#industrial steel silos

Explore tagged Tumblr posts

Text

The best Steel fabrication company | AFCO STEEL

AFCO STEEL experience in structural steel design, engineering, drafting, detailing, procurement, fabrication, surface treatment and erection commitment to safety, quality and scheduling allow us to reduce risk for our clients. The result: greater peace of mind for our clients, who can trust us to deliver exactly what they need when they need it. From start to finish, we meticulously organize every project for extreme efficiency. When materials reach their destination, they are properly itemized and sequenced, drastically reducing field labour time. We are passionate about giving our clients the best products possible with delivery and service they can trust.

#steel silo manufacturers#steel storage tank#steel tank manufacturers#Steel fabrication services#steel structure company in saudi arabia#industrial steel fabrication#steel structure manufacturers#Steel product manufacturing#Steel fabrication company#Industrial steel structures#Bulk storage silos#Warehouse construction

0 notes

Text

The Ocean Sciences Building at the University of Washington in Seattle is a brightly modern, four-story structure, with large glass windows reflecting the bay across the street.

On the afternoon of July 7, 2016, it was being slowly locked down.

Red lights began flashing at the entrances as students and faculty filed out under overcast skies. Eventually, just a handful of people remained inside, preparing to unleash one of the most destructive forces in the natural world: the crushing weight of about 2½ miles of ocean water.

In the building’s high-pressure testing facility, a black, pill-shaped capsule hung from a hoist on the ceiling. About 3 feet long, it was a scale model of a submersible called Cyclops 2, developed by a local startup called OceanGate. The company’s CEO, Stockton Rush, had cofounded the company in 2009 as a sort of submarine charter service, anticipating a growing need for commercial and research trips to the ocean floor. At first, Rush acquired older, steel-hulled subs for expeditions, but in 2013 OceanGate had begun designing what the company called “a revolutionary new manned submersible.” Among the sub’s innovations were its lightweight hull, which was built from carbon fiber and could accommodate more passengers than the spherical cabins traditionally used in deep-sea diving. By 2016, Rush’s dream was to take paying customers down to the most famous shipwreck of them all: the Titanic, 3,800 meters below the surface of the Atlantic Ocean.

Engineers carefully lowered the Cyclops 2 model into the testing tank nose-first, like a bomb being loaded into a silo, and then screwed on the tank’s 3,600-pound lid. Then they began pumping in water, increasing the pressure to mimic a submersible’s dive. If you’re hanging out at sea level, the weight of the atmosphere above you exerts 14.7 pounds per square inch (psi). The deeper you go, the stronger that pressure; at the Titanic’s depth, the pressure is about 6,500 psi. Soon, the pressure gauge on UW’s test tank read 1,000 psi, and it kept ticking up—2,000 psi, 5,000 psi. At about the 73-minute mark, as the pressure in the tank reached 6,500 psi, there was a sudden roar and the tank shuddered violently.

“I felt it in my body,” an OceanGate employee wrote in an email later that night. “The building rocked, and my ears rang for a long time.”

“Scared the shit out of everyone,” he added.

The model had imploded thousands of meters short of the safety margin OceanGate had designed for.

In the high-stakes, high-cost world of crewed submersibles, most engineering teams would have gone back to the drawing board, or at least ordered more models to test. Rush’s company didn’t do either of those things. Instead, within months, OceanGate began building a full-scale Cyclops 2 based on the imploded model. This submersible design, later renamed Titan, eventually made it down to the Titanic in 2021. It even returned to the site for expeditions the next two years. But nearly one year ago, on June 18, 2023, Titan dove to the infamous wreck and imploded, instantly killing all five people onboard, including Rush himself.

The disaster captivated and horrified the world. Deep-sea experts criticized OceanGate’s choices, from Titan’s carbon-fiber construction to Rush’s public disdain for industry regulations, which he believed stifled innovation. Organizations that had worked with OceanGate, including the University of Washington as well as the Boeing Company, released statements denying that they contributed to Titan.

A trove of tens of thousands of internal OceanGate emails, documents, and photographs provided exclusively to WIRED by anonymous sources sheds new light on Titan’s development, from its initial design and manufacture through its first deep-sea operations. The documents, validated by interviews with two third-party suppliers and several former OceanGate employees with intimate knowledge of Titan, reveal never-before-reported details about the design and testing of the submersible. They show that Boeing and the University of Washington were both involved in the early stages of OceanGate’s carbon-fiber sub project, although their work did not make it into the final Titan design. The trove also reveals a company culture in which employees who questioned their bosses’ high-speed approach and decisions were dismissed as overly cautious or even fired. (The former employees who spoke to WIRED have asked not to be named for fear of being sued by the families of those who died aboard the vessel.) Most of all, the documents show how Rush, blinkered by his own ambition to be the Elon Musk of the deep seas, repeatedly overstated OceanGate’s progress and, on at least one occasion, outright lied about significant problems with Titan’s hull, which has not been previously reported.

A representative for OceanGate, which ceased all operations last summer, declined to comment on WIRED’s findings.

5K notes

·

View notes

Text

Even though it's constructed of thick concrete-insulated walls, built into the hillside, concrete floors, steel I beams, and custom made steel doors, it still has lots of glass and is above ground, so how can it be an apocalypse house? Built in 2004 in Willow Creek, Montana, it has 1bd (screw everyone else), 2ba, $850K.

Greenhouse has a glass ceiling and contamination can creep into the soil.

I just don't get this house.

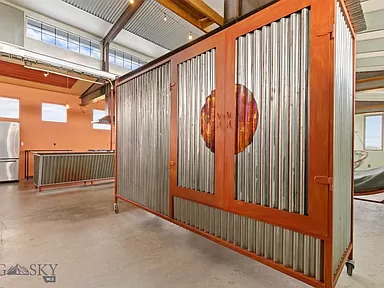

Huge living room/kitchen space. This structure in the corner is the kitchen.

Not sure what this is above the kitchen.

Behind the kitchen counter. This is seriously industrial.

Combination bath/utility room.

Storage cabinet on wheels acts as a divider between the bedroom and living area.

A rear entrance has a small lofted area and goes down to the bedroom.

Entrance to bath #2 is behind the screen.

Industrial style farm doors.

The 2nd bath is a shower room.

I don't know what this building is, but it's partially underground.

40x60 shop on the property has a separate 500-gallon propane tank.

The grain silo is an art studio that comes equipped with 2 kilns.

27.87 acres. There are no restrictive covenants or zoning, so you have the freedom for multiple uses including, but not limited to, commercial, industrial, recreational, agricultural, small business, residential, and farming.

