#fasteners machines

Text

One of the top wholesalers, suppliers, and importers of a variety of high-quality Fasteners and Fixing including nuts and bolts, metal screws, machine tools, fastener expansion tubes, heavy-duty anchors, anchors for general fixing, pipe clamps, industrial screws, and other items is Kaizen Metals india Screw India.

Our cutting-edge infrastructure facility located in Jamnagar guarantees standardized product manufacture.

These items, which come in a variety of shapes and sizes, are renowned for their smooth finishes, resistance to corrosion, dimensional precision, and durable construction.

For timely, safe, and secure product delivery to customers, our logistic support specialists leverage a large distribution network.

The superior quality of the things our business creates is the single aspect that supports it, and we never compromise on that in any way.

All of our goods are rigorously tested for their durability and safety. We take steps to ensure that none of our valued customers have ever complained about any of our items.

Our company has achieved an unachievable height that is only attained by a very small number of businesses thanks to our moral business methods and unwavering dedication.

We have been able to provide our clients very consistent and trustworthy items at rock bottom prices because of our extensive experience, thorough understanding of this company range, and the presence of incredibly committed and assiduous employees in our crew.

With the help of a group of knowledgeable, skilled, committed, and diligent individuals, this team approached every assignment with great care. Our staff includes purchasing agents, quality inspectors, packaging specialists, and many more.

These individuals were hired based on their expertise and understanding of their respective fields. Their upbeat demeanor and expert understanding of the field create a productive atmosphere where employees love the work they do. Additionally, this team is periodically refreshed in accordance with the most recent market trends.

#nuts and bolts#metal screw#machine tools#fastener expansion tube#heavy duty anchors#general fixing anchors#pipe clamps#industrial screws#fixings and fasteners#fixings and fastener#screws#bolts#nuts#coach-screws#screw hooks#rivets#cotters#cotter-pins#washers

1 note

·

View note

Text

Okay, so... I tried searching for crochet and sewing supplies online, and... it turns out, materials are expensive. :/ So I guess that's part of why I hadn't thought much about making or selling stuff before. (although $36 worth of yarn to make one thing sounds like I must've done the math wrong, because that's a lot of balls of yarn, and why wouldn't one ball of yarn make one item? So it can't be that expensive.)

But would anyone be interested in buying something I would hypothetically make if I were to buy a bunch of yarn and/or fabric and/or a sewing machine?

Like... keyboard cushion with filling, sleeveless jacket/cloak thing (I just think that would be neat), scarf of some sort, curtain tiebacks, pencil holder, ...some random custom-made thing that you can't find at the store...? Maybe weird blankets and throws?

I... thought I would be able to think of more things than this.

#if I had a sewing machine and some fabric I would be able to take the stitching out of a pair of cheap jeans#and turn them into a cool-looking pair of wide-leg pants.#...without worrying about ruining the jeans and/or my sloppy hand stitching falling out.#I would love to have a nice pair of wide-leg jeans... they're never sold in stores. (sigh)#And with a sewing machine I could modify a shirt to make it sleeve-optional. Shirts would look really cool with custom sleeve stuff.#And that cloak idea would be neat. Though I wish I still had the cloak-pin my mom gave me when I was a teen. I'd had no idea what it was.#It was a gold-colored circle. She'd said it was a brooch or something but it hadn't made any sense for just pinning to a shirt.#but as a fastener... it would've been pretty.#I've made two computer cushions for myself in the past ten or eleven years. (couldn't find one in a store)#they flatten after a few years with the filler I'd bought but they're not bad (and my newer one is washable like a pillowcase).#I made some green fabric belt tiebacks as well as fastener rope tiebacks. (...they're available in-store but I didn't like the styles.)#More recently I've made a pencil holder out of some heavy-duty black fabric (with green trim).#(because putting my pencil in my pants pockets was shredding my good pants)

5 notes

·

View notes

Video

youtube

Auto CNC Groove Lathe Machine for PEM Hex Blind Standoff Self Clinching Rivet Nut Cabinet Metal Sheet Fasteners.

