#gas turbine engine

Explore tagged Tumblr posts

Text

Steam Turbine Manufacturers In India

0 notes

Text

Ford Thunderbird PSV-102, 1955. An experimental first generation Thunderbird fitted with a Boeing gas turbine engine. Accounting for inflation, $188,000 in 1955 is worth $2,159,859 in 2024 so that was quite an investment

#Ford#Ford Thunderbird#Ford Thunderbird PSV-102#gas turbine#Boeing engine#experimental car#test vehicle#1955#1950s#first generation#turbine

697 notes

·

View notes

Text

57 notes

·

View notes

Text

Old project turbo charger making a gas turbine posible

8 notes

·

View notes

Text

Sustainable Power Generation: Renewable Energy Solutions

Total Power Solutions

Kaltimex Energy is a well-known company in Bangladesh that specializes in providing engineering, procurement, and construction (EPC) services, particularly in the energy sector.

Kaltimex Energy Bangladesh is involved in various projects related to power generation, including the installation and maintenance of power plants, electrical and mechanical works, and other energy-related services. They have been involved in the development of both conventional and renewable energy projects in Bangladesh.

Kaltimex Energy has been working in the field of power plant business for over 2 decades. They deal with natural Gas Engine, Industrial Gas Generator, Diesel Generator, Exhaust Gas Boiler, Gas Fired Boiler, Vapor Absorption Machine (Chiller), Thermal Fluid Heater, Transformer, Radial Gas Turbine and Steam Turbine for power plants on turnkey basis projects from concept to commissioning within stipulated time period & budget.

MWM, HTT, VIESSMANN, VOLTAS, ENMAX & MAXWATT, and others are marketed brands.

#Gas Engine#Power Generation#Power Plants#Natural Gas Engine#Industrial Gas Generator#Diesel Generator#Exhaust Gas Boiler#Gas Fired Boiler#Vapor Absorption Machine#Industrial Boiler#Thermal Fluid Heater#Transformer#Radial Gas Turbine#Steam Turbine

4 notes

·

View notes

Text

The global Air Starter Market in terms of revenue was estimated to be worth $449 million in 2024 and is poised to reach $559 million by 2029, growing at a CAGR of 4.5% from 2024 to 2029 according to a new report by MarketsandMarkets™. The demand for air starters is on the rise globally, driven by a multitude of factors. Ongoing advancements in air starter technology, such as the use of enhanced materials and designs that improve durability and efficiency and provide increased torque capabilities are particularly being focused. Unlike electric starters, air starters can withstand extreme temperatures and dusty environments and eliminate the risk of sparks. Further, expansion in key industries such as oil & gas, marine, aviation significantly contributes to the increased adoption of air starters. These sectors largely use heavy equipment which require a reliable and robust engine starting solutions to sustain their operations, making air starters an ideal choice.

#air starter#air starter market#air starters#turbine#turbine air starter#vane air starter#electric air starter#gas turbines#gas turbine#turbines#energy#energia#power#aviation#oil industry#oil and gas companies#oil rig#oil and gas#oil and gas industry#oil and gas drilling#marine#marine engine

0 notes

Text

Fuel-Efficient Turbofans: Revolutionizing Modern Aviation

Introduction

The aviation industry is in a constant quest for efficiency, reliability, and environmental sustainability. Central to this mission are fuel-efficient turbofan engines, which represent the forefront of modern aerospace engineering. These engines are integral to the performance of contemporary aircraft, including the iconic Airbus A380. This article delves into the intricate workings of fuel-efficient turbofans, the evolution of gas turbine technology, and the various types of aircraft engines that power our skies.

Fuel-Efficient Turbofans: The Heart of Modern Aircraft

Fuel-efficient turbofan engines are designed to maximize thrust while minimizing fuel consumption and emissions. Unlike traditional turbojet engines, which produce thrust solely through the high-speed expulsion of exhaust gases, turbofans generate most of their thrust through a large fan at the front of the engine.

Key Components and Functionality

Fan: The large fan at the front of the engine draws in a significant amount of air. A portion of this air is directed through the core of the engine for combustion, while the rest bypasses the core, providing additional thrust. This bypassed air helps reduce fuel consumption and noise.

