#impacttest

Explore tagged Tumblr posts

Text

Impact Test: Ensuring Material Strength and Durability

Impact test is a crucial procedure used in various industries to assess the toughness and durability of materials under sudden force or impact. This test helps determine how well a material can withstand sudden shocks, ensuring that it is strong enough for applications in construction, automotive, aerospace, and manufacturing industries.

The impact test is essential for evaluating the ability of materials to resist fracture under high-stress conditions. It helps engineers and manufacturers select the right materials for structures, machinery, and components that require high impact resistance. By simulating real-world forces, this test provides insights into the structural integrity and safety of materials used in critical applications.

There are different types of impact tests, with the Charpy and Izod tests being the most commonly used. The Charpy test measures the energy absorbed by a material when struck by a weighted pendulum, while the Izod test evaluates a material's notch sensitivity and toughness under sudden impact. Both tests provide valuable data for quality control and material selection.

Impact testing is particularly important for construction materials, as it ensures that building components such as steel beams, concrete structures, and safety barriers can withstand external forces like wind, earthquakes, or accidental collisions. In the automotive industry, impact tests help assess the crashworthiness of vehicle components, enhancing passenger safety.

In addition to safety, impact testing plays a key role in regulatory compliance. Industries must meet strict quality standards, and impact tests help ensure that materials adhere to international safety guidelines. This is especially important for manufacturers producing materials for high-risk environments, such as oil and gas facilities, bridges, and industrial plants.

Regular impact testing is crucial for maintaining quality and durability in products. It helps identify material weaknesses early, preventing costly failures and ensuring that end-users receive high-performance products. By investing in professional impact testing services, businesses can enhance product reliability, reduce risks, and meet industry standards.

0 notes

Text

https://www.wattpad.com/1513270339-the-head-game-chapter-24-a-question-of-balance

The Head Game – Chapter 24: "A Question of Balance" is here! Eric’s concussion recovery takes center stage as he undergoes the ImPACT test, a pivotal moment in his journey. Will he match his baseline? Can he regain his footing, both mentally and physically?

This chapter is packed with tension, heart, and a touch of humor. Catch up now on Wattpad and join the conversation!

0 notes

Text

Common Problems Solved by Falling Weight Impact Testers

Discover how falling weight impact testers help solve everyday issues in material testing. This post breaks down the common problems and how these testers improve accuracy, reliability, and safety in quality control processes.

Follow for more testing equipment insights and quality control tips!

0 notes

Text

💥 Stronger Products, Fewer Returns! 💥

Ensure your products withstand real-world drops with Pacorr’s High-Precision Drop Testers! ✅

🔹 Adjustable Drop Heights 🔹 Accurate & Reliable Impact Testing 🔹 Meets ASTM, ISTA & ISO Standards 🔹 Ideal for Packaging, Electronics, Automotive & More!

📦 Protect your products, enhance quality, and boost customer trust!

📲 Upgrade your testing today! Visit 👉 Pacorr.com

#Pacorr#DropTester#StrongerProducts#QualityControl#DurabilityMatters#ImpactTesting#Manufacturing#DropTesting#DropTesterPrice#DropImpactTester

0 notes

Text

At SKG Lab, we’re more than engineers—we’re the problem solvers shaping tomorrow. 🌟 From groundbreaking research to innovative solutions, we tackle challenges head-on to create a brighter, smarter future. Whether it’s precision in tensile strength testing, accuracy in impact testing, or reliability in hardness testing, our expertise drives excellence in every project. Join us on our journey to engineer possibilities into reality. 🌍⚙️ Get in Touch: 🌐 www.skglab.com 📞 +91 22 2756 2145 📧 [email protected] 📍 Navi Mumbai

#engineeringinnovation hashtag#skglab hashtag#tensiletesting hashtag#impacttesting hashtag#hardnesstesting hashtag#civilengineeringlab hashtag#mumbai hashtag#india

0 notes

Text

What is the Standard for the Falling Dart Impact Test?

The falling dart impact test is crucial for evaluating the impact resistance of materials such as films and sheets. The standard procedures for this test are primarily outlined in ASTM D1709 and ISO 7765. These standards provide detailed methodologies for measuring how well a material withstands impact forces.

