#food manufacturing systems

Explore tagged Tumblr posts

Text

boys i'm starting to think building a society where the primary imperative of business is to make as big a profit as possible might have been a bad idea

lads stop me if i'm wrong, but was it a mistake to make money so central to our society that rich people become functionally omnipotent?

gents i can't believe i'm saying this but am i wrong for not trusting the private sector to have my best interests at heart??

#i'm talking about healthcare#i'm talking about the arts#i'm talking about the Internet#i'm talking about the postal service#i'm talking about power#i'm talking about roads#i'm talking about water#i'm talking about food#i'm talking about manufacturing#i'm talking about transit#i'm talking about communications#i'm talking about the arms trade l#i'm talking about the kegal system#legal system shit

718 notes

·

View notes

Text

So little thing that I learned recently; under the FDA, drug manufacturers are not required to disclose presence of major allergens in their products. While most medications do not contain gluten-containing ingredients, if you have any food allergy you need to make sure it's on file with your pharmacy, and speak with your pharmacist to find out how they flag for allergens in their system. Sometimes you may need to contact the manufacturer--if so, have the drug NDC (National Drug Code)# on hand, as they often need that to look it up. You can get this information (as well as manufactuer name) from your pharmacy.

#most manufacturers will say they are not made with gluten ingredients but not tested#food allergies#drug allergies#info#celiac disease#celiac#coeliac#this post brought to you by me finding out my beta blocker might have been low key poisoning me over the past year#while it isnt likely and it may be less than 20ppm for some people thats still enough to trigger symptoms or your immune system

622 notes

·

View notes

Text

#twitter#tweet#tweets#food desert#brain fog#food apartheid#covid#pandemic#systemic oppression#systemic inequality#inequality#manufacturing consent

171 notes

·

View notes

Text

grrr.... my boss came in and asked to talk to me for a moment and basically she was asking how I distinguish between production stock/my stock bc the stock/supply staff had insinuated to her that I'd been stealing their stock which I HAVEN'T!!!! I would never + my boss knows that but she still had to ask.... so annoying

#and i have PROOF i dont steal their shit bc i keep a meticulous spreadsheet of every sample in the food lab (my) stock#and i organise everything by location + have a separate section for stuff in the cold room that belongs to production#bc part of my job is managing emails from sales/marketing asking abt the production stock for test/developmental products#so i have to monitor it. but i dont ever ise those samples i fill out and email the request form to supply if i need one for smth!!!#*use#which supply would fucking know if they were competent at their jobs and fulfilled my requests without me chasing them up 16 times#half the time i have to go to quality control and request THEIR retained samples instead bc i dont get stuff in time#but qc stock is completely isolated from production bc its for assay use only and i always return the samples to them when im done anyway#the only reason theyre accusing me is bc they found a sample in one of my fridges that was logged on their stock system#but I DIDNT PUT IT THERE. THEY DID. i sent the fucking request form and they fulfilled it but didnt log it out of their own stock system#but i have their stupid form attached to a timestamped email i sent them so proof it was a legit request they fulfilled 👍#whatever......#im mainly just annoyed bc for some reason i thought it was almost 4pm and i could go home soon. but its only 2:30 sigh#at least my boss was impressed at my stock spreadsheet lmao she was like wow i didnt realise you were this organised#girl how do u think i respond so fast when u ask if we have xyz sample. of course im not going thru 400+ individual samples in multiple-#locations and boxes/fridges every single time just to find ONE thing. all i have to do is check my spreadsheet.....#i record batch numbers n manufacture/expiry dates of everything too they can go thru it if they doubt smth is mine lmao#i hate being blamed for shit i didnt do especially accusations of dishonesty. im not that shit at my job >:^/#.diaries

4 notes

·

View notes

Text

Great food for thought.

#food#home cooking#agriculture#adulting#family#i suspect this is part of why we're starting to see such an interest in polyamory#as a response to the manufactured pressures of the two adult household#as the economy and our current political system just keeps. making. living. harder.#i have a lot of thoughts about this stuff#clearly#maybe even a couple of good ones rattling around in here somewhere

55K notes

·

View notes

Text

Enhancing Food Safety with Traceability Systems

A Traceability System For Food Manufacturing plays a crucial role in ensuring food safety and quality control. By integrating Manufacturing Traceability Software, businesses can track ingredients and products at every stage of production. This system allows manufacturers to quickly identify and address any issues related to food safety, reducing risks and enhancing compliance with regulatory standards. Furthermore, Traceability Software For Food Manufacturing enables efficient recall management and fosters transparency throughout the supply chain. As a result, food manufacturers can build consumer trust while improving operational efficiency. Ultimately, adopting a traceability system is key to maintaining high standards in food production.