Compressor: The compressor increases the pressure of the incoming air before it enters the combustion chamber. Modern turbofans use multi-stage compressors to achieve high pressure ratios, which improve efficiency.

Combustion Chamber: In this section, fuel is mixed with the compressed air and ignited, producing high-temperature, high-pressure gases.

Turbine: The turbine extracts energy from the high-pressure gases produced in the combustion chamber to drive the fan and compressors. It is divided into high-pressure and low-pressure sections, each playing a critical role in the engine’s operation.

Bypass Duct: This duct allows the bypassed air to flow around the engine core, contributing to the overall thrust and improving fuel efficiency.

The Evolution of Gas Turbine Technology

Gas turbine engines have undergone significant advancements since their inception, evolving from simple turbojets to sophisticated high-bypass turbofans. This evolution has been driven by the need for greater fuel efficiency, reliability, and environmental performance.

Historical Development

Turbojets: The earliest jet engines, turbojets, were developed during World War II. They are characterized by their simple design, where all incoming air passes through the combustion chamber. Turbojets are efficient at high speeds but consume more fuel compared to modern engines.

Low-Bypass Turbofans: Post-World War II, engineers introduced turbofans with a low bypass ratio, where a portion of the air bypasses the core engine. This design improved fuel efficiency and reduced noise.

High-Bypass Turbofans: Modern commercial aviation relies on high-bypass turbofans, where a significant amount of air bypasses the core engine. This design achieves superior fuel efficiency and lower emissions, making it the standard for contemporary jetliners.

Technological Innovations

Materials: Advances in materials, such as composites and high-temperature alloys, have allowed engines to operate at higher temperatures and pressures, improving efficiency.

Aerodynamics: Improved aerodynamic designs, including blade shapes and fan configurations, have reduced drag and enhanced the overall performance of turbofan engines.

Noise Reduction: Innovations in acoustic technology and engine design have significantly reduced noise levels, making modern turbofans quieter and more environmentally friendly.

Types of Aircraft Engines

Aircraft engines are diverse, each type tailored to specific operational requirements and aircraft sizes. The main types include:

Turbojets

Turbojets are the simplest form of jet engines. They operate by compressing incoming air, mixing it with fuel, igniting the mixture, and expelling the exhaust gases at high speed to generate thrust. Turbojets are efficient at high speeds and altitudes but are less fuel-efficient compared to other engine types.

Turbofans

Turbofans are the most common engines used in commercial aviation today. They come in two main varieties:

Low-Bypass Turbofans: Suitable for military and high-speed aircraft, these engines provide a balance between speed and efficiency.

High-Bypass Turbofans: Used in commercial airliners, these engines offer superior fuel efficiency by bypassing a significant portion of air around the engine core. This design makes them ideal for long-haul flights and large passenger jets.

Turboprops

Turboprops combine the principles of jet propulsion with propeller-driven thrust. They are commonly used in regional and small commuter aircraft. A gas turbine engine drives a propeller through a reduction gearbox. Turboprops are highly efficient at lower speeds and shorter distances, making them suitable for regional flights.

Piston Engines

Piston engines are similar to those found in cars. They operate by igniting an air-fuel mixture within cylinders to drive pistons, which in turn rotate a propeller. Piston engines are typically used in small, general aviation aircraft and are known for their simplicity and reliability.

The Airbus A380: A Marvel of Modern Engineering

The Airbus A380, the world’s largest passenger airliner, exemplifies the pinnacle of aviation technology and engineering excellence. Equipped with four advanced turbofan engines, the A380 is designed to offer unparalleled capacity, range, and fuel efficiency.

Engine Technology

The A380 typically uses either the Rolls-Royce Trent 900 or the Engine Alliance GP7200 engines. Both engines are high-bypass turbofans, incorporating the latest advancements in materials, aerodynamics, and noise reduction.

Rolls-Royce Trent 900: This engine features a three-shaft design, providing high efficiency and reliability. Advanced materials and aerodynamic improvements contribute to its exceptional performance and fuel economy.

Engine Alliance GP7200: A product of a collaboration between General Electric and Pratt & Whitney, the GP7200 combines the best technologies from both companies. It offers high thrust, fuel efficiency, and reduced maintenance costs.

