#Water Booster Pump Control Panel

Explore tagged Tumblr posts

Text

A Powerful Resource: An All-Inclusive Manual on Booster Pump Systems

Efficiency Enhancement through the Use of Booster Pump Systems

Booster Pump Systems are essential instruments for fluid dynamics and effective water management. It would be impossible to exaggerate the importance of booster pump systems in various settings, including industrial applications, maritime environments, and leisure facilities such as swimming pools.

A Comprehensive Guide to Booster Pumps

Unheralded throughout its many uses, booster pump systems maintain a constant water pressure. The importance of the major components becomes clear when we examine them more closely:

Booster Pump: System Central

The booster pump is the engine that keeps the water flowing steadily through the pipes by pushing it against obstacles. The booster pump is the engine that drives water distribution systems, whether they are in tall buildings or in agricultural fields, to ensure effective irrigation.

A Lifeboat Battery Charger for Seafaring

The lifeboat battery charger is the show-stopper in underwater settings. In an emergency, this vital part keeps the lifeboat batteries charged to power the boat’s vital systems. The importance of the Lifeboat Battery Charger in ensuring the safety of mariners is highlighted by the fact that its dependability might have a fatal impact.

Control Panels for Marine Vessels: The Hub of Shipboard Operations

Shipboard Control Panels Revealed

Ships’ central nervous systems marine control panels oversee a wide range of operations critical to the ship’s navigation, security, and efficiency. These panels perfectly harmonize with Booster Pump Systems, coordinating a maritime symphony of activities.

Integrating Booster Pump Systems: A Seafaring Synergy

Marine Control Panels and Booster Pump Systems must work in perfect harmony for marine applications. Booster Pump System performance may be monitored and adjusted in real-time with the help of these panels, which optimizes efficiency and guarantees a pleasant sailing experience.

Marine Control Panels with a Lifeboat Battery Charger for Your Peace of Mind

The Marine Control Panel’s Lifeboat Battery Charger is crucial to keep life-saving machinery running. The readiness of lifeboats for deployment is ensured by a dependable charger, adding an essential safeguard for crew and passengers.

Creating a Havoc: Pool Control Panels

Immerse Yourself in Efficiency: Pool Control Panels

Regarding pools used for enjoyment, Swimming Pool Control Panels are the main attraction. Designed to make swimming fun and safe, these panels control the pool’s pumps, filtration, and other features.

Recreational Harmony: Optimizing Booster Pump Systems

Preserving pristine water quality and maximizing circulation efficiency may be achieved by optimizing booster pump systems using swimming pool control panels. Whether it’s a public or private pool, these panels are necessary for water temperature regulation and energy efficiency.

Conclusion

The most advanced devices for managing water resources are lifeboat battery chargers, control panels for ships, and panels for pools and spas. These systems guarantee uninterrupted water flow and are crucial in many areas of our lives, including industrial processes, marine safety, and recreational activities.

#Booster Pump Control Panel#Water Booster Pump Control Panel#Transfer Pump Control Panel#Pump control Panels#Marine Control Panels#Marine Switch Panels#VSD Control Panel#Star Delta Starter Panel#Customised Marine Panels#Cold Room Alarm Panel#FCU Control Panel#FCU Starter Panel#RCV Control Panel#Custom Motor Control Panel#Lifeboat Battery Charger#Lifeboat Charger#Propeller Shaft Tachometer#Emergency Engine Order Telegraph#Booster Pump System#Transfer Pump System#Fountain Control Panel#Swimming Pool Control Panel

0 notes

Text

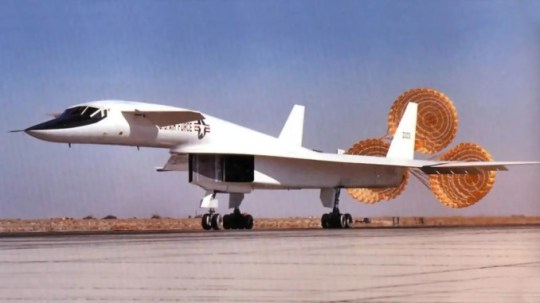

OTD in 1969, The Iconic XB-70 Valkyrie Mach 3 Super Bomber Made Its Last Flight

February 4, 2021 Military Aviation, Military History

Three drag chutes were needed to slow down the landing roll of the XB-70. (Image credit: Reddit edit The Aviationist)

The massive XB-70 Valkyrie is the largest and heaviest airplane ever to fly at Mach 3.

The North American XB-70 Valkyrie was the most ambitious super-bomber project of the Cold War. The massive six-engine bomber was slated to be the ultimate American high-altitude, high-speed, deep-penetration manned nuclear bomber designed to fly high and fast, so as to be safe from Soviet interceptors.

Two Valkyrie prototypes were been built at North American Aviation before the Kennedy Administration cancelled the program as a consequence of the doubts that surrounded the future of manned bombers believed to be obsolete platforms. The threat posed by Soviet SAMs (Surface-to-Air Missiles) put the near-invulnerability of the strategic bomber at high altitudes in doubt. In low-level penetration role, the B-70 offered little performance improvement over the B-52 it was designed to replace (!) and it was much more expensive with shorter range.

Some fascinating variants of the aircraft were proposed. Some envisaged the B-70 carrying an Alert Pod, or flying as a Supersonic Refueler or as a Recoverable Booster Space System (RBSS). You can find all the details about these crazy concepts in this story we have posted last year.

Ezoic

The B-70 program was canceled in 1961 and development continued as part of a research program to study the effects of long-duration high-speed flight with the two XB-70A.

XB-70A number 1 (62-001) made its first flight from Palmdale to Edwards Air Force Base, CA, on Sept. 21, 1964. The second XB-70A (62-207) made its first flight on Jul. 17, 1965. The latter differed from the first prototype for being built with an added 5 degrees of dihedral on the wings as suggested by the NASA Ames Research Center, Moffett Field, CA, wind-tunnel studies.

While the 62-001 made only one flight above Mach 3, because of poor directional stability experienced past Mach 2.5, the second XB-70, achieved Mach 3 for the first time on Jan. 3, 1966 and successfully completed a total of nine Mach 3 flights by June on the same year.

Photo of the XB-70 #1 cockpit, which shows the complexity of this mid-1960s research aircraft. On the left and right sides of the picture are the pilot’s and co-pilot’s control yokes. Forward of these, on the cockpit floor, are the rudder pedals with the NAA North American Aviation trademark. Between them is the center console. Visible are the six throttles for the XB-70’s jet engines. Above this is the center instrument panel. The bottom panel has the wing tip fold, landing gear, and flap controls, as well as the hydraulic pressure gages. In the center are three rows of engine gages. The top row are tachometers, the second are exhaust temperature gages, and the bottom row are exhaust nozzle position indicators. Above these are the engine fire and engine brake switches. The instrument panels for the pilot left and co-pilot right differ somewhat. Both crewmen have an airspeed/Mach indicator, and altitude/vertical velocity indicator, an artificial horizon, and a heading indicator/compass directly in front of them. The pilot’s flight instruments, from top to bottom, are total heat gage and crew warning lights; stand-by flight instruments side-slip, artificial horizon, and altitude; the engine vibration indicators; cabin altitude, ammonia, and water quantity gages, the electronic compartment air temperature gage, and the liquid oxygen quantity gage. At the bottom are the switches for the flight displays and environmental controls. On the co-pilot’s panel, the top three rows are for the engine inlet controls. Below this is the fuel tank sequence indicator, which shows the amount of fuel in each tank. The bottom row consists of the fuel pump switches, which were used to shift fuel to maintain the proper center of gravity. Just to the right are the indicators for the total fuel top and the individual tanks bottom. Visible on the right edge of the photo are the refueling valves, while above these are switches for the flight data recording instruments. (Image credit: NASA)

A joint agreement signed between NASA and the Air Force planned to use the second XB-70A prototype for high-speed research flights in support of the American supersonic transport (SST) program.

However, on June 8, 1966, the XB-70 62-207 was involved in one of the most famous and tragic accidents in military aviation when it collided with a civilian registered F-104N while flying in formation as part of a General Electric company publicity photo shoot over Barstow, California, outside the Edwards Air Force Base test range in the Mojave Desert. The aircraft were flying in formation with a T-38 Talon, an F-4B Phantom II, and a YF-5A Freedom Fighter.

North American XB-70A Valkyrie just after collision. Note the F-104 is at the forward edge of the fireball and most of both XB-70A vertical stabilizers are gone. (U.S. Air Force photo)

As explained in a previous post here at The Aviationist:

Towards the end of the photo shooting NASA registered F-104N Starfighter, piloted by famous test pilot Joe Walker, got too close to the right wing of the XB-70, collided, sheared off the twin vertical stabilizers of the big XB-70 and exploded as it cartwheeled behind the Valkyrie. North American test pilot Al White ejected from the XB-70 in his escape capsule, but received serious injuries in the process. Co-pilot Maj. Carl Cross, who was making his first flight in the XB-70, was unable to eject and died in the crash.

The root cause of the incident was found to be wake turbulence: wake vortices spinning off the XB-70’s wingtip caused Walker’s F-104N to roll, colliding with the right wingtip of the huge XB-70 and breaking apart. As explained in details in this post, wingtip vortices form because of the difference in pressure between the upper and lower surfaces of a wing. When the air leaves the trailing edge of the wing, the air stream from the upper surface is inclined to that from the lower surface, and helical paths, or vortices, result. The vortex is strongest at the tips and decreasing rapidly to zero nearing midspan: at a short distance from the trailing edge downstream, the vortices roll up and combine into two distinct cylindrical vortices that constitute the “tip vortices.

Although research activities continued with the first prototype with a first NASA flight on April 25, 1967, the last one was on Feb. 4, 1969.

The only remaining XB-70 Valkyrie super bomber in on display at the National Museum of the U.S. Air Force at Wright-Patterson AFB in Dayton, Ohio. In October last year, it had to briefly moved outside for display maintenance. Here you can watch a video of the monumental move.

A view of the six massive afterburners on the XB-70 Valkyrie as the aircraft is towed out of its display hangar temporarily for museum maintenance. (Photo: National Museum of the U.S. Air Force via YouTube)

About David Cenciotti

David Cenciotti is a journalist based in Rome, Italy. He is the Founder and Editor of “The Aviationist”, one of the world’s most famous and read military aviation blogs. Since 1996, he has written for major worldwide magazines, including Air Forces Monthly, Combat Aircraft, and many others, covering aviation, defense, war, industry, intelligence, crime and cyberwar. He has reported from the U.S., Europe, Australia and Syria, and flown several combat planes with different air forces. He is a former 2nd Lt. of the Italian Air Force, a private pilot and a graduate in Computer Engineering. He has written five books and contributed to many more ones.

@TheAviationist via X

21 notes

·

View notes

Text

🔷️ Project: Private Office Building

📍 Location: Irqah, Riyadh

A range of pumps was #supplied and #assembled to meet the water needs of the building in a reliable and efficient manner.

🔹 #Grundfos CR vertical multistage booster pumps to ensure stable and efficient water flow.

🔹 Submersible pumps to meet the project’s requirements with reliable performance.

🔹 Custom control panels with LS VFD for operational efficiency and precise performance control.

The Pumps were assembled according to the highest global standards and tested to ensure safe and sustainable operation.

#SaudiArabia #Contracting #supply #pumps #grundfos #Infrastructure

#InfrastructureInSaudiArabia

#Vision2030 #SaudiProjects #AdvancedPumpsCo

🔷️ المشروع: مبنى إداري خاص

📍 الموقع: الرياض| امارة عرقة

تم #توريد و #تجميع مجموعة مضخات لمختلف تطبيقات المياه لتلبية احتياجات المبنى بشكل موثوق وفعال.

🔹 مضخات التعزيز العمودية متعددة المراحل CR من جراندفوس لضمان تدفق المياه بشكل مستقر وفعال.

🔹 مضخات غاطسة لتلبية متطلبات المشروع بأداء موثوق.

🔹 لوحات تحكم مخصصة مع VFD من LS لتحقيق كفاءة تشغيلية وتحكم دقيق في الأداء.

تم تجميع المضخات وفق أعلى المعايير العالميّة مع اختبارها لضمان تشغيل آمن ومستدام.

#الرياض #مضخات #جراندفوس #البنية_التحتية_في_السعودية #رؤية2030 #مشاريع_السعودية #شركة_المضخات_المتقدمة

0 notes

Text

How to Maintain a Booster Pump for Long-Lasting Performance

Booster pumps play a crucial role in maintaining adequate water pressure in homes, commercial buildings, and industrial systems. However, like any mechanical system, they require regular maintenance to بوستر پمپ ensure optimal performance and longevity. Proper maintenance prevents breakdowns, improves efficiency, and extends the pump’s lifespan.

In this article, we will explore the key steps to maintain a booster pump, common maintenance issues, and tips for ensuring long-term performance.

1. Why Booster Pump Maintenance is Important

Regular maintenance helps:

✔ Prevent sudden failures that can disrupt water supply ✔ Improve energy efficiency, reducing electricity costs ✔ Extend the pump’s lifespan, saving on replacement costs ✔ Maintain consistent water pressure for smooth operation ✔ Reduce repair expenses by identifying issues early

By following a structured maintenance routine, you can keep your booster pump running efficiently for years.

2. Daily and Weekly Maintenance Checks

✔ Inspect for Leaks

Check for any water leaks around the pump, pipes, or connections. Leaks can cause pressure loss and water damage over time.

✔ Monitor Pressure Levels

Ensure that the pump maintains the required pressure range. Fluctuations in pressure may indicate blockages, leaks, or pump inefficiencies.

✔ Listen for Unusual Noises

Loud or unusual sounds like grinding, knocking, or whining may signal worn-out bearings, cavitation, or air in the system. Addressing these issues early can prevent serious damage.

✔ Check Electrical Connections

Loose or damaged wiring can lead to power supply issues or electrical failures. Inspect the control panel, wiring, and connections for signs of wear.

