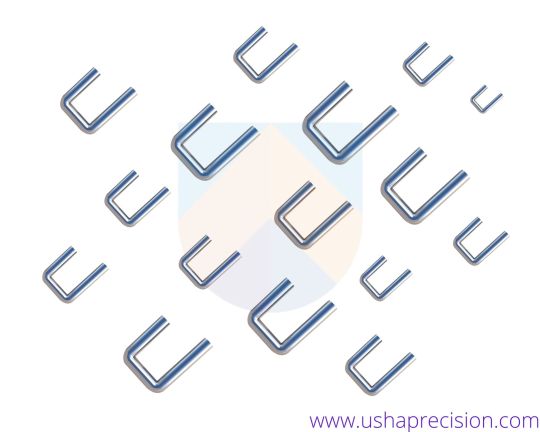

#Semi-Tubular Rivets

Text

#types of fasteners#socket screws#machine screws#tapping screws#hex bolts#blind rivets#Semi-Tubular Rivets

0 notes

Text

Usha Precision

#ss shaft#Piston rod#Brass Rivets#Hollow Rivets#Semi Tubular Rivets#Achse#Micro Rivets#Stainless Steel Rivets

0 notes

Text

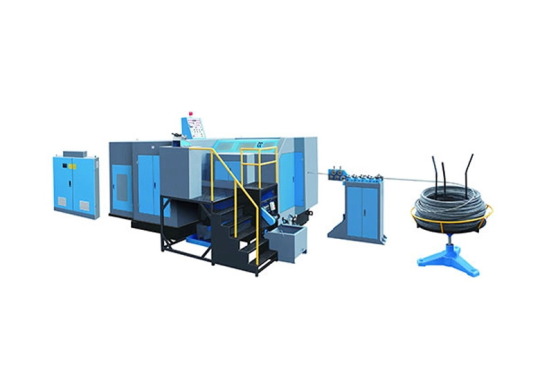

Rainbow Fastener Manufacturing Machinery Display

Bolt Forging Machine

Rainbow's Bolt Forging Machine is a robust, adaptable equipment for bolt forging processes, transforming metal blanks into components such as bolts, screws, and fasteners.

RBF Series 4 Station Bolt Former

RBF Series 5 Station Bolt Former

RBF Series 6 Station Bolt Former

QLBF Series 3 Station Bolt Former

Nut Forging Machine

Rainbow' s Nut Forging Machine is a powerful, flexible tool for nut forging processes, converting metal blanks into components such as nuts, couplings, and connectors.

RNF Series 6 Station Nut Former

RNF Series 7 Station Nut Former

Cold Heading Machine

Rainbow's Cold Heading Machine is a specialized equipment used for cold forming and heading processes. It efficiently and accurately shapes metal materials, producing high-quality and reliable fasteners.

RSH Series 1 Die 2 Blow Cold Heading Machine

RSR Series Semi-Tubular Rivet Cold Heading Machine

RB Series 2 Die 4 Blow Cold Heading Machine

Nut Tapping Machine

Rainbow Nut Tapping Machine: Achieve precise and efficient nut tapping with our reliable equipment. Ensuring high-quality results, our machine is designed for versatility and ease of use.

4 Spindle Nut Tapping Machine

2 Spindle Nut Tapping Machine

Cold Heading Machine

Rainbow's Cold Heading Machine is a specialized equipment used for cold forming and heading processes. It efficiently and accurately shapes metal materials, producing high-quality and reliable fasteners.

RSH Series 1 Die 2 Blow Cold Heading Machine

RSR Series Semi-Tubular Rivet Cold Heading Machine

RB Series 2 Die 4 Blow Cold Heading Machine

Thread Rolling Machine

Offering precision and efficiency for seamless metal rolling. Achieve high-quality results with our reliable and versatile equipment.

