#glass-lined-reactor-manufacturer

Explore tagged Tumblr posts

Text

0 notes

Text

Kilolab equipment | Glass Pilot Plant | manufacturer & suppliers | Goel Scientific | Canada

We serve best Kilolab equipment, Kilolab equipment price, best glass pilot plant, glass pilot plant equipment price, Assemblies Over Glass Lined Reactor Manufacturers, in canada

#Buy Kilolab equipment#Kilolab equipment price#best glass pilot plant#glass pilot plant equipment price#Assemblies Over Glass Lined Reactor#Reaction Unit#Extraction Unit#Fractional Distillation#Metal Jacketed Glass Reactor#Mobile Mixing System#Multi Purpose Unit#Reaction Distillation#Simple Distillation Units#Distributors#Dealers#Suppliers#Wholesalers#Manufacturers#in canada#Goel Scientific Glass Works Ltd#Canada#Ontario#Toronto#Ottawa#British Columbia#Vancouver#Burnaby#Victory#Quebec#Montreal

1 note

·

View note

Text

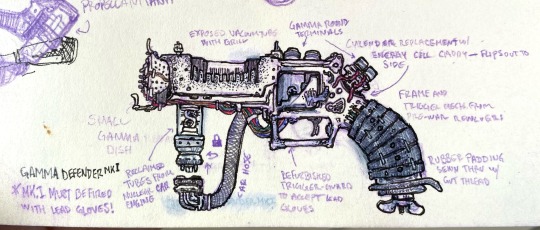

Whitehall Workshops Experimental Weapons pt 2/???

I got bit by the bug again & have booted up my console Fallout 4 files, which means the Wacky Weapons Workshop is back in my greedy little hands. Here’s some more ideas for arms that might come out of the various settlements being half-run by my Vault 49er, Whipstitch Whitehall.

Gamma Defender Mk I

Gamma Defenders were ideated as a solution to handmade energy weapons being able to carry a payload beyond traditional energy damage from lasers or plasma reactors. Parts were sourced from relatively common sights; glass tubes & hose connections from prewar Corvega engines, broken down Gamma Guns from scavenging the outskirts of the Glowing Sea, and any rusted-out revolver frame that still has a working trigger and cylinder hinge. The traditional revolver magazine is converted into a hinged energy cell caddy, and electrical components replace much of the revolver frame forward of the magazine.

Unfortunately, the weapon was quite clumsy and not easily transported over long distances, as it couldn’t fit into traditional chest or hip holsters. Another problem arose from the unstable radiation sinks installed around the “barrel tube”, which required operators to handle the active weapon strictly with lead-lined gloves. To accommodate this, a late-stage modification was added to the Mk I’s blueprints—an extended trigger guard to more-comfortably accept lead-lined gloves. With its long list of manufacturing nuances the Mk I saw minor use defending small settlements across the northern stretch of the Commonwealth. After a few short years however the availability of other Whitehall Workshop weapons like the Salvaged SynthLaz & the LACS began overshadowing the Gamma Defender Mk I, and its blueprints soon cluttered the shelves of many an isolated workshop.

Further experimentation needed.

#fallout#fallout 2#fallout 3#fallout 4#fallout 76#concept art#fallout concept art#fallout fanart#fallout fan art#fan concept#energy weapons#fallout energy weapons#gamma defender#whipstitch#whitehall workshop#art#mine#illustration#illustrators on tumblr#scifi#sci fi concept art

27 notes

·

View notes

Text

Glass-Lined Dark Green Anaerobic Digester Tank with EGSB Reactor: A Sustainable Solution for Efficient Biogas Production

At Shijiazhuang Zhengzhong Technology Co., Ltd, we are dedicated to pioneering innovative solutions in the field of renewable energy and waste management. Our Glass-Lined Dark Green Anaerobic Digester Tanks, paired with the Expanded Granular Sludge Bed (EGSB) Reactor, offer a robust and efficient system for converting organic waste into valuable biogas. This combination not only maximizes biogas production but also ensures environmental sustainability.

Understanding Anaerobic Digestion

Anaerobic digestion is a biological process that transforms organic materials—such as agricultural residues, food waste, and livestock manure—into biogas in the absence of oxygen. This process is facilitated by specialized microorganisms that break down organic matter, producing biogas primarily composed of methane, which can be used for electricity generation, heating, or as a vehicle fuel. The remaining digestate can be utilized as a nutrient-rich fertilizer, supporting sustainable agricultural practices.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Key Features of Our Glass-Lined Dark Green Anaerobic Digester Tank with EGSB Reactor

1. Superior Glass-Lining Technology

Our anaerobic digester tanks are lined with high-quality glass enamel, offering exceptional resistance to corrosion and chemical degradation. The glass lining enhances the durability of the tank, ensuring a long operational life and minimizing maintenance costs. The dark green color not only provides an aesthetically pleasing appearance but also helps in temperature regulation, contributing to the efficiency of the digestion process.

2. Integrated EGSB Reactor Design

The EGSB reactor is designed to enhance the anaerobic digestion process by providing a high hydraulic retention time (HRT) while maintaining a compact footprint. This innovative design allows for efficient biogas production, even at high organic loading rates. The expanded granular sludge bed promotes effective contact between the microorganisms and the organic substrate, maximizing biogas yield.

3. High Airtightness

The airtight design of our glass-lined anaerobic digester tank ensures optimal anaerobic conditions, preventing the ingress of oxygen that could disrupt the digestion process. This feature is critical for maintaining the efficiency and stability of biogas production.

4. Efficient Biogas Production

The combination of the glass-lined tank and EGSB reactor allows for rapid degradation of organic materials, resulting in efficient biogas production. This biogas can be further processed to generate renewable energy, contributing to sustainable energy solutions.

Benefits of Glass-Lined Anaerobic Digester Tanks

Corrosion Resistance

The glass lining provides superior corrosion resistance, protecting the tank structure from aggressive materials and ensuring longevity. This is especially important in anaerobic digestion, where the environment can be harsh.

Reduced Maintenance

The smooth surface of glass lining makes cleaning and maintenance easier, helping to maintain hygienic conditions within the tank. This reduces downtime and operational costs, allowing for more efficient waste processing.

Environmental Benefits

Utilizing organic waste for biogas production significantly reduces greenhouse gas emissions compared to traditional waste disposal methods. Our glass-lined anaerobic digester tanks contribute to a circular economy by transforming waste into renewable energy, aligning with global sustainability goals.

Comprehensive Services Offered

At Center Enamel, we are committed to providing not just high-quality products, but also comprehensive services tailored to meet the needs of our clients:

Custom Engineering Design: Our experienced engineering team collaborates with you to develop tailored anaerobic digester solutions that meet your specific project requirements.

Professional Installation Services: We provide expert installation services to ensure that your anaerobic digester tank and EGSB reactor are set up correctly, optimizing performance and minimizing disruptions.

Ongoing Support and Maintenance: Our commitment extends beyond installation. We offer ongoing support and maintenance services to ensure the longevity and efficiency of your anaerobic digestion system.

Global Expertise and Reach

With over 30 years of experience, Center Enamel has established a strong global presence, delivering our Glass-Lined Dark Green Anaerobic Digester Tanks with EGSB Reactors to clients worldwide. We are dedicated to helping organizations transition to sustainable energy solutions that are economically viable and environmentally responsible.

Shijiazhuang Zhengzhong Technology Co., Ltd’s Glass-Lined Dark Green Anaerobic Digester Tanks with EGSB Reactors offer an ideal solution for organizations looking to harness the power of anaerobic digestion for renewable energy production. Our focus on quality, innovation, and sustainability positions us as a leader in the industry, enabling our clients to effectively manage organic waste while contributing to a cleaner, greener future. Choose Center Enamel for your anaerobic digestion needs and become part of the renewable energy revolution.

0 notes

Text

Europe Aluminium Magnesium Spinel Market Industry Trends, Competition Strategies, Revenue Analysis and Forecast to 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Europe Aluminium Magnesium Spinel Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the Europe Aluminium Magnesium Spinel Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Europe Aluminium Magnesium Spinel Market?

Europe aluminium magnesium spinel market was valued at US$ 166.4 Million in 2023 and is expected to register a CAGR of 4.1% over the forecast period and reach US$ 238.3 Mn in 2032.

What are Europe Aluminium Magnesium Spinel?

Aluminium Magnesium Spinel in Europe is a high-performance ceramic known for its outstanding thermal and mechanical properties. Made from aluminum oxide (Al₂O₃) and magnesium oxide (MgO), it offers excellent resistance to thermal shock, corrosion, and mechanical wear. This material is widely used in industrial applications including refractory linings in furnaces and reactors, as well as in aerospace components and advanced ceramic products. Its exceptional combination of high melting point, hardness, and chemical stability makes it ideal for demanding environments where durability and reliability are essential.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/2351

What are the growth prospects and trends in the Europe Aluminium Magnesium Spinel industry?

