#how to measure camshaft

Explore tagged Tumblr posts

Note

OMG I'm such a dumbass I knew you did one on the GR Yaris before too, and I love her ALSO, but I actually meant the GR Supra 😳🫣 (slip of the tongue)

Gotcha.

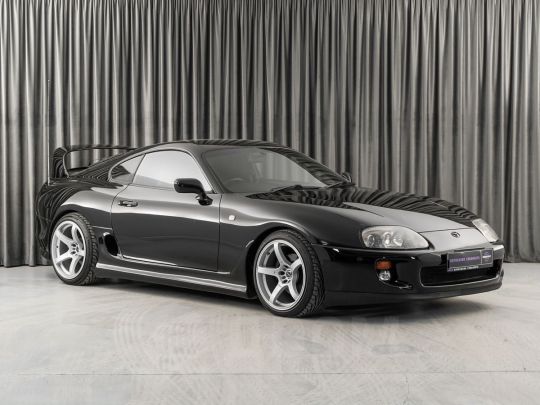

Since I managed to take some two weeks to answer this (got distracted both by real life obligations and other posts that were meant to be very quick to make. Meant to.) y'all may have forgotten, but our dear friend of the blog had asked for opinions on the GR Yaris, hinting to its controversial status. Turns out the GR Supra is what that request, and thus that hint, was actually about - so let's talk about the car and the controversy that engulfs it.

In 1993, Toyota launched the fourth generation of its rear wheel drive sportscar (well, arguably a bit of a Grand Tourer, i.e. something more oriented to cruising than a sportscar) the Supra - which was born a quarter century earlier as a more upmarket, six cylinder version of the Celica, graduating from Celica Supra to its own dignified name with the third generation I talked about that one time I forgot to check what blog I was reblogging with.

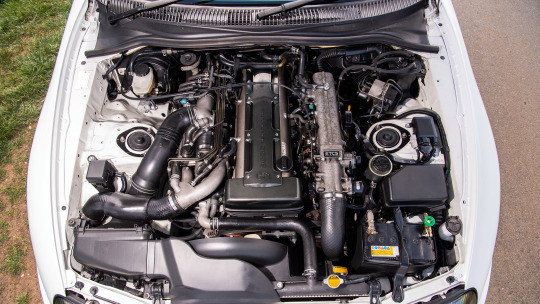

But this time, things would be different. Most notably because the inline six the Mk4 Supra came out with was an absolute MONSTER.

Remember how I talked about the GT-R's RB26 engine being one of the greatest, most coveted production engines to ever come out of Japan? Well, the 2JZ-GTE is the other.

It was larger at 3 liters, no less powerful, and to reduce turbocharger lag it used two of them sequentially: first air goes in the smaller, more responsive turbo, then gradually some of it gets sent to the bigger turbo to make it start spinning, then when it gets going the two are finally used in conjunction. (Imagine the big turbo as a hung husband that takes a while to get it up and the small turbo as an eager stepson ready to take over until the hung one can join in for a spitroast. Or something. I don't watch porn with real people, but from what I gather the plots seem to resemble how sequential turbos work.) It even at one point got Variable Valve Timing, i.e. the ability to vary the time in which the valves open depending on engine speed, which allows to optimize tuning for performance and efficiency! (Cool thing to go over in detail if y'all want me to.) And also, the kind of things that engine is able to take make me wish I hadn't used up my porn analogy quota.

See, to chop off eons of nuance, an engine is just a big block of metal with a lot of bits attached, and the two main measures of an engine's potential are the slope of the line in the Bits Fiddled With / Power Output graph and how far up (It's up, right? The second axis you specify is the vertical one, right?) you can take it before the block becomes the weakest link - with another important point being when you need to start messing with internals, i.e. the components inside the engine, e.g. pistons (the things the boom pushes down), camshaft (the thing the pistons spin) and connecting rods (you can guess).

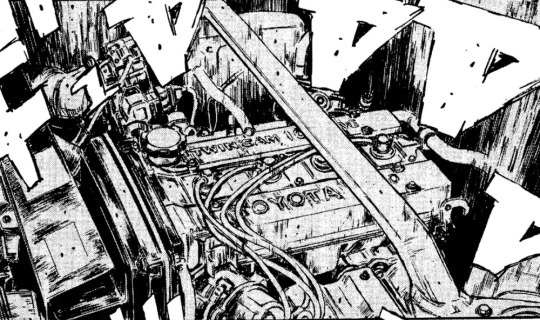

So for instance, just to make the point that an engine can be beloved without having much overall tuning potential, in one of Toyota's most beloved engines, the 4A-GE four cylinder illustrated above (yes, the one from that white and black car in all the eurobeat videos), some pin the block's limit as low as 250hp. The 2JZ, tho? It can take 800hp without even messing with the internals, and once you get your grubby hands on those you can keep pushing the line to some 2000hp. That is two Bugattis. That is 40 times my car. That is well above the power level where "tires that will at any point grip" and "tires that are in any way road legal" stop intersecting.

I am not in the slightest exaggerating when I say that this and the Skyline GT-R are widely regarded as the top of Japan's 20th century automotive production. The Messi & Ronaldo of the Japanese Domestic Market. It is absolutely no coincidence this was the hero car in The Fast And The Furious.

And then in 2002, as all things, its production ended, and given the abysmal sales and catastrophic recession, Toyota decided that would be that.

And then, years later, The Teasening began.

I want to stress, almost half of my conscious life (I choose to believe the stretch from birth to kindergarten is just run-up) the world was in some state of getting teased with talk of a new Supra. The trademark on the name was renewed in 2010. In 2014 they dropped the FT-1 concept, and of course that became speculation about what the production version would look like.

Because come the fuck on, it's not gonna look like that.

Or was it?

Only five entire years and much more teasing later would we officially get an answer, when after seventeen years, the Toyota GR Supra (and for those wondering what GR means, y'all should've clicked the Yaris link >:C) hit the streets.

You know what, good enough.

Good enough to earn itself a sea of words of praise, Jason Cammisa's "The most punch-above-its-weight sportscar ever made" just some among them.

It did have its share of problems at the start, like its power being 335hp and not 382, a lack of manual transmission, and the inability to spec it with a less powerful 4 cylinder engine - well, I don't know who considered that last one a problem, but Toyota's updates solved that one too.

The Supra has a much bigger problem than those though, one no little update can solve. That red car in the background.

See, the new Supra is actually a joint venture with BMW, who made a new model of its Z4 roadster out of the platform. And unlike with the other joint-venture sportscar Toyota sells, people are big mad about that. Why?

See, the interior is engulfed in BMW switchgear and the drivetrain is all BMW (the manual gearbox took until this year to come out because BMW did not have one for that engine so Toyota had to modify another BMW transmission to fit), giving people the impression that this was less of a joint venture and more of a BMW project that Toyota tacked its design on top of, which is a problem whether true or not.

See, a range-topping sportscar is supposed to represent what the brand is capable of - having it done by someone else (or so the criticism goes) is a bit like performing Hallelujah in playback.

Actually, a better musical analogy: You know "I'm back bitch" singles? When a humongous artist drops a new record with a humongous lead single about absolutely nothing but reaffirming they're the biggest fucking deal in the universe? Without Me, Bad, Gimme More, so on. Well, think of SexyBack - one of the most monumental phenomenons of its decade, most incontrovertibly proving Justin Timberlake sat atop the goddamn world. Now, imagine if, after all the years that went by between that record and the next, when he finally came out with Suit And Tie all the verses were Jay-Z. Going from a humongous statement about having the power to reach the top of the game and stay there to having to get absolutely carried by what in this logic is essentially a competitor. Basically, that's the critics' complaint: the supra went from 2JZ to too much Jay-Z.

And therein lies the other problem of the Supra: the Supra.