For accurate and reliable results, it's essential to use a high-quality dart impact testing machine. The Dart Impact Testing Machine offers precise measurement of impact resistance, ensuring compliance with industry standards.

Want to ensure your materials meet the highest quality and durability standards? Discover the capabilities of our advanced Dart Impact Testing Machine and see how it can enhance your testing processes.

Curious to learn more? Click the link to explore our top-rated Dart Impact Testing Machine and elevate your material testing standards: Dart Impact Testing Machine

#DartImpactTester#MaterialTesting#QualityControl#PrecisionTesting#LabEquipment#TestingSolutions#IndustrialTesting#ImpactResistance#FilmTesting#SheetTesting#PanelTesting#ReliableResults#TestingEquipment#QualityAssurance#InnovativeTesting#MaterialStrength#PrecisionMeasurement#ImpactTesting#DurabilityTesting#EngineeringTools#ResearchEquipment#TestWithConfidence#TestingExcellence#TopQualityTesting#PerformanceTesting#AdvancedTesting

0 notes

Photo

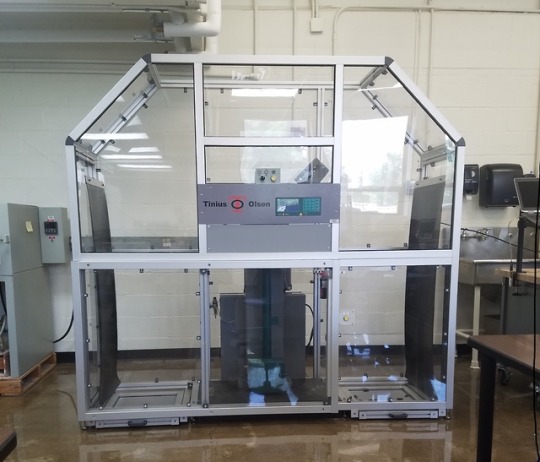

Cincinnati State Technical College, a Tinius Olsen Success Story

Tinius Olsen has helped one of the leading Technical Colleges in America, the Cincinnati State Technical and Community College, to up-grade and further develop its materials testing laboratory.

This is the culmination of a partnership between the two organisations that goes back to the establishment of the College in 1969, as Mike DeVore, Professor & Program Chair of the Mechanical Engineering Technology & Welding Technology Dept explains:

“I started teaching at Cincinnati State 29 years ago and at that time we had a very old Tinius Olsen tensile test machine that still worked extremely well on a day to day basis.”

“Our testing lab had been in operation since almost the establishment of the school so we decided to update our lab in 1993 and, due to the reliability and generally good history that we had with the old machine, I decided to purchase another from Tinius Olsen.”

“I visited the factory in Pennsylvania and was very impressed with the quality of work and professionalism of the employees at the company, so we purchased our second Tinius Olsen machine, a 60L Super L Tensile Tester. Again we enjoyed great service with the machine until the controls unfortunately failed last year.”

“Fortunately, we had obtained funding to upgrade our materials test lab with all new equipment and it was a relatively easy decision to once again look to Tinius Olsen, thanks in the main to the great experience we have had with the company over the years. It was also important to me to try to purchase American made equipment, whenever possible.”

The machines installed at the Colleges’ testing lab are a 10,000 In/lb Bench Top Torsion Tester, a Model IT406 Pendulum Impact tester, four Rockwell and one Brinnel Hardness Testing machines, as well as retro-fitting the 60L Super L. This has resulted in a substantial investment by the College into their state of the art testing laboratory, which should see at least another 30 years problem free use.

“The new equipment is used in several courses within our Mechanical Engineering Technology, Welding Technology, and Civil Engineering Technology programs. The primary use is in our MET 140 Engineering Materials course where our students spend the semester doing destructive testing.”

“Between the three programs we have over 500 hundred students - all of which will use this lab at some point in their curriculum. The tests we currently perform within the lab include Tensile, Bend, Hardness, Torsion and Impact testing as well as Heat treating.”

Cincinnati State Technical and Community College, which is celebrating its 50th anniversary this year, provides student-focused, accessible, high-quality technical and general education, academic transfer, experiential and cooperative education and workforce development.

The College offers more than 130 associate degree and certificate programs through its four academic divisions and the Workforce Development Center.

