#faster microprocessor

Explore tagged Tumblr posts

Text

The new Smart Device V2 with faster microprocessor with two RGB LED strips

Two RGB lighting channels and three fan channels (for voltage regulated or PWM fans)

USB 3.1 Gen 2-compatible USB-C connector

Iconic cable management bar, and uninterrupted tempered-glass side panel showcase stunning RGB builds

Patented cable routing kit with pre-installed channels and straps makes wiring easy and intuitive.

Four fans are included for optimal internal airflow

Removable front panel and PSU intake filters.

Includes a reversible, removeable, top-mounted bracket designed for radiators up to 360mm

Graphics card can be highlighted with a built-in mounting bracket for installing any GPU vertically*

0 notes

Text

The new Smart Device V2 with faster microprocessor with two RGB LED strips. Two RGB lighting channels and three fan channels (for voltage regulated or PWM fans). USB 3.1 Gen 2-compatible USB-C connector Iconic cable management bar, and uninterrupted tempered-glass side panel showcase stunning RGB builds.

0 notes

Text

𝐁𝐄𝐃 𝐂𝐇𝐄𝐌 (s.jy)

PAIRING: nerdy!jake x reader (f)

SUMMARY: well, it’s not your fault that your boyfriend is perfect, good at school, kind enough tutor you in math and so skilled in bed chem.

WARNINGS: smut. freshman college (they’re 19), jake lives with his parents, grinding, dirty talking, pet names (baby, jakey), manhandling, overstimulation, protected sex (wrap your willies guys), missionary, doggy, lmk if more. NOT PROOFREAD.

PUBLISHED: 18th April 2025.

WC: 2.7k

TAGLIST: (permanent) TAGLIST: @stolasisyourparent @jaeyunsbimbo @jwnghyuns @bangtancultsposts @shawnyle @jooniesbears-blog @skzenhalove @ro-diaries @onlyhyunjin @xcosmi @strawberrhypen @heeheeswifey @jakeflvrz @astratlantis @tunafishyfishylike @branchrkive @insommni4 @kirinaa08 @leiclerc @nxzz-skz @laurradoesloveu @beomluvrr @heeshlove @17ericas @riribelle @cloud-lyy @enhamonsterghoul @star-hoon @slut4hee

Jake’s room smelled of books, fresh laundry, and that faint scent of cologne he always wore— clean, crisp. It smelled like home.

His desk was cluttered but organized in a way that made sense only to him: thick textbooks stacked neatly, a cup overflowing with pens and mechanical pencils, and his laptop open to what looked like an impossibly complicated physics simulation.

You, on the other hand, were sprawled across his bed, your maths textbook abandoned beside you as you dramatically flopped onto your stomach.

"Jake," you groaned, voice muffled against his pillow. "I’m going to fail this test, you have to accept that."

You thought that after high school, all you problems would be resolves. What you didn’t expect, though, was to be forced to take an extra curricular trigonometry lecture that made you want to smash your head against the wall.

Jake, who was sitting at his desk, barely looked up. "You’re not going to fail," he said. "You just need to focus."

"I have been focusing," you argued, rolling onto your back and stretching out like a starfish. "For, like, fifteen minutes."

"Exactly," he deadpanned, finally turning to look at you. "That’s not nearly enough."

You pouted. "But I hate math, it’s stupid and unnecessary. When am I ever going to need to find the limit of a function in real life?"

Jake sighed, closing his book with a quiet thump. "Math is everywhere," he said, pushing his glasses up his nose, a habit of his that you found way too attractive. "It’s in physics, engineering, technology, everything that makes the world work."

You rolled your eyes, sitting up. "Okay, Professor Sim, but I don’t want to make the world work.” You scoffed, “i just want to pass this stupid class and never think about numbers again."

Jake gave you a pointed look. "And I want to make sure my girlfriend doesn’t flunk out of college."

You grinned, crawling off the bed and walking over to him. "Speaking of your genius brain," you murmured, sliding into his lap without hesitation, straddling his thighs as his chair rolled back slightly from the sudden weight. "How’s your project going?"

Jake tensed for half a second before exhaling, hands automatically settling on your waist to steady you.

"It’s going well," he said, though his voice was already shifting, lower, rougher. "But I’ll never finish it if you keep distracting me."

You tilted your head, feigning innocence. "I’m just curious," you purred, looping your arms around his neck. "Tell me what you’re working on, baby."

Jake sighed, but you could see the way his lips twitched, like he knew exactly what you were doing and was helpless against it anyway.

"Fine," he said, adjusting his glasses again. "I’m designing a new type of microprocessor, something that can process data faster and more efficiently than the ones currently in use..." Blah blah blah.

You weren’t really listening, if you were being honest.

You liked hearing him talk, loved the way his voice got all passionate when he explained something he cared about, but the actual words? They went right over your head.

Instead, you focused on the way his hands, so warm and steady, were resting on your waist. Absentminded, like he wasn’t really paying attention, he traced slow circles against the fabric of your sweater, fingertips dipping just beneath the hem to brush against your bare skin.

You bit your lip, shifting slightly on his lap. "Mmm, keep going."

Jake didn’t seem to register what you were doing at first. "Right, so, the idea is that instead of using classical bits, ones and zeroes, you use qubits—" Again more smart words.

You rocked against him, slow, almost imperceptible, but enough. Jake inhaled sharply, fingers digging into your skin.

You smirked. "Go on," you teased.

His jaw clenched. "You’re evil."

You hummed, leaning in to press a soft kiss to his jaw. "No, I just really like hearing you talk, baby."

His hands flexed on your waist, like he was debating something. Then, as if giving in, he exhaled a low chuckle. "You’re such a fucking brat," he muttered, and the way his voice dropped made heat pool between your thighs.s

He moved one hand up, running it along your spine, pushing your sweater up just enough to expose more of your skin to the cool air. The other hand slid lower, gripping your thigh as you ground against him again.

"You’re not even listening, are you?" he murmured, his lips grazing your ear now. "Not really," you admitted, breathless.

His grip tightened, guiding your movements now, encouraging you to move against him with more purpose. "You just like teasing me, huh?"

"Mmh," you hummed, pressing another kiss to the corner of his lips, then his jaw, then his throat. "I like how worked up you get."

Jake let out a soft curse under his breath, his hips shifting up just slightly to meet yours. "You’re lucky I love you," he muttered, voice strained.

You grinned. "I know."

Then, finally, he broke. His lips crashed against yours, his hands gripping you tighter as he deepened the kiss, swallowing the little sounds you made as you melted into him.

His glasses pressed against your cheek, cool against your flushed skin, but neither of you cared.

"You drive me crazy," he murmured against your lips, his breath warm, his hands wandering. "Always so fucking needy."

You whimpered, rolling your hips again, and he groaned "Jakey," you breathed.

He exhaled shakily, then kissed you again, hungrier this time, like he couldn’t get enough. "You should be studying," he muttered between kisses, even as he ran his hands up your thighs, pushing your sweater higher.

You smirked. "Make me."

And, oh, he did.

Jake groaned against your lips, his grip on your waist firm as he lifted you from his lap, standing up with you in his arms.

Your legs wrapped around his hips instinctively, and you buried your face in his neck, feeling his pulse race under your lips. Your core pulsated with need, and he could feel it even through your shorts.

"You’re gonna be the death of me," he muttered, his voice thick with frustration and desire as he carried you across the room.

Jake pushed your math book on the floor, and he laid you down, his body pressing against yours as he kissed you again,, like he’d been holding back for too long.

His hands roamed, slipping under your sweater, pushing it up over your ribs. You arched your back, helping him, and he pulled it off in one smooth motion, tossing it aside.

"Fuck," he breathed, eyes raking over you. His glasses had slid down his nose, and he pushed them up absentmindedly before leaning down to kiss you again.

His hands moved with practiced precision, knowing exactly where to touch, where to squeeze, how to make you shiver beneath him.

His fingers brushed over your thighs, pushing up the fabric of your shorts before he hooked his thumbs in the waistband and dragged them down along with your panties,leaving you bare beneath him.

"You really don’t like making things easy for me, do you?" he murmured, fingers tracing up your inner thigh.

You smirked, breathless. "Where’s the fun in that?"

Jake huffed a quiet laugh, but it was strained, like he was barely holding himself together.

He sat back for a second, pulling off his sweater in one swift motion, revealing the toned muscle beneath.

His skin was warm under your fingers as you reached up, running your hands over his stomach, his chest, feeling him tense beneath your touch.

"Condom," he muttered, reaching into the drawer of his nightstand. You groaned, letting your head fall back against the pillow. "You always do this."

"Yeah," he said, tearing the foil packet open with his teeth, "because I’m not stupid."

You pouted. "I’m on the pill."

"And I like knowing you’re safe." He leaned down, brushing his lips against yours, his glasses sliding down again. "Quit pouting."

You sighed dramatically but let him roll the condom on, watching as his long fingers worked quickly.

Then he was over you again, lips on your neck, his weight pressing you into the mattress as he lined himself up. "You have to be quiet," he murmured, his voice rough as he kissed along your jaw.

"Or what?" you teased, just to test him.

Jake exhaled sharply, then pushed into you in one slow, deep stroke. Your breath hitched, your fingers gripping his shoulders as your back arched off the bed.

"Or I’ll make you," he murmured, his lips brushing against your ear.

Your eyes fluttered shut as he started moving, slow at first, like he was savoring every inch of you, but then he set a pace that had you struggling to keep quiet.

He knew what he was doing, exactly how to angle his hips to make your breath stutter, exactly how to roll his hips so you were gripping at his arms, trying so hard not to moan too loudly.

His glasses fogged up from how close he was, the heat between you making them useless, but he didn’t stop to take them off.

You did it for him, reaching up with trembling fingers and sliding them off his face, setting them aside on the nightstand.

He thanked you with a warm smile.

His eyes, dark and heavy-lidded with desire, met yours as he thrust deeper, harder, stealing the air from your lungs. His hand came up, covering your mouth as you let out a soft whimper, muffling the sound.

"Shh," he murmured, his voice like gravel against your skin. "Don’t want my mother hearing how good I’m fucking you, do you?"

You shook your head, but your body betrayed you, your nails digging into his back as he snapped his hips into you again. It was all too much.

You clenched around him, your thighs trembling as pleasure coiled tight in your stomach. Jake cursed under his breath, feeling you squeeze around him, and his grip on your hip tightened as he sped up, chasing your release.

"Come for me," he muttered, his lips brushing against your ear. "I wanna feel you."

That was all it took.

Your body tensed, pleasure hitting you like a tidal wave as you bit down on his hand to keep from crying out. Your vision blurred, your fingers digging in his skin as you came undone beneath him.

Jake groaned, his movements faltering for half a second before he found his rhythm again, his thrusts rougher now, more desperate.

He grabbed your leg, hooking it over his hip, pushing deeper, hitting that spot that had you gasping against his palm.

He hadn’t slowed down. His rhythm was deep, fast, relentless. the bed creaking under both of your weight, the headboard softly hitting the wall in time with his thrusts.

You were still whimpering from your second orgasm, your thighs trembling around his waist, your nails digging red crescents into his shoulder blades. Your breath hitched, another moan slipping past your lips before you could stop it. “Jakey! oh—”

His hand came up instantly, covering your mouth again, palm warm and firm.

“Quiet,” he hissed against your cheek. “You’re gonna get us caught.”

Your body arched off the bed beneath him, mouth smothered by his hand, eyes rolling back from the sheer pressure, the stretch, the heat. Your muffled cries only made him thrust harder.

“You like this, huh?” he breathed, watching your every twitch, every gasp, every time you tried to cry out under his hand. “You like when I fuck you like this.”

You nodded desperately, the pleasure building again even though your body felt like it couldn’t take more. Your skin burned, your thighs ached, but none of it mattered. Jake was everything— all you could feel, all you could hear, all you could take.

You released against him, hard, back arching as your whole body seized up and shuddered. Your vision blurred. You felt tears sting your lashes, your voice cracking beneath his hand as your second orgasm ripped through you.

He grunted, letting his hand slide away from your mouth only when your cries became soft gasps His lips found yours in a hungry, breathless kiss, tongue sliding into your mouth like he couldn’t stand even a second of distance.

“Shit,” he panted, pulling back just a little to brush his hair from his eyes. He kissed your jaw, your throat, sucking a mark just below your ear before whispering, “Turn over for me.”

You blinked up at him, dazed. “Jake, I can’t—”

“You can,” he said firmly, kissing you again. “Just one more, baby, you’re doing so good.”

And because it was him uou obeyed.

You turned, limbs shaky, chest pressed to the mattress, ass in the air as you grabbed onto the pillow and buried your face into it. Jake groaned softly behind you.

“Fuck, you look so good like this,” he muttered, dragging his fingers over your lower back, down to your ass, squeezing firmly. “Messy and fucked out… all for me.”

You felt him line himself up again, the blunt head of his cock sliding through your slick folds before pushing into you in one hard thrust that had you biting into the pillow to stifle a scream.

“Oh my God… Jake.”

“Shhh,” he hushed you, hand curling around your hip to pull you back into him, setting a brutal pace that left your legs shaking, your voice broken into helpless sobs. “You have to be quiet.”

“I can’t,” you cried into the pillow, half-laughing, half-sobbing from how good it felt, how completely he wrecked you. “Jake— it’s too much—”

“You’re taking it so well,” he said, voice strained, one hand gripping your waist while the other slid up your spine, pushing between your shoulder blades to press you further into the mattress. “So fucking good for me.”

His thrusts grew rougher, deeper, dragging cries from you no matter how hard you tried to bite them back. You fisted the sheets, knuckles white, body trembling as he angled his hips just right, hitting that spot over and over again until your legs gave out.

Jake leaned down, chest against your back, his breath hot against your ear as he murmured, “You pretend to be all innocent, all shy in front of everyone… but in here? With me? You just want to be ruined.”

You moaned, louder than you meant to, and he growled, his hand flying to your mouth again, fingers pressing your cheek into the pillow.

“You don’t listen,” he hissed, thrusting harder, until the sound of skin against skin echoed through the room. “You want my mother to hear how desperate you are for my cock?”

You shook your head wildly, sobbing beneath his hand as he slammed into you again, and again, and again, until your entire body clenched and your mind blanked. One last orgasm crashed over you, white-hot and dizzying, tearing a scream from your throat that was completely muffled by his palm.

Jake groaned into your neck, biting your shoulder as he came hard, his body collapsing against yours, twitching with aftershocks as he held you tightly, his breath loud and shaky in your ear.

You both stayed like that for a moment, tangled, gasping, hearts pounding like they wanted to leap out of your chests.

Jake pulled out gently, sighing contentedly as he rolled to the side and took the condom off, tying it quickly and tossing it into the bin beside the bed.