The Europe aluminium magnesium spinel market growth is driven by various factors and trends. The Aluminium Magnesium Spinel market in Europe is experiencing growth, fueled by its widespread adoption in multiple industries due to its strong thermal and mechanical properties. This high-performance ceramic, comprised of aluminum oxide (Al₂O₃) and magnesium oxide (MgO), is prized for its resilience against thermal shock, corrosion, and mechanical wear. It is utilized extensively in industrial refractories, aerospace components, and advanced ceramics, leveraging its high melting point, hardness, and chemical stability. Market expansion is driven by rising demand for durable materials in industrial applications and continuous advancements in technology to enhance its effectiveness across various uses. Hence, all these factors contribute to Europe aluminium magnesium spinel market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type

Fused Spinel

Reaction Bonded Spinel

Sintered Spinel

Others

By Composition

Al2O3 (76/78%)

MgO (24/22%)

By Form

Powder

Granules

Bricks

Others

By Production Method

Sol-Gel Process

Conventional Solid-State-Reaction

Spray Drying (Atomization)

Chemical Vapor Deposition (CVD)

Electrical Fusion Process

Wet Synthesis Techniques

Mechano-Chemical Alloying

Molten Salt Synthesis

Others

By Purity

99%

Above 99%

By Packaging

Steel Drum

Container

By Application

Refractory Materials

Metal Casting

Electrical Insulators

Iron And Steel Smelting

Glass Furnace

Calcined Lime Furnace Lining

Cement Rotary Kiln

Steel Ladles

Alumina-Magnesia Brick

Sliding Nozzle

Ceramics Manufacturing

HumiditySensors

Others

By End-Use Industry

Automotive

Electronics

Refractories

Cement

Iron and Steel

Glass

Water Treatment

Others

Europe

Germany

Austria

Switzerland

Italy

Spain

Portugal

Greece

Cyprus

Malta

Poland

Czech Republic

Slovakia

Hungary

Ukraine

Moldova

Balkan Countries

Rest of Europe

Who are the key players operating in the industry?

The report covers the major market players including:

Almatis

Refratechnik Group

Keralit LLC

Surmet Corporation

CeraNova Corporation

Washington Mills

Baikowski

MFE Magnesium

View Full Report: https://www.reportsandinsights.com/report/Europe Aluminium Magnesium Spinel-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

#Europe Aluminium Magnesium Spinel Market share#Europe Aluminium Magnesium Spinel Market size#Europe Aluminium Magnesium Spinel Market trends

0 notes

Text

TSTCABLES 10 Tips for B-Side Purchasing Demystifying High Temperature Cable Shopping Tips

I. High temperature cable Overview

High temperature cable is a special type of cable that can work normally in a high-temperature environment, and can usually withstand high temperatures above 200°C. Even some types of high-temperature cables can safely and stably transmit power signals and data signals at temperatures as high as 600°C or higher. Such cables have the following characteristics and uses:

Second, high temperature cable product characteristics

High temperature resistance: can operate stably in environments up to hundreds of degrees Celsius.

Anti-corrosion and anti-corrosion: Long-term performance in corrosive environments.

High efficiency and low consumption: special design to reduce energy consumption and enhance energy efficiency.

Strong anti-interference: Super anti-interference (EMI) shielding ability to ensure stable signal transmission in high temperature and electromagnetic interference environment.

High safety: low smoke and halogen-free flame retardant, reducing fire and other safety risks.

Long life: reduce the frequency of replacement, reduce maintenance costs.

Third, high temperature cable product standards

The production and testing of high-temperature cables follow strict standards. For example, according to the national standard GB12666.6-90, the long-term use of high-temperature cables can reach a working temperature of 200 ℃, and the short-term use of the temperature can even reach 1000 ℃. In addition, the products have passed a number of international certifications, such as CE, EN (EN 50264, EN50382, EN50306) certification, etc., to ensure their quality and safety.

Four, High-temperature cable application cases and scenes

Industrial production of High-temperature cable

Iron and steel smelting: high-temperature cables transmit power and data in steel furnaces and high-temperature production lines to ensure continuous production. Glass manufacturing: used in high-temperature furnaces to ensure the stability and safety of the production process.

Petrochemical High-temperature cable

Chemical reactors: connecting high-temperature reaction equipment and control systems to ensure precise control of chemical reactions.

Pipeline Conveying: Used in high temperature fluid conveying and monitoring systems.

Power and Energy High Temperature Cables

Solar power generation: connecting solar panels and inverters for efficient transmission of electricity.

Wind power generation: in wind turbines to ensure stable transmission of power in high temperature and high humidity environments.

Aerospace High Temperature Cables

Aero-engine: Ensure stable transmission of power and signal under extreme high temperature and vibration environment.

Satellite communication: in the space environment, to provide stable power and data transmission support.

Transportation High Temperature Cables

High-speed trains: Ensure stable power and signal in high temperature, high humidity and vibration car environment.

Electric Vehicle Charging: Support high temperature environment power transmission in fast charging station.

Medical Equipment High Temperature Cables

Medical equipment connection: Ensure stable power and signal transmission in high temperature sterilization and surgical equipment.

Military & Defense High Temperature Cables

Missile Systems: Ensure stable operation of missile systems under extreme conditions.

Mobile equipment: provide stable power support for military mobile equipment.

high temperature resistant cables

V. B-end buyers procurement to avoid the pit guide: High Temperature Cables 10 purchase skills

TST CABLES(www.tstcables.com) senior engineers summarized ten tips for you, I hope to help you choose high-quality high-temperature cables, if you want to buy cables do not step on the pit, pay attention to TST CABLES on the line.

