#limit switch actuator

Explore tagged Tumblr posts

Text

Enhance Your Electrical System with Top Products from Creative Automation

At Creative Automation, we offer a wide range of high-quality products designed to meet the needs of any electrical system. Whether you're looking for transformers, relays, or sensors, our inventory has got you covered.

Split Core CT

For accurate current measurement, our Split Core CT is an essential tool. It is ideal for retrofitting applications where the current transformer needs to be installed without disconnecting the conductor.

Wago Power Supply

Ensure stable and efficient power distribution with the trusted Wago Power Supply. Perfect for industrial applications, Wago's power supplies are known for their reliability and durability.

Earth Leakage Relay

Protect your electrical systems from faults and leaks with our Earth Leakage Relay. This essential safety device helps in preventing electrical hazards, ensuring a safer environment for both equipment and personnel.

Energy Meter

Monitor and manage your energy consumption effectively with our advanced Energy Meter. These meters are designed to provide precise energy data, helping businesses to optimize power usage.

Temperature And Humidity Sensor

Keep track of environmental conditions with our reliable Temperature And Humidity Sensor. These sensors ensure accurate readings to help maintain optimal operating conditions for sensitive equipment.

Conclusion

At Creative Automation, we provide top-quality electrical solutions in Sharjah. For more information, contact us at +971 55 761 2347.

0 notes

Text

Explore a wide selection of high-quality valve limit switches and monitors at Valworx. Our reliable and durable products are designed to provide precise valve position feedback for a variety of industrial applications. Ensure optimal performance and control with our easy-to-install and maintain solutions. Shop now for competitive prices and excellent customer support.

2 notes

·

View notes

Text

Pneumatic Components in Dubai: Alphatronic Machinery's Comprehensive Offerings

Dubai's industrial sector relies heavily on pneumatic systems for various applications. Alphatronic Machinery has established itself as a key supplier of essential pneumatic components in the region. This article explores their offerings across several product categories.

Pneumatic Fittings and Tubing Suppliers in Dubai: Alphatronic Machinery offers a wide range of pneumatic fittings and tubing solutions. Their product line includes push-to-connect fittings, compression fittings, and tubing in various materials and sizes, catering to diverse industrial needs.

FRL Suppliers in Dubai: As a leading FRL (Filter, Regulator, Lubricator) supplier in Dubai, Alphatronic Machinery provides units crucial for maintaining air quality in pneumatic systems. These components filter contaminants, regulate pressure, and provide necessary lubrication, extending the life of downstream components.

Air Cylinders Suppliers in Dubai: Alphatronic Machinery supplies a diverse selection of air cylinders to the Dubai market. Their range includes single-acting, double-acting, and specialized designs, catering to various force requirements and stroke lengths across different industries.

Solenoid Valve Suppliers in Dubai: As a prominent solenoid valve supplier in Dubai, Alphatronic Machinery offers a wide range of configurations, including 2-way, 3-way, and 5-way valves. These electrically controlled valves are essential for automating pneumatic systems in various applications.

Electropneumatic Pressure Regulators Suppliers in Dubai: Alphatronic Machinery has positioned itself as a key supplier of advanced electropneumatic pressure regulators in Dubai. These components allow for precise electronic control of air pressure in sophisticated pneumatic applications, meeting the demands of modern industrial processes.

Alphatronic Machinery's comprehensive product range and strong presence in Dubai make it a preferred choice for businesses requiring high-quality pneumatic components. Their expertise in the field ensures customers receive appropriate solutions for their specific pneumatic system needs, solidifying their position as a leading supplier in the region.

#mag drive pumps suppliers in dubai#frlsuppliersindubai#limit switch suppliers in dubai#worm gearbox suppliers in dubai#pneumatic fittings and tubing suppliers in dubai#ball valve with actuators suppliers in dubai#positioners suppliers in dubai#bestpumpsuppliersinuae#magdrivepumpssuppliersindubai#limitswitchsuppliersindubai

0 notes

Text

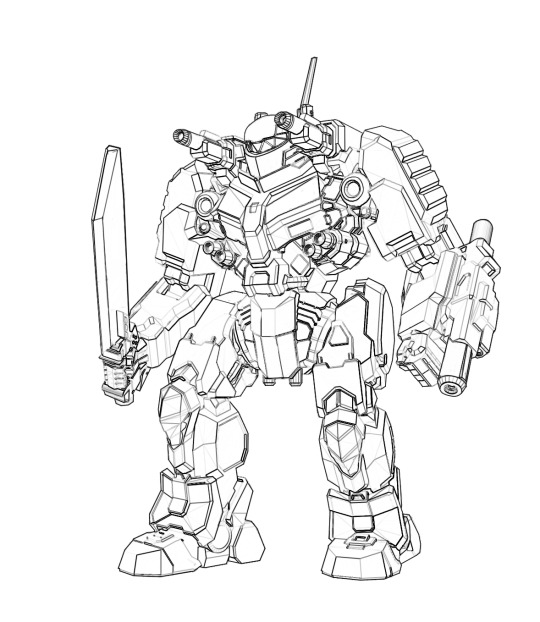

WLF-Xb-KNT Wolf Knight

Description:

