#level gauge manufacturers

Explore tagged Tumblr posts

Text

Capsule Sensing Pressure Gauge Suppliers: A Deep Dive into Precision and Reliability

In the realm of industrial instrumentation, pressure measurement is crucial for maintaining operational efficiency and safety. One of the most reliable types of pressure gauges available today is the capsule-sensing pressure gauge. This blog will explore the role of capsule sensing pressure gauge suppliers, highlighting their importance in various industries and what to consider when selecting a supplier.

What is a Capsule Sensing Pressure Gauge?

A capsule-sensing pressure gauge utilizes a unique design that employs a thin, flexible diaphragm (the capsule) to detect pressure changes. As pressure is applied, the capsule expands or contracts, causing a mechanical movement that is translated into a readable pressure measurement. These gauges are especially effective for low-pressure applications and are widely used in:

Laboratory settings: For precise measurement of gases and liquids.

HVAC systems: To monitor air pressure and optimize system performance.

Food and beverage industries: For maintaining quality and safety standards in production processes.

The capsule design allows for excellent sensitivity and accuracy, making these gauges ideal for many applications.

Why Choose Reputable Capsule Sensing Pressure Gauge Suppliers?

Quality Assurance: Leading capsule sensing pressure gauge suppliers adhere to strict quality control standards, ensuring that their products are reliable and accurate. High-quality gauges contribute significantly to safe and efficient operations.

Wide Product Range: Reputable suppliers offer a variety of capsule sensing pressure gauges to suit different operational needs. This includes various pressure ranges, materials, and mounting options, allowing businesses to select the best gauge for their specific applications.

Customization Options: Many suppliers provide customization services to meet unique requirements. This can include modifications in size, material, and additional features to enhance functionality, ensuring that the gauges fit seamlessly into your existing systems.

Technical Support: Working with experienced suppliers means having access to expert advice and technical support. They can assist in selecting the right gauge and provide guidance on installation and maintenance practices.

Key Considerations When Choosing Capsule Sensing Pressure Gauge Suppliers

When searching for capsule sensing pressure gauge suppliers, consider the following factors:

Experience and Reputation: Opt for suppliers with a proven track record in the industry. Established suppliers often have extensive knowledge and experience, ensuring high-quality products.

Certifications and Compliance: Ensure that the supplier's products meet relevant industry standards and certifications. This compliance is vital for ensuring product reliability and safety.

Customer Reviews: Researching customer feedback can provide insights into the supplier's reliability and the performance of their pressure gauges. Positive reviews indicate that the supplier consistently delivers quality products.

After-Sales Support: A reliable supplier will offer comprehensive after-sales support, including troubleshooting assistance and access to spare parts when needed.

Leading Capsule Sensing Pressure Gauge Suppliers in India

Several suppliers in India are recognized for their quality capsule sensing pressure gauges. Here are a few notable companies:

Company A: Known for its extensive range of capsule sensing pressure gauges, Company A has built a reputation for delivering reliable and accurate products across various industries.

Company B: This supplier specializes in customized solutions, offering tailored capsule sensing pressure gauges designed to meet specific operational requirements.

Company C: With a focus on innovation, Company C provides advanced capsule sensing pressure gauges that incorporate the latest technology, ensuring high accuracy and efficiency.

Conclusion

Choosing the right capsule sensing pressure gauge supplier is essential for ensuring accurate pressure measurement in your operations. By prioritizing quality, customization, and technical support, you can enhance the reliability and efficiency of your pressure measurement processes.

When evaluating suppliers, consider their reputation, product range, and after-sales support to find the best fit for your needs. Investing in high-quality capsule sensing pressure gauges from reputable suppliers will ultimately lead to improved operational efficiency and greater safety in your applications.

#general instruments consortium#pressure gauge manufacturers in india#level gauge manufacturers#capsule sensing pressure gauge suppliers

0 notes

Text

A thermocouple is an easy to use and budget friendly temperature sensor that works well for various temperature measurement tasks. Typically, a thermocouple consists of two different metals connected at two points, creating junctions.

Identifying a reliable thermocouple supplier begins with clearly outlining your specific needs, including the required accuracy and cable length. Conduct thorough online research to discover potential suppliers that meet your criteria. Notably, KEVIT Industrial Technologies, a prominent Thermowell Manufacturer in Dubai, excels in providing high-performance thermocouples tailored for challenging applications. They offer an extensive selection of sensors, accessories, and data acquisition systems to suit your requirements.

#Thermocouple Manufacturers in Dubai#Temperature Gauge Manufacturers in Uae#flow meter supplier in dubai#level transmitter supplier in dubai

0 notes

Text

#non destructive testing#Magnetic Particle Inspection Services#non destructive testing solutions#non destructive testing equipment manufacturers#penetrant inspection near me#non destructive hardness testing#non destructive testing companies near me#non destructive thickness measurement#magnetic particle inspection near me#ndt labs near me#hardness test non destructive#ultrasonic testing gauge#ultrasonic metal thickness tester#ultrasonic gauge thickness tester#material thickness tester#metal thickness testing#ultrasonic level detection#non destructive testing systems#ndt radiography#non destructive testing radiography

0 notes

Text

The Ocean Sciences Building at the University of Washington in Seattle is a brightly modern, four-story structure, with large glass windows reflecting the bay across the street.

On the afternoon of July 7, 2016, it was being slowly locked down.

Red lights began flashing at the entrances as students and faculty filed out under overcast skies. Eventually, just a handful of people remained inside, preparing to unleash one of the most destructive forces in the natural world: the crushing weight of about 2½ miles of ocean water.