See, any time you evaluate something, you do so relative to its context - and when you give it a nameplate, you make that context include where else that nameplate has been. An undeserved name may not just be stupid, but even outright kill the car in some's eyes, see the case of the Dodge Dart, or get me to talk about the Ford Capri prototype recently spotted if you want to find out what I'm like when I lose my cool. (I'd liken this phenomenon to undeserved Grammies but I already used my music analogy quota too.) So the Toyota Supra does not just need to be good, it needs to deserve the name. And some argue it doesn't. But why? This thing is no less powerful, no slower, hell it's not even any bigger or heavier and we've gone over how rare that is these days! So is it the lack of backseats and a targa version? No, no one gives a crap about those. It's something deeper.

Sometimes, the problem with a revival is people base their expectation not on what the original was like in the context of its time but what it's like in the context of today (for example, I've heard people call the latest GT-R "too computerized, too assisted, far from the pure driving experience of its predecessors", when its predecessors had some of the most technologically advanced driving assists of their time and could only be called "pure" and "analog" by comparison with cars decades newer). But of course, that'll only be some people - so if what the original car looks like to modern eyes and what the original car represented at its time are two different enough concepts, any revival will receive some criticism for not being one of the two.

But for the Supra, this compounds with another problem: the original Supra (as in the previous generation, since no one gives a crap about the first three), to modern eyes, looks like a thousand-horsepower flame-spitting beast, because that's what all Supras have been turned into, and that's why you know of Supras in the first place (it sure isn't because people bought it!), and that, consciously or not, exacerbates the problem of misplaced expectations to a level akin to hearing an NBA player is about to have a brother and expecting the baby to be a 6'4" three-shooter.

But I wasn't asked about the controversies, I was asked about my take. And my take is: no realistic expectation of what a Supra would look like today was disappointed - at least not by where the car stands today. Well, unless the expectation involved backseats.

"But it was made by BMW" and so? This is a new Supra, and a good one - what does it matter how it got here? Especially when this is an upgrade over the Z4 in every way - looks way better, drives better, and now has a manual that the Z4 doesn't.

Okay, almost every way: the Supra's roof won't get out of the way. If only though, if only. Could you imagine a Toyota product that looks this good, sounds this good, goes this fast, and has a drop top? ...and maybe backseats?

Well, I can.

Yes, the badge and core concept may have some people consider it from midlife crisis mobile to old man's car. (though we know it's not a car bought by old men because if that was the case someone would be buying these). But just try to imagine sitting in this thing.

Take a couple of seconds to take in that picture and truly immerse yourself. You're in a Lexus LC500 Convertible, with a V8 at your right foot's command, its spectacular sound ready to battle the perfect sound system serenading you with your fanciest CD, because of course Lexuses still come with CD players.

Are you immersed? Okay: Someone just called your Lexus a midlife crisis car. See? You don't give a shit either, do ya.

Automatic only though. The pain. Oh, and it kind of costs as much as two Supras. But, you know, neither of those Supras will be convertibles!

Links in blue are posts of mine about the topic in question - if you liked this post, you might like those!

52 notes

·

View notes

Text

At Waiting's End - 6 Safe Landing

Though his originator had commed Prowl when he had boarded the last shuttle, Prowl waited on the tarmac as it came into land. Camshaft was no in anyway an impulsive mech but he was one with a deep sense of duty. If in the last moment he spotted a straggle, an unknown survivor of the carnage, Prowl knew his originator would go after them, even if that meant ordering the shuttle to leave without him. There had been no contact but there may not be due to the continued threat of the Decepticons to the transports. It had taken five mega-cycles to evacuate the ten thousand plus survivors, largely due to the need to ward off not only ground but air attacks against the transports. To Prowl’s great relief, not a single transport had been lost and this was the last one. His spark had not stopped racing for joors.

“Don’t worry, Prowl,” Bluestreak said, giving his servo a squeeze as he stood beside him. “The transport will land soon.”

The mechling had served as a good distraction. He was traumatized, how could he not be, but he was still the sweetest young mech. His entire family had been murdered, procreators, grandprocreators, uncles, aunts and cousins. There was no next of kin to contact to take custody of him. Bluestreak’s family had farmed that simple plot of land for millennia and none in their history had ever seen reason to leave. Prowl had taken formal custody of him, alongside Jazz. He was comfortable with them, both of them, but when someone spooked him, he always ran to hide behind Prowl’s doorwings, as Praxians sparklings were coded to do. Autobots, as they learned of him, wanted to spoil the war orphan but as a whole, they scared him, but none more than the Seekerkin. For now, Prowl guarded Bluestreak from the well-intention-ed and noisy with equal measure. He had heard himself called broody, as though there was something wrong with how he guarded Bluestreak and Smokescreen. It did not matter at all to him what they thought. Though, it seemed to matter to Jazz. No one raised a glyph of criticism against Prowl when Jazz was in hearing, not after Jazz had made an example of the first few.

Prowl smiled as he turned his optics to the sky. The transport was just a speck among the clouds but with each nanoklik, it came closer and clearer into view. They were not the only ones waiting on the tarmac. The youngest, the oldest and the weakest had arrived on the first transport. Still, Fixit was there to do triage and a quick visual exam of this final transport. Autobots would remain in the ruins of Praxus for another quartex or so, if they could maintain control of the area, to continue searching for survivors. There would not be many, if any. It was incredible how complete the destruction of Praxus had been but Prime would keep searchers there until his spark told him it was time to lay Praxus to rest. Perhaps it would be the wisdom of the Primes, or simply reality setting in, Prowl was not prepared to debate the legitimacy of the Matrix at this point.

The pilot landed the transport perfectly smoothly. Prowl watched the ramp descended and stared without ventilating as Autobots guided the last of his grim and resolute compatriots off the vessel. Finally, finally, Prowl saw his originator at the same moment as Camshaft saw him. He broke from the Autobots’ gentle corral in a blink. They would not know how he had done it, how they had not even one of them raised an arm to stop him. He bypassed Fixit and his medical team and the administrators in place to direct these mechanisms to their new homes. Prowl clasped his servo around his originator’s elbow as Camshaft stopped in front of him and cupped Prowl’s helm with both servos as he brought their crests together. They did not speak. For both of them, losing Smokescreen or losing each other had been the fear that had followed them with every step. Finally, they could ventilate. Camshaft lowered his helm to brush his crest against Smokescreen’s tiny helm before he looked over to Bluestreak. He knelt.

“You’re Bluestreak?” Camshaft asked.

“Uh huh,” the mechling replied. “You’re Camshaft, Prowl’s ori. I’m very pleased to meet you.”

“You are a treasure,” Camshaft replied and he brushed his crest against Bluestreak’s. “You won’t find cause with us to forget it.”

“Do you wish to wait for Fixit to finish with the others before you see him?” Prowl asked. His originator scoffed and Prowl smiled over at Jazz who gave him a questioning look.

“I know when I need a medic,” Camshaft replied.

“So that’s somethin’ ya got in common,” Jazz said and Camshaft smiled.

“If anything,” he said. “I am worse than Prowl.”

There was not much space in Jazz’s habsuite but Camshaft but there was a sofa berth in the living room. Jazz tried, he tried hard to convince Camshaft as they made their way home, that he could take the sofa berth, originator and creation could share for now. Camshaft had refused, insisting the sofa berth would be perfectly fine for him and that Jazz should be close to Prowl and Smokescreen in case they needed him. Prowl did not tell Jazz it was a losing battle from the beginning, they needed to learn each other’s quirks and Prowl knew his originator had a few. He, as Prowl had known he would, preferred to leave the emergency housing to those who really needed it. Iacon was a large territory but finding homes for ten thousand was still a strain. Temporary accommodations were being provided by the Academy, permanent housing would take longer.

Prowl was in no hurry to chase his originator away. In the stellar-cycles they had spent sabotaging Nightstalker’s purge and hiding from his security forces, they had become that much closer than they had ever been and they had always been close, as close as an originator and creation could sanely be. At least Prowl knew that Jazz would understand this attachment; he was very close to his originator and twin. Their habsuite, as Jazz insisted he should think of it as theirs, would be extra crowded when Punch arrived in the coming mega-cycles. But Prowl absolutely did not begrudge Jazz’s originator his excitement. He was thrilled to know he had a grand creation and desperate to meet not only Smokescreen but also the foundling Bluestreak. Cramped as the catacombs had been, Prowl thought the crowd would be even a little comforting.

#anon-e-miss writes#at waiting's end#valveplug#maccadams#tf prowl#tf jazz#tf bluestreak#mechpreg#bamf camshaft#bitty smokescreen

71 notes

·

View notes

Text

Porsche IMS Bearing Issues: How to Detect, Prevent, and Fix Problems

The Intermediate Shaft (IMS) bearing issue in Porsche models, particularly in the 996 and 997 generations of the Porsche 911, as well as the Porsche Boxster and Cayman, is a well-known problem that can have devastating consequences for the engine. Understanding the function of the IMS bearing, how to detect potential issues early, and the best ways to prevent or repair the problem is crucial for maintaining the health and longevity of your Porsche engine.

What is the IMS Bearing and Why is it Important?

The IMS (Intermediate Shaft) bearing is a component of the engine that supports the intermediate shaft, which drives the camshafts and ensures the proper timing of the engine’s valves. In certain Porsche models, particularly those with M96 and M97 engines, the IMS bearing has shown a tendency to fail prematurely, often due to poor lubrication. When the IMS bearing fails, it can lead to catastrophic engine damage, requiring a complete engine rebuild or replacement.

Common Causes of IMS Bearing Failure

Understanding the reasons behind IMS bearing failure can help you take proactive steps to avoid it. Here are the primary causes:

Insufficient Lubrication: Many IMS bearings are sealed and rely on lifetime lubrication that can degrade over time, leading to metal-on-metal contact and wear.

Bearing Design Flaws: Early Porsche engines used a single-row bearing in certain models, which has been found to be more prone to failure compared to the later dual-row bearings.

Aging and Wear: As the bearing ages, it can begin to deteriorate due to regular engine operation, leading to the risk of failure over time.

Symptoms of IMS Bearing Problems

Detecting IMS bearing issues early can potentially save you from costly repairs. Be alert to these common warning signs:

1. Metal Shavings in the Oil

One of the earliest and most common indicators of IMS bearing failure is the presence of metal shavings in the engine oil. Regular oil changes and the use of magnetic drain plugs can help capture these metal particles, giving you an early warning of potential problems.

2. Unusual Engine Noise

If you hear grinding, rattling, or knocking noises from the rear of the engine, it could indicate a failing IMS bearing. These sounds are due to the internal components moving out of sync due to bearing wear.

3. Oil Leaks

A failing IMS bearing may lead to oil leaks around the rear of the engine. While oil leaks can have various causes, it’s essential to investigate any leaks in Porsche models prone to IMS bearing issues.

4. Check Engine Light

In some cases, a failing IMS bearing might cause the engine's timing to go off, leading to a check engine light. If the light comes on and there are no other obvious reasons, it’s worth having the IMS bearing checked.

Preventive Measures to Avoid IMS Bearing Failure

While IMS bearing failure cannot be entirely avoided, there are steps Porsche owners can take to minimize the risk:

1. Regular Oil Changes

Frequent oil changes help ensure that your engine stays well-lubricated and reduce the likelihood of metal particles building up. This is especially important for models with sealed IMS bearings, which rely on oil around the bearing housing to prevent excessive wear.

2. Upgrading the IMS Bearing

One of the most effective preventative measures is to upgrade the IMS bearing with a more durable replacement. Many aftermarket solutions, such as ceramic bearings or oil-fed bearings, are designed to handle higher stress and provide better lubrication than the original parts.

3. Magnetic Drain Plug Installation

Installing a magnetic drain plug during your oil change can help capture any metal particles in the oil. This provides an early detection method, as the metal debris collected on the plug can indicate bearing wear.

4. Regular Inspections

Routine inspections by a certified Porsche technician can help identify early signs of IMS bearing wear. They can inspect the oil for metal particles, check for oil leaks, and evaluate any unusual engine noises.

Repair Solutions for IMS Bearing Failure

If your IMS bearing shows signs of failure, prompt action is essential to avoid severe engine damage. Here are the primary repair solutions:

1. IMS Retrofit Kit

A popular solution for resolving IMS issues is the installation of an IMS retrofit kit. These kits typically include a redesigned bearing with better durability and lubrication, allowing for a more reliable performance compared to the original part. Aftermarket kits are available from several reputable suppliers and offer various options, such as ceramic bearings or oil-fed systems.

2. Oil-Fed IMS Bearing Conversion

Another advanced solution involves converting the sealed bearing system into an oil-fed system. This modification allows engine oil to flow directly into the bearing, providing continuous lubrication. Oil-fed systems are generally more resistant to wear and have a longer lifespan.

3. Full Engine Rebuild

In cases where IMS bearing failure has already caused significant engine damage, a full engine rebuild may be required. This option is costly but ensures that any damage from bearing debris or misaligned engine components is addressed, restoring the engine to peak performance.

Final Thoughts

Porsche IMS bearing issues are a serious concern for owners of affected models, but with proactive care and the right preventive measures, you can significantly reduce the risk. Regular maintenance, monitoring for signs of wear, and upgrading the bearing if necessary are essential steps to ensure the longevity of your Porsche engine. Consulting with a certified Porsche technician and staying on top of maintenance will help keep your vehicle performing at its best, allowing you to enjoy the legendary driving experience Porsche is known for.

#porsche car#porsche ims bearing service#porsche service center#porsche car maintenance#porsche car mechanic

0 notes

Text

How Can You Verify The Quality Of A Used Range Rover 2.0 Engine?

When considering the purchase of a used Range Rover 2.0 engine, it's crucial to verify its quality to ensure reliability and performance. Understanding the key factors to look for can save you time and money while providing peace of mind. We explores the essential steps in assessing a used Range Rover 2.0 engine's condition, including visual inspections, history checks, and professional evaluations. Additionally, we’ll discuss the benefits of engine replacement and the advantages of opting for reconditioned engines, including supply and fit services.

Visual Inspection

A thorough visual inspection is the first step in verifying the quality of a used Range Rover 2.0 engine. Look for any signs of damage, corrosion, or wear and tear. Check for oil leaks, as they can indicate underlying issues such as worn seals or gaskets. Inspect the engine block and cylinder head for cracks or warping, which could compromise the engine's structural integrity. Pay attention to the condition of the belts, hoses, and wiring, as these components can give clues about how well the engine has been maintained. Additionally, examine the oil and coolant levels and their condition. Dirty oil or coolant can signal neglect or potential internal problems. Look for any unusual smells or discoloration, which might indicate contamination. Performing a visual inspection can help you identify obvious red flags and determine if further evaluation is necessary.

Engine History and Documentation

Reviewing the engine's history and documentation is vital in verifying its quality. Request maintenance records, service history, and any previous repair documentation. These records can provide insights into how well the engine has been cared for and if it has undergone any significant repairs or replacements. Consistent maintenance and timely repairs often indicate a well-maintained engine. Additionally, check the engine’s mileage. Lower mileage generally suggests less wear and tear, but it’s essential to consider how the vehicle was used. Highway miles are less taxing on an engine compared to city driving. Verify if the engine has been involved in any accidents or has undergone major overhauls. A transparent history can help you make an informed decision about the engine's quality and reliability.

Compression Test

A compression test is a crucial diagnostic tool for assessing the health of a used Range Rover 2.0 engine. This test measures the pressure in the engine's cylinders, indicating the condition of the pistons, rings, and valves. Low compression in one or more cylinders can signal significant internal problems, such as worn piston rings or leaking valves. Performing a compression test involves removing the spark plugs and using a compression gauge to measure the pressure in each cylinder. Compare the readings to the manufacturer’s specifications. Consistent and within-specification readings across all cylinders indicate a healthy engine. Significant variations or low compression readings necessitate further investigation and may be a sign to avoid the engine.

Professional Mechanical Inspection

Engaging a professional mechanic for a detailed inspection is a crucial step in verifying a used engine's quality. A trained mechanic can perform various diagnostic tests, including a compression test, leak-down test, and computer diagnostics. They can also inspect the engine's internal components, such as the timing chain or belt, camshaft, and crankshaft, for wear and damage. A professional inspection provides an expert opinion on the engine's condition and potential future issues. The mechanic can identify problems that might not be evident during a visual inspection or history check. Investing in a professional inspection can save you from costly repairs down the road and ensure you are purchasing a high-quality used engine.

Engine Replacement Options

When considering the purchase of a used Range Rover Engine, it's worth exploring engine replacement options. Sometimes, replacing the engine might be more cost-effective and reliable than repairing or rebuilding an existing one. Engine replacement involves installing a new or reconditioned engine into your vehicle, which can enhance performance and extend the vehicle's lifespan. Reconditioned engines are a popular choice for replacements. These engines have undergone a thorough refurbishment process, including cleaning, machining, and replacing worn components. Opting for a reconditioned engine ensures you are getting a unit that meets or exceeds factory specifications, providing peace of mind and reliability.

Benefits of Reconditioned Engines

Reconditioned engines offer several benefits, making them an excellent option for those seeking a quality replacement. Firstly, they undergo a rigorous reconditioning process, including disassembly, cleaning, inspection, and replacement of worn or damaged parts. This ensures the engine performs like new, meeting manufacturer specifications. Secondly, reconditioned engines are often more cost-effective than brand-new ones, providing significant savings without compromising quality. They also come with warranties, offering protection against potential issues. Additionally, opting for a reconditioned engine is an environmentally friendly choice, as it reduces waste and promotes recycling of engine components.

Supply and Fit Services

Choosing supply and fit services for your used Range Rover 2.0 engine replacement can simplify the process and ensure a seamless installation. These services provide both the engine and the installation, performed by experienced technicians. This eliminates the need to find a separate mechanic, reducing the risk of errors and ensuring the engine is installed correctly. Supply and fit services often include warranties, covering both the engine and the installation. This provides peace of mind, knowing that any issues arising from the engine or installation will be addressed. Additionally, these services can save you time and effort, as they handle all aspects of the replacement process, from sourcing the engine to fitting it into your vehicle.

Conclusion

Verifying the quality of a used Range Rover 2.0 engine involves several critical steps, including visual inspections, history checks, compression tests, and professional mechanical evaluations. Exploring engine replacement options and understanding the benefits of reconditioned engines can provide reliable and cost-effective solutions. Opting for supply and fit services ensures a seamless and hassle-free installation process. By following these guidelines, you can make an informed decision and ensure the longevity and performance of your Range Rover 2.0 engine. Read the full article

0 notes

Text

How Does the Reconditioning Process Ensure the Reliability of Ford Ranger Engines?

The Ford Ranger, known for its robust performance and reliability, has been a favorite among truck enthusiasts for years. However, like all engines, the Ranger’s engine can face wear and tear over time. This is where the reconditioning process plays a crucial role. Reconditioning, also known as engine rebuilding, involves restoring an engine to its original condition or even improving it. This process not only extends the life of the engine but also enhances its performance and reliability. In this article, we will delve into the various stages of the reconditioning process and how each step contributes to the overall reliability of Ford Ranger engines.

Initial Inspection and Disassembly

The first step in the reconditioning process is a thorough inspection and disassembly of the engine. Technicians begin by examining the engine for any visible signs of damage or wear. This includes checking for cracks, leaks, and worn-out components. Once the initial inspection is complete, the engine is carefully disassembled. Each part is meticulously cataloged and inspected for wear and damage. This step is crucial as it helps identify the components that need replacement or reconditioning. The initial inspection and disassembly ensure that no issue goes unnoticed, setting the stage for a comprehensive reconditioning process.

Cleaning and Degreasing

After disassembly, the engine components undergo a thorough cleaning and degreasing process. Over time, engine parts accumulate dirt, grease, and other contaminants that can affect performance. Technicians use specialized cleaning solutions and equipment to remove all traces of dirt and grease. This step is vital as it prepares the components for detailed inspection and reconditioning. Clean parts allow for a more accurate assessment of their condition and ensure that reassembly is free from contaminants that could cause future issues. The cleaning and degreasing process is a cornerstone of engine reconditioning, ensuring that all parts are in optimal condition for the subsequent steps.

Detailed Inspection and Measurement

Once the components are clean, a detailed inspection and measurement phase follows. Technicians use precision tools to measure each part against the manufacturer's specifications. This includes checking the cylinder bores, crankshaft, camshaft, and other critical components. Any part that does not meet the specifications is either reconditioned or replaced. This meticulous inspection ensures that only parts that meet the stringent criteria are used in the reassembly process. By adhering to these high standards, the reliability and performance of the reconditioned Ford Ranger engine are significantly enhanced.

Machining and Reconditioning

Machining is a critical phase in the reconditioning process. This step involves restoring worn or damaged parts to their original specifications. For instance, the cylinder bores may be honed, the crankshaft may be reground, and the valve seats may be recut. Advanced machinery and skilled technicians are essential in this phase to ensure precision and accuracy. The goal is to bring all components back to or better than their original condition. By doing so, the reconditioned engine can perform reliably under various conditions, ensuring the longevity and dependability of the Ford Ranger.

Replacement of Worn Parts

In addition to reconditioning existing parts, the process often involves replacing components that are beyond repair. Common replacements include pistons, rings, bearings, gaskets, and seals. These new parts must meet or exceed the original equipment manufacturer (OEM) standards. The replacement of worn parts is crucial for restoring the engine's integrity and performance. By integrating high-quality components, the reconditioned engine achieves a level of reliability that matches or surpasses a new engine. This step ensures that the engine will perform efficiently and reliably for an extended period.

Reassembly and Testing

Reassembly is a meticulous process that involves putting all the cleaned, inspected, and reconditioned parts back together. Technicians follow a precise sequence to ensure that each component is correctly installed. During reassembly, torque specifications and clearances are strictly adhered to. Once the engine is reassembled, it undergoes a series of tests to verify its performance. These tests include pressure testing, compression testing, and running the engine on a test bench. The goal is to ensure that the engine operates smoothly and efficiently. Reassembly and testing are critical in confirming that the reconditioned engine meets all reliability and performance standards.

Quality Control and Final Inspection

Quality control is an integral part of the reconditioning process. After testing, the engine undergoes a final inspection to ensure that it meets all specifications and performance criteria. This involves a detailed review of all components and a verification of the test results. Any discrepancies are addressed, and the engine is fine-tuned to ensure optimal performance. The final inspection acts as a safeguard, ensuring that the reconditioned engine is ready for reliable operation. By maintaining strict quality control standards, the reliability of the Ford Ranger engine is assured.

Documentation and Warranty

The final step in the reconditioning process is documentation and warranty provision. Detailed records of the reconditioning process, including parts replaced and tests conducted, are maintained. This documentation is crucial for future reference and for ensuring transparency. Additionally, reconditioned engines typically come with a warranty that covers potential defects and issues. This warranty provides peace of mind to the vehicle owner, knowing that the engine has been thoroughly reconditioned and is backed by a guarantee of reliability. Documentation and warranty are essential in building trust and confidence in the reconditioned Ford Ranger engines.

Conclusion

The reconditioning process is a comprehensive and meticulous procedure that ensures the reliability of Ford Ranger engines. From initial inspection to final testing and documentation, each step is designed to restore the engine to its optimal condition. By addressing wear and damage, replacing worn parts, and adhering to stringent quality control standards, the reconditioned engine achieves a level of performance and reliability that rivals new engines. For Ford Ranger owners, a reconditioned engine offers a cost-effective solution that extends the life of their vehicle while ensuring dependable performance. Through the reconditioning process, the enduring reliability of the Ford Ranger engine is preserved, providing confidence and peace of mind for its owners. Read the full article

#FordRangerEngines#FordRangerEnginesforsale#FordRangerEnginesreplacement#RECONDITIONEDENGINES#reconditionedFordRangerEngines

0 notes

Text

What is the Importance of the Common rail test bench?

In the rapidly evolving realm of automotive technology, the pursuit of enhanced engine performance and efficiency remains a constant goal. Integral to modern diesel engines is the common rail system, pivotal in achieving these advancements. Mastering and optimizing this system is crucial for both automotive engineers and enthusiasts alike. This is where the common rail test bench comes into play—a sophisticated tool that plays a vital role in testing and refining these critical systems.

Understanding the Common Rail System

The Common rail test bench depicts an improvement in diesel engine technology. It features a high-pressure pump that delivers fuel to a central manifold (the rail), which then distributes fuel to individual injectors. Unlike traditional diesel setups that relied on camshaft lobes for injector operation, common rail systems utilize electronic control to precisely manage fuel delivery to each cylinder. This innovation leads to notable gains in efficiency, reduced emissions, and overall engine performance.

The Significance of a Common Rail Test Bench

Essential for development, testing, and calibration, a common rail test bench enables engineers to replicate diverse operational conditions. By connecting components to the bench, technicians can meticulously measure parameters such as fuel pressure, injection timing, and fuel discharge rates with exceptional accuracy. This controlled environment is indispensable for evaluating the performance of injectors and pumps.

Features and Functionality

Modern common rail test benches are equipped with advanced capabilities tailored for comprehensive testing:

High Pressure Simulation: Capable of replicating the extreme pressures encountered during real-world engine operation.

Data Acquisition: Facilitates precise data collection on injector response times, fuel flow rates, and other critical metrics for thorough analysis.

Injector Programming: Allows for the customization and programming of injectors to align with specific engine requirements.

Diagnostic Tools: Identifies any anomalies or malfunctions in injector performance, thereby assisting in troubleshooting and maintenance efforts.

Applications in the Automotive Industry

Throughout the automotive sector, common rail test benches play a pivotal role in the development of new engine models and the optimization of existing ones. Manufacturers rely on these benches to ensure compliance with rigorous standards for performance, efficiency, and emissions. Service centers also utilize them extensively for diagnosing injector issues and conducting essential maintenance tasks.

Conclusion

As automotive technology advances, the common rail test bench emerges as an increasingly indispensable tool. Whether in research labs, production facilities, or service workshops, the ability to conduct precise tests and calibrations ensures that vehicles meet the stringent demands of today's automotive market.

For those intrigued by the intricate workings of diesel engine technology, exploring the capabilities of a common rail test bench provides valuable insights into the future of automotive innovation.

To delve deeper into the impact of common rail test benches on automotive technology, visit Wunfa Group and discover how these tools are shaping the vehicles.

#common rail test bench#engine parts#diesel engine parts manufacturer#diesel engine parts#remanufacture injector#pizo valve#denso valve#delivery valve#test bench#bosch injector

0 notes

Text

How Does The Reconditioning Process Improve The Performance Of A BMW 7 Series Engine?

The BMW 7 Series is synonymous with luxury, performance, and advanced engineering. As one of BMW’s flagship models, it showcases the pinnacle of the brand’s automotive technology. Over time, however, even the most meticulously engineered engines can experience wear and tear. This is where the reconditioning process comes into play. Reconditioning BMW 7 Series engine involves a series of precise and detailed steps designed to restore and often enhance the engine's original performance. We delves into how this process works and the transformative impact it has on engine performance.

Understanding Engine Reconditioning

Engine reconditioning is a comprehensive process aimed at restoring the engine to its optimal state. It involves disassembling the engine, cleaning and inspecting each part, replacing worn components, and reassembling the engine with precision. For a BMW 7 Series engine, this meticulous approach ensures that every part operates at peak efficiency, closely resembling the performance of a new engine. Key steps include cleaning, machining, replacing or refurbishing components, and rigorous testing. Cleaning the engine is crucial as it removes carbon deposits, sludge, and other contaminants that can impede performance. Machining involves refinishing critical surfaces such as the cylinder head and block, ensuring they meet precise specifications. Worn components, including pistons, bearings, and valves, are replaced or refurbished to restore functionality. Finally, the reassembled engine undergoes testing to ensure it meets or exceeds original performance standards.

The Benefits of Engine Reconditioning

Reconditioning a BMW engine provides several significant benefits. Firstly, it enhances performance by restoring power and efficiency lost due to wear and tear. This leads to better acceleration, smoother operation, and improved fuel economy. Secondly, it extends the engine's lifespan by replacing worn parts and addressing potential issues before they become serious problems. Thirdly, reconditioning is cost-effective compared to purchasing a new engine, offering a high return on investment. Moreover, reconditioning ensures that the engine meets stringent emission standards, contributing to environmental sustainability. It also maintains the vehicle's value, as a well-maintained engine is a key factor in resale value. Ultimately, reconditioning provides peace of mind, knowing that the engine is in optimal condition and less likely to encounter unexpected failures.

Detailed Inspection and Diagnostics

A critical component of the reconditioning process is the detailed inspection and diagnostics phase. This step involves a thorough examination of the engine to identify any underlying issues. Advanced diagnostic tools are used to measure wear and detect faults that may not be visible to the naked eye. For the BMW 7 Series, this phase is particularly important due to the complexity of its engine. Technicians check for signs of wear in critical areas such as the crankshaft, camshaft, and connecting rods. They also inspect the cylinder head for cracks or warping and measure the cylinder bores for wear. Using precision instruments, they ensure that all tolerances are within manufacturer specifications. This detailed inspection helps create a comprehensive plan for the reconditioning process, ensuring that no detail is overlooked.

Machining and Component Refurbishment

Once the inspection is complete, the machining and component refurbishment phase begins. Machining involves resurfacing critical engine components to restore them to their original specifications. For example, the cylinder head and block are machined to ensure a perfect seal, which is essential for maintaining compression and preventing leaks. The crankshaft may be polished or reground to restore smooth operation. Component refurbishment includes restoring or replacing parts such as pistons, bearings, and valves. In some cases, advanced techniques like sleeving cylinder bores are used to restore them to their original diameter. For the BMW 7 Series, which features advanced engineering and high-performance components, this phase is crucial for achieving optimal engine performance. Precision machining and refurbishment ensure that each part works seamlessly within the engine assembly.

Precision Assembly Process

The assembly process in engine reconditioning is executed with precision and care. After machining and refurbishing components, the engine is carefully reassembled to ensure all parts work harmoniously. This involves setting correct clearances and torques, aligning components accurately, and ensuring that all seals and gaskets are properly fitted. For the BMW 7 Series, this phase is particularly critical due to the engine’s sophisticated design and tight tolerances. Technicians use specialized tools and techniques to assemble the engine, ensuring that each component is installed correctly. This meticulous assembly process helps prevent issues such as oil leaks, poor compression, and premature wear. The result is an engine that runs smoothly and reliably, delivering performance akin to a new engine.

Testing and Quality Assurance

Once the engine is reassembled, it undergoes rigorous testing and quality assurance checks. This phase ensures that the reconditioned engine meets or exceeds original performance standards. For the BMW 7 Series, this involves a series of tests to evaluate engine performance, including compression tests, leak-down tests, and dynamometer testing. Compression tests check the integrity of the combustion chambers, ensuring that each cylinder maintains the correct pressure. Leak-down tests identify any leaks in the cylinder head, valves, and piston rings. Dynamometer testing measures the engine’s power output and efficiency, providing a comprehensive assessment of its performance. These tests ensure that the reconditioned engine delivers the power, efficiency, and reliability expected of a BMW 7 Series.

Enhancing Performance with Modern Technologies

The reconditioning process also provides an opportunity to enhance the engine’s performance using modern technologies. For the BMW 7 Series, this can include upgrades such as improved engine management systems, high-performance components, and advanced materials. These enhancements can increase power output, improve fuel efficiency, and reduce emissions. Modern engine management systems provide more precise control over fuel injection, ignition timing, and other critical parameters. High-performance components, such as forged pistons and high-flow cylinder heads, can increase the engine’s power and responsiveness. Advanced materials, such as ceramic coatings, can reduce friction and wear, further enhancing performance and durability. These modern technologies ensure that the reconditioned engine not only meets but often exceeds original performance specifications.

Cost-Effectiveness and Environmental Benefits

Reconditioning a BMW 7 Series engine is a cost-effective alternative to purchasing a new engine. It offers significant savings while delivering comparable performance and reliability. Additionally, reconditioning is environmentally friendly, as it reduces the need for new parts and minimizes waste. By refurbishing and reusing existing components, the process conserves resources and reduces the environmental impact associated with manufacturing new parts. This eco-friendly approach aligns with the growing emphasis on sustainability in the automotive industry. Reconditioning helps reduce the vehicle's overall carbon footprint, contributing to a greener future. Moreover, by extending the engine's lifespan, reconditioning helps owners maximize the value of their investment, providing a high-performance vehicle at a fraction of the cost of a new engine. Read the full article

0 notes

Text

How does the reconditioning process ensure the reliability of Range Rover engines?

Introduction

The Range Rover, a symbol of luxury and performance, demands a high level of reliability from its engines to maintain its reputation. Ensuring the reliability of these engines involves a meticulous reconditioning process that goes beyond standard repairs. This process revitalizes used engines, restoring them to optimal condition and ensuring they meet the stringent standards required by Range Rover vehicles. We delves into the detailed reconditioning process, highlighting how each step contributes to the overall reliability of Range Rover engines.

Inspection and Assessment: The First Crucial Step

The reconditioning process begins with a thorough inspection and assessment of the engine. Technicians conduct a comprehensive examination to identify wear and tear, damage, and potential issues. This step is critical as it forms the basis for the entire reconditioning process. Advanced diagnostic tools and techniques are employed to assess the engine's condition accurately. The assessment includes checking for leaks, measuring compression, and evaluating the performance of various engine components.

Dismantling and Cleaning: Stripping Down to the Basics

Once the initial assessment is complete, the engine is dismantled. Each component is carefully removed and cataloged. This step is essential to access all parts of the engine, allowing for a more detailed inspection and ensuring that no potential issue goes unnoticed. After dismantling, each component undergoes an intensive cleaning process. Specialized cleaning solutions and equipment are used to remove carbon deposits, grime, and other contaminants. This thorough cleaning is crucial for the subsequent inspection and reassembly stages.

Component Testing and Replacement: Ensuring Each Part Meets Standards

After cleaning, each engine component is tested individually. This includes checking for cracks, wear, and other forms of damage that might compromise the engine's performance. Components such as the pistons, crankshaft, camshaft, and valves undergo rigorous testing. Any part that does not meet the manufacturer's specifications is either repaired or replaced with high-quality, genuine parts. This step ensures that only components that meet the strict standards required for Land Rover engines are used.

Precision Machining: Restoring Components to Their Optimal State

Precision machining plays a vital role in the reconditioning process. Components that have been deemed reusable but require refinishing undergo precision machining to restore them to their original specifications. This includes resurfacing cylinder heads, re-boring cylinders, and grinding crankshafts. The use of advanced machinery and techniques ensures that each component is restored to its optimal state, enhancing the overall reliability of the engine.

Reassembly: Meticulous Attention to Detail

The reassembly process is carried out with meticulous attention to detail. Each component is carefully reinstalled, ensuring that all parts fit together perfectly. The use of precision tools and adherence to manufacturer specifications is crucial during this stage. Technicians follow a detailed reassembly plan to ensure that the engine is rebuilt to its original design. This step is fundamental in ensuring that the engine operates smoothly and efficiently once reconditioned.

Testing and Quality Control: Verifying Performance and Reliability

Once the engine is reassembled, it undergoes extensive testing to verify its performance and reliability. This includes both static and dynamic tests. Static tests involve running the engine at various speeds and loads to check for any abnormalities. Dynamic tests simulate real-world driving conditions to ensure the engine performs well under different scenarios. Additionally, the engine is subjected to a series of quality control checks to ensure it meets all the necessary standards and regulations.

Final Inspection and Certification: Guaranteeing Quality

The final inspection is a critical step in the reconditioning process. Experienced technicians perform a thorough examination of the reconditioned engine to ensure it meets all specifications and quality standards. This includes checking for leaks, verifying compression levels, and ensuring all components are functioning correctly. Once the engine passes the final inspection, it is certified as reconditioned. This certification guarantees that the engine has undergone a comprehensive reconditioning process and meets the high standards required for Range Rover engines.

Benefits of Engine Reconditioning: Enhancing Longevity and Performance

Reconditioning a Range Rover engine offers numerous benefits. Firstly, it significantly enhances the engine's longevity by addressing wear and tear and replacing damaged components. Secondly, it improves performance, ensuring the engine runs smoothly and efficiently. Thirdly, reconditioning is cost-effective compared to purchasing a new engine, making it an attractive option for Range Rover owners. Lastly, the reconditioning process is environmentally friendly as it reduces waste and promotes the reuse of engine components.

Conclusion

The reconditioning process for Range Rover engines is a comprehensive and meticulous procedure designed to ensure reliability and performance. From initial inspection to final certification, each step is carried out with precision and care. By addressing potential issues, replacing worn components, and restoring parts to their optimal state, the reconditioning process revitalizes engines, ensuring they meet the high standards expected of Range Rover vehicles. For owners seeking a reliable and cost-effective solution to engine issues, reconditioning offers a viable and beneficial option. Read the full article

0 notes

Text

Auto Care Checklist: Maintaining Your Car in Prime Condition

Introduction

When it involves possessing a vehicle, frequent routine maintenance is essential making sure that your automobile stays in prime condition. By next an automobile routine maintenance checklist and keeping up with plan responsibilities, you may prevent main difficulties from arising and increase the lifespan of your car. On this page, We'll present you with an extensive guide regarding how to keep your car in ideal situation.

Why is Vehicle Maintenance Crucial?

Car servicing performs an important position in preserving the functionality, reliability, and basic safety of the automobile. Neglecting typical servicing jobs can cause pricey repairs, lowered gas efficiency, and even mishaps. By Autonomous Driving having proactive measures and being on top of your car's routine maintenance wants, you could avoid these problems and luxuriate in a clean driving expertise.

Car Servicing Checklist: Holding Your Vehicle in Prime Shape

1. Regular Oil Changes

Keeping your motor correctly lubricated is essential for its longevity. Often shifting the oil ensures that it continues to be clear and no cost from contaminants that can result in harm. Refer to your automobile's operator handbook for the advised oil adjust intervals.

2. Test Fluid Levels

Regularly examining and topping off fluid stages such as coolant, brake fluid, transmission fluid, and ability steering fluid is essential for best performance. Minimal fluid concentrations can cause overheating or other mechanical concerns.

3. Inspect Tires

Maintaining appropriate tire tension and tread depth is vital for both basic safety and gas effectiveness. Regularly Test tire tension utilizing a gauge and assure it matches the advised degrees specified because of the company. In addition, inspect the tires for just about any signs of wear or problems and rotate them frequently.

4. Battery Maintenance

The battery is accountable for powering many electrical factors in your car. Make sure the battery terminals are clean up and absolutely free from corrosion. Should you detect any indications of a weak battery, for example dim headlights or issues starting up the motor, it might be time for your substitute.

5. Brake Program Inspection

The brakes are Probably the most vital safety components within your auto. Often inspect the brake pads, rotors, and calipers for indications of have on. In case you detect any squeaking or grinding noises when braking, have them inspected by knowledgeable mechanic promptly.

6. Air Filter Replacement

A clogged air filter can restrict airflow for the engine, causing reduced overall performance and fuel performance. Check out your vehicle's air filter often and switch it in accordance with the company's tips.

7. Spark Plug Replacement

Spark plugs Engage in a vital function in igniting the fuel-air mixture inside the engine cylinders. After a while, they may become worn out and influence motor functionality. Switch spark plugs at the encouraged intervals to make sure ideal combustion.