Whatsapp: +86 13431255254

#youtube#CNC Lathe machine#groove cutting machine#self clinching rivet nut#standoff rivet nut machine#cold forging#standoff rivet nut groove cutting machine#hex blind rivet nut#fasteners#auto cnc lathe machine#metal sheet rivet nut#rivet nut manufacturer#rivet nut supplier#self clinching rivet nut price#standoff self clinching nut#cnc machine#groove cutting machine supplier

2 notes

·

View notes

Text

#types of fasteners#socket screws#machine screws#tapping screws#hex bolts#blind rivets#Semi-Tubular Rivets

0 notes

Text

0 notes

Text

hi, I am Zoe from China, businesswoman dealing in tungsten carbide industry

nice to meet you ~

1 note

·

View note

Text

The Role of Portable Tapping Machines in Modernizing UAE Workshop Operations

In the UAE's dynamic industrial sector, workshop efficiency and precision are crucial. Among the latest workshop tools, portable tapping machines in UAE play a key role. These compact yet powerful devices streamline tapping processes essential for assembling components across various industries, enhancing productivity significantly.

Enhancing Precision and Efficiency

Portable tapping machines in UAE workshops have modernized the way tapping is performed manually. These tools are equipped with features like adjustable speeds, user-friendly designs, and precise torque control. They ensure consistent thread cutting in materials such as aluminum and hardened steel, reducing errors, minimizing waste, and significantly speeding up production timelines.

Versatility Across Industries

Portable tapping machines in UAE workshops are used in various industries such as automotive manufacturing and aerospace engineering. They can be integrated smoothly into automated production lines or used independently for maintenance tasks. This adaptability not only improves how efficiently things are done but also supports UAE's efforts to advance technologically and diversify its industries.

Cost-Effectiveness and Sustainability

In UAE's competitive industrial scene, saving costs is crucial. Portable tapping machines in UAE workshops reduce labor expenses by replacing manual work, improving the quality of outputs. Their energy-efficient operations also align with sustainability goals, supporting UAE's commitment to eco-friendly practices in industrial settings.

Integration with Digital Technologies

Portable tapping machines in UAE workshops work more effectively when integrated with digital technologies. They can connect to IoT systems, allowing real-time monitoring of tapping processes, scheduling maintenance before problems arise, and using data for continuous improvement. These advanced capabilities ensure workshops run smoothly and enable informed decisions based on detailed analytics.

Training and Skill Development

As UAE workshops introduce advanced tools like portable tapping machines, there's a stronger focus on training workers to use them effectively. Knowing how to operate, maintain, and troubleshoot these machines ensures they integrate smoothly into daily tasks, creating a skilled workforce ready to meet industry demands.

Future Prospects and Innovation

Looking ahead, portable tapping machines in UAE workshops are expected to become more crucial as technology advances. Innovations like improved automation, augmented reality (AR) for maintenance, and AI-driven process improvements will likely change how things are done. These advancements highlight UAE's commitment to excellence in industry and establish portable tapping machines as essential tools in the era of Industry 4.0.

Conclusion

In conclusion, portable tapping machines in UAE workshops play a vital role in boosting efficiency, accuracy, and innovation. They enhance productivity, lower expenses, and promote eco-friendly practices, highlighting their essential contribution to modernizing industrial operations. As UAE advances in technology, these machines will continue to be pivotal in achieving and exceeding global manufacturing and engineering standards.

#Portable tapping machines in UAE#Workshop Tools In UAE#Workshop Equipment supplier in UAE#Fastener Insertion Machines in UAE#Tapping Machines in UAE

0 notes

Text

life will have you stressed about laundry or work but sometimes you just have to take a step back and remember that people were using buttons 2000 years before the common era (indus valley civilisation) and yet button holes apparently weren’t a thing until well around 1200 after death (ancient persians)

#that’s over 3000 years#buttons were like just for decoration for a long time#and then they got used to fasten things#and then eventually you had button holes#revolutionary#that doesn’t sound right but I don’t know enough about the history of buttons to dispute it#what do you MEAN button holes didn’t come into use at the same time as buttons#that just#they should have#this is the hill I will die on#if I ever had a Time Machine I would go back and introduce button holes way earlier#idk what kind of knock on effect that would have but I’m willing to risk it

0 notes

Text

- Would you trust a robot to look after your cat?

New Post has been published on https://petn.ws/CYNxb

- Would you trust a robot to look after your cat?

