme environments wherein each immoderate pressure and temperature are common. Hastelloy bars are used to manufacture valves, pumps, and different devices that need to perform reliably under such conditions. Their durability permits reduce downtime and protection charges.

4. Marine Applications

Given its corrosion resistance, Hastelloy bars also are favored in marine programs. Components uncovered to seawater, which incorporates shafts, propellers, and distinct structural parts, revel in the durability and reliability that Hastelloy gives.

5. Power Generation

In strength generation, particularly in nuclear and fossil fuel vegetation, the want for substances that could face up to severe situations is paramount. Hastelloy bars are frequently implemented in essential regions wherein failure isn't an alternative. Their resistance to corrosion and immoderate temperatures ensures the sturdiness of crucial components.

Advantages of Choosing Hastelloy Bars from a Manufacturer

When deciding on a round bar producer, it’s vital to remember the following blessings:

1. Quality Assurance

Reputable manufacturers like Piyush Steel Round Bar put in force rigorous exquisite management measures. This guarantees that the Hastelloy bars produced meet corporation requirements, decreasing the risk of failure in important programs.

2. Customization

Manufacturers can provide customized answers tailor-made to precise needs. Whether you require a sure diameter, period, or form, a reliable round bar manufacturer can meet your specs.

3. Expertise

Working with professional manufacturers guarantees you an advantage from their knowledge in selecting the proper substances for your assignment. They can provide precious insights into which Hastelloy alloy fits your particular requirements.

4. Timely Delivery

Established producers regularly have green logistics structures in the area, ensuring properly timed shipping of materials. This is critical for responsibilities with tight cut-off dates.

Conclusion

Hastelloy round bars are an outstanding innovation in substances technology, providing unmatched typical overall performance across numerous industries. Their unique properties make them a skip-to desire for programs that demand resilience, reliability, and excessive standard performance. By selecting true producers like Piyush Steel Round Bar, businesses can ensure they get hold of superb Hastelloy bars that meet their true goals, paving the manner for successful duties and enduring products.

As industries continue to comply and face new challenges, the importance of choosing the proper materials will expand. Hastelloy bars are poised to stay at the leading edge, assisting the upgrades of the modern-day worldwide.

0 notes

Text

What is Monel Alloy vs Inconel Alloy?

When discussing high-performance alloys, the terms Inconel and Monel come up frequently. These alloys are essential in many industries because of their outstanding properties. They do, however, have amazing qualities and uses. In this blog, we're capable of discovering the versions among Monel and Inconel alloys, supporting you in understanding which fabric can be fantastic and applicable to your precise needs. As an established Inconel alloy product supplier and Monel alloy product supplier, Jay Steel Corporation is dedicated to providing you with awesome substances for your tasks.

Understanding the Alloys

Monel Alloy

Monel alloys are by use and large composed of nickel (about 67%) and copper (approximately 30%). It also consists of small quantities of iron, manganese, carbon, and silicon. The most normally used grade is Monel 400, recognized for its tremendous corrosion resistance in harsh environments, mainly in seawater. Monel’s specific composition gives advanced resistance to pitting and pressure corrosion cracking, making it ideal for marine and chemical applications.

Inconel Alloy

Inconel alloys, as an alternative, are nickel-chromium superalloys designed to resist high temperatures and corrosive environments. The maximum famous grade is Inconel 625, which includes approximately 58% nickel and 20% chromium. There are some traces of molybdenum and niobium. Inconel is widely recognized for its capacity to keep energy and oxidation resistance at high temperatures, making it a preferred desire in aerospace, chemical processing, and strength generation.

Key Differences Between Monel and Inconel

1. Composition

The primary difference lies in their composition. Monel alloys contain a better percentage of copper, even as Inconel alloys are rich in chromium and nickel. This difference notably influences their properties and applications.

2. Corrosion Resistance

Both alloys exhibit high-quality corrosion resistance, but they excel in different environments. Monel is especially powerful in seawater and special acidic conditions, making it ideal for marine applications. In assessment, Inconel performs notably well in high-temperature environments, wherein oxidation and heat can be bad. This makes Inconel alloys appropriate for gasoline turbine engines and heat exchangers.

3. Temperature Tolerance

Inconel alloys are designed for high-temperature applications, retaining their mechanical homes and electricity even at increased temperatures. Monel alloys, whilst evidence in opposition to corrosion, aren't as adept at withstanding intense warmness. Therefore, Inconel is regularly the material of desire for industries that require warmth resistance.

4. Mechanical Properties

In terms of mechanical properties, Inconel usually has higher tensile energy and fatigue resistance compared to Monel. This makes Inconel more perfect for excessive-pressure programs, at the same time as Monel is often preferred for its splendid ductility and sturdiness in greater moderate conditions.

5. Weldability and Fabrication

Monel alloys are normally much less hard to weld and fabricate compared to Inconel. However, each alloys require particular techniques to avoid problems like cracking throughout the welding procedure. Understanding the requirements of each product is essential for manufacturing.