Environmental Impact

The A380’s engines are designed to meet stringent environmental standards. They produce lower emissions and noise levels compared to previous-generation engines, aligning with global efforts to reduce the aviation industry’s environmental footprint.

Operational Efficiency

The A380 can carry up to 853 passengers in an all-economy configuration, making it ideal for high-density routes. Its fuel-efficient engines enable it to cover long distances with fewer refueling stops, reducing operational costs and enhancing route flexibility.

Conclusion

The development of fuel-efficient turbofan engines has revolutionized modern aviation, enabling aircraft to fly farther, faster, and with greater environmental responsibility. The Airbus A380 stands as a testament to these advancements, showcasing the capabilities of cutting-edge gas turbine technology. As the aviation industry continues to evolve, the pursuit of efficiency, sustainability, and innovation remains at the forefront, promising a future where air travel is more economical and environmentally friendly than ever before.

0 notes

Text

Understanding Gas Turbine Engines: Components, Functionality, and Applications

Gas turbine engines, a marvel of modern engineering, are integral to various industries, most notably in aviation and power generation. These engines convert natural gas or other liquid fuels into mechanical energy, which can then be used to generate electricity or power aircraft. In this blog, we'll explore the key components, functionality, and applications of gas turbine engines.

Components of Gas Turbine Engines

Gas turbine engines consist of three primary components: the compressor, the combustor, and the turbine.

Compressor: The compressor's primary function is to draw in air from the environment and compress it to a high pressure. This compressed air is then directed into the combustor. Compressors can be axial or centrifugal, with axial compressors being more common in modern engines due to their efficiency and ability to handle higher airflow rates.

Combustor: The combustor is where the magic happens. Here, the high-pressure air from the compressor is mixed with fuel and ignited. The combustion process generates a high-temperature, high-pressure gas. The design of the combustor is critical to ensure efficient combustion while minimizing emissions.

Turbine: The high-pressure gas from the combustor expands rapidly as it passes through the turbine, causing the turbine blades to spin. This spinning turbine drives the compressor and, in the case of aircraft engines, provides thrust. In power generation, the mechanical energy from the turbine is used to turn a generator and produce electricity.

Functionality of Gas Turbine Engines

The basic functionality of gas turbine engines can be summarized in three steps: intake and compression, combustion, and expansion and exhaust.

Intake and Compression: Air is drawn into the engine and compressed by the compressor, increasing its pressure and temperature.

Combustion: The high-pressure air is mixed with fuel in the combustor and ignited. This process generates a high-temperature, high-pressure gas.

Expansion and Exhaust: The high-pressure gas expands through the turbine, causing it to spin and generate mechanical energy. The expanded gas is then expelled through the exhaust, creating thrust in aircraft engines or driving a generator in power plants.

Applications of Gas Turbine Engines

Gas turbine engines are incredibly versatile and are used in various applications:

Aviation: Gas turbine engines are the backbone of modern aviation. They power nearly all commercial aircraft, providing the necessary thrust for takeoff, flight, and landing. The high power-to-weight ratio of gas turbine engines makes them ideal for aircraft propulsion.

Power Generation: In power plants, gas turbines are used to generate electricity. These plants can be either simple cycle, where the turbine's mechanical energy directly drives a generator, or combined cycle, where the waste heat from the gas turbine is used to generate additional electricity via a steam turbine.

Industrial Applications: Gas turbines are also used in various industrial applications, including oil and gas extraction, marine propulsion, and mechanical drives for compressors and pumps.

Military Applications: The military employs gas turbine engines in a variety of vehicles, including tanks and ships, due to their high power output and reliability.

Advantages of Gas Turbine Engines

Gas turbine engines offer several advantages over other types of engines:

High Efficiency: Gas turbines are highly efficient, especially when used in combined cycle power plants, where efficiency can exceed 60%.

Reliability: Gas turbines have fewer moving parts compared to other types of engines, leading to higher reliability and lower maintenance costs.

Environmental Benefits: Modern gas turbines are designed to minimize emissions, making them a more environmentally friendly option compared to traditional coal or oil-fired power plants.

Versatility: Gas turbines can run on a variety of fuels, including natural gas, diesel, and biofuels, providing flexibility in fuel choice.

Gas turbine engines represent a pinnacle of engineering, playing a crucial role in powering our modern world. Whether in the sky, on the ground, or at sea, these engines provide the necessary power to drive our industries and daily lives.