14 May 2024 A new research project is using AI to strengthen the relationships between humans and their cats in a bid to design robots capable of looking after our loved ones. New research suggests it takes more than a carefully designed robot to care for your cat, the environment in which they operate is […]

See full article at https://petn.ws/CYNxb

#CatsNews #8216Electrical8217, #Adhesives, #Automation, #Bearings, #Design, #DesignEngineering, #DpaMagazine, #Drives, #Electronic, #Enclosures, #EngineeringSoftware, #Fasteners, #Hydraulics, #MachineBuilding, #Materials, #Mechanical, #MotionControl, #Motors, #Pneumatics, #Sensors, #Springs

#&8216;electrical&8217;#adhesives#automation#bearings#design#design engineering#dpa magazine#drives#electronic#enclosures#engineering software#fasteners#hydraulics#machine building#materials#mechanical#motion control#motors#pneumatics#sensors#springs#Cats News

0 notes

Text

Exploring Metashell Engineering Fasteners

Metashell Engineering is known for producing high-quality fasteners that meet the stringent needs of various industries. Among its offerings, stainless steel fasteners, specifically SS 202, SS 304, and SS 316, stand out for their exceptional corrosion resistance, durability, and versatility. In this overview, we delve into the distinctive features and applications of these stainless steel fasteners.

SS 202: Affordable and Corrosion-Resistant

SS 202 stainless steel fasteners strike a balance between affordability and corrosion resistance. Comprising chromium, manganese, and nickel, SS 202 offers satisfactory resistance to corrosion in mildly corrosive environments.

SS 304: The Standard for General-Purpose Applications

SS 304 stainless steel fasteners are widely used, offering excellent corrosion resistance and versatility.In various environments, SS 304, which is made up of chromium and nickel, demonstrates exceptional resistance to corrosion..

SS 316: Superior Corrosion Resistance in Harsh Environments

In aggressive and corrosive environments, SS 316 stainless steel fasteners are known for their superior corrosion resistance. With added molybdenum, SS 316 offers enhanced resistance to pitting and crevice corrosion, making it ideal for marine and chemical processing applications.

Metashell Engineering’s stainless steel fasteners, including SS 202, SS 304, and SS 316, offer a spectrum of options to meet diverse industrial needs. Whether it’s affordability, general-purpose versatility, or superior corrosion resistance, these fasteners cater to various applications across industries. By understanding the unique properties and applications of each stainless steel grade, engineers and manufacturers can make informed decisions to optimize performance, longevity, and cost-effectiveness in their projects.

#machines#fasteners#industrialtools#specialpurposemachines#screws#sockets#manufacturer#supplier#exporter#lathe machine suppliers

1 note

·

View note

Text

Vertical machining centers may create components and items for various markets and usage. These are normally used for high-accuracy, high-precision, and mass-production applications. The adaptability of VMCs in dealing with different products and their ability to implement intricate machining procedures make them crucial in contemporary production.

#Precision Components#Precision Parts#Precision machined Parts#CNC Machined Parts#Precision Turned Components#VMC Machined Components#Custom made fasteners

1 note

·

View note

Text

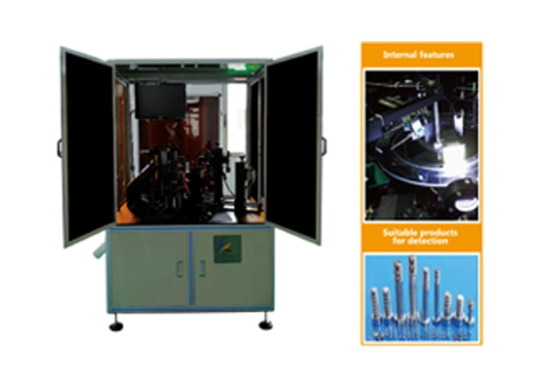

Professional Straightening Solutions Supplier

Project Background:

Straightening Machine is required for surgical drills to ensure accuracy, precision, and safety during surgical procedures. There are several reasons why straightening surgical drills is essential:

The drills blank straightening is a necessary process before grinding. Normally, the runout should be within 0.1mm.

Proper Alignment: Surgical drills need to be perfectly aligned to access the surgical site accurately. Straightening ensures that the drill bit is in line with the intended path, reducing the risk of damaging surrounding tissues or structures.

Control and Stability: A straightened drill offers better control and stability during the drilling process. This is particularly important when operating in delicate areas or working with small, intricate structures.

Minimizing Tissue Trauma: Using a straightened drill helps minimize tissue trauma by avoiding unnecessary lateral movements. Reduced tissue trauma contributes to faster healing and better patient outcomes.

Depth Control: Straightened drills allow the surgeon to maintain consistent depth control while drilling. This is crucial when dealing with bones or during procedures where precise hole depths are required.