#Traceability System For Food Manufacturing#traceability software#food traceability software#food traceability

0 notes

Text

ERP Software for Meat Processors: A Comprehensive Guide for UK Manufacturer

Meat manufacturing is one of the most complex industries in the food sector not just in the United Kingdom (UK) but globally. If meat is not handled properly, there is a higher risk of infection and diseases – making this industry one of the most sensitive and challenging segments amongst the other food verticals.

Also, there are hiccups related to catch weight calculations, poultry management (in terms of feeding, hygiene, and wellness), perishability, and the complexities of assigning grades and cuts to meat products. Adding more are the health issues related to meat consumption, that often stem from the living conditions of the animals, and any negligence in the supply chain or storage can lead to contamination.

This poses serious risks to consumer health and often raises red flags among regulators. Consequently, meat manufacturers are under constant pressure to comply with industry standards, while navigating intensifying competition, shrinking profit margins, delivering high-quality products, and managing the entire supply chain. Not to forget, today's consumers are increasingly health-conscious and demand products that meet strict nutritional and safety standards. This puts additional pressure on manufacturers, who not only have to meet these expectations but also face the challenge of accurately conveying all the necessary information on labels and packaging. But wait, there are more challenges in the basket, such as:

Adhering to cGMP (current Good Manufacturing Practices) requirements

Managing raw materials and their shelf life

Ensuring worker safety and hygiene

Managing fluctuating demand for products like beef and pork

Ensuring traceability throughout the production cycle

To effectively tackle these challenges, UK meat manufacturers are increasingly adopting ERP Software for Meat Processors. Meat Processing ERP software can streamline operations, ensure regulatory compliance, and uphold product quality across the production process.

Why Meat Processing ERP is the pressing need for UK Meat Manufacturers

A generic ERP system may fall short when it comes to meeting the unique demands of meat processors but ERP software for meat processors fit best, offering unique capabilities such as:

Inventory Management: Efficiently tracks raw materials, ingredients, co-products, and by-products. It also enables the better organization of inventory using various classification methods such as LIFO, FIFO, and FEFO while maintaining optimal stock levels to prevent stock-outs or overstocking.

Traceability: Monitors the entire journey of a product, from raw material intake to finished goods, ensuring complete traceability. It also helps meet product recall requirements with ease.

Yield and Cost Management: Accurately measures yield, scales production, and tracks costs, enabling manufacturers to optimize profitability by aligning production with demand.

Catch-Weight Functionality: Handles variable weights, ensuring that meat is priced accurately based on its exact weight, providing transparency and accuracy in pricing.

Quality Control: Implements comprehensive quality checks to meet industry standards like HACCP and cGMP. It also enables detailed sample inspections to ensure product quality.

Production: Streamlines the entire production process by optimizing production schedules, reducing downtime, helping monitor work-in-progress (WIP) inventory, tracking production output, and ensuring timely order fulfillment.

Expiration Tracking: Reduces waste by closely monitoring expiration dates and providing timely alerts when products are approaching their expiry.

Regulatory Compliance: Ensures compliance with industry-specific standards, including the Products Containing Meat (England) Regulations 2014, Food Information Regulations 2014, and the European Food Information to Consumers Regulation No 1169/2011 (FIC), helping avoid legal risks.

One ERP solution that offers all above stated and more capabilities to the meat industry is BatchMaster ERP. More than just software, it’s a strategic competitive advantage tailored specifically for the unique needs of UK meat processors. It enables them to digitize and optimize their entire supply chain cycle while offering all the capabilities essential to meet Formulation, R&D, Processing, Quality, Compliance, Finance & Accounting, Inventory management, Planning and such needs.

Benefits of Meat ERP Software

Adopting a Meat ERP software offers several benefits to meat manufacturers, including:

Enhanced accountability, predictability, and scalability along with consistent and assured quality products.

Tight control over the costs and increased profit margin.

Unparalleled command over the business processes such as inventory management, production & distribution.

Improved efficiency as well as bottom line.

Consistency in operations.

Informed decision making.

Ability to demonstrate regulatory compliance.

Improved customer service that results in greater customer satisfaction.

Competitive advantage.

Discover how a ERP for food like BatchMaster can help you stay ahead of the curve, tackle industry challenges, and grow your business confidently. Click here to transform your operations today!