“We have a long history with Tinius Olsen. We have used their material testing equipment for nearly 50 years here at Cincinnati State and intend to keep the relationship intact for years to come. They are a great American company and we are proud to use their equipment to educate our students,” continued Mr DeVore.

“Through the use of our Tinius Olsen equipment we are able to prepare our students to go out into industry with a thorough knowledge of material testing. Tinius Olsen test equipment is used by many of our employers and they appreciate the fact that our students are learning to use industry standard equipment.”

#testing#education#cincinnati#commitment#support#cincinnatistatecollege#materialstesting#students#programs#hardnesstesting#tensile testing#torsion#engineering#technology#impacttest#degree#courses#curriculum#equipment#madeinusa#prepare#employers#industry#standards#teaching#testing labs#reliable#relaibility#rockwell#brinell

1 note

·

View note

Text

CDG conduct impact protection test in Mumbai, India. CDG is an accredited testing services in India. Impact testing is testing an object's ability to resist high-rate loading. An impact test is a test for determining the energy absorbed in fracturing a test piece at high velocity. Most of us think of it as one object striking another object at a relatively high speed. WHY IS IMPACT TESTING IMPORTANT? Impact resistance is one of the most important properties for a part designer to consider, and without question, the most difficult to quantify. The impact resistance of a part is, in many applications, a critical measure of service life. More importantly these days, it involves the perplexing problem of product safety and liability. One must determine: The impact energies the part can be expected to see in its lifetime. The type of impact that will deliver that energy, and then Select a material that will resist such assaults over the projected life span Molded-in stresses, polymer orientation, weak spots (e.g. weld lines or gate areas), and part geometry will affect impact performance. Impact properties also change when additives, e.g. coloring agents, are added to plastics. DUCTILE VS. BRITTLE, Most real world impacts are biaxial rather than unidirectional. Further complication is offered by the choice of failure modes: ductile or brittle. Brittle materials take little energy to start a crack, little more to propagate it to a shattering climax. Other materials possess ductility to varying degrees. Highly ductile materials fail by puncture in drop weight testing and require a high energy load to initiate and propagate the crack. Many materials are capable of either ductile or brittle failure, depending upon the type of test and rate and temperature conditions. They possess a ductile/brittle transition that actually shifts according to these variables. Please contact us on +919643077962 Visit our website https://www.cdginspection.com/

#india#Impactprotectiontest#impactprotection#cdginspectionlimited#cdg#testservicesinmumbai#testing#IK#impacttest

0 notes

Text

Plastic Impact Tester

Determine the mechanical properties like Izod, Charpy, Tension, Impact of metals, plastics, composites, and other materials with Plastic Impact Tester from Tinius Olsen Limited, U.K.

http://bit.ly/2vatUYt

0 notes

Video

instagram

Impact Test ICS Glasses at 3.5 Joules using 0.45gr bb. Prueba de las gafas de ICS a 3.5 Julios. En el video de Youtube de mi canal estoy sorteando una de las gafas, solo tienes que ir al video de mi canal de youtube y comentar. @icsbbairsoft #dpa #dpairsoft #ics #icsglases #airsoft #impacttest #glasses

0 notes

Photo

Испытываем углепластиковые клюшки Российского производства на ударную прочность #заряд #cct_kai #инстрон #центркомпозитныхтехнологий #работа #impacttesting #impacttest #testing #testinglab #compositecarbon #compositetechnologylab #instron #science #research #технологиякомпозитов #испытание #исследование #разработка #углепластик #композитныематериалы #каи #казань #кафедрапла #cctkai (at КАИ)

#заряд#compositecarbon#казань#инстрон#технологиякомпозитов#кафедрапла#испытание#testing#science#cct_kai#testinglab#углепластик#композитныематериалы#research#исследование#работа#compositetechnologylab#impacttesting#impacttest#cctkai#каи#центркомпозитныхтехнологий#instron#разработка

0 notes

Text

https://www.wattpad.com/1513267191-the-head-game-chapter-23-what-an-impact

Chapter 23: "What an IMpact" is LIVE!

The tension is HIGH, the stakes are HIGHER, and Eric’s future hangs in the balance. As the Cleveland Crusaders fight to keep their playoff dreams alive in a nail-biting Game 7, Eric sits on the sidelines, battling his own demons. Will his ImPACT test reveal he’s ready to return to the ice? Or will he be forced to watch as his team fights without him?