Define the temperature range of high-temperature cables: Need to understand the maximum temperature and duration of the required high temperature cable can withstand, to ensure the safe operation of the cable in a high temperature environment.

Select the appropriate high temperature cable material: According to the different needs of the use of the environment, select the appropriate high temperature cable insulation materials and sheath materials, such as silicone rubber, graphitized polyimide, fluoroplastics, etc. These materials can maintain excellent electrical properties and mechanical strength at high temperatures.

Consider high temperature cable structure and size: The structure of high-temperature cables should meet the requirements of specific environments, such as high-temperature resistance and corrosion resistance.

The size and length of the cable should ensure that it can be adapted to the requirements of the equipment, while taking into account the bending radius and installation space.

High-temperature cable core number and cross-sectional area: According to the specific needs of the appropriate number of cores and cross-sectional area to meet the needs of high-power electrical equipment.

Focus on the safety of high-temperature cables: Select high temperature cables that meet the relevant standards and regulations, such as with UL, CE, EN and other certifications to ensure the safety performance of the cable.

Understand the high-temperature cable technical standards: Familiarize yourself with the relevant technical standards at home and abroad, such as IEC or specific national standards, to ensure that the cable purchased meets the specification requirements.

Consider the special environmental conditions of high-temperature cables: Cables used in special environmental conditions (such as high temperature, high humidity, corrosion, etc.) need special attention to their weather resistance and corrosion resistance.

High-temperature cable packaging and transportation: For high temperature cables exported or transported over long distances, the packaging should be tight and in accordance with international transportation standards to reduce the risk of damage during transportation.

High-temperature cable supplier technical information and certification: Ensure that high temperature cable suppliers provide complete technical information and certification documents, so that there is a clear reference and guidance in the process of use.

Consider High Temperature Cables supplier after-sales service: Choose high temperature cable manufacturer with good after-sales service, TST CALBES is a one-on-one engineer to provide full after-sales guidance, so that when problems arise during the use of the cable can be resolved in a timely manner.

TST CALBES engineers suggest that you need to consider many aspects when purchasing high-temperature cables, including the temperature range of the cable, the choice of materials, structure and size, safety, and the supplier’s after-sales service. Through careful comparison and selection, you can ensure that you get the right high temperature cable for your specific working environment, thus guaranteeing the stability and safety of power transmission.

High Temperature Cables Manufacturer TST CABLES

TST CABLES High Temperature Cables, stable transmission, in control! TST CABLES High Temperature Cables are made of high standard military materials, with excellent moisture-proof, anti-corrosion, anti-damage, anti-radiation, low-smoke, halogen-free, flame-retardant characteristics, to ensure stable and error-free signal transmission. The multi-core design meets the needs of complex circuits, making your industrial automation, energy transportation, aviation, nuclear power, wind power, ships and other projects more reliable and efficient. Strictly enforcing several national standards and passing multiple quality tests, it guarantees the stable operation of your project.

TST CABLES–Specializing in high temperature resistant cable applications and solutions.

For more information on railway cables, Silicone Cables, marine cables, low-smoke, halogen-free, flame-retardant, high temperature resistant cables or to customize cables for your machinery or system, visit https://www.tstcables.com/product/ orsend an e-mail to:[email protected]

0 notes

Text

Introduction of Monolithic Refractory Products

Monolithic refractory products are a type of unshaped refractory material that is used to create a seamless, protective lining in furnaces, kilns, and other high-temperature applications. Unlike traditional shaped refractories, which are made from pre-formed bricks or tiles, monolithic refractory products are installed in a plastic or dry state and then cured to form a hard, monolithic structure.

Advantages of Monolithic Refractory Products

Monolithic refractory products offer several advantages over traditional shaped refractories, including:

Versatility: Monolithic refractories can be cast, vibrated, gunned, or rammed into place, making them suitable for a wide variety of shapes and applications.

Joint-free construction: Monolithic refractories create a seamless lining that is less susceptible to gas leaks and heat loss.

Improved strength and durability: Monolithic refractories can be made to be stronger and more durable than traditional shaped refractories, as they are not limited by the size and strength of individual bricks or tiles.

Ease of repair: Monolithic refractories can be easily repaired by patching or resurfacing, which can extend the life of the lining.

Types of Monolithic Refractory Products

There are several different types of monolithic refractory products available, each with its own unique properties and applications. Some of the most common types include:

Castable refractories: Castable refractories are mixed with water or a liquid binder and then poured into place. They are typically used for applications where a smooth, monolithic surface is required.

Plastic refractories: Plastic refractories are pre-mixed with a binder and can be formed by hand or with a tool. They are often used for patching and repairs.

Ramming mixes: Ramming mixes are dry materials that are compacted into place using a hammer or press. They are typically used for applications where high density and strength are required.

Gunning mixes: Gunning mixes are dry materials that are sprayed onto a surface using a pneumatic gun. They are often used for large-scale applications or for applications where access is limited.

Patching mixes: Patching mixes are used to repair damaged areas of monolithic refractory linings. They are typically made from the same type of material as the original lining.

Applications of Monolithic Refractory Products

Monolithic refractory products are used in a wide variety of applications, including:

Industrial furnaces: Monolithic refractories are used to line industrial furnaces used for processes such as metal melting, heat treating, and incineration.

Kilns: Monolithic refractories are used to line kilns used for firing ceramics, glass, and other materials.

Power plants: Monolithic refractories are used to line boilers and other components in power plants.

Petrochemical plants: Monolithic refractories are used to line reactors, crackers, and other components in petrochemical plants.

Waste incineration: Monolithic refractories are used to line incinerators used to dispose of hazardous waste.

Choosing the Right Monolithic Refractory Product

The type of monolithic refractory product that is right for you will depend on a number of factors, including the specific application, the desired properties of the lining, and the budget. It is important to consult with a qualified refractory specialist to get the best possible recommendation.

Installation of Monolithic Refractory Products

The installation of monolithic refractory products should be done by experienced and qualified personnel. The specific installation process will vary depending on the type of product and the application. However, some general steps include:

Surface preparation: The surface to be lined must be clean, dry, and free of debris.

Mixing: The refractory material is mixed according to the manufacturer's instructions.

Application: The refractory material is applied using the appropriate method (casting, vibrating, gunning, or ramming).

Curing: The refractory material is allowed to cure according to the manufacturer's instructions.

Maintenance of Monolithic Refractory Products

Monolithic refractory products should be inspected regularly for signs of wear or damage. Damaged areas should be repaired promptly to prevent further damage to the lining. Regular maintenance can help to extend the life of the lining and reduce downtime.

Monolithic refractory products are an essential component of many high-temperature applications. They offer a number of advantages over traditional shaped refractories, including versatility, joint-free construction, improved strength and durability, and ease of repair. With the right product selection, installation, and maintenance, monolithic refractory products can provide years of reliable service.

Additional Tips

When selecting a monolithic refractory product, it is important to consider the chemical environment in which it will be used. Some refractory materials are more resistant to certain chemicals than others.

The temperature

1 note

·

View note

Text

Sachin Industries Limited (SIL) is a leading provider of filter presses, glass reactors & special alloys offering a broad portfolio of products, services, and expertise to support industrial customers.

Since 1982, SIL has been manufacturing, designing, and supplying filter presses, polypropylene filter plates, and P.P. Membrane Filter Plates in India. As a part of innovation & growth in 2011, the organization started developing a glass-lined equipment manufacturing plant “SILGLAS” that served as a global benchmark. The facility was built in technical collaboration with JP Laboratories, Inc., a US company with more than 80 patents globally. We take great pride in introducing ourselves as one of the largest, most qualified, and most experienced technocrat teams in the country.

For more information visit the website https://www.sachininternational.com/

1 note

·

View note

Text

0 notes

Text

Tips for Optimizing Efficiency in Your Chemical Engineering Lab with the Right Equipment

Chemical engineering is that branch of engineering that touches the lives of all of us. They are the engineering wizards that turn raw materials into useful and valuable products. With the principles of chemistry, math, and physics and the aid of equipment by top chemistry engineering lab equipment manufacturers, they design processes and equipment for making things like chemicals, medicines, fuels, and even food on a large scale.

Chemical engineers figure out how to do it efficiently, safely, and economically. They're like the chefs of the industrial world, creating the instructions for making stuff in factories. Chemical engineering lab equipment manufacturers are proud to be collaborators with chemical engineers worldwide. They are on board as the official chemical engineering lab equipment manufacturers and suppliers to the topmost chemical engineering companies in the world.

Tips for Optimizing Efficiency By Chemical Engineering Lab Equipment Suppliers

Optimizing efficiency in a chemical engineering lab relies on several key factors, including having the right equipment from the best chemical engineering lab equipment manufacturer and employing effective practices. Here are some tips for achieving greater efficiency, along with suitable examples:

Material Compatibility:

Consider the materials you'll be working with and ensure that the equipment is compatible with those substances. Carefully assess the materials that will come into contact with the equipment. Ensure it can handle the corrosiveness, reactivity, and potential chemical interactions with your substances. Consult material compatibility charts and guidelines for reference provided along with the chemical engineering lab equipment list.

Example: When working with highly corrosive chemicals, choose equipment made from corrosion-resistant materials such as PTFE (Teflon), stainless steel, or glass-lined reactors. For handling reactive substances, consider specialized reactors like Hastelloy reactors, designed for chemical resistance.

Harness The Power Of Automation:

Whenever possible, leverage automation and computer-controlled systems to increase precision and reduce human error. Check with chemical engineering lab equipment manufacturers and suppliers of the latest automated equipment that shall significantly enhance efficiency. Here's how automation achieves this:

Precision and Consistency

24/7 Operation

Reduced Human Error

Accurate and real-time data acquisition

Parallel Processing

Task Integration within a single system

Remote Monitoring and Control

Better safety standards with handling of hazardous or toxic materials without direct human contact

Workflow Efficiency

Resource Optimization

Instrument Integration:

Mostly, chemical engineers plan to use multiple instruments in sync. Ensure to source equipment from experienced chemical engineering lab equipment suppliers that are compatible and integrate seamlessly with automated processes.

Example: Gas chromatography-mass spectrometry (GC-MS) systems combine the separation capabilities of GC with mass spectrometry for compound identification. These integrated systems streamline chemical analysis.

Optimizing Energy Use

Modern Chemical engineering labs must strategize and take practical steps to reduce energy consumption while maintaining or improving productivity. Some of these practices are:

Invest in energy-efficient lab equipment and instrumentation, such as energy-efficient refrigeration systems, ovens, and pumps.

Ensure that lab equipment is correctly sized, as it reduces energy waste.

Use smart controls and sensors to implement heating, ventilation, and air conditioning (HVAC) systems with controls and sensors.

LED lighting for less consumption of electricity.

Use automated timers that turn off lighting, fume hoods, and equipment during non-operational hours or when not in use.

It is a great thing to practice periodic energy audits to identify areas of energy inefficiency within the lab.

Avoid energy wastage by optimizing temperature and pressure.

Implement energy management systems for real-time monitoring and control of lab equipment.

Every step must be taken to lower the carbon footprint, and partial reliance on clean energy is the best and proven step for it.

Design or revamp chemical engineering labs with Energy-Efficient Lab Design

Regulatory Compliance & Supplier Reputation

Undoubtedly, chemical engineering labs witness the use of chemical engineering lab equipment at all times. Thus, it is one of the labs where there can be no quality compromise of the equipment. Chemical engineers can optimize the efficiency of their lab operation by selecting equipment that complies with relevant industry regulations and safety standards. With the leading chemical engineering lab equipment suppliers comes the guarantee of certifications and approvals that validate the equipment's suitability for use in the chemical engineering lab.

With chemical engineering lab equipment suppliers and exporters, every aspect of lab equipment comes verified. They have a proven track record of providing equipment that is certified to meet safety and regulatory standards, ensuring compliance.

Setting Up Of Safety Enclosures

These enclosures protect both operators and the surrounding environment during experiments involving hazardous materials or reactions. The following measures are effective steps for lab operations in chemical engineering labs:

Set-up safety enclosures provide a physical barrier between these hazardous materials and laboratory personnel.

Ensure these enclosures have built-in trays, catchment systems, or containment chambers. They help to capture and safely manage any spills, preventing them from spreading into the lab environment.

Check with chemical engineering lab equipment suppliers to install fume hoods. They ensure that the lab air remains clean and safe to breathe.

The Safety enclosures must have transparent windows or panels that allow engineers to observe and manipulate experiments without direct contact with the chemicals.

Safety enclosures, like glove boxes and isolation chambers, must be sourced from top chemical engineering lab equipment manufacturers. They are essential when working with air-sensitive or moisture-sensitive materials.

Provision of emergency shut-off systems for quick deactivation of equipment or experiments in case of emergencies or unexpected events.

Safety enclosures are designed and manufactured to meet strict safety standards and regulations. Using compliant enclosures ensures that the lab adheres to safety guidelines and protocols, which is essential for both research integrity and personnel safety.

Safety enclosures by chemical engineering lab equipment suppliers come in various configurations to accommodate different experimental requirements. Share your lab requirements with them, and the experts will install safety enclosures that sync absolutely with your lab goals.

Many more tips by chemical engineering lab equipment suppliers can help you make informed decisions when selecting equipment for your chemical engineering lab. Following these tips ensures that your choices align with your research goals and contribute to the overall efficiency and productivity of your laboratory operations.

0 notes

Text

Stirring Assembly | Mobile Mixing Reactor | manufacturer & suppliers | Goel Scientific | Canada

We serve the best Stirring Assembly for Glass Reactors, Mixing Reactors, Stirring Assembly SS PTFE lined, Stirring Drives, VFD, Canada, USA, Ontario, BC Quebec

#Best#Top#the Stirring Assembly for Glass Reactors#Mixing Reactors#Stirring Assembly SS PTFE lined#Stirring Drives#VFD#Canada#USA#Ontario#BC Quebec

1 note

·

View note

Text

Easy Expansion Stainless Steel Tanks for CSTR Reactors: The Ultimate Solution for Industrial Efficiency

At Shijiazhuang Zhengzhong Technology Co., Ltd, we pride ourselves on providing top-of-the-line solutions for a wide range of industrial applications. Among our most innovative offerings are stainless steel tanks designed for Continuous Stirred Tank Reactors (CSTRs). These tanks are not only durable but also offer a unique advantage—easy expansion capabilities, making them the perfect choice for industries requiring flexibility and efficiency.

The Role of CSTR Reactors in Industrial Applications

CSTR reactors are widely used in industries such as wastewater treatment, bio-energy, chemical production, and food processing. They ensure continuous mixing and maintain uniform reaction conditions, making them ideal for processes that require a consistent flow of input materials and output products. The efficiency of a CSTR system depends heavily on the quality and versatility of its tank, which is where stainless steel tanks from Shijiazhuang Zhengzhong Technology Co., Ltd come into play.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Why Choose Stainless Steel for CSTR Reactors?

Stainless steel offers several key advantages for tanks used in CSTR reactors, including:

Corrosion Resistance: Stainless steel is highly resistant to corrosion, making it an excellent material for tanks that handle corrosive materials or are exposed to harsh environments. This ensures a longer lifespan and reduced maintenance costs.

Durability and Strength: Stainless steel tanks are built to withstand high pressure and extreme temperatures, which are common in industrial processes. This makes them reliable and safe for continuous operations in CSTR reactors.

Hygienic and Easy to Clean: For industries such as food processing and pharmaceuticals, hygiene is a top priority. Stainless steel’s non-porous surface is easy to clean and sanitize, preventing contamination and ensuring the integrity of the product.

Customizable Design: Our stainless steel tanks can be customized in terms of size, shape, and configuration to meet specific requirements for CSTR reactors. Whether it's for large-scale industrial applications or smaller setups, we provide tailored solutions to meet your exact needs.

Easy Expansion for Growing Industrial Needs

One of the standout features of our stainless steel tanks for CSTR reactors is their easy expansion capability. As industries grow and demand increases, expanding existing infrastructure becomes a critical need. Traditional tanks often require significant effort and cost to modify or replace, but our stainless steel tanks are designed with scalability in mind.

Key benefits of easy expansion include:

Modular Design: Our tanks feature a modular design that allows for seamless expansion. Additional tank sections can be added with minimal disruption to ongoing operations, enabling facilities to scale up their production capacity quickly and efficiently.

Cost Efficiency: Expanding an existing system is far more cost-effective than building new infrastructure from scratch. With easy expansion capabilities, industries can gradually increase their capacity without incurring the high costs of complete system overhauls.

Flexibility: Industries dealing with variable production demands can benefit from the flexibility of our stainless steel tanks. Whether there's a temporary surge in demand or a long-term need for increased capacity, our tanks can easily accommodate changes in production volumes.

Meeting International Standards for Quality and Safety

At Shijiazhuang Zhengzhong Technology Co., Ltd, we are committed to delivering products that meet the highest international standards. Our stainless steel tanks are manufactured in strict compliance with ISO 9001, CE, and other relevant certifications, ensuring top-tier quality and safety. Each tank undergoes rigorous testing and inspection to ensure it meets the requirements of the specific industrial applications in which it will be used.

Applications of Easy Expansion Stainless Steel Tanks

Our stainless steel tanks are versatile and can be used across a wide range of industries, including:

Wastewater Treatment: CSTR reactors in wastewater treatment facilities benefit from the durability and easy expansion features of our stainless steel tanks. They can handle various sludge processing and anaerobic digestion processes with ease.

Bio-Energy Production: In the bio-energy sector, our stainless steel tanks support the digestion of organic matter, enabling the efficient production of biogas.

Chemical Processing: The corrosion resistance and easy cleaning properties of stainless steel make our tanks ideal for chemical manufacturing, ensuring consistent and safe production.

Food and Beverage Industry: Our hygienic stainless steel tanks are perfect for food processing applications, where cleanliness and scalability are crucial.

At Shijiazhuang Zhengzhong Technology Co., Ltd, our stainless steel tanks for CSTR reactors are designed to provide unmatched reliability, durability, and flexibility. With easy expansion capabilities, these tanks offer a scalable solution that can grow alongside your industrial needs. Whether you’re in wastewater treatment, bio-energy production, or any other industrial sector, our stainless steel tanks provide the perfect combination of strength, hygiene, and adaptability to meet your operational requirements.

Ready to upgrade your CSTR reactor system? Contact us today to learn how our stainless steel tanks can help you achieve efficiency and scalability for your next project!

0 notes

Text

The use of magnesia bricks

What is a Magnesia brick?Magnesia brick is a refractory material mainly composed of magnesium oxide, which has the following uses:

1. Furnace lining: Magnesia bricks are widely used as lining materials for various industrial furnaces. Because magnesia bricks have excellent refractory performance and high temperature stability, and can withstand erosion and impact at extremely high temperatures, they are very suitable as protective materials for the inner wall of the furnace.

