#fused silica

Explore tagged Tumblr posts

Text

Fused Silica Prices, News, Trend, Graph, Chart, Monitor and Forecast

The fused silica market has witnessed notable price fluctuations due to various factors, including raw material availability, production costs, demand from key industries, and global economic conditions. Fused silica, known for its high purity, excellent thermal stability, and optical clarity, is a critical material in several high-tech industries such as semiconductors, optics, telecommunications, aerospace, and solar energy. These applications drive the overall market demand, influencing pricing trends. The global supply chain plays a significant role in determining fused silica prices, as disruptions in raw material sourcing, transportation costs, and geopolitical factors can lead to price volatility. Additionally, environmental regulations governing the extraction and processing of silica impact overall production expenses, affecting the final market price.

The semiconductor industry remains a major consumer of fused silica, given its application in photomasks, optical components, and wafer processing. The increasing demand for advanced electronics and high-performance computing devices has directly contributed to the rising need for high-purity fused silica. As technology companies continue to innovate and manufacture chips with smaller nodes, the requirement for ultra-pure fused silica materials is expected to remain strong. The solar energy sector is another major driver of the market, as fused silica is used in photovoltaic cells, glass panels, and other components of solar modules. With the increasing global push toward renewable energy adoption, the demand for fused silica in solar applications has grown, further affecting market prices.

Get Real time Prices for Fused Silica: https://www.chemanalyst.com/Pricing-data/fused-silica-1591

Regional dynamics play a crucial role in fused silica pricing, with Asia-Pacific being a dominant market due to its strong semiconductor and electronics manufacturing base. China, Japan, South Korea, and Taiwan are key players in the semiconductor supply chain, driving the demand for high-quality fused silica. China, in particular, has a significant presence in the production of fused silica, benefiting from abundant raw material resources and advanced manufacturing capabilities. However, geopolitical tensions, trade policies, and environmental restrictions can impact supply levels, influencing price trends. North America and Europe also contribute to the market, with demand stemming from aerospace, defense, and optical applications. These regions often experience higher production costs due to stringent environmental regulations and labor expenses, which reflect in higher fused silica prices compared to Asia.

Raw material availability is a fundamental aspect of fused silica pricing. The primary source of silica is high-purity quartz, which undergoes complex processing to produce fused silica. Variations in quartz mining output, disruptions in supply chains, and rising extraction costs influence the price of the final product. Energy costs also play a significant role in the pricing structure, as fused silica manufacturing involves high-temperature melting processes that require substantial energy consumption. Any fluctuations in energy prices, including natural gas and electricity costs, directly impact the overall production expenses and, consequently, market prices.

The COVID-19 pandemic had a temporary yet significant impact on the fused silica market, causing supply chain disruptions, reduced industrial output, and fluctuating raw material availability. Manufacturing facilities faced shutdowns, leading to reduced production volumes and supply shortages. As economies began to recover, the demand for semiconductor chips, optical components, and solar panels surged, leading to increased consumption of fused silica and subsequent price adjustments. Post-pandemic, the industry has experienced supply chain restructuring, with companies focusing on localizing production and diversifying sourcing strategies to mitigate risks associated with global disruptions.

Technological advancements and innovations in fused silica manufacturing processes have influenced market pricing. Companies are continuously working on improving production efficiency, reducing waste, and enhancing material properties to cater to evolving industry requirements. The development of synthetic fused silica, produced through chemical processes rather than natural quartz melting, has introduced an alternative supply source. Although synthetic fused silica tends to be more expensive due to its complex production method, it offers superior purity and consistency, making it ideal for high-precision applications in optics and photonics.

Competitive market dynamics also impact fused silica prices, as multiple manufacturers operate within the industry, each with different production capacities, technological capabilities, and regional advantages. Large-scale producers often benefit from economies of scale, allowing them to offer competitive pricing compared to smaller manufacturers. Mergers, acquisitions, and strategic partnerships among key players influence market trends, as consolidation leads to greater control over supply chains and pricing strategies. The presence of alternative materials, such as borosilicate glass and aluminosilicate, also affects fused silica pricing, as industries evaluate cost-effective substitutes based on performance and budget considerations.

