#machine for making brick

Explore tagged Tumblr posts

Text

Boost your brick making business with Snpc Machines.

SnPC Machines: Factory of bricks on wheel

Brick making truck for fast brick production and modernization in brick making methods by SnPC Machines with fully automotive structure. Due to its fully automotive structure kiln owner can produce bricks independently with minimum human labor. BMM410, BMM310 and BMM160 are the main machines invented by SnPC Machines, Kharkhuda, Haryana. These machines are proudly made in India and revolutionizing construction industry due to its high production speed and budget-friendly nature. SnPC supplies its products world wide so that clients can easy reach our manufacturing location or can order from any state or country according to their satisfaction.

#Snpc Machines#brick making machine#clay brick making machine#machine for making brick#BMM410#BMM400#BMM404#BMM310#BMM300#Mobile brick making machine#off road construction machinery#building material suppliers India#brick press#Snpc India#team Snpc#brick machine India#brick machine priceIndia

3 notes

·

View notes

Text

Durable Clay brick making machine

SnPC Machines: Clay brick making machine manufacturers in India

SnPC Machines India Is A Leading Manufacturer Of Brick Making Machines Specially The Mobile Brick Making Machines Bmm160, Bmm310, Bmm400, Bmm404 And Sbm180 All The Models Can Be Tailored As Per The Customers Requirements For Both Indian And Overseas Customers.

#SnPC Machines#clay brick making machine#machine for making brick#red clay brick machine#BMM310#best clay brick machine in India#innovation in brick machine#red soil brick machine#brick machine India#brick machine Gujarat

2 notes

·

View notes

Text

working on more old wips. i spent so long on this one i really should finish it, messing around with rough colors. idk how i want to color this one yet.

#wip#think this brush is too grainy though. i should use something smoother since the lines are so fine and low res#sleep anxiety is still making my brain feel like a washing machine with a brick in it so i cant promise when this will be done#but it will be done#paladin danse

186 notes

·

View notes

Text

Conficcare 🤝 Cecio

wanting to go into professions that are often unsympathetic to their community so someone who actually cares about them is in that profession, but by forces outside their control they end up causing harm to the people they went down that path to save and perpetuating the status quo that they once fought against...

#gold & silver#oc: conficcare#oc: cecio#i am chewing on them#shaking them in my teeth#they wanted to help!!!!#but they find out the hard ways why more people who care arent in those professions...#the way both of them are promised scholarships and that is what is used to trap them...#the powers will only give you the money and access if it benefits them...#you think you can bit the hand that feeds but its a well oiled machine in taking in bright eyed kids who want to make a difference#and breaking them down till they are just another brick in the wall#just another rat in the rat race...#[yes its about student debt and apprenticeships and how the military uses education to recruit]

4 notes

·

View notes

Text

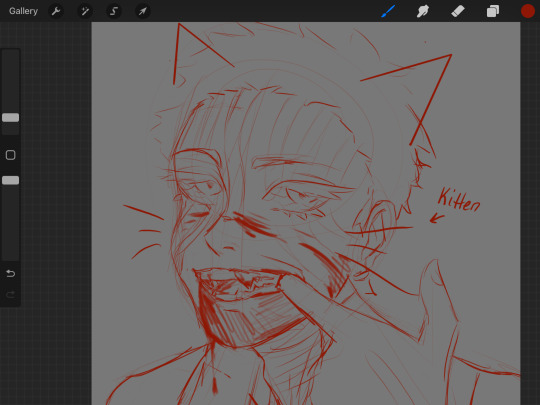

Hello I offer you this once in a lifetime WIP and then I go back to the abyss

If you would like to see more bloody Akaza doodles, stick around

#akaza#kny akaza#akaza kimetsu no yaiba#akaza fanart#kny#I need to make him all bloody all the time#my little pookie bear#my little meow meow#my little messy eater#need to throw bricks at him and grab him by the hair and yank him around#I need to put him in a washing machine and watch him swirl and spin around#hopey’s doodles

17 notes

·

View notes

Text

my father telling me how scared he was when i ran away from the house but i cant express how scared i was 2 b in the house

hey, whats up w/that?

#whenever we ‘hang out’ he likes 2 make the topic as depressing as possible by always talking abiut the past#& it is the most annoying shit ever i will not lie BC I DONT WANT 2 TALK ABOUT DEATH & THE ABUSE EVERY TIME I SPEAK 2 U#yk? thag makes sense in my head#anyways he started talking abiut how terrified he was when i had ran away multiple times a couple yrs ago & when i say a couple i mean#i have no idea how long ago bc memory is a bitch#but it had 2 b like middle school - sophmore?#multiple times & like i just wanna shake him bc LITERLLY WHAT & WHO DO U THINK I WAS RUNNING AWAY FROM#GODDAMNN I H8 BING THE ONLY PERSON IN THIS HOUSE WHO CAN EXPRESS EMOTIONS & NOT LET THEM EFFECT HOW I VIEW THE OTHER#‘oh u ran in the park u ran in the park’ i didnt run in the fuckinggppaaarrkrkkkk AAAAAAAAAA I MET A NICE LADY WHO HAD A GOAT IN THE#SPARTMENTS I FRIECIENTED OFTEN WHEN I WAS YOUNGER#i cant express how safe the goddamn goat lady & her kid made me feel vs my parents who started hunting 4 me#like ive been dragged home so many times im not going through that shit again#i miss the goat the mom & the kid we were just chilling @ like midnight 4 a bit#did this turn in2 a vent? idk#i do this a lot ill prolly delete this soonish when im kore calm#bc rn i want 2 chuck bricks in my laundry machine & watch them fly out & hit whatever#im going back 2 watching anime if i have 2 talk 2 1 other person i will actually explode#like irl person not online the silly gay ppl in my phone r super cool & amazing & i love them#im srry 4 bing a dick btw#i cant explain it i mean i could but i cant im just my brain is telling me eveyr1 h8s me & MAN i h8 it when it does#so im just frightened & by golly & am i havign a cheery time yipyipyip#typing in tags is sm easier than in a post bc i dont think most ppl read tags lol#the more i think about my past the more i wonder wtf am i doing here#bc how did i even get out of the house in the 1st place & then ontop of that was able 2 hide#like what……#bc they were fucking grabbing me n shit & they have CARS like i didnt go in the park i walked the sidewalks HOW DID I MOT GET CAUGHT??#MULTIPLE TIMES??? LIKE I ‘ran away’ MULTIPLE TIMES#i didnt exactly run away tho bc i didnt want them 2 file police shit i didnt eant 2 deal w/that & also hirt the pll i stayed over w/#so i always went back. obviously blehhh#ug hj hhhh my heads hurting again this is like the 4th day in a row :((

4 notes

·

View notes

Text

me, after any minor or major inconvenience: i should listen to how big, how blue, how beautiful again

#listen if nobody got me i know florence got me#delilah in of itself makes me want to run through a brick wall and leave a gabi shaped imprint#gabi overshares#florence and the machine#hbhbhb

2 notes

·

View notes

Text

I may or may not have started a project that will probably overwhelming me...

#by the time that copper tower completely ages i should have prepared everything...#the tall pallete is for the fantasy towers i will build on a windswept mountain next to my base#the small pallete is for the entire village#i dont get why most minecraft players hate the new bamboo blocks.. they're pretty!!#a bit biased because I use bamboo for my little Filipino hut as a main base#but really there's so much to bamboo people are probably missing on... it works well with cherry. blackstone. warped and crimson. mud bricks#and there's so much variety you get from crafting bamboo blocks as well...#BUT YEAH this is my first minecraft project and tbh i am scared 😂 but ey... been wanting to do this for the longest time...#my last village didn't quite do well... now im determined to make this work...#this is gonna be a big task as i cant build redstone machines... it'll kill my phone 😂😂😭😭😭... no automation all manual...#that's enough rambling from me... have a good day! ✨#wyn talks :)#minecroof

14 notes

·

View notes

Text

sewing shed time tomorrow, finally gonna make that apron for work and the black hoodie inspired by Maya from the newest Silent Hill game 👀🙏

#willing it into existence tbh#idk how i'll feel after stripping down the walls of my room to the brick#i just wanna CREATE!!!!!!!!! AUGHHHHH!!!!!#also just wanna see how i'll fare with the apron at work. if it'll keep me safe from all the popcorn and nacho crumbs#and the splashback from the soda fountain and the slushie machine#alsooooo oversized sporty hoodie!!!!! with big pockets and long sleeves with thumbholes to make sweater paws!!!!!!

3 notes

·

View notes

Text

A Comprehensive Guide to Hydraulic Paver Block Making Machine

Welcome to "A Comprehensive Guide to Hydraulic Paver Block Making Machine." In the ever-evolving world of construction and infrastructure development, the significance of efficient and eco-friendly building materials cannot be overstated. Paver blocks have emerged as a popular choice due to their durability, versatility, and aesthetic appeal. At the heart of this revolution lies the Hydraulic Paver Block Making Machine – a game-changing technology that has transformed the production of paver blocks.

This article aims to delve into the intricacies of Hydraulic Paver Block Making Machine, providing a detailed exploration of their working principles, key components, and various types available in the market. We will uncover tips and some troubleshooting steps.

Moreover,we will highlight essential considerations for selecting the right machine that aligns with specific project requirements. Whether you are an industry professional seeking to optimize production processes or an enthusiast eager to grasp the mechanics behind paver block manufacturing, this guide will equip you with invaluable insights.

Understanding Hydraulic Paver Block Machine Specifications

When it comes to hydraulic paver block machines, understanding their specifications is crucial for making informed decisions. These machines are essential for producing high-quality, durable, and aesthetically pleasing paver blocks used in various construction projects.

Hydraulic paver block machine specifications encompass a range of key features. The capacity, which determines the number of blocks produced per hour, directly impacts productivity. The molding area size affects the dimensions and shapes of the blocks. Additionally, the power and pressure rating influence the machine's efficiency and performance.

Moreover, it's essential to consider the automation level and control system, as advanced automation ensures precision and ease of operation. The type of molds compatible with the machine allows for versatility in block design. Understanding these specifications empowers buyers to select the ideal hydraulic paver block machine that aligns with their specific project requirements, resulting in cost-effective and successful paving solutions.

Choosing the Right Paver Type: Interlocking vs. Non-interlocking

When it comes to selecting the right paver type for your project, the choice between interlocking and non-interlocking pavers plays a crucial role in determining the overall outcome. Here are some key points to consider for each option:

Interlocking Pavers:

Interlocking pavers are designed to fit tightly together, creating a durable and stable surface.

They offer excellent load-bearing capabilities, making them ideal for driveways, walkways, and high-traffic areas.

The interlocking design provides flexibility, allowing them to withstand ground movement without cracking.

These pavers come in various shapes, colors, and patterns, enabling versatile and visually appealing designs.

Installation is relatively easier due to the interlocking system, reducing labor time and costs.

Repairs are simple, as individual pavers can be replaced without affecting the entire surface.

Non-Interlocking Pavers:

Non-interlocking pavers are more affordable compared to their interlocking counterparts.

They are suitable for light to moderate traffic areas like patios, garden pathways, and decorative landscape elements.

Installation may require more precision and skill as they do not have the interlocking mechanism.

Although repairs are possible, they might be more labor-intensive and could involve replacing larger sections.

Pro Tips for Maintaining Your Paver Block Making Machine

Regular Cleaning: Clean the machine daily to remove any residual concrete and debris that can cause blockages or malfunctions.

Lubrication: Keep all moving parts well-lubricated to reduce friction and prevent wear and tear.

Inspection: Conduct routine inspections to identify and address any signs of wear, damage, or misalignment promptly.

Tighten Bolts: Check and tighten all bolts and nuts regularly to maintain stability and prevent vibrations.

Replace Worn Parts: Replace worn-out parts immediately to prevent further damage and ensure optimal performance.

Calibration: Calibrate the machine regularly to ensure accurate and consistent block dimensions.

Electrical Connections: Inspect and secure electrical connections to prevent electrical issues.

Professional Maintenance: Schedule periodic maintenance by qualified technicians to address complex servicing and extend the machine's lifespan.

Operating Guidelines: Train operators on proper machine operation and safety protocols to prevent mishandling or accidents.

Store in Shelter: Store the machine in a sheltered area to protect it from weather conditions and extend its longevity.

Troubleshooting Hydraulic Paver Block Making Machine

Low Block Quality: Adjust the hydraulic pressure and ensure proper alignment of molds to improve block quality.

Block Disintegration: Check the mix proportions of raw materials and the curing process for better block strength.

Oil Leaks: Inspect hydraulic hoses and connections, repair or replace damaged parts, and refill hydraulic oil as needed.

Excessive Noise/Vibrations: Tighten loose components and bolts, and ensure proper leveling of the machine.

Uneven Block Height: Verify uniform material distribution in the mold and calibrate the machine for consistent block height.

Machine Not Starting: Check power supply, fuses, and safety switches; repair or replace faulty electrical components.

Insufficient Block Production: Clean and maintain the machine regularly, and optimize the production process for efficiency.

Irregular Block Shapes: Inspect mold condition, ensure proper vibration, and adjust mold settings to achieve uniform shapes.

Safety Hazards: Implement strict safety protocols, provide training to operators, and display safety guidelines prominently.

Seek Professional Help: If issues persist, consult experienced technicians or manufacturers for advanced troubleshooting and repairs.

Conclusion

A Comprehensive Guide to Hydraulic Paver Block Making Machine highlights the indispensable role of perfect hydraulic machines in revolutionizing paver block production. The detailed exploration of working principles, types, and maintenance underscores their efficiency and eco-friendly advantages. By embracing these cutting-edge technologies, the construction industry gains a competitive edge in creating durable and visually appealing infrastructure. As Perfect Hydraulic Machines continue to shape the future of paver block manufacturing, their impact on sustainable construction practices remains unparalleled.

#Hydraulic Paver Block Making Machine#perfect hydraulic machines#hydraulic machines#Fly Ash Brick Machine

2 notes

·

View notes

Text

https://karanengineering.com/

Fly Ash Brick Making Machine manufacturers

2 notes

·

View notes

Text

World fastest brick making machine: BMM410

Snpc Machines: Factory of bricks on wheel

1st of it's kind. Patented technology by SnPC Machines Which comes with Massive production capacity. Fully Automatic and easy to use. It's a Mobile unit that gives us the freedom to produce bricks any-where, any-quantity, any-time.

#Snpc Machines#brick making machine#clay brick machine#machine for making brick#brick machine India#BMM410#BMM404#BMM400#innovation in brick making#brick press#Snpc India#team Snpc#brick machine price India

2 notes

·

View notes

Text

The bricks, the better foundation!

Snpc Clay Brick making machine

Red Brick Making Machine: There Are Many Players In The Brick Making Machines Around The Globe But SnPC Machines India Is The Only Team/Group Of Kiln Owners Whose Focus Is Not Only In The Selling Of Brick Making Machines But To Introduce The New Age Technology For The Brick Production Process And The Mobile Brick Making Machine Model Bmm400, Bmm404 Is The Latest Example Of That YouTube Link Given, Whereas Other Machines Are Even Stationary Or Fixed That Can Produce Up To 6000-8000 Bricks Even In 01 Hour Or A Day Here Bmm404 Can Produce Up To 25000. Bricks In Just 01 Hour. It Is An Achievement Itself Of Team SnPC That A Single Mobile Brick Making Machine Can Produce Up To 25000 Bricks In Just 01 Hour With The Help Of Only 02 Manpowers Or Technicians And Available For Both Indian And Overseas Customers.

#Snpc Clay brick making machine#machine for making brick#brick machine India#brick machine Delhi#brick machine Odisha#clay brick machine#red clay brick#top quality bricks#brick press#off road construction machinery#off road brick making machine

1 note

·

View note

Text

Best Fly Ash Brick Making Machines: Features, Prices & Benefits

Fly ash brick manufacturing is an essential part of modern construction, offering an eco-friendly alternative to traditional clay bricks. Whether you're starting a new venture or upgrading your existing setup, choosing the best fly ash brick making machine is crucial for efficiency, durability, and cost-effectiveness. In this guide, we will explore the key features, pricing, and benefits of these machines, helping you make an informed decision.

What is a Fly Ash Brick Making Machine?

A fly ash brick making machine is specialized equipment designed to produce bricks using fly ash, cement, sand, and other raw materials. These machines come in various models, including manual, semi-automatic, and fully automatic types, catering to different production needs. Companies like BTM Product offer high-quality machines that ensure precision and efficiency in brick manufacturing.

Key Features of the Best Fly Ash Brick Making Machine

When selecting the best fly ash brick making machine, consider the following essential features:

1. Automation Level

Manual Machines: Require human intervention for operations.

Semi-Automatic Machines: Partially automated, reducing labor costs.

Fully Automatic Machines: Operate with minimal human involvement, increasing efficiency.

2. Production Capacity

Different models offer varying production capacities, from a few hundred to several thousand bricks per hour. Businesses should choose a machine based on their daily output requirements.

3. Raw Material Compatibility

A high-quality machine should be capable of processing multiple raw materials, including fly ash, cement, sand, and stone dust, ensuring flexibility in brick production.

4. Durability & Build Quality

The machine should be made from high-grade materials to withstand heavy-duty operations. BTM Product manufactures machines with robust steel bodies, ensuring long-term durability.

5. Energy Efficiency

Machines with energy-efficient motors and hydraulic systems help reduce electricity consumption, making production more cost-effective.

6. Customization Options

Some machines offer mold customization, allowing businesses to produce bricks of different sizes and shapes as per market demand.

Price Range of Fly Ash Brick Making Machines

The pricing of these machines varies based on their type, capacity, and features. Here is an approximate price breakdown:

Manual Fly Ash Brick Making Machine: $2,000 - $5,000

Semi-Automatic Fly Ash Brick Making Machine: $6,000 - $15,000

Fully Automatic Fly Ash Brick Making Machine: $20,000 - $50,000

BTM Product provides competitive pricing and high-quality machines that offer value for money. Investing in a reliable machine ensures higher production rates and better profit margins.

Benefits of Using a Fly Ash Brick Making Machine

1. Eco-Friendly Production

Using fly ash, a byproduct of coal combustion, reduces environmental waste and minimizes reliance on clay, helping conserve natural resources.

2. High Strength & Durability

Bricks made from fly ash are stronger, more durable, and have better thermal insulation compared to traditional clay bricks.

3. Cost-Effective

Investing in the best fly ash brick making machine leads to reduced labor costs and increased production efficiency, resulting in higher profits.

4. Low Maintenance & Long Lifespan

Modern machines require minimal maintenance and offer long-term performance, ensuring consistent brick quality.

5. Government Incentives

Many governments promote fly ash brick production by providing subsidies and incentives, making it a lucrative business opportunity.

Where to Find Fly Ash Brick Making Machine Sale

If you're looking for a fly ash brick making machine sale, it's essential to purchase from a trusted manufacturer. BTM Product offers high-quality machines with excellent after-sales support, ensuring a smooth production process. Check online marketplaces, industrial equipment suppliers, or directly contact manufacturers for the best deals.

Conclusion

Investing in a fly ash brick making machine and paver block making machine is a smart choice for businesses looking to produce high-quality bricks efficiently. Understanding the features, pricing, and benefits will help you select the right machine for your needs. With reliable manufacturers like BTM Product, you can ensure durability, efficiency, and cost savings in your brick-making operations. Whether you're a startup or an established business, now is the perfect time to explore the best machines on the market!

0 notes

Text

Best Paver Block and Brick Making Solutions from Ultra Tiles Machine

When it comes to producing high-quality paver blocks, bricks, and other concrete products, having the right equipment is crucial. Ultra Tiles Machine has established itself as a leading name in the industry, providing top-notch machinery for all your block and brick-making needs. With a wide range of machines designed to meet the demands of various construction projects, we cater to businesses that require efficiency, reliability, and precision in their manufacturing processes.

In this blog, we’ll explore the different types of machines offered by Ultra Tiles Machine, including Paver Block Making Machine, Hollow Solid Block Making Machine, Fly Ash Brick Making Machine, Concrete Block and Brick Making Machine, Chemical Hardener Manufacturers, Interlocking Paver Block Making Machine, and Automatic Brick Making Machine Manufacturer.

Paver Block Making Machine

A Paver Block Making Machine is essential for creating durable, aesthetically pleasing paving stones used in roads, driveways, walkways, and other outdoor spaces. At Ultra Tiles Machine, we offer advanced paver block machines that produce high-quality interlocking paver blocks in various shapes and sizes.

Our machines are designed to cater to both small and large-scale production needs, ensuring consistent output with minimal labor.

These machines are designed for optimal performance, ensuring that each paver block produced has the desired strength, texture, and finish.

Whether you need blocks for residential, commercial, or industrial projects, our Paver Block Making Machine will meet your specific requirements, ensuring efficiency, precision, and cost-effectiveness.

The Hollow Solid Block Making Machine offered by Ultra Tiles Machine is designed for producing high-strength blocks that are both cost-effective and versatile. Hollow blocks are widely used in the construction of walls, foundations, and other structures, offering excellent insulation and soundproofing properties. Our machine can produce both hollow and solid blocks, depending on your project’s requirements.

The machine is engineered with precision and advanced technology, ensuring that the blocks produced are uniform in size and shape. This ensures a smooth construction process, reducing material wastage and improving overall building quality. Additionally, our Hollow Solid Block Making Machine is designed to be durable, ensuring a long service life with minimal maintenance.

Fly Ash Brick Making Machine

Ultra Tiles Machine is a prominent Fly Ash Brick Making Machine manufacturer, offering state-of-the-art machines that are environmentally friendly and economically viable. Fly ash bricks are an eco-conscious alternative to traditional clay bricks, made from industrial waste products like fly ash, cement, and sand. These bricks are stronger, lighter, and more durable than conventional bricks, making them an ideal choice for modern construction projects.

Our Fly Ash Brick Making Machine uses innovative technology to ensure the production of high-quality fly ash bricks with consistent strength and size. This machine is perfect for businesses looking to reduce their environmental footprint while maintaining high standards of construction. With high automation and low energy consumption, it helps reduce production costs and enhances overall operational efficiency.

Concrete Block and Brick Making Machine

Our machines are designed to create blocks and bricks in various sizes, including standard, interlocking, and custom designs. The flexibility of our Concrete Block and Brick Making Machine ensures that it can cater to the specific needs of different construction projects. Whether you're building residential complexes, commercial buildings, or infrastructure projects, our machines deliver the perfect solution.

Chemical Hardener Manufacturers

In the production of paver blocks, bricks, and other concrete products, it’s essential to ensure high strength and durability. This is where the role of chemical hardeners comes into play. Ultra Tiles Machine is a trusted Chemical Hardener Manufacturer, offering top-quality hardening agents that improve the overall strength and resistance of concrete products.

Chemical hardeners are used to enhance the surface hardness of concrete products, providing them with greater resistance to wear, moisture, and weathering. By using the right chemical hardeners in your production process, you can ensure the longevity and durability of your paver blocks, bricks, and other concrete products.

Interlocking Paver Block Making Machine

At Ultra Tiles Machine, we ensure that the Interlocking Paver Block Making Machine we offer delivers precision and consistency in every block produced. With advanced technology and efficient production processes, these machines provide excellent results in a variety of sizes and designs to suit different project needs.

As an Automatic Brick Making Machine Manufacturer, Ultra Tiles Machine offers machines that automate the process of brick production, resulting in reduced labor costs and increased efficiency. Our Automatic Brick Making Machines are designed to produce high-quality bricks with minimal manual intervention. These machines are ideal for businesses that need to produce large volumes of bricks quickly while maintaining high standards of quality.

Our automatic machines are equipped with advanced features such as automated brick molding, high-pressure forming, and easy-to-use control systems. This ensures that each brick produced meets the highest quality standards while reducing the need for manual labor and increasing overall productivity.

Why Choose an Ultra Tiles Machine?