CY Series Flat Die Thread Rolling Machine

ZP Series Round Die Thread Rolling Machine

Nut Tapping Machine

Rainbow Nut Tapping Machine: Achieve precise and efficient nut tapping with our reliable equipment. Ensuring high-quality results, our machine is designed for versatility and ease of use.

4 Spindle Nut Tapping Machine

2 Spindle Nut Tapping Machine

Screw Washer Assembly Machine

Washer assembling machine is a specialized machine with high speed, to assemble bolt, plain washer, spring washer, then thread. The machine has stable performance and strong practicality.

Nut Bolt Assembly Machine

The Nut Bolt Assembly Machine is a specialized equipment used for efficiently and accurately assembling nuts and bolts. It automates the assembly process, reducing labor requirements and ensuring precise and consistent results. This machine is ideal for manufacturers in need of high-volume nut and bolt assembly capabilities.

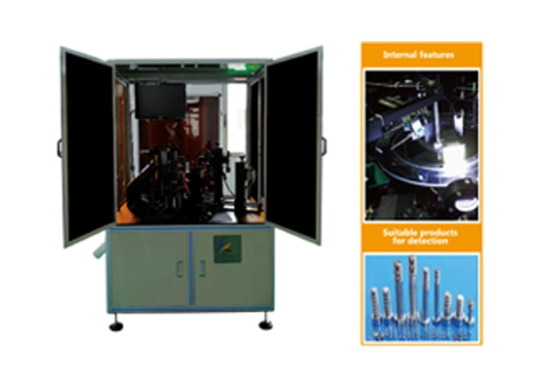

Screw Sorting Machine

The Screw Sorting Machine is a specialized equipment used for automated sorting of screws based on size, shape, and other specified criteria, increasing efficiency in assembly processes.

U Shape Bolt Equipment

Rainbow U Shape Bolt Equipment: Delivering precise and efficient U-shaped bolt production. Our reliable machine ensures high-quality results and is designed for versatility and ease of use.

W58 Straightening & Cutting Machine

XM-B38NC Spline Head Hydraulic Pipe Bending Machine

ZD-3-B Thread Bar Automatic Receiving Machine

ZD-3 Thread Bar Automatic Feeding Maching

Maintenance Tips for Fastener Making Machinery

Regular Cleaning and Lubrication

Keep the fastener making machinery clean and free from debris. Regularly lubricate moving parts to reduce friction and ensure smooth operation.

Inspection and Replacement of Wear Parts

Periodically inspect the cold forging machine for any signs of wear or damage. Replace worn-out parts, such as belts, bearings, or cutting tools, to prevent breakdowns and maintain optimal performance.

Calibration and Alignment

Check the alignment of the machine components, such as guides, rollers, and cutter heads, to ensure accurate operation. Calibrate the machine according to manufacturer specifications to maintain precise dimensions and tolerances in the produced fasteners.

Importance of Automation in Fastener Production Processes

Automation plays a crucial role in fastener production processes, offering numerous benefits and advantages.

Firstly, automation improves productivity and efficiency. Automated machines can perform tasks at a much faster pace than manual labor, resulting in increased production rates and throughput. This allows manufacturers to meet higher demand and achieve greater output with fewer resources.

Secondly, automation ensures consistent quality and precision. Automated machines perform tasks with high accuracy and repeatability, reducing human error. This results in the production of fasteners that meet stringent quality standards and have consistent dimensions, ensuring a reliable and consistent end product.

Thirdly, automation enhances worker safety. By automating repetitive and hazardous tasks, workers are protected from potential injuries and risks associated with manual labor. This creates a safer working environment and reduces the occurrence of work-related accidents.

Moreover, automation enables real-time monitoring and data collection. Automated machines can gather data on production rates, quality metrics, and machine performance. This data can be analyzed to identify bottlenecks, optimize processes, and make data-driven decisions for improving overall efficiency and quality.