The WLF-Xb-KNT Wolf Knight is highly specialised one of a kind mech made from primarily the chassis of a Black Knight and a number of parts from a Battlemaster. Made to the whims of a mechwarrior with a strange idea with some mechtech experience, the Wolf Knight was constructed allegedly from a dream, that was then committed to paper, explored and executed. Its primary purpose is to be an upgraded Black Knight with heavier armour, jump jets and extensive re-engineering of the Black Knights interior and sensor suite. The interior was remade to fit a powerful Extra-Light engine. The chassis and frame was remodeled extensively and changing to a more common frame model of pieces of changed BL-7-KNT Black Knight pieces and that of a BLR-1G Battlemaster. Despite its Frankenmech design, the focus on off the shelf parts allows the Wolf Knight an ease of access for repairs and maintenance to a surprising degree despite the heavy modifications. The most taxing parts are its dual Myomer and servo system and the cockpit to sensor connections. The refit process documented the notes of these two extensively but nevertheless requires a very qualified engineer to repair and maintain. It makes extensive use of Triple Strength Myomers that run through the mech coupled with finely and highly tuned actuators, calibrated after the pilot's movements, the Wolf Knight can swing the great blade's motions in its hand with tilts, flicks and even whips in its attacks. This is made possible with a secondary Myomer system that works on tandem with the more powerful one, giving increased agility and precision. Lastly this secondary Myomer system is backed up and tied into an integrated hydraulic servo system with the fibres themselves attached to limit switches for a natural pullback and resistance. The practical nature or battlefield application was contentious even by the refitting engineers but it was found difficult to argue against the one placing the order. One of its most curious features and the namesake is the re-engieering of the sensor suite of the Black Knight. It uses similar principles as the originals Beagle Active Probe system which uses the small laser to scan. Instead it has a second sensor tower, giving it two "ears" on the Knight helmet. Together with the pilot harness this is called the High Oscilation Wave-Length system or H.O.W.L. for short. It functions by generating pulses and frequencies through the heart rate monitor and neurohelmet's brain wave readings. Which in turn create an algorithm that is impossible to predict or even anticipate for a computer. This forms the basis of the skip-frequencies used in the sensor system in its pulses. The effect shifts the Mech's position by one to two meters between pulses on hostile sensors, slightly distorting the Wolf-Knight position, velocity and direction. Even skilled combatants can be caught unaware of their mech suddenly shifting the targeting to compensate. Leading to glancing shots. However the H.O.W.L. system distorts command and control communication over long distance, forcing it rely on short wave range bands. For this reason, it is usually only active during active combat operations in order to allow for strategic coordination. This, along with the precise movements of the arms is achieved by a specially made cockpit. Rather than the usual joystick configuration, the mechwarrior wears a harness that can mimic arm movements of the pilot. In addition it keeps track of the pilot's vitals and uses these together with the helmet to modify the frequencies of of the sensor suite and probe. The harness is heavy to move and is is wholly integrated with the neurohelmet and cockpit at large and tailored for a single individual and does not interact well with ejections.

Armament:

The Wolf Knight wields a large sword in the right, though functionally is follows the design principles of Fedcom-era hatchets. Otherwise the loadout is very similar to that of a Black Knight. A Lord's Light 2 rather than the royal versions' Kinslaughter ERPPC in the left arm allows for long range sniping with an original Maxell DT medium laser mounted under the main cannon. It is supported by two Magna Mk III large lasers as shoulder cannons along with parts of the housing used for a Rifleman. Instead of the the original torso mounted McCorkel mounted in order to make space for the new internal systems. Using parts and housing from a a Catapult on each side of the torso is a pair of Martell Medium Lasers and Omnicron 1000 Small lasers. Allowing the Wolf Knight to brawl with to a similar degree as a standard Black Knight.

Sixteen Double heat sinks allows the Wolf Knight to remain at range and fight without significant overheating. Once it gets close and pounces with the shorter range lasers it can easily activate the full potential of the Triple Strength Myomer system.

Inside the chest of the Wolf Knight however remains the Beagle Active Probe from which the black knight was noted for carrying. It has been wired to a Ceres Metals model 666 Communication system that connects into the Beagle Active Probe together with the original TransComm Beta targeting system.

The engine is connect to a RedLine-F Series Outland Supercharger system that allows the Wolf Knight to pounce on targets with the blade. Four Chillton model 600 Jump jets give it an extra level of mobility. However the XL is a weak point in long engagements where endurance becomes the dominating factor as a single torso side being blown apart would stall the engine.

Made in blender by kitbashing a number of things together.

26 notes

·

View notes

Text

Tomb Raider I-III Remastered Nitro Deck+

'Limited production of only 1,000 Worldwide! A Tomb Raider is always equipped! This Special Edition Nitro Deck+ controller for Nintendo® Switch™ has everything you need to be prepared! Enhance your gaming experience with this Tomb Raider-themed deck! Embark on an odyssey of discovery, danger, and untold wonders, where adventure awaits in the depths of every shadow and beyond each rugged rock.

This design showcases Lara's resilience and determination featuring artwork symbolic of her journey's challenges & obstacles. A towering mountain and intricate hieroglyphic symbols intertwined with foliage and cracked rocks evoke ancient civilizations and mysteries awaiting to be discovered.

Only 1000 of each will be made, so get your hands on one before they are locked in the vault for the rest of time!

Whether you’re playing at home or on the go, casually or competitively, the Nitro Deck+ delivers the responsiveness and precision you need to enjoy your favorite games comfortably, for longer.'

Created by Limited Run Games for the Nintendo Switch and OLED Model, it features artwork that represent Lara's adventures, such as Egyptian hieroglyphs and pyramids, cracked stone and jungle foliage. It has the teal and gold colouring that has become the colours for the unified era of the franchise, as well as the logo for 'Tomb Raider I-II-III Remastered'. Here are further details from the official store page: - Limited Production - Only 1,000 worldwide! - Transforms your Nintendo Switch™ into a stylish handheld console Teal and yellow Tomb Raider I-III Remastered Starring Lara Croft theme - Updated with a symmetrical thumbstick layout for enhanced comfort. - Equipped with Hall Effect thumbsticks for precise & responsive stick drift-free control. - Play in Docked Mode while connected to a TV. USB-C to HDMI adapter sold separately. - New fully programmable Sidekick buttons allow for more customization options. - Adjustable Trigger Sensitivity. Onboard with Hall Effect Triggers, allowing you to fine-tune the preferred actuation point of your triggers. - Low Latency Direct connection via USB-C allows for a more responsive, lag-free gaming experience. - Programmable back buttons add versatility to your play style. - Compatible with the "True Collection System" CRKD Companion App where you can tap your product into your collection of CRKD products, revealing the product # and rarity rank of your controller. In the future, the App will include a full suite of customization options including button programming, adjustable trigger sensitivity, and more.