8. Timing Belt Inspection

The timing belt is liable for synchronizing the rotation in the camshaft and crankshaft as part of your motor. If it fails, it can cause severe damage to inside components. Talk to

1 note

·

View note

Text

Unveiling the Common Quirks of Porsche Cars

Introduction:

Porsche, the epitome of luxury and performance, has captured the hearts of automotive enthusiasts for decades. With their sleek designs, powerful engines, and precision engineering, Porsche cars are a symbol of status and driving pleasure. However, even these masterpieces aren't immune to a few quirks that might catch their owners off guard. In this blog, we'll take a closer look at some common issues that Porsche owners may encounter, shedding light on the not-so-well-known aspects of these high-performance vehicles.

1. The Mysterious "Check Engine" Light:

Picture this: You're cruising down the highway, enjoying the exhilarating roar of your Porsche's engine, when suddenly, the dreaded "Check Engine" light makes an appearance. While it may send a shiver down your spine, fear not – this isn't uncommon in the world of high-performance cars. Often, it's a minor issue like a faulty sensor or a loose gas cap. However, it's crucial not to ignore it, as it could be a signal of a more serious problem that needs attention.

2. Electronic Gremlins:

Porsches are equipped with cutting-edge technology, from advanced infotainment systems to electronic stability control. However, with great technology comes the potential for electronic quirks. Some owners have reported issues with electronic components, such as malfunctioning touchscreens or glitches in the adaptive cruise control. While these instances are relatively rare, they highlight the importance of staying up-to-date with software updates and regular maintenance checks.

3. Oil Leaks:

Porsche engines are known for their power and efficiency, but they are not immune to oil leaks. Owners, especially those with older models, may encounter oil leaks around the engine. These leaks can be attributed to worn gaskets or seals. Regularly checking oil levels and addressing leaks promptly can prevent more significant issues down the road.

4. IMS Bearing Woes:

One of the more notorious issues associated with certain Porsche models is the intermediate shaft (IMS) bearing failure. While not all Porsches are affected, this problem gained attention in the early 2000s. The IMS bearing, responsible for supporting the intermediate shaft that turns the camshafts, has been known to fail, leading to catastrophic engine damage. Porsche has addressed this in later models, but owners of older Porsches must be aware of this potential concern and take preventive measures.

5. Suspension Struggles:

The firm and responsive suspension system that contributes to Porsche's superb handling can, over time, present its own set of challenges. Some owners have reported issues with worn-out suspension components, leading to a less-than-smooth ride. Regular inspection and maintenance of the suspension system can help mitigate these problems and ensure a comfortable driving experience.

How Service My Car Assist You?

Have you reached a point where you’re questioning, “Where can I find the top mg service sharjah center for my MG car?” Look no further, Service My Car assists you by providing convenient, reliable servicing for your MG vehicle, right at the MG service center in Sharjah. Our skilled technicians ensure thorough maintenance, using genuine parts and advanced diagnostics. From routine check-ups to major repairs, we prioritize your MG's performance and safety. With our streamlined processes and commitment to quality, Service My Car ensures your MG car stays in prime condition, giving you peace of mind on the road. Trust us for top-notch service and care for your vehicle.

Conclusion:

Owning a Porsche is an exhilarating experience, but it comes with its unique set of challenges. From electronic quirks to engine intricacies, understanding and addressing these common issues can help Porsche enthusiasts continue to enjoy the thrill of the open road. As with any high-performance vehicle, regular maintenance and a keen eye for early signs of trouble are key to preserving the longevity and performance of these automotive masterpieces. Embrace the quirks, stay informed, and let the thrill of driving a Porsche continue to be an unmatched experience.

1 note

·

View note

Text

Boost Horsepower and Protect Your Engine with Oil Additives

The pursuit of more horsepower is a passion shared by automotive enthusiasts and performance-minded drivers alike. Whether you're looking to enhance your vehicle's power for a thrilling ride or seeking to maximize its efficiency for everyday use, oil additives offer a compelling solution. In this comprehensive article, we will explore how oil additives can boost horsepower and, at the same time, protect your engine, providing you with the best of both worlds. Please contact AwSUM Outcomes for more info.

The Importance of Horsepower

Horsepower is a crucial metric in the world of automotive performance. It measures an engine's ability to produce work, and in a vehicle, this translates to speed and acceleration. More horsepower means quicker acceleration, faster top speeds, and an overall more exhilarating driving experience.

However, increasing horsepower often involves pushing an engine to its limits, which can lead to increased wear and stress. This is where oil additives come into play, offering a way to both boost power and safeguard your engine's health.

How Oil Additives Boost Horsepower

Oil additives are carefully formulated chemical compounds that are mixed with engine oil to improve its properties and performance. Here's how they contribute to increasing horsepower:

Reducing Friction: Friction between engine components saps power and generates heat. Oil additives, particularly those with friction modifiers, work to reduce friction, making it easier for your engine to operate efficiently. Less friction means more power is available for acceleration.

Enhancing Lubrication: Proper lubrication is essential to reduce wear and tear on engine components. Some oil additives contain advanced lubrication properties that ensure smoother operation, reducing the power losses associated with friction and heat.

Cleaning the Engine: Deposits and sludge can accumulate in your engine over time, restricting airflow and reducing power. Oil additives with detergents and dispersants help keep the engine clean, preventing deposits and maintaining optimal airflow.

Heat Dissipation: Excessive heat can be detrimental to engine performance. Certain oil additives are designed to dissipate heat effectively, keeping the engine cooler and preventing power loss due to overheating.

Minimizing Wear: Oil additives with anti-wear properties reduce the wear and tear on critical engine components, such as pistons, camshafts, and bearings. This extends the life of your engine, ensuring consistent power delivery.

Protection for Your Engine

While increasing horsepower is an exciting prospect, protecting your engine is equally important. Oil additives not only boost power but also provide crucial protection in several ways:

Wear Reduction: Anti-wear additives create a protective barrier on engine surfaces, reducing metal-to-metal contact and minimizing wear.

Deposit Prevention: Detergent and dispersant additives prevent the formation of harmful deposits, ensuring that your engine operates smoothly and efficiently.

Longevity: By reducing friction and wear, oil additives contribute to the extended life of your engine, allowing you to enjoy increased horsepower without compromising engine health.

Improved Efficiency: Reduced friction and cleaner engine components translate into improved fuel efficiency, allowing you to harness the additional power without significantly affecting fuel consumption.

Choosing the Right Oil Additive

Selecting the right oil additive is essential to achieve the desired results while safeguarding your engine. Consider the following factors when choosing an additive:

Vehicle Type: Different vehicles may have varying requirements. High-performance cars might benefit from specific additives, while older vehicles or daily drivers may need a more general-purpose solution.

Driving Conditions: Consider the conditions in which you typically drive. If you encounter extreme temperatures, heavy traffic, or frequent stop-and-go situations, choose an oil additive tailored to those challenges.

Manufacturer Recommendations: Always consult your vehicle's owner's manual for manufacturer recommendations or restrictions regarding oil additives.

Customer Reviews: Reading customer reviews and seeking recommendations from trusted sources can help you identify effective oil additives that have worked well for others.

Boosting horsepower and protecting your engine need not be conflicting goals. Oil additives offer a powerful solution that enhances engine performance while ensuring long-term engine health. By reducing friction, enhancing lubrication, preventing deposits, and dissipating heat, these additives contribute to increased power and efficiency.

When selecting an oil additive, consider your vehicle's specific requirements, follow manufacturer recommendations, and adhere to dosage instructions. With the right oil additive, you can enjoy the exhilaration of increased horsepower while having the peace of mind that your engine remains protected and reliable for years to come.