In the building’s high-pressure testing facility, a black, pill-shaped capsule hung from a hoist on the ceiling. About 3 feet long, it was a scale model of a submersible called Cyclops 2, developed by a local startup called OceanGate. The company’s CEO, Stockton Rush, had cofounded the company in 2009 as a sort of submarine charter service, anticipating a growing need for commercial and research trips to the ocean floor. At first, Rush acquired older, steel-hulled subs for expeditions, but in 2013 OceanGate had begun designing what the company called “a revolutionary new manned submersible.” Among the sub’s innovations were its lightweight hull, which was built from carbon fiber and could accommodate more passengers than the spherical cabins traditionally used in deep-sea diving. By 2016, Rush’s dream was to take paying customers down to the most famous shipwreck of them all: the Titanic, 3,800 meters below the surface of the Atlantic Ocean.

Engineers carefully lowered the Cyclops 2 model into the testing tank nose-first, like a bomb being loaded into a silo, and then screwed on the tank’s 3,600-pound lid. Then they began pumping in water, increasing the pressure to mimic a submersible’s dive. If you’re hanging out at sea level, the weight of the atmosphere above you exerts 14.7 pounds per square inch (psi). The deeper you go, the stronger that pressure; at the Titanic’s depth, the pressure is about 6,500 psi. Soon, the pressure gauge on UW’s test tank read 1,000 psi, and it kept ticking up—2,000 psi, 5,000 psi. At about the 73-minute mark, as the pressure in the tank reached 6,500 psi, there was a sudden roar and the tank shuddered violently.

“I felt it in my body,” an OceanGate employee wrote in an email later that night. “The building rocked, and my ears rang for a long time.”

“Scared the shit out of everyone,” he added.

The model had imploded thousands of meters short of the safety margin OceanGate had designed for.

In the high-stakes, high-cost world of crewed submersibles, most engineering teams would have gone back to the drawing board, or at least ordered more models to test. Rush’s company didn’t do either of those things. Instead, within months, OceanGate began building a full-scale Cyclops 2 based on the imploded model. This submersible design, later renamed Titan, eventually made it down to the Titanic in 2021. It even returned to the site for expeditions the next two years. But nearly one year ago, on June 18, 2023, Titan dove to the infamous wreck and imploded, instantly killing all five people onboard, including Rush himself.

The disaster captivated and horrified the world. Deep-sea experts criticized OceanGate’s choices, from Titan’s carbon-fiber construction to Rush’s public disdain for industry regulations, which he believed stifled innovation. Organizations that had worked with OceanGate, including the University of Washington as well as the Boeing Company, released statements denying that they contributed to Titan.

A trove of tens of thousands of internal OceanGate emails, documents, and photographs provided exclusively to WIRED by anonymous sources sheds new light on Titan’s development, from its initial design and manufacture through its first deep-sea operations. The documents, validated by interviews with two third-party suppliers and several former OceanGate employees with intimate knowledge of Titan, reveal never-before-reported details about the design and testing of the submersible. They show that Boeing and the University of Washington were both involved in the early stages of OceanGate’s carbon-fiber sub project, although their work did not make it into the final Titan design. The trove also reveals a company culture in which employees who questioned their bosses’ high-speed approach and decisions were dismissed as overly cautious or even fired. (The former employees who spoke to WIRED have asked not to be named for fear of being sued by the families of those who died aboard the vessel.) Most of all, the documents show how Rush, blinkered by his own ambition to be the Elon Musk of the deep seas, repeatedly overstated OceanGate’s progress and, on at least one occasion, outright lied about significant problems with Titan’s hull, which has not been previously reported.

A representative for OceanGate, which ceased all operations last summer, declined to comment on WIRED’s findings.

5K notes

·

View notes

Text

Versatile Tubular Level Gauges - Application-Driven Solutions

Discover versatile tubular level gauges designed for various applications, including cooling towers, chemical storage, and industrial processes. Process Control Devices has you covered.

#tubular level gauge supplier#tubular level gauge manufacturers#tubular level gauge suppliers in mumbai

0 notes

Text

Reflex level gauge Manufacturer

Reflex level gauges are commonly used for level detection within a specific vessel, and the primary principle is based on the difference in refractive indices of vapor and liquid. Reflex gauges, also referred to as prismatic level gauges, offer a well-defined image of water levels.

We are Reflex Level Gauge Manufacturer in India, you can buy Reflex Level Gauge at the best price, check-out type, size, and more about Reflex Level Gauge.

0 notes

Text

Maintaining Tire Traction for Safely Shipping

Evaluating tread depth is a crucial step in assessing the overall condition and safety of your tires, especially when preparing your car for shipping with Florida car transport companies. Proper tread depth is essential for maintaining traction, particularly in wet conditions, and for overall vehicle handling and performance.

The most common and straightforward method to measure tread depth is the penny test. Here’s how to perform it:

Take a penny and insert it into the tread groove with Lincoln’s head upside down and facing you.

If you can see all of Lincoln’s head, your tread depth is less than 2/32 inches, and it’s time to replace the tire.

Repeat this test at several points around the tire, as wear may not be uniform.

While the penny test is a quick and easy method, for more precise measurements, you can use a tread depth gauge. These tools are inexpensive and provide an exact measurement of your tread depth. Here’s how to use one:

Place the base plate of the gauge across the tread.

Push the probe down into the tread groove until the base plate is flush with the tread.

Read the measurement on the gauge.

In the United States, tires are considered legally worn out when they reach 2/32 inches of remaining tread depth. However, tire performance, especially in wet conditions, begins to decline well before this point. Many experts recommend considering replacement when the tread depth reaches 4/32 inches.