Applications of Monel and Inconel Alloys

Monel Alloy Applications

Monel alloys are extensively used in packages in which corrosion resistance is paramount. Common makes use of encompassing:

Marine Engineering: Components together with pumps, valves, and propeller shafts.

Chemical Processing: Equipment exposed to acidic environments, which includes warmness exchangers and reactors.

Oil and Gas: Downhole tubing and piping systems that come across harsh situations.

Aerospace: Parts that require first-rate resistance to each seawater and excessive temperatures.

Inconel Alloy Applications

Inconel alloys shine in high-temperature and corrosive environments. Key applications include:

Aerospace: Turbine blades, combustion chambers, and exhaust systems.

Chemical Processing: Heat exchangers, reactors, and piping in immoderate-temperature eventualities.

Power Generation: Components for gas mills and nuclear reactors.

Marine Applications: Parts that require excessive resistance to corrosion and warmth.

Choosing the Right Alloy

When figuring out between Monel and Inconel, it’s critical to not forget the particular necessities of your software. If you need corrosion resistance in a marine environment, Monel can be the better preference. However, if you are working in high-temperature conditions, Inconel is probably more suitable.

Partnering with the Right Supplier

As you study your alternatives, partnering with a reliable provider is crucial. Jay Steel Corporation stands out as a relied-on Inconel alloy product provider and Monel alloy product dealer, supplying a complete selection of notable materials. Our informed organization can assist and guide you in choosing the right alloy for your task, ensuring you've got the resources necessary to prevail.

Conclusion

Both Monel and Inconel alloys offer particular advantages and properties that reason them to be imperative in several industries. Understanding their versions will help you make knowledgeable selections about which alloy exceptionally fits your needs. Whether you're in aerospace, chemical processing, or marine engineering, Jay Steel Corporation is right here to provide you with very high-quality alloys and expert guidance. By deciding on us as your supplier, you may rest confident that you’re getting the first-class substances in your applications.

Explore our offerings nowadays and discover how Monel and Inconel can improve your projects to new heights!

0 notes

Text

What industries or types of machinery commonly require grease guns?

Grease guns are essential tools in a wide range of industries and applications where machinery requires regular lubrication to operate efficiently and prevent wear. These tools are commonly used in industries that involve heavy machinery, moving parts, or equipment under high stress. Here are some of the key industries and types of machinery that commonly require grease guns:

1. Manufacturing and Industrial Equipment

Assembly Lines: Grease guns are used to lubricate the moving components in German type grease gun conveyor belts, robotic arms, bearings, and motors. Proper lubrication reduces friction and prevents machinery breakdown, ensuring smooth operation in high-demand environments.

Presses and Stamping Machines: In metal fabrication or stamping processes, machinery components like hydraulic cylinders, bearings, and slides must be greased to handle repetitive motions and high loads.

2. Automotive and Transportation

Vehicle Maintenance: Grease guns are widely used in automotive shops and transportation fleets to lubricate parts like ball joints, steering systems, universal joints, and suspension components in cars, trucks, and buses. Regular lubrication reduces wear and extends the life of these parts.

Heavy-Duty Vehicles: Grease guns are critical for maintaining heavy-duty vehicles such as trucks, buses, and construction vehicles. These vehicles have numerous grease fittings that require frequent lubrication, especially in high-stress areas like the axles, brake systems, and steering components.

3. Agriculture

Farm Equipment: Tractors, combines, plows, and other farming equipment have numerous moving parts, such as bearings, pivot points, and gears, that must be regularly lubricated. Grease guns are used to keep these parts working smoothly, especially in environments where dirt, dust, and moisture can increase wear.

Irrigation Systems: In agricultural settings, irrigation pumps and motors also need regular lubrication to prevent breakdowns and ensure efficient operation.

4. Construction and Heavy Equipment

Excavators, Bulldozers, and Loaders: These heavy machines rely on grease guns to lubricate joints, pins, bushings, and bearings. Given the extreme conditions and heavy loads they operate under, regular lubrication helps prevent premature wear and damage.

Cranes and Lifting Equipment: Grease guns are used to lubricate the moving parts of cranes, hoists, and other lifting equipment to ensure they function safely and reliably in construction and material handling applications.

5. Mining and Quarrying

Drilling Machines: Mining equipment, such as drill rigs, crushers, and haul trucks, requires regular lubrication of their joints, bearings, and gears to handle the demanding loads and harsh conditions in mining environments.

Conveyor Systems: Conveyor belts and associated machinery in mining and quarrying operations also need frequent lubrication to maintain smooth movement and reduce downtime.

6. Railroads and Public Transportation

Railroad Maintenance: Grease guns are used to lubricate the bearings, switches, and mechanical parts of railroad cars and engines. Proper lubrication ensures that the trains run smoothly and reduces the risk of mechanical failure.