As of writing this item is in pre-sale and is expected to ship in December 2024, for £70.00 from the official Tomb Raider Gear Store and was for sale on Limited Run Games for $79.99 but is now sold out.

2 notes

·

View notes

Text

How do automatic headlights work?

How Automatic Headlights Work: A Technical Breakdown Automatic headlights rely on sensors, control modules, and predefined logic to adjust vehicle lighting based on ambient conditions. Here’s a detailed explanation of their operation:

1. Core Components Ambient Light Sensors: These are typically photoresistors, photodiodes, or cameras installed near the windshield, rearview mirror, or dashboard. They detect changes in external light intensity (e.g., dusk, tunnels, or heavy rain) . Example: A photoresistor’s resistance decreases in bright light and increases in darkness, triggering the system . Electronic Control Unit (ECU): The ECU processes sensor data and sends commands to activate or deactivate headlights. Advanced systems integrate with other modules (e.g., rain sensors or GPS) for context-aware adjustments . Actuators: Relays or transistors physically switch the headlights on/off or adjust brightness (e.g., dimming high beams when oncoming traffic is detected) . 2. Workflow Light Detection: Sensors continuously monitor ambient light. For instance, when entering a tunnel, sensors detect a sudden drop in light intensity . Signal Processing: The ECU compares sensor data against preset thresholds. If light falls below a critical level (e.g., <100 lux), it activates the headlights . Light Activation: Basic Systems: Headlights turn on/off automatically. Advanced Systems: Adaptive Lighting: Headlights swivel with steering input (e.g., RAM 4500’s directional LED system) . High Beam Assist: Automatically dims high beams when detecting other vehicles . Delays and Overrides: Delay Shutoff: Lights stay on for 30–180 seconds after ignition off (e.g., Nissan Armada’s 45-second default) . Manual Override: Drivers can disable auto mode via the headlight switch . 3. Advanced Features Rain-Light Sensors: Some systems link headlights to windshield wipers. If wipers are active for >1 minute, headlights activate regardless of ambient light . GPS Integration: Vehicles with navigation may pre-activate headlights in known low-light areas (e.g., tunnels) . Matrix LED Systems: Pixel-based LEDs block light toward specific objects (e.g., pedestrians) while maintaining full illumination elsewhere. Note: U.S. regulations lag behind Europe in approving such systems . 4. Limitations and User Tips Tunnel Delay: Most systems take 2–5 seconds to activate in sudden darkness. Drivers must manually switch lights in tunnels to comply with traffic laws . Sensor Placement: Dirty or obstructed sensors (e.g., covered by a sunshade) can cause malfunctions . Regional Variations: U.S. vs. Europe: Adaptive headlights with dynamic beam shaping are limited in the U.S. due to outdated regulations . Key Takeaways Automatic headlights blend light sensing, real-time processing, and actuator control to enhance safety. While basic systems focus on on/off functionality, advanced versions integrate with vehicle networks for smarter adaptations. For optimal use, ensure sensors are clean and understand system limitations in extreme conditions.

For deeper technical insights, refer to vehicle manuals (e.g., Nissan Armada ) or regulatory discussions .

#led lights#car lights#led car light#youtube#led auto light#led headlights#led light#led headlight bulbs#ledlighting#young artist#car culture#cars#car#american cars#car light#headlight bulb#headlamp#headlight#Automatic headlight

0 notes

Text

In its broadest sense, remote control systems also include those systems that rely on the use of extended physical control links (i.e., using a physical link such as cables or wires and other similar conductors). More typically, however, the phrase is used to refer to wireless connections. There are four important kinds of remote control systems in common use: radio control, infrared remote control, remote-handling equipment, and telemetry (Cavendish, 2006). Radio control technology Radio control is the most common type of remote control, and at times the two terms are used interchangeably. As the term implies, this is a way of directing the operation of one or several devices from some distance away, through the use of radio waves. There are single-channel and multichannel control equipment. Single channel equipment are designed to control only one function, while multichannel equipment can control several functions (Cavendish, 2006). The single-channel radio control is comprised of a transmitter, a relay, and an actuator or escapement. The transmitter is the device that sends a constant-frequency radio signal when its keying switch is moved. The signal is detected by the receiver and then amplified, triggering the relay which activates the actuator. It is the actuator that executes the single function command which the operator desires to be done. Because the single channel control can only operate one function, it is rather limited and operates basically by switching the function on and off (Cavendish, 2006). The multichannel radio control system, on the other hand, is designed to handle more than one function. Early models used tone transmitters that produced up to 12 ultrasonic tones; today, however, multichannel RC systems use digital pulsing systems which are more reliable and precise and therefore provide for finer control than tone transmitters. When the transmitter is switched on, it produces a series of pulses continuously. The message is encoded in the spaces between pulses; the signal containing the pulses is received and amplified by the receiver, after which it is passed on to a decoder (Cavendish, 2006). Infrared remote control On the other hand, infrared remote control is probably the most familiar because it is widely used in a home setting, for operating electrical entertainment systems and similar devices. Infrared RC uses pulses of invisible infrared light as the medium of control; unlike radio control, it is important that infrared transmitters have a line-of-sight path to the sensor on the device being controlled. One characteristic of infrared is that it may bounce off walls, but not penetrate them (Cavendish, 2006). Upon depressing a button on an infrared remote-control handset, a microchip in it activates a signal to which the button relates. The signal is amplified by transistors and sent to a light-emitting diode (LED) that translates the signal to infrared light. The LED is located at the handset’s front, so the light that is generated is sent to the device where a sensor detects it and prompts the desired action (Cavendish, 2006). Read the full article

0 notes

Text

CNC Wood Router

Do you have a thought to DIY or buy a reliable CNC Wood Router? Browse the 2024 new Wood Router buyer’s guide as follows, we’ll provide you with the competitive Wood Routers of 2024 with expert customer service to satisfied your requirements.