0 notes

Text

ERP for Manufacturing in the Food Industry

In the highly competitive food manufacturing sector, efficiency, quality, and regulatory compliance are critical to success. Managing these aspects can be challenging, given the complexities of sourcing, production, inventory, and distribution. This is where Enterprise Resource Planning (ERP) software plays a transformative role, offering a streamlined approach to managing operations across the entire value chain.

The Role of ERP in Food Manufacturing

ERP software serves as a central hub that integrates all business functions, from procurement to production and distribution. In the food industry, where factors like perishability, food safety regulations, and fluctuating market demand add extra layers of complexity, ERP systems provide the necessary tools to navigate these challenges effectively.

By consolidating operations into a single platform, ERP software allows manufacturers to manage processes with greater accuracy, speed, and reliability. From tracking raw materials to monitoring production and ensuring timely delivery, ERP systems enhance efficiency while minimizing waste and errors.

Addressing Industry-Specific Challenges

Food manufacturers face unique challenges, such as maintaining product quality, adhering to stringent safety standards, and managing inventory efficiently. ERP software is specifically designed to address these needs.

Traceability is one of the most critical aspects of food manufacturing. With ERP, businesses can track every ingredient and product batch from origin to delivery. This not only ensures compliance with safety regulations but also facilitates quick responses in case of product recalls or quality concerns.

Another key feature is regulatory compliance management. Food manufacturers must adhere to various standards, including HACCP, FDA, and FSSAI guidelines. ERP systems simplify this by automating documentation, tracking safety measures, and generating reports as required.

Additionally, inventory management is streamlined with real-time tracking and monitoring. This is especially important in the food industry, where perishable goods require careful handling to minimize waste and reduce costs. ERP solutions for the food industry help businesses maintain optimal inventory levels and avoid overstocking or shortages.

Benefits of ERP for Food Manufacturers

Implementing ERP software in manufacturing brings a host of advantages. It improves operational efficiency by automating repetitive tasks and reducing manual errors. The system also provides real-time insights into production, inventory, and costs, enabling manufacturers to make informed decisions quickly.

Moreover, ERP software enhances customer satisfaction by ensuring timely delivery and consistent product quality. Its ability to adapt to changing market demands gives businesses the flexibility to respond to new trends and consumer preferences with ease.

ERP software is no longer a luxury for food manufacturers—it’s a necessity. By integrating and automating critical processes, ERP systems empower businesses to stay competitive, improve efficiency, and ensure compliance in a rapidly evolving industry.

For tailored ERP solutions designed to meet the unique needs of food manufacturing, you can explore more on ERP for Food and Beverage Industry here: https://www.lighthouseindia.com/Food-Beverages-erp.html.

#erp#erp software#erp system#techsolutions#erp implementation#erp services#erp solutions provider#innovation#technology#industry solutions#manufacturing#erp for manufacturing#erp for food agro and dairy#food erp#agro erp#dairy erp

0 notes

Text

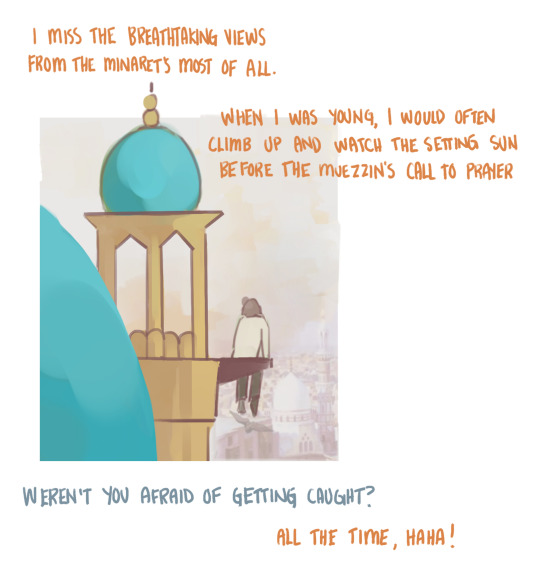

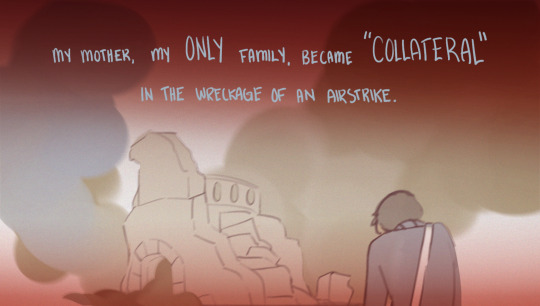

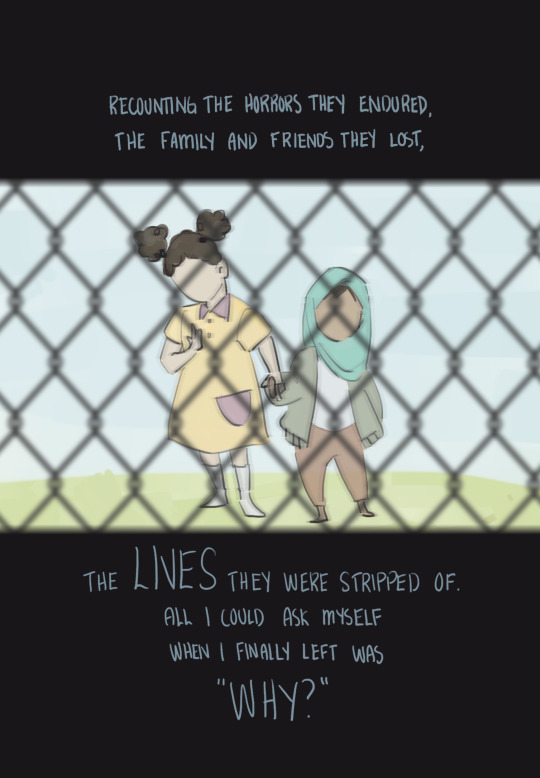

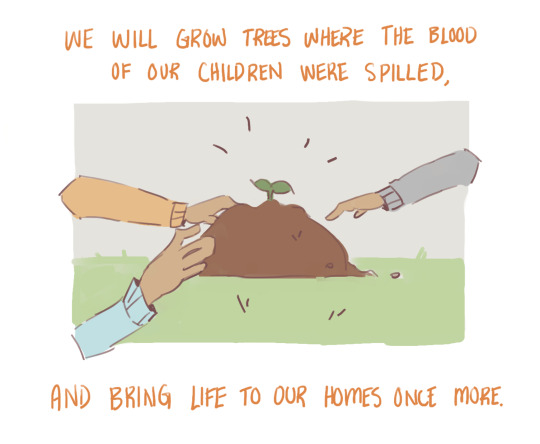

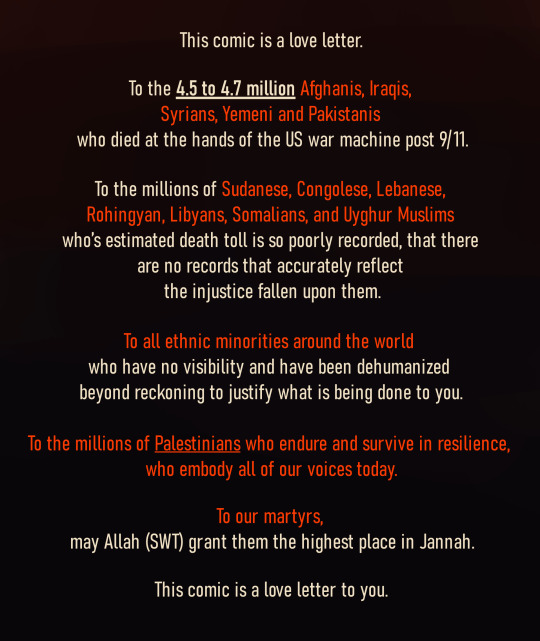

A piece about survivors guilt.

This comic isn't perfect. I started it back in October 2023, and every time I picked up my pen, I wept.

I bring this to you today, on 9/11, in hopes that you reflect on this day a little differently than how most Americans would. Let it move you to continue to boycott, protest and challenge your family, friends and colleagues. You have a bigger impact than you would believe.

Thank you for reading this with an open heart.

From the river to the sea...

I'd like to bring to attention the fact that the figures depicted above are a gross undercount of the actual number of deaths. I scoured the internet high and low to source my findings and not a single one could break down the devastation that befell an individual ethnicity. Instead, they lumped a bunch of ethnicities together, provided a general timeline, and called it a day, reinforcing the sheer scale of dehumanization propagated in the west. The only consistency between all the articles I looked up was the 4.5 to 4.7 million figure I've included above, and even then, they were all published by western media news outlets... the very same that have been so unreliable and complicit in the genocide of Palestinians today. So I have to take everything they say with a grain of salt.