He turned to you immediately, pulling you into his chest, wrapping his arms around your exhausted body. Your skin was damp with sweat, your legs trembling, your eyes heavy with sleep and satisfaction.

For a long moment, the only sound in the room was heavy breathing, your bodies tangled together, sweat-slicked and trembling.

Jake finally lifted his head, his dark hair sticking to his forehead, his cheeks flushed. He looked wrecked, but somehow, still devastatingly handsome.

"You okay?" he murmured, pushing your hair out of your face.

You nodded, still catching your breath. "Mh.. It was so good.”

Jake huffed a quiet laugh, leaning down to kiss your forehead. "You are a menace."

You smirked. "You love it."

"You’re exhausting," he muttered, but his arm was already tightening around you, pulling you close.

You grinned, snuggling into his chest. "You love that too."

Jake sighed, pressing a kiss to the top of your head. "Yeah," he admitted softly. "I really do."

#enhypen#enhypen smut#enhypen fics#enhypen x reader#enhypen hard thoughts#enhypen hard hours#enhypen au#jake#sim jake#sim jaeyun#jake smut#sim jake smut#sim jaeyun smut#jake hard hours#sim jake hard hours#sim jaeyun hard hours#jake hard thoughts#sim jake hard thoughts#sim jaeyun hard thoughts#sim jake x reader#sim jaeyun x reader#jaeyun smut#jaeyun hard hours#jaeyun hard thoughts#jake enhypen#sim jake enhypen#jake sim smut#jake fics#jake x reader#enhypen jake

4K notes

·

View notes

Text

Child in Time

Chapter 18

Warnings: none

Chapter 1: link

Previous chapter: link

Eo had been gone for 3 days. The Sesame Street theme song wouldn't stop playing in Barry's head. Instead of being the mild annoyance it usually was, it made Barry's heart ache and his stomach twist with anxiety. He gripped the underside of the desk for dear life, the nervous tension singing down his arms as he waited for any answer. When that didn't ease his nerves, he resumed pacing behind the desk where Cisco, Caitlin, and Dr. Wells were working.

"Anything?" Barry asked, unable to keep silent any longer.

"Still nothing," Cisco replied, not even looking up. "Same as five minutes ago. And five minutes before that. And the six times before that."

Barry winced. "I know, I'm sorry, I just-"

"We will find him, Barry," Dr. Wells assured him.

Barry nodded, rubbing his hands together anxiously.

"Maybe I'll just go see what Hartley's working on," he said, zipping out of the Cortex in a flash of lightning before anyone could suggest otherwise.

"Hey. Anything?" He repeated.

Hartley didn't look up. "I'm not going to reach a result faster with you hovering, Flash."

Barry approached the workbench, furrowing his brow. "Well, maybe I can help you."

"Doubtful," Hartley said curtly, pushing Barry back with an elbow to the stomach.

"What is this anyway?"

The pieces Barry could see didn't look like much of anything. Wires. Microprocessors. Ceramic housing components.

Hartley sighed in exasperation, leaning back to glare at Barry, crossing his arms and legs and tilting his head.

"If you must know, I'm modifying Cisco's power-dampening cuffs to use against the Reverse Flash."

Barry furrowed his brow. "Why? I mean, they already work on speedsters, they worked on me just fine."

Hartley rolled his eyes and returned to his work. "If you're not going to be useful then go elsewhere."

When he returned to the Cortex, Cisco and Dr. Wells were exactly as they had been but Caitlin was on her phone.

"Everything okay?" Barry asked.

"Yeah," Caitlin said without looking up. "Just a friend, Eliza. She wanted to grab a coffee since she's off work, said there was a total system outage at Mercury Labs this morning."

Cisco suddenly straightened.

"Oh frak me," Cisco said, rushing to the nearest computer and tucking his hair behind his ears so he could work.

Barry rounded the desk to join him at a barely normal speed. "What? What is it?"

"I can't believe I forgot- I put a tracker in Beary!"

Barry blinked, gesturing to himself. "You...put a tracker in me?"

Cisco looked up with a frown. "What? No, not you Barry, Beary! Eo's bear. You know, the one that goes missing like twice a day and brings chaos every time?" He resumed typing. "I put a tracker in the left foot so we could find it easier and...Yahtzee!"

A map loaded, slowly zooming in on the familiar grid of Central City. A red blinking dot popped up, pulsing gently like a heartbeat. Eo. Barry's heart leapt.

"Where is that? Is that-"

"Mercury Labs." Caitlin finished for Barry, glancing down at her cell phone.

"Barry, we need a plan, don't just-" Dr. Wells began but Barry had already grabbed his suit and run out the door.

#child in time#baby eo au#the flash#cw the flash#the flash cw#vexic writes#vexic lives#caitlin snow#cisco ramon#barry allen#eobard thawne#harrison wells#eowells#hartley rathaway

8 notes

·

View notes

Text

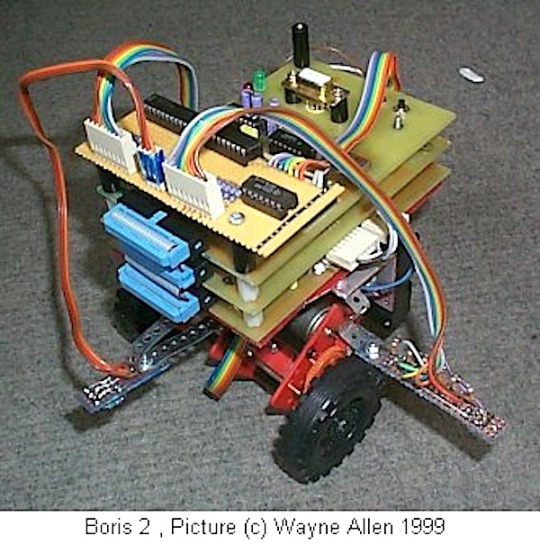

Boris (1997) by Wayne Allen, UK.

"The Royal Holloway Micromouse Design Group was founded in 1998, by a then student Wayne Allen. That year a mouse, Boris was entered into the micromouse event being held at Exeter University. We managed a total of five squares before Boris decided that the fastest route was over the walls!. However we were hooked. The following year the finals were held at Royal Holloway, and this time we entered a number of mice. The rest as they say is history!" – Wayne Allen.

"Boris was first built in late 1997, early 1998. The microprocessor unit, a Z80, was designed around 3 home built PCB, one for the processor, 32K RAM, 32K EPROM, one for the serial port and one for the I/O (24 pin I/O via an 8255 and 8bit A/D). The motor unit was made from two 3v motors and gear boxes, purchased from Maplin, driven by a number of nicad AAs. Wall detection was achieved via direct IR transmitter/receiver pairs, mounted just under the chassis, fore and aft of the drive wheels. Boris was slow. The motors drew far too much current given their size, and had no form of feed back. a later modification was to fit a small slotted disk to the output shaft of the motor, and fit an interrupter, this was fed to the Z80 as an interrupt, but was never really satisfactory Towards the end of testing, Boris exhibited a rather nasty habit of resetting the processor whenever the motors stalled. Attempts were made to isolated the power supplies, but were not entirely successful. Boris competed at Exeter University in 1998, completing a total of 5 squares. Boris 2 was a modified Boris. With the same motors but uprated gearing it was certainly faster. It used the ubiquitous wings for wall detection which were certainly more effective, but Boris still suffered from reset problems. Experiments were made changing the drive voltage, but Boris 2 never competed in event." – Wayne Allen, Boris Family Homepage

4 notes

·

View notes

Text

Unleashing Innovation: How Intel is Shaping the Future of Technology

Introduction

In the fast-paced world of technology, few companies have managed to stay at the forefront of innovation as consistently as Intel. With a history spanning over five decades, Intel has transformed from a small semiconductor manufacturer into a global powerhouse that plays a pivotal role in shaping how we interact with technology today. From personal computing to artificial intelligence (AI) and beyond, Intel's innovations have not only defined industries but have also created new markets altogether.