What is a CNC Wood Router? CNC Wood Router is a wood router machine controlled by the computer. It can process 2D/3D, milling, carving (relief, plane engraving, hollow carving, 3D carving), cutting, slotting and drilling of most popular wood materials and other soft materials, including woodworking crafts, wood carving, wooden marks, wooden toys, wooden gifts, cabinet making, wooden door making, wooden modelling, production of wooden furniture such as wardrobe.

The main structure of CNC Wood Router includes spindle, bed, gantry, servo motor and actuator, CNC operating system, CNC software, rack guide, screw, worktable, power supply, limit switch and so on.

CNC Wood Router is also known as wood CNC machine, woodworking CNC router, wood CNC router, CNC wood carving machine, wood CNC cutter, CNC wood milling machine, wood CNC table, CNC wood table, CNC wood router machine, CNC woodcarver, CNC wood engraver, CNC woodcutter, CNC wood cutting machine, c and c wood router, CNC woodworking machine, CNC wood engraver, wood c and c machine.

ATC CNC ROUTER SERIES

ATC CNC router is the first choice for enterprises with large production volume. According to the different tool changing methods, automatic tool changing engraving machines can be subdivided into linear ATC CNC machine and disc ATC engraving machines.Compared with the traditional manual tool change production method, this type of ATC CNC engraving machine has an independent tool magazine with different tool bits.Request a Quote

Small CNC Machine for Small Business

IGW-ATC 1325(PRO)ATC CNC Machine

ATC CNC Wood Router Table Kit

Wood CNC Router and Laser Engraver Combo

4×8 Wood CNC Router for Sale

Linear ATC CNC Router with Oscillating Knife Cutting

3d Atc Auto Tool Changer Wood Woodworking Machine

Wood CNC Router Rotation Head With Rotation Table

ATC CNC ROUTER SERIES

ATC CNC router is the first choice for enterprises with large production volume. According to the different tool changing methods, automatic tool changing engraving machines can be subdivided into linear ATC CNC machine and disc ATC engraving machines.Compared with the traditional manual tool change production method, this type of ATC CNC engraving machine has an independent tool magazine with different tool bits.Request a Quote

Small CNC Machine for Small Business

IGW-ATC 1325(PRO)ATC CNC Machine

ATC CNC Wood Router Table Kit

Wood CNC Router and Laser Engraver Combo

4×8 Wood CNC Router for Sale

Linear ATC CNC Router with Oscillating Knife Cutting

3d Atc Auto Tool Changer Wood Woodworking Machine

Wood CNC Router Rotation Head With Rotation Table

ATC CNC ROUTER, CNC ROUTER MACHINE, CNC WOOD ROUTERCNC Wood Router Machine

CNC ROUTER, CNC WOOD ROUTERBest Wood CNC Machine for Small Business

CNC WOOD ROUTERBest CNC Router Machines for Woodworking

CNC WOOD ROUTERLatest 1325 Wood CNC Machine 4×8

CNC WOOD ROUTERCNC Wood Router Manufacturers and Supplier

ATC CNC ROUTER, CNC ROUTER MACHINE, CNC WOOD ROUTERCNC Wood Carving Machine

3 AXIS CNC ROUTER, CNC WOOD ROUTER3 Axis CNC Router with automatic tool changer

HOT3 AXIS CNC ROUTER, CNC ROUTER, CNC WOOD ROUTER3 Axis ATC CNC Router with Automatic Tool Changer for Wood Furniture5.00 out of 5

HOT3 AXIS CNC ROUTER, CNC ROUTER, CNC WOOD ROUTERWood 3 Axis 4*8 CNC Router Machine for Sale

3D CNC ROUTER, 4 AXIS CNC ROUTER, CNC ROUTER, CNC WOOD ROUTERMulti Use 4 Axis Woodworking CNC Router with Rotary Axis

3D CNC ROUTER, 4 AXIS CNC ROUTER, CNC ROUTER, CNC WOOD ROUTER4 Axis CNC Wood Engraving Machine with Spindle Swing 180 Degree

READ MOREQUICK VIEW3D CNC ROUTER, 4 AXIS CNC ROUTER, CNC ROUTER, CNC WOOD ROUTERRotary Spindle 4 Axis CNC Wood Engraving Machine with Auto Tool Change

0 notes

Text

The Soldo Controls SW0140E-2TE23A6 Limit Switch Box is a reliable solution for monitoring valve positions in industrial automation. Designed for durability, it features a compact, corrosion-resistant housing, making it ideal for harsh environments. This limit switch box ensures precise feedback, enhancing process efficiency and safety. It supports various mounting options and provides clear visual indicators for easy monitoring. Compatible with a wide range of actuators, it is widely used in industries like oil & gas, water treatment, and manufacturing. The Soldo SW0140E-2TE23A6 helps streamline operations by offering accurate and consistent valve position feedback.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#Automation#manufacturing#Soldo Controls#Switches#Industrial Switches

0 notes

Text

Telescopic Sliding Gate Manufacturer In India | NIHVA

Telescopic Gates

In situations where a single-side sliding arrangement to install the conventional sliding gates is not possible due to very little or no run-back space available, a Telescopic sliding gate system proves to be the perfect solution.