3. Monthly Maintenance Tasks

✔ Clean Filters and Strainers

Filters and strainers prevent debris from entering the pump and causing clogs or damage. Clean or replace filters monthly to maintain smooth water flow.

✔ Inspect Valves and Seals

Check the check valve, pressure relief valve, and seals for signs of wear, leaks, or mineral buildup. Faulty valves can cause pressure loss or inefficient operation.

✔ Lubricate Moving Parts

If the pump has bearings or mechanical seals, apply lubrication as needed to reduce friction and prevent overheating. Use the manufacturer’s recommended lubricants and grease.

✔ Flush the System

Sediment and mineral buildup can reduce pump efficiency. Flushing the system removes debris and maintains optimal water flow.

4. Quarterly and Annual Maintenance

✔ Test the Motor and Electrical Components

Check the motor’s voltage, amperage, and insulation resistance to ensure efficient operation. If the motor is running hotter than normal, it may require servicing.

✔ Inspect and Tighten Bolts and Fittings

Vibrations from daily operation can loosen bolts, nuts, and fittings. Tightening these components helps prevent leaks and misalignment.

✔ Examine Pump Impellers and Bearings

Impellers push water through the system, and any damage reduces efficiency. Bearings also wear out over time, leading to increased friction and noise. Inspect these parts annually and replace them if necessary.

✔ Perform a Full System Pressure Test

Testing the system under maximum load conditions helps identify hidden issues like pipe blockages, valve failures, or pressure inconsistencies.

✔ Replace Worn-Out Parts

Hoses, seals, and gaskets degrade over time. Replacing them before they fail helps maintain optimal performance.

5. Common Problems and How to Fix Them

🔴 Low Water Pressure

✔ Check for leaks, clogged filters, or a failing pressure sensor ✔ Ensure valves are fully open and functioning ✔ Inspect for air in the system and bleed it out if necessary

🔴 Overheating Pump

✔ Ensure the motor is properly ventilated ✔ Check for blockages in the water supply ✔ Lubricate bearings and moving parts

🔴 Pump Cycling On and Off Frequently

✔ Adjust the pressure switch settings ✔ Check for water leaks in the system ✔ Ensure the pressure tank is functioning properly

🔴 Noisy Operation

✔ Look for loose fittings or cavitation issues ✔ Clean the impeller and check for damage ✔ Ensure there is no air trapped in the system

6. Tips for Long-Term Booster Pump Performance

✅ Follow the Manufacturer’s Maintenance Guidelines – Always use the recommended parts and servicing schedule ✅ Keep a Maintenance Log – Tracking inspections, repairs, and replacements helps identify patterns ✅ Invest in a Backup Pump – If the pump is critical, having a backup unit prevents disruptions ✅ Use Energy-Efficient Settings – Variable Frequency Drives (VFDs) adjust pump speed to save energy ✅ Hire a Professional for Annual Servicing – A certified technician can perform detailed inspections and repairs

7. Conclusion

Maintaining a booster pump is essential for consistent water pressure, efficiency, and long-term reliability. By following a structured maintenance plan, checking for common issues, and scheduling regular servicing, you can extend the lifespan of your pump while minimizing repair costs.

0 notes

Text

Low Hot Water Output in Solar Water Heaters: Causes and Solutions

One of the most common issues homeowners face with solar water heaters is low hot water output. It can be frustrating, especially when you rely on your system for everyday needs. In this post, we’ll explore the most frequent causes of this problem and provide practical solutions to help restore your system’s efficiency.

1. Cloudy or Overcast Weather

Cause: Solar water heaters rely on sunlight to heat the water. Overcast or cloudy days can limit the amount of solar energy absorbed, resulting in insufficient hot water.

Solution:

Ensure your system has a backup heating source, such as an electric or gas booster, to compensate for cloudy weather.

Consider installing a larger collector area to capture more sunlight when available.

2. Dirty or Shaded Solar Panels

Cause: Dirt, dust, bird droppings, or shading from nearby trees can block sunlight from reaching the panels, reducing the system's efficiency.

Solution:

Regularly clean the solar panels to remove dust and debris.

Trim back any vegetation that may cast shadows on the panels, particularly during peak sunlight hours.

Inspect for any structural shading that may require repositioning the panels.

3. Incorrect Sensor Settings or Faulty Sensors

Cause: The sensors in your solar water heating system measure temperature and control the circulation of water. If these sensors are malfunctioning or improperly set, they may fail to activate the system or circulate water at the wrong times.

Solution:

Check the sensor settings to ensure they are programmed correctly according to the manufacturer’s specifications.

Test the sensors by monitoring temperature readings. If they appear inaccurate, replace faulty sensors.

4. Blockages in the System

Cause: Blockages in the pipes or heat exchanger can impede the flow of water, causing less heated water to reach your faucets.

Solution:

Inspect the system for blockages and clear any obstructions.

Flush the system to remove sediment buildup, especially in areas with hard water.

Check the heat exchanger for debris or scaling and clean it as needed.

5. Circulation Pump Malfunction

Cause: The circulation pump moves the heated water from the solar collectors to the storage tank. If the pump is failing or not functioning efficiently, hot water won’t reach the storage tank.

Solution:

Listen for unusual sounds from the pump, which may indicate a problem.

Check the power supply and wiring to ensure the pump is receiving electricity.

If necessary, replace the pump with a model compatible with your system.

6. Poor Insulation or Heat Loss

Cause: Inadequate insulation in pipes or the storage tank can cause heat loss, resulting in lower temperatures at the tap.

Solution:

Insulate pipes and the storage tank to reduce heat loss, especially in cold climates.

Check for any leaks in the insulation and repair them to improve efficiency.

7. System Age and Wear

Cause: Older systems may experience wear and tear that affects performance, including loss of efficiency in the solar collectors or degradation in components.

Solution:

If your system is over 10-15 years old, consider upgrading key components or replacing the entire system with a more energy-efficient model.

Regularly maintain the system to extend its lifespan and prevent efficiency losses.

Low hot water output in your Solar Water Heater can stem from a variety of causes, from cloudy weather to system blockages. Fortunately, many of these issues can be resolved with simple maintenance or repairs. By keeping your system clean, checking the sensors, and ensuring proper insulation, you can maximize your solar water heater’s efficiency and enjoy consistent hot water. If you’re unable to fix the problem on your own, don’t hesitate to contact a professional for assistance. For more info contact Solar Water Heater Maintenance Dubai in UAE or call us at +971 4 2522966.

0 notes

Text

Heating Up Your Savings: Ways to Maximize the Efficiency of Your Water Heater

Introduction: Why Water Heater Efficiency Matters

A water heater is essential for daily comfort, but it can also be a significant part of your energy bill. Maximizing its efficiency not only saves you money but also reduces your environmental impact. In this guide, we explore effective ways to improve the efficiency of your water heater.

Tips for Maximizing Water Heater Efficiency

1. Set the Optimal Temperature

Why It Matters: Setting your water heater to the right temperature can make a big difference in energy consumption. The U.S. Department of Energy recommends setting the thermostat to 120°F (49°C) for optimal performance and energy savings.