Future price trends in the fused silica market will be shaped by evolving industry demands, advancements in material science, and macroeconomic factors. The continuous growth of the semiconductor sector, driven by artificial intelligence, 5G technology, and quantum computing, is expected to sustain strong demand for fused silica. Similarly, the global transition toward clean energy solutions will drive further investments in solar panel manufacturing, reinforcing the need for high-quality fused silica. However, regulatory developments, environmental sustainability initiatives, and fluctuating energy prices will continue to pose challenges and opportunities for market participants.

Overall, the fused silica market remains dynamic, with pricing trends influenced by multiple interconnected factors. Manufacturers, suppliers, and end-users must closely monitor supply chain developments, technological innovations, and industry demand shifts to make informed decisions. As industries advance and new applications for fused silica emerge, maintaining a balance between supply and demand will be crucial in ensuring stable pricing and sustainable market growth.

Get Real time Prices for Fused Silica: https://www.chemanalyst.com/Pricing-data/fused-silica-1591

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Fused Silica#Fused Silica Prices#Fused Silica Price#India#united kingdom#united states#Germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

1 note

·

View note

Text

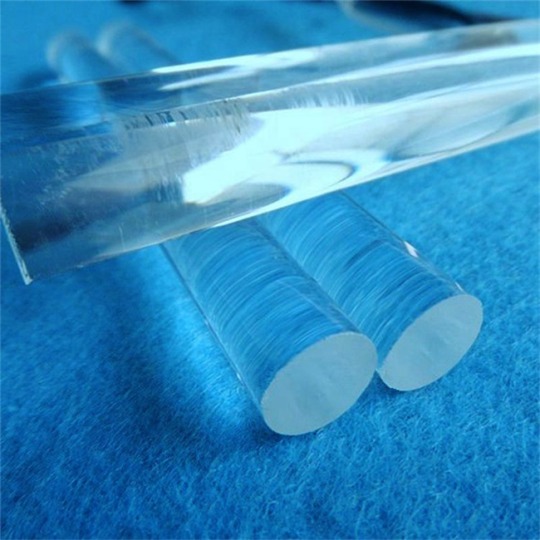

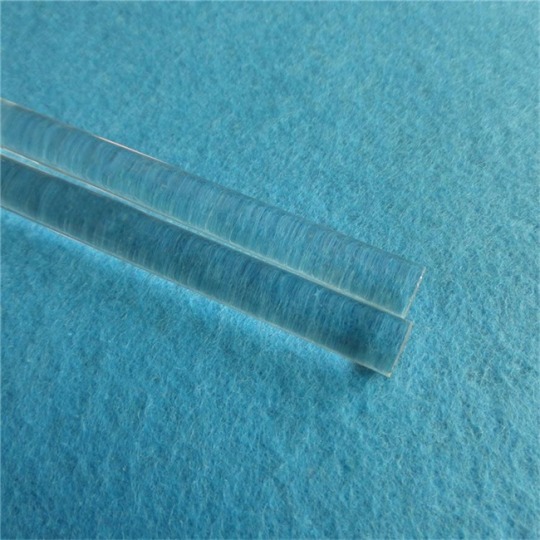

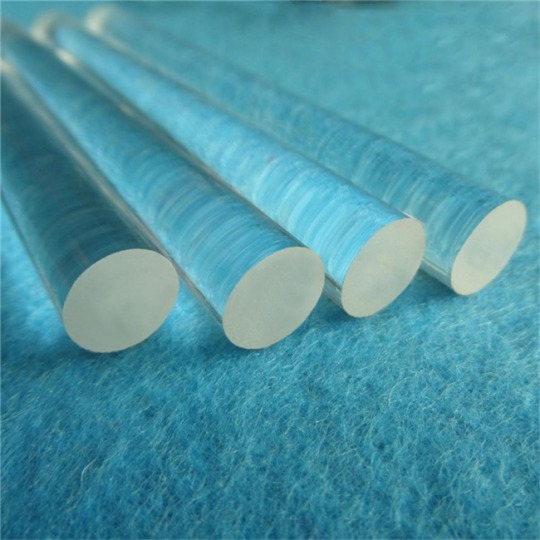

Polished Crystal Transparent Fused Silica Glass Rods are made of high quality natural quartz raw material through precise fusion process and strict polishing treatment. The product plays an important role in many fields such as scientific research, laboratory analysis, semiconductor manufacturing, optical devices and so on with its excellent optical properties, excellent chemical stability and high temperature resistance.