Ultimately, the implementation of automation in fastener production processes helps manufacturers stay competitive in the global market by increasing productivity, improving quality, enhancing worker safety, and driving overall operational excellence.

Different Types of Fastener Making Machinery

1. Heading Machines: Used to create the head of fasteners, such as screws and bolts, by applying pressure to a metal blank.

2. Thread Rolling Machines: Used to create threads on fasteners through a rolling process, ensuring strong and precise threading.

3. Nut Tapping Machines: Designed specifically for tapping threads into nuts, providing efficient and accurate threading operations.

4. Wire Drawing Machines: Used to reduce the diameter of metal wire by pulling it through a series of dies. This process creates the basic material used in fastener manufacturing.

5. Bolt Making Machines: Purpose-built machines that form bolts by cutting and shaping metal blanks, creating the desired dimensions and shapes for specific applications.

6. Screw Making Machines: Similar to bolt making machines, but specifically designed to manufacture screws, including self-tapping and machine screws, with various thread types.

7. Rivet Making Machines: These machines are used to form rivets by cutting and shaping metal blanks, enabling the production of different types and sizes of rivets.

8. Washer Making Machines: Designed for producing washers, these machines enable the cutting and shaping of metal blanks into washers of various shapes and sizes.

9. Nut Formers: Specialized machines that shape metal blanks into nuts by applying pressure and forming the desired dimensions and threading.

10. Fastener Packaging Machines: Used for automated packaging and labeling of fasteners, improving efficiency and ensuring proper packaging for shipment and distribution.

1 note

·

View note

Text

Multi-Grip Rivet Manufacturer in India

At Dojo Rivet, we are the best rivets manufacturer in India. We offer a wide range of blind rivets, aluminum blind rivets, semi-tubular and round head rivets as well as flat head solid rivets, and much more. To manufacture these rivets, we take care of acquiring the best raw material thereby ensuring superior quality products at economical prices. No need to find it online, order rivets manufacturer here now.

0 notes

Text

A Guide to Professional Riveting

What is Riveting?

Riveting is a process used to join two or more pieces of material together by setting a rivet with a riveting tool. The process involves the use of either mechanical or hydraulic pressure to form a strong, permanent bond between the objects being joined. Riveting is often utilized in construction and engineering as it provides an easy way to fasten materials such as steel and aluminium. In addition, it can be used for decorative purposes and for applications where welding may not be feasible due to thermal expansion issues.

The main components involved in professional riveting include the rivet itself, which is usually made from aluminium or copper; the head of the rivet which holds everything together; and the setting tool which applies force onto the rivet's head so that it forms a secure hold on materials being joined together. To ensure proper installation, each piece must be correctly aligned before any pressure is applied - otherwise, there could be potential risks associated with improper alignment leading to dangerous situations such as weak joints or breakage during operation. Additionally, correct hole sizing should also be taken into consideration when using this method since incorrect sizes could affect how well your joint performs over time.

Tools and Techniques

Tools and techniques for riveting are an important part of the trade. The first tool to be familiar with is the pneumatic press or hammer, which is used to place the rivets in their holes. Depending on the size of the rivet, it may be necessary to use a drill bit for pre-drilling before using the pneumatic press. Next, you should learn how to properly set and shape your rivets with a bucking bar. This metal device helps form your fasteners into their proper shapes by applying pressure while they are being secured with the pneumatic press or hammer. Finally, air tools are useful for loosening and tightening bolts as needed when making adjustments during installation. It’s important to understand that all these tools must be used together in order to achieve strong, secure joints that will last through years of wear and tear. Additionally, certain materials can require unique methods; aluminium requires special high strength adhesive instead of traditional rivets while brass often needs soft solder instead of hard steel rivets. Lastly, practice makes perfect - learning how much pressure needs to be applied for various situations takes time and repetition in order to become proficient in this skill set.

Safety Considerations

Riveting is a very useful, versatile and effective process that should be done responsibly with safety precautions in mind.