How to Adjust:

Locate the Thermostat: On most water heaters, the thermostat is found on the side of the unit.

Turn Down the Temperature: Use a screwdriver to adjust the temperature setting. Lowering it by just 10 degrees can reduce your energy bill by up to 5%.

2. Insulate Your Water Heater

Why It Matters: Insulating your water heater reduces heat loss, keeping the water hot for longer periods and reducing the need for frequent reheating.

How to Insulate:

Wrap the Heater: Purchase an insulation blanket from a hardware store and wrap it around the tank. Be sure not to cover the thermostat or any vents.

Insulate the Pipes: Insulating hot water pipes also helps keep water hot as it travels to the tap.

3. Perform Regular Maintenance

Why It Matters: Regular maintenance ensures your water heater runs efficiently and prevents costly repairs.

Maintenance Tasks:

Flush the Tank: Sediment build-up can decrease efficiency. Drain the tank every 6-12 months to remove sediment.

Check the Anode Rod: This rod prevents tank corrosion. Replace it if it’s worn out.

4. Install a Timer for Your Water Heater

Why It Matters: A timer allows you to control when your water heater operates, so it only heats water when needed.

How to Install:

Purchase a Timer: Find a timer designed for water heaters at a home improvement store.

Set Heating Times: Program the timer to turn the water heater on only during peak usage times.

5. Upgrade to a More Efficient Water Heater

Why It Matters: Modern water heaters are more energy-efficient than older models. Upgrading can result in significant long-term savings.

Options to Consider:

Tankless Water Heaters: These on-demand systems heat water only when needed.

Heat Pump Water Heaters: These use heat from the air or ground to heat water, offering high efficiency.

6. Seal Leaks in the Water Heater Area

Why It Matters: Leaking hot water or steam wastes energy. Sealing leaks helps maintain efficiency.

How to Seal Leaks:

Inspect the Area: Check around the water heater for drafts or leaks.

Use Caulk or Weatherstripping: Seal any gaps to prevent heat loss.

7. Reduce Hot Water Usage

Why It Matters: Using less hot water decreases the amount your water heater needs to heat.

Ways to Reduce Usage:

Install Low-Flow Fixtures: Use low-flow showerheads and faucets.

Take Shorter Showers: Reduce the time spent in the shower to save hot water.

Advanced Tips for Water Heater Efficiency

8. Consider a Solar Water Heater

Why It Matters: Solar water heaters use the sun’s energy to heat water, which can greatly reduce your energy costs.

How It Works:

Install Solar Panels: These collect sunlight and transfer it to a water storage tank.

Evaluate Costs: While initial costs can be high, long-term savings and potential incentives can offset the investment.

9. Insulate Your Home

Why It Matters: Better home insulation helps retain heat, reducing the workload on your water heater.

Insulation Tips:

Insulate Walls and Attics: Proper insulation keeps your home warmer, which helps maintain the temperature of hot water.

10. Use a Water Heater Booster

Why It Matters: A water heater booster increases the efficiency of your existing water heater without requiring a full replacement.

How to Install:

Purchase a Booster: These devices improve the efficiency of your current water heater.

Install It: Follow the manufacturer’s instructions for proper installation.

Conclusion: Enhance Efficiency and Save Money

Maximizing the efficiency of your water heater can lead to significant energy savings and lower utility bills. By setting the optimal temperature, insulating your water heater, performing regular maintenance, and considering upgrades, you can improve efficiency and extend the life of your water heater. Implement these tips to enjoy hot water at a lower cost and with greater environmental responsibility.

0 notes

Text

Booster Pump Repair Service Provider in Dubai?

Giving clientele quality plumbing services is fundamental for every service provider in UAE. Pro fixers dubai is one of the most dependable booster pump repair Dubai providers for all your home and business needs. The organization has practical experience in repairing any booster pump. So, you are searching for a specialist who can provide quality booster siphon fixing services at a fair cost. In that case, we are the best in the market.

Booster Siphons are utilized to increase the pressure in the water system. It may be in-line circulator end suction, or it can be a single or multi-vertical turbine pump. bathtub repair dubai These siphons are utilized in applications where the normal framework pressure is low and should be increased. These siphons help water pressure in urban cities, well water frameworks, rainwater assortment systems, and irrigation applications. Booster Pumps are typically situated close to the water source, somewhere close to the building and the main water outlet. Most booster pump systems need a storage pressure tank.

Storage pressure tanks do three main functions, i.e., safeguard and extend the pump life span through rapid cycling of the siphon motor. It also gives water under pressure between the cycles. It only provides additional space for water storage if the water supply cannot supply the usual water volume during the process.

The most common issue with pumps is rapid cycling. So, if there is no pressure tank, Water Heater Repair all the essential water used, flushing toilets and washing hands, can trigger the pump to start cycling. The booster pump has come equipped with Variable Frequency Drives in the past few years. It helps lower the power costs, and the booster pumps have fewer chances of wear and tear.

What Are the Booster Pump Services pro fixers dubai Offers?

Below mentioned are all the booster pump services our company has to offer:

On location troubleshooting

Control Panel investigating and fix

Pressure Controller Valve modification and fix

Converting to Variable Recurrence Drives (VFD)

Removal of booster Siphon from workspace

Pressure Tank fixes and substitutions

Complete disassembly and review with testing and accurate measurements

Thorough cleaning and bead blasting of all siphon parts and other components of water systems

Reassembly

Shaft Arrangements

Engine investigation

Engine fix and substitution if important

Our team can fix, remake, redesign, or update your booster siphon to get it back running as fast as possible with the unwavering quality you anticipate. We stand behind each revamp or fix with the maximum efficiency and provide a guarantee on our workmanship to give you the best results possible.

0 notes

Text

The Role of Booster Pumps in Irrigation Systems

Boosting agricultural productivity is a critical goal for farmers and growers around the world, and booster pumps play a vital role in achieving this objective, especially in the context of irrigation systems. Here's an in-depth exploration of how booster pumps contribute to enhancing agricultural productivity through efficient irrigation:

1. Efficient Water Distribution:

Booster pumps help ensure even and efficient distribution of water across the entire agricultural field.

By maintaining consistent water pressure, booster pumps prevent under-watering or over-watering of crops, optimizing growth conditions.

2. Overcoming Elevation Challenges:

In hilly or sloped landscapes, water may not naturally flow to all areas of the field.

Booster pumps help transport water uphill or across uneven terrains, extending irrigation coverage to previously challenging areas.

3. Maximizing Crop Yield:

Proper irrigation with booster pumps enables timely and adequate hydration for crops.

Enhanced water availability results in increased crop yield, improved crop quality, and reduced loss due to drought stress.

4. Water Efficiency:

Booster pumps enable the use of advanced irrigation methods, such as drip or sprinkler systems, which are more water-efficient than traditional methods.

Precise water application minimizes wastage and runoff, conserving water resources.

5. Customizable Irrigation Schedules:

Booster pumps facilitate the implementation of automated irrigation schedules based on crop needs and environmental factors.

Farmers can adjust irrigation frequency and duration to match specific growth stages, further optimizing yield.