In this comprehensive article, we'll delve deep into how Intel is unleashing innovation and shaping the future of technology across various domains. We’ll explore its history, key products, groundbreaking research initiatives, sustainability efforts, and much more. Buckle up as we take you on a journey through Intel’s dynamic landscape.

Unleashing Innovation: How Intel is Shaping the Future of Technology

Intel's commitment to innovation is foundational to its mission. The company invests billions annually in research and development (R&D), ensuring that it remains ahead of market trends and consumer demands. This relentless pursuit of excellence manifests in several key areas:

The Evolution of Microprocessors A Brief History of Intel's Microprocessors

Intel's journey began with its first microprocessor, the 4004, launched in 1971. Since then, microprocessor technology has evolved dramatically. Each generation brought enhancements in processing power and energy efficiency Click for more that changed the way consumers use technology.

youtube

The Impact on Personal Computing

Microprocessors are at the heart of every personal computer (PC). They dictate performance capabilities that directly influence user experience. By continually optimizing their designs, Intel has played a crucial role in making PCs faster and more powerful.

Revolutionizing Data Centers High-Performance Computing Solutions

Data centers are essential for businesses to store and process massive amounts of information. Intel's high-performance computing solutions are designed to handle complex workloads efficiently. Their Xeon processors are specifically optimized for data center applications.

Cloud Computing and Virtualization

As cloud services become increasingly popular, Intel has developed technologies that support virtualization and cloud infrastructure. This innovation allows businesses to scale operations rapidly without compromising performance.

Artificial Intelligence: A New Frontier Intel’s AI Strategy

AI represents one of the most significant technological advancements today. Intel recognizes this potential and has positioned itself as a leader in AI hardware and software solutions. Their acquisitions have strengthened their AI portfolio significantly.

AI-Powered Devices

From smart assistants to autonomous vehicles, AI is embedded in countless devices today thanks to advancements by companies like Intel. These innovations enhance user experience by providing personalized services based on data analysis.

Internet of Things (IoT): Connecting Everything The Role of IoT in Smart Cities

2 notes

·

View notes

Text

Beyond Processors: Exploring Intel's Innovations in AI and Quantum Computing

Introduction

In the rapidly evolving world of technology, the spotlight often shines on processors—those little chips that power everything from laptops to supercomputers. However, as we delve deeper into the realms of artificial intelligence (AI) and quantum computing, it becomes increasingly clear that innovation goes far beyond just raw processing power. Intel, a cornerstone of computing innovation since its inception, is at the forefront of these technological advancements. This article aims to explore Intel's innovations in AI and quantum computing, examining how these developments are reshaping industries and our everyday lives.

Beyond Processors: Exploring Intel's Innovations in AI and Quantum Computing

Intel has long been synonymous with microprocessors, but its vision extends well beyond silicon. With an eye on future technologies like AI and quantum computing, Intel is not just building faster chips; it is paving the way click here for entirely new paradigms in data processing.

Understanding the Landscape of AI

Artificial Intelligence (AI) refers to machines' ability to perform tasks that typically require human intelligence. These tasks include visual perception, speech recognition, decision-making, and language translation.

The Role of Machine Learning

Machine learning is a subset of AI that focuses on algorithms allowing computers to learn from data without explicit programming. It’s like teaching a dog new tricks—through practice and feedback.

Deep Learning: The Next Level

Deep learning takes machine learning a step further using neural networks with multiple layers. This approach mimics human brain function and has led to significant breakthroughs in computer vision and natural language processing.

Intel’s Approach to AI Innovation

Intel has recognized the transformative potential of AI and has made significant investments in this area.

AI-Optimized Hardware

Intel has developed specialized hardware such as the Intel Nervana Neural Network Processor (NNP), designed specifically for deep learning workloads. This chip aims to accelerate training times for neural networks significantly.

Software Frameworks for AI Development

Alongside hardware advancements, Intel has invested in software solutions like the OpenVINO toolkit, which optimizes deep learning models for various platforms—from edge devices to cloud servers.

Applications of Intel’s AI Innovations

The applications for Intel’s work in AI are vast and varied.

Healthcare: Revolutionizing Diagnostics

AI enhances diagnostic accuracy by analyzing medical images faster than human radiologists. It can identify anomalies that may go unnoticed, improving patient outcomes dramatically.

Finance: Fraud Detection Systems

In finance, AI algorithms can scan large volumes of transactions in real-time to flag suspicious activity. This capability not only helps mitigate fraud but also accelerates transaction approvals.

Quantum Computing: The New Frontier

While traditional computing relies on bits (0s and 1s), quantum computing utilizes qubits that can exist simultaneously in multiple states—allowing for unprecede

youtube

2 notes

·

View notes

Text

Beyond Processors: Exploring Intel's Innovations in AI and Quantum Computing

Introduction

In the rapidly evolving world of technology, the spotlight often shines on processors—those little chips that power everything from laptops to supercomputers. However, as we delve deeper into the realms of artificial intelligence (AI) and quantum computing, it becomes increasingly clear that innovation goes far beyond just raw processing power. Intel, a cornerstone of computing innovation since its inception, is at the forefront of these technological advancements. This article aims to explore Intel's innovations in AI and quantum computing, examining how these developments are reshaping industries and our everyday lives.

Beyond Processors: Exploring Intel's Innovations in AI and Quantum Computing

Intel has long been synonymous with microprocessors, but its vision extends well beyond silicon. With an eye on future technologies like AI and quantum computing, Intel is not just building faster chips; it is paving the way for entirely new paradigms in data processing.

Understanding the Landscape of AI

Artificial Intelligence (AI) refers to machines' ability to perform tasks that typically require human intelligence. These tasks include visual perception, speech recognition, decision-making, and language translation.

youtube

The Role of Machine Learning

Machine learning is a subset of AI that focuses on algorithms allowing computers to learn from data without explicit programming. It’s like teaching a dog new tricks—through practice and feedback.

Deep Learning: The Next Level

Deep learning takes machine learning a step further using neural networks with multiple layers. This approach mimics human brain function and has led to significant breakthroughs in computer vision and natural language processing.

Intel’s Approach to AI Innovation

Intel has recognized the transformative potential of AI and has made significant investments in this area.

AI-Optimized Hardware

Intel has developed specialized hardware such as the Intel Nervana Neural Network Processor (NNP), designed specifically for deep learning workloads. This chip aims to accelerate training times for neural networks significantly.

Software Frameworks for AI Development

Alongside hardware Click to find out more advancements, Intel has invested in software solutions like the OpenVINO toolkit, which optimizes deep learning models for various platforms—from edge devices to cloud servers.

Applications of Intel’s AI Innovations

The applications for Intel’s work in AI are vast and varied.

Healthcare: Revolutionizing Diagnostics

AI enhances diagnostic accuracy by analyzing medical images faster than human radiologists. It can identify anomalies that may go unnoticed, improving patient outcomes dramatically.

Finance: Fraud Detection Systems

In finance, AI algorithms can scan large volumes of transactions in real-time to flag suspicious activity. This capability not only helps mitigate fraud but also accelerates transaction approvals.