95 notes

·

View notes

Text

After a long span of not remembering any dreams, last night I had a couple doozies.

The first dream: (mix of first and third person perspectives, my character was me-but-not-me) took place in some kind of gargantuan facility buried under ice and snow. One of those classic unrealistic video game style locations implying the existence of some group with enough power to ship tens of thousands of tons of concrete and steel to build a (half-submerged!) sprawling industrial-scientific facility on some isolated arctic coast, in total secrecy.

I can't remember a lot of the details, which is tragic because I have the impression it was a rousing adventure story. There were at least three major interests there: one a detachment from a government, one well-funded private group, and then the people I was with, hapless cash-strapped adventurers that thought we were... getting ocean salvage? It had a shit-load of twists and betrayals, and I remember sobbing in a locked vault after the woman that lead my crew trapped me there so she could take the science-macguffin (or something??) to the rich heiress (whom she was also fucking). Can't remember how I escaped.

The climactic denouement was after the facility defenses activated and shot down the government helicopter detachment and sank the heiress's luxury icebreaker ship. A bunch of us were inside a massive silo of a room with a colossus sized robot woman that constantly rained sparks from her head and shoulders.

Dream number two: (first person, me as myself), my niece was sick so I brought her soup.

Dream three was some kind of... Handmaiden's Tale thing, crossed with a bit of Equilibrium, featuring a messianic John Wick esque character‽‽‽ (mostly first person, me as some me-like character, a member of the violence master's inner circle; a third person bit like a flashback when he told some story.)

If a person had written this as a story I would've said it was some kind of parable about the use of violence to change the world.

The deal was, this guy was actually preaching peace! He lead a non-violent movement! But the hyper authoritarian religious conservative government kept trying to do him in with violence out of some institutional ego-crisis, and every time someone pointed a gun at him he would Rambo his way through the squads. Like, at one point he willingly went to some kind of government diplomatic facility as part of some kind of "peace talk", and when they decided to forcibly take him prisoner (despite giving their assurances that they wouldn't), he escaped, killing dozens of guards on his way out. He left them alive if they dropped their guns.

The dream definitely also had a lot of color theory stuff. Women mostly wore these massive, over-elaborate dresses of white lace to indicate solidarity with the government, while the rebellious groups wore functional and plain clothing. I had a raggedy brown suit, and the leader guy wore a black suit. Red played a big part too; and not just in the obvious red blood on white suits and dresses aspect. I think the military/police type Enforcers wore red and white tuxedo like uniforms.

I wish I could remember more of this dream's plot too (even if it leaned a bit more into symbology than I prefer). There was this big deal final confrontation with some kind of big procession or motorcade. The President-for-Life was either naming their heir or getting married or something, and Jesus Wick was going to protest it by blocking traffic. He begged me not to but I showed up with a sniper rifle and posted up on a nearby building. And then, uh... I... woke up? Briefly? By falling asleep in the dream? Or something like that? And when I came to, there were literally hundreds of the enforcers dead, but they'd finally killed our guy. There was a hysterical young woman (in the big white dress) talking about the oceans of blood she saw come out of this one man, more than one person could possibly hold.

I staggered drunkenly around this nearby... shopping complex? That had been cordoned off for the enforcers to hold prisoners. The few left were all so weary and exhausted that they barely paid attention to me. I found a couple of my compatriots dead, and then one of the women chained, spread-eagled, in the middle of an open area. I broke off her manacles and we just kind of staggered off as the dream ended.

3 notes

·

View notes

Text

All-Steel Stress, Blast and Coating

All-Steel Stress, Blast & Coating is a subsidiary steel heating treating company under the All-Steel Brand. All-Steel Stress, Blast and Coating provides heat treatment of steel, thermal stress relieving, industrial sandblasting/steel shotblasting and steel coating of: Fabricated weldments Machined parts Machine components Dry Outs

Their Massachusetts Facility offers a 40 Ton lifting capacity, 20 Ton forklift capacity and a dedicated, professional staff with over 50 years of combined experience in thermal stress relieving, sandblasting and priming/painting.

Thermal Stress Relieving, also referred to as Stress Relieving, Heat Treating, Post Weld Heat Treating (PWHT) and can also be referred to as annealing.

In our new, state of the art industrial size stress relieving oven we can stress relieve: Fabricated Weldments for post-weld heat treatment Machined Parts Metal Components In addition, we provide dry-out services for paint and refractory process curing. Our furnace will operate between 250 degrees F and 1600 degrees F. We perform quality inspections during the stress relieving process and we can provide our customers with Certificates of Compliance and detailed Heat Charts when required.

Our Stress Oven can accommodate customer jobs that are 12’H x 11’ W x 31’L and our rail-car capacity is 54,000lbs.

We meet the following standards: ASME Section I: (900 – 1300F) Stress relieve /post -weld heat treat in accordance with ASME Sect. I, PW-39 for carbon steel weldments. ASME Section VIII: (900 – 1300F) Stress relieve/post-weld heat treat in accordance with ASME Sect. VIII, USC-56 for carbon steel weldments. AWS D1.1 (900-1200F): Stress relieve/post-weld heat treat in accordance with AWS D1.1, 5.8 for carbon steel weldments. Westinghouse 83030QA: (1175F +/- 25F) Westinghouse-approved stress relieve procedure for carbon steel welded structures. General Electric P8A-AG1, P10G-AL-0003 & 0004: (1125 – 1275F, 1125-1200F and 125-1300F) General Electric-approved stress relieve procedures for carbon steel. Standard Stress Relieve: (1100-1200F) Applied to ferrous materials to reduce residual stresses for improved dimensional stability or reduced risk of premature failure in service. Low Temperature Stress Relieve: (325-775F) Typically applied to stainless steel and aluminum welded fabrications to reduce residual stresses with little or no effect of the corrosion resistance and/or mechanical properties. Industrial Sandblasting Services, also referred to as shot blasting can be done in our state-of-the-art facility in Central Massaschusetts. Our new, industrial-size facility provides our customers with sandblasting for: Fabricated Weldments Machined Parts Metal Frames and Components

In our modern, clean blast room, our experienced blasters can accommodate the most specific blast media required for the job. We can blast customer jobs that are 16’H x 13’W x 30’L; and we have 40,000lbs rail-car capacity for our blasting facility.