6. Rapid Coverage:

Booster pumps allow for quick and efficient filling of irrigation tanks or reservoirs.

This enables timely irrigation during critical growth periods and reduces the risk of crop stress.

7. Hydroponic and Greenhouse Farming:

Booster pumps play a crucial role in hydroponic and greenhouse farming by maintaining the circulation of nutrient solutions and water to plants.

Consistent and controlled irrigation enhances plant growth in these controlled environments.

8. Frost Protection:

Booster pumps support the application of protective measures, such as frost protection irrigation, during cold periods.

The ability to quickly apply water can help mitigate frost damage and preserve crops.

9. Scaling Operations:

As farms expand or new fields are brought into production, booster pumps can accommodate increased irrigation demands.

This scalability allows farmers to adapt to changing agricultural needs.

10. Remote and Off-Grid Farming:

- In remote or off-grid areas, booster pumps can be powered by alternative energy sources like solar panels or wind turbines.

- This enables irrigation in areas with limited access to conventional power infrastructure.

11. Sustainable Agriculture:

- By optimizing water use and minimizing wastage, booster pumps contribute to more sustainable agricultural practices.

- Efficient irrigation reduces environmental impact and promotes long-term soil health.

12. Tailored Solutions:

- Booster pump systems can be customized to suit specific crop types, soil conditions, and farm layouts, providing tailored solutions for diverse agricultural needs.

Incorporating booster pumps into irrigation systems empowers farmers to manage water resources effectively, improve crop yield and quality, and contribute to food security. As agriculture continues to face challenges related to water scarcity and climate variability, booster pumps remain a valuable tool in enhancing agricultural productivity and sustainability. For more info contact booster pump suppliers in uae or call us at +971 4 252 2966

0 notes

Text

What is an RO plant?

Throughout human history, problems with the production of freshwater have remained. Many elements, including geography, temperature, pollutants, salinity, dissolved solids, and others, have made it difficult to provide clean water in many areas. Fortunately, the development of reverse osmosis has offered a successful answer to this issue.

Reverse osmosis eliminates dissolved ions from water by using cutting-edge filtration technology. An elemental force called osmosis pulls water toward saltier water. This is the method used to take dissolved ions out of water. Utilizing pumps and semi-permeable membranes, which force water across the membrane and remove dissolved salt from the water, it is possible to overcome this elemental force.

What is reverse osmosis system?

Reverse osmosis filters undesired contaminants from water by applying pressure to the treated water, which pushes water molecules through a semipermeable membrane and removes bacteria, viruses, and other microbiological organisms. Pure water is created as a result of the procedure, which separates and flushes out the impurities from the water.

High pressure pumps are used in the reverse osmosis process to increase pressure on the concentrated side of the RO system and force water through a membrane. It is a very efficient method for treating water, although depending on how many toxins are present overall in the feed water, it may require more pressure.

Reverse osmosis is more comparable to cross-flow filtration than it is to traditional filtration. Since cross-flow filtration has two outlets for the solution to run through, it is more efficient at handling higher pollutant concentrations. The membrane surface can stay clean and accumulation is significantly reduced thanks to the permeate and concentrated water flowing in opposite directions. This filtration technique guarantees a longer system and component lifespan while requiring less membrane cleaning.

Which elements make up a reverse osmosis system?

Five essential components make up a reverse osmosis system:

Pressure vessels and membranes:

Without membrane components, a reverse osmosis system would obviously not function very well. Depending on the type of intake water and ending clarity, different proteins make up the various membrane components. Membrane components can be used to purify brackish water, hospital-grade disinfection seawater, and specific pollutants, to mention a few. You can be sure that a membrane component exists for the task if water treatment is required. The size and quantity of reverse osmosis membranes in a system will depend on the task's scale (municipal, commercial, or industrial).

Reverse Osmosis Skid:

Using a powder-coated, carbon steel frame to attach all of your components on will help your reverse osmosis system be as tough as it can be. It mounts to the ground, is resistant to the environment, and is built to withstand the intense vibration of high-pressure pumps.

Cartridge Filter:

A cartridge filter is typically included with reverse osmosis water systems to guarantee that no particles big enough to harm the membranes even get close to them. On request, this cartridge can be anything other than the standard five micron spun polypropylene filter. The cartridge is packaged in a tough shell that can withstand the pressure from the booster or main feed pumps.

High Pressure Reverse Osmosis Pump:

The rejection rate for a reverse osmosis system is too high in most commercial or industrial situations without a high-quality pump. Ensuring that the pump is properly matched to the membrane quantity and size is crucial for the system. The permeate rejection and recovery rates are often better the more horsepower the intake pump has.

Control Panel:

The reverse osmosis system also needs to be managed by a human. The controls also allow for the simultaneous management of many systems, thereby creating a one-man water production facility.

There are various additional components that can be added to or integrated into a reverse osmosis system. For example, the entire skid may be constructed as a containerized system, making your desalination by RO system mobile. An RO system can also be equipped with a variety of add-on skids for jobs including membrane cleaning, pretreatment, chemical dosing, and other duties as needed.

What kind of commercial and industrial applications are served by RO systems?

The likelihood is that a reverse osmosis system can treat water if it is necessary. Highly pure reverse osmosis water is advantageous to a wide range of industries, as well as to several applications where water treatment is necessary. A reverse osmosis system is frequently the best, most affordable option due to the enormous amounts of water needed; it also uses less energy than the majority of large-scale treatment techniques.

A reverse osmosis system is frequently the most energy-efficient choice as well as the environmentally beneficial one.

We take great satisfaction in being your go-to source for information and assistance with municipal, commercial, and industrial water treatment needs at Netsol.

For support, inquiries, or product purchases, call on +91-9650608473 or email at [email protected]

#industrial ro plant manufacturer commercialroplant.com#commercial ro plant manufacturer#commercial ro plant manufacturers#industrial ro plant manufacturers#industrial ro plant manufacture

0 notes

Text

Download Workshop Manuals

Workshop Manuals for every make and model of Car or Van or Commercial Vehicle available for download.