We are not just numbers.

All of us have ambitions and desires and lives worth living.

With that said, this is your friendly reminder to:

Donate an e-sim

Donate to PCRF to provide Palestinian children aid

Donate to Pious Projects to provide woman with feminine hygiene kits

Donate to CareForGaza to provide food to displaced families in Gaza either through their Gofundme or their paypal

Donate to any of the vetted gofundme campaigns on GazaFunds to help Palestinians trying to flee Gaza.

And if you or someone you know sees or experiences a hate crime and can afford it, SUE. This is a more effective use of your money than most realise. The reason zionists act with impunity is because of the normalization of white supremacy and oppression of ethnic minorities. Challenging that in any capacity tells them that there are consequences to their actions and makes them think twice before engaging in hate crimes and helps raise all of us up against the systems currently in place that let them get away with it.

If you can't donate or spend any money, you can:

Do your daily clicks.

Boycott targeted companies on the BDS list (if you're like me and you don't want a single dollar to go towards anything supporting Israel right now, you can use Bdnaash to double check what products are okay to buy, but the BDS list is sufficient as it is a strategic attack and proven very effective thus far)

Flood your representatives emails and voicemails with how you won't be voting for them unless their politics align with an immediate ceasefire in Gaza.

Attend a protest, be LOUD.

Challenge your circle of friends, family and colleagues with conversations about Palestine. (THIS IS THE MOST UNDERRATED AND MOST EFFECTIVE THING YOU CAN DO)

and if you're really up to, be disruptive in any capacity that you can think of towards major corporations benefiting from this onslaught. (i.e. halting military manufacturers from production + shipments, sticking boycott stickers on products at your market etc)

And finally, if your country wasn't mentioned in the above excerpt, it was no deliberate omission on my part and I encourage you to come forward and tell your story about the suffering of your people so that this may be a learning opportunity for everyone.

You are seen.

You are not alone.

Thank you again if you've read this far.

From the river to the sea...

16K notes

·

View notes

Text

Why an AMC is Essential for Your Water System in Pharmaceuticals, Biotech, Cosmetics, and Food Industries

In today's fast-paced and regulated business environment, ensuring the quality and integrity of water systems is paramount, especially in industries such as pharmaceuticals, biotechnology, cosmetics, and food. One critical element that significantly impacts these sectors is the use of an Automated Monitoring and Control (AMC) system. Understanding the importance of an AMC for water systems can help organizations maintain compliance, enhance product quality, and streamline operations.

The Role of Water Quality in Regulated Industries

Water serves as a fundamental ingredient in the production processes of pharmaceuticals, biotech products, cosmetics, and food. As a result, the quality of water utilized directly influences the efficacy and safety of end products. Strict regulatory standards govern these industries, requiring meticulous monitoring of water systems to detect contaminants, measure physical and chemical properties, and ensure compliance with established guidelines.

What is an AMC?

An Automated Monitoring and Control (AMC) system continuously tracks the quality parameters of water within a facility. This technology integrates various sensors and data analytics tools to provide real-time insights into the water system's status. By automating monitoring processes, organizations can ensure that water quality remains within acceptable limits and proactively address any deviations before they escalate into major issues.

Key Benefits of Implementing an AMC for Water Systems

Enhanced Compliance: Regulatory bodies such as the FDA in the United States and the EMA in Europe impose stringent standards on water quality. An AMC assists organizations in maintaining compliance by continually monitoring critical water parameters, such as conductivity, pH, total organic carbon (TOC), and microbiological content. Automated alerts can be configured to notify teams of any deviations, enabling swift corrective actions.

Improved Product Quality: In the pharmaceutical and biotech industries, even the slightest variation in water quality can lead to contamination and product recalls, affecting both safety and efficacy. An AMC ensures consistent monitoring, which helps maintain the high standards required for producing safe and effective products. Similarly, in cosmetics and food industries, quality assurance is vital to ensuring customer safety and satisfaction.

Operational Efficiency: Manual monitoring of water systems can be labor-intensive and prone to human error. An AMC streamlines operations by reducing the reliance on manual checks and interventions. Automated systems can also generate detailed reports, enhancing data accessibility for audits and quality management processes.

Cost Savings: By preventing water quality issues before they become critical, an AMC can lead to significant cost savings. Whether through reduced waste, fewer recalls, or minimized downtime caused by contamination events, the return on investment in AMC technology can be substantial.