Designed with multiple panels/leaves operating in a telescopic fashion, they require very low run-back space and are highly space-efficient. Using the multi-actuator system, multiple leaves can be made to move simultaneously, greatly increasing the speed of operation of the gate. Each leaf of the telescopic gate can be made to move at a different speed so that the final position can be reached simultaneously, thanks to the specially designed telescopic mechanism. The telescopic gates are manufactured as per specific site requirements; they are suitable for medium to heavy-duty applications, and especially for very large openings.

Features of Telescopic gates

Widely used where there are space constraints for sliding gate alongside the boundary wall or limited space for Run back.

Also Suitable for very large entrances.

Can be Telescopic gates manufactured in two or three gate leaves which makes it possible to achieve a Larger clear opening. Fabricated for gates up to 18000 kgs weights capacity

Two or three bottom rails are required depending on clear width requirement.

High precision sprocket & chain mechanism, guide rollers, bottom rollers, and limit switch ensure smooth & safe operation of the gate.

Download Telescopic Gates

1 note

·

View note

Text

Optimize Your Environment with Temperature and Humidity Sensors!

Ensure the perfect atmosphere for your home or business with our advanced Temperature and Humidity Sensors! Monitor conditions accurately and maintain comfort with our reliable solutions. Explore our range today for better environmental control! Shop Now!

0 notes

Text

Insulation Safety Breakthrough for Medical-Grade Rocker Switches: IEC 60601-1 Leakage Current Control and Lifecycle Reliability Design

Introduction

In medical devices, rocker switches serve as critical interfaces for life-support equipment (e.g., ventilators, dialysis machines) and diagnostic tools (e.g., ultrasound systems, endoscopes). Their electrical safety directly impacts patient and clinician lives. The IEC 60601-1 standard mandates stringent requirements for leakage current, insulation strength, and mechanical durability, with leakage current control and insulation design as core compliance challenges. This article dissects medical-grade rocker switch design through material selection, structural optimization, and process validation, supported by failure analyses and innovations tailored to medical environments (e.g., frequent sterilization, high humidity).

1. IEC 60601-1 Leakage Current Limits and Risk Scenarios

1.1 Leakage Current Categories and Thresholds

Earth Leakage Current: ≤0.5mA (normal), ≤1mA (single fault).

Enclosure Leakage Current: ≤0.1mA (normal), ≤0.01mA (patient-contact parts).

Patient Leakage Current: ≤0.01mA DC / 0.1mA AC (CF-type devices).

1.2 High-Risk Scenarios and Failure Modes

Sterilization Corrosion: Ethanol/hydrogen peroxide infiltration swells insulation (PA66吸水率: 1.8%→3.5%), dropping insulation resistance from 10^12Ω to 10^8Ω.

High Humidity: Operating room humidity ≥70% reduces creepage distances, causing flashover.

Mechanical Fatigue: 200+ daily actuations degrade seals (IP67→IP54).

2. Insulation Design Essentials for Medical Rocker Switches

2.1 Material Selection: Dielectric Strength vs. Chemical Resistance

Base Materials:Housing: PPS (CTI≥600V) outperforms PC/ABS in chemical resistance.Insulation Barriers: Ceramic-filled epoxy (FR-4) withstands 5x longer arc exposure.

Contact Materials:AgSnO₂: 70% slower oxidation than pure silver in humidity.Gold Plating (≥0.5μm): Prevents sulfidation-induced leakage fluctuations.

2.2 Structural Design: Creepage and Clearance Control

Primary-Secondary Isolation:Basic Insulation: ≥3.0mm between contacts and metal housing (250V).Supplementary Insulation: Polyimide films (0.2mm, 4kV withstand) shield PCBs.

Leakage Prevention:"Labyrinth" seals + medical silicone gaskets (50±5 Shore A) extend liquid paths to 12mm.Case Study: A ventilator switch reduced disinfectant ingress from 0.1mL to 0.01mL via dual O-rings and drainage channels.

2.3 Process Validation: Lifecycle Testing

Dielectric Strength Test: 1.5kV AC applied for 1 minute (IEC requires 1kV), leakage ≤0.5mA.

Damp Heat Test: 40°C/93% RH for 168 hours; insulation resistance ≥100MΩ.

Mechanical Endurance: 100,000 cycles; seal compression ≤15% (ISO 815).

3. Extended Design: Medical-Specific Innovations

3.1 EMI Shielding and Filtering

Shielding: Copper foil (≥0.1mm) cuts RF noise by 30dB.Case Study: An MRI-compatible switch reduced RFI from 50mV/m to 5mV/m.

RC Snubber Circuits: 100Ω + 0.1μF limits inrush current from 20A to 5A.

3.2 Ergonomics and Sterility

Antimicrobial Coatings: Silver-ion UV coatings reduce bacterial colonies by 99.5%.

Tactile Feedback: Spring stiffness increased from 8N/mm to 12N/mm for glove-compatible actuation.

3.3 Traceability and Compliance

Material Certifications: USP Class VI and ISO 10993-5 compliance.

UDI Laser Marking: Links materials, testing, and sterilization records.

4. Case Study: Hemodialysis Machine Switch Upgrade

4.1 Requirements

250V AC, 16A rating.

Patient leakage current ≤0.01mA (CF-type).

Sodium hypochlorite (500ppm) resistance.

100,000-cycle lifespan.

4.2 Design Solutions

Material Upgrades:PPS housing (CTI=625V) replaced PC (CTI=250V).Gold plating thickened from 0.3μm to 0.8μm (contact resistance: 0.5mΩ).