0 notes

Text

Unraveling the Excellence: Industrial Fused Silica Glass in Advanced Manufacturing

Industrial fused silica glass stands as a pinnacle material in modern manufacturing, revered for its exceptional purity and thermal stability. This specialized form of silica glass finds extensive utility across diverse industries, owing to its remarkable properties. https://himanshuugulati.medium.com/unraveling-the-excellence-industrial-fused-silica-glass-in-advanced-manufacturing-c5905dd9bb2d

0 notes

Text

The Key properties of sapphire windows and UV fused silica windows

Sapphire windows are known for their extreme hardness, high strength, and excellent optical transmission. They have a wide transmission range, from the ultraviolet (UV) to the mid-infrared (IR), and they are also very resistant to scratching and corrosion. Sapphire windows are often used in applications where high performance and durability are essential, such as in laser, high power LEDs, and aerospace systems.

0 notes

Text

youtube

Fingered goblet sponges support bustling communities of life.

Much like coral reefs in tropical waters or the old-growth forests on land, countless critters make their home in these spectacular sponge gardens.

The fingered goblet sponge (Heterochone calyx) is one of the largest sponges on the Pacific coast. Their funnel-shaped bodies can grow up to two meters (nearly seven feet) tall and fan out two meters (nearly seven feet) across.

Remarkably, the skeleton of this massive animal is made of microscopic slivers of silica glass called spicules. As the sponge grows, the glass spicules fuse together, creating rigid joints in between. This intricate three-dimensional structure remains intact long after the tissues die.

Decisions we make in our everyday lives can affect all animals, even in out-of-sight places like the deep sea. Increased demand for metallic minerals could lead to mining in pristine areas of the deep sea, harming animals like Heterochone. Share what you have learned about Heterochone and sponge gardens to help protect these unique habitats. Help us spread the word about safeguarding the ocean’s pristine wilderness. The future of our big blue backyard depends on us.

Learn more about this and other fascinating animals of the deep.

263 notes

·

View notes

Text

Solid state physics professor: And so because we can describe things as infinite repeating lattices, we can use these relatively simple structural mechanics to describe semiconductors! Poor naive students: What about glass and other amorphous materials? Professor: Hahaha, we don't talk about glasses. They don't work like that. Students: Oh. So they have different properties than semiconductors? Professor: … well. No. Students: Wait. What? What do you mean no? Professor: They behave very similarly to semiconductors with respect to electric properties and are very similar to high mosaic crystals physically. Students: Oh. So … how do you describe the underlying physics leading to that behavior? Is it similar to lattice structures? Professor: Haha. Hah. Hah. Students: … we can describe the underlying physics right? Professor: … sure. Students: For more than high purity fused silica? Professor: … alright class dismissed, go home, study crystals, have fun, and if you hear me weeping horribly in my office no you didn't!

#science#I am a glass scientist#every day I am thankful I work on the laser processing side of things#with the most arcane and fucked up physics breaking lasers imaginable#and not as a glass material scientist

22 notes

·

View notes

Text

EVAN BUCKLEY 9-1-1 | 6x10 – IN A FLASH

When lightning hits the sand, it's so hot that it instantly melts the silica, or quartz, found in the sand. The heat is so intense that the sand fuses together, creating glass. This glass forms in the shape of the lightning’s path, resulting in tube-like structures called fulgurites.