For more information on sourcing gas turbine engine parts and components, visit Sourcing Streamlined. They offer a wide range of high-quality parts to ensure the optimal performance of your gas turbine engines.

1 note

·

View note

Text

Gas Turbine Cycles | Open Cycle and Closed Cycle Gas Turbine.

The classification of the gas turbine cycle refers to the path of the working substance. In an open cycle, the working substance or fluid, usually air, flows in and out. Heat is added by burning fuel in the air and the combustion products are released to the atmosphere. Such open-cycle gas turbines, by definition, are internal combustion engines because the combustion process is internal to the cycle.

Read More- https://automobilehut.in/2023/12/gas-turbine-cycles.html

#engineering#gearbox#motorcycle#transmission#engine#automotive#automobile#automatic transmission#gas turbine services market

0 notes

Text

Diesel Engine Expansion Bellows in India

Title: Diesel Engine Expansion Bellows: Preserving Efficiency and Reliability

Introduction

In the realm of heavy machinery and industrial applications, diesel engines reign supreme for their power and durability. Yet, beneath the surface of these mighty engines, there lies a seemingly unremarkable but indispensable component – the diesel engine expansion bellows. These unassuming devices play a vital role in preserving the efficiency, reliability, and longevity of diesel engines. In this essay, we'll explore the significance of diesel engine expansion bellows and their essential contributions to the world of heavy-duty machinery.

Understanding Diesel Engine Expansion Bellows

Diesel engine expansion bellows often referred to simply as bellows, are flexible connectors installed in the exhaust systems of diesel engines. They are designed to absorb and accommodate the thermal expansion and contraction of exhaust piping, which occurs during the engine's operation. These bellows are typically constructed from high-quality materials such as stainless steel to withstand the extreme conditions they face.

Applications in Diesel Engines

Exhaust Systems: Diesel engines generate a tremendous amount of heat during combustion. This heat causes the exhaust piping to expand, which, if not properly managed, can lead to stress, vibration, and structural damage. Diesel engine expansion bellows are strategically placed within the exhaust system to absorb these movements, ensuring that the exhaust system remains intact.

Marine Engines: Diesel engines are commonly used in marine applications, where they power ships, boats, and other vessels. In these settings, bellows play a crucial role in preventing exhaust system failures caused by the engine's vibrations and movements on the water.

Industrial Generators: Diesel generators are relied upon for backup power in various industries. The robustness of these engines is essential, and expansion bellows help maintain the integrity of the exhaust system, ensuring that power generation is uninterrupted.

youtube

Advantages of Diesel Engine Expansion Bellows

Stress Reduction: Bellows effectively reduce stress on exhaust components, such as pipes and manifold connections. This stress reduction extends the lifespan of these parts and reduces the likelihood of costly failures.

Vibration Dampening: Diesel engines produce substantial vibrations during operation. Bellows act as dampers, absorbing vibrations that can otherwise weaken the exhaust system and lead to damage.

Preventing Leaks: Expansion bellows help prevent exhaust leaks, which can compromise engine efficiency and pose health and safety hazards due to the release of harmful emissions.

Maintenance Cost Savings: By protecting the exhaust system from damage, bellows contribute to lower maintenance costs, as there is less need for frequent repairs or replacements.

Compliance with Regulations: In many industries, including marine and power generation, compliance with emissions regulations is critical. Bellows help maintain the efficiency and effectiveness of exhaust after-treatment systems, ensuring that emissions remain within acceptable limits.

Conclusion

Diesel engine expansion bellows may be hidden away within the machinery, but their significance cannot be overstated. These unassuming components quietly go about their business, absorbing the heat, stress, and vibrations generated by powerful diesel engines. In doing so, they play a vital role in preserving the integrity of exhaust systems, ensuring that these engines operate efficiently, reliably, and safely.

As industries continue to rely on diesel engines for their power and performance, diesel engine expansion bellows will remain essential in preventing costly failures and emissions compliance. These uncelebrated but invaluable components are a testament to the intricate engineering and attention to detail that underpin the efficiency and durability of heavy-duty machinery. In the world of diesel engines, expansion bellows are the unsung heroes that keep the engines running smoothly.