When evaluating tread depth, be sure to check multiple points across the tire’s width and around its circumference. Uneven wear can indicate other issues such as misalignment or improper inflation.

Pay special attention to any tread wear indicators. These are raised sections of rubber at the bottom of the tread grooves. When the tread has worn down to the level of these indicators, it’s time to replace the tire.

For winter tires, the recommended minimum tread depth is typically higher – around 6/32 inch – to maintain effective performance in snow and slush.

Remember that tread wear can vary between tires on the same vehicle. The front tires on a front-wheel-drive vehicle, for example, often wear faster than the rear tires. If you find significant differences in tread depth between tires, consider having your tires rotated or replaced as needed before transport.

Lastly, don’t forget to check the spare tire if your vehicle has one. Even if it hasn’t been used, spare tires can degrade over time and may need replacement.

Proper evaluation of tread depth is not just about meeting legal requirements – it’s about maintaining the safety and performance of your vehicle during transport and beyond.

Signs of Uneven Wear and Tear on Tires

Uneven wear and tear on tires can indicate various issues with your vehicle or tire maintenance practices. Identifying these signs early can help prevent more serious problems and extend the life of your tires. Here are some common patterns of uneven wear to look out for:

Center Wear: If the center of your tire tread is more worn than the outer edges, your tires are likely overinflated. Over-inflation causes the center of the tire to bear more of the vehicle’s weight, leading to faster wear in this area. Regularly check and adjust your tire pressure to the manufacturer’s recommended levels.

Edge Wear: Conversely, if the outer edges of your tire are more worn than the center, your tires are probably under-inflated. Under-inflation causes the tire’s edges to bear more weight, leading to increased wear on the sides. This condition can also generate excess heat, potentially leading to tire failure.

One-Sided Wear: If one side of your tire tread is wearing faster than the other, it could indicate an alignment problem. Misaligned wheels cause tires to drag instead of rolling freely, leading to uneven wear. This issue requires professional alignment service to correct.

Cupping or Scalloping: This appears as dips or scalloped patterns around the tire’s circumference. It can be caused by worn suspension components, improper balance, or misalignment. If you notice this pattern, have your suspension and wheel balance checked by a professional.

Feathering: This occurs when the tread ribs are smooth on one side and sharp on the other. It’s often the result of improper toe alignment, where the wheels are not pointing straight ahead. This requires a professional alignment to correct.

Flat Spots: These appear as unusually smooth or flat areas on the tire and are often caused by sudden, hard braking that locks the wheels. They can also develop if a vehicle is parked for an extended period without movement. Minor flat spots may work themselves out with driving, but severe cases may require tire replacement.

Heel/Toe Wear: This pattern appears as saw-tooth wear across the tread blocks and is often more easily felt than seen. It’s a normal result of the tire design but can be exacerbated by lack of rotation. Regular tire rotations can help prevent this type of wear from becoming severe.

Sidewall Wear: Any signs of wear on the sidewall of the tire are cause for immediate concern. This can indicate that the wheels are out of alignment to a severe degree, or that the vehicle has been driven with extremely underinflated tires. Sidewall damage can compromise the structural integrity of the tire and may require immediate replacement.

Remember, uneven wear not only shortens the life of your tires but can also affect your vehicle’s handling, fuel efficiency, and safety. If you notice any of these wear patterns, especially before transporting your vehicle, it’s advisable to have your tires inspected by a professional. They can determine the cause of the uneven wear and recommend appropriate corrective actions, whether that’s a simple tire rotation, a wheel alignment, or replacement of worn components.

youtube

11 notes

·

View notes

Text

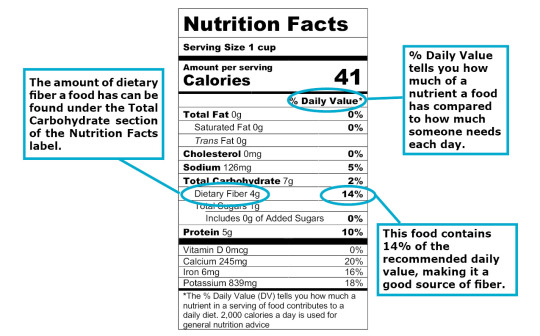

Understanding FDA Guidance: "Excellent Source of Fiber" and "Good Source of Fiber"

Welcome to fitscientist! I'm a food scientist irl and I see a lot of misconceptions about packaging claims out there - I'm trying to be more active on my tumblr (instead of just reblogging/queuing pretty pictures - which obviously I will continue to do!!) and I'd like to share my expertise with you all so we're all more knowledgeable about food labeling, packaging, and more - especially as we are all on our fitness journies together :) The more you know!

Today, we'll be discussing the FDA's guidance on "Excellent Source of Fiber" and "Good Source of Fiber" claims found on food packaging. Understanding these claims can help you make informed choices when selecting products that contribute to your daily fiber intake. Let's dive in!

FDA Guidance on "Excellent Source of Fiber" and "Good Source of Fiber"

The FDA has established specific criteria for food manufacturers to use the terms "Excellent Source of Fiber" and "Good Source of Fiber" on their packaging. These claims are intended to inform consumers about the fiber content of a particular food product.

Here's a breakdown of the FDA's guidance:

1. "Excellent Source of Fiber": - To make an "Excellent Source of Fiber" claim, a food product must contain at least 20% of the Daily Value (DV) for fiber per serving. - The DV for fiber is 28 grams per day based on a 2,000 calorie diet. - Therefore, a food item must contain at least 5.6 grams of fiber per serving to qualify as an "Excellent Source of Fiber."

2. "Good Source of Fiber": - To make a "Good Source of Fiber" claim, a food product must contain at least 10% of the DV for fiber per serving. - This means the food item should contain at least 2.8 grams of fiber per serving.