Structural Enhancements:1.5mm Al₂O₃ ceramic insulators increased creepage from 2.5mm to 4.0mm.Triple sealing: silicone gaskets + labyrinth channels + hydrophobic coating.

Validation Results:Insulation resistance: 1.2×10^12Ω post-damp heat.Post-100k cycles: leakage current rose only 2% (0.008mA).

4.3 Outcomes

Safety: Zero leakage incidents in 3 years.

Costs: Sterilization-related failures dropped 80%.

5. Future Trends: Smart and Miniaturized Medical Switches

5.1 Integrated Health Monitoring

Self-Diagnostics: MEMS humidity sensors detect seal breaches.

Wireless Alerts: BLE modules transmit insulation-failure warnings.

5.2 Nano-Coatings

Superhydrophobic Layers: Fluorosilane composites (contact angle ≥150°) repel liquids.

Self-Healing Insulation: Microencapsulated epoxy auto-repairs cracks.

5.3 3D-Printed Customization

Ergonomic Shapes: Reduce misclicks by 50% via patient-specific designs.

Rapid Prototyping: 24-hour insulation design iterations.

6. Conclusion: The Ultimate Safety Barrier

Medical-grade rocker switch design demands end-to-end collaboration across simulation, production, and clinical feedback. Compliance with IEC 60601-1 drives innovation from "meeting standards" to "proactive protection," solidifying global healthcare safety.

en.dghongju.com

0 notes

Text

The Oil-Tight LS-Series Limit Switches are designed for durability and precision in demanding industrial environments. Built to withstand oil, dust, and harsh conditions, these switches ensure reliable operation in automation, machinery, and safety applications. With high-quality materials and robust construction, they provide long-lasting performance and secure actuation. Explore our catalog to find the perfect oil-tight limit switch solution for your needs. Download now for detailed specifications and product insights!

Let me know if you need any modifications!

0 notes

Text

How do automatic headlights work?

How Automatic Headlights Work: A Technical Breakdown Automatic headlights rely on sensors, control modules, and predefined logic to adjust vehicle lighting based on ambient conditions. Here’s a detailed explanation of their operation:

1. Core Components Ambient Light Sensors: These are typically photoresistors, photodiodes, or cameras installed near the windshield, rearview mirror, or dashboard. They detect changes in external light intensity (e.g., dusk, tunnels, or heavy rain) . Example: A photoresistor’s resistance decreases in bright light and increases in darkness, triggering the system . Electronic Control Unit (ECU): The ECU processes sensor data and sends commands to activate or deactivate headlights. Advanced systems integrate with other modules (e.g., rain sensors or GPS) for context-aware adjustments . Actuators: Relays or transistors physically switch the headlights on/off or adjust brightness (e.g., dimming high beams when oncoming traffic is detected) . 2. Workflow Light Detection: Sensors continuously monitor ambient light. For instance, when entering a tunnel, sensors detect a sudden drop in light intensity . Signal Processing: The ECU compares sensor data against preset thresholds. If light falls below a critical level (e.g., <100 lux), it activates the headlights . Light Activation: Basic Systems: Headlights turn on/off automatically. Advanced Systems: Adaptive Lighting: Headlights swivel with steering input (e.g., RAM 4500’s directional LED system) . High Beam Assist: Automatically dims high beams when detecting other vehicles . Delays and Overrides: Delay Shutoff: Lights stay on for 30–180 seconds after ignition off (e.g., Nissan Armada’s 45-second default) . Manual Override: Drivers can disable auto mode via the headlight switch . 3. Advanced Features Rain-Light Sensors: Some systems link headlights to windshield wipers. If wipers are active for >1 minute, headlights activate regardless of ambient light . GPS Integration: Vehicles with navigation may pre-activate headlights in known low-light areas (e.g., tunnels) . Matrix LED Systems: Pixel-based LEDs block light toward specific objects (e.g., pedestrians) while maintaining full illumination elsewhere. Note: U.S. regulations lag behind Europe in approving such systems . 4. Limitations and User Tips Tunnel Delay: Most systems take 2–5 seconds to activate in sudden darkness. Drivers must manually switch lights in tunnels to comply with traffic laws . Sensor Placement: Dirty or obstructed sensors (e.g., covered by a sunshade) can cause malfunctions . Regional Variations: U.S. vs. Europe: Adaptive headlights with dynamic beam shaping are limited in the U.S. due to outdated regulations . Key Takeaways Automatic headlights blend light sensing, real-time processing, and actuator control to enhance safety. While basic systems focus on on/off functionality, advanced versions integrate with vehicle networks for smarter adaptations. For optimal use, ensure sensors are clean and understand system limitations in extreme conditions.

For deeper technical insights, refer to vehicle manuals (e.g., Nissan Armada ) or regulatory discussions .

#led lights#car lights#led car light#youtube#led auto light#led headlights#led light#led headlight bulbs#ledlighting#young artist#car culture#cars#car#american cars#car light#headlight bulb#headlamp#headlight#Automatic headlight

0 notes

Text

Growth of Aerosol Valves Market: Key Factors Driving Demand

The global aerosol valves market size is estimated to reach USD 24.01 billion by 2030, expanding at a CAGR of 6.6% from 2025 to 2030, according to a new report by Grand View Research, Inc. Increasing product penetration in the healthcare industry for products, such as asthma inhalers and other types of sprays, is expected to boost the demand over the forecast period. Growing consumption of personal care and household products in various countries is also anticipated to drive the product demand. In addition, the introduction of innovative personal care and household products by FMCG manufacturers, such as P&G, is expected to augment the demand for aerosol components including valves.

The components used for the manufacturing of aerosol valves, such as gaskets, seals, springs, and dip tubes, are available in abundance owing to the presence of a large number of manufacturers. In addition, low product differentiation enables easy supplier switching at a low cost. The combined effect of this has resulted in low bargaining power of suppliers. Companies in the industry are focusing on product innovation for the development of eco-friendly components using latest aerosol technologies. Over the past few years, there has been a shift from traditional manufacturing to enhanced sustainability, which includes reduced use of energy and raw materials.