We have the full range of main dealer garage workshop manuals available on the internet worldwide, Worldwide specifications fully covered. Petrol, Gasoline, Diesel, Left and Right hand Drive all covered. Full coverage of all varients of Manual and automatic transmissions. Hybrid and electric vehicle manuals also available. Partial List of Procedures you can carry out with these factory workshop service repair manuals troubleshooting, replace fix spare parts, electrical wiring diagrams, engine starting problems, mechanical issues, engine control system, emission control systems, drive shafts, drive belt, differential case assembly, cylinder head assembly, block assembly, air bag assembly, cooling system, cooling fan system, clutch unit, clutch system, clutch start switch assembly, clutch release cylinder assembly, clutch pedal sub-assembly, clutch master cylinder assembly, cigarette lighter, charging system, charcoal canister, chain sub-assembly, center stop lamp assembly, center cluster module switch, air bag sensor, camshaft, brake system, brake pedal, brake master cylinder, brake fluid, brake booster, brake actuator, body repair, yaw rate sensor, wiring diagrams, wire harness repair, wiper and washer system, windshield wiper motor, windshield glass replacement, wheels and tires, water pump, valve clearance, transmission wire, transmission valve body, transmission revolution sensor, transmission control cable, torque converter clutch replacement, throttle body assembly, thermostat, seat belts, sun roof, steering, steering sensor, steering column, starting system, starter switch, starter assembly, spiral cable sub-assembly, speed sensor, skid control sensor, indicators, air bag sensor assembly, shift lock system, shift & select lever shaft, sfi system, seat position air bag sensor, seat belt warning system, seat belt, seat, roof headlining, roof moulding, roof antenna pole, receiver condenser assembly, rear wiper motor assembly, wheel alignment, suspension, speakers, shock absorbers, door and window frame mouldings, glass weatherstrips, combination lamp assembly, coil springs, bumpers, brakes, axle hub, axle beam, radio receiver, radiator, quarter window assembly, pulley compressor assembly, body repair preparation, power window control system, power steering link assembly, power steering, power source, power mirror control system, power door lock control system,partial engine, park neutral position switch, parking brake lever, parking brake cable, parking brake, output shaft assembly, oil pump, oil filter, number plates, transaxle system, transaxle oil, transaxle assembly, maintenance, lubrication system, lighting system, license plate lamps, knock sensor, instrument panel, input shaft assembly, inner rear view mirror assembly, ignition system, horn button assembly, horn, hood, heater radiator assembly, heater or boost ventilator control, air conditioner, aircon, headlamp protector retainer, headlamp dimmer switch assembly, headlamp assembly, generator assembly, altenator repair and replacement, fuel tank, fuel system, fuel pump, fuel injector, wheel alignment, suspension system, suspension arm, stabilizer bar, speaker assembly, shock absorbers, seat airbag assembly, marker lamp assembly, drive shafts, doors, differential oil seal, axle hub, floor shift parking lock cable, floor shift assembly, fender panel mudguard, exhaust pipe, exhaust system, door glass, door garnish, automatic transaxle fluid, automatic transaxle assembly, audio & visual system, antenna cord sub-assembly, amplifier antenna assembly, air conditioning system, air conditioning blower assembly, air conditioning amplifier assembly, air conditioner refrigerant, air bag sensors, fix car, and much more

1 note

·

View note

Text

Download Workshop Manuals

Workshop Manuals for every make and model of Car or Van or Commercial Vehicle available for download.

We have the full range of main dealer garage workshop manuals available on the internet worldwide, Worldwide specifications fully covered. Petrol, Gasoline, Diesel, Left and Right hand Drive all covered. Full coverage of all varients of Manual and automatic transmissions. Hybrid and electric vehicle manuals also available. Partial List of Procedures you can carry out with these factory workshop service repair manuals troubleshooting, replace fix spare parts, electrical wiring diagrams, engine starting problems, mechanical issues, engine control system, emission control systems, drive shafts, drive belt, differential case assembly, cylinder head assembly, block assembly, air bag assembly, cooling system, cooling fan system, clutch unit, clutch system, clutch start switch assembly, clutch release cylinder assembly, clutch pedal sub-assembly, clutch master cylinder assembly, cigarette lighter, charging system, charcoal canister, chain sub-assembly, center stop lamp assembly, center cluster module switch, air bag sensor, camshaft, brake system, brake pedal, brake master cylinder, brake fluid, brake booster, brake actuator, body repair, yaw rate sensor, wiring diagrams, wire harness repair, wiper and washer system, windshield wiper motor, windshield glass replacement, wheels and tires, water pump, valve clearance, transmission wire, transmission valve body, transmission revolution sensor, transmission control cable, torque converter clutch replacement, throttle body assembly, thermostat, seat belts, sun roof, steering, steering sensor, steering column, starting system, starter switch, starter assembly, spiral cable sub-assembly, speed sensor, skid control sensor, indicators, air bag sensor assembly, shift lock system, shift & select lever shaft, sfi system, seat position air bag sensor, seat belt warning system, seat belt, seat, roof headlining, roof moulding, roof antenna pole, receiver condenser assembly, rear wiper motor assembly, wheel alignment, suspension, speakers, shock absorbers, door and window frame mouldings, glass weatherstrips, combination lamp assembly, coil springs, bumpers, brakes, axle hub, axle beam, radio receiver, radiator, quarter window assembly, pulley compressor assembly, body repair preparation, power window control system, power steering link assembly, power steering, power source, power mirror control system, power door lock control system,partial engine, park neutral position switch, parking brake lever, parking brake cable, parking brake, output shaft assembly, oil pump, oil filter, number plates, transaxle system, transaxle oil, transaxle assembly, maintenance, lubrication system, lighting system, license plate lamps, knock sensor, instrument panel, input shaft assembly, inner rear view mirror assembly, ignition system, horn button assembly, horn, hood, heater radiator assembly, heater or boost ventilator control, air conditioner, aircon, headlamp protector retainer, headlamp dimmer switch assembly, headlamp assembly, generator assembly, altenator repair and replacement, fuel tank, fuel system, fuel pump, fuel injector, wheel alignment, suspension system, suspension arm, stabilizer bar, speaker assembly, shock absorbers, seat airbag assembly, marker lamp assembly, drive shafts, doors, differential oil seal, axle hub, floor shift parking lock cable, floor shift assembly, fender panel mudguard, exhaust pipe, exhaust system, door glass, door garnish, automatic transaxle fluid, automatic transaxle assembly, audio & visual system, antenna cord sub-assembly, amplifier antenna assembly, air conditioning system, air conditioning blower assembly, air conditioning amplifier assembly, air conditioner refrigerant, air bag sensors, fix car, and much more

1 note

·

View note

Text

🔷️Booster Pump System for #Namar Sub-Municipality🔷️

#AdvancedPumpsCo successfully assembled, supplied, and commissioned a booster pump system for the rehabilitation of Namar Sub Municipality in Riyadh, ensuring efficient and reliable water supply to the facility.

🔹️ Project Name: Rehabilitation of Namar Sub Municipality

📍 Location: Riyadh, Saudi Arabia | Al Hazm

🔹️Contractor: Establishment AHMAD KHALID SALEH ZEEN AL-DEEN for General Contracting.

🔹️Scope of Work:

✔ Factory #assembly of booster pump sets in compliance with international standards

✔ #Supply and commissioning of fully integrated pump systems tailored to project specifications

System Configuration:

🔹 Two Grundfos CM15-2 Booster Pumps

🔹 Two SAMNAN STAR-HIGH SHC100 Booster Pumps

🔹 Each booster set is equipped with a dedicated control panel for optimized operation

✅With a focus on precision assembly and system integration, Advanced Pumps delivers solutions that meet project demands with efficiency and reliability.

#SaudiVision2030 #SaudiProjects #Construction #SaudiArabia #Riyadh #Infrastructure #WaterSolutions

🔷️أنظمة ضخ معززة لمشروع إعادة تأهيل بلدية #نمار الفرعية🔷️

أتمّت #شركة_المضخات_المتقدمة #تجميع و#توريد وتشغيل نظام ضخ معزز لمشروع إعادة تأهيل بلدية نمار الفرعية في الرياض وفق معايير تضمن كفاءة واستمرارية إمدادات المياه للمبنى.