Safety considerations are paramount when selecting and using rivets. The material being joined must be compatible with the rivet material, and the strength of the joint must match or exceed that of the materials being joined. Incorrectly chosen or applied rivets can lead to dangerous structural failure.

When performing a riveting operation, all personnel should wear appropriate protective gear such as gloves, eye protection and face shields. Additionally, it is essential to ensure proper ventilation when working with volatile adhesives and solvents. Adequate lighting should also be provided for workers to see what they are doing accurately. Lastly, having a fire extinguisher nearby and making sure that flammable materials are kept away from hot surfaces is recommended when using any type of heat-activated adhesive during a riveting process.

Identifying Different Types of Rivets

Rivets are one of the most common types of fasteners used in a variety of applications. Identifying different types of rivets can be tricky, as there are many variations available on the market. There are three main categories of rivets: solid, semi-tubular, and blind. Solid rivets require two tools to install; a hammer or press to set the pin into the hole and an anvil to flatten it. Semi-tubular rivets require only one tool for installation; a press that pushes a mandrel through the hole and forms the head on both sides at once. Blind rivets have two parts: a small cylindrical body with an expandable mandrel inside that pulls in when compressed as it is inserted into a pre-drilled hole and expands outward against the inner wall creating its own head on one side. Each type has its own unique advantages depending upon application requirements such as size, strength, cost, ease of installation and access to both sides of material being joined. Rivet selection should be made carefully after considering all factors relevant to each particular job in order to ensure optimal results during assembly operations.

Setting and Sealing Rivets

Rivets are an excellent choice for fastening two materials together, as they provide a strong and secure bond. Setting and sealing rivets is an important part of the riveting process that helps to ensure a reliable seal. This involves inserting the rivet into a pre-drilled hole and then setting it in place with a hammer or other tool. Once the head of the rivet has been set, it should be sealed with either a caulking compound or epoxy to prevent corrosion and water damage.

When setting a rivet, it is important to ensure that the material being joined is sufficiently clamped together so that there won't be any gaps between them when the rivet is inserted. Additionally, care should be taken to make sure that the head of the rivet does not protrude from either side of the material being joined; if this occurs, then there may be issues with proper sealing later on. A small amount of lubricant can also help ease insertion and prevent over-tightening which can cause problems down the road.

Once set, apply some form of sealant around both sides of each joint - this will help reduce moisture penetration, preventing rusting and other forms of corrosion from occurring over time. The quality of sealant used will depend on where you are installing your rivets; for example marine grade sealants should always be used in wet environments such as near oceans or rivers due to their superior resistance against salt water corrosion.

Troubleshooting Common Issues

One of the most common issues when riveting is hole size. If there isn't enough clearance for the rivet, it won't go through the material properly. To address this issue, you should use a drill bit that is slightly bigger than the diameter of the rivet you are using. This will ensure there's plenty of space for it to pass through both pieces of material. Additionally, you can countersink the holes in order to allow for more surface area on each side and help with alignment.

Another potential issue is having a misaligned joint due to not clamping or holding together your materials securely before inserting a rivet. To prevent this from happening, make sure to place some pressure on both sides before adding a rivet so that they stay flush and even during installation. It’s also important to check that all parts are level and placed correctly beforehand in order to achieve an even finish once complete. Lastly, unclamp after insertion but leave pressure on until cooled down if possible; this will help keep everything aligned while solidifying your joint.

Conclusion: Professional Riveting Success

The conclusion of any riveting project can be a daunting task. For the professional riveter, however, the process should be much easier. By taking the time to understand the riveting process and by having a clear plan of action in mind, any professional riveter can achieve success and complete their project with confidence. Professional riveters have an arsenal of tools at their disposal to help them get the job done quickly and efficiently. The key is to use these tools in combination with techniques that will ensure reliable results while also minimizing mistakes or over-tightening. Additionally, it is important to understand how different materials react when exposed to heat or pressure during the riveting process in order to minimize damage or destruction of materials. Taking all of these factors into consideration will help professionals achieve a successful outcome for any riveting project they work on.