Gather more insights about the market drivers, restrains and growth of the Aerosol Valves Market

Aerosol Valves Market Report Highlights

• The other products segment dominated the overall market with a revenue share of over 59.0% in 2024 and is expected to witness robust growth with a CAGR of 6.8% over the forecast period.

• Metered aerosol valves are designed to deliver a specific, pre-measured dose of the product with each press of the actuator. owing to the increase in demand for consumer products such as household cleaners, and automotive products.

• The personal care segment held the largest revenue share of 33.0% in 2024. The segment is driven by the growing demand for personal care products in emerging economies owing to the changing lifestyle, rising consumer spending, and emphasis on gender-specific products.

• Europe dominated the market and accounted for the largest revenue share of 27.0% in 2024. Continuous technological improvement in aerosol valve design has led to the development of more efficient aerosol valves.

• In North America, the pharmaceutical and healthcare sector has also been a crucial driver for aerosol valve demand.

Aerosol Valves Market Segmentation

Grand View Research has segmented the global aerosol valves market based on type, end use, and region:

Aerosol Valves Product Outlook (Volume, Million Units; Revenue, USD Million, 2018 - 2030)

• Continuous

• Metered

• Others

Aerosol Valves Application Outlook (Volume, Million Units; Revenue, USD Million, 2018 - 2030)

• Personal Care

• Household

• Automotive & Industrial

• Foods

• Paints

• Medical

• Others

Aerosol Valves Regional Outlook (Volume, Million Units; Revenue, USD Million, 2018 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o Germany

o UK

o France

o Italy

o Spain

• Asia Pacific

o China

o India

o Japan

o South Korea

• Central & South America

o Brazil

o Argentina

• Middle East & Africa

o Saudi Arabia

o UAE

o South Africa

List of Key Players in Aerosol Valves Market

• LINDAL Group

• Ehrensperger AG

• Coster Tecnologie Speciali S.p.A.

• Precision Valve Corporation

• Summit Packaging Systems

• MITANI VALVE CO., LTD

• AptarGroup, Inc.

• The Salford Valve Company Ltd. (Salvalco)

• The YingBo Aerosol Valve (ZhongShan) Co., Ltd.

• Newman Green Inc.

• Jinxing Aerosol Valve Manufacture Co., Ltd.

• Power Container Corp.

• Clayton Corp.

• Aroma Industries

• EC Pack Industrial Limited

• Majesty Packaging Systems Limited

• ECPlaza Network Inc.

Order a free sample PDF of the Aerosol Valves Market Intelligence Study, published by Grand View Research.

#Aerosol Valves Market#Aerosol Valves Market Analysis#Aerosol Valves Market Report#Aerosol Valves Market Size#Aerosol Valves Market Share

0 notes

Text

Soft Computing. Volume 29, Issue 2, January 2025

1) Using covering approaches to study concept lattices

Author(s): Guilong Liu, Xiuwei Gao

Pages: 425 - 434

2) Convergence Analysis of a Picard–CR Iteration Process for Nonexpansive Mappings

Author(s): Bashir Nawaz, Kifayat Ullah, Krzysztof Gdawiec

Pages: 435 - 455

3) Dynamical behavior and chaos control of the conflicting information propagation on a homogeneous network system

Author(s): Ankur Jain, Joydip Dhar, Vijay K. Gupta

Pages: 457 - 469

4) Ring structure of rough sets

Author(s): Arun Kumar, Bisham Dewan

Pages: 471 - 483

5) Bidirectional online sequence extreme learning machine and switching strategy for soft-sensor model of SMB chromatography separation process

Author(s): Yong-Cheng Sun, Jie-Sheng Wang, Song-Bo Zhang

Pages: 485 - 507

6) Addition-meet fuzzy relational inequality systems, product-join relational inequality systems and their generalizations

Author(s): Esko Turunen

Pages: 509 - 520

7) Unification of methods for new types of fuzzy sets: general approximation spaces with relational morphisms

Author(s): Jiří Močkoř

Pages: 521 - 542

8) On hierarchical clustering-based identification of PWA model with model structure selection and application to automotive actuators for HiL simulation

Author(s): Zhenxing Ren

Pages: 543 - 558

9) Multiscale risk spillover analysis of China’s stock market industry: evidence supported by a novel hybrid model based on signal decomposition technology

Author(s): Zhan Linjie, Tang Zhenpeng

Pages: 559 - 577

10) On the maximization of the likelihood for the generalized gamma distribution: the modified maximum likelihood approach

Author(s): Talha Arslan, Sukru Acitas, Birdal Senoglu

Pages: 579 - 591

11) Robust security risk estimation for android apps using nearest neighbor approach and hamming distance

Author(s): Mahmood Deypir, Toktam Zoughi

Pages: 593 - 611

12) Zoom method for association rules in multi-granularity formal context

Author(s): Lihui Niu, Jusheng Mi, Meizheng Li

Pages: 613 - 627

13) A novel approach of multi-channel attention mechanism for long-sequential multivariate time-series prediction problem

Author(s): Tham Vo, Linh Nguyen Thi My

Pages: 629 - 644

14) Trustworthy deep learning for encrypted traffic classification

Author(s): Zheng Li, Yanbei Liu, Xiaoming Zhu

Pages: 645 - 662

15) STA-CN-BiGRU: a spatial-temporal attention based ChebNet and BiGRU model for traffic flow prediction

Author(s): Feng Hui, fangYang Rui

Pages: 663 - 672

16) Federated learning for Healthcare 5.0: a comprehensive survey, taxonomy, challenges, and solutions