16 notes

·

View notes

Text

G.I. Joe Battlefront 1987 - Vehicle: Defiant (Space Vehicle Launch Complex) Part Three - Space Vehicle

Technical Specifications:

•PRIMARY AVIONICS BAY

•GUIDANCE/NAVIGATION/ CONTROL SYSTEMS

•FORWARD-LIFT COCKPIT CANOPY

•MULTI-LAYER FUSED SILICA GLASS WINDSHIELD

•THREE STATION CREW COCKPIT/OPERATIONS CENTER

•ALUMINUM ALLOY FRAME PAYLOAD BAY DOORS

5 notes

·

View notes

Text

My Gemsona OCs easily summarized (Part 1):

Zebra Jasper = Mob boss/The Mafia.

Quantum Quattro Silica = Vox from Hazbin Hotel/TVs.

Lemon Quartz = Jeremy Jordan (*Cough* Lucifer *cough*)

Pietersite = Holy angel.

Mystic Topaz = Headless Horseman.

Axinite = "My the power of Odin"/Viking.

Bixbyite = "What have I created?"/Reptilian Boogeyman.

Pyrope = 'Hot-shot' lawyer (Able to manipulate fire)

Ametrine = Two-Face/Harvey Dent rip-off but horizontal split with colors of purple and yellow.

Hematite = Yandere.

Cotton Candy Quartz = Beelzebub from Helluva Boss.

Iolite = Shark gal.

Amethyst = Punk rock star.

Nephrite = Nepeta and Meulin Leijon from Homestuck but fused together. Is a werecat gal.

Bi-Color Fluorite = 'Obsessed with beauty' fashion model.

Strawberry Quartz = "I love strawberries!"

Green Zebra Jasper = Alastor from Hazbin Hotel.

Angel Aura Quartz = "She was a fairy."

Chrysocolla = Stressed geek/nerd.

Leopard Skin Jasper = Two-faced and mean cheerleader. Obsessed with Zebra Jasper.

Yellow Zebra Jasper = Demisexual DJ.

Sunshine Aura Quartz = Elf.

Red Phantom Quartz = Samurai.

Mexican Fire Opal = Luchador.

Mexican Matrix Opal = "Remember me, thought I have to travel far."

Ice Jade = Arctic Hare gal.

Egyptian Zebra Jasper = Anubis.

Shattuckite = Velvette from Hazbin Hotel.

Alexandrite = Two-Face but a gal who changes personalities and appearance depending on the lighting between cowgirl and outlaw.

Blizzard Stone = Ryan Reynolds but if he was a snowboarder.

Bi-Color Citrine = Has a phone for a head.

Serpentine = Mad scientist but as an anthropomorphic snake/Sir Pentious from Hazbin Hotel.

Smoky Quartz = Anthropomorphic wolf who's a mercenary and bounty hunter but respects women immensely.

Sardonyx = Robo Fizzaroli from Helluva Boss.

Cherry Quartz and Strawberry Aura Quartz = Glitz and Glam from Helluva Boss.

Jelly Opal = A messenger who's a Longma.

Citrine = Chris Pine but if he was a Greek prince.

Imperial Topaz = Japanese Emperor.

Moss Aquamarine = Playful and mischievous Indian belly dancer.

Zoisite = "Ninja!"

Purple Zebra Jasper = Deeply sadistic and has immense hate for others.

Prasiolite = "I know what I'm doing. Afterall, I'm the Mayor."

Ammolite = Aroace, Victorian-era poet.

The Nine Tales Council: (Parti Sapphire, Cornflower Blue Sapphire, Padparadscha Sapphire, Purple Sapphire, Pink Sapphire, Black Star Sapphire, Green Sapphire, Orange Sapphire and Yellow Sapphire) = A group of anthropomorphic fox ladies.

Pyrite = Female pirate captain.

Jet = "Oh captain, my captain."/Pyrite's first mate.

Blue Goldstone = "Can we fix it?"

Milky Quartz = Opera singer.

Ruby = This

Emerald = Butler.

Amazonite = Tribal warrior.

Black Onyx = A polite CEO by day and by night, a serial killer known as 'The Bunny Man'. He's also bisexual.

Calcite = Takes inspiration from Maneki-neko statues. Is a werecat gal.