🔥 Relive the heart-stopping moments of Games 5 and 6, where Slava Dropniak stands on his head, P.J. DeBlaker shines, and the Crusaders claw their way back into the series.

💔 Eric’s frustration is palpable. He wants to be the difference—not just a spectator. But with his concussion recovery still up in the air, the question remains: Can he make it back in time to help his team when it matters most?

📖 Dive into the latest chapter of The Head Game and feel the adrenaline, the heartbreak, and the hope as Eric’s journey takes another dramatic turn.

👉 Read it now and join the conversation! What would YOU do in Eric’s skates? Drop your thoughts below! 🏒

#TheHeadGame#HockeyDrama#PlayoffPressure#ImPACTTest#EricVsTheIce#Wattpad#WattpadBooks#SportsFiction#HockeyLife#PageTurner#MustRead#WattpadMustRead#EmotionalReads#TeamEric#HockeyRomance#WattpadCommunity

0 notes

Text

iPhone 7 Plus 5.5 Funda para cinturón Original Encased [slimshie

Proveedor: Encased Tipo: Estuches Precio: 17.95

Encased Somos una empresa orgullosos de nosotros lo esencial productos que nosotros mismos amor para uso diario Nuestro Core creencia es simple El diablo vive en los detalles It es el Pulgadas Pulgadas pequeno pero Vital cambios para que la diferencian de diseno e ingenieria promedio de productos de la gran intuitiva ones Disenos que pueden integrar perfectamente en nuestra vida diaria Aqui esta filosofia se llama PulgadasLa XFactor Pulgadas El BAR que con orgullo Set We medida de cada producto solo por su abilty operar sin problemas a traves de meses y anos de uso repetido Hemos probado y retest cada diseno para garantizar la version final se Siempre cumplir con esta referencia Que es la nueva sencilla razon de nuestros clientes siguen regresando para sus accesorios Mas alla de la calidad del producto Respaldamos cada compra con knowledgeable Ingles hablando y un servicio de atencion al cliente incondicional PulgadasGarantia de Lifetime felicidad Si son cualquier cosa menos satisfecho Con tu compra nuestro equipo trabajara con usted hasta que son realmente feliz La experiencia de la diferencia de Encased hoy Preguntas comunes Q Auriculares Apple permitira trabajar con este caso? A Si| el slimshield esta disenado para dar cabida a los auriculares EarPods de Apple asi como la mayoria de otros modelos Q ¿Como puedo registrar el producto para garantia? Una garantia de por favor| visite nuestra pagina web| seleccione el Tab usted facilmente puede activar la garantia en linea Q se puede utilizar un protector de visualizacion con esta carcasa? A Si| la funda tiene un perfil bajo borde frontal por lo que es compatible con la mayoria de los Protectores de visualizacion Q El clip se puede utilizar WEl telefono hacia fuera? Una manera puede| mas frecuentes que con el construido en funcion atril para ver peliculas Q ¿El clip para cinturon gira? A Si| el clip se puede llevar tanto en vertical o horizontal basado en preferencias del usuario

Built Awesome – aqui son solo algunas de las slimshields muchos grandes caracteristicas superficie de suciedad y manchas| de alta calidad| acabado ligero construccion de PCR| diseno ergonomico| antideslizante Micro| raisedlip Protector de visualizacion y la lista es interminable Reforzado con clip – la beltclip se ajusta facilmente 180 ° de rotacion SecureFit Holster es robusta para uso diario fiable uso tanto para diestros y zurdos Suregrip – acabado de tacto suave anade proteccion y hace que su telefono facil y comodo agarre recortes de puerto y boton de facil acceso para adaptarse casi todos los cables de carga y auriculares Disenado en los Estados Unidos aqui| con practico y la durabilidad en mente slimshields son impacttested para ofrecer una proteccion superior contra los golpes y contusiones de uso diario Anadir al carrito para experimentar la diferencia| cada producto incluye una garantia incondicional vida felicidad respaldado por nuestro amable y experto equipo de soporte