Steel Coating Services: Industrial Priming, Painting and Coating for Steel and other Metals. Our new coating facility will be capable of providing priming/painting/coating services up to 16’H x 20’W x 50’L and weigh up to 80,000lbs. Our painters have extensive experience coating: Fabricated Weldments Industrial Machine Bases Industrial Frames Construction Equipment Holding Tanks & Silos

Address: 84 Creeper Hill Road,North Grafton MA 01536 Phone: (508) 839-4471

Our Social Pages:

facebook

twitter

linkedin

youtube

pinterest

3 notes

·

View notes

Text

Stainless Steel Silos: Durable and Efficient Storage Solutions for Modern Industries

Stainless Steel Silos: Durable and Efficient Storage Solutions for Modern Industries

In today's fast-paced and competitive industries, efficient storage solutions are paramount. Whether you're dealing with grains, chemicals, powders, or other bulk materials, the right storage system can make all the difference in ensuring smooth operations. Stainless Steel Silos, offered by Shijiazhuang Zhengzhong Technology Co., Ltd. (Center Enamel), provide a durable, reliable, and high-performance solution for bulk storage needs.

Our stainless steel silos are designed to meet the rigorous demands of various industries, ensuring that stored materials remain secure, clean, and easily accessible. With superior corrosion resistance, customizable design, and long-lasting performance, our silos are the ideal choice for businesses that require a high-quality storage solution.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Why Choose Stainless Steel Silos?

1. Exceptional Durability and Corrosion Resistance

One of the primary reasons for choosing stainless steel silos is their exceptional durability and corrosion resistance. Stainless steel is naturally resistant to rust, corrosion, and various chemicals, making it an ideal material for storing bulk materials, especially those exposed to moisture, extreme weather, or harsh environments. This ensures that your stored goods remain safe and intact without the risk of contamination or degradation over time.

2. Hygiene and Cleanliness

In industries such as food processing, pharmaceuticals, and chemicals, maintaining a high standard of hygiene is critical. Stainless steel is non-reactive, smooth, and easy to clean, preventing contamination from external sources. Unlike other materials, stainless steel does not retain odors or residues, ensuring that your stored products remain pure and uncontaminated. This makes stainless steel silos a preferred choice for food-grade storage applications, as they are capable of meeting strict regulatory standards for cleanliness.

3. High Strength and Structural Integrity

Stainless steel is known for its high tensile strength and structural integrity, ensuring that silos can withstand heavy loads and high pressures. Whether you're storing dry or liquid materials, our stainless steel silos offer robust performance, preventing any structural issues that could compromise the safety and efficiency of your storage system.

4. Long-Term Investment and Cost Efficiency

While stainless steel may have a higher initial cost compared to other materials, its long-term performance makes it a cost-effective investment. The corrosion resistance and minimal maintenance requirements ensure that your stainless steel silos will serve you for years to come, minimizing the need for repairs or replacements. This makes them a highly cost-effective solution in the long run.

5. Customizable Design for Specific Needs

At Center Enamel, we understand that different industries have different storage needs. That's why our stainless steel silos can be customized to meet the exact specifications of your business. Whether you need silos for grain storage, liquid storage, chemical storage, or other bulk materials, we offer a variety of sizes, shapes, and features to fit your specific requirements.

Key Features of Center Enamel’s Stainless Steel Silos

1. Superior Corrosion Protection

Our stainless steel silos are designed to provide optimal corrosion resistance, ensuring the longevity and integrity of your storage system. This is particularly important for industries that handle moisture-sensitive or aggressive materials.

2. Hygienic Storage Solutions

The non-porous surface of stainless steel makes it easy to clean and prevents the growth of bacteria, mold, and other contaminants. This feature is essential for food-grade storage and pharmaceutical applications where contamination can lead to significant quality issues.

3. Modular Design for Easy Installation

We offer modular designs for easy transportation and quick installation. This reduces downtime and makes it easier to install large-scale storage solutions with minimal disruption to your ongoing operations.

4. Compliance with Industry Standards

Our stainless steel silos comply with international standards and industry regulations, ensuring that they meet the safety, hygiene, and quality standards required for your industry. Whether you're in the food, chemical, or agricultural sector, our silos are designed to meet your needs.

5. Advanced Safety Features

Our silos are equipped with advanced safety features, including ventilation systems, overflow protection, and level monitoring to ensure smooth and safe storage of materials. These features enhance the safety and efficiency of your storage system, minimizing risks associated with overflows or pressure build-ups.

Applications of Stainless Steel Silos

Stainless steel silos are highly versatile and can be used across various industries for storing bulk materials. Some of the most common applications include:

1. Grain Storage

Grain storage is one of the most common uses of stainless steel silos. These silos offer excellent protection against pests, moisture, and contamination, ensuring that grains remain dry, clean, and safe for consumption or processing.

2. Food and Beverage Industry

The food and beverage industry demands strict hygiene and sanitation standards, which makes stainless steel the perfect material for storing ingredients, powders, and liquids. Stainless steel silos ensure that materials remain uncontaminated and retain their quality during storage.

3. Chemical Industry

In the chemical industry, it's essential to store raw materials and finished products safely. Stainless steel silos offer superior chemical resistance, making them ideal for storing a wide range of chemicals without risk of corrosion or contamination.

4. Pharmaceutical Industry

The pharmaceutical industry requires hygienic and non-reactive storage systems to ensure that materials like active pharmaceutical ingredients (APIs) and other sensitive compounds are stored in a safe environment. Stainless steel silos provide the necessary cleanliness and chemical resistance for such applications.

5. Plastic and Powder Storage

For industries that handle plastics or powders, stainless steel silos provide a secure and efficient storage solution. These silos help maintain the quality of powdered materials while preventing contamination or moisture absorption.

Why Choose Center Enamel for Stainless Steel Silos?

1. Proven Track Record

With over 30 years of experience, Center Enamel is a leading manufacturer of high-quality bulk storage systems. Our stainless steel silos are trusted by industries worldwide for their durability, safety, and performance.

2. Customization and Flexibility

We offer customizable solutions to meet the unique needs of your business. Whether you need a silo for grain, liquid, or chemical storage, we can design and manufacture a solution that fits your exact requirements.

3. International Certifications

Our stainless steel silos meet global standards for safety, hygiene, and environmental compliance. We hold certifications including ISO 9001 and NSF/ANSI, ensuring that our products meet international quality standards.

4. Exceptional Customer Support

At Center Enamel, we are committed to providing exceptional customer support. From the initial consultation to installation and ongoing maintenance, we ensure that you receive the highest level of service at every stage of your project.

Stainless Steel Silos offer a durable, reliable, and hygienic solution for storing bulk materials across various industries. Whether you need to store grains, chemicals, powders, or liquids, Center Enamel provides high-quality silos that meet your specific needs. Our customizable, corrosion-resistant, and easy-to-maintain silos are designed to offer long-term performance and value.

For industries that require secure and efficient storage systems, Center Enamel’s Stainless Steel Silos are the ideal choice. Contact us today to learn more about how our stainless steel silos can meet your storage needs and provide a sustainable solution for your business.

0 notes

Text

Considerations for Cement Cooling Processes

In cement production, the cooling process plays a crucial role in ensuring the quality and performance of cement. The cement cooling process mainly consists of two methods: online cooling and post-storage cooling. The latter method is particularly suitable for processes that require strict temperature control due to its large cooling range and controllable temperature. To ensure effective cooling and the normal operation of equipment, it is essential to pay attention to several key issues during application.

1. Local Cooling Issues

When using a single silo cooling process, cement exits the silo, enters the cooler, and then returns to the same silo via an elevator. This method may lead to a situation where the cooler's discharge temperature meets the requirements, but the temperature of the material released from the silo remains high and does not meet standards. The root cause of this phenomenon lies in the formation of a material flow channel between the silo's entrance and exit. Since the material flows continuously in and out, other materials in the silo cannot enter this channel, resulting in rapid cooling of the material in the channel while the rest remains inadequately cooled.

To solve this problem, I recommend using a dual-silo process. Specifically, the material from one silo passes through the cooler and enters another silo. If the temperature still does not meet the requirements, the material can be released from the second silo and returned to the first silo for a cyclical operation. This method effectively improves cooling efficiency and ensures that the cement temperature meets the standards.

2. Cement Caking Issues

During storage, temperature differences often cause cement to cake on the walls of the silo, especially in steel silos. As the cement level decreases, some of these caked materials may fall off and enter the cooler along with the cement. The accumulation of these caked materials can affect the moving parts inside the cooler and may lead to mechanical failures.

To address this issue, I suggest installing equipment to remove cement caking before the cooler or setting up inspection ports at appropriate locations on the cooler. This allows for regular cleaning of the caked cement, ensuring the normal operation of the equipment.

3. Expansion Box Issues

The expansion box phenomenon occurs when cement fills the cooler's housing. Mechanical action causes the cement to expand, leading to deformation of the cooler's housing and potentially causing blockages or damage to mechanical parts. This situation primarily arises when the discharge amount from the silo exceeds the processing capacity of the cooler or elevator.

To resolve this issue, I recommend installing flow-stabilizing feeding equipment under the silo. This ensures that the discharge amount does not exceed the processing capacity of the cooler and elevator, thereby avoiding overload situations.

Conclusion

The external circulation cooling process of cement silos plays a vital role in cement production. Through proper process design and equipment maintenance, we can effectively enhance cooling efficiency and ensure cement quality. I hope the above suggestions provide valuable insights for industry professionals and contribute to the smooth operation of cement production.

If you would like to learn more about the external circulation cooling process of cement silos or have any questions, please feel free to contact us. We look forward to providing you with professional support and services!

0 notes

Text

All you need to know about the ISO Tank containers | INOXCVA

In the realm of global logistics, the efficient and safe transportation of bulk liquids, gases, and powders is paramount. ISO tank containers have emerged as a pivotal solution, offering a standardised, reliable, and versatile method for transporting a wide array of substances across various modes of transport.

Understanding ISO Tank Containers

An ISO tank container, commonly referred to as an ISO tank, is a stainless steel vessel encased within a protective frame built to the specifications of the International Organisation for Standardisation (ISO). This standardisation ensures uniformity in dimensions and design, facilitating seamless integration across different transportation systems, including road, rail, and sea. Typically, these containers measure about 6 meters in length, 2.4 meters in width, and between 2.4 to 2.5 meters in height, with capacities ranging from 21,000 to 40,000 litres.

Advantages of ISO Tank Containers

Safety and Durability: Constructed from high-grade stainless steel and equipped with insulation and protective layers, ISO tanks are designed to withstand the rigours of transportation. Their robust construction ensures a long lifespan, typically between 20 to 35 years, making them a cost-effective investment.

Versatility: ISO tanks are suitable for transporting both hazardous and non-hazardous materials, including chemicals, food-grade liquids, gases, and powders. This versatility makes them indispensable across various industries, from chemical manufacturing to food and beverage processing.

Efficiency: Designed for intermodal transport, ISO tanks can be easily transferred between different modes of transportation without the need to unload and reload the contents. This intermodal capability reduces handling times and minimises the risk of contamination or spillage.

Types of ISO Tank Containers

ISO tanks are categorised based on the type of cargo they are designed to carry:

Standard Tanks: Used for non-hazardous liquids such as food-grade oils and juices.

Specialised Tanks: Designed for specific cargoes, including:

Refrigerated (Reefer) Tanks: Equipped with cooling systems to transport temperature-sensitive liquids.

Gas Tanks: Built to carry gases under pressure, such as liquefied petroleum gas (LPG) and ammonia.

Silo Tanks: Intended for the transport of dry bulk materials like powders and granules.

Lined Tanks: Feature specialised linings, such as rubber, for transporting corrosive acids and chemicals.

Applications Across Industries

The adaptability of ISO tank containers allows them to serve a broad spectrum of industries:

Chemical Industry: Transporting both hazardous and non-hazardous chemicals safely and efficiently.

Food and Beverage: Ensuring the hygienic transport of edible oils, juices, and other consumable liquids.

Pharmaceuticals: Maintaining the integrity of sensitive pharmaceutical ingredients during transit.

Energy Sector: Facilitating the movement of liquefied natural gas (LNG) and other energy-related substances.

INOXCVA's Commitment to Excellence

As a leader in cryogenic engineering, INOXCVA offers a comprehensive range of ISO tank containers tailored to meet the diverse needs of various industries. Our tanks are engineered with precision, adhering to stringent quality standards to ensure safety, reliability, and longevity.

Key Features of INOXCVA's ISO Tanks

High-Quality Materials: Using premium stainless steel and advanced insulation materials to maintain product integrity.

Customisation: Ability to design tanks for specific applications, including refrigeration options, specialised linings, and pressure ratings.

Global Compliance: Manufactured in accordance with international standards, ensuring compatibility and acceptance across global markets.

Conclusion

ISO tank containers represent a cornerstone in the modern logistics landscape, offering a safe, efficient, and versatile solution for transporting a wide range of bulk materials. INOXCVA's dedication to quality and innovation ensures that our ISO tanks meet the highest standards, providing our clients with reliable solutions tailored to their needs.All you need to know about the ISO Tank containers

0 notes

Text

A New World Rising: Tech and the Efficient Future of Innovation

A New World Rising: Tech and the Efficient Future of Innovation

The recent revelation of China's DeepSeek, or Shendu has hit the tech world wth the ferocity of a hypersonic missile. Apparently China, like most, smart targetted economies were working to become self sufficient. While the new technology is a function of innovation, it also demonstrates something fundemental about human development and capacity. We see in DeepSeek thathuman capacity cannot be stifled, and wherever it is stifled it will move to better environs.

DeepSeek has not only been revealed to be a far superior AI model, but also more cost. Efficient. Business Insider reported that the new open source is cost competitive and has higher inference speed. And this does make greater sense, as Al-Arabia News reported that China increased its R&D to 500 million USD in 2024. And that number is expected to rise after even more after its 8.3 percent rise from 2023.

Western trade and tech sanctions have forced China and the international world to look elswere for innovation, trade partners, growth and financial levity without rancor or coercion. Most nations like people, seek greater freedoms and not less. The world has chafed of living under threat for its success and strides toward modernity. Punitive measures have limited result and often create entrenched enemies rather than docile and compliant partners. Particularly as the world watches the unfortunate results of purported friendships.

MSN reported Japanese chip stocks fell after the DeepSeek unveiling. Like Japan, Korea and other non-Western allies have also staked their fortunes and futures on the empty promises of a friend-shored world that maintains the old hegemonic order. A concept that fails the test of supply chain and efficient innovation. The old order is unravelling on its own. The self delusion is palpable along with its staggering losses, which the Biden Administration demonstrated when it torpedoed the robust US Steel and Nippon Steel acquisition, Reuters reported. Talks are currently in the works for a new deal via Activist Ancora to halt all merger talks and oust the US Steel CEO.

The US has been mobilizing its oligarchs and billionaires to save the US economy and various industries teetering on the verge of collapse. Tech unfortunately falls among those sensitive industries as Silicon Valley dries up and innovation and funding lock up in silos of limited access. Therefore those with exclusive access are tasked with discovering the fix. Therefore, the gravity cannot be lost that Berkshire Hathaway has bought billions in unwanted US treaauries and CNA Insider reports Bloomberg has indicated an intent to fund UN climate initiatives under the Paris Agreement. The Tesla owner has been leveraged heavily by the Pentegon and the Biden Administration on everything from rocket science, satelites and social media platforms.

But take a closer look, these mechanizations are inefficient and slow. They do not possess the dynamics of people to people process which requires the voluntary participation of the general population in innovation, industry and economic growth. This late stage model decline can be seen in various similar form nations. These silos make saving the economy and industry clunky and slow. The reams of regulations, anti-small business measures and low liquidity make innovation in the system clumsy. In fact the averice for greater profits, valuations and cloistered investors networks often bolster good ideas, but not great ideas that innovate or lead to market dominance. And while a closed market may be dominated through policy and controls, an open world market teuly cannot. It will find a way

Instead of inclusive reinvention and innovation, aging technology becomes forced and over monetized without adequate user benefit. Even access is made difficult and algorithms work against users making new tech less and less enjoyable or useful in some enclaves. A death nell for innovation. The pending Tiktok ban offers a great example of slick, modern tech weighed down by reams of regulation and protectionism--paranoia if you will. Roughly one week before the initial Tiktik ban in January, thousands of US users CrowdPlatformed a Chinese app called Xiaohonshu or Red Notebook. An Estimated 500,000 migrated to that similar app. There is handwriting on the wall if one cares to read it.

There will be old tech and new tech in the future. The most efficient and cost effective may win the day. Much as we see the power of supply chain and the revitalization of novel international trade relations, the world has a mandate to grow. And as we see with DeepSeek/Shengdu it will grow. Western industry began globalizing in earnest in the 1960s, but tech is globalizing powerfully again in the present age.

Former colonial states and colonies often grapple with this delima as well. They are often too married to the concept of class and tribal stratification to harness the ingenuity of all their citizens. Resources are always behind a paywall and therefore growth is incremental and small. The 10 percent in those economies cannot innovate like a well resourced and supported 90 could. Early US growth was enormous because it had free labor and intellectual property which it leveraged from its enslaved class. Also many Western Eurozone states had access to US advancement and a massive footprint in Africa, Asia and Latin America. That footprint is shrinking, by a slowing population and less valuable financial status Such measures were also undergirded in a small way by its diversity measures which were recently scrapped.

And as these new tech measures revolutionize the market, the need for special minerals will grow. It will be necessary to move excavation, mining and sale into a more organized system. Currently the upheavals in central Africa and other mineral rich enclaves underscore this need. The advanced age is moving toward efficiency and not just access. It will be necessary to change the dialogue surrounding the free movement of "rebels" and mercenary groups and weapons to create systems that fit the future and more modern supply chains. The tech leaders of the future will become more efficient.

It will be interesting to see how nations will grow by applying a limited approaches to innovation and latent talent pools. Many Western states are cutting off their lifeline to talent domestically. There will be silent revolts like the Tiktok Crowdplatforming as local populations realize they have been disenfranchised. More financial, intellectual, educational and resource prohibitions will only serve to slow innovation and economic growth in needed areas. That is apparent.

Shendu technology reveals not only its innovation, but its freedom to innovate. It also demonstrates that many quadrants of the world are growing more savvy on their own, growing more advanced, and more strategic over time. Many have falsely assumed the world would sit still and wait. Or that the world would follow them into more restrictions that limit innovation and global competitiveness. Rather, some states have taken the initiative to move forward in powerful ways.

Change is constant, and the new DeepSeek AI reveals just that. It also reveals that some states when forced to innovate answer the call. Punitive sanctions and adversarial geopolitical moves are forcing nations to become more competent and more self reliant. They are creating an entirely new world. Many are not relying on financial gifts and status quo umbrage to merely maintain. Many are making their own way, and it seems in the future we will all have to follow their lead

Geochange is on:

+TikTok @geochangeworld

+Podcastle.ai +Odysee.com

○ htps://www.tumblr.com/gcworld

○ https://www.quora.com/profile/GeoChange-World

○ http://odysee.com/geochangeworld

0 notes

Text

Rockstar 400 Plate

Vandan Steel & Engg. Co. can become a recognized industry, capable of producing and supplying high-quality ROCKSTAR 400 blades. We are customer-oriented and supply these boards in several standards, widths, lengths, heat treatments and styles . Specifications for special applications also can be provided. Our products meet various quality standards. The wear-resistant ROCKSTAR 400 PLATTEN welding plate has good versatility, like formability, hardness, wear resistance and flatness. Manufacturing requirements.

Rockstar 400 has been delivered to customers on the average . Specially developed waste recycling can ensure minimal ductility.Rockstar 400 is right for yellow mining products. Kstar 400 is that the ideal solution for applications like excavators, crushers and truck linings. It also can be found in silos, excavators, conveyor pipes and silos. vacuum , sweeping and tilting the ground . The label is reinforced to make sure the mechanical properties of ROCKSTAR 400. it'll harden quickly and harden again when necessary. After use, it cannot maintain any exchange state outside the temperature range of 250°C. Rockstar 400 isn't suitable. Wear-resistant plates made from manganese, carbon, molybdenum, chromium, sulfur, phosphorus, silicon, boron, nickel and other chemical materials are often used. The palette are often utilized in a spread of applications. These inserts are equipped with heated cutting edges.Various processes like cutting, testing, forming, machining, grinding, etc. are usually performed on these plates with none problems.

ROCKSTAR 400 Plate Specification :

Item: Abrasion Resistant Plate

Thickness : 6mm to 75mm

Length : 6,000mm to 12,000mm

Width : 1,500mm to 2,500mm

Production : Hot-Rolled (HR) / Cold-Rolled (CR)

Applications : concrete industry, metallurgy, fan industry, coal industry, mining machinery, construction machinery,etc.

Heat Treatment: N, Q+T

Material : ROCKSTAR 400 Plates, ROCKSTAR 400 Abrasion Resistant Steel Plates, ROCKSTAR 400 Wear Resistant Plates

ROCKSTAR 400 PLATES CHEMICAL COMPOSITION

Plate ThicknessCMnPSSiCrNiMoBCEPCMmmMax %Max %Max % Max % Max %Max %Max %Max %Max %MaxMax6.0 – 20.00.161.600.0250.0100.700.500.250.250.00400.450.2821.0 – 32.00.181.600.0250.0100.701.000.250.250.00400.480.2932.1 – 50.00.221.600.0250.0100.701.400.500.600.00400.570.3350.1 – 75.00.221.600.0250.0100.701.400.500.600.00400.650.40

ROCKSTAR 400 PLATES MECHANICAL PROPERTIES

Hardness360-430 BHN (On a milled surface 0.5-2 mm below the plate surface)Yield Strength (MPa)Tensile Strength (MPa)% ElongationImpact at -30°C(L0=50 mm)(In Joules)Typical values for 20 mm100012501240

0 notes

Text

Steps for Cleaning and Inspecting Bulk Storage Silos

Discover essential steps for cleaning and inspecting bulk storage silos to maintain efficiency and safety. Learn from expert insights on silo manufacturers, stainless steel silos, and industrial steel silos for quality storage structures.

#Bulk storage silos#silo manufacturers#bulk storage silos manufacturers#stainless steel silo manufacturers#industrial steel silos#silo tank manufacturers#quality storage tanks & silos#bulk storage structures#steel storage structures

0 notes

Text

Marigold Services

As a leading provider of innovative solutions for the grain storage and poultry industries, Marigold Services has established itself as a trusted name in Pakistan. Proudly serving as the local representative of GSI International (USA), Marigold Services brings world-class expertise, cutting-edge technology, and unparalleled reliability to agricultural and commercial operations nationwide. Partnering with GSI International GSI International is renowned worldwide as a leading manufacturer of steel farm and commercial storage bins and silos. By partnering with this industry giant, Marigold Services delivers products that combine durability, efficiency, and advanced engineering. The technologically advanced grain storage solutions and material handling systems offered by Marigold Services cater to the diverse needs of farmers and commercial enterprises, ensuring optimum performance and productivity. Comprehensive Grain Storage Solutions Proper grain storage is vital for preserving the quality of crops and ensuring their long-term usability. Marigold Services provides state-of-the-art grain storage solutions designed to meet the needs of farms and commercial facilities of all sizes. 1. Steel Storage Bins and Silos Marigold Services offers a wide range of steel bins and silos designed to handle large volumes of grain securely. Manufactured by GSI International, these structures are built to withstand environmental challenges while maintaining the integrity of stored grain. 2. Material Handling Systems Efficient grain movement is critical for seamless operations. Marigold Services provides an extensive selection of material handling systems, including: Grain Bin Sweeps: Ensure complete cleanout of grain storage bins. Grain Spreaders: Achieve even grain distribution within bins. Grain Dryers: Maintain optimal moisture levels to preserve grain quality. Chain Loop Systems: Enable quick and efficient grain movement. Bucket Elevators: Transport grain vertically with minimal energy consumption. Chain Conveyors and Enclosed Belt Conveyors: Move grain securely and efficiently over short and long distances. Poultry Solutions for Growing Businesses In addition to grain storage, Marigold Services supports poultry businesses by providing solutions that enhance operational efficiency and productivity. The company’s offerings are designed to meet the specific needs of poultry farms, ensuring they can thrive in a competitive market. Why Choose Marigold Services? 1. Expertise You Can Trust Marigold Services leverages its partnership with GSI International to provide globally recognized products and solutions. With in-depth knowledge of the grain storage and poultry industries, the company is well-equipped to address the unique challenges faced by its clients. 2. Technologically Advanced Solutions The products offered by Marigold Services are at the forefront of technological innovation. From automated grain handling systems to robust storage silos, every solution is designed to deliver superior performance. 3. Tailored to Your Needs Marigold Services understands that no two businesses are alike. That’s why the company offers customized solutions that align with the specific requirements of each client, ensuring maximum efficiency and value. 4. Commitment to Quality Quality is a cornerstone of Marigold Services. Every product and service is carefully evaluated to meet the highest industry standards, providing clients with peace of mind and long-term reliability. 5. Local Support with Global Standards As the local representative of GSI International in Pakistan, Marigold Services combines the benefits of global innovation with the convenience of local support. Clients can rely on prompt assistance, expert guidance, and efficient after-sales services. Transforming Agriculture and Poultry in Pakistan With a mission to empower the agriculture and poultry sectors, Marigold Services is committed to driving growth and innovation. By delivering cutting-edge grain storage and handling solutions, the company helps clients optimize their operations, reduce losses, and maximize profitability. Contact Marigold Services Today Ready to take your grain storage or poultry business to the next level? Marigold Services is here to help. Contact us to learn more about our products, services, and how we can support your business goals. Make the smart choice with Marigold Services – where expertise meets innovation. Read the full article

0 notes

Text

Concrete Batching Plants in Guyana

Gajjar Equipments Private Limited Offers Concrete Batching Plants in Guyana.

Our Compact Concrete Plants Manufacturing Unit is based in Ahmedabad, Gujarat, India.

Gajjar Equipments Private Limited Stationary Concrete Batching Plants are engineered for robust storage, uniform mixing, and high-production demands.

We Designed to deliver reliability and long-lasting performance, these plants set the industry standard. Whether your project is large or small, our stationary batching plants offer a complete concrete production solution.

Available Models: GECS-60 GECS-75 GECS-90 GECS-120 GECS-160 GECS-200 GECS-240

With the ability to handle substantial production volumes, they are ideal for a variety of construction projects.

The stationary batch mix plants ensure a consistent mix, resulting in high-quality concrete for every batch.

Generously Dimensioned Mixing Platform: Designed for optimal mixing efficiency. Quick Installation: Pre-assembled modules ensure fast setup and reduced installation time. Modular Construction: Allows for easy access to all components for maintenance. Heavy-Duty Chassis: Built with structural steel for enhanced durability and stability. High Productivity: Short cycle times and uniform concrete quality increase overall productivity. Efficient Dosing System: Simultaneous dosing of aggregates, sand, water, and cement for faster mixing and reduced cycle time.

Components of Static Concrete Batching Plant: Aggregate Bins: Store different types and sizes of aggregates like sand, gravel, and crushed stone. Conveyor Belts: Move aggregates from the bins to the mixing unit. Mixing Unit: The heart of the batching plant, ensuring uniform concrete mix. Control Panel: Allows operators to monitor and control the plant’s performance. Cement Silos: Store cement for mixing and production. Water and Additive Tanks: Store water and additives to be mixed with the concrete.

FAQs. Q1: What capacity ranges are available for your concrete batching plants? A1: Our concrete batching plants come in various models ranging from 60 M3 to 240 M3, catering to different production needs.

Q2: How fast can your batching plants be installed? A2: Our plants are designed for quick installation with pre-assembled modules, reducing the overall setup time significantly.

Q3: Can your batching plants handle large projects? A3: Yes, the GEC-S plants can handle both small and large projects with high production demands, offering exceptional mix output and consistency.

Q4: Do you offer maintenance and support for the batching plants? A4: Yes, we provide ongoing maintenance and support services, ensuring the smooth operation of the batching plants throughout their lifecycle.

Gajjar Equipments Private Limited Offers Concrete Batching Plants in Guyana and including locations Georgetown, Linden, New Amsterdam, Anna Regina, Princetown, Bartica, Crabwood Creek, Parika, Rose Hall, Lethem, Uitvlugt, Rosignol, Mahdia, Kwakwani, Skeldon, Mahaicony Village, Saint Cuthberts Mission, Cane Grove, Windsor Forest, Karasabai Village, Charity, Paramakatoi, Adventure, Annandale, Mabaruma, Clonbrook, Port Kaituma, Port Mourant, Onderneeming, Aishalton, Karaudanawa, Orealla, Den Amstel, Santa Rosa Mission, Sand Creek Village, Marurawaunawa Village, Belladrum, Hosororo, Monkey Mountain, Ituni, Hampton Court, Awaruwaunawa, Achiwib, Kamwatta Hill, Koriabo, Yupukarri, Capoey, Sawariwaunawa, Saint Francis Mission, Kumaka, Annai, Queenstown, Vreed-en-Hoop, Kabakaburi, Kato Village, Matthews Ridge, Dadanawa, Barakara, Kamarang, Woweta Village, Weldaad, Hiawa, Santa Mission, Surama Village, Apoteri, Imbaimadai, Hyde Park, Rockstone, Zeelandia, Fort Wellington.

For more information or to request a quote, feel free to contact us today!

0 notes

Text

Exploring the Benefits of Concrete Precast Molds for Sale

In the ever-growing construction industry, efficiency, durability, and innovation are paramount. One solution that meets these needs head-on is the use of concrete precast molds. As a cornerstone of modern construction practices, these molds are revolutionizing how builders approach various projects. If you are considering concrete precast molds for your next project, here’s a detailed look at their benefits and applications. With Moldtech, a trusted leader of precast concrete equipment, you can access high-quality concrete precast molds for sale designed to meet your needs and deliver exceptional results.

What Are Concrete Precast Molds?

Precast concrete molds are specially designed frameworks used to shape and produce precast concrete elements. These molds are typically made from materials like steel, fiberglass, or polyurethane, ensuring durability and reusability. The precast concrete components created using these molds can range from simple blocks and tiles to complex architectural elements such as columns, beams, and decorative facades.

Why Choose Precast Molds?

Quality and Precision

Molds provide a high level of accuracy, resulting in uniform shapes and dimensions for each precast component. This precision minimizes material waste and enhances the overall quality of construction.

Cost-Effective

While the initial investment in molds might seem significant, their reusability makes them cost-effective in the long run. A single mold can produce hundreds of components, saving money on materials and labor.

Versatility

Concrete precast molds come in various shapes and sizes, offering flexibility for diverse construction needs. Whether it’s for residential, commercial, or industrial projects, there’s a mold to suit every requirement.

Durability

Precast molds are designed to withstand repetitive use and harsh working conditions, ensuring a long lifespan. This durability makes them a reliable asset for construction companies.

Applications of Concrete Precast Molds

Concrete precast molds are widely used in a range of applications, including:

Infrastructure Projects: Bridges, tunnels, and retaining walls.

Residential Construction: Precast walls, flooring panels, and decorative elements.

Commercial Buildings: Façades, columns, and beams.

Landscaping: Garden pavers, benches, and boundary walls.

Industrial Applications: Precast tanks, silos, and utility vaults.

Where to Find High-Quality Concrete Precast Molds

When investing in precast molds, it’s essential to choose a reliable supplier. Look for manufacturers that offer:

A diverse range of mold designs.

Durable and high-quality materials.

Competitive pricing.

Excellent customer support.

Online marketplaces and specialized construction equipment retailers are excellent places to find concrete precast molds for sale. Ensure you read reviews and inquire about customization options to meet your specific needs.

Concrete precast molds are a game-changer in modern construction, offering speed, quality, and cost-efficiency. By investing in the right concrete precast molds for sale, you can elevate the standards of your projects and achieve remarkable results. With Moldtech’s innovative solutions and commitment to quality, you can ensure that your construction projects are built to last. You can also check our precast tilting table for your next project. Ready to learn more? Explore our blog for additional insights and share your thoughts and experiences.