Turquoise = Homelander from The Boys.

Tanzine Aura Quartz = Ali Baba and his Forty Thieves but if Tanzine Aura Quartz was also a vlogger/blogger.

2 notes

·

View notes

Text

Reproduction among these organisms is asexual by binary fission, during which the diatom divides into two parts, producing two "new" diatoms with identical genes. Each new organism receives one of the two frustules – one larger, the other smaller – possessed by the parent, which is now called the epitheca; and is used to construct a second, smaller frustule, the hypotheca. The diatom that received the larger frustule becomes the same size as its parent, but the diatom that received the smaller frustule remains smaller than its parent. This causes the average cell size of this diatom population to decrease.[15] It has been observed, however, that certain taxa have the ability to divide without causing a reduction in cell size.[58] Nonetheless, in order to restore the cell size of a diatom population for those that do endure size reduction, sexual reproduction and auxospore formation must occur.[15]

Vegetative cells of diatoms are diploid (2N) and so meiosis can take place, producing male and female gametes which then fuse to form the zygote. The zygote sheds its silica theca and grows into a large sphere covered by an organic membrane, the auxospore. A new diatom cell of maximum size, the initial cell, forms within the auxospore thus beginning a new generation.

14 notes

·

View notes

Text

Fused Silica Prices Trend | Pricing | News | Database | Chart

Fused silica, a non-crystalline form of silicon dioxide, plays a critical role in a wide range of industries due to its remarkable properties, including high purity, superior thermal stability, low thermal expansion, and excellent transparency in the ultraviolet (UV) to infrared (IR) spectrum. These characteristics make it indispensable in applications such as semiconductor manufacturing, optics, telecommunications, and scientific instrumentation. Over recent years, the prices of fused silica have experienced notable fluctuations, driven by a mix of supply and demand dynamics, raw material costs, geopolitical factors, and advancements in manufacturing technologies. Understanding these market forces provides crucial insights for businesses and investors navigating this complex market landscape.

One of the key factors influencing the pricing of fused silica is its production process, which demands high-purity raw materials and precise manufacturing techniques. Unlike standard glass, fused silica requires a meticulous melting process that minimizes impurities to achieve its exceptional properties. As a result, even minor variations in the cost of high-grade silicon dioxide feedstock can significantly impact the final price of fused silica. Additionally, energy costs play a crucial role, as the high-temperature processes involved in the production of fused silica consume substantial energy. Any increase in energy prices or disruptions in energy supply chains can lead to a direct rise in the cost of production, ultimately reflected in market prices.

Get Real Time Prices for Fused silica: https://www.chemanalyst.com/Pricing-data/fused-silica-1591

Demand for fused silica is largely shaped by the performance of its key end-use sectors. The semiconductor industry, for instance, is a major consumer of high-purity fused silica due to its use in photomasks, lenses, and other critical components of chip manufacturing. With the global semiconductor market experiencing both rapid growth and periods of cyclical demand, any shifts in this sector can lead to corresponding changes in the demand for fused silica. When semiconductor production booms, so does the demand for high-purity materials, often driving up prices. Conversely, a slowdown or inventory correction in the semiconductor sector may exert downward pressure on fused silica prices.

The optics and photonics industries also contribute significantly to the demand for fused silica, as it is used in a wide range of optical components, including lenses, windows, and mirrors. These sectors are driven by technological advancements in laser systems, medical devices, and other optical technologies. As innovations in these fields accelerate, the demand for high-performance materials like fused silica rises, leading to potential price increases. Additionally, fused silica is essential in fiber optic communications, a key enabler of modern telecommunications and high-speed data transfer. The growing deployment of 5G networks and expansion of data centers globally are expected to continue supporting robust demand for fused silica, affecting its price trajectory.

Geopolitical factors and international trade dynamics can also significantly impact fused silica prices. Many countries that produce high-purity silica materials are subject to export controls, tariffs, and trade restrictions. For example, trade tensions between major economies can disrupt supply chains, limiting access to raw materials or driving up production costs due to tariffs and other trade barriers. Any political instability or regulatory changes in key producing regions can lead to market uncertainty and price volatility, influencing the cost and availability of fused silica for global buyers.

On the supply side, the availability of high-quality silicon dioxide feedstock is critical for fused silica production. Natural quartz, the primary source of silicon dioxide, must meet stringent purity requirements to be suitable for high-end applications. Variability in mining conditions, extraction costs, and environmental regulations can all affect the supply of high-purity quartz. In recent years, increased attention to environmental sustainability has prompted stricter regulations on mining practices, potentially raising costs for producers and impacting the price of fused silica in the market. Furthermore, environmental concerns have led to investments in cleaner and more sustainable production methods, which may carry higher initial costs but ultimately contribute to long-term stability and innovation within the industry.

Technological advancements also play a role in shaping fused silica prices. Improvements in production processes, such as precision melting techniques and automated quality control systems, can enhance efficiency and reduce waste, potentially lowering production costs. However, implementing new technologies often requires significant capital investment, which can initially drive prices higher. Over time, as these technologies become more widely adopted, they may contribute to price stabilization and greater consistency in product quality, benefiting both producers and consumers.

In recent years, the global market for fused silica has also been affected by supply chain disruptions, particularly during the COVID-19 pandemic. Lockdowns, labor shortages, and logistical challenges led to delays and increased costs in the production and distribution of high-purity silica materials. Even as economies gradually recover, lingering supply chain issues and fluctuations in demand across various sectors continue to influence market dynamics. Companies have increasingly sought to diversify their supply chains and invest in localized production capabilities to mitigate future risks, which could have long-term implications for pricing trends.

In conclusion, fused silica prices are shaped by a complex interplay of factors, including production costs, demand from key industries, geopolitical influences, and technological advancements. Understanding these dynamics is essential for stakeholders navigating the market, whether as producers, buyers, or investors. As the global economy continues to evolve and new technologies emerge, the fused silica market will likely experience further changes in pricing trends, requiring continuous monitoring and adaptation to stay ahead in this critical sector.

Welcome to ChemAnalyst App: https://www.chemanalyst.com/ChemAnalyst/ChemAnalystApp

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Fused Silica#Fused Silica Prices#Fused Silica Price#Fused Silica News#Fused Silica Monitor#Fused Silica Market

0 notes

Note

i healed up alright, but it took a long time. ( but also clar/des)

Desandra looks up from the scrap she’s sorting through. Spacer stations — ‘specially the ones near bigger planets — got the best shit, if you know where to look for it. Clarence is on the other side of the scrap pile, wrestling with an old, broken-down console. There’s a window behind him: two feet of fused silica glass. The view is incredible. Too many stars to count. The occasional freight ship cutting across the dark. The orange-sized outline of a planet she’s never been to, with three looping moons.

Her brow furrows. “I’m sorry,” she says, slowly, and a little bit hesitantly. Because she knows she wasn’t the one who hurt him — but it’s also her fault she couldn’t know him sooner. She picks up a half-shorn drone-armor frame and rips into the metal with her bare hands. Metal whines. It hurts, but she doesn’t stop. The anger has to go somewhere. Beneath her fingers, the frame twists, but does not snap.

Her eyes never leave Clarence.

“Do you think — ”

Another metal screech. The rough edge of the drone-armor bites hungrily into her palms. She should let go. She doesn’t. Desandra closes her eyes, tightens her grip, and tries again.

“People like us. You and me.” No need to elaborate what she means by that. He’ll get it. She knows he will. They’re both people who should’ve died tens of times ago. Now it’s strange. Now it’s a weird in-between. Now sometimes she wonders whether it’s a matter of can’t, or won’t. “Sometimes, when you’re not around, I think I might never heal up. All right, I mean. Heal up all right.” Heal up whole.

She finally looks down at the frame in her hands. It’s twisted beyond all belief, but still stands. Something catches her eye: a small, bright sticker, clinging for dear life near its edge. Des blinks, brings it closer to her face. “Hey.” She lifts the frame for Clarence to see. There’s a grin on her face as she points to the sticker. “Look.”

In bold, pink tacky lettering: PAPARINA’S ORCHARDS. And underneath it: a basket of fruit. Some she recognizes, others she doesn’t. And, last but not least, Grown organically on Planet XZ-II. The last few roman numerals are faded off, but that doesn’t matter. There’s a faint but undeniable glow in the depths of Desandra’s eyes. Excitement.

“We should go, yeah? Can’t remember the last time we got you fresh fruit. Think you can decipher the planet? Plot us a course?” Hole gone, fear forgotten. Even if it’s far away, she won’t mind. She could use it. The long time.

@tewwor babies only

2 notes

·

View notes

Text

New fossil brings us a step closer to unravelling the mystery of feather evolution

- By Zixiao Yang , Maria McNamara , University College Cork , The Conversation -

Strong but light, beautiful and precisely structured, feathers are the most complex skin appendage that ever evolved in vertebrates. Despite the fact humans have been playing with feathers since prehistory, there’s still a lot we don’t understand about them.

Our new study found that some of the first animals with feathers also had scaly skin like reptiles.

Following the debut of the first feathered dinosaur, Sinosauropteryx prima, in 1996, a surge of discoveries has painted an ever more interesting picture of feather evolution.

We now know that many dinosaurs and their flying cousins, the pterosaurs, had feathers. Feathers came in more shapes in the past – for example, ribbon-like feathers with expanded tips were found in dinosaurs and extinct birds but not in modern birds. Only some ancient feather types are inherited by birds today.

Paleobiologists have also learnt that early feathers were not made for flying. Fossils of early feathers had simple structures and sparse distributions on the body, so they may have been for display or tactile sensing. Pterosaur fossils suggest they may have played a role in thermoregulation and in colour patterning.

Fascinating as these fossils are, ancient plumage tells only part of the story of feather evolution. The rest of the action happened in the skin.

The skin of birds today is soft and evolved for the support, control, growth and pigmentation of feathers, unlike the scaly skin of reptiles.

Fossils of dinosaur skin are more common than you think. To date, however, only a handful of dinosaur skin fossils have been examined on a microscopic level. These studies, for example a 2018 study of four fossils with preserved skin, showed that the skin of early birds and their close dinosaur relatives (the coelurosaurs) was already very much like the skin of birds today. Bird-like skin evolved before bird-like dinosaurs came around.

So to understand how bird-like skin evolved, we need to study the dinosaurs that branched off earlier in the evolutionary tree.

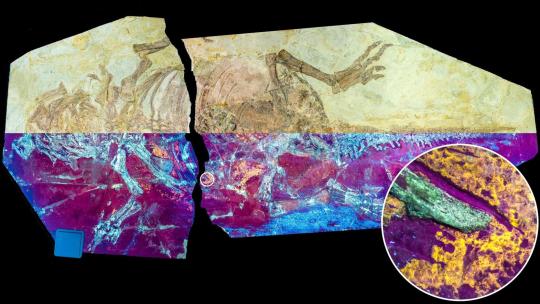

Our study shows that at least some feathered dinosaurs still had scaly skin, like reptiles today. This evidence comes from a new specimen of Psittacosaurus, a horned dinosaur with bristle-like feathers on its tail. Psittacosaurus lived in the early Cretaceous period (about 130 million years ago), but its clan, the ornithischian dinosaurs, diverged from other dinosaurs much earlier, in the Triassic period (about 240 million years ago).

In the new specimen, the soft tissues are hidden to the naked eye. Under ultraviolet light, however, scaly skin reveals itself in an orange-yellow glow. The skin is preserved on the torso and limbs which are parts of the body that didn’t have feathers.

These luminous colours are from silica minerals that are responsible for preserving the fossil skin. During fossilisation, silica-rich fluids permeated the skin before it decayed, replicating the skin structure with incredible detail. Fine anatomical features are preserved, including the epidermis, skin cells and skin pigments called melanosomes.

The fossil skin cells have much in common with modern reptile skin cells. They share a similar cell size and shape and they both have fused cell boundaries – a feature known only in modern reptiles.