Mass Transit Systems: Public transportation systems such as subways and light rail rely on grease guns for maintaining the mechanical parts that keep vehicles running efficiently.

7. Marine and Offshore Industries

Boats and Ships: Marine vessels require lubrication for parts like propeller shafts, winches, and steering systems. In saltwater environments, proper lubrication is vital to protect against corrosion and wear.

Offshore Oil Rigs: Grease guns are used to maintain machinery on offshore oil platforms, such as drilling equipment, cranes, and pumps that operate under harsh, corrosive conditions.

In all these industries, regular lubrication with a grease gun helps prevent mechanical failure, reduces wear, and extends the lifespan of expensive machinery.

0 notes

Text

Learn About the Types and Uses of Round Aluminum Bronze Bars at Rajkrupa Metal Industries

Rajkrupa Metal Industries is one of the Premium Quality Aluminium Bronze Round Bars Manufacturer In India. We have purposefully established ourselves as a premier producer and vendor in the global market for aluminium bronze round bars because of our superior technical and corporate people capabilities.

Round bars made of aluminium bronze are an alloy that contains silicon, nickel, iron, manganese, and copper in addition to aluminium. This alloy has a strong resistance to corrosion, superior electrical and thermal conductivity, and high strength. Round bars made of aluminium bronze are frequently used in a variety of sectors because of their special set of qualities. The following are some varieties and uses for round bars made of aluminium bronze:

Types of Aluminium Bronze Alloys:

C63000 (AMS 4640):

This alloy has a reputation for being extremely strong and resistant to corrosion. It is frequently used in settings like maritime situations and the aerospace sector, where wear resistance is essential.

C95400 (9C):

Because there is more aluminium in this alloy, it can be used in situations where great strength and hardness are required. It is frequently used in demanding applications like bearings and gears.

C62400 (AMS 4590):

Because of its exceptional wear resistance, the C62400 alloy is frequently utilised in parts like valve seats, gears, and bushings.

C63020 (UNS C63020):

Similar to C63000 alloy, C63020 alloy has more nickel, which improves corrosion resistance. It works well in maritime applications and other settings where corrosion is an issue.

Applications of Aluminium Bronze Round Bars:

Marine Applications:

Round bars made of aluminium bronze are frequently seen in maritime settings because of their superior resistance to corrosion. They are utilised for parts including valve parts, maritime hardware, and propeller shafts.

Aerospace Industry:

Aluminium bronze is a good material for aircraft applications because of its high strength and resistance to corrosion. It is utilised in parts such as bearings, bushings, and landing gear sections.

Oil and Gas Industry:

Round bars made of aluminium bronze are utilised in the oil and gas sector, especially in equipment that is exposed to corrosive conditions. They are utilised for drilling equipment, pump parts, and valve components.

Heavy Equipment Manufacturing:

Certain alloys of aluminium bronze have great strength and resistance to wear, which makes them ideal for use in heavy-duty machinery such bearings, bushings, and gears.

Chemical Processing:

Equipment used in chemical processing uses aluminium bronze because it is resistant to corrosion from a variety of substances. It is used in fittings, pumps, and valves.

Electrical Components:

Aluminum bronze has strong electrical conductivity, which makes it useful for switchgear components, electrical connections, and other electrical applications.

Automotive Industry:

Aluminium bronze round bars can be used for gears, bushings, and bearings in some automotive applications where high strength and resistance to corrosion are necessary.

It's crucial to take the climate, the required mechanical qualities, and the particular needs of the application into account when choosing an aluminum bronze alloy.Talk about any impending advances in science or technology.

We have manufacturers of round bars made of aluminium bronze all throughout India, including Aluminum Bronze Round Bars Manufacturer in Pune, Aluminum Bronze Round Bars Manufacturer in Mumbai , and Aluminum Bronze Round Bars Manufacturer in Bengaluru.

#Round Bars Manufacturer#Round Bars Manufacturer in India#Round Bars#Aluminium Bronze Round Bar Manufacturer in India#Aluminium Bronze Round Bar Manufacturer#Aluminium Bronze Round Bar#Aluminium Round Bar#Bronze Round Bar#Aluminium bronze#Aluminum Bronze Round Bars Manufacturer in Mumbai#Aluminum Bronze Round Bars Manufacturer in Pune#Aluminum Bronze Round Bars Manufacturer in Bengaluru

0 notes

Text

Benefits of Customized CNC Machined Monel

Customized CNC machined Monel is changing the game for industries that demand high strength and corrosion resistance. This nickel-copper alloy, known for its durability and versatility, is perfect for applications in marine, aerospace, chemical processing, and more.

Why Choose Monel?

Corrosion Resistance: Ideal for harsh environments.

High Strength: Reliable under heavy loads.

Precision: CNC machining ensures exact specifications.

Versatility: Suitable for various industries.

Longevity: Reduces need for frequent replacements.

Applications: