#innovations in pcb industry

Explore tagged Tumblr posts

Text

#pcb#printed circuit board#pcb industry#electronics circuit devices#innovations in pcb industry#electronics circuit devices services#new pcb innovations#latest pcb innovations#pcb industry for elctronics circuit devices

0 notes

Text

🔧 Unlock the Power of FR-4 Epoxy Fiberglass Sheets! 🔧

Discover how FR-4 epoxy fiberglass sheets are revolutionizing industries with their exceptional electrical insulation and mechanical strength. From PCBs to industrial machinery, these materials are the backbone of modern engineering.

Explore our comprehensive guide to understand their applications and benefits.

#fr43#fr4#fiberglass#epoxy resin#engineering#pcb#industrial design#customsolutions#technology#innovation#manufacturing#materials#electronics

0 notes

Text

𝐄𝐱𝐜𝐞𝐥𝐥𝐞𝐧𝐜𝐞 𝐢𝐧 𝐄𝐥𝐞𝐜𝐭𝐫𝐨𝐧𝐢𝐜 𝐌𝐚𝐧𝐮𝐟𝐚𝐜𝐭𝐮𝐫𝐢𝐧𝐠 𝐒𝐞𝐫𝐯𝐢𝐜𝐞𝐬

Avalon stands as a premier provider of Electronic Manufacturing Services (EMS), offering comprehensive solutions tailored to meet the needs of various industries. With advanced manufacturing capabilities and state-of-the-art facilities, Avalontec ensures precision and efficiency in every project. Their vertically integrated services cover all aspects of product development, from design and engineering to assembly and logistics. Known for their innovation and commitment to quality, Avalontec serves diverse sectors, including clean energy, mobility, communications, and industrial automation, while maintaining a strong focus on sustainability.

Key Highlights:

Innovation & Quality: Equipped with state-of-the-art facilities and the latest technologies.

Vertically Integrated Services: Design, engineering, assembly, testing, and logistics for a seamless product development journey.

Industry Versatility: Serving clean energy, mobility, communications, and industrial automation sectors.

Trusted Partner: Deep industry knowledge and cross-functional capabilities for OEMs.

Sustainability & Responsibility: Dedication to sustainable practices and environmental responsibility.

Awards & Certifications: An impressive track record reflecting excellence.

Why Choose Avalontec:

Global Reach & Local Expertise: Positioned to drive innovation and deliver unparalleled value.

Adaptability: Embracing emerging technologies and evolving with client needs.

Streamlined Operations: Helping OEMs optimize manufacturing processes.

Discover how Avalontec can unlock new possibilities in the dynamic world of electronics.

#ElectronicManufacturing#EMS#Innovation#Quality#Sustainability#OEM#ManufacturingExcellence#Avalontec#EMSProvider#us#trendy#trending#USA#Electronic#Electronic manufacturing services#Electronic manufacturer#EMS Industry#electronics#electronic contract manufacturing#quality#services#industry servcies#cable harness#pcb#pretotype

1 note

·

View note

Text

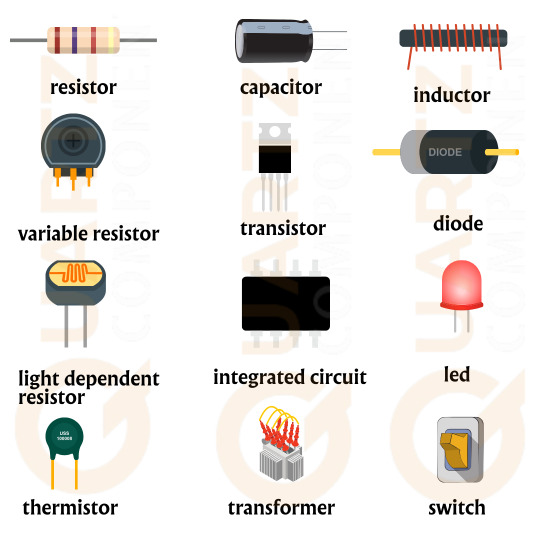

Electronics Components #components #electronics #engineering #electrical #arduino #electronic #innovation #design #robotics #electroniccomponents #raspberry #technology #manufacturing #industrial #gaming #school #learningbydoing #solar #bahrain #pc #pcb #budaiya #muhharaq #manama #engineeringforkids #saar #riffa #makersgonnamake #isatown #summerprogram

#Electronics Components#components#electronics#engineering#electrical#arduino#electronic#innovation#design#robotics#electroniccomponents#raspberry#technology#manufacturing#industrial#gaming#school#learningbydoing#solar#bahrain#pc#pcb#budaiya#muhharaq#manama#engineeringforkids#saar#riffa#makersgonnamake#isatown

10 notes

·

View notes

Text

PCB Manufacturing in Toronto: Expertise, Services, and Local Industry Insights

Discover PCB manufacturing in Toronto, a hub of innovation and quality in electronic manufacturing services. Learn about the specialized capabilities, technological advancements, and diverse offerings of PCB manufacturers Toronto. Explore how local expertise and cutting-edge facilities contribute to producing high-quality printed circuit boards for various industries and applications worldwide. For more details visit our website www.crimpcircuits.com

#pcb manufacturing toronto#printed circuit board design#metal clad pcb#printed circuits#rigid flex pcb#full turnkey pcb services#turnkey pcb services#pcb parts#eagle software#pcb designing#flexible pcb#pcb assembly#printed circuit board manufacturers#pcb manufacturers in canada#circuit board manufacturers in canada#pcb quote#pcb prototype services in canada

2 notes

·

View notes

Text

LED PCB Assembly

What is the LED Circuit Board assembly?

Generally, LED PCB assembly is considered to be a circuit board that has the LED components soldered to it. The LED is soldered to the printed circuit board and features a chip that creates the light as electrically connected. A thermal heat sink and a ceramic base are used to bond the chip. Not all the PCB products can be used in Led industry, as an LED PCB is easy to create a high volume of heat, but making it hard to cool with traditional methods. For this reason, metal core PCB is widely used in LED application because of their enhanced ability to dissipate heat, especially aluminum pcb is often used to fabricate PCB for LED lights.

