#lubricent for plastic industry

Text

Understanding Glycerol Monostearate: Uses and Benefits Explained

Understanding Glycerol Monostearate: Uses and Benefits Explained" delves into the multifaceted applications of this versatile compound. Commonly used as an emulsifier in food production, glycerol monostearate helps stabilize and improve the texture of various products. In the cosmetics industry, it enhances the consistency and moisturizing properties of skincare items. Additionally, it finds its place in dietary supplements and pharmaceuticals for its stabilizing effects. This guide provides a comprehensive overview of glycerol mono stearate's essential roles and health benefits.

For more information click on this link :- https://spellorganics.com/

0 notes

Text

"An environmental toxicologist in California is cleaning up areas contaminated with heavy metals or other pollutants using fungi and native plants in a win-win for nature.

Where once toxic soils in industrial lots sat bare or weed-ridden, there are now flowering meadows of plants and mushrooms, frequented by birds and pollinators: and it’s thanks to Danielle Stevenson.

Founder of DIY Fungi, the 37-year-old ecologist from UC Riverside recently spoke with Yale Press about her ongoing work restoring ‘brownfields,’ a term that describes a contaminated environment, abandoned by industrial, extraction, or transportation operations.

A brownfield could be an old railway yard or the grounds of an abandoned oil refinery, but the uniting factor is the presence of a toxic containment, whether that’s a petrochemical, heavy metal, or something else.

Noting that she had read studies about mushrooms growing around the Chernobyl nuclear plant, she came to understand further, through her work, that fungi are an extraordinarily resilient species of life that consume carbon, and even though petroleum products are toxic to plants, to mushrooms they are essentially a kind of carbon.

In fact, mushrooms break down several categories of toxic waste with the same enzymes they use to consume a dead tree. They can also eat plastic and other things made out of oil, like agrochemicals.

At the Los Angeles railyard, as part of a pilot project, Stevenson and colleagues planted a variety of native grass and flower species alongside dead wood that would incubate specific fungi species called arbuscular mycorrhizal fungi, which assists plants in extracting heavy metals like lead and arsenic from the soil.

Alongside traditional decomposer fungi, the mixture of life forms demonstrated tremendous results in this brownfield.

“In three months we saw a more than 50 percent reduction in all pollutants. By 12 months, they were pretty much not detectable,” Stevenson told Yale 360.

Decontaminating soil like this typically involves bringing in a bulldozer and digging it all up for transportation to a landfill. This method is not only hugely expensive, but also dangerous, as contaminated material can scatter on the winds and fall out of the backs of trucks carting it away.

By contrast, the plants that draw out the toxic metals can be harvested and incinerated down to a small pile of ash before cheap transportation to a hazardous waste facility.

The technique, which Stevenson says has some scaling issues and issues with approval from regulators, is known officially as bioremediation, and she’s even used it to safely break down bags of lubricant-soaked rags from bicycle repair shops.

“People who live in a place impacted by pollution need to have a say in how their neighborhood is being cleaned up. We need to empower them with the tools to do this,” she said."

-via Good News Network, July 16, 2024

#mushrooms#fungi#mycology#mushroom#contamination#bioremediation#hazardous waste#hazardous materials#soil#mining#heavy metals#good news#hope#ecopunk#solarpunk

979 notes

·

View notes

Text

Let's Talk About BENTONITE

There's nothing worse than minding your own business, walking along in the desert when all of a sudden your feet start to feel weighted down. It gets harder and harder to pick up your feet. The mud is sticky and pulling you into the ground. That's bentonite.

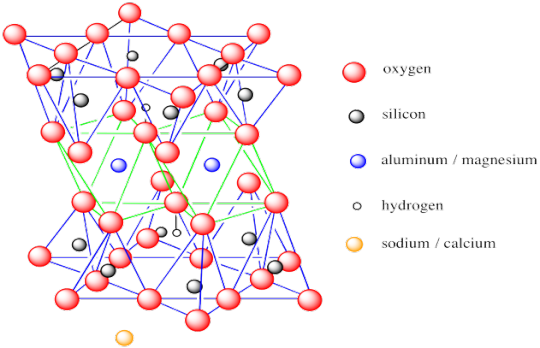

Bentonite is type of very soft, plastic clay made primarily of montmorillonite clay.

Montmorillonite is a hydrous, aluminum silicate in the smectite group (often you will hear bentonite and smectite used interchangeably).

Bentonite is formed by the alteration of volcanic ash when it comes in contact with water. Clays in general form from the chemical breakdown of feldspars (check out October's posts for more on feldspar!) and when ash gets thrown in the mix something very nasty occurs: swelling clays.

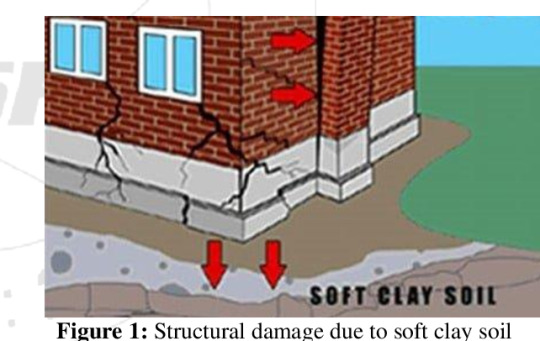

Bentonite increases greatly in volume when water is added...and decreases just as much when the water evaporates or gets absorbed in the groundwater system. This causes the popcorn texture you see in badlands topography.

Popcorn texture in Brushy Basin Member, Morrison Formation, near Evil Tree Bonebed. Sauropod rib found in it.

This can also cause structural damage. That is why the building around the Wall at Dinosaur National Monument had to be repaired a few years ago. Basically, the swelling of the bentonite split the foundation.

It also becomes very dangerous to drive on or walk on when it gets wet, becoming a slurry, sticky mess.

This is the main reason why we have to wait for summer to come before we head out to the dig site. We physically cannot get there until the Mancos Shale bentonite is dry enough to drive on.

Bentonite is not all bad though. It has some good uses too.

We actually use it to trap moisture in our skin and hair when we dry out. It's a natural sunblock and relieves burns and itching from bug bites. We even put it in Wendy's Frosty's to give them that smooth texture!

Bentonite is also used in agriculture as a natural pesticide, herbicide, and fungicide in fertilizers.

They also use it to coat drills in the oil industry to keep the drill bit lubricated, as well as coating well walls to keep them from collapsing. If you're a geek, like me, think Avatar, the Last Air Bender and the Fire Nation drill.

Hope you learned a little about bentonite today! Fossilize you later!

63 notes

·

View notes

Text

More Factorio speculation!

Vulcanus's metallurgic science introduces the Foundry, a sort of super-smelter that can make metal plates, gears, wire, etc with an inherent +50% production bonus and five module slots.

Fulgora's electromagnetic science introduces the Electromagnetic Plant, a sort of specialized assembler that can make circuits, electrical equipment, modules, etc with an inherent +50% production bonus and five module slots.

I expect that a building like that will be present on every planet in the Space Age expansion. So what's left?

The only big category of resources that isn't touched by either the electromagnetic plant or foundry is oil/chemical stuff; plastic, sulfur, lubricant, fuel, etc. So I feel confident that the third planet's special building will be some kind of enhanced chemical plant.

Which probably means we'll be getting a novel oil processing process on planet #3. Maybe the reverse of what Fulgora's oil sands have? Something that makes heavy oil important for more things than lubricant, some resource type that gives lots of petroleum gas, and a reverse cracking recipe?

If that's true, maybe planet #3 will be something like Titan, or like Titan crossed with Europa. A barren world, cold enough that ethylene condenses into pools on the surface.

But that's just a guess built on a foundation of more guesses. It could be something completely different, like a planet whose industry focuses on weapon stuff or uranium processing or something.

We'll find out eventually. We found out about Vulcanus three months ago, and Wube estimated a release date "about a year" after almost exactly six months from now. So I'm guessing we'll see a FFF about planet #3 some time around late May, and the final frontier either right before or right after the August release. Or at least, that's what I'm guessing Wube has scheduled; time will tell whether that works out!

While I'm here I'm guessing the final planet's Special Building is either some kind of super-rocket-silo, or a way to use science packs for purposes other than science. I think it would make sense for some of the last (non-infinite) technologies unlocked to be things that make linking planets together easier—a way to get resources from planetside to space platforms more easily, or upgrades for space platforms, or maybe something wild like interplanetary teleportation.

18 notes

·

View notes

Text

flicked to a random page and came across the phrase “primordial flamboyance”. god i love open access scholarly work

Freddie Mason’s “The Viscous: Slime, Stickiness, Fondling, Mixtures”

Slime, goo, gunge, gloop, gels, sols, globules, jellies, emulsions, greases, soaps, syrups, glues, lubricants, liquid crystals, moulds, plasmas, and protoplasms – the viscous is not one thing, but rather a quality of resistance and flow, of stickiness and slipperiness. It is a state of matter that oozes into the gaps of our everyday existence, across age groups, between cultures and disciplines.Since the large-scale extraction of petroleum in the 19th century, the viscous has witnessed a proliferation in the variety of its forms. Mechanized industry required lubricants and oil distillation produced waste products that were refined to form Vaseline. From this age, new viscous forms and technologies emerged: products from plastic (and plastic explosives) to cosmetics, glycerine, asphalt, sexual lubrication, hydro- and aero-gels, and even anti-climb paint.Based on unique and wide-ranging research, The Viscous is the first major investigation of encounters with and possibilities of the viscous over the course of the last century, not simply as a material state, but also as an imaginative event. We enter into a story of matter at its most wayward, deviant, hesitant, and resistant.From asphalt lakes to industrial molasses tanks, from liquid crystals squirming in our screens to milk fetishes, The Viscous discloses gooeyness as a peculiarly modern phase of matter. "Everything oozes," as Beckett’s Estragon famously proclaims in Waiting for Godot. Viscous dynamics are exposed as not only hugely various in a post-industrial age, but particularly useful ways of thinking, feeling, writing, and making in a time of ecological anxiety.

#slime#primordial flamboyance#Freddie Mason#figuring out how to tag interesting things i find as i stroll across the internet is hard

32 notes

·

View notes

Text

Zero Friction Coatings Market: Charting the Course for Enhanced Performance and Sustainable Solutions

The global zero friction coatings market size is estimated to reach USD 1,346.00 million by 2030 according to a new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 5.6% from 2022 to 2030. Growth can be attributed to the fact that these coatings reduce friction and wear resulting in low fuel consumption and less heat generation. According to the European Automobile Manufacturers' Association, 79.1 million motor vehicles were produced across the globe in 2021 which was up by 1.3% as compared to 2020. Zero friction coatings can extend the time between component maintenance and replacement, especially for machine parts that are expensive to manufacture.

Zero Friction Coatings Market Report Highlights

In 2021, molybdenum disulfide emerged as the dominant type segment by contributing around 50% of the revenue share. This is attributed to its properties such as low coefficient of friction at high loads, electrical insulation, and wide temperature range

The automobile & transportation was the dominating end-use segment accounting for a revenue share of more than 35% in 2021 due to the rapid growth of the automotive industry across the globe

The energy end-use segment is anticipated to grow at a CAGR of 5.7% in terms of revenue by 2030, owing to the excessive wear on the drill stem assembly and the well casing during the drilling operations in the oil and gas sector

In Asia Pacific, the market is projected to witness the highest CAGR of 5.8% over the predicted years owing to the presence of car manufacturing industries in the countries such as Japan, South Korea, and China

For More Details or Sample Copy please visit link @: Zero Friction Coatings Market Report

Several applications in the automobile industry use wear-resistant plastic seals that require zero tolerance for failure and lifetime service confidence. Increasing demand for the product from the automotive industry across the globe for various applications including fuel pumps, automatic transmissions, oil pumps, braking systems, and others is expected to drive its demand over the forecast period.

Low friction coatings can be used in extreme environments comprising high pressure, temperatures, and vacuums. These coatings can provide improved service life and performance thereby eliminating the need for wet lubricants in environments that require chemicals, heat, or clean room conditions. The product containing molybdenum disulfide (MoS2) are suitable for reinforced plastics while those free from MoS2 are suitable for non-reinforced plastics.

Zero friction coatings are paint-like products containing submicron-sized particles of solid lubricants dispersed through resin blends and solvents. The product can be applied using conventional painting techniques such as dipping, spraying, or brushing. The thickness of the film has a considerable influence on the anti-corrosion properties, coefficient of friction, and service life of the product. Its thickness should be greater than the surface roughness of the mating surfaces.

ZeroFrictionCoatingsMarket #FrictionlessTechnology #CoatingInnovations #IndustrialEfficiency #ZeroFrictionSolutions #AdvancedMaterials #SurfaceCoatings #ManufacturingAdvancements #GlobalIndustryTrends #InnovativeCoatings #PerformanceOptimization #MechanicalSystems #SustainableTechnology #IndustrialApplications #FutureTech #InnovationInMaterials #EfficiencySolutions #ZeroFrictionMarket #TechnologyInnovation #EngineeringMaterials

#Zero Friction Coatings Market#Frictionless Technology#Coating Innovations#Industrial Efficiency#Zero Friction Solutions#Advanced Materials#Surface Coatings#Manufacturing Advancements#Global Industry Trends#Innovative Coatings#Performance Optimization#Mechanical Systems#Sustainable Technology#Industrial Applications#Future Tech#Innovation In Materials#Efficiency Solutions#Zero Friction Market#Technology Innovation#Engineering Materials

2 notes

·

View notes

Text

Perfluoropolyether (PFPE)

Perfluoropolyether (PFPE) is a highly specialized lubricant that offers exceptional performance in various industrial applications. PFPE grease, oil, and lubricants are widely used in demanding environments where extreme temperatures, chemical resistance, and low friction are crucial.

PFPE grease is a type of lubricating grease made from perfluoropolyether oil as its base. With its excellent thermal stability, PFPE grease can withstand high temperatures without compromising its lubricating properties. This makes it ideal for use in industries such as aerospace, automotive, and semiconductor manufacturing, where equipment operates under extreme conditions.

PFPE oil, also derived from perfluoropolyether, is known for its superior chemical resistance and non-flammability. It provides long-lasting lubrication and protection for various mechanical components, even in harsh chemical environments. PFPE oil finds applications in chemical processing plants, pharmaceutical manufacturing, and vacuum systems where the integrity of the lubricant is critical.

As a perfluoropolyether-based lubricant, PFPE offers unique advantages over traditional oils and greases. Its low surface tension and high thermal stability contribute to reduced friction and wear, enhancing the overall durability and efficiency of machinery. Moreover, PFPE's inert nature prevents it from reacting with most materials, ensuring compatibility with a wide range of metals, elastomers, and plastics.

When it comes to choosing the right lubricant, PFPE lube stands out as an excellent choice. Its high viscosity index and exceptional load-carrying capacity make it suitable for heavy-duty applications. Whether it's providing lubrication in gears, bearings, or seals, PFPE lube ensures optimal performance and extends the lifespan of critical equipment.

In summary, perfluoropolyether (PFPE) lubricants, including PFPE grease, oil, and lubricants, offer unparalleled performance in extreme conditions. Their thermal stability, chemical resistance, and low friction properties make them indispensable in various industries. With their exceptional reliability and versatility, PFPE-based lubricants play a crucial role in ensuring the efficiency and longevity of industrial machinery.

2 notes

·

View notes

Text

JWZ-BM05D/12D/20D Double Station Blow Molding Machine

Performance and advantages

1. Suitable for producing 1-5L different size of gear oil bottle, lubrication oil bottle, cooling water tank etc.

2. Optional multi-layer co-extrusion.

3. Optional view strip line system.

4. According to the product size,select different cavity of die head.

5. According to the different material,optional JW-DB single station hydraulic screen-exchanger system.

6. According to customer's requirement,optional auto-deflashing on line,scrap conveying on line,finished product conveying on line.

Technical Parameters

Model

Unit

BM05D

BM12D

BM20D

Max product volume

L

5

12

20

Dry cycle

Pc/h

700*2

600*2

600*2

Die head structure

Continuous type

Main screw diameter

mm

75

90

90

Max plasticizing capacity (PE)

kg/h

90

160

160

Driving motor

Kw

30

45

45

Oil pump motor power

Kw

11

15

15

Clamping force

KN

70

120

160

Space between platen

mm

150-510

240-640

280-680

Platen size W*H

mm

350*400

450*500

500*520

Max.mould size

mm

360*400

500*520

560*520

Platen moving stroke

mm

450/520

600/650

650

Heating power of die head

Kw

7.5

10

12.5

Machine dimension L*W*H

m

3.7*3.1*2.7

4.2*3.2*3.0

4.3*3.2*3.1

Machine weight

T

8.5

12

14

Total power

Kw

60

90

93

Note: Informations listed above are for reference only, the production line can be designed by customer’s requirements.

Product image display

JWELL Co., Ltd. was founded in 1978, the Chinese biggest plastic extrusion machinery manufacturers with over 24 years in extrusion industry .Now we have 6 production base , more than 3000 employees, having a strong technical & after sales service team for serving more than 150 countries.

Core components: screw and barrel, mold, roller, all processed by us. jwell group has 16 professional branches, each of which produces different products, You can get all the plastic extrusion equipments you need in jwell company and provide you with one-stop service.

Our processing equipment is all CNC imported from Japan and Europe.

The steel used in our machine is superior to our peers. For the same equipment, the lifetime of jwell company's equipment is generally two or three times longer than our peers.

The electrical components used in our equipment are imported brands or Chinese famous brands, and they are specially optimized and designed according to the requirements of jwell company, which can well match our equipment. Other companies do not have such strength and influence.

There is an old saying in China:You get what you pay for!

Read the full article

2 notes

·

View notes

Text

The Role of Zinc Stearate in Plastics Manufacturing

Zinc Separate is a commonly used chemical compound in the plastics manufacturing industry. It is a white, fluffy powder that is used as a lubricant, release agent, and stabilizer in plastics processing. Zinc Stearate supplier in Ecuador is made by combining stearic acid with zinc oxide, and it has several benefits in plastic manufacturing. In this blog, we will explore the role of Zinc Stearate in plastics manufacturing and discuss its importance in the industry.

One of the key benefits of Zinc Stearate is its ability to act as a lubricant. In the plastic manufacturing process, the resin can stick to the machinery and cause significant problems. Zinc Stearate helps to reduce friction and allows the plastic to flow more smoothly through the machinery. This results in less downtime and increased productivity.

Another important role that Zinc Stearate Distributor in Ecuador plays in the plastic manufacturing industry is as a release agent. When plastic is being molded or extruded, it can stick to the molds and other surfaces. Zinc Stearate helps to prevent this from happening by creating a barrier between the plastic and the mold surface. This reduces the likelihood of defects and ensures that the final product is of high quality.

Zinc Stearate also acts as a stabilizer in plastic manufacturing. It helps to prevent the breakdown of the plastic due to heat or UV exposure. This is especially important for plastics that are exposed to outdoor environments or high temperatures. By adding Zinc Stearate to the plastic, manufacturers can ensure that their products will last longer and maintain their quality over time.

When it comes to sourcing Zinc Stearate for plastic manufacturing, it is important to find a reliable supplier. In Ecuador, there are several Zinc Stearate Exporter in Ecuador who can provide high-quality Zinc Stearate for plastic manufacturers. These include Zinc Stearate suppliers like Industrias Químicas del Ecuador and Zinc Stearate distributors like J.J. Llobet E.I.R.L. It is important to work with a reputable supplier who can provide consistent and high-quality Zinc Stearate.

In conclusion, Zinc Stearate plays a vital role in the plastic manufacturing industry. It is a versatile compound that can act as a lubricant, release agent, and stabilizer, making it an essential ingredient in the production of high-quality plastics. For plastic manufacturers in Ecuador, there are several reliable Zinc Stearate Distributors in Ecuador who can provide high-quality Zinc Stearate to meet their needs. By using Zinc Stearate in plastic manufacturing, manufacturers can ensure that their products are of high quality and will last longer.

#Zinc Stearate supplier in Ecuador#Zinc Stearate Distributor in Ecuador#Zinc Stearate Exporter in Ecuador#palvichemical

3 notes

·

View notes

Photo

Illustration Photo: Sugarcane is one of the most efficient producers of biomass of all plant species and can be used as a renewable fuel. The new variety Ho 06-9002 has a high fiber content, excellent regrowth ability over 4 to 5 years, is cold-tolerant, has a high stalk population, and produces excellent biomass yields. (credits: USDA Media by Lance Cheung / Public domain)

Repsol Entrepreneurs Fund for Startups in the Energy Transition

At the Repsol Foundation, we have been supporting entrepreneurship and entrepreneurs for more than 10 years through Fondo de Emprendedores, our accelerator for start-ups that provide technological solutions to meet the challenges of the Energy Transition. This is a perfect program for start-ups in the testing phase with real customers, or that will reach this phase in 1–2 years.

This program aims to accelerate startups working in any of the following:

SCOPE 1: LOW-CARBON ENERGY TECHNOLOGIES AND CIRCULAR ECONOMY

1. Recycling and treatment technologies: conversion of biomass, new processes for converting waste into chemical products

2. Biogas production, upgrading, transport and end use technologies

3. Low environmental impact H2 renewable solutions for production, blending, transport and storage

4. Advanced biofuel production and conversion technologies (liquefaction or de novo, gasification) and synthetic fuels for road, maritime and aviation transport

5. Processing of chemicals and other organic materials for circular economy

6. Low-carbon lubricants for industrial and automotive applications

7. CO2 Capture, Use and/or Storage Technologies. CO2 Direct Air Capture: new absorbent materials and efficient process design

8. COX, H2 conversion processes to Hydrocarbons

9. Low carbon technologies for Oil & Gas operations, including energy efficiency, GHG direct emissions (scopes 1 and 2), Methane emissions, CCS or Geothermal.

10. Other technologies related to this scope’s heading

SCOPE 2: BIOTECHNOLOGY AND NANOTECHNOLOGY FOR SUSTAINABLE SOLUTIONS

1. Bio conversion of organic material to chemicals. Biorefinery, biofactory

2. Protein engineering, development of biocatalysts and enzymes

3. Gene editing technologies and applications in energy and materials

4. Plastic biodegradation technologies

5. Biosensors design, production and end use.

6. Anti-corrosive, anti-bacterial, thermal nanocoating for pipelines and infrastructures

7. Organic and inorganic membrane technologies, including new materials

8. Improvement of the properties of fuels, lubricants and chemicals

9. Other technologies related to this scope’s heading

SCOPE 3: PRODUCTS AND SERVICES BASED ON ENERGY MANAGEMENT AND RENEWABLES

1. Intelligent energy management systems

2. New batteries and fuel cells technologies

3. Distributed energy solutions

4. Energy conversion and storage systems

5. Advanced mobility solutions

6. Renewable energy generation, maintenance and control and commercialization.

7. Other technologies related to this scope’s heading

SCOPE 4: DIGITAL TECHNOLOGIES FOR THE ENERGY SECTOR

1. Artificial intelligence applied to process optimization and energy efficiency.

2. Digital twins and intelligent interfaces for process control

3. Digital technologies for predictive and prescriptive maintenance

4. Smart trading for the energy marketplace

5. Computational chemistry tools for energy applications

6. Remote sensing, IoT and robotic solutions for industrial assets and environment

7. Quantum computing applications in energy sector

8. Other technologies related to this scope’s heading

SCOPE 5: NATURAL SOLUTIONS FOR CARBON FOOTPRINT REDUCTION

1. Reforestation and afforestation technologies for resilient CO2 absorption sinks

2. Advanced monitoring, reporting and verification technologies in CO2 absorption

3. Digital technologies applied to carbon markets value chain

4. Technologies for ESG (Environmental, Social and Governance) project certification

5. Other technologies related to this scope’s heading

Startups admitted to the Program will receive during the acceleration period a contribution of FIVE THOUSAND EUROS (€ 5,000) per month as ordinary funds.

Additionally, admitted Startups may request up to a maximum of FORTY THOUSAND EUROS (€ 40,000) per year as extraordinary funds for strategic expenses to achieve the milestones of the Work Plan (as defined in section 4.4), mainly to complete the pilot test.

The disbursement of this additional contribution will be subject to the exclusive decision of Fundación Repsol.

Application Deadline: March 10, 2023

Check more https://adalidda.com/posts/c4qmPwNwToZAAbf2L/repsol-entrepreneurs-fund-for-startups-in-the-energy/call

2 notes

·

View notes

Text

/PRNewswire/ -- Refinery and Petrochemical Filtration Market is projected to reach USD 6.1 billion in 2028 from USD 4.6 billion in 2023 at a CAGR of 6.0% according to a new report by MarketsandMarkets™. Refinery and petrochemical filtration are essential processes in downstream oil and gas production. Refinery filtration purifies crude oil and feedstocks, creating high-quality fuels and lubricants. Petrochemical filtration eliminates contaminants from chemicals and gases used in plastics and industrial goods. Filters are crucial to guarantee the quality and purity of final products while minimizing environmental impact and reducing operational costs.

#refinery#refineries#petrochemicals#petrochenical#petroleum#energy#energia#oil industry#oil rig#oil and gas companies#oil and gas#filtration#refinery and petrochemical filtration

0 notes

Text

Extrusion Granulator: Efficient and Eco-Friendly Solution for Fertilizer and Feed Production

Extrusion granulator is a widely used piece of equipment in fertilizer production that forms powder or fine granular materials into specific shapes and sizes through mechanical extrusion. This process is commonly applied in the production of compound fertilizers, granular fertilizers, feed, and other pelletized products. It is known for being efficient, environmentally friendly, and energy-saving. Below is a detailed explanation of the extrusion granulator.

Working Principle of Extrusion Granulator:

The core principle of the extrusion granulator is to physically compress materials under high pressure, typically through screws or roller pressing, transforming them into solid granules. The process does not require liquid binders and relies solely on the physical properties of the materials to form granules. The steps are as follows:

Material Feeding: Powder or small granular materials are fed evenly into the granulator through the feeding system.

Extrusion Process: Inside the granulation chamber, the material is pressed by two rotating rollers or screws, causing plastic deformation.

Granule Formation: Under pressure, the material is compressed into granules of a specified shape and size.

Granule Discharge: The formed granules are discharged through an outlet, then screened and cooled to produce the final granulated product.

Advantages of Extrusion Granulators:

Environmentally Friendly and Energy-Efficient: The extrusion process does not require heating or drying, saving significant amounts of energy.

High Production Efficiency: Granulation speed is fast, with high output, making it suitable for large-scale production.

No Chemical Binders: Granules are formed through physical compression without the need for binders, maintaining product purity.

Flexible Product Shapes: By changing the mold, the extrusion granulator can produce granules of different shapes and sizes, catering to varying market demands.

Extrusion Granulator Application Areas:

Compound Fertilizer Production: Extrusion granulators are widely used for producing NPK compound fertilizers, especially for low- and medium-concentration fertilizers.

Organic Fertilizer Production: Suitable for processing organic materials such as animal manure and straw into organic fertilizer granules.

Feed Processing: Can be used to make pelletized feed for livestock, poultry, and fish, improving feed’s physical properties and storability.

Other Industrial Applications: The extrusion granulation process is also used in industries such as chemicals and pharmaceuticals to produce granular products.

Common Types of Extrusion Granulators:

Double-Roller Extrusion Granulator: Forms granules by compressing material through two rotating rollers, suitable for producing compound fertilizers, potash fertilizers, and more.

Screw Extrusion Granulator: Uses rotating screws to push material toward the outlet to form granules, widely used in feed, plastics, and other industries.

Equipment Maintenance:

Regularly inspect extrusion components for wear and replace damaged parts in time.

Ensure proper lubrication of the equipment to avoid prolonged operation under dry friction.

Clean residual material to prevent clogging, which can reduce production efficiency.

How to selcet the right Extrusion Granulator for your production?

Here are the top 5 Request for Quotation (RFQ) items typically included when inquiring about an Extrusion Granulator:

1. Production Capacity

Specify the desired output (e.g., tons per hour or per day) to ensure the granulator meets your production needs.

2. Material Type and Characteristics

Provide details about the materials you intend to process (e.g., NPK compound, organic fertilizer, feed), including particle size, moisture content, and any special characteristics.

3. Granule Size and Shape

Indicate the preferred granule size and shape (e.g., diameter, cylindrical, spherical) to ensure the machine can deliver the desired product.

4. Power Requirements and Energy Consumption

Request details about the machine’s power specifications (e.g., voltage, power consumption), especially for ensuring compatibility with your facility’s infrastructure.

5. Customization Options and Additional Features

Ask about available customization options, such as mold changes for different granule shapes, or additional features like automatic feeding, cooling, and screening systems.

These RFQs will help you gather essential technical specifications and pricing to make an informed decision.

Due to its high efficiency, environmental benefits, and adaptability, the extrusion granulator has become an essential piece of equipment in industries such as fertilizer and feed production. If you have specific equipment requirements or would like more technical details, feel free to reach out for further discussion.

0 notes

Text

Ala Polystabs: Leading Calcium Stearate & Zinc Stearate Manufacturers in India

In the all God's creatures of industrial chemical amalgams and additives, Calcium Stearate and Zinc Stearate play an indispensable role all over more than one wholes. Whether it's in plastics, rubber, construction, or paints, these stearates serve as important pushers for lubrication, stabilization, and dealing out. As one of the most efficient Calcium Stearate Manufacturers in India and Zinc Stearate Manufacturers in India, Ala Polystabs has constructed a reputation for turning in excellent, dependable merchandise that meet the needs of current industries.

This manual will discover the numerous aspects of Calcium Stearate and Zinc Stearate, their programs, and why Ala Polystabs is the desired accomplice for companies throughout India and beyond.

Understanding Stearates: Calcium Stearate and Zinc Stearate

Before diving into the assistances of pick out Ala Polystabs as your dealer, let's first diagnose what Calcium Stearate and Zinc Stearate are and why they're so important to a huge range of commerce.

What is Calcium Stearate?

Calcium Stearate is a calcium salt derived from stearic acid, a clearly going on fatty acid. This white, waxy powder is broadly used as a lubricant, launch agent, and stabilizer in diverse manufacturing approaches. It is non-toxic, secure to handle, and enormously effective in improving the performance and pleasant of production procedures.

Applications of Calcium Stearate:

1. Plastics Industry: In plastics, Calcium Stearate acts as a stabilizer and grease, ration to prevent deprivation of polymers at some point of processing. It enhances waft houses and reduces friction among polymers, making it less thorny to mold and extrude plastic products.

2. Rubber Industry: Calcium Stearate is usually used within the rubber enterprise to prevent sticking at some stage in handing out and to improve the ejection houses of rubber goods from molds.

3. Construction Industry: In construction, Calcium Stearate is used in actual as a waterproofing agent, helping to reduce water absorption and decorate the sturdiness of concrete systems.

4 . Cosmetics and Pharmaceuticals: It is also widely used as an anti-caking agent in cosmetics and arranged drugs due to its smooth texture and water-repellent houses.

What is Zinc Stearate?

Zinc Stearate is any other stearate compound fashioned by using the response of stearic acid with zinc. It is regularly considered the handiest release agent within the rubber and plastic industries. Like calcium stearate, it appears as a fine, white powder but is specifically valued for its water-repellent and non-reactive houses.

Applications of Zinc Stearate:

1. Plastic and Rubber: Zinc Stearate is used as a effective mould release agent and fat inside the business of plastic and rubber merchandise. It prevents products from sticking to molds, making sure smooth finishes and improving overall production performance.

2. Paints and Coatings: In the coats industry, Zinc Stearate features as a matting agent, supplying unevenness, water repellency, and a unbroken finish. It is too used to progress the texture and consistency of coatings.

3 . Pharmaceuticals and Cosmetics: Due to its non-toxicity, Zinc Stearate is widely used in the pharmaceutical and cosmetics industries as a lubricant and anti-caking agent. It improves the go with the flow houses of powders and forestalls them from clumping collectively.

4 . Construction: Just like Calcium Stearate, Zinc Stearate unearths use in creation as a hydrophobic agent in concrete, supporting to make systems greater waterproof and sturdy.

Why Choose Ala Polystabs for Calcium and Zinc Stearates?

In the fantastically competitive world of commercial chemical substances, Ala Polystabs has mounted itself as a depended on name amongst Calcium Stearate Manufacturers in India and Zinc Stearate Manufacturers in India. But what units Ala Polystabs aside from the relaxation? Let's explore the important thing motives why groups select Ala Polystabs as their stearate provider:

1. High-Quality Products

At Ala Polystabs, great is the cornerstone of the entirety we do. Our Calcium Stearate and Zinc Stearate products are manufactured the use of excessive-grade uncooked substances, ensuring regular purity and overall performance across all batches. We adhere to stringent quality manipulate tactics at each stage of manufacturing, from raw material sourcing to the final product, to ensure our customers acquire handiest the exceptional.

2. Customized Solutions

Different industries and programs require specific formulations and specifications. Ala Polystabs gives custom designed answers to meet the specific needs of our clients. Whether you need a specific grade of Calcium Stearate on your plastic manufacturing method or a tailor-made system of Zinc Stearate in your coatings, our team of specialists will work closely with you to increase the proper solution.

3. Advanced Manufacturing Technology

At Ala Polystabs, we delight ourselves on staying at the vanguard of technological advancements inside the chemical production industry. Our ultra-modern production facilities are equipped with the brand new machinery and era, allowing us to produce tremendous Calcium Stearate and Zinc Stearate successfully and at scale. Our strategies are optimized for pace, consistency, and first-rate, ensuring that we are able to meet even the maximum annoying production schedules.

4. Environmentally Responsible Practices

Sustainability is a middle price at Ala Polystabs. We are dedicated to minimizing our environmental effect via accountable sourcing, electricity-green production processes, and waste discount tasks. Our merchandise are designed to be green and non-toxic, making sure that they're safe for both our clients and the surroundings.

5. Reliable Supply Chain and On-Time Delivery

In the quick-paced international of manufacturing, delays in material supply can cause large disruptions. That’s why Ala Polystabs ensures a reliable deliver chain and on-time shipping of our Calcium Stearate and Zinc Stearate merchandise. Our logistics crew works effectively to satisfy orders quickly and as it should be, ensuring that our clients never experience downtime due to fabric shortages.

6. Competitive Pricing

At Ala Polystabs, we apprehend the importance of value efficiency in nowadays’s aggressive markets. While we in no way compromise on high-quality, we attempt to provide our customers the most competitive pricing feasible. Our optimized manufacturing approaches and economies of scale allow us to pass savings on to our clients, making Ala Polystabs one of the most fee-effective Calcium Stearate Manufacturers in India.

7. Exceptional Customer Support

Our commitment to purchaser delight goes past the sale. Ala Polystabs offers complete customer service to make sure which you get the most out of our products. From technical assistance to product hints and after-sales support, our committed group is always equipped to assist.

Industry Applications for Ala Polystabs Stearates

1. Plastics and Rubber Industry

In the plastics and rubber industries, Calcium Stearate and Zinc Stearate are essential additives that improve the processing and great of merchandise. Calcium Stearate acts as a stabilizer and lubricant in plastic production, helping to enhance flow residences and reduce friction at some stage in molding and extrusion. Zinc Stearate is broadly used as a launch agent in rubber molding, ensuring that finished products pop out of molds without problems and with out surface defects.

2. Paints and Coatings Industry

For the paints and coatings industry, Zinc Stearate is mainly valued for its matting properties, supporting to create smooth, uniform finishes in paints. It additionally imparts water repellency, making it a perfect choice for out of doors packages where moisture resistance is crucial. Calcium Stearate is used as a lubricant and dispersant, making sure that pigments and other components are frivolously allotted throughout the paint, ensuing in a steady colour and texture.

3. Construction Industry

In the development area, each Calcium Stearate and Zinc Stearate are used as waterproofing sellers in concrete and different constructing substances. By reducing water absorption, those stearates decorate the sturdiness of concrete structures, supporting them face up to weathering and environmental stress. Ala Polystabs presents excessive-overall performance stearates for construction corporations trying to enhance the toughness of their buildings and infrastructure.

4. Pharmaceuticals and Cosmetics

For pharmaceutical and cosmetic manufacturers, Ala Polystabs stearates provide critical features such as anti-caking, drift improvement, and lubrication. Calcium Stearate and Zinc Stearate are broadly used in powders, tablets, and skin care products to prevent clumping, improve product consistency, and ensure smooth software.

Conclusion: Choose Ala Polystabs for Superior Stearates

As one of the main Calcium Stearate Manufacturers in India and Zinc Stearate Manufacturers in India, Ala Polystabs is devoted to turning in super, reliable, and value-powerful solutions for a extensive range of industries. With our superior manufacturing era, dedication to sustainability, and recognition on customer delight, we're the correct companion for all of your stearate desires.

Whether you’re in the plastics, rubber, creation, paints, or pharmaceutical industries, Ala Polystabs has the understanding and enjoy to provide you with the right stearate merchandise to your application. Contact us today to analyze greater approximately our product offerings and the way we are able to assist your business thrive.

0 notes

Text

United Kingdom Pelargonic Acid : Growing Applications Boosting Demand

The United Kingdom pelargonic acid has witnessed significant growth over the past few years owing to rising awareness and applications of the product. Pelargonic acid, also known as nonanoic acid, is a saturated fatty acid that occurs naturally in several plant and animal fats and oils. Some key properties of pelargonic acid include high acidity, stability, and easy availability.

Multiple End-Use Industries Driving Consumption

Pelargonic acid finds wide usage as a feedstock in the production of numerous industrial and household chemicals. It is a important industrial intermediate that is used to synthesize lubricants, plasticizers, surfactants, fungicides, herbicides, and several other products. The expanding crop protection in the United Kingdom Pelargonic Acid is a major demand generator, with pelargonic acid serving as a crucial starting material in the manufacture of fungicides and herbicides.Growing agriculture sector and rising need to boost crop yields is propelling the fungicide and herbicide.

Personal care is another major end-user, utilizing pelargonic acid in cosmetic formulations such as cleansers, creams, lotions, and shampoos due to its cleansing properties. Its emulsifying ability makes it ideal for use in hair and skin care products. Strong demand from the thriving cosmetics and toiletries in the country is augmenting revenues. Rapid urbanization, high disposable incomes, and increasing health and beauty consciousness among British consumers are some factors bolstering the personal care space.

Household insecticides represent yet another high-growth application area. With changing lifestyles and busy schedules, demand for easy to use and effective household insecticides is witnessing an upswing in the country. Key properties that make pelargonic acid suitable for insecticides include high insecticidal activity against many pests and microbes coupled with low toxicity to humans and most animals. Rising sales of household insecticides is a chief contributor to the sales of pelargonic acid in the country.

Surfactants constitute another major application segment. Pelargonic acid finds application as an intermediate in the production of non-ionic surfactants that are used extensively across home care, I&I cleaning, personal care, and industrial sectors. Strong demand from several end-use industries has been favoring the surfactants, consecutively boosting the consumption of pelargonic acid.

Regional Manufacturers Expanding Production Capacities

Leading players in the United Kingdom Pelargonic Acid are ramping up their output capacities in view of new project announcements and capacity expansion initiatives by end-use players. Croda International plc, one of the prominent suppliers, has been steadily expanding its regional production of pelargonic acid to keep pace with the growing demand from personal care producers and various other industrial customers. Similarly, other key manufacturers like Oxiteno UK Ltd. and Fine Organic Industries Ltd. have implemented capacity expansions at their UK production bases over the recent years.

With consistently rising commercial and industrial activity levels creating sustained demand, manufacturers are making focused investments in technology advancements and new production facilities. This will enable them to ensure adequate supply and capture new opportunities. Additionally, the availability of locally sourced raw materials is encouraging domestic production of pelargonic acid in the country. The UK is consequently expected to witness continued healthy growth over the coming years.

Get more insights on this topic: https://www.trendingwebwire.com/united-kingdom-pelargonic-acid-pelargonic-acid-in-the-united-kingdom/

About Author:

Priya Pandey is a dynamic and passionate editor with over three years of expertise in content editing and proofreading. Holding a bachelor's degree in biotechnology, Priya has a knack for making the content engaging. Her diverse portfolio includes editing documents across different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. Priya's meticulous attention to detail and commitment to excellence make her an invaluable asset in the world of content creation and refinement. (LinkedIn - https://www.linkedin.com/in/priya-pandey-8417a8173/)

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it

0 notes

Text

0 notes

Text

Zinc Stearate Supplier in Ecuador | Palvichemical

Palvi Chemical is your reliable supplier of high-quality Zinc Separate in Ecuador. Our Zinc Separate is produced using state-of-the-art technology and is of superior quality, making it an excellent choice for a wide range of applications.

Zinc Stearate is commonly used in the plastics, rubber, and paint industries as a lubricant, stabilizer, and release agent. It is also used in the production of pharmaceuticals, cosmetics, and food packaging.

We take great pride in our commitment to providing our customers with the highest quality products and exceptional customer service. Our experienced team is dedicated to ensuring that you receive your Zinc Stearate on time and in perfect condition.

Contact Palvi Chemical today to learn more about our Zinc Stearate and how we can help meet your needs.

#Zinc Stearate supplier in Ecuador#Zinc Stearate Distributor in Ecuador#Zinc Stearate Exporter in Ecuador#palvichemical

3 notes

·

View notes