Author(s): Muhammad Sadiq Amin, Shabir Ahmad, Woong-Kee Loh

Pages: 673 - 700

17) Enhancing voltage stability and load shedding optimization through a fusion of gravitational search algorithm and particle swarm optimization with deep learning

Author(s): Masoud Ahmadipour, Zaipatimah Ali, Hussein Mohammed Ridha

Pages: 701 - 721

18) A surrogate archive assisted multi-objective evolutionary algorithm under limited computational budget

Author(s): Le Wang, Qinqin Fan, Xuefeng Yan

Pages: 723 - 753

19) A fault-tolerant scheduling strategy through proactive and clustering techniques for scientific workflows in cloud computing

Author(s): Suha Mubdir Farhood, Reihaneh Khorsand, Mohammadreza Ramezanpour

Pages: 755 - 781

20) Spark workflow task scheduling with deadline and privacy constraints in hybrid cloud networks

Author(s): Kamran Yaseen Rajput, Li Xiaoping, Abdullah Lakhan

Pages: 783 - 801

21) Improved snake optimizer based on forced switching mechanism and variable spiral search for practical applications problems

Author(s): Yanfeng Wang, Bingqing Xin, Junwei Sun

Pages: 803 - 838

22) Period regulated particle swarm optimization algorithm

Author(s): Zhilong Liu, Huhai Jiang

Pages: 839 - 860

23) A new mathematical optimization-based method for the m-invariance problem

Author(s): Adrián Tobar Nicolau, Jordi Castro, Claudio Gentile

Pages: 861 - 873

24) Knowledge-based optimization in epidemics prevention

Author(s): Krzysztof Michalak

Pages: 875 - 893

25) Enhancing teaching learning based optimization algorithm through group discussion strategy for CEC 2017 benchmark problems

Author(s): Muhammad Sagheer, Muhammad Asif Jan, Meshal Shutaywi

Pages: 895 - 932

26) A Fuzzy-Bayesian belief network approach to compute efficiency as a metric for IoT systems

Author(s): Rishabh Deo Pandey, Itu Snigdh

Pages: 933 - 944

27) Inverse fuzzy graph colouring and its application

Author(s): Kadeeja Mole Koyalinte Purakkal, Sameena Kalathodi

Pages: 945 - 956

28) Nonlinear complex dynamic system identification based on a novel recurrent neural network

Author(s): Kartik Saini, Narendra Kumar, Rajesh Kumar

Pages: 957 - 976

29) Modeling of the blockchain-empowered cloud 4D printing services collaboration digital twin platform oriented on supply–demand

Author(s): Jiajia Liu, Edi Syams Zainudin, Chenglei Zhang

Pages: 977 - 1004

30) Enhancing the combined compromise solution method for group decision-making under intuitionistic fuzziness: an application to blended English teaching quality evaluation in vocational colleges

Author(s): Bin Xie, Hongmiao Yuan

Pages: 1005 - 1017

31) A semantic approach for cultural heritage ontology matching and integration based on textual and multimedia information

Author(s): Antonio Maria Rinaldi, Cristiano Russo, Cristian Tommasino

Pages: 1019 - 1034

32) Global vision, local focus: the semantic enhancement transformer network for crowd counting

Author(s): Mingtao Wang, Xin Zhou, Yuanyuan Chen

Pages: 1035 - 1052

33) Nonlinear convergence factor-based manta ray foraging optimization algorithm for combined economic emission dispatch problem

Author(s): Xing-Yue Zhang, Jie-Sheng Wang, Wen-Kuo Hao

Pages: 1053 - 1089

34) A novel cluster based reliable security enhancement in FANET directed by game theory

Author(s): Shikha Gupta, Neetu Sharma

Pages: 1091 - 1106

35) A distance based similarity measure on trapezoidal intuitionistic fuzzy numbers and its applications

Author(s): P. Dhanasekaran, S. Kalidasan

Pages: 1107 - 1119

36) Fast resistivity imaging of transient electromagnetic using an extreme learning machine

Author(s): Ruiyou Li, Yong Zhang, Min Li

Pages: 1121 - 1131

37) A GA-FGM-RTA combined model for predicting seawall settlement in under insufficient data volume

Author(s): Peng Qin, Chunmei Cheng, Huaizhi Su

Pages: 1133 - 1146

38) Mechanical properties estimation of multi-layer friction stir plug welded aluminium plates using time-series neural network models

Author(s): Mohammad Reza Chalak Qazani, Moosa Sajed, Seyed Mohammad Hossein Seyedkashi

Pages: 1147 - 1168

39) A genetic-based approach for vehicle routing problem with fuzzy alpha-cut constraints

Author(s): He-Yau Kang, Amy H. I. Lee

Pages: 1169 - 1189

40) Boosting cervical cancer detection with a multi-stage architecture and complementary information fusion

Author(s): Pranab Sahoo, Sriparna Saha, Samrat Mondal

Pages: 1191 - 1206

41) Channel pruning method driven by similarity of feature extraction capability

Author(s): Chuanmeng Sun, Jiaxin Chen, Tiehua Ma

Pages: 1207 - 1226

42) Solving trajectory tracking of robot manipulators via PID control with neural network compensation

Author(s): Marco Moran-Armenta, Carlos Aguilar-Avelar, Javier Moreno-Valenzuela

Pages: 1227 - 1241

43) Enhancing demand forecasting through combination of anomaly detection and continuous improvement

Author(s): Meysam Jahani, Zahra Zojaji, Fatemeh Raji

Pages: 1243 - 1258

44) Free-text keystroke authentication using transformers: a comparative study of architectures and loss functions

Author(s): Saleh Momeni, Bagher BabaAli

Pages: 1259 - 1272

0 notes