Informacion importante Diagonal visible en pantalla 6 14 cm

Otras caracteristicas

Color Smooth Black

Marca Encased

Modelos de telefono compatibles Iphone 7 plus| Iphone7 plus| Iphone7 plus| Apple iphone 7 plus 55| Iphone 7 plus

Tipo de sujetador Clip On

Dimensiones del producto 63 x 32 x 3 pulgadas

Peso del producto 0023 onzas

ASIN B01LYCHZPM

Numero de modelo del producto IP7PSLIMHBKL

Opinion media de los clientes 212 calificaciones

43 de 5 estrellas

Clasificacion en los mas vendidos de Amazon nº69,557 en Celulares y Accesorios Ver el Top 100 en Celulares y Accesorios

nº2,087 en Fundas y Clips de Celular

Is Discontinued By Manufacturer No

Producto en amazoncom desde Septiembre 29| 2016

Fabricante Encased

source https://www.electroika.com/products/iphone-7-plus-5-5-funda-para-cinturon-original-encased-slimshie

0 notes

Text

Impact Testing: Determining One’s Strength!

I know what you’re thinking and NO this article is not about Hercules or someone who is powerful or strong. This article is about testing the strength of materials. Have you ever wondered how the durability and strength of a material are tested? For starters, of course, their impact is measured which is, of course, called Impact Tests.

Impact tests are tests simply designed to measure the resistance of an object in a collision, falling objects or a blow. It measures the Impact Energy or the energy absorbed by the object after a collision. The common methods that are used in measuring Impact energy are Charpy Test and Izod Test.

Impact Energy

It measures the work done to make damage to a specimen.

For example, there is object A and B. Object A is the striker and object B is the object to be observed. When object A strikes object B, object B will receive damage and create a deformation. The test will continue until Object B occur damage.

This is the measurement of how strong an object is. Remember that brittle materials have low impact strengths than those with high impact strengths. Impact tests are conducted by impact testers.

IZOD TEST

Izod test is the standard test made for plastics and other materials. It is commonly used to test the toughness or impact energy of materials. This test is commonly used for quality controls wherein it needs to be fast and cheaper.

Here are the factors that can affect the Izod test:

Ductility

Notches or incision at an edge of a surface

Temperature

Fracture mechanism

Materials

The specimens used in this test vary in which material will be tested. Commonly, metallic samples have a square in cross section. On the other hand, plastics or polymeric tests are rectangular with parallel struck to a long axis.

PROCEDURE OF THE IMPACT TEST

The specimen is placed like a pendulum. Let’s assume again that object A is the striker and object B is the material to be tested. Object B is placed at the bottom of Object A or the striker. Object A will swing in a vertical direction and Object B will receive the impact. Different sizes of Object A are used to utilize the toughness and brittleness of an object.

Aside from the impact, the temperature of the object is also a common factor to consider in testing the durability of an object. They are usually placed in a freezer until they show signs of brittleness then removed from the freezer for the second test of temperature.

This temperature test is used to test the ductility to the brittleness of an object. Carbon steels usually undergo this procedure since steels are known to change their brittleness depending on the temperature applied to them

UNITS OF MEASUREMENT

Strikers used in measuring the impact energy are no doubt has a stored kinetic energy. ISO and ASTM are the standards in measuring the impact strengths. ISO system is measured by kj/m2 wherein the impact energy (kj) is divided in the cross area or (m2). While ASTM is J/m where the impact energy is divided by the length of the notch.

0 notes

Photo

(via Mike Hopper, MS, ATC on Twitter: "Education of sport related injuries/conditions #NATM2017 Another part of being a Safe Sports School.. this time presenting @impacttest https://t.co/m6YONT9F1C")

0 notes

Text

Dart Impact Testers

A Dart Impact tester or Dart Drop Tester is a lab testing instrument that is used to measure the Impact Resistance of Plastic film, Coated paper, and Composite sheets. The dart weight expresses the energy required to tear or puncture the test specimen. This method is also known as Free Falling Dart Impact test.

#dartimpacttesters#darttesting#impacttesters#dartimpact#testingequipment#qualitycontrol#producttesting#materialtesting#industrialtesting#manufacturing#productdevelopment#engineering#safetytesting#durabilitytesting#impactresistance#productquality#testingstandards#qualityassurance#productperformance#reliabilitytesting

0 notes