What is the conventional method for straightening surgical drills?

The surgical drills are normally straightened manually. However, the practice of manual straightening for surgical drills poses several challenges.

Firstly, manual alignment can be time-consuming and labor-intensive;

Secondly, human error may lead to imperfect alignment, compromising the drill's accuracy and risking patient safety.

Additionally, manual straightening might not achieve the same level of precision as automated methods, affecting surgical outcomes.

Finally, the process relies heavily on the expertise of technicians, and faces the problem of shortages of skilled workers.

To address these issues, researchers and manufacturers are exploring advanced automated solutions for surgical drill straightening.

What solutions we can offer?

Automatic Fasten Straightening Machine for surgical drills offer several advantages over manual straightening methods, providing an efficient and precise solution for maintaining surgical instruments. Here are some of the key advantages:

Enhanced Precision: Automatic straightening machines utilize advanced technologies, such as computer-controlled algorithms and sensors, to achieve precise alignment. This ensures that the drill bits are perfectly straight and aligned, minimizing the risk of inaccuracies during surgical procedures.

Consistency: Automated machines provide consistent results with every straightening process. This uniformity is essential in maintaining the performance and longevity of surgical drills, as well as ensuring standardization across various procedures.

Time-saving: Automated straightening significantly reduces the time required to align surgical drills compared to manual methods. This time-saving advantage translates to quicker turnaround times for maintenance and ensures that surgical instruments are readily available for use.

Reduced Human Error: By eliminating manual intervention, automatic straightening machines minimize the risk of human errors, such as over-bending or under-bending the drill. This helps improve patient safety and reduces the chances of instrument damage.

Scalability: Automated systems are easily scalable to accommodate high volumes of surgical drills, making them suitable for large healthcare facilities or manufacturing settings.

Operator-Friendly: Although these machines require trained operators, they are designed to be user-friendly, simplifying the straightening process and reducing the skill level required compared to manual methods.

Maintenance Alerts: Some advanced machines can detect wear and tear in drill bits and alert operators when replacement or further inspection is necessary. This proactive approach aids in preventing potential equipment failures during critical procedures.

Cost-effectiveness: While initial investments might be higher, automatic straightening machines can lead to long-term cost savings by reducing the need for manual labor and minimizing the chances of expensive drill replacements due to damage or inaccuracies.

Applications

Raw seamless tube stock

Threaded pipe

Bar stock in different geometries - (round, square, rectangular)

Shafts – axles, cams, drives, gearbox

Industrial profiles – guides, racks, I-beams, drilling rods and tools

0 notes

Text

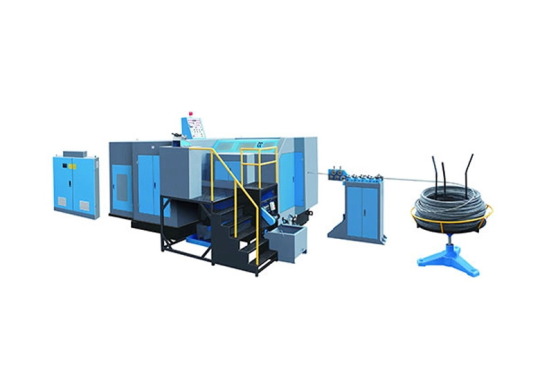

Rainbow Fastener Manufacturing Machinery Display

Bolt Forging Machine

Rainbow's Bolt Forging Machine is a robust, adaptable equipment for bolt forging processes, transforming metal blanks into components such as bolts, screws, and fasteners.

RBF Series 4 Station Bolt Former

RBF Series 5 Station Bolt Former

RBF Series 6 Station Bolt Former

QLBF Series 3 Station Bolt Former

Nut Forging Machine

Rainbow' s Nut Forging Machine is a powerful, flexible tool for nut forging processes, converting metal blanks into components such as nuts, couplings, and connectors.

RNF Series 6 Station Nut Former

RNF Series 7 Station Nut Former

Cold Heading Machine

Rainbow's Cold Heading Machine is a specialized equipment used for cold forming and heading processes. It efficiently and accurately shapes metal materials, producing high-quality and reliable fasteners.

RSH Series 1 Die 2 Blow Cold Heading Machine

RSR Series Semi-Tubular Rivet Cold Heading Machine

RB Series 2 Die 4 Blow Cold Heading Machine

Nut Tapping Machine

Rainbow Nut Tapping Machine: Achieve precise and efficient nut tapping with our reliable equipment. Ensuring high-quality results, our machine is designed for versatility and ease of use.