The distribution of the fossil skin pigment is identical to that in modern crocodile scales. The fossil skin, though, seems relatively thin by reptile standards. This suggests the fossil scales in Psittacosaurus were also similar in composition to reptile scales.

Reptile scales are hard and rigid because they are rich in a type of skin-building protein, the tough corneous beta proteins. In contrast, the soft skin of birds is made of a different protein type, the keratins, which are the key structural material in hair, nails, claws, hooves and our outer later of skin.

To provide physical protection, the thin, naked skin of Psittacosaurus must have been composed of tough reptile-style corneous beta proteins. Softer bird-style skin would have been too fragile without feathers for protection.

Collectively, the new fossil evidence indicates that Psittacosaurus had reptile-style skin in areas where it didn’t have feathers. The tail, which preserves feathers in some specimens, unfortunately did not preserve any feathers or skin in our specimen.

However, the tail feathers on other specimens show that some bird-like skin features must have already evolved to hold feathers in place. So our discovery suggests that early feathered animals had a mix of skin types, with bird-like skin only in feathered regions of the body, and the rest of the skin still scaly, like in modern reptiles.

This zoned development would have ensured that the skin protected the animal against abrasion, dehydration and pathogens.

What next?

The next knowledge gap for scientists to explore is the evolutionary transition from the reptile-style skin of Psittacosaurus to the skin of other more heavily feathered dinosaurs and early birds.

We also need more experiments studying the process of fossilisation itself. There is a lot we don’t understand about how soft tissues fossilise, which means it is difficult to tell which skin features in a fossil are real biological features and which are simply artefacts of fossilisation.

Over the last 30 years, the fossil record has surprised scientists in regard to feather evolution. Future discoveries of fossil feathers may help us understand how dinosaurs and their relatives evolved flight, warm-blooded metabolisms, and how they communicated with each other.

Zixiao Yang, Postdoctoral researcher, University College Cork and Maria McNamara, Professor, Palaeobiology, University College Cork

This article is republished from The Conversation under a Creative Commons license. Read the original article.

--

Header image: The studied Psittacosaurus under natural (upper half) and UV light (lower half). Credit: Zixiao Yang (author provided).

Read Also

Evolution: Primitive fish fossils reveal origins of teeth

5 notes

·

View notes

Text

Fused Silica Glass - Alfa Heaters Fused silica quartz glass rod is mainly used in electric light sources, electrical appliances (electric), semiconductor, optical communications, military industry, and other fields. Call us now!

0 notes

Text

Quality UV Fused Silica Windows

Coe Optics is a leading manufacturer of high-quality UV fused silica windows. Our windows are made from synthetic fused silica, We offers excellent transmission in the UV, visible, and near-infrared regions. Coe Optics' UV fused silica windows are ideal for a wide range of applications, including laser systems, spectroscopy, and imaging. With a low coefficient of thermal expansion and excellent thermal shock resistance, Our windows can withstand high temperatures and rapid temperature changes without damage. Trust Coe Optics for reliable and precise UV fused silica windows that meet your exact specifications.

0 notes

Text

Study reveals inconsistency in nanoindentation testing using different Berkovich indenters

Nanoindentation testing is a high-precision instrumented indentation test technique that has the advantages of non-destructive testing and simplicity. However, researchers found that when testing the same sample with different Berkovich indenters, inconsistency still arises even if the indenters are regularly calibrated. This inconsistency poses challenges in accurately testing material hardness and comparing data from different laboratories. In a study published in the Journal of Materials Research and Technology, researchers from the Materials Research Center of the Institute of Modern Physics (IMP) of the Chinese Academy of Sciences (CAS) reported that using different Berkovich indenters for nanoindentation testing, excluding fused silica, yields inconsistent results, and they analyzed the reasons behind this inconsistency. The researchers identified two main factors contributing to the inconsistent experimental results, i.e., defects in the indenter tip and the indentation size effect.

Read more.

#Materials Science#Science#Materials testing#Nanoindentation#Materials hardness#Computational materials science

7 notes

·

View notes