It's important to note that these claims are based on the fiber content per serving of the food product. Different products may have varying serving sizes, so it's crucial to check the serving size stated on the packaging to accurately gauge the fiber content you'll be consuming. Why Fiber is Important (as covered in a previous post, but a reminder on why fiber is important for our health!): - Fiber aids in digestion, promoting regular bowel movements and preventing constipation. - It helps control appetite by keeping us feeling full for longer periods, which can support weight management goals. - Fiber plays a role in regulating blood sugar levels, making it beneficial for individuals with diabetes or those aiming for stable energy levels. - A high-fiber diet has been linked to a reduced risk of heart disease and improved cardiovascular health. When shopping for food products, the "Excellent Source of Fiber" and "Good Source of Fiber" claims can be helpful indicators of a product's fiber content. By understanding the FDA's guidance, you can make informed choices to meet your daily fiber needs. Remember to check the serving size and consider incorporating a variety of fiber-rich foods into your diet for optimal health benefits. Stay nourished and enjoy a fiber-filled lifestyle! Disclaimer: The information provided in this blog post is for educational purposes only and should not replace professional medical advice nor guidance for front-of-pack labeling claims. Please consult with a healthcare professional or registered dietitian for personalized dietary recommendations, and consult with a regulatory professional for guidance on product content or other claims for your own products.

#informational#health#nutrition#fitblr#fitfam#fitness#fitblrs#running#food#fitspo#workout#weightlifting#gym motivation#healthy food#healthy living#healthyfood#healthy eating#nutrients#healthy#fiber#fiber intake#soluble fiber#insoluble fiber#public health#personal#my post#personal fitblr#healthy lifestyle#healthy diet#food packaging

33 notes

·

View notes

Text

How to Choose the Best ERP for Engineering and Manufacturing Industry

In today’s fast-paced world, engineering and manufacturing companies face increasing pressure to deliver high-quality products while maintaining efficiency and cost-effectiveness. Implementing the right Enterprise Resource Planning (ERP) software can significantly enhance operations, streamline workflows, and boost productivity. However, with numerous options available, selecting the best ERP software for the engineering and manufacturing industry can be challenging. This guide will help you navigate this decision-making process and choose the most suitable solution for your business.

Why ERP is Crucial for Engineering and Manufacturing

ERP software integrates various business processes, including production, inventory management, supply chain, finance, and human resources. For engineering and manufacturing companies, ERP solutions are particularly vital because they:

Facilitate real-time data sharing across departments.

Enhance supply chain management.

Optimize production planning and scheduling.

Ensure compliance with industry standards.

Reduce operational costs.

Partnering with the right Engineering ERP software company ensures that your organization leverages these benefits to stay competitive in a dynamic market.

Steps to Choose the Best ERP for Engineering and Manufacturing

1. Understand Your Business Needs

Before exploring ERP solutions, evaluate your company’s specific requirements. Identify the pain points in your current processes and prioritize the features you need in an ERP system. Common features for engineering and manufacturing companies include:

Bill of Materials (BOM) management

Production planning and scheduling

Inventory control

Quality management

Financial reporting

Consulting with a reputed ERP software company can help you match your needs with the right features.

2. Look for Industry-Specific Solutions

Generic ERP software might not address the unique needs of the engineering and manufacturing sector. Opt for an ERP software in India that offers modules tailored to your industry. Such solutions are designed to handle specific challenges like multi-level BOM, project costing, and shop floor management.

3. Check Vendor Expertise

Choosing a reliable vendor is as important as selecting the software itself. Research ERP solution providers with a strong track record in serving engineering and manufacturing companies. Look for reviews, case studies, and client testimonials to gauge their expertise.

4. Evaluate Scalability and Flexibility

Your business will grow, and so will your operational requirements. Ensure that the ERP system you choose is scalable and flexible enough to accommodate future needs. The top 10 ERP software providers in India offer scalable solutions that can adapt to changing business demands.

5. Assess Integration Capabilities

An ERP system must integrate seamlessly with your existing tools, such as Computer-Aided Design (CAD) software, Customer Relationship Management (CRM) systems, and IoT devices. A well-integrated system reduces redundancies and enhances efficiency.

6. Prioritize User-Friendliness

A complex system with a steep learning curve can hinder adoption. Choose an ERP software with an intuitive interface and easy navigation. This ensures that your employees can use the system effectively without extensive training.

7. Consider Customization Options

No two businesses are alike. While standard ERP solutions offer core functionalities, some companies require customization to align with specific workflows. A trusted ERP software company in India can provide custom modules tailored to your unique needs.

8. Focus on Data Security

Engineering and manufacturing companies often deal with sensitive data. Ensure that the ERP solution complies with the latest security standards and offers robust data protection features.

9. Compare Pricing and ROI

While cost is an important factor, it should not be the sole criterion. Evaluate the long-term return on investment (ROI) offered by different ERP software. A slightly expensive but feature-rich solution from the best ERP software provider in India may deliver better value than a cheaper alternative with limited functionalities.

10. Test Before You Commit

Most ERP software companies offer free trials or demo versions. Use these opportunities to test the software in a real-world scenario. Gather feedback from your team and ensure the solution meets your expectations before finalizing your decision.

Benefits of Partnering with the Best ERP Software Providers in India

India is home to some of the leading ERP software providers in India, offering state-of-the-art solutions for the engineering and manufacturing sector. Partnering with a reputable provider ensures:

Access to advanced features tailored to your industry.

Reliable customer support.

Comprehensive training and implementation services.

Regular updates and enhancements to the software.

Companies like Shantitechnology (STERP) specialize in delivering cutting-edge ERP solutions that cater specifically to engineering and manufacturing businesses. With years of expertise, they rank among the top 10 ERP software providers in India, ensuring seamless integration and exceptional performance.

Conclusion

Selecting the right ERP software is a critical decision that can impact your company’s efficiency, productivity, and profitability. By understanding your requirements, researching vendors, and prioritizing features like scalability, integration, and security, you can find the perfect ERP solution for your engineering or manufacturing business.

If you are looking for a trusted ERP software company in India, consider partnering with a provider like STERP. As one of the best ERP software providers in India, STERP offers comprehensive solutions tailored to the unique needs of engineering and manufacturing companies. With their expertise, you can streamline your operations, improve decision-making, and stay ahead in a competitive market.

Get in touch with STERP – the leading Engineering ERP software company – to transform your business with a reliable and efficient ERP system. Take the first step toward a smarter, more connected future today!

#Manufacturing ERP software company#ERP solution provider#Engineering ERP software company#ERP software company#ERP software companies

4 notes

·

View notes

Text

Safety Driving Tips for Transport Without Worry

If you're driving the car yourself, safety on the road is just as important as preparation. Stick to speed limits and maintain a safe following distance from other vehicles. Long trips may require frequent breaks, so plan rest stops to avoid fatigue.

For those relying on an open air car shipping services, ask about their safety policies and guidelines. Verify that drivers are licensed and insured. Reputable companies take precautions to make sure vehicles are delivered without unnecessary risks.

Safety Driving Tips

Road safety plays a key role in minimizing risks during car transport. Lucky Star Auto Transport follows strict safety guidelines to keep accidents at bay and vehicles secure.

Inspect the Vehicle Before Transport

Inspecting your car before shipment is essential. A thorough inspection helps document the vehicle’s existing condition, which is important if potential claims arise.

Start by washing the car so scratches or dents are easier to spot. Take clear photographs from various angles to maintain an accurate record. These images will serve as proof in the unlikely event of damage during transport. It’s also wise to verify that the car’s interior and exterior components, such as mirrors or wipers, are in proper shape.

Make Sure That All the Car Fluids Are Topped Off

Checking the car's fluids before transport is a simple yet critical step. Make sure that oil, coolant, and brake fluid levels are adequate. Keeping fluids topped off not only helps maintain the car’s mechanical health but also prevents leaks during shipment.

Low fluid levels can make the engine vulnerable to wear and tear, especially if it needs to be started for any reason. By taking care of this step beforehand, you reduce potential problems and keep the vehicle ready to run after delivery.

Properly Remove Personal Belongings from the Car

For safety reasons, always remove personal belongings from your car before transport. Items left inside can shift during transit, increasing the risk of damage to the vehicle's interior. Loose objects may also create safety hazards if they break or become dislodged.

Clearing your car also lightens its weight, which can improve transport efficiency. Additionally, most car shipping companies do not take responsibility for damages caused by personal items left inside. A clean slate ensures both your car’s safety and compliance with shipping regulations.

Secure Loose Parts and Accessories in Your Car

Secure all loose parts to avoid damage during transit. Items like antennas, spoilers, and rearview mirrors need attention, as they are prone to movement. If possible, detach these components or fold them in to ensure stability.

Non-fixed accessories, like bike racks or custom attachments, should also be removed. This precaution reduces the risk of scratching or breaking parts due to vibration while the vehicle is in motion.

Maintain Proper Car Tire Pressure

Keeping tires inflated to the recommended car tire pressure is just as important as securing the car itself. Properly inflated tires provide stability during loading and unloading. Under- or overinflated tires may cause handling issues, and in worst cases, they can burst under strain.

Check the tire pressure using a reliable gauge and adjust it according to your car manufacturer's specifications. This proactive measure guarantees your car is secure during all steps of the transport process.

Proper preparation, regular maintenance and safety checks, with a clear communication are important to keep your car safe before and during transport, whether driven by you or a professional carrier. Lucky Star Auto Transport shows how proper planning makes car shipping a safe and secure process.

The important source every car owner must know when it comes to safely shipping your car with a reliable car shipping service! Find out how to guarantee it! You won’t believe how easy it is to make sure your car’s safety while shipping!

youtube

2 notes

·

View notes

Text

Your Guide to Choosing a Five-Valve Manifold Supplier in India

In the industrial sector, the efficiency of fluid control systems plays a crucial role in ensuring smooth operations. One essential component that significantly impacts fluid control is the five-valve manifold. As a key element in pressure measurement and control systems, the choice of a reliable five valve manifold supplier in India can make a substantial difference in the performance of your operations.

What is a Five Valve Manifold?

A five-valve manifold is a sophisticated assembly used primarily in pressure measurement applications. It consists of five valves that control the flow of fluids, allowing for precise measurement and control in various systems. These valves typically include:

Two isolation valves - for isolating the pressure instrument from the process.

One equalizing valve - to equalize pressure between the process and the instrument.

Two bleed valves - to release pressure from the system and ensure safety during maintenance.

By integrating these components, a five-valve manifold provides better accuracy and control, making it an indispensable tool in industries such as oil and gas, chemicals, and pharmaceuticals.

Why Choose a Reliable Five Valve Manifold Supplier in India?

Quality Assurance: A reputable five valve manifold supplier in India ensures that their products meet stringent quality standards. Quality materials and precise manufacturing processes are crucial for the durability and reliability of the manifold.

Customization Options: Every industrial application is unique. A reliable supplier offers customized solutions tailored to specific operational needs, ensuring compatibility with your existing systems.