4 Spindle Nut Tapping Machine

2 Spindle Nut Tapping Machine

Cold Heading Machine

Rainbow's Cold Heading Machine is a specialized equipment used for cold forming and heading processes. It efficiently and accurately shapes metal materials, producing high-quality and reliable fasteners.

RSH Series 1 Die 2 Blow Cold Heading Machine

RSR Series Semi-Tubular Rivet Cold Heading Machine

RB Series 2 Die 4 Blow Cold Heading Machine

Thread Rolling Machine

Offering precision and efficiency for seamless metal rolling. Achieve high-quality results with our reliable and versatile equipment.

CY Series Flat Die Thread Rolling Machine

ZP Series Round Die Thread Rolling Machine

Nut Tapping Machine

Rainbow Nut Tapping Machine: Achieve precise and efficient nut tapping with our reliable equipment. Ensuring high-quality results, our machine is designed for versatility and ease of use.

4 Spindle Nut Tapping Machine

2 Spindle Nut Tapping Machine

Screw Washer Assembly Machine

Washer assembling machine is a specialized machine with high speed, to assemble bolt, plain washer, spring washer, then thread. The machine has stable performance and strong practicality.

Nut Bolt Assembly Machine

The Nut Bolt Assembly Machine is a specialized equipment used for efficiently and accurately assembling nuts and bolts. It automates the assembly process, reducing labor requirements and ensuring precise and consistent results. This machine is ideal for manufacturers in need of high-volume nut and bolt assembly capabilities.

Screw Sorting Machine

The Screw Sorting Machine is a specialized equipment used for automated sorting of screws based on size, shape, and other specified criteria, increasing efficiency in assembly processes.

U Shape Bolt Equipment

Rainbow U Shape Bolt Equipment: Delivering precise and efficient U-shaped bolt production. Our reliable machine ensures high-quality results and is designed for versatility and ease of use.

W58 Straightening & Cutting Machine

XM-B38NC Spline Head Hydraulic Pipe Bending Machine

ZD-3-B Thread Bar Automatic Receiving Machine

ZD-3 Thread Bar Automatic Feeding Maching

Maintenance Tips for Fastener Making Machinery

Regular Cleaning and Lubrication

Keep the fastener making machinery clean and free from debris. Regularly lubricate moving parts to reduce friction and ensure smooth operation.

Inspection and Replacement of Wear Parts

Periodically inspect the cold forging machine for any signs of wear or damage. Replace worn-out parts, such as belts, bearings, or cutting tools, to prevent breakdowns and maintain optimal performance.

Calibration and Alignment

Check the alignment of the machine components, such as guides, rollers, and cutter heads, to ensure accurate operation. Calibrate the machine according to manufacturer specifications to maintain precise dimensions and tolerances in the produced fasteners.

Importance of Automation in Fastener Production Processes

Automation plays a crucial role in fastener production processes, offering numerous benefits and advantages.

Firstly, automation improves productivity and efficiency. Automated machines can perform tasks at a much faster pace than manual labor, resulting in increased production rates and throughput. This allows manufacturers to meet higher demand and achieve greater output with fewer resources.

Secondly, automation ensures consistent quality and precision. Automated machines perform tasks with high accuracy and repeatability, reducing human error. This results in the production of fasteners that meet stringent quality standards and have consistent dimensions, ensuring a reliable and consistent end product.

Thirdly, automation enhances worker safety. By automating repetitive and hazardous tasks, workers are protected from potential injuries and risks associated with manual labor. This creates a safer working environment and reduces the occurrence of work-related accidents.

Moreover, automation enables real-time monitoring and data collection. Automated machines can gather data on production rates, quality metrics, and machine performance. This data can be analyzed to identify bottlenecks, optimize processes, and make data-driven decisions for improving overall efficiency and quality.

Ultimately, the implementation of automation in fastener production processes helps manufacturers stay competitive in the global market by increasing productivity, improving quality, enhancing worker safety, and driving overall operational excellence.

Different Types of Fastener Making Machinery

1. Heading Machines: Used to create the head of fasteners, such as screws and bolts, by applying pressure to a metal blank.

2. Thread Rolling Machines: Used to create threads on fasteners through a rolling process, ensuring strong and precise threading.