Scalability and Flexibility: As organizations in the pharmaceutical, biotech, cosmetics, and food industries grow, their water systems must adapt accordingly. An AMC can scale with the operation, allowing companies to easily expand their monitoring capabilities in line with production increases, new product lines, or regulatory changes.

Data Integration and Analysis: The data generated by an AMC can be invaluable for decision-making. Advanced data analytics can provide insights into long-term trends, allowing organizations to optimize their water treatment processes, troubleshoot recurring issues, and make informed adjustments to system design or operation.

In conclusion, the importance of an AMC for water systems in the pharmaceuticals, biotech, cosmetics, and food industries cannot be overstated. By facilitating enhanced compliance, improving product quality, driving operational efficiency, providing cost savings, enabling scalability, and integrating data analytics, an AMC is an essential investment for any organization committed to delivering safe and high-quality products. As industries continue to evolve, embracing innovative technologies such as AMC systems will be crucial in preparing for the challenges of an increasingly complex regulatory and market landscape. Organizations prioritizing the integrity of their water systems are better positioned to succeed and maintain their competitive edge.

#AMC services#Water treatment plant#water treatment system#RO EDI Plant#DM Water Plant#Pure Steam Generation Plant#Water for injection Plant#Swjal process#manufacturer#pharmacutical industry#biotech industry#Food Process industry#cosmentic industry

0 notes

Text

Advanced Traceability Solutions for Seamless Tracking

Our Advanced Traceability Solutions provide businesses with the tools to track products and processes with unmatched accuracy and efficiency. Using cutting-edge technology, we offer real-time data tracking across all stages of production, ensuring full visibility and control. These solutions are designed to enhance quality management, improve compliance, and streamline operations. By offering detailed insights into each step of the supply chain, our system helps businesses minimize risks, reduce errors, and optimize decision-making. With Advanced Traceability Solutions, you can achieve a higher level of operational transparency and reliability in your industry.

#Food Traceability Software System#Advanced Traceability Solutions#Traceability Software For Manufacturing

1 note

·

View note

Text

Industrial Cooking Fire Protection Systems for Food Manufacturing Market Size, Share, Trends, Growth and Competitive Outlook

"Global Industrial Cooking Fire Protection Systems for Food Manufacturing Market – Industry Trends and Forecast to 2030

Global Industrial Cooking Fire Protection Systems for Food Manufacturing Market, By Product (Fire Detection Systems and Fire Management Systems), Services (Engineering Services, Installation and Design Services, Maintenance Services, Managed Services and Other Services) - Industry Trends and Forecast to 2030.

Access Full 350 Pages PDF Report @

**Segments**

- **Product Type**: - Fire Detection Systems - Fire Suppression Systems - Fire Extinguishers - **End-user**: - Large Food Manufacturing Facilities - Small and Medium Food Processing Units - **Region**: - North America - Europe - Asia Pacific - Latin America - Middle East and Africa

The Industrial Cooking Fire Protection Systems for Food Manufacturing Market can be segmented based on product type, end-user, and region. In terms of product type, the market can be categorized into fire detection systems, fire suppression systems, and fire extinguishers. Fire detection systems are crucial for early identification of potential fire hazards, while fire suppression systems are designed to contain and extinguish fires swiftly. Fire extinguishers are portable devices that can be used for immediate fire response. When it comes to end-users, the market serves both large food manufacturing facilities and small to medium food processing units. Large facilities may require more sophisticated and integrated fire protection systems, while smaller units may opt for simpler solutions. Geographically, the market can be analyzed across regions such as North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa, each with its own set of regulations and market dynamics.

**Market Players**

- Honeywell International Inc. - Johnson Controls - Siemens AG - Halma plc - Gentex Corporation - Robert Bosch GmbH - Hochiki Corporation - United Technologies Corporation - Emerson Electric Co. - Tyco International Plc

Key players in the Industrial Cooking Fire Protection Systems for Food Manufacturing Market include Honeywell International Inc., Johnson Controls, Siemens AG, Halma plc, Gentex Corporation, Robert Bosch GmbH, Hochiki Corporation, United Technologies Corporation, Emerson Electric Co., and Tyco International Plc. These companies are at the forefront of developing innovative fire protection solutions for the food manufacturing industry, catering to the specific needs and requirements of different facilitiesThe Industrial Cooking Fire Protection Systems for Food Manufacturing Market is witnessing significant growth driven by the increasing focus on workplace safety and the stringent regulations mandating the installation of fire protection systems in food processing facilities. The market players mentioned above are key contributors to this growth, offering a wide range of advanced fire detection, suppression, and extinguishing solutions tailored to the unique requirements of food manufacturing environments. Honeywell International Inc., a leading player in the market, provides state-of-the-art fire detection and suppression systems that combine cutting-edge technology with reliability to ensure early detection and efficient containment of fire incidents in food processing units.