#Fan Acoustic Enclosure in India#Turbine Acoustic Enclosures in India#Gas Engine Acoustic Enclosures in India#Diesel Engine Acoustic Enclosure in India#Sound Proof Enclosures in India#Gas Compressor Noise Hoods in India#Ball Mill Acoustic Enclosures in India#Boiler Feed Pump Acoustic Enclosure in India#Centrifugal Blower Acoustic Enclosures in India#Gas Compressor Acoustic Enclosures in India#Air Compressor Acoustic Enclosures in India#Steam Turbine Acoustic Enclosures in India#Steam Turbine Silencers in India#Youtube

0 notes

Text

Writing master's thesis is harder than I expected. Technically, I haven't even started writing yet, I only made a Simulink model of a gas turbine (my thesis is about gas turbine start-up SFC), but it's not even fully functional yet 😕. I spent the whole night trying to figure out, what's wrong with the turbine rotor speed control, and still idk 😫. I could have chosen and easier topic, but I wanted to be ambitious, not make it the easiest way. I know, I have to calm down and accept, that it's going to takie me way longer than 2 days, but I'm already angry 😠 and sometimes I just wanna give up and not write the thesis at all.

#studyblr#motivation#studying#engblr#electrical engineering#engineering#lightningstormstudies#personal#grad student#master's degree#master's thesis#electricity#electrical engineer#electrical engineering student#engineering student#engineering studyblr#engineer#gas turbine#ccgt#power plant#turbine#generator#static frequency converter#power electronics#college student#university student#study#student#grad school#uni

1 note

·

View note

Text

Explore a greener future with TurboTech Steam Turbines in the rice(agro) industry. ECT enhances sustainability, cuts costs, and reduces emissions, revolutionizing rice production. TurboTech's Energy Conversion Technology (ECT) leads the way, offering real-world savings and operational efficiency.

0 notes

Text

The global gas turbine market is expected to grow from an estimated USD 18.9 Billion in 2021 to USD 22.5 Billion by 2026, at a CAGR of 3.6% during the forecast period.

#gas turbine#gas turbine market#gas turbines#gas turbine technology#energy#power generation#power#power plant#power plants#electricity#turbine#turbines#jet engines

0 notes

Photo

Info Seminar Bolier-Turbine-Generator. Jadwal Pelatihan Engineering 2023. Training Bolier-Turbine-Generator di Bandung dan kota lainnya. Topik training engineering: 1. Kompresor Sentrifugal Operasi, Pemeliharaan, Dan Troubleshooting 2. LV And MV Generator 3. Machinery Fluid Mechanics 4. Operasi Dan Pemeliharaan Turbin Gas Dan Generator 5. Operation & Maintenance Of Boiler 6. Operation, Maintenance And Troubleshooting Of Gas Turbine 7. Pembangkit Uap (Boiler) 8. Performance Analisys And Operating Of Generator Set For Senior Operator And Engineer 9. Pompa Dan Kompresor Operasi, Perawatan DanTroubleshooting 10. Pompa Operasi Dan Perawatan 11. Preventive Maintenance Generator 12. Pump And Compressor Operation, Maintenance &Troubleshooting 13. Pump And Compressor Operation, Maintenance And Troubleshooting 14. Pump Operation And Maintenance 15. Pump Operation, Maintenance & Troubleshooting Info seminar training lengkap: WA: 0851-0197-2488 Jadwal training lengkap: https://www.informasi-seminar.com #teknisi #machine #machinery #fluid #mechanic #turbin #gas #generator #pembangkituap #boiler #engineer #pompa #bandung #jakarta #yogya #infoseminar #infotraining #jadwalpelatihan #jadwalseminar #jadwaltraining |Jadwal Training Kompresor Sentrifugal | Training Machinery Fluid | Training Pembangkit Uap (Boiler)| Training Pompa | Jadwal Training Gas Turbine | Jadwal Training Engineering | https://www.instagram.com/p/CneGdO3p4YV/?igshid=NGJjMDIxMWI=

#teknisi#machine#machinery#fluid#mechanic#turbin#gas#generator#pembangkituap#boiler#engineer#pompa#bandung#jakarta#yogya#infoseminar#infotraining#jadwalpelatihan#jadwalseminar#jadwaltraining