0 notes

Text

How to test ignition control module honda civic

1.How to test ignition control module honda civic

The ignition control module is an essential component in a vehicle's ignition system. In the case of the GM 3.8, the ignition control module is responsible for controlling the ignition spark in each cylinder of the engine. Knowing how to test this component is important to diagnose ignition problems and avoid costly and unnecessary replacement. In this article, we'll explain how to test the GM 3.8 ignition control module, including the necessary steps, required tools, and common problems that can be encountered during the process.

2. What is GM 3.8 Ignition Control Module?

The GM 3.8 Ignition Control Module is an electronic device that controls the ignition spark in each cylinder of the engine. The module receives signals from the crankshaft position sensor and the camshaft position sensor to determine the proper time to produce the ignition spark. It then sends a signal to the ignition coil to spark at the correct time.

2.1 Ignition Control Module Functions

The GM 3.8 Ignition Control Module is responsible for several important functions, including:

Check engine ignition timing

Monitor engine speed and engine load

Produce the ignition spark at the right time

Check the intensity of the ignition spark

2.2 Ignition Control Module Location

The GM 3.8 Ignition Control Module is typically located on top of the engine, near the ignition coil. It may be attached to the engine with screws or clips, depending on the model of the vehicle.

3. Why is it important to test the GM 3.8 Ignition Control Module?

The ignition control module is a critical component of a vehicle's ignition system. If the module is faulty, it can cause ignition problems such as difficulty starting the engine, loss of power, and increased fuel consumption. It is important to test the GM 3.8 Ignition Control Module to diagnose any ignition problems and avoid unnecessary costly replacement of other parts in the system.

4. Tools Needed to Test GM 3.8 Ignition Control Module

To test the GM 3.8 Ignition Control Module, you will need the following tools:

Digital multimeter

ignition test probe

vehicle service manual

5. Steps to Take Before Testing the GM 3.8 Ignition Control Module

Before testing the GM 3.8 Ignition Control Module, it is important to follow the steps below:

5.1 Verification of electrical connections

Check the electrical connections going to the ignition control module to make sure they are good and fit properly. If there are any problems with the connections, resolve them before continuing with the test.

5.2 Visual inspection of the ignition control module

Perform a visual inspection of the ignition control module. Look for signs of physical damage, such as cracks, burns, or corrosion. If the module appears to be damaged, replace it before continuing with the test.

6. GM Ignition Control Module Test Procedure 3.8

The procedure for testing the GM 3.8 Ignition Control Module is as follows:

6.1 Ignition Control Module Internal Resistance Test

Using the digital multimeter, measure the internal resistance of the ignition control module. Consult the vehicle's service manual for reference values. If the measured resistance is outside the specified range, the module may be faulty and need to be replaced.

6.2 Ignition Control Module Output Signal Test

Using the ignition test probe, verify that the ignition control module is producing proper output signals. Connect the ignition test probe to the ignition coil and adjust the reference values according to the vehicle's service manual. If the output signal is out of range, the module may be faulty and need to be replaced.

6.3 Ignition Control Module Input Voltage Test

Using the digital multimeter, measure the input voltage of the ignition control module. The value must be within the range specified in the vehicle's service manual. If the input voltage is out of range, the module may be faulty and need to be replaced.

7. Interpretation of GM Ignition Control Module Test Results 3.8

If the test results indicate that the GM 3.8 Ignition Control Module is working properly, it means that the ignition problem is not related to the module. In that case, you can continue to search for other ignition system problems. If the test results indicate that the ignition control module is defective, it is necessary to replace it to correct the ignition problem.

8. Troubleshooting Common Problems Testing the GM Ignition Control Module 3.8

During testing of the GM 3.8 Ignition Control Module, common problems may arise, such as:

8.1 Electrical connection problems

If there are problems with the electrical connections, such as loose or corroded connections, they can affect the signal from the ignition control module. Check the connections and resolve them as necessary before continuing with the test.

8.2 Ignition Control Module Output Signal Problems

If the ignition control module output signal is not within the range specified in the vehicle's service manual, it may be necessary to replace the ignition control module.

8.3 Ignition Control Module Input Voltage Problems

If the ignition control module input voltage is not within the range specified in the vehicle's service manual, it may be necessary to replace the ignition control module.

9. Care and Precautions When Testing the GM 3.8 Ignition Control Module

When testing the GM 3.8 Ignition Control Module, it is important to take certain precautions to avoid damaging the component or putting your personal safety at risk. The following are some important tips and precautions:

Follow vehicle service manual instructions at all times

Use proper, quality tools to avoid damaging the ignition control module

Disconnect the battery before starting the test to avoid electric shock

Do not touch metal parts of the vehicle while testing to avoid electric shock

Wear appropriate clothing and personal protection, such as gloves and safety glasses

10. GM 3.8 Ignition Control Module Maintenance Tips

To keep your GM 3.8 ignition control module in good condition, it is important to follow these tips:

Perform periodic visual inspections of the module for signs of damage or corrosion

Clean the module's electrical connections regularly to prevent dirt or corrosion buildup

Replace the GM 3.8 Ignition Control Module per vehicle service manual recommendations

11. Conclusion

Testing the GM 3.8 ignition control module is an important task in diagnosing ignition problems on a vehicle. By following the proper steps and using the correct tools, it can be determined if the module is working properly or if it needs to be replaced. It is important to follow proper precautions when testing to avoid damaging the module or putting your personal safety at risk. If you are not comfortable performing the test yourself, it is best to seek the help of a professional mechanic.

12. Frequently asked questions

1. What is GM 3.8 Ignition Control Module?

The GM 3.8 Ignition Control Module is an electronic component that controls the ignition spark in each cylinder of the engine. It is responsible for controlling the ignition timing of the engine, monitoring the speed and load of the engine, producing the ignition spark at the proper time, and controlling the intensity of the spark.

2. Why is it important to test the GM 3.8 Ignition Control Module?

It is important to test the GM 3.8 Ignition Control Module to diagnose ignition problems in the vehicle. If the module is defective, it can cause ignition problems such as difficulty starting the engine, loss of power, and increased fuel consumption. Testing the module also helps avoid unnecessary costly replacement of other parts of the system.

3. What are the tools needed to test the GM 3.8 Ignition Control Module?

The tools needed to test the GM 3.8 ignition control module are a digital multimeter, an ignition test probe, and the vehicle's service manual. These tools are needed to measure the internal resistance of the module, check the output signal, and measure the input voltage. It is important to use proper, quality tools to avoid damaging the ignition control module.

0 notes

Text

MbenzGram: Camshafts What are They and What Do They are doing?

You might presently recognize that the camshaft is one of the integral parts of a vehicle’s motor. But what precisely will it do? How can it work within an motor, and what are its particular features? In what strategies does it impact the general performance within your motor?

When you need to interchange the camshaft of the engine, how must you go over it? What are the significant things to remember when picking the right camshaft in your motor? What variables really should you take into consideration?

Several auto house owners may possibly truly feel far more than a small perplexed when faced with these concerns. Having said that, being aware of the answers to your above inquiries is important for choosing the correct camshaft to your motor vehicle.

This submit addresses the essentials of a camshaft that all motorists will need to learn. We'll often draw on worthwhile insights from industry experts at MbenzGram, also called MBGRAM, a world brand specializing in vehicle effectiveness parts whose crew of authorities share a enthusiasm for racing and motorsports.

Camshaft: What It truly is and exactly how Will it Work?

The camshaft controls the engine valves’ opening and shutting; given that the MbenzGram professionals put it, the component is usually regarded the “brain of your engine.” A camshaft works by changing rotational motion into linear or reciprocating movement then transfers this motion, generated through the cams, by various parts of the valve educate to regulate the operations from the ingestion and exhaust valves.

Mounted within the ‘top end’ of the engine (proper above the piston within the cylinder head), the camshaft works the poppet valves observed inside the pumps, the inner combustion engines, along with other relevant mechanisms. As soon as the motor begins operating, the cams around the camshaft turn or rotate at 50 % the velocity on the crankshaft. For the duration of each and every cylinder’s power/exhaust and intake/compression strokes, cam lobes to the camshaft work to correctly open and close the intake/exhaust valves.