2. Starting plates and roofs: Magnesia bricks can also be used in the construction of starting plates and roofs. In the steelmaking and metallurgical industry, the high refractory performance and corrosion resistance of magnesia bricks make it an ideal material choice for the manufacture of starting plates and furnace roofs of blast furnaces, electric arc furnaces, converters and other equipment.

3. Glass kiln: Because magnesia bricks are less corrosive to glass melt and have good thermal conductivity and heat resistance, magnesia bricks are widely used in the inner lining and heat insulation layer of glass kilns. It can withstand thermal stress and thermal expansion under high temperature conditions, protect the kiln structure stability and provide good heat insulation effect.

4. Ladles, converters, electric arc furnaces: In the iron and steel industry, magnesia bricks are widely used in the lining of smelting equipment such as ladles, converters and electric arc furnaces. Magnesia bricks can withstand high temperature and erosion, and have good thermal conductivity and thermal expansion properties, suitable for environments that withstand high temperatures and chemical reactions during the smelting process.

5. Chemical equipment: Due to its excellent acid and alkali resistance, magnesia bricks are widely used in acid and alkali resistant linings and reactor linings in chemical equipment. It can resist the erosion and corrosion of chemical substances and ensure the stable operation of the device.

In short, magnesia bricks are widely used in furnace lining, starting plate, furnace roof, glass furnace, ladle, converter, electric arc furnace, chemical equipment and power industry due to their excellent refractory performance, corrosion resistance and high temperature stability.

0 notes

Text

"The Science Behind Refractories: How They Withstand Extreme Heat and Chemical Reactions"

Refractories are specialized materials that are designed to withstand high temperatures, extreme mechanical stress, and chemical corrosion in various industrial processes. They are used to line furnaces, kilns, reactors, and other equipment where materials are subjected to intense heat or harsh conditions.

The primary function of refractories is to provide thermal insulation and resistance to heat transfer. They are made from materials with high melting points, such as clay, silica, alumina, magnesia, and zirconia. These materials have excellent heat resistance and can withstand temperatures ranging from several hundred degrees Celsius to several thousand degrees Celsius without significant deformation or damage.

Refractories are essential in industries such as steelmaking, cement production, glass manufacturing, petrochemical processing, and non-ferrous metal production. In steelmaking, for example, refractories are used to line the walls and floors of blast furnaces, converters, and ladles to withstand the high temperatures and corrosive gases involved in the process.

Refractories are chosen based on their properties, including thermal conductivity, thermal expansion, chemical resistance, and mechanical strength. Different applications require specific refractory materials with tailored compositions and properties to meet the specific requirements of the process.

0 notes

Text

Unwavering Strength and Resilience: The Emergence of Refractories Market in Modern Industries

The Refractories Market has been witnessing steady growth over the past few years, driven by the increasing demand from various end-use industries, such as steel, cement, glass, and non-ferrous metals. Refractories are high-temperature-resistant materials that are used in lining furnaces, kilns, reactors, and other high-temperature equipment. They provide excellent thermal stability, corrosion resistance, and mechanical strength, making them ideal for extreme conditions in these industries.

The steel industry is the largest consumer of refractories, accounting for a significant share of the market demand. The use of refractories in steelmaking is essential for maintaining high temperatures in furnaces and minimizing heat loss. The cement and glass industries are also major end-users of refractories, where they are used for lining kilns and melting tanks, respectively. Moreover, the increasing demand for non-ferrous metals, such as aluminum, copper, and nickel, is also driving market growth, as refractories are crucial for the extraction and refining processes.

Request For The Sample Copy of The Report @ https://www.persistencemarketresearch.com/samples/3510

The market has witnessed a shift towards more sustainable and energy-efficient refractories in recent years, with manufacturers focusing on developing advanced materials that reduce greenhouse gas emissions and energy consumption. Moreover, the adoption of green building practices and increasing environmental regulations have led to the development of eco-friendly refractories. The Asia-Pacific region dominates the global refractories market, with China being the largest consumer and producer of refractories in the world. With the growing demand from end-use industries and the increasing focus on sustainable materials, the refractories market is expected to witness significant growth in the coming years.

About us: –

Persistence Market Research is a U.S.-based full-service market intelligence firm specializing in syndicated research, custom research, and consulting services. Persistence Market Research boasts market research expertise across the Healthcare, Chemicals and Materials, Technology and Media, Energy and Mining, Food and Beverages, Semiconductors and Electronics, Consumer Goods, and Shipping and Transportation industries. The company draws from its multi-disciplinary capabilities and high-pedigree team of analysts to share data that precisely corresponds to clients’ business needs.

Contact Us:

Persistence market research Address – 305 Broadway, 7th Floor, New York City, NY 10007 United States U.S. Ph. – +1-646-568-7751 USA-Canada Toll-free – +1 800-961-0353 Sales – [email protected]

0 notes