0 notes

Text

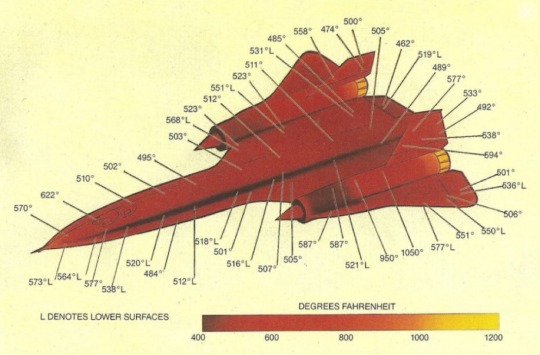

‘Flying at over Mach 3 is a thermal problem. Everything is too hot, including any air you slow down to interact with the vehicle. You are trying to make the vehicle (and the pilots inside) survive for hours in a pizza oven, while they are getting cozy with two 500 million BTU/hour flamethrowers,’ Iain McClatchie, an aviation and turbine engine expert

Quora.

‘When you look at a graph like this, your first impression might be that the vehicle is this glowing hot thing slicing through the icy -52 C air at 80,000 feet. So naturally, you think of the air as cooling the airplane down.

NO…Not so much. The air has to change to the vehicle’s speed to touch the vehicle, and that requires work. That work heats the air. At Mach 3.2, the stagnation temperature of the air is 740 F, which is hotter than every (labelled) point on the above graph! (The nacelles around the engine afterburners, unlabelled, are in fact hotter than the air around them

Basically, the shocks from the airplane heat the air around it, but the vehicle itself cools the air in contact with it down. Once the airplane passes by, all that disturbed air tumbles to a stop, leaving a path of hot air through the upper atmosphere.

‘So back to life in the pizza oven. The basic solution is (a) leave most of the airframe hot and make it out of stuff like titanium and stainless steel that are strong when hot, and (b) start with a large amount of cold fuel, and then dump heat from critical areas into the fuel before burning it. When decoupling from an aerial tanker, half the SR-71’s weight was fuel.

‘A special type of kerosene fuel, JP-7, was developed for the SR-71 to be good as a heat sink. It boils away at 285 C at 1 atmosphere pressure, which is the upper end of the kerosene range. When the plane tanked up at 30,000 feet, the kerosene might start below 0 C. At speed, it would be used to cool the avionics and cockpit, and by the time it arrived at the engine it would get up to 177 C. It was then used as hydraulic fluid for the various engine actuators, primarily the variable geometry nozzle. By the time it got to the fuel injectors it had gotten up to 316 C (but wasn’t boiling because it was at several atmospheres of pressure). At cruise the burner cans were at 330 kPa (about 3.3x the pressure at sea level), so the fuel still didn’t boil as it left the nozzles but the droplets would have evaporated very quickly.’

McClatchie continues;

‘JP-7 is mostly a mix of hydrocarbons centered around C12H26 (dodecane). The graph above shows the vapor pressure of dodecane as a function of reciprocal absolute temperature. That makes it a bit hard to read. 0.0024, for instance, is 417 Kelvin which is 143 Celsius. Liquids start to boil when their vapor pressure is greater than the ambient pressure. I’ve labelled the boiling point of dodecane at 2900 Pa, which is the absolute pressure at 80,000 feet, and 13000 Pa, which is the minimum absolute pressure in the SR-71 fuel tanks. Note that the dodecane component of JP-7 starts to boil at 162 C at sea level… quite a bit less than the advertised 285 C which is actually when the stuff boils away completely.

‘The flash point of JP-7 is 60 C. The fuel was held in tanks whose walls were formed of the skin of the vehicle. Since fuel vapor against the top skin of the vehicle would be well over 60 C during cruise, if air was allowed in any ignition source in the tank would cause a deflagration and destruction of the vehicle. Instead, nitrogen gas from a 260-liter liquid nitrogen dewar was used to pressurize the tanks. This would have mostly been an issue during descent, when the ambient pressure rose and extra gas was needed to fill the tank ullage space. Click on the full article to read more.