Quantum Computing: The New Frontier

While traditional computing relies on bits (0s and 1s), quantum computing utilizes qubits that can exist simultaneously in multiple states—allowing for unprecede

2 notes

·

View notes

Text

Unleashing Innovation: How Intel is Shaping the Future of Technology

Introduction

In the fast-paced world of technology, few companies have managed to stay at the forefront of innovation as consistently as Intel. With a history spanning over five decades, Intel has transformed from a small semiconductor manufacturer into a global powerhouse that plays a pivotal role in shaping how we interact with technology today. From personal computing to artificial intelligence (AI) and beyond, Intel's innovations have not only defined industries but have also created new markets altogether.

youtube

In this comprehensive article, we'll delve deep into how Intel is unleashing innovation and shaping the future of technology across various domains. We’ll explore its history, key products, groundbreaking research initiatives, sustainability efforts, and much more. Buckle up as we take you on a journey through Intel’s dynamic Extra resources landscape.

Unleashing Innovation: How Intel is Shaping the Future of Technology

Intel's commitment to innovation is foundational to its mission. The company invests billions annually in research and development (R&D), ensuring that it remains ahead of market trends and consumer demands. This relentless pursuit of excellence manifests in several key areas:

The Evolution of Microprocessors A Brief History of Intel's Microprocessors

Intel's journey began with its first microprocessor, the 4004, launched in 1971. Since then, microprocessor technology has evolved dramatically. Each generation brought enhancements in processing power and energy efficiency that changed the way consumers use technology.

The Impact on Personal Computing

Microprocessors are at the heart of every personal computer (PC). They dictate performance capabilities that directly influence user experience. By continually optimizing their designs, Intel has played a crucial role in making PCs faster and more powerful.

Revolutionizing Data Centers High-Performance Computing Solutions

Data centers are essential for businesses to store and process massive amounts of information. Intel's high-performance computing solutions are designed to handle complex workloads efficiently. Their Xeon processors are specifically optimized for data center applications.

Cloud Computing and Virtualization

As cloud services become increasingly popular, Intel has developed technologies that support virtualization and cloud infrastructure. This innovation allows businesses to scale operations rapidly without compromising performance.

Artificial Intelligence: A New Frontier Intel’s AI Strategy

AI represents one of the most significant technological advancements today. Intel recognizes this potential and has positioned itself as a leader in AI hardware and software solutions. Their acquisitions have strengthened their AI portfolio significantly.

AI-Powered Devices

From smart assistants to autonomous vehicles, AI is embedded in countless devices today thanks to advancements by companies like Intel. These innovations enhance user experience by providing personalized services based on data analysis.

Internet of Things (IoT): Connecting Everything The Role of IoT in Smart Cities

2 notes

·

View notes

Text

Beyond Processors: Exploring Intel's Innovations in AI and Quantum Computing

Introduction

In the rapidly evolving world of technology, the spotlight often shines on processors—those little chips that power everything from laptops to supercomputers. However, as we delve deeper into the realms of artificial intelligence (AI) and quantum computing, it becomes increasingly clear that innovation goes far beyond just raw processing power. Intel, a cornerstone of computing innovation since its inception, is at the forefront of these technological advancements. This article aims to explore Intel's innovations in AI and quantum computing, examining how these developments are reshaping industries and our everyday lives.

Beyond Processors: Exploring Intel's Innovations in AI and Quantum Computing

Intel has long been synonymous with microprocessors, but its vision extends well beyond silicon. With an eye on future technologies like AI and quantum computing, Intel is not just building faster chips; it is paving the way for entirely new paradigms in data processing.

Understanding the Landscape of AI

Artificial Intelligence (AI) refers to machines' ability to perform tasks that typically require human intelligence. These tasks include visual perception, speech recognition, decision-making, and language translation.

Click here The Role of Machine Learning

Machine learning is a subset of AI that focuses on algorithms allowing computers to learn from data without explicit programming. It’s like teaching a dog new tricks—through practice and feedback.

youtube

Deep Learning: The Next Level

Deep learning takes machine learning a step further using neural networks with multiple layers. This approach mimics human brain function and has led to significant breakthroughs in computer vision and natural language processing.

Intel’s Approach to AI Innovation

Intel has recognized the transformative potential of AI and has made significant investments in this area.

AI-Optimized Hardware

Intel has developed specialized hardware such as the Intel Nervana Neural Network Processor (NNP), designed specifically for deep learning workloads. This chip aims to accelerate training times for neural networks significantly.

Software Frameworks for AI Development

Alongside hardware advancements, Intel has invested in software solutions like the OpenVINO toolkit, which optimizes deep learning models for various platforms—from edge devices to cloud servers.

Applications of Intel’s AI Innovations

The applications for Intel’s work in AI are vast and varied.

Healthcare: Revolutionizing Diagnostics

AI enhances diagnostic accuracy by analyzing medical images faster than human radiologists. It can identify anomalies that may go unnoticed, improving patient outcomes dramatically.

Finance: Fraud Detection Systems

In finance, AI algorithms can scan large volumes of transactions in real-time to flag suspicious activity. This capability not only helps mitigate fraud but also accelerates transaction approvals.

Quantum Computing: The New Frontier

While traditional computing relies on bits (0s and 1s), quantum computing utilizes qubits that can exist simultaneously in multiple states—allowing for unprecede

2 notes

·

View notes

Text

The 2023 Nobel Prize in Physics

Post #9 on Physics and Astronomy, 06/11/23

The Nobel Prize. Arguably one of the highest achievements someone could attain. This year, three laureates won the Nobel Prize for their work in attoseconds. Pierre Agostini, Ferenc Krausz, and Anne L’Huiller found a way to create extraordinarily small pulses of light that can be used to measure the processes in which electrons move.

Your first question may be: what actually is an attosecond? We all know that there are prefixes to seconds to measure increasing or decreasing magnitudes, i.e. milliseconds, nanoseconds, etc. Attoseconds, however, in comparison, are so small that there are as many in one second as there have been seconds since the dawn of the universe.

Before this, a femtosecond was regarded as the limit for the shortest pulse of light we could produce. For reference, there are 1,000,000,000,000,000 femtoseconds in one second. One femtosecond is tiny as-is, and there are 1,000 attoseconds within one femtosecond.

The reason why this work is so pivotal is because it enables for the investigation of processes that were previously imperceptible, the first one that comes to mind being the mechanisms of electrons.

For us, it is important to understand how electrons work, after all, a lot of daily appliances are electrical. This Nobel Prize work opens those doors. Another good example is the function of microprocessors. If they worked based on attoseconds, they could process information a billion times faster.

This, currently, is out of reach, but scientists hope to be able to manipulate, or control, electron motion for various reasons, one being for electronics, like aforementioned.

All three of the Nobel laureates had held the record for the shortest pulse of light at one point. Agostini’s team, in 2001, flashed a pulse lasting only 250 attoseconds. This was shortly beaten by L’Huillier in 2003, with 170 attoseconds. Krausz beat this in 2008 with a pulse lasting 80 attoseconds. The current record, achieved by Hans Jakob Woerner, stands in the Guinness World Records at an astonishing 43 attoseconds.

Who do you think will win the next Nobel Prize?