3. Nut Tapping Machines: Designed specifically for tapping threads into nuts, providing efficient and accurate threading operations.

4. Wire Drawing Machines: Used to reduce the diameter of metal wire by pulling it through a series of dies. This process creates the basic material used in fastener manufacturing.

5. Bolt Making Machines: Purpose-built machines that form bolts by cutting and shaping metal blanks, creating the desired dimensions and shapes for specific applications.

6. Screw Making Machines: Similar to bolt making machines, but specifically designed to manufacture screws, including self-tapping and machine screws, with various thread types.

7. Rivet Making Machines: These machines are used to form rivets by cutting and shaping metal blanks, enabling the production of different types and sizes of rivets.

8. Washer Making Machines: Designed for producing washers, these machines enable the cutting and shaping of metal blanks into washers of various shapes and sizes.

9. Nut Formers: Specialized machines that shape metal blanks into nuts by applying pressure and forming the desired dimensions and threading.

10. Fastener Packaging Machines: Used for automated packaging and labeling of fasteners, improving efficiency and ensuring proper packaging for shipment and distribution.

1 note

·

View note

Text

0 notes

Text

Monel alloy fastners manufacturer and supplier in India | Fastnersllp

Fastenersllp is a leading manufacturer and supplier of Monel alloy fasteners in India. We offer a wide range of Monel alloy fasteners, including Monel Alloy 400 and Monel Alloy K500 fasteners. Monel alloy fasteners are widely used in a variety of industries, including marine, chemical processing, and petrochemical industries. They are also used in power generation, aerospace, and other high-tech industries. If you are looking for high-quality Monel alloy fasteners, contact Fastenersllp today. We offer a wide range of fasteners to meet your specific needs.

#monel alloy properties#Monel Alloy 400 fastener#Monel Alloy K500 fastener#monel alloy 400 machinability

0 notes

Text

The Essential Role of a Fastener Distributor in Modern Industries

In today's fast-paced industrial landscape, the significance of a reliable Fastener Distributor cannot be overstated. These unsung heroes of production lines ensure that the nuts, bolts, screws, and other essential fasteners that hold machinery and structures together are readily available when needed.

Let's delve into the world of fastener distribution and explore why it's a critical component of seamless operations.

Meeting Industry Needs with Precision

Fasteners are the unsung heroes of machinery and construction, holding everything together with steadfast reliability. A proficient Fastener Distributor understands the diverse requirements of different industries.

From automotive to aerospace, construction to electronics, each sector demands specific fasteners that adhere to stringent standards.

Ensuring Quality and Compliance

In an era where precision and quality are paramount, fastener distributors and Machine Screw Malaysia play a pivotal role in maintaining industry standards. They meticulously source fasteners that meet not only the required specifications but also comply with regulatory guidelines.

This attention to detail ensures that the end products are safe, reliable, and in accordance with industry norms.

Streamlining the Supply Chain

Efficiency is the cornerstone of modern industries, and a fastener distributor contributes significantly to streamlining the supply chain. By maintaining an extensive inventory and employing just-in-time strategies, they ensure that manufacturers receive the necessary fasteners precisely when they need them.

This approach minimizes downtime and optimizes production schedules.

Reducing Costs and Maximizing Profit

Fastener distributors also assist manufacturers in reducing costs. By offering a one-stop-shop for a wide range of fasteners, they eliminate the need for manufacturers to maintain extensive inventories themselves.

This not only reduces storage expenses but also enables companies to allocate resources more effectively, ultimately maximizing profits.

Expertise in Fastener Solutions

Fastener distributors are not merely suppliers; they are experts in their domain. Their in-depth knowledge of fasteners allows them to recommend the most suitable options for specific applications.

This expertise ensures that manufacturers make informed decisions that enhance the quality and performance of their products.

Responsive Customer Support

In a dynamic industrial landscape, the ability to provide quick solutions is invaluable. Fastener distributors excel in offering responsive customer support.

Whether it's a rush order or technical assistance, they are always just a call away, ensuring that production lines keep running smoothly.

Conclusion

In conclusion, the role of a Fastener Distributor in modern industries cannot be underestimated. They are the silent champions who ensure that the nuts and bolts of our world are always in place. From maintaining quality standards to streamlining supply chains, their contributions are pivotal in keeping industries moving forward. So, the next time you see a skyscraper or drive a car, remember that behind the scenes, a Fastener Distributor played a vital role in making it all possible.

0 notes