🔹️ اسم المشروع: إعادة تأهيل بلدية نمار الفرعية

📍 الموقع: الرياض | السعودية | الحزم

🔹️ المقاول: مؤسسة أحمد خالد صالح زين الدين للمقاولات العامّة.

🔹️نطاق العمل:

✔ تجميع أنظمة الضخ داخل مصنع الشركة وفق المواصفات والمعايير الدولية

✔ توريد وتشغيل أنظمة متكاملة مصممة وفق متطلبات المشروع

مواصفات النظام:

🔹 مضختان Grundfos CM15-2 Booster

🔹 مضختان SAMNAN STAR-HIGH SHC100 Booster

🔹 كل بوستر مزود بلوحة تحكم مستقلة لضمان التشغيل الأمثل.

✅تركيزنا على دقة التجميع وتكامل الأنظمة يضمن تلبية متطلبات المشاريع بكفاءة وموثوقية.

#رؤيةالسعودية2030 #مشاريع_السعودية #مقاولات #السعودية #الرياض #البنية_التحتية #حلول_المياه

0 notes

Text

Download Workshop Manuals

Workshop Manuals for every make and model of Car or Van or Commercial Vehicle available for download.

We have the full range of main dealer garage workshop manuals available on the internet worldwide, Worldwide specifications fully covered. Petrol, Gasoline, Diesel, Left and Right hand Drive all covered. Full coverage of all varients of Manual and automatic transmissions. Hybrid and electric vehicle manuals also available. Partial List of Procedures you can carry out with these factory workshop service repair manuals troubleshooting, replace fix spare parts, electrical wiring diagrams, engine starting problems, mechanical issues, engine control system, emission control systems, drive shafts, drive belt, differential case assembly, cylinder head assembly, block assembly, air bag assembly, cooling system, cooling fan system, clutch unit, clutch system, clutch start switch assembly, clutch release cylinder assembly, clutch pedal sub-assembly, clutch master cylinder assembly, cigarette lighter, charging system, charcoal canister, chain sub-assembly, center stop lamp assembly, center cluster module switch, air bag sensor, camshaft, brake system, brake pedal, brake master cylinder, brake fluid, brake booster, brake actuator, body repair, yaw rate sensor, wiring diagrams, wire harness repair, wiper and washer system, windshield wiper motor, windshield glass replacement, wheels and tires, water pump, valve clearance, transmission wire, transmission valve body, transmission revolution sensor, transmission control cable, torque converter clutch replacement, throttle body assembly, thermostat, seat belts, sun roof, steering, steering sensor, steering column, starting system, starter switch, starter assembly, spiral cable sub-assembly, speed sensor, skid control sensor, indicators, air bag sensor assembly, shift lock system, shift & select lever shaft, sfi system, seat position air bag sensor, seat belt warning system, seat belt, seat, roof headlining, roof moulding, roof antenna pole, receiver condenser assembly, rear wiper motor assembly, wheel alignment, suspension, speakers, shock absorbers, door and window frame mouldings, glass weatherstrips, combination lamp assembly, coil springs, bumpers, brakes, axle hub, axle beam, radio receiver, radiator, quarter window assembly, pulley compressor assembly, body repair preparation, power window control system, power steering link assembly, power steering, power source, power mirror control system, power door lock control system,partial engine, park neutral position switch, parking brake lever, parking brake cable, parking brake, output shaft assembly, oil pump, oil filter, number plates, transaxle system, transaxle oil, transaxle assembly, maintenance, lubrication system, lighting system, license plate lamps, knock sensor, instrument panel, input shaft assembly, inner rear view mirror assembly, ignition system, horn button assembly, horn, hood, heater radiator assembly, heater or boost ventilator control, air conditioner, aircon, headlamp protector retainer, headlamp dimmer switch assembly, headlamp assembly, generator assembly, altenator repair and replacement, fuel tank, fuel system, fuel pump, fuel injector, wheel alignment, suspension system, suspension arm, stabilizer bar, speaker assembly, shock absorbers, seat airbag assembly, marker lamp assembly, drive shafts, doors, differential oil seal, axle hub, floor shift parking lock cable, floor shift assembly, fender panel mudguard, exhaust pipe, exhaust system, door glass, door garnish, automatic transaxle fluid, automatic transaxle assembly, audio & visual system, antenna cord sub-assembly, amplifier antenna assembly, air conditioning system, air conditioning blower assembly, air conditioning amplifier assembly, air conditioner refrigerant, air bag sensors, fix car, and much more

1 note

·

View note

Text

Download Workshop Manuals

Workshop Manuals for every make and model of Car or Van or Commercial Vehicle available for download.

We have the full range of main dealer garage workshop manuals available on the internet worldwide, Worldwide specifications fully covered. Petrol, Gasoline, Diesel, Left and Right hand Drive all covered. Full coverage of all varients of Manual and automatic transmissions. Hybrid and electric vehicle manuals also available. Partial List of Procedures you can carry out with these factory workshop service repair manuals troubleshooting, replace fix spare parts, electrical wiring diagrams, engine starting problems, mechanical issues, engine control system, emission control systems, drive shafts, drive belt, differential case assembly, cylinder head assembly, block assembly, air bag assembly, cooling system, cooling fan system, clutch unit, clutch system, clutch start switch assembly, clutch release cylinder assembly, clutch pedal sub-assembly, clutch master cylinder assembly, cigarette lighter, charging system, charcoal canister, chain sub-assembly, center stop lamp assembly, center cluster module switch, air bag sensor, camshaft, brake system, brake pedal, brake master cylinder, brake fluid, brake booster, brake actuator, body repair, yaw rate sensor, wiring diagrams, wire harness repair, wiper and washer system, windshield wiper motor, windshield glass replacement, wheels and tires, water pump, valve clearance, transmission wire, transmission valve body, transmission revolution sensor, transmission control cable, torque converter clutch replacement, throttle body assembly, thermostat, seat belts, sun roof, steering, steering sensor, steering column, starting system, starter switch, starter assembly, spiral cable sub-assembly, speed sensor, skid control sensor, indicators, air bag sensor assembly, shift lock system, shift & select lever shaft, sfi system, seat position air bag sensor, seat belt warning system, seat belt, seat, roof headlining, roof moulding, roof antenna pole, receiver condenser assembly, rear wiper motor assembly, wheel alignment, suspension, speakers, shock absorbers, door and window frame mouldings, glass weatherstrips, combination lamp assembly, coil springs, bumpers, brakes, axle hub, axle beam, radio receiver, radiator, quarter window assembly, pulley compressor assembly, body repair preparation, power window control system, power steering link assembly, power steering, power source, power mirror control system, power door lock control system,partial engine, park neutral position switch, parking brake lever, parking brake cable, parking brake, output shaft assembly, oil pump, oil filter, number plates, transaxle system, transaxle oil, transaxle assembly, maintenance, lubrication system, lighting system, license plate lamps, knock sensor, instrument panel, input shaft assembly, inner rear view mirror assembly, ignition system, horn button assembly, horn, hood, heater radiator assembly, heater or boost ventilator control, air conditioner, aircon, headlamp protector retainer, headlamp dimmer switch assembly, headlamp assembly, generator assembly, altenator repair and replacement, fuel tank, fuel system, fuel pump, fuel injector, wheel alignment, suspension system, suspension arm, stabilizer bar, speaker assembly, shock absorbers, seat airbag assembly, marker lamp assembly, drive shafts, doors, differential oil seal, axle hub, floor shift parking lock cable, floor shift assembly, fender panel mudguard, exhaust pipe, exhaust system, door glass, door garnish, automatic transaxle fluid, automatic transaxle assembly, audio & visual system, antenna cord sub-assembly, amplifier antenna assembly, air conditioning system, air conditioning blower assembly, air conditioning amplifier assembly, air conditioner refrigerant, air bag sensors, fix car, and much more