#studyblr#physics#stem#sixth form#alevels#gcse#engineering#100 days of productivity#astronomy#astrophysics#nobel prize#nobel prize in physics#attoseconds#now this is just fascinating#like i know no one needs it but imagine we had cameras with that kind of frequency#even one second in 4k would probably requires terabytes of storage but it's still so freaking funny to think about#even the movie nerds might find fun with this one

21 notes

·

View notes

Text

Liquid Thermal Interface Materials Market Share Analysis, Sales Outlook, Growth Trends, Insights and Business Overview By 2034

According to a recent study by Fact.MR, the global thermal interface material (TIM) market is anticipated to reach a valuation of US$ 3.3 billion in 2024. The market is further projected to grow at an impressive CAGR of 11%, reaching US$ 9.4 billion by 2034.

Thermal interface materials are essential for managing heat transfer between surfaces or components. These materials play a critical role in improving energy efficiency, regulating temperatures, and enhancing comfort in applications such as appliances and clothing. In the automotive sector, TIMs are particularly valuable for managing the heat generated by batteries and electronic components, ensuring optimal performance and longevity of electric vehicles and advanced automotive systems.

𝐅𝐨𝐫 𝐦𝐨𝐫𝐞 𝐢𝐧𝐬𝐢𝐠𝐡𝐭𝐬 𝐢𝐧𝐭𝐨 𝐭𝐡𝐞 𝐌𝐚𝐫𝐤𝐞𝐭, 𝐑𝐞𝐪𝐮𝐞𝐬𝐭 𝐚 𝐒𝐚𝐦𝐩𝐥𝐞 𝐨𝐟 𝐭𝐡𝐢𝐬 𝐑𝐞𝐩𝐨𝐫𝐭: https://www.factmr.com/connectus/sample?flag=S&rep_id=879

Country-wise Insights

China’s thermal interface material (TIM) market is valued at US$ 600.7 million and is projected to reach US$ 1.93 billion by the end of 2034. With the rapid growth of the electric vehicle (EV) industry, thermal management has become a critical factor, enabling faster charging, extending battery lifespan, and enhancing fire safety. This growth aligns closely with the expanding EV sector in China.

As reported by the International Energy Agency, China witnessed a 70% increase in demand for vehicle batteries and an 80% rise in electric car sales in 2022. These trends position China as a dominant player in the TIM market, driven by its leadership in EV adoption and battery manufacturing.

Category-wise Insights

The global sales of thermal pads are currently valued at US$ 2.1 billion and are projected to reach US$ 6.1 billion by the end of 2034. Thermal pads are vital for providing insulation between electronic components such as semiconductors and microprocessors. They are particularly useful in situations where conventional thermal pastes or greases are ineffective due to air gaps or uneven surfaces. Available in various thicknesses, thermal conductivity levels, and filler materials, thermal pads command a significant share of the thermal interface material (TIM) market.

Thermal pads are favored for their ease of handling and adaptability, being available in a range of sizes and thicknesses to meet diverse customer requirements. They are primarily used in CPUs and densely packed PCBs found in computers, with demand increasing in tandem with the growth of the electronics and computer industries. This rising adoption underscores their critical role in ensuring efficient heat management in modern electronic devices.

Read More: https://www.factmr.com/report/879/thermal-interface-materials-market

Competition Landscape

Prominent players in the thermal interface material (TIM) market include The Dow Chemical Company, DuPont, 3M, Honeywell International, Henkel AG & Co., Momentive Performance Materials, Parker Hannifin Corp., and Shin-Etsu Chemical Co., Ltd. These industry leaders are actively working to enhance their production capacities to meet the growing global demand for advanced TIM solutions.

Honeywell International collaborated with Reaction Engines Limited, a British aerospace company, on August 24, 2022. This partnership aims to develop sustainable thermal management technologies, emphasizing innovation in eco-friendly solutions.

In July 2021, DuPont acquired Laird Performance Materials, a global leader in high-performance electromagnetic shielding and thermal management. This strategic acquisition strengthens DuPont’s product portfolio and expertise in advanced thermal management technologies, positioning it as a key player in the market.

These initiatives highlight the industry's focus on innovation, sustainability, and expanding capabilities to address the evolving needs of sectors such as electronics, automotive, and aerospace.

𝐆𝐞𝐭 𝐂𝐮𝐬𝐭𝐨𝐦𝐢𝐳𝐚𝐭𝐢𝐨𝐧 𝐨𝐧 𝐭𝐡𝐢𝐬 𝐑𝐞𝐩𝐨𝐫𝐭 𝐟𝐨𝐫 𝐒𝐩𝐞𝐜𝐢𝐟𝐢𝐜 𝐑𝐞𝐬𝐞𝐚𝐫𝐜𝐡 𝐒𝐨𝐥𝐮𝐭𝐢𝐨𝐧𝐬: https://www.factmr.com/connectus/sample?flag=RC&rep_id=879

Segmentation of Thermal Interface Material Market Research

By Type :

Pads

Material

Silicone-based

Non-Silicone-based

Property

Thermally Conductive

Thermally Insulating

Foam

Material

Silicone-based

Non-Silicone-based

Property

Thermally Conductive

Thermally Insulating

Encapsulants/Gel

Material

Silicone-based

Non-Silicone-based

Property

Thermally Conductive

Thermally Insulating

By Application :

Automotive

EV Batteries

Others

Aerospace & Defense

By Region :

North America

Latin America

East Asia

South Asia & Pacific

Western Europe

Eastern Europe

Middle East & Africa

𝐂𝐨𝐧𝐭𝐚𝐜𝐭: US Sales Office 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583, +353-1-4434-232 Email: [email protected]

1 note

·

View note

Text

Apple M4 Powers Up the iMac: Blazing Speed for Creatives

Apple M4 iMac Predictions

24 Apple iMac

Apple M4 chips may be introduced when Apple updates the 24-inch iMac in 2024. Apple intends to update the Mac series, including the iMac, with AI-focused M4 CPUs. This document details Apple’s M4 iMac ambitions.

Apple M4

Apple may incorporate the M4 chip from the latest iPad Pro models in the forthcoming 24-inch iMac. Since iMacs have M3 chips, the M4 will be a direct upgrade.

Apple M4 is a second-generation chip based on the M3’s 3-nanometer technology with performance and efficiency improvements. Apple M4 CPU outscored M3 chip by 25% in Geekbench benchmark test, suggesting considerable performance boost.

The Apple M4 had 3,695 single-core and 14,550 multi-core scores, compared to 3,087 and 11,702 for the M3.

Apple’s M4 processor has a 10-core GPU and CPU with four performance and six efficiency cores. Apple uses an M4 with a 9-core CPU in the iPad Pro, but the iMac may not have it.

Other Macs will have upgraded M4 Pro, M4 Max, and M4 Ultra CPUs, while the 24-inch iMac, which is equal in price to the MacBook Air, will only have the M4 chip.

Create

No signs suggest Apple will revamp the iMac soon the last overhaul was in 2021. The 2024 iMac refresh may focus internal improvements over exterior design changes.

Computers and displays are merged in the iMac. It fits on a desktop due to its narrow profile and 11.5mm thickness. It has a pastel chin and comes in bright shades.

They know of no iMac enhancements other than the Apple M4 chip.

Larger iMac?

Despite rumours, a 30-inch iMac was still in development in mid-2023. Its release date is unknown. As of May 25, 2024, Apple has no larger iMac. Current 24-inch iMacs include M3 chips. In 2024, rumours of a bigger iMac with an M-series CPU had faded. Apple hasn’t confirmed a 30-inch model for 2025.

Expect a larger iMac: Rumours say Apple may sell a larger iMac in the future.

Connect Mac to external display: You can add a larger external monitor to your iMac or Mac mini. This maximises screen space and lets you choose size and resolution.

Consider Mac Studio: The Mac Studio is fast and may be used with a larger display for a strong desktop arrangement.

Launch Day

Bloomberg’s Mark Gurman expected a 24-inch iMac M4 processor update “around the end of the year.” The iMac may launch at October or November Apple events with new Macs. Pre-year MacBook Pro and Mac mini improvements are anticipated. Since the iMac was updated in October 2023, an October 2024 release would conclude the year.

The M4 processor outperforms the M3 with a 10-core CPU (6 efficiency and 4 performance) and GPU. Hardware-accelerated ray tracing and 16-core Neural Engine are featured. The M4 iMac could handle video editing and 3D rendering.

Apple iMac M3

They expect the new iMac to have a 24-inch Retina 4.5K display like the M3 model. Apple may possibly offer more colours for the upcoming iMac, like the M2 model. The M4 iMac will be a major upgrade from the M3. Keep an eye out for Apple’s M4-powered iMac later this year if you want a powerful and adaptable desktop.

Based on rumours and leaks, the M4 iMac may include these features:

The next-generation 24-inch iMac is believed to have the M4 chip, which Apple used in the current iPad Pro versions.

The M4, a second-generation microprocessor with faster and more efficient performance, uses the same 3-nanometer technology as the M3.

The M4 outperformed the M3 on Geekbench by 25%. Apple’s M4 processor contains a 10-core CPU and GPU with six efficiency and four performance cores.

Design: The M4 iMac will have a slim, colourful aluminium casing like the M3.

Seven brilliant colors blue, green, pink, silver, space grey, yellow, and orange are likely.

256GB of M4 iMac storage can be expanded to 2TB of SSD storage.

The M4 iMac will have 8GB of starting memory and up to 16GB of unified memory.

Reports and leaks suggest these specs for Apple’s M4 iMac:

M4 Chip had 10 cores: 4 efficient, 6 performant.

Ten cores and second-generation 3-nanometers make the GPU more efficient and performant than M3.

24-inch 4.5K Retina screen, True Tone, P3 colour gamut.

SSDs start at 256GB and RAM up to 2TB.

Standard unified memory is 8GB, customisable to 16GB.

Dual SDXC card slots, USB-C connections, Thunderbolt 4 connectors.

From last update, there was no mention of a “M4 iMac.” Apple regularly updates their products with newer processors and features. Apple’s custom Mac CPUs are generally labelled “M”.

The M1 chip, which delivered exceptional performance and energy economy, changed Apple’s desktop and laptop computers. An M4 iMac may use this special silicon to boost power and efficiency. I prefer Apple’s official releases or trusted tech sources for the most accurate and current information.

Read more on Govindhtech.com

3 notes

·

View notes

Text

I work in IT part-time and am a CS major going into software engineering. I consider myself an incredibly patient person that's pretty slow to anger, and am down to sit down and figure out a problem for hours.

Nothing, and I mean NOTHING, makes me angrier than tech issues.

If you don't have a love-hate relationship with computers in that position, idk how you cope. There's something about literally banging your head again your keyboard trying to figure out what the fuck is going wrong that humbles a woman, and nothing as utterly infuriating as this box of wires and binary sits unmoving, uncaring in front of you, but yet still taunting you.

The worst is when it was your fault. You installed something wrong, the logic of your code was off, or maybe you simply mistyped. No matter. It laughs at you all the same. Laughing at you from the intangible network of code and microprocessors that comprises its being. Even though its body and brain have been charted out, true understanding takes decades, almost as a doctor to the human form. Even then, the human body stays relatively the same. Diagnosis is difficult for both, yes, and gaps of knowledge remaining for each, but the being of a computer will remain alien. Compact forms that are neat and tidy. Boxes the size of dogs and heavy as one too. Server farms with sprawling tentacles. I work with the wifi and ethernet for my job, and the data closets that hold the switches look less like machines, and more like a plant that has rooted and infested the entire building with its vines.

Each machine is different, and they don't stop multiplying and evolving, forever changing, faster than we are able to comprehend. The body and brain evolve at speeds unheard of, blueprints and documentation unable to keep up. Linguistics shift, forms morph, it ingrains itself so deeply into our lives and yet we still struggle to understand it and the problems they bring us.

I'm working on a project now. Refurbishing an old Android app so that it can be used once more. The old developer isn't with the company anymore, and he neglected to write any documentation. It seemed simple enough: just fix it up. It just took in forms, and allowed the user to fill out the info. Simple enough. The thing to remember is complexity to you and to a machine are two different things. Your interaction may be simple, but that's because the support structure you have is already there, your brain hardwired to learn. The computer requires more, something more akin to neurosurgery, if you will, to add the necessary abilities to its routine. And so much must be added.

Folders in folders. Files thousands of lines long. Errors and warnings popping up in the interpreter. Depreciated. Unsupported. Code hopeless out of date yet ingratiated so deeply as if a tumor. This was all written less than a decade ago. Evolution, as I said. Routines pointing to methods pointing to classes as the logic wove and intertwined, and I remain helpless to untangle it. I spend hours reading through, trying to understand, and researching how to bring this back to life, and for every file I open, the deeper the program runs and deeper the pit in my stomach drops.

The one problem with the neurosurgery comparison is there is an implication of precision. Measured, delicate cuts with the steadiest of hands. That's not what coding is. No, coding is more like a lobotomy. An unethical experiment. You can plan. You can try to plan meticulously, but breaking shit and flinging mud at the wall to see what sticks is and will remain a fundamental part of the process. You will poke and prod, delete and add, test and retest as the program screams exceptions and crashes, and you will do it all over again until it obeys. Trial and error.

So yes, I relate to Colin. Pulling wires out, cursing at the errors, and wishing that the system had better documentation comes with the territory. But for all your tinkering, your insults, your intrusions, your imprecise cuts that are more like stabs leaving large gaping wounds, what happens when a computer, with wires more akin to nerves, that can truly feel your experimentation suffers through that indignity? All I can say is you should be very, very afraid.

I'm fine, btw.

I'm loving all the IT people going "No, no, Colin's behavior is perfectly normal."

It's like the opposite of all the archivists yelling at Jon

#bro i was just going to bitch about computers and shit#turned this into a whole creative writing project#sorry for dropping this on your post LMAO

4K notes

·

View notes

Text

Gliding into the Future: Your Ultimate Hoverboard Guide for 2025

Remember the first time you saw a hoverboard? Maybe it was in a movie, or perhaps you recall the craze that swept the world a few years back. Well, good news: hoverboards are still very much a thing, and they’re better than ever! In 2025, these self-balancing marvels are not just a fleeting trend but a growing market, offering fun, convenience, and even a touch of futuristic flair to personal transportation.

Whether you’re a seasoned rider or curious about getting your first board, this blog post is your go-to guide for everything hoverboard.

Are Hoverboards Still Popular? The Market Says YES!

If you thought hoverboards were a fad of the past, think again! The global hoverboard market is not just alive; it’s thriving. Experts predict the market will continue to grow significantly, reaching an estimated USD 1,644.53 million by 2034. This growth is driven by several factors:

Increased Demand for Personal Mobility: As urbanization continues, people are seeking compact, efficient, and eco-friendly ways to get around for short distances. Hoverboards fit this bill perfectly.

Technological Advancements: Better batteries, enhanced safety features (like UL 2272 certification), and integration of smart tech are making hoverboards more appealing and reliable.

Youth Appeal: Teenagers and young adults continue to be a significant driving force, viewing hoverboards as both a recreational gadget and a trendy mode of transport.

Social Media Influence: User-generated content showcasing hoverboards in action keeps the excitement alive and inspires new buyers.

So, rest assured, you’re not jumping on a dying trend — you’re joining a growing community!

How Do These Marvels Work? The Science Behind the Glide

It might feel like magic, but the technology behind hoverboards is quite clever! Here’s a simplified breakdown:

At their core, hoverboards are self-balancing electric scooters. They don’t actually “hover” above the ground in the sci-fi sense, but they use a sophisticated system of sensors and motors to keep you upright and moving:

Gyroscope: This is the brain of the operation. Each wheel has its own gyroscope, which detects the tilt and angle of the board in real-time.

Pressure Pads: Located under your feet, these pads sense your weight distribution.

Microprocessors/Logic Board: This acts as the central processing unit, taking data from the gyroscopes and pressure pads.

Motors: Each wheel has an independent motor.

Here’s how it all comes together:

Moving Forward/Backward: When you lean slightly forward, the pressure on the front of the board increases. The gyroscopes detect this tilt, and the logic board tells the motors to spin the wheels forward. Leaning backward reverses the process. The more you lean, the faster you go!

Turning: To turn, you simply apply more pressure with one foot. For example, to turn left, you press down with your right toes, causing that wheel to speed up relative to the left wheel, initiating a turn.

Balance: The constant feedback loop between the sensors, logic board, and motors allows the hoverboard to make micro-adjustments, helping you maintain your balance effortlessly.

Choosing Your Ride: What to Look for in a 2025 Hoverboard

The market offers a wide variety of hoverboards, each with its own strengths. Here are some key factors to consider:

UL 2272 Certification: This is crucial! It ensures the electrical systems and batteries meet rigorous safety standards, significantly reducing fire hazards. Never buy a hoverboard without this certification.

Wheel Size:

6.5-inch: Ideal for younger riders and smooth, indoor surfaces.

8-inch to 10-inch: Great for a smoother ride, especially on varied or slightly rougher terrains (often called “off-road” hoverboards).

Battery Life and Range: Look for models with lithium-ion batteries that offer decent run time (e.g., 60–120 minutes) and range (several miles) on a single charge.

Motor Power: Higher wattage motors (e.g., 2 x 350W) provide more torque, allowing for better performance on inclines and rougher surfaces.

Weight Limit: Ensure the hoverboard can safely support the rider’s weight.

Features: Many hoverboards now come with Bluetooth speakers, LED lights, and even smartphone apps for tracking stats or adjusting settings.

Brand Reputation: Stick to reputable brands known for quality and customer support. Some popular names in 2025 include Segway Ninebot, Hover-1, Epikgo, and Swagtron.

Ride Smart, Ride Safe: Essential Hoverboard Safety Tips

While hoverboards are much safer now thanks to improved standards, safety should always be your top priority.

Wear Protective Gear: A helmet is non-negotiable. Also consider knee pads, elbow pads, and wrist guards, especially for beginners.

Choose the Right Environment: Start in a flat, open, and obstacle-free area. Avoid busy streets, crowded spaces, and uneven/wet surfaces.

Start Slow: Practice mounting and dismounting, and get comfortable with basic movements before attempting speed or tricks. Many boards have a “beginner mode” — use it!

Mind Your Surroundings: Be aware of cracks, obstacles, and curbs. Stay alert and avoid distractions like your phone.

Follow Manufacturer Guidelines: Read your hoverboard’s manual for specific instructions on weight limits, charging, and maintenance. Never overcharge your battery.

Regular Maintenance: Check tires, battery connections, and the overall condition of your board regularly.

Visibility: If riding at dusk or night, ensure your hoverboard has lights and consider wearing reflective gear.

Stay Sober and Alert: Never ride under the influence of alcohol or drugs, or when tired.

Beyond the Basics: Getting Creative with Your Hoverboard

Once you’ve mastered the fundamentals, the fun truly begins!

Hoverboard Go-Karts: Attachments are available that transform your hoverboard into a mini go-kart, allowing you to sit and steer. A fantastic option for extended rides and a different kind of thrill.

Learning Tricks: From “The Stork” to more advanced maneuvers, there’s a world of hoverboard tricks to explore. Just remember to practice safely!

Customization: Personalize your ride with skins, stickers, or even DIY accessories to make your hoverboard truly unique.

Recreational Activities: Incorporate your hoverboard into games or simply enjoy it as a fun way to explore parks and paved paths.

Hoverboards have come a long way since their initial surge in popularity. With advancements in technology and a continued focus on safety, they remain a thrilling and practical form of personal mobility. So, whether you’re looking for a new way to commute, a fun recreational activity, or just want to experience a slice of the future today, a hoverboard might just be your next favorite gadget!

1 note

·

View note

Text

Beyond Processors: Exploring Intel's Innovations in AI and Quantum Computing

Introduction

In the rapidly evolving world of technology, the spotlight often shines on processors—those little chips that power everything from laptops to supercomputers. However, as we delve deeper into the realms of artificial intelligence (AI) and quantum computing, it becomes increasingly clear that innovation goes far beyond just raw processing power. Intel, a cornerstone of computing innovation since its inception, is at the forefront of these technological advancements. This article aims to explore Intel's innovations in AI and quantum computing, examining how these developments are reshaping industries and our everyday lives.

youtube

Beyond Processors: Exploring Intel's Innovations in AI and Quantum Computing

Intel has long been synonymous with microprocessors, but its vision extends well beyond silicon. With an eye on future technologies like AI and quantum computing, Intel is not just building faster chips; it is paving the way for entirely new paradigms in data processing.

Understanding the Landscape of AI Go to this site

Artificial Intelligence (AI) refers to machines' ability to perform tasks that typically require human intelligence. These tasks include visual perception, speech recognition, decision-making, and language translation.

The Role of Machine Learning

Machine learning is a subset of AI that focuses on algorithms allowing computers to learn from data without explicit programming. It’s like teaching a dog new tricks—through practice and feedback.

Deep Learning: The Next Level

Deep learning takes machine learning a step further using neural networks with multiple layers. This approach mimics human brain function and has led to significant breakthroughs in computer vision and natural language processing.

Intel’s Approach to AI Innovation

Intel has recognized the transformative potential of AI and has made significant investments in this area.

AI-Optimized Hardware

Intel has developed specialized hardware such as the Intel Nervana Neural Network Processor (NNP), designed specifically for deep learning workloads. This chip aims to accelerate training times for neural networks significantly.

Software Frameworks for AI Development

Alongside hardware advancements, Intel has invested in software solutions like the OpenVINO toolkit, which optimizes deep learning models for various platforms—from edge devices to cloud servers.

Applications of Intel’s AI Innovations

The applications for Intel’s work in AI are vast and varied.

Healthcare: Revolutionizing Diagnostics

AI enhances diagnostic accuracy by analyzing medical images faster than human radiologists. It can identify anomalies that may go unnoticed, improving patient outcomes dramatically.

Finance: Fraud Detection Systems

In finance, AI algorithms can scan large volumes of transactions in real-time to flag suspicious activity. This capability not only helps mitigate fraud but also accelerates transaction approvals.

Quantum Computing: The New Frontier

While traditional computing relies on bits (0s and 1s), quantum computing utilizes qubits that can exist simultaneously in multiple states—allowing for unprecede

1 note

·

View note