Technical Expertise: Partnering with an experienced supplier means you have access to their technical knowledge and expertise. They can guide you in selecting the right manifold for your application and provide support during installation and maintenance.

After-Sales Support: A trustworthy supplier offers comprehensive after-sales support, including maintenance services, spare parts availability, and troubleshooting assistance. This support is essential for minimizing downtime and ensuring the smooth operation of your systems.

Key Considerations When Selecting a Five Valve Manifold Supplier

When searching for a five valve manifold supplier in India, consider the following factors:

Reputation: Look for suppliers with a solid reputation in the industry. Read reviews and testimonials to gauge customer satisfaction.

Certifications: Ensure the supplier's products meet relevant industry certifications and standards, which reflect their commitment to quality.

Experience: Choose a supplier with extensive experience in the field. Their knowledge can be invaluable in helping you make informed decisions.

Pricing: While price is an important factor, it should not be the sole consideration. Evaluate the overall value, including quality, support, and customization options.

Conclusion

In summary, selecting the right five valve manifold supplier in India is essential for the efficiency and safety of your fluid control systems. By focusing on quality, customization, technical expertise, and after-sales support, you can ensure that your operations run smoothly and effectively. Partnering with a reputable supplier will not only enhance your system's performance but also contribute to long-term operational success.

For those looking to elevate their fluid control systems, investing in a quality five-valve manifold from a reliable supplier can be a game-changer. Ensure that you do your research, assess potential suppliers, and choose a partner that aligns with your business needs.

#general instruments consortium#pressure gauges#level gauge manufacturers#diaphragm seal pressure gauges

0 notes

Text

Many HVAC systems and industrial operations depend on temperature monitoring. Offering a range of temperature measurement solutions, Kevitits.com is a prominent Temperature Gauges Supplier in Saudi Arabia. Temperature Gauges Suppliers in Saudi Arabia are designed to provide precise and trustworthy readings, guaranteeing the functionality and safety of your equipment.

Kevitits.com provides temperature gauges for industrial boilers, ovens, and HVAC systems, among other applications. Among the thermometers in their range that are appropriate for different temperature measuring demands are digital, gas-actuated, and bimetallic thermometers.

#Temperature Gauges Suppliers in Saudi Arabia#flow meter suppliers in saudi arabia#thermocouple manufacturers in dubai#level transmitter supplier in dubai

0 notes

Text

How to Do a Load Bank Test on a Generator?|EMAX Load Bank

Load bank testing is a crucial aspect of generator maintenance. It ensures optimal performance, identifies potential issues, and safeguards against unexpected failures. By simulating real-world conditions, you can verify your generator's capacity to deliver consistent power when needed most. In this blog post, we'll guide you through the process of conducting a load bank test on your generator.

Understanding Load Bank Testing

A load bank is essentially a resistive load that simulates various electrical loads. By connecting it to your generator, you can assess its performance under different load conditions. This testing helps identify issues such as voltage regulation problems, engine performance, and overall system efficiency.

Preparing for the Test

Before commencing the test, ensure the following:

Safety First: Adhere to all safety guidelines, including wearing appropriate personal protective equipment (PPE).

Qualified Personnel: The test should be conducted by trained professionals familiar with generator operation and load bank usage.

Proper Equipment: Ensure you have the right load bank capacity to match your generator's output. Other necessary equipment includes voltage and current meters, temperature gauges, and a reliable power source.

Generator Condition: Verify that your generator is in good operating condition with adequate fuel and coolant levels.

Test Environment: Choose a well-ventilated area for the test to prevent overheating.

Steps Involved in Load Bank Testing

Connect the Load Bank: Carefully connect the load bank to the generator's output terminals, following the manufacturer's instructions.

Start the Generator: Start the generator and allow it to reach operating temperature.

Apply Load Gradually: Begin by applying a light load to the generator and gradually increase it to the desired level. Monitor the generator's performance throughout the process.

Monitor Parameters: Continuously monitor key parameters such as voltage, current, frequency, and engine temperature. Record these readings for analysis.

Check for Overloads: If the generator shows signs of overload, such as excessive voltage drop or overheating, reduce the load immediately.

Maintain Load for Specified Duration: Keep the load applied for the recommended duration to assess the generator's sustained performance.

Cool Down: After the test, gradually reduce the load and allow the generator to cool down before shutting it down completely.

Analyzing Test Results

Once the test is complete, analyze the collected data to evaluate the generator's performance. Look for any deviations from the manufacturer's specifications or unexpected trends. Common parameters to assess include:

Voltage Regulation: Check if the voltage remains within acceptable limits under varying load conditions.

Current and Power Factor: Verify that the generator delivers the required current and maintains a suitable power factor.

Frequency Stability: Ensure the generator maintains a stable frequency.

Engine Performance: Assess engine parameters like RPM, oil pressure, and coolant temperature.

Exhaust Emissions: Monitor exhaust emissions for any signs of abnormal combustion.

Benefits of Load Bank Testing

Regular load bank testing offers several advantages:

Early Detection of Issues: Identifies potential problems before they lead to costly breakdowns.

Performance Verification: Confirms the generator's ability to meet power demands.

Extended Equipment Life: Proper maintenance through load testing prolongs the generator's lifespan.

Compliance with Regulations: Demonstrates adherence to safety and performance standards.

Improved Efficiency: Optimizes generator performance for fuel efficiency.

Conclusion

Load bank testing is an indispensable tool for ensuring the reliability and efficiency of your generator. By following these guidelines and conducting regular tests, you can maximize the performance of your equipment and minimize the risk of unexpected failures.