Written by Linda Sheffield

@Habubrats71 via X

#sr 71#sr71#sr 71 blackbird#blackbird#aircraft#usaf#lockheed aviation#skunkworks#aviation#mach3+#habu#reconnaissance#cold war aircraft

93 notes

·

View notes

Text

Technology from 1870-1899 (For Encanto fic writers)

So, A mutual of mine @miracles-and-butterfliess pointed out that everyone (including me) tends to forget that Encanto was literally made when the triplets were born. Which is literally 1900 or 1901. Regardless, it was the very beginning of the 19th century so let me tell you about the technology/things they would/wouldn’t have. (And please keep in mind that most of these may or may not have been imported into Colombia yet.)

1870 - 1879

1872—A.M. Ward creates the first mail-order catalog. NO

1873—Joseph Glidden invented barbed wire. NO

1876—Alexander Graham Bell patents the telephone. NO

1876—Nicolaus August Otto invents the first practical four-stroke internal combustion engine. NO

1876—Melville Bissell patents the carpet sweeper. NO?

1878—Thomas Edison invents the cylinder phonograph (known then as the tin foil phonograph). MAYBE

1878—Eadweard Muybridge invents moving pictures. NO?

1878—Sir Joseph Wilson Swan invents the prototype for a practical electric lightbulb. YES?

1879—Thomas Edison invented the first commercially viable incandescent electric light bulb. NO?

1880 - 1889

1880—The British Perforated Paper Company debuts toilet paper. YES

1880—English inventor John Milne creates the modern seismograph. NO

1881—David Houston patents camera film in roll format. NO?

1884—Lewis Edson Waterman invents the first practical fountain pen. YES

1884—L. A. Thompson built and opened the first roller coaster in the United States at a site on Coney Island, New York. NO

1884—James Ritty invents a functional mechanical cash register. YES?

1884—Charles Parson patents the steam turbine. NO

1885—Karl Benz invented the first practical automobile powered by an internal-combustion engine. NO (even before Encanto, Alma’s town looked rural so I doubt the automobile reached them yet.)

1885—Gottlieb Daimler invented the first gas-engine motorcycle. NO

1886—John Pemberton introduces Coca-Cola. NO

1886—Gottlieb Daimler designs and builds the world's first four-wheeled automobile. NO

1887—Heinrich Hertz invents radar. NO

1887—Emile Berliner invented the gramophone. YES

1887—F.E. Muller and Adolph Fick invented the first wearable contact lenses. NO

1888—Nikola Tesla invents the alternating current motor and transformer. NO

1890 - 1899

1891—Jesse W. Reno invents the escalator. NO

1892—Rudolf Diesel invents the diesel-fueled internal combustion engine, which he patents six years later. NO

1892—Sir James Dewar invents the Dewar vacuum flask. NO

1893—W.L. Judson invents the zipper. NO (zippers didn’t become popular globally until a little bit later; buttons, ribbons/laces and whatever else were still the norm/in fashion for fastening and tying (which is still the case in some places today)

1895—Brothers Auguste and Louis Lumière invent a portable motion-picture camera that doubles as a film-processing unit and projector. The invention is called the Cinematographe and using it, the Lumières project the motion picture for an audience. NO?

1899—J.S. Thurman patents the motor-driven vacuum cleaner. NO (if you're running from being killed, the last thing you're going to bring is a vacuum cleaner)

I remember a post listing the sort of jobs there would be in Encanto but I forgot so I’ll just list the ones I know (let me know if I need to add anything.):

Seamstress/tailor

Embellisher

Field worker

Teacher (of any kind; music, dance, art, etc)

Woodworker - wood carver

Toy maker

Construction worker

Joining a Local band/ Orchestra - being apart of a choir

Carpenter

Metal worker

Jeweler (though I’m not sure if Jewelery of the diamond/gem kind is common in Encanto)

bladesmith/ knifemaker

Inventor? (Inventors should exist in Encanto by now…just one other genius besides Mirabel?)

I know some of these are very obvious but I’m just giving people options okay?

@miracles-and-butterflies you seem to know a lot more about this kind of stuff so if you have anything to add/take away or me to fix please let me know. I tried to search up “When was X invention imported into Colombia” and literally nothing of use comes up.

#camilo madrigal#bruno madrigal#mirabel madrigal#dolores madrigal#antonio madrigal#isabela madrigal#pepa madrigal#encanto 2021#encanto au#encanto fanfic

163 notes

·

View notes