0 notes

Photo

FERRARI 156 F1 1963 . THE 156 F1-63 WAS LINED OUT 1963 AND IN SEVERAL RACES THE FOLLOWING SEASON ALSO . A new driver, John Surtees, drove the Ferrari to victory in one Grand Prix, winning at the Nürburgring, but this was not enough to beat Jim Clark’s Lotus. The 1963 156 boasted two innovative features. The first was a semi-monocoque chassis, i.e. one with external panels riveted to the load-bearing tubular structure, which improved the overall robustness of the car. The second feature was a direct fuel injection engine developed in association with Swiss technician May, who used the high pressure Bosch pump in it. Despite these modifications, however, the car still failed to convince, so much so, in fact, that the direct fuel injection also used on the V8, was abandoned. . #ferrari #diecast #owners #club #indonesia #fdoci #scuderiaferrari #modelscale #scalecar #instagood #picoftheday #pictureoftheday #keepfightingmichael #supercar #carporn #forzaferrari #redseason #formulaone #scuderiaferrariclub #f1racing #readysetred #f1 #liveyourferraripassion #essereferrari #shell (at Jayapura city) https://www.instagram.com/p/CnahVzlyGUE/?igshid=NGJjMDIxMWI=

#ferrari#diecast#owners#club#indonesia#fdoci#scuderiaferrari#modelscale#scalecar#instagood#picoftheday#pictureoftheday#keepfightingmichael#supercar#carporn#forzaferrari#redseason#formulaone#scuderiaferrariclub#f1racing#readysetred#f1#liveyourferraripassion#essereferrari#shell

1 note

·

View note

Text

Ten Common Purposes of Rivets

The globe continues to be operating upon rivets intended for a large number of years. From Vikings to Historic Egyptians, folks have depended on these types of fasteners to protected items together to get make use of in everyday existence, and the same holds true today. Rivets are crucial in the building of structures, cookware, jewellery, therefore a lot more because they're cost-effective and the favoured way to completely secure a number of components like solid wood, metallic, and plastic.

Listed below are 10 prevalent uses for rivets:

Pots and pans

Pointe are the house specialty. No more than they are, container and skillet rivets will be a fundamental element of durable cookware in your kitchen. Aluminium frying cookware, cast flat iron trays, stainless pots, and ceramic skillets frequently have deals with fastened to the primary kitchenware body applying solid rivets or semi-tubular rivets.

Aircraft

Facing solid headwinds, high elevations, and weighty loads, plane of any sort needs to be created from solid, solid components. Captivating can be an important section of the structure of airplane for long term metal attachment. Rivets will be the ultimate decision for equipment since often fastening can only just be performed in one part of the materials.

Dog and horse leashes

Four-legged friends make use of rivets, as well. The majority of doggie leashes depend on simple catch or hold for connecting into a training collar cycle for an easy, protected interconnection. The same could be stated pertaining to horses and saddlery. In both instances, the rivet allows the system to spread out very easily and close safely.

Aluminium boats

Keeping you afloat, a good rivet acts a useful and all-important function with regards to aluminium boat. Rivets will be the ideal decision for sea make use of due to their stability and capability to hold parts as well as a good enough seal off to maintain water away.

Window treatments and covers

From tones, to window blinds, to window shutters, rivets certainly are a key element of this each day important. As you open up the blinds initially light to when it is time to carefully turn in for the night time, rivets help to make this basic act feasible. Rivets are accustomed to secure the average person blinds towards the framework from the windows masking therefore if the window blinds happen to be shuddered or perhaps open up, the blinds will be guaranteed for the frame whilst having the capability to revolves open and shut.

Trailers and campers

These types of small, mushroom-shaped bits of equipment will be the nails of choice for most