We’ve had great LED PCB assembly experiences with top LED chips to brand such as Cree, Luxeon, Osram, Nichia, Lumileds, MLS, EVERLIGHT, Samsung, LG, Seoul., etc. PCB LED lights can be incorporated into numerous lighting applications due to their combination of excellent energy efficiency, low cost and maximum design flexibility.

Application of LED PCB Assembly

Hitechpcba serves customers in different industries, providing highly reliable and innovative LED PCBs for various applications:

• Horticulture light LED PCB Assembly

• LED controller PCB Assembly

• Computer LED display and indicators

• LED lights PCB Assembly for medical use

• Automotive LED PCBs Assembly include PCBs for brake lights and headlights

• Street lighting LED PCB Assembly

• Flashlights and camping accessories

• Traffic light PCB Assembly

• Commercial lighting LED PCB Assembly

LED PCB Assembly specification

Number of layers for LED PCB

These layers are made up of aluminum and magnesium, but now have Copper base material and Ceramic base materials for LED PCB industry, we can meet it.

Aluminum LED PCBs stand out among other PCBs because it has a good insulation characteristic and has a better machinery performance, the cheap cost is one important factor too.

Types of layers for LED PCB Assembly

Normally, the base layer is made using aluminum alloy metal.

This aluminum alloy substrate used in making the base makes it ideal for through-hole technology which transfers and dissipates heat.

A thermal insulation layer is made using some ceramic polymer which has good viscoelasticity characteristics.

It is highly heat resistant and protects the PCB against heat and mechanical stress.

The circuit layer, which is covered by a copper foil which can range from one to ten ounces.

LED Board type- single or in panel

Some boards are shapeless. For this reason, LED PCB panels are used. This reduces time, labor production and testing time.

Some LED PCB Assembly is done on a single board while others are done on panel boards.

LED PCB Assembly Process

Roughly, the PCBA process can be divided into theses phases: soldering paste printing > SMT (surface mounted technology) > reflow soldering > AOI (automated optical inspection)> THT (through-hole technology) > wave soldering > touch-up and cleaning > IC-programming > FCT (functional tests) > aging testing.

Below we show you the process.

Step1. Summarizing Project Information

Before contacting your supplier, make sure you have all the project information. Suppliers will need info following for quoting LED PCB assembly:

Gerber

BOM

LED PCB specification

Quotation quantity

Once you have gathered these information, you can contact us and request for a quote.

Of course, you can also provide the schematic, LED PCB Assembly pictures and even samples to us. The more details they have, the more accurate the supplier’s quotation will be.

Step2. Discussion and details about custom LED PCB Assembly

Different projects will have different requirements. Remember the special requirements mentioned in step 1? That’s going to be the focus of this session. Equipment and engineering capacity will not be identical between suppliers. Make sure your supplier has the equipment to produce and assemble major components and the corresponding testing capabilities.

For example, some vendors don’t have X-ray testing equipment, which means they can’t check the mount quality of BGA chips. Outsourcing this step will increase risk and cost. That’s what you don’t want.

Also, pay attention to time taken by the supplier to quote. Motherboards often contain hundreds or even thousands of components, and they are supplied by different manufacturers. To ensure the quality of the components, the supplier sourcing team will make multi-inquiries from these manufacturers or authorized suppliers to match customer’s requirement, which usually takes 2-3 business days, and even longer for some scarce chips. Therefore, if your project is complex and the supplier quotes you within few hours, double check with them.

Step3. Sample and feedback

After confirming the PI, the supplier will usually provide pre-production samples for your approval. At the same time, the supplier will also confirm with you the logistics plan of the bulk goods. Make sure they understand your shipping requirements, including details on packaging, customs clearance, taxes, etc.

For us to have a successful LED PCB Assembly process, its functions must be defined. Compliance requirement is defined to reduce the effect when components are selected.

The Bill of Materials is then generated from the information installed on the LED PCB.

All this information is used to assemble components which are identified from MOB to the LED PCB.

After that, the routing of traces is determined to each component, based on the size, shape of the circuit board and location of connectors.

Hitech Circuits is trusted by thousands of electronic engineers on their LED PCB assembly projects, from consumer, led bulb to precisely medical LED light, we can help you from the beginning of design stage; From commercial flood LED to industrial high power LED, from automotive LED to military LED, Venture is the perfect place for your LED PCB assembly requirement.

Hitech Circuits has been participated in hundreds and thousands of LED lighting projects, by providing LED PCB and also LED PCB assembly service.

Our LED PCB assembly had covered both ends of the Lighting Class LED size spectrum, assembling some of the largest (2 meter long boards) and some of the smallest LED Lighting applications which used in Medical Endoscopes.

LED PCB Assembly is very crucial in the current industrial development. Many electrical devises are being innovated and the old once being improved.

LED PCBs are useful due to the fact that they are made using materials that can transfer and dissipate heat. This characteristic increases device durability.

The world is changing with new technology, especially PCB technology that plays an essential role in the application of LED circuits. And the LED industry is taking advantage of this technology and growing faster.

As a full feature PCB solutions provider with more than a decade of experience, we're capable to provide LED PCB fabrication, components procurement and LED PCB assembly all under one roof. We can work with you to develop metal core PCB, aluminum circuit boards customized to your specific applications. We feature competitively priced PCBs made with standard FR-4 material that includes a thermal aluminum clad layer that will efficiently dissipate heat, keep all LED PCB components cool and significantly enhance the performance of your products.

LED pcb board, LED pcb assembly

LED with its advantages of high brightness, high efficiency, low heat, long life, is considered the most development potential in the 21st century lighting. In the market and policy driven by the rapid development of the domestic LED industry blowout has formed a relatively complete industrial chain, including the production of epitaxial wafers, chip preparation, packaging, integration, LED application. In 2010, China's LED industry scale, up from $ 827 billion in 2019 to 220 billion yuan, an annual growth rate of over 70%, higher than the 50% level of growth of the global LED lighting industry output value. Among them, the middle and lower reaches of the most complete industrial chain, accounting for 90% of the overall percentage of the GDP.Chinahas become the world's leading LED manufacturing base and important application market.

To further promote the technological innovation of the LED industry, construction and wide application of independent industry chain, China Electronic Appliance Corporation and industry associations to organize the theme of "Focus on the core energy LED Exhibition will be held November 9-11, 2010 in Shanghai International Expo Center and the 78th China Electronics Fair over the same period will be held will create from raw materials, epitaxial wafers, chip, LED bracket, LED accessories, LED packaging and supporting materials, the LED backlight upstream firm to the upstream and downstream enterprises of the display, lighting, landscaping, decorative lighting, traffic lights, automotive lighting, special lighting, to the equipment, instrumentation, software, finance, consulting and other service enterprises and technological exchanges and market trading platform, help the domestic industry sustained and healthy development, and promote the steady expansion of the LED application market.

In the LED industry chain upstream of the epitaxial wafers and LED chips accounted for 70% of the profits of the whole industry, and technology-intensive, capital-intensive, where the core technology of the LED. Well-known epitaxial wafer and chip production enterprises will be exhibited a number of energy-efficient, low heat, cost-effective LED products, many of whom have excellent products of international advanced level.

LED electronic pcb assembly manufacturing 100% Original LED Chip with one-stop in-house pcba services

3 notes

·

View notes

Text

Perca is a leading provider of advanced solutions in water treatment and waste management. Specializing in innovative technologies, they focus on offering sustainable methods for wastewater purification. Their services aim to address environmental challenges by efficiently treating wastewater and improving water quality. By using cutting-edge processes and tailored solutions, Perca supports industries in managing waste responsibly. Their expertise in wastewater purification ensures compliance with environmental regulations while contributing to sustainable development. With a commitment to eco-friendly practices, Perca is at the forefront of water treatment solutions.

#pcb wastewater#pfas wastewater#waste water management#waste water purification#water treatment process

0 notes

Text

Top PCB Manufacturers in Delhi: Delivering Precision, Innovation, and Quality in Custom Printed Circuit Boards for Diverse Industries

In the fast-paced world of electronics, the demand for high-quality, reliable Printed Circuit Boards (PCBs) is ever-growing. PCBs are the backbone of most modern electronic devices, from consumer electronics like smartphones and laptops to complex systems used in the automotive, medical, and telecommunications industries. With India’s expanding electronics industry, Delhi has emerged as a major hub for PCB manufacturing. Among the key players in the capital’s PCB sector, Sassin Electro has established itself as one of the top PCB manufacturers in Delhi, offering precision, innovation, and exceptional quality across a range of industries.

In this article, we’ll explore the landscape of PCB manufacturing in Delhi, highlight the role of companies like Sassin Electro, and discuss why they are a trusted name when it comes to custom PCBs for various industries.

The Growing Role of PCB Manufacturers in Delhi

Delhi, being the capital of India, has always been at the center of economic and technological advancements. The city’s electronics manufacturing ecosystem has grown rapidly over the years, with a thriving network of suppliers, manufacturers, and innovators in the PCB sector. As the demand for sophisticated electronics increases, especially in industries like automotive, healthcare, consumer electronics, telecommunications, and the rapidly growing Internet of Things (IoT) space, the need for high-quality, custom-designed PCBs has never been greater.

PCB manufacturers in Delhi are tasked with meeting the growing demand for more compact, efficient, and durable circuit boards that can handle increasingly complex and power-hungry devices. The key to their success lies in their ability to provide cost-effective, high-performance solutions with fast turnaround times. This is where Sassin Electro has earned its reputation as one of the top PCB manufacturers in Delhi, offering cutting-edge technologies and expert solutions to cater to a diverse range of industries.

Why Sassin Electro is Leading the Way in PCB Manufacturing

Sassin Electro is one of the premier PCB manufacturers in Delhi, known for its commitment to delivering precision, quality, and innovation in custom PCB solutions. The company has built a reputation for providing reliable and high-performance PCBs for a variety of industries. Below are some key reasons why Sassin Electro stands out in a competitive market:

1. Expertise in Custom PCB Solutions

One of the primary reasons businesses choose Sassin Electro is their specialization in providing custom PCB solutions. Unlike other manufacturers that focus on mass production, Sassin Electro works closely with clients to design and develop PCBs that are tailored to their specific requirements. Whether it's a single-layer PCB, a multi-layer PCB, or a flexible PCB, the company has the expertise to deliver the right solution for diverse applications.

The company's team of skilled engineers ensures that each custom PCB is designed to meet the technical specifications of the project. This attention to detail helps Sassin Electro deliver PCBs that work seamlessly in complex environments, from wearable devices and medical gadgets to advanced automotive systems and industrial machinery.

2. State-of-the-Art Manufacturing Facilities

To meet the growing demands of the PCB industry, Sassin Electro has invested heavily in state-of-the-art manufacturing facilities. The company’s production lines are equipped with the latest machinery, allowing them to offer high precision, fast turnaround times, and exceptional consistency. Sassin Electro uses automated processes, such as pick-and-place machines, soldering machines, and advanced testing equipment, to manufacture PCBs with superior quality and reliability.

Advanced equipment also allows for the production of high-density interconnect (HDI) PCBs, multi-layer boards, and flexible PCBs—products that are often required in industries like telecommunications, aerospace, and consumer electronics.

3. Quality Assurance and Rigorous Testing

For any electronic device to perform reliably, the PCB that powers it must meet stringent quality standards. Sassin Electro places a strong emphasis on quality control, ensuring that every PCB leaving their factory adheres to both national and international standards. The company follows a rigorous testing process that includes:

Electrical testing: Ensures that the circuit board functions correctly and the components are properly connected.

Thermal cycling: Tests the PCB’s durability under temperature fluctuations to ensure it performs well in harsh environments.

Environmental testing: Verifies the PCB’s ability to withstand moisture, corrosion, and other environmental factors.

By incorporating these quality checks into every stage of production, Sassin Electro ensures that their PCBs are of the highest quality and can meet the rigorous demands of various industries.

4. Industry-Specific Expertise

Each industry has unique requirements when it comes to PCBs, and Sassin Electro is adept at creating custom PCBs to meet these specialized needs. The company’s ability to design and manufacture PCBs for a wide range of applications has made it a preferred partner for businesses across various sectors:

Automotive industry: With the rise of electric vehicles (EVs) and advanced driver-assistance systems (ADAS), automotive companies require high-performance PCBs that are durable, reliable, and capable of handling high-speed data transmission. Sassin Electro manufactures PCBs that meet the stringent demands of automotive electronics.

Telecommunications: The telecommunications industry requires PCBs that can handle high-frequency signals, such as those used in 5G technology. Sassin Electro provides high-quality PCBs designed for fast data transfer and signal integrity.

Medical devices: Medical equipment such as pacemakers, ECG monitors, and diagnostic tools require precision-engineered PCBs that are both reliable and biocompatible. Sassin Electro manufactures medical-grade PCBs that comply with international quality and safety standards.

Consumer electronics: Whether it’s a smartphone, tablet, or wearable device, Sassin Electro provides custom PCBs that meet the compact size, durability, and performance demands of modern consumer electronics.

By working closely with clients in these sectors, Sassin Electro ensures that their products are designed to meet the specific needs of each industry, ensuring better performance and reliability.

5. Faster Turnaround Times and Cost Efficiency

In the electronics industry, speed to market is crucial, and Sassin Electro understands the need for quick turnarounds without compromising on quality. The company’s streamlined manufacturing processes and highly efficient production lines ensure that clients receive their custom PCBs in a timely manner, even for complex projects that require multiple iterations.

Additionally, Sassin Electro offers competitive pricing, making it an attractive option for businesses looking for high-quality PCBs at affordable rates. By optimizing their production process and using advanced technologies, the company can reduce costs, providing cost-effective solutions for both small and large-scale projects.

6. Commitment to Sustainability

As the global focus on sustainability increases, Sassin Electro is committed to adopting environmentally friendly practices. The company uses eco-friendly materials and follows sustainable manufacturing practices to minimize waste and reduce energy consumption. By adhering to global environmental standards and regulations, Sassin Electro is contributing to a greener and more sustainable PCB manufacturing industry.

The Future of PCB Manufacturing in Delhi

The future of PCB manufacturing in Delhi looks promising, with continued growth expected in industries like consumer electronics, telecommunications, automotive, and healthcare. As technology continues to advance, the demand for more complex and high-performance PCBs will increase. Companies like Sassin Electro are well-positioned to take advantage of these trends by continually innovating and providing cutting-edge solutions to meet the evolving needs of their clients.

With advancements in IoT, artificial intelligence (AI), and 5G, there will be a growing need for custom-designed, high-density, and flexible PCBs. As a leading PCB manufacturer in Delhi, Sassin Electro is ready to meet these challenges by continuing to offer precision, reliability, and innovation in every product they create.

Conclusion

As one of the top PCB manufacturers in Delhi, Sassin Electro has proven its ability to deliver high-quality, custom-designed PCBs for a variety of industries. By combining state-of-the-art manufacturing technology, a highly skilled workforce, and a commitment to quality, they continue to lead the way in PCB innovation. Whether for automotive, medical, telecommunications, or consumer electronics, Sassin Electro remains a trusted partner for businesses in need of precision-engineered PCBs that meet the most demanding industry standards.

For companies looking to stay ahead of the curve in the ever-evolving world of electronics, Sassin Electro provides the expertise, technology, and dedication to deliver superior PCB solutions that power the next generation of electronic devices.

0 notes

Text

Understanding 3D IC Technology - An Overview | PCB Power

As the world demands faster, more powerful, and smaller devices, traditional chip designs are hitting their limits. That’s where 3D IC technology steps in. Instead of spreading circuits out flat, like in conventional 2D designs, 3D ICs stack layers of integrated circuits, opening up new possibilities for performance, power efficiency, and space-saving. Imagine more computing power packed into a smaller area with better communication between layers—that’s the promise of 3D ICs.

In this blog, we'll dive into how 3D IC technology works, the benefits it brings, and the hurdles we need to overcome as we look toward the future of electronics…

What is 3D IC Technology?

Over the past four decades, advancements in ASIC (Application-Specific Integrated Circuit) technology have drastically improved the power and efficiency of semiconductors. However, as we try to pack more power into devices, making chips larger has become increasingly difficult, expensive, and time-consuming. We're reaching the limits predicted by Moore’s Law, where doubling the number of transistors on a chip is no longer as easy or cost-effective as it used to be.

This challenge has led to the rise of 3D IC (Integrated Circuit) technology. A 3D IC is made up of two or more smaller chipsets—essentially mini integrated circuits—designed to work together within the same package. These chipsets are connected using advanced packaging methods, whether it's 2D, 2.5D, or fully stacked 3D techniques. Instead of relying on the traditional approach of cramming everything into a single layer, 3D ICs divide the workload across smaller, more manageable pieces that are either stacked on top of each other or connected side by side. This not only reduces the overall size of the chip but also dramatically boosts performance without needing to duplicate components.

By embracing 3D IC technology, we can keep pushing the boundaries of semiconductor innovation, even as traditional methods reach their limits.

Benefits of 3D-IC Technology

The benefits of 3D-IC Technology are as follows:

Low Expenditures: Components such as analog circuits and memory can be fabricated on older generations of technology without additional cost.

Enhanced Capability: Boosted speed and bandwidth support up to 100 Gbps in advanced memory applications.

Space Efficiency: Miniature 3D ICs are used on smaller boards. It is useful for compact mobile devices.

Less Wasted Energy: Provided smaller I/O drivers and fewer RLC parasitics cause better efficiency in power consumption.

Faster Time-to-Market: Modular design and possibilities of “die reuse” accelerate project development.

Increased Integration: Allows one system to implement photonics, MEMS, and other new technologies.

Enhanced Signal Integrity: The use of TSVs lowers parasitics, which leads to better performance and saves power much better than traditional SiP designs.

Flexibility: Different technological nodes of dies can be stacked, making the system design more versatile.

3D ICs have a denser configuration, quicker interconnects, and better power characteristics; therefore they revolutionize the concept of high-performance applications, through design, heat control, and ramp-up production.

Applications of 3D IC Technology

3D IC technology is transforming industries that require high-performance and compact designs. Its ability to stack layers of circuits has made it an essential component in advanced computing, AI, and data centers, where speed and efficiency are critical.

It’s also revolutionizing the smartphone and wearable tech markets, enabling thinner devices with more power. In automotive applications, 3D ICs contribute to smarter, faster processing for autonomous driving systems. Additionally, 3D ICs are increasingly used in healthcare devices, powering sophisticated imaging and diagnostic equipment that rely on speed and accuracy.

Challenges in 3D IC Technology

Setbacks experienced with 3D IC Technology:

Heat Management: Ever-rising vertical stacks create a high level of power density and hence create thermal hot spots which may negatively affect performance and reliability. Also, adequate control of heat flow between the layers is necessary to avoid thermal crossover which may lead to defects in the circuitry.

Manufacturing Difficulty: The extent of tolerances required for the alignment and bonding of the dies in 3D IC exceeds that of 2D IC resulting in greater manufacturing costs and time as well as problems in increasing production volume.

Design Validation: The features of a 3D IC make design validation processes very difficult. Existing methods are ineffective due to the complexity of multilayer interactions and new ones need to be developed.

Differential Thermal Expansion Ratios: Materials with differing thermal expansion coefficients can result in mechanical stresses that lead to distortion and failure. Therefore appropriate materials and designs should be employed to avoid such occurrences.

Electromagnetic and power management problems: The performance of power-integrated circuits with multiple layers may be limited because of the complex power distribution within the stacked layers. Designers would require high-end software to model power distribution and temperature effects precisely to ensure the systems work well.

The Future of 3D IC Technology & PCB Power's Role in Driving Innovation

3D IC technology is shaping the future of electronics, bringing forth smaller, faster, and more energy-efficient devices. With its ability to stack circuits vertically, 3D ICs significantly reduce signal delays and improve overall performance, making them key to advancing AI, IoT, and other emerging technologies.

However, the journey to full adoption is not without challenges. Thermal management, manufacturing complexity, and the need for reliable interconnects are crucial hurdles that the industry needs to address. This is where PCB Power steps in.

At PCB Power, we understand that as IC designs become more sophisticated, the demand for high-performance PCBs will only grow. Our expertise in creating multi-layer and high-density interconnect (HDI) PCBs ensures that we can meet the evolving needs of 3D IC technology. We continuously adapt our processes to support cutting-edge designs and ensure that signal integrity and heat dissipation are prioritized.

Whether you’re looking for custom PCBs for advanced 3D IC applications or turnkey solutions that streamline the PCB manufacturing and assembly process, we are here to partner with you every step of the way.

As we look to the future, PCB Power remains committed to pushing the boundaries of PCB technology, helping businesses like yours thrive in this exciting era of innovation.

Read the original blog post here: Understanding 3D IC Technology - An Overview

0 notes

Text

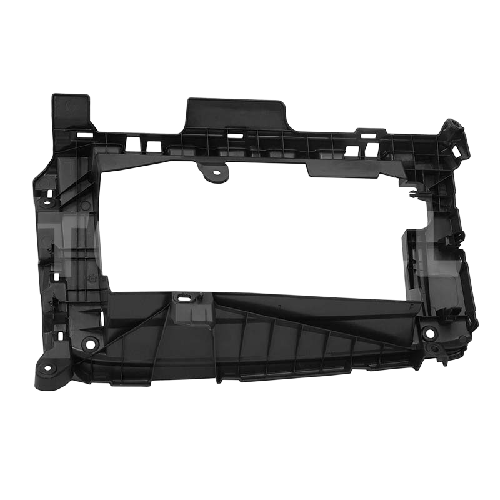

Custom PCB and ABS Plastic Molds: Revolutionizing Manufacturing with Topwell Moulding

In the world of manufacturing, customization, precision, and quality are essential. Topwell Moulding stands at the forefront, offering advanced solutions in Custom PCB design and ABS Plastic Mold manufacturing, driving success across diverse industries. Here, we explore how Topwell Moulding meets unique production demands and why they’re the go-to choice for companies requiring custom circuit boards and durable plastic molds.

1. The Power of Custom PCBs

Printed Circuit Boards (PCBs) are fundamental components in electronics, acting as the backbone for transmitting electrical signals across various devices. However, a one-size-fits-all approach doesn’t suit industries with unique or complex requirements. Custom PCBs from Topwell Moulding are tailored to each client’s specifications, ensuring enhanced performance and adaptability for various applications.

Advantages of Custom PCBs:

Precise Specifications: Custom PCBs allow for specific configurations, from material types and sizes to layer counts and component layouts, making them suitable for specialized electronics.

Enhanced Reliability: Topwell's precision engineering ensures that each PCB meets the highest standards, reducing potential failures and extending product lifespan.

Optimized Performance: With tailored designs, devices operate efficiently with improved signal integrity and reduced electrical noise, ideal for critical sectors like medical devices, telecommunications, and automotive systems.

Topwell Moulding leverages cutting-edge technology and expert engineering to deliver PCBs that support innovation and performance, tailored to meet each client’s functional and technical requirements.

2. ABS Plastic Molds: The Foundation of Durable and Versatile Parts

ABS (Acrylonitrile Butadiene Styrene) plastic is one of the most widely used materials in mold manufacturing. Known for its durability, resistance to impact, and ease of molding, ABS is ideal for creating complex parts with precision. Topwell Moulding specializes in designing and producing custom ABS plastic molds that are reliable, versatile, and meet the demands of high-quality production.

Key Benefits of ABS Plastic Molds:

High Durability: ABS molds withstand rigorous use, making them suitable for products requiring strength, like automotive parts, appliances, and toys.

Custom Design Flexibility: ABS can be molded into complex shapes with intricate details, allowing for customized designs tailored to unique project requirements.

Cost-Effective Production: ABS plastic is affordable and, combined with Topwell’s efficient manufacturing, provides high-quality results without excessive costs.

Topwell Moulding’s expertise in ABS plastic molds ensures consistent, top-quality parts that meet each client’s unique specifications, helping businesses achieve durability and efficiency in their products.

3. Topwell Moulding: The Ideal Mold Manufacturer

As a leader in both custom PCB and ABS plastic mold manufacturing, Topwell Moulding excels by combining expertise, technology, and a commitment to quality. Their services extend across various industries, providing solutions that range from prototype development to mass production.

Why Choose Topwell Moulding?

Advanced Manufacturing Facilities: Equipped with the latest technology, Topwell ensures precision and quality in every product, whether it’s a custom PCB or an ABS plastic mold.

Experienced Engineering Team: The team of specialists at Topwell works closely with clients to understand their needs, provide guidance, and deliver products that align with specific requirements.

Quality Assurance: Every product undergoes rigorous testing and quality control measures, ensuring it meets international standards and exceeds client expectations.

Scalability: Whether you need a small prototype run or large-scale production, Topwell has the capacity to meet diverse volume demands while maintaining quality.

Applications of Custom PCBs and ABS Plastic Molds

From consumer electronics and medical devices to automotive and industrial applications, the versatility of custom PCBs and ABS plastic molds is vast. With Topwell Moulding, clients can expect solutions that fit seamlessly into any production line and elevate the quality of the final product.

Partnering with Topwell Moulding

With years of experience and a commitment to innovation, Topwell Moulding is the preferred partner for companies looking to elevate their manufacturing capabilities. Custom PCBs and ABS plastic molds from Topwell are not just components; they’re integral parts of products that define quality and functionality.

To explore Topwell Moulding’s capabilities and see how they can meet your manufacturing needs, visit topwellmoulding.com.

0 notes

Text

Top Reasons Vasantha Advanced Systems is India’s First Choice in EMS

In the rapidly evolving world of electronics, choosing the right partner for electronic manufacturing services (EMS) can make all the difference. Vasantha Advanced Systems has emerged as India’s first choice in EMS, thanks to its dedication to quality, innovation, and client satisfaction. With over two decades of experience in the industry, Vasantha Advanced Systems has established itself as a trusted and reliable EMS provider. Let’s explore the top reasons why Vasantha Advanced Systems is the go-to EMS partner for both national and international clients.

1. Commitment to Quality and Certification Standards

One of the primary reasons Vasantha Advanced Systems is regarded as a top EMS provider in India is its unwavering commitment to quality. The company is ISO 9001:2015 and IATF 16949:2016 certified, demonstrating its dedication to maintaining high standards in manufacturing and operational processes. These certifications are recognized globally and ensure that all products and services meet stringent quality requirements. By adhering to these standards, Vasantha Advanced Systems guarantees reliability and excellence in every project.

For clients in industries that demand precision and quality, such as automotive, healthcare, and consumer electronics, Vasantha Advanced Systems’ certifications serve as a testament to its adherence to international standards. This focus on quality has helped the company earn a solid reputation as one of India’s most dependable EMS providers.

2. Customized Solutions for Diverse Industries

Vasantha Advanced Systems understands that every client has unique needs. Whether you’re a small startup or a large multinational, the team at Vasantha Advanced Systems tailors its EMS solutions to meet your specific requirements. From prototyping to full-scale production, the company offers a wide range of services, including PCB assembly, testing, and complex system integration.

The flexibility to customize solutions sets Vasantha Advanced Systems apart from other EMS providers. The company collaborates closely with clients to understand their goals, challenges, and specific requirements. This collaborative approach ensures that clients receive exactly what they need, making Vasantha Advanced Systems an invaluable partner for companies across various industries.

3. Innovative and Future-Ready Technology

In the EMS industry, staying ahead of technological advancements is crucial for success. Vasantha Advanced Systems is dedicated to innovation, continuously investing in the latest tools, equipment, and technology to provide cutting-edge solutions. By embracing new technologies, Vasantha Advanced Systems ensures that its clients benefit from faster turnaround times, improved accuracy, and enhanced product performance.

The company’s mission to pioneer innovation in electronic manufacturing aligns with the fast-evolving demands of the industry. By focusing on technological advancement, Vasantha Advanced Systems consistently delivers products that are efficient, reliable, and aligned with modern requirements. This commitment to staying future-ready has solidified its status as a leading EMS provider in India.

4. Experienced and Dedicated Team of Professionals

Behind the success of Vasantha Advanced Systems is a team of skilled professionals who are passionate about delivering high-quality EMS solutions. The company’s team consists of experienced technocrats and trendsetters with a deep understanding of the electronic manufacturing industry. Each team member brings valuable expertise to the table, enabling Vasantha Advanced Systems to tackle complex projects with precision and efficiency.

The dedication of the team at Vasantha Advanced Systems goes beyond just technical skill. They are committed to upholding the highest standards of professional ethics and operational excellence, ensuring that every project is handled with care and attention to detail. This commitment to excellence is one of the key reasons why clients choose Vasantha Advanced Systems as their EMS provider.

5. Strong Focus on Client Satisfaction

Vasantha Advanced Systems places client satisfaction at the heart of its operations. The company’s client-centric approach means that it prioritizes the needs and expectations of each client. From the initial consultation to the final delivery, Vasantha Advanced Systems works closely with clients to ensure their requirements are met at every stage.

By offering personalized service and maintaining open communication, Vasantha Advanced Systems builds long-lasting relationships with its clients. The company’s commitment to customer satisfaction is reflected in its high client retention rate and positive feedback from both national and international partners. When you choose Vasantha Advanced Systems, you’re choosing an EMS provider that genuinely cares about your success.

6. Trusted by National and International Clients

Over the years, Vasantha Advanced Systems has built a diverse portfolio of clients that includes both national and international businesses. The company’s ability to deliver high-quality EMS solutions to a wide range of industries has earned it a loyal client base. Vasantha Advanced Systems has become a trusted EMS provider not only in India but also on a global scale, serving clients from various regions and sectors.

This widespread trust from clients speaks volumes about the company’s reliability, quality, and expertise. By consistently delivering on its promises, Vasantha Advanced Systems has established itself as a leading name in the EMS industry, trusted by businesses worldwide to provide dependable and innovative electronic manufacturing services.

Conclusion

Vasantha Advanced Systems stands out as India’s first choice in EMS due to its commitment to quality, innovation, and client satisfaction. With industry-leading certifications, customized solutions, a focus on cutting-edge technology, and a dedicated team, Vasantha Advanced Systems has proven itself as a reliable and trusted EMS partner. Whether you need a simple PCB assembly or a complex electronic system, Vasantha Advanced Systems has the expertise and resources to bring your project to life with precision and care.

0 notes

Text

Luphi Electronics see you at Electronica 2024(Munich,Germany)

Electronica 2024 will cover the entire electronics spectrum, featuring everything from components to systems. Luphi Electronics participates in the 2024 Germany Munich Electronics Fair, from November 12 to 15, 2024. Welcoming numerous professionals from various countries to visit LuphiTouch ( Hall C6, Booth 341.8)!

About Luphi Electronics

Dongguan Luphi Electronics Technology Co., Ltd. (Trademark: LuphiTouch) was established in 2015. The factory covers 4500 square meter. We have 80+ workers and we have been certified by ISO9001, ISO13485, ISO14001 and ISO45001. LuphiTouch mainly focuses on various kinds of human machine interface switch panels, keypads and modules development and manufacturing. Our capabilities cover from mechatronic design, graphic art design, function control PCBA development, MCU development, IC programming, embedded system development to tools making, prototypes making, function testing, mass production and shipping of one-stop total solutions service. We also provide circuit board manufacturing, components sourcing, SMT&PTH assembly, EMS contract manufacturing service for our end clients.

On this fair, Luphi Electronics will show our high quality Products include:

· Medical Membrane Switches(Medizinische Folientasten)

· Backlighting Membrane Switches(Hinterleuchtete Folientasten)

· FPC Membrane Switches(FPC-Folientasten)

· PCB Membrane Switches(PCB-Folientasten)

· Silicone Rubber Keypads(Gummitasten)

· Capacitive Membrane Switches(Kapazitive Folientasten)

· Backpanel Membrane Keypads (Rückseiten-Folientasten)

· Touchscreen & LCDs(Touchscreens und LCDs)

· User Interface Modules(Benutzeroberflächen module)

......

We serve various industries such as medical, industrial control, home appliances, new energy, instrumentation, rail transportation, aviation and navigation, network communications, and mechanical equipment.

Our Commitment to Quality

At Luphi Electronics, we prioritize quality and innovation. Our manufacturing processes are certified under ISO standards (ISO9001, ISO14001, ISO13485, and ISO45001), ensuring that our products meet the highest industry standards. We are proud to be the first ISO13485-certified membrane switch factory in China, we sincerely expect your inquires and look forward to the long-term & stable cooperation with your company!

Professional HMI Switch Sub-assemblies & Touch Display Modules Provider!

Luphi Electronics official website: https://www.luphitouch.com

0 notes

Text

A Comprehensive Guide to Circuit Card Assembly

Introduction

Circuit Card Assembly (CCA) is a critical process in the electronics manufacturing industry, involving the assembly of electronic components onto a printed circuit board (PCB). This process transforms a bare PCB into a fully functional electronic assembly, enabling the operation of various devices across numerous applications.

Key Components of CCA

Printed Circuit Board (PCB):

The foundation of the assembly, a PCB consists of a non-conductive substrate with conductive pathways etched onto it, connecting different components.

Soldering Techniques:

Different methods are employed to attach components to the PCB:

Hand Soldering: Used for small-scale or repair work.

Wave Soldering: Suitable for through-hole components; the board passes over a wave of molten solder.

Surface Mount Technology (SMT): Allows for the mounting of components directly onto the surface of the PCB, facilitating high-density assemblies.

The CCA Process

1. Design and Layout:

The assembly begins with the design of the PCB using Computer-Aided Design (CAD) software. This step involves laying out the components and their interconnections.

2. Component Placement:

Once the PCB is fabricated, components are placed on the board. Automated pick-and-place machines are commonly used to ensure precision and efficiency.

3. Soldering:

After placement, components are soldered to the PCB using one of the aforementioned techniques. Proper soldering is essential to create reliable electrical connections.

4. Inspection:

The assembled boards undergo inspection to check for defects, misalignments, or soldering issues. Techniques such as automated optical inspection (AOI) are often used.

5. Testing:

Functional testing is performed to verify that the assembly meets design specifications. This may include in-circuit testing, where each component's functionality is checked, and final functional tests to assess overall performance.

Quality Assurance

Quality assurance is paramount in CCA, involving rigorous testing and inspection processes to ensure that assembled boards meet industry standards. Common practices include:

ISO Certification: Many manufacturers adhere to ISO standards to ensure quality management.

Environmental Testing: Assemblies may undergo thermal cycling, humidity, and vibration tests to simulate real-world conditions.

Reliability Testing: Long-term tests assess the durability and performance of the assembly over time.

Applications of Circuit Card Assembly

CCAs are used in a wide range of industries, including:

Consumer Electronics: Smartphones, tablets, and home appliances.

Industrial Equipment: Robotics, automation systems, and control panels.

Medical Devices: Diagnostic equipment, monitoring devices, and surgical tools.

Telecommunications: Network devices, routers, and communication systems.

Automotive: Control units, infotainment systems, and safety features.

Conclusion

Circuit Card Assembly is a fundamental process in electronics manufacturing, bridging the gap between design and functionality. By transforming raw PCBs into operational assemblies, CCA plays a crucial role in the performance and reliability of electronic devices. As technology advances, innovations in assembly techniques and quality assurance continue to enhance the efficiency and capabilities of CCAs across diverse applications.

1 note

·

View note

Text

Powering Electronics With Quality PCB Manufacturing

At Pcbcircuit, we specialize in high-quality PCB manufacturing, ensuring reliability and performance in every circuit board we create. Our advanced manufacturing techniques support the demands of modern electronics, providing strength and precision for various industries. Trust Pcbcircuit for expertly crafted PCBs that power innovation, keeping your electronics running smoothly and efficiently.

0 notes

Text

Beginner’s Guide to Free Sample PCB Assembly in India

At PCBcircuit, we understand the importance of prototyping in the electronics industry. That’s why we offer Free sample PCB assembly in India to help innovators and engineers bring their ideas to life without the burden of upfront costs. Our experienced team provides high-quality assembly for various PCB designs, ensuring precision and reliability in every project.

#PCB manufacturer#PCB fabrication In india#custom PCB manufacturing in india#prototype PCB manufacturing#low-cost PCB manufacturer#high-quality PCB manufacturing#quick turn PCB fabrication#flex PCB manufacturer#multilayer PCB manufacturer#Best pcb manufacturer#Top 10 pcb manufacturer#Pcb manufacturer near me#Pcb manufacturer in Maharashtra#Pcb manufacturer in haryana#Pcb manufacturer in delhi#Pcb manufacturer in india#Pcb manufacturer in Bombay#Pcb manufacturer in jaipur#Best pcb assemble in hyderabad

0 notes

Text

PCB Electronic Board and the Role of Electronic Components Distributors

Printed Circuit Boards (PCBs) are essential to advanced innovation, serving as the establishment upon which electronic components are fastened to make utilitarian gadgets. From shrewd phones to mechanical apparatus, PCBs are fundamental in nearly each industry. In this article, we’ll investigate the part of the PCB electronic board, the significance of an electronic components merchant, and the centrality of circuit board components in guaranteeing smooth gadgets manufacturing.

What is a PCB Electronic Board?

A PCB Electronic Board is a pivotal component in any electronic gadget. It serves as a physical stage to interface and organize electronic components such as resistors, capacitors, and transistors through conductive pathways, flag follows, or tracks. The essential work of a PCB is to mechanically bolster and electrically interface different components, permitting them to work together seamlessly.

Types of PCB Electronic Boards

1. Single-Sided PCB: This is a clear sort where components are put on one side, whereas conductive copper follows are found on the inverse side.

2. Double-Sided PCB: In differentiate, this sort obliges components on both sides of the board, with conductive layers too on both sides.

3. Multi-Layer PCB: Numerous layers of PCBs stacked together, utilized for more complex electronic circuits, frequently seen in progressed computing frameworks and communication devices.

Importance of PCB Electronic Boards in Cutting edge Electronics

• Compact Plan: PCBs permit for the miniaturization of gadgets, empowering the creation of littler, more capable contraptions like smart phones, portable workstations, and wearable devices.

• Cost-Efficiency: Mass generation of PCBs guarantees that electronic gadgets can be made cost-effectively, whereas still guaranteeing tall performance.

• Reliability: A well-designed PCB moves forward the in general unwavering quality and toughness of electronic gadgets, as components are safely mounted and connected.

Defining an Electronic Components Distributor

An Electronic Components Distributor is crucial within the electronics supply chain. These merchants act as mediators between producers and businesses, giving a wide run of components required to collect PCBs and other electronic frameworks. Whether you're a large-scale hardware producer or a little commerce, having get to dependable merchants guarantees that you get high-quality components on time.

Role of Electronic Components Distributors

1. Wide Item Accessibility: Wholesalers give a wide choice of components, from essential things like resistors and capacitors to progressed chip and coordinates circuits.

2. Quality Confirmation: Legitimate wholesalers work with certified producers to guarantee that all components meet industry measures and are free from defects.

3. Supply Chain Productivity: Wholesalers guarantee convenient conveyance of components, lessening the hazard of delays in generation due to supply shortages.

4. Technical Bolster: Numerous merchants offer extra administrations such as specialized back and plan exhortation, making a difference producers select the right components for their particular needs.

Key Circuit Board Components

A PCB electronic board requires a assortment of components to work accurately. Here are a few of the most basic Circuit Board Components:

1. Resistors: These components direct the stream of electrical current, guaranteeing that circuits work inside secure working limits.

2. Capacitors: Capacitors store electrical vitality and discharge it when required. They are pivotal in sifting signals and stabilizing voltage in circuits.

3. Diodes: Diodes permit current to stream in one heading as it were, securing the circuit from harm due to switch current.

4. Transistors: These components act as switches or speakers, playing a critical portion in controlling the stream of electrical signals in a circuit.

5. Integrated Circuits (ICs): ICs are small chips that contain distinctive components like transistors, diodes, and resistors, allowing complex capacities to be performed on a single piece of silicon.

6. Inductors: Inductors store vitality in a attractive field when current passes through them, commonly utilized in sifting applications and control supplies.

How to Select the Right Circuit Board Components

• Compatibility: Guarantee that the components are congruous with the plan of your PCB, counting measure, control prerequisites, and execution specifications.

• Reliability: Select high-quality components from trusted producers or wholesalers to guarantee the long-term unwavering quality of your devices.

• Availability: Guarantee that the components you select are promptly accessible in the showcase, particularly if you're arranging for large-scale production.

Conclusion

PCB electronic Boards, electronic components merchants, and circuit board components are basic in the world of hardware fabricating. A well-designed PCB, combined with high-quality components sourced from dependable merchants, guarantees the effective generation of tough, high-performance electronic gadgets. Understanding these components permits producers to enhance and create the innovation that powers our advanced world.

0 notes