1 note

·

View note

Text

Download Workshop Manuals

Workshop Manuals for every make and model of Car or Van or Commercial Vehicle available for download.

We have the full range of main dealer garage workshop manuals available on the internet worldwide, Worldwide specifications fully covered. Petrol, Gasoline, Diesel, Left and Right hand Drive all covered. Full coverage of all varients of Manual and automatic transmissions. Hybrid and electric vehicle manuals also available. Partial List of Procedures you can carry out with these factory workshop service repair manuals troubleshooting, replace fix spare parts, electrical wiring diagrams, engine starting problems, mechanical issues, engine control system, emission control systems, drive shafts, drive belt, differential case assembly, cylinder head assembly, block assembly, air bag assembly, cooling system, cooling fan system, clutch unit, clutch system, clutch start switch assembly, clutch release cylinder assembly, clutch pedal sub-assembly, clutch master cylinder assembly, cigarette lighter, charging system, charcoal canister, chain sub-assembly, center stop lamp assembly, center cluster module switch, air bag sensor, camshaft, brake system, brake pedal, brake master cylinder, brake fluid, brake booster, brake actuator, body repair, yaw rate sensor, wiring diagrams, wire harness repair, wiper and washer system, windshield wiper motor, windshield glass replacement, wheels and tires, water pump, valve clearance, transmission wire, transmission valve body, transmission revolution sensor, transmission control cable, torque converter clutch replacement, throttle body assembly, thermostat, seat belts, sun roof, steering, steering sensor, steering column, starting system, starter switch, starter assembly, spiral cable sub-assembly, speed sensor, skid control sensor, indicators, air bag sensor assembly, shift lock system, shift & select lever shaft, sfi system, seat position air bag sensor, seat belt warning system, seat belt, seat, roof headlining, roof moulding, roof antenna pole, receiver condenser assembly, rear wiper motor assembly, wheel alignment, suspension, speakers, shock absorbers, door and window frame mouldings, glass weatherstrips, combination lamp assembly, coil springs, bumpers, brakes, axle hub, axle beam, radio receiver, radiator, quarter window assembly, pulley compressor assembly, body repair preparation, power window control system, power steering link assembly, power steering, power source, power mirror control system, power door lock control system,partial engine, park neutral position switch, parking brake lever, parking brake cable, parking brake, output shaft assembly, oil pump, oil filter, number plates, transaxle system, transaxle oil, transaxle assembly, maintenance, lubrication system, lighting system, license plate lamps, knock sensor, instrument panel, input shaft assembly, inner rear view mirror assembly, ignition system, horn button assembly, horn, hood, heater radiator assembly, heater or boost ventilator control, air conditioner, aircon, headlamp protector retainer, headlamp dimmer switch assembly, headlamp assembly, generator assembly, altenator repair and replacement, fuel tank, fuel system, fuel pump, fuel injector, wheel alignment, suspension system, suspension arm, stabilizer bar, speaker assembly, shock absorbers, seat airbag assembly, marker lamp assembly, drive shafts, doors, differential oil seal, axle hub, floor shift parking lock cable, floor shift assembly, fender panel mudguard, exhaust pipe, exhaust system, door glass, door garnish, automatic transaxle fluid, automatic transaxle assembly, audio & visual system, antenna cord sub-assembly, amplifier antenna assembly, air conditioning system, air conditioning blower assembly, air conditioning amplifier assembly, air conditioner refrigerant, air bag sensors, fix car, and much more

1 note

·

View note

Text

Water Pump Repair in Dubai

Has your water pump malfunctioned? The only way to get it into perfect working condition is by calling a water pump repair expert in Dubai. That’s because water pump motors are a bit complicated, bathtub repair dubai making them hard to repair by yourself. When your water pump gets damaged, you need to get it fixed within the shortest time possible, considering the importance of water in our lives. When you call for water pump repair in Dubai, here are some of the things the experts can fix

· Water softeners

· Jet pumps

· Booster pumps

· Sump pumps

· Irrigation pumps

· Submersible pumps

· Pressure tanks

· Iron filters

· Water holding tanks

· Reverse osmosis

Submersible pump repair

If you have a submersible water pump that isn’t working correctly, you need to call for repair services immediately. The experts will start by inspecting the pump to identify the problem. The professionals will assess your pump’s surroundings, equipment, and control system.

The experts might also involve plumbers to help extend your pump’s lifespan. Usually, regular checks have to be conducted on the pump’s control panel. That helps the repair experts to identify potential issues before they become more severe.

The repair services might entail ventilating the well and checking for pollutants, cleaning level sensors, Water Heater Leak Fixing and eliminating debris from the top of the surface. Additionally, the experts will clean the spectro photometric detection and inspect the electric power steering and power cables.

Well pump repair

Well pumps may sometimes experience problems. When this happens on your property, you need to call qualified professionals to handle the issue. A professional company has trained and well-skilled personnel who can handle any well pump repair.

The experts ensure to show up within the shortest time possible to remediate any issue. After assessing your well pump, they’ll determine the specific problem. After identifying the problem, they’ll use appropriate tools to ensure the pump works to its full potential. The qualified experts will only leave your property after the problem is fixed.

Jet pump repair

Some residential and commercial properties rely on water streams to get water. To bring the required water pressure on such properties, rely on jet pumps, whereby the water gets circulated in loop systems. The jet pumps have an on/off switch to control the water. As a result, your pump may experience some issues. Here are the common jet pump repair services in Dubai.

· A lot of pump cycles

· When the pump starts and stops on its own

· When the water moves too slow

· When you can’t turn off your jet pump

· When air rushes out when you open the faucet

Vertical turbine pump repair

Water pump repair in Dubai also entails fixing vertical turbine pumps. Such pumps are used in fire pumps, irrigation, process pumps, booster pumps, and cooling pumps. water pumps in dubai That’s why they’re commonly utilized as deep well pumps. Usually, they need minimal floor space while the immersed pump removes priming. Here are some of the repair services you will get if your pump gets damaged.

· Wear rings replacement

· Rebuilding of levels

· Bearings replacement

· Shafts machining

· Repairing the discharge head

· Maintaining the mechanical seal

0 notes