Johnson Controls is another prominent player known for its innovative fire protection solutions designed to safeguard large food manufacturing facilities against the risk of fires. Siemens AG offers a comprehensive portfolio of fire detection systems that utilize advanced sensors and monitoring technologies to enhance the safety standards of food processing units. Halma plc focuses on delivering high-quality fire suppression systems that are effective in quickly extinguishing fires and minimizing damage to equipment and property. Gentex Corporation specializes in manufacturing fire extinguishers that are easy to use and provide quick response in case of emergencies in small to medium food processing units.

Robert Bosch GmbH is renowned for its diverse range of fire protection products, including fire detection systems with intelligent features for early fire detection and alarm triggering. Hochiki Corporation's expertise lies in developing advanced fire suppression systems that utilize cutting-edge technologies such as foam suppression agents and water mist systems for effective fire control. United Technologies Corporation offers integrated fire protection solutions that combine detection, suppression, and evacuation systems to ensure comprehensive safety measures in food manufacturing facilities.

Emerson Electric Co. is a key player in the market known for its innovative approach to fire protection, providing solutions that are energy-efficient and environmentally friendly. Tyco International Plc specializes in designing and installing customized fire protection systems tailored to the specific needs of different food processing units, ensuring optimal safety and compliance with industry standards. These market players are instrumental in driving the adoption of industrial cooking fire protection systems in the**Segments**

- Global Industrial Cooking Fire Protection Systems for Food Manufacturing Market, By Product: - Fire Detection Systems - Fire Suppression Systems - Fire Extinguishers - Global Industrial Cooking Fire Protection Systems for Food Manufacturing Market, By End-user: - Large Food Manufacturing Facilities - Small and Medium Food Processing Units - Global Industrial Cooking Fire Protection Systems for Food Manufacturing Market, By Region: - North America - Europe - Asia Pacific - Latin America - Middle East and Africa

The global industrial cooking fire protection systems for food manufacturing market is segmented based on product type, end-user, and region to provide a comprehensive analysis of the industry landscape. In terms of product type, the market is categorized into fire detection systems, fire suppression systems, and fire extinguishers, each serving a unique purpose in ensuring fire safety within food processing facilities. Fire detection systems play a crucial role in early hazard identification, while fire suppression systems are designed to swiftly contain and extinguish fires. Fire extinguishers offer immediate response options to combat small fires efficiently. The market caters to both large food manufacturing facilities and small to medium food processing units, with different levels of fire protection system requirements based on the scale and complexity of operations. Geographically, the market is spread across regions such as North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa, each showcasing specific regulatory frameworks and market dynamics influencing the adoption of

Major Points Covered in TOC:

Industrial Cooking Fire Protection Systems for Food Manufacturing Market Overview: It incorporates six sections, research scope, significant makers covered, market fragments by type, Industrial Cooking Fire Protection Systems for Food Manufacturing Market portions by application, study goals, and years considered.

Industrial Cooking Fire Protection Systems for Food Manufacturing Market Landscape: Here, the opposition in the Worldwide Industrial Cooking Fire Protection Systems for Food Manufacturing Market is dissected, by value, income, deals, and piece of the pie by organization, market rate, cutthroat circumstances Landscape, and most recent patterns, consolidation, development, obtaining, and portions of the overall industry of top organizations.

Industrial Cooking Fire Protection Systems for Food Manufacturing Profiles of Manufacturers: Here, driving players of the worldwide Industrial Cooking Fire Protection Systems for Food Manufacturing Market are considered dependent on deals region, key items, net edge, income, cost, and creation.

Industrial Cooking Fire Protection Systems for Food Manufacturing Market Status and Outlook by Region: In this segment, the report examines about net edge, deals, income, creation, portion of the overall industry, CAGR, and market size by locale. Here, the worldwide Industrial Cooking Fire Protection Systems for Food Manufacturing Market is profoundly examined based on areas and nations like North America, Europe, China, India, Japan, and the MEA.

Industrial Cooking Fire Protection Systems for Food Manufacturing Application or End User: This segment of the exploration study shows how extraordinary end-client/application sections add to the worldwide Industrial Cooking Fire Protection Systems for Food Manufacturing Market.

Industrial Cooking Fire Protection Systems for Food Manufacturing Market Forecast: Production Side: In this piece of the report, the creators have zeroed in on creation and creation esteem conjecture, key makers gauge, and creation and creation esteem estimate by type.

Keyword: Research Findings and Conclusion: This is one of the last segments of the report where the discoveries of the investigators and the finish of the exploration study are given.

Browse Trending Reports:

Smart Agriculture Market Instant Noodles Market Ai In Fashion Market Infantile Hemangioma Market Waste To Diesel Market Contactless Payment Market Necrotizing Enterocolitis Treatment Market Metalized Flexible Packaging Market Customer Analytics Market Plastic Bags Sacks Market Sports Energy Drinks Market Vacuum Packaging Market Pneumococcal Vaccine Market Micro And Nano Plc Market Wireless Medical Device Connectivity Market Herbal Beverages Market Plastic Surgery Devices Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

0 notes

Text

Best STP Plant Manufacturer for the Food Industry

In the food industry, efficient wastewater management is critical not only for regulatory compliance but also for maintaining operational efficiency and environmental sustainability. The processing and production of food generate significant volumes of wastewater that often contain organic matter, fats, oils, and grease, along with various contaminants from cleaning processes and product…

#3D Aqua#DAF systems#food industry wastewater treatment#food processing STP#India STP supplier#MBBR technology#MBR technology#sewage treatment plant supplier#STP plant manufacturer#Water Treatment Technology

0 notes

Text

Enhancing System Performance with Inhibited Propylene Glycol | Tono Frost-593 | Chemtex

Chemtex Speciality Limited has leveraged this technology to develop Tono Frost 593, an inhibited propylene glycol solution that stands out for its exceptional performance. This solution not only offers superb protection against corrosion but also enhances the efficiency of heat transfer systems, ensuring they operate at peak conditions with minimal maintenance.

#propylene glycol#glycol#antifreeze coolant#heat transfer fluid#tono frost#cooling systems#corrosion inhibitors#food grade#chemicals manufacturer#chemtex

1 note

·

View note

Text

Cip System

#cip#cip system#cip system manufacturers#clean in place#clean in place system manufacturers#cip for food industry#cip for dairy industry

0 notes

Text

Diesel Fired Thermic Fluid Heater

Introducing our cutting-edge Diesel Fired Thermic Fluid Heater – an epitome of innovation in industrial heating solutions. This advanced heater redefines heat transfer, offering a seamless blend of speed, reliability, durability, and precision temperature control for diverse industrial applications.

Key Features:

Experience the efficiency of quick and uniform heat transfer using thermic fluid with Avon engineering Diesel Fired Thermic Fluid Heater. Rapid Heat Transfer ensures a reliable exchange of heat for various operational needs. Additionally, it adeptly converts diesel fuel into heat, providing seamless and efficient energy utilization.

Moreover, Powered by Reliable Diesel Fuel, our heater harnesses the reliability of diesel fuel as an energy source. It utilizes this dependable fuel type, offering continuous and dependable heat for a wide range of applications, ensuring uninterrupted operation.

Furthermore, Designed with longevity in mind, our heater boasts Durable Construction for Lasting Use. Its robust construction can withstand the demands of industrial environments, ensuring consistent performance and reliability over time.

Lastly, Achieve accurate temperature control within your processes with our product. Precise Temperature Control is enabled through its advanced control systems, allowing you to maintain desired temperature ranges crucial for applications requiring specific heat levels.

#Diesel fired thermic fluid heater#Thermic fluid heater#Diesel heater for heat transfer#Rapid heat transfer fluid heater#Efficient diesel-fired heater#Industrial thermic fluid heater#Uniform heat transfer heater#Reliable diesel fuel heater#Durable construction heater#Precise temperature control heater#Process heating solutions#Heat exchange equipment#Thermic fluid heating system#Quick heat transfer heater#Uniform heat distribution heater#Reliable diesel fuel utilization heater#Robust construction for industrial use#Accurate temperature control heater#Dependable heat source heater#Energy-efficient heating solution#Industrial-grade thermic fluid heater#Long-term reliability heater#Versatile heat transfer equipment#Industrial heating solution for manufacturing#Heater for process industries#Heat transfer equipment for textile industry#Heater for food processing#Heater for pharmaceutical industry#Heater for chemical industry#Benefits of diesel-fired thermic fluid heaters

0 notes