2 notes

·

View notes

Text

Tubular level gauge suppliers in Mumbai - Process control Devices

Process Control Devices, A tubular level gauge supplier, provides a range of level gauges designed for monitoring liquid levels in enclosed tanks. The side-mounted tubular type level indicator offered by them is a dependable device for precise direct reading.

#tubular level gauge supplier#tubular level gauge manufacturers#tubular level gauge suppliers in mumbai

0 notes

Text

L4D2 Nick x Reader

Office AU

Gender neutral reader Nick does call them sweetheart condescendingly (because hes an asshole)

Recently rediscovered this oneshot I wrote over a year ago as a joke(?) thing with a friend, not my best work but I think the concept was cute so if anyone's interested !! I don't know how to format fanfics on here bear with me. ALSO I edited it a little but also not really . not my best work so apologies D:

“As you both probably know, Ellis’ birthday is tomorrow.” You shuffled in your chair, attempting to make yourself comfortable. Of all the things your boss, Rochelle Torres, could have pulled you into her office for you were rather surprised it had to do with the birthday of one of your coworkers. Ellis Thompson was relatively new to your small sales office- he recently moved from manufacturing- but you got on quite well with him. The man seated to your left, however, did not.

“And? What, do I need to bake overalls a birthday cake or something, maybe hire some strippers to jump out of it?” This sarcastic quip came from no other than Nicolas “Nick” Wright, the well dressed and, admittedly, rather attractive salesman with a rather unnatractive attitude. He was known around the office for his pessimism and sarcasm, and the damned white suit, blue shirt combo he wore to work every day. However, he was great at his job and an excellent leader. In fact, he wasn’t half bad when he was focused. You’d even managed to coax a compliment out of him the last time the two of you were assigned to a project together.

“No.” Rochelle responded after a moment, giving him a warning glance. It was obvious she was amused yet unenthused by his comment, the newly promoted woman was still finding a balance between banter with her subordinates and the level of professionalism needed by a regional manager. She was doing a good job, though, you noted internally. Much better than Nick, who so clearly struggled with professionalism. Rochelle spoke again, interrupting your thoughts about the suited salesman. “Actually, I need you two to decorate the conference room. Louis normally takes care of it, as you know, but his sister’s wedding happened to coincide with Ellis’ birthday.

“I approved his time off in advance and told him I’d take care of finding someone to set up the party, but then I forgot. I’ve just been really busy and it slipped my mind, I’m sorry for the short notice, guys.” Rochelle sighed, pinching the bridge of her nose before looking back apologetically at you and Nick. You glanced to your left to gauge Nick’s reaction, which was unsurprisingly not a happy one. He looked like he was about to say something he’d later regret, so you cut him off.

“Don’t worry! We know you’ve had a lot on your hands as of late, it’s okay to make a mistake once and a while. Just tell us what we need to do specifically and we’ll do it, no problem.” You could practically feel Nick’s blank stare boring into the side of your head, but as Rochelle smiled you realized that he realized that you just saved his fucking ass. You’re welcome, Nick.

“Well, I went ahead and took care of the cake, so don’t worry about that. I took some time and dug around to find what party supplies we had on hand, so you’ll find that stuff in the conference room. Just go in there and do your best to spruce up the room, that’s all I can really ask.” You nodded, taking her statement as a que to exit. You stood up and looked toward Nick, who still hadn’t left his chair.

“Why did you choose me for this? At least the country boy and (Y/N) are actually friends.” He huffed, crossing his arms and sliding down in his seat slightly. It was almost funny to watch a grown man act so juvenile, especially a man who acted as macho as Nick did. This time there was no amusement in Rochelle’s stare.

“You two are my top salespeople. I figured you both deserved a break for all the hard work you do around here, however if doing things for your coworkers feels like a punishment to you I can make it one. Get working on it, now.” She said sternly, pointing a pink painted nail toward the door. He seemed to get the message as he scurried out after you.

A pack of 24 assorted multicolor balloons, a pile of colored construction paper, and a spool of twine were waiting on the conference room table for the two of you. Beside them sat various office supplies, including a tape dispenser, a hole puncher, and a pair of scissors.

“Alright, here’s the game plan. Take the hole puncher and make some confetti with the construction paper. The custodians will hate us but it’ll make the table look more festive. I’ll make a banner with the paper and twine, then we’ll blow some balloons.” You directed, handing him the hole puncher before turning to grab the supplies you’d need. You had a vivid picture of what you needed to do in your mind. If you cut the letters in “Happy Birthday Ellis” out of the construction paper, then punched holes into the tops of them, you could string them on the twine and hang it up above the tabl-

“Who died and put you in charge?” Nick retorted, begrudgingly reaching for a piece of paper to begin his confetti making journey with. His scowl was even worse than it typically was, which was saying something.

“Probably the same person who died and made you a huge bitch. Like seriously, what’s your deal? Might do you some good to take the stick out of your ass and try to enjoy things once and a while.” You didn’t spare him a glance, instead beginning to cut an H out of a piece of orange construction paper. The room fell silent, save for the clicking of the hole puncher and the sound of scissors gliding across paper. Yes, what you said was unprofessional. That much you acknowledged, and if he decided to take that up with HR (that is, when the HR representative Louis came back from vacation) you were willing to take the consequences that came along with it. However it was the truth, and it needed to be said. You kept cutting.

“Sweetheart, if anyone else had said that I would have punched them.” Nicholas replied quietly, a few moments after the silence had gotten awkward. His voice was so soft, it was startling. What he said didn’t feel rude or like a threat, it just felt personal. The silence returned. You finished cutting H, then A, and P, another P, and then Y. You set your paper scraps between you and Nick’s seats and in some unspoken agreement, he turned it into confetti.