#concrete precast molds for sale#precast concrete molds#precast tilting table#precast concrete equipment

0 notes

Text

Pre Engineered Steel Structures | New Life Steel

New Life Steel offers pre-engineered steel structures designed with flexibility in mind. Our customizable solutions cater to a range of industries, including agriculture, manufacturing, and logistics. Built to withstand diverse weather conditions, our structures ensure safety and efficiency. From design to delivery, we focus on meeting your specific requirements with precision pre engineered steel structures

Revolutionizing Construction: Pre-Engineered Steel Structures

The construction industry has witnessed significant advancements over the years, and pre-engineered steel structures (PES) stand out as one of the most transformative solutions. Designed with precision and assembled with efficiency, PES have redefined the possibilities for a wide range of projects. From industrial buildings to residential complexes, the versatility and practicality of these structures make them an ideal choice for modern construction.

Defining Pre-Engineered Steel Structures

Pre-engineered steel structures are systems where all the components, such as frames, roof panels, and wall panels, are pre-designed and fabricated in a factory. These components are then transported to the site for quick assembly. This method eliminates the need for extensive on-site work and ensures a streamlined construction process. PES are tailored to meet specific requirements, making them suitable for various applications.

Advantages of Pre-Engineered Steel Structures

Accelerated Construction:

Pre-fabrication allows simultaneous site preparation and component manufacturing, significantly reducing project timelines.

Assembly is straightforward, minimizing delays associated with traditional construction.

Cost Efficiency:

Optimal use of materials and reduced labor costs make PES a budget-friendly option.

The absence of on-site fabrication reduces overall expenditure.

Design Flexibility:

PES can be customized to accommodate diverse requirements, including unique shapes, sizes, and load capacities.

The modular nature of PES allows for future expansions with minimal disruption.

Superior Strength and Durability:

Steel’s inherent strength ensures that PES can withstand harsh environmental conditions, including high winds and seismic activity.

Corrosion-resistant coatings enhance longevity, reducing maintenance needs.

Sustainability:

Steel is 100% recyclable, and the construction process generates minimal waste.

The energy efficiency of PES contributes to reduced carbon footprints in operational phases.

Space Optimization:

PES enable the creation of large, column-free spaces, which are crucial for warehouses, auditoriums, and manufacturing units.

Applications of Pre-Engineered Steel Structures

Industrial Facilities:

Factories, warehouses, and logistics hubs benefit from PES due to their spacious layouts and ability to accommodate heavy equipment.

Commercial Buildings:

Office complexes, shopping centers, and exhibition halls leverage PES for their contemporary designs and rapid construction.

Agricultural Structures:

From grain silos to livestock shelters, PES cater to diverse agricultural needs while offering robustness and weather resistance.

Infrastructure Projects:

Bridges, railway stations, and airports use PES for their large spans and structural integrity.

Residential Developments:

Modern housing projects are increasingly adopting PES for their aesthetic appeal and cost savings.

Why Choose Pre-Engineered Steel Structures?

The demand for faster, more efficient construction methods has driven the adoption of PES. Beyond their practical benefits, these structures embody modernity and innovation. Their lightweight yet robust framework reduces the burden on foundations, making them suitable for challenging terrains. Additionally, PES adapt seamlessly to future technological integrations, such as solar panels and smart building systems.

Conclusion

Pre-engineered steel structures have emerged as a cornerstone of contemporary construction. Their blend of speed, affordability, and sustainability addresses the pressing demands of urbanization and industrialization. By providing durable and customizable solutions, PES ensure that functionality and design go hand in hand. As the world seeks greener and smarter construction practices, pre-engineered steel structures are set to lead the way, reshaping skylines and redefining possibilities in the built environment.

0 notes

Text

Galvanized Steel Process: A Comprehensive Guide

Galvanized steel is a cornerstone of modern construction and industrial applications, prized for its durability, corrosion resistance, and long-term performance. The key to its resilience lies in the galvanization process, which involves coating steel or iron with a protective layer of zinc. This article explores the galvanized steel process step by step, providing a deeper understanding of its benefits and applications.

What is Galvanized Steel?

Galvanized steel is steel that has been coated with a layer of zinc to protect it from corrosion. This zinc layer acts as a barrier against environmental elements such as moisture and oxygen, which can cause rust and weaken the material over time. The galvanization process is particularly beneficial for steel used in construction, automotive, and agricultural industries, where exposure to harsh conditions is common.

The Galvanization Process

The galvanization process typically involves hot-dip galvanizing, a method that ensures a durable and uniform zinc coating. Here is a step-by-step breakdown of the process:

1. Surface Preparation

Degreasing: The steel is cleaned using an alkaline solution to remove grease, oil, and dirt. This ensures the zinc coating adheres properly.

Pickling: The steel is immersed in a bath of diluted acid to remove rust, scale, and other surface impurities.

Rinsing: The steel is rinsed thoroughly to remove residual chemicals, ensuring a clean surface for galvanizing.

2. Pre-Fluxing

The cleaned steel is dipped into a flux solution, typically containing zinc ammonium chloride. This step prevents oxidation before the steel is immersed in molten zinc, ensuring a uniform coating.

3. Hot-Dip Galvanizing

The steel is submerged in a bath of molten zinc at a temperature of approximately 450°C. The zinc reacts with the steel surface, forming a series of zinc-iron alloy layers. This process not only provides a strong bond but also enhances the durability of the coating.

4. Cooling and Inspection

After the steel is removed from the zinc bath, it is cooled in water or air. The coated steel is then inspected for uniformity, thickness, and any surface imperfections to ensure quality.

Benefits of the Galvanized Steel Process

Corrosion Resistance: The zinc coating acts as a barrier and provides sacrificial protection, preventing rust even if the coating is scratched.

Durability: Galvanized steel has a long service life, often exceeding decades, even in harsh environments.

Low Maintenance: Once galvanized, steel requires minimal upkeep, reducing maintenance costs over time.

Versatility: The process is suitable for a wide range of steel products, from structural beams to small bolts and fasteners.

Eco-Friendly: Zinc is a recyclable material, and the process itself aligns with sustainable practices in construction and manufacturing.

Applications of Galvanized Steel

Galvanized steel is used in a variety of industries, including:

Construction: Structural beams, roofing, and fencing.

Automotive: Body panels and chassis components.

Agriculture: Irrigation systems, silos, and farm equipment.

Infrastructure: Bridges, highways, and utility poles.

Energy: Solar panel frames and wind turbines.

Conclusion

The galvanized steel process is a critical innovation that has revolutionized the durability and utility of steel. By providing a robust protective layer, it ensures that steel products can withstand the test of time and harsh conditions. Whether for large infrastructure projects or everyday applications, galvanized steel is an essential material for building a sustainable and resilient future.

To learn more about galvanized steel and its wide-ranging applications, visit Galvanizers Connect with industry experts for high-quality galvanizing services tailored to your needs.

0 notes