At Ultra Tiles Machine, we are committed to providing our customers with the best machinery solutions for their block and brick-making needs. Here’s why you should choose us:

Advanced Technology: We use the latest technology to manufacture machines that deliver high-quality products with minimal labor.

Customization: We offer customized solutions tailored to your specific production needs, ensuring that you get the perfect machine for your requirements.

Durability and Reliability: Our machines are built to last, with high-quality materials and precision engineering ensuring long service life.

Eco-friendly Solutions: We are committed to providing eco-friendly machinery, including Fly Ash Brick Making Machines that help reduce your carbon footprint.

Customer Support: We offer excellent customer support, ensuring that you have the assistance you need at every step of the way.

Conclusion

Whether you're looking for a Paver Block Making Machine, Hollow Solid Block Making Machine, Fly Ash Brick Making Machine, Concrete Block and Brick Making Machine, Chemical Hardener Manufacturers, Interlocking Paver Block Making Machine, or Automatic Brick Making Machine Manufacturer, Ultra Tiles Machine is the trusted partner for all your block and brick-making needs.

With our high-quality machines, advanced technology, and exceptional customer service, we guarantee that your production process will be efficient, cost-effective, and reliable.

Contact Ultra Tiles Machine today to learn more about our products and how we can help you take your construction business to the next level.

#Paver Block Making Machine Manufacturer#Hollow Solid Block Making Machine#Fly Ash Brick Making Machine#Concrete Block and Brick Making Machine#Chemical Hardener Manufacturers#Interlocking Paver Block Making Machine#Automatic Brick Making Machine Manufacturer

0 notes

Text

Automatic Flyash Brick Making Machine Belt Type – 15 Bricks

The Automatic Flyash Brick Making Machine Belt Type – 15 Bricks is an advanced solution designed to meet the growing demand for sustainable and efficient brick manufacturing. As a leading automatic fly ash brick machine manufacturer in Coimbatore, we focus on delivering precision-engineered equipment that ensures quality and durability.

This state-of-the-art model, ABMH 8SP Ultra DX 15 Bricks System, is powered by a 15 H.P hydraulic motor and features a brick eject system supported by a 2 H.P motor. The machine is built to perform under high pressure with a maximum of 440 BAR, utilizing a turbo twin vane hydraulic pump for seamless operations. Its efficient conveyor system, driven by a 3 H.P motor, ensures smooth material handling. Complementing the process is a 20 H.P pan mixer that guarantees uniform mixing of fly ash, cement, and other materials.

Engineered for reliability, the machine’s robust build includes 63 EN8 grained hard-chromed sliding rods and steel casting sliding bushes. The ejector conveyor, made from tough polymer, ensures quick and easy mold changes, reducing downtime. With a cyclic time of just 15 seconds, this automatic fly ash brick making machine can produce up to 15 bricks per cycle, maximizing productivity while minimizing labor costs.

Ideal for industries requiring high-quality fly ash bricks, this system is backed by PLC control for precision and automation. It requires a 1.5-acre land area and a shed of 60’x120’ feet for operation, along with a water capacity of 15,000 liters per shift.

Recognized as a trusted automatic fly ash brick machine exporter in Coimbatore, India, we provide machines that cater to both domestic and international markets. This model’s durability, ease of maintenance, and high efficiency make it a top choice for businesses seeking reliable brick manufacturing solutions.

Website Link : -http://www.bennyenterprises.net/

Contact no : - 9360623765

Mail id : - [email protected]

Address :- Site No:13, Thadagam Road,K.N.G.Pudur Pirivu,Opp: Indian Oil Petrol Pump, Next to Agarwal School, Somayampalayam (PO), Coimbatore - 641 108,Tamil Nadu, India

Socail media link

facebook link :- https://www.facebook.com/Bennyindustries

short describiton :- Benny Enterprises specializes in manufacturing innovative block-making machines and construction equipment. With a commitment to quality and precision, the company provides cutting-edge solutions for the construction industry, including automatic block-making machines, tile-making machines, and custom-designed equipment to meet various industrial needs.

#brick manufacturing#Automatic Flyash brick making machine belt type#Automatic Flyash brick making machine#Automatic Flyash brick making

0 notes