Clearly, there was something on your coworkers mind. Nick was never this quiet. As much as he seemed like he disliked people, you just got the feeling he thrived around them. When the two of you went for a meeting with one of the company’s customers he talked nonstop. He really is charismatic, especially when he’s not so rude. The longer the silence between you two went on, devoid of even a sarcastic crack or a mumbled string of curses, the more uncomfortable it became until finally you just had to ask.

“What’s wrong?” You inquired, finally turning to focus your (E/C) eyes on the suited man beside you. He took a deep breath, set down his tools, and turned to face you. Nick’s grey eyes were watering, tears threatening to spill out. He sniffled, averting his gaze and smiling crookedly. Instinctively, you reached out and embraced him, pulling him into a hug. His composure broke and he began to cry into your shoulder, melting into the physical contact that he so desperately needed. You could faintly make out muffled apologies and explanations coming from the crying man, nothing that really made sense but you realized this was more for him than it was for you. You just let him get it all out, one hand around his back and the other cradling his head.

After a few minutes, his sobs slowed, then eventually stopped. Nick broke away from the hug, red eyed and sniffling. His true nature finally hit you: he’s a good guy, just scared to be vulnerable.

“I’m sorry.” He sniffed, your gazes still locked.

“I know you are.” You smiled gently.

“So much has happened but that doesn’t excuse being a dick. I’m so sorry.” Nick continued weakly.

“Do you want to talk more about it?” You offered.

He nodded.

“Over drinks tonight? The bar downtown?”

He nodded yet again, smiling.

With that, the two of you simultaneously turned back to your birthday party prepwork, the silence much more comfortable this time. He’s a good guy deep down, and you’re determined to meet the real him. For now, though, you were content cutting letters.

#left 4 dead 2#left 4 dead#l4d2#l4d2 nick#nick l4d2#l4d2 nick x reader#office au#idk how to tag this#x reader#gender neutral reader

53 notes

·

View notes

Text

Choosing the Best Penis Extender: Factors to Consider

Penis extenders are devices designed to promote penis enlargement through traction therapy. Selecting the right one involves considering several key factors to ensure safety, effectiveness, and comfort. This guide explores essential considerations when choosing a penis extender to help you make an informed decision.

Understanding Penis Extenders

Penis extenders, also known as traction devices or penis stretchers, work on the principle of traction. They apply a gentle stretching force to the penis over time, stimulating cell growth and promoting increased length and girth. This non-invasive method is favored by many men seeking to enhance their penis size without surgery or medication. Penis extenders are typically composed of a base, adjustable rods, and a support system to hold the penis in place comfortably during wear.

Effectiveness of Penis Extenders

Research supports the effectiveness of penis extenders for penis enlargement when used correctly and consistently. Studies have shown that traction devices can lead to significant increases in penile length, especially when used over several months. The gradual stretching encourages tissue expansion and cellular division, contributing to permanent gains in both flaccid and erect states. However, individual results may vary based on factors such as adherence to usage guidelines and initial penis size.

Safety Considerations

Safety is paramount when using a penis extender. Look for devices that are FDA-approved or CE-certified to ensure they meet health and safety standards. Opt for models made from medical-grade materials to minimize the risk of allergic reactions or skin irritation. It's essential to follow the manufacturer's instructions regarding usage duration and tension levels to prevent discomfort or injury. Regularly check the device for any signs of wear and tear and replace components as needed to maintain safety and effectiveness.

Comfort and Fit

Choosing a penis extender that fits comfortably is crucial for long-term use. Look for devices with adjustable settings to customize the tension and accommodate your size comfortably. The base should provide adequate support without causing pain or constriction, especially around the glans (head) of the penis. Some extenders come with additional padding or cushioning to enhance comfort during wear. Ensure the device allows for natural blood circulation and does not restrict movement or cause discomfort during daily activities.

Adjustability and Customization

An effective penis extender should offer adjustable settings to tailor the traction force according to your comfort level and progress. Devices with interchangeable rods or springs allow for gradual increases in tension as your penis adapts to the stretching regimen. This flexibility is essential for optimizing results while minimizing discomfort or potential side effects. Consider how easily you can adjust the device and whether it offers a range of tension levels suitable for beginners and experienced users alike.

User Reviews and Testimonials

Reading user reviews and testimonials can provide valuable insights into the effectiveness and reliability of a penis extender. Look for feedback on comfort, ease of use, and noticeable changes in penis size over time. Real-life experiences can help you gauge the device's performance and decide if it aligns with your expectations and goals. Pay attention to reviews that discuss customer support, warranty issues, and overall satisfaction with the purchase process, as these factors contribute to a positive user experience.

Price and Value

While price shouldn't be the sole determining factor, consider the overall value offered by the penis extender. Compare prices across different brands and models, taking into account features, materials, and customer support. Some extenders come with additional accessories or warranty options that enhance their value proposition. Balance your budget with the device's reputation for quality and effectiveness to make an informed investment in your sexual health.

Where to Buy

Purchase your penis extender from reputable retailers or official manufacturer websites to ensure authenticity and quality. Avoid unauthorized sellers or significantly discounted products that may compromise safety or effectiveness. Look for retailers that offer secure payment options, discreet packaging, and reliable customer support to address any concerns or issues after purchase. Consider reading customer reviews and ratings to verify the retailer's reputation and satisfaction levels among previous buyers.

Choosing the best penis extender requires careful consideration of factors such as effectiveness, safety, comfort, adjustability, and user reviews. By understanding these considerations and selecting a device that aligns with your needs and goals, you can embark on a safe and effective journey towards penis enlargement. Remember to prioritize safety, follow usage guidelines, and maintain realistic expectations for gradual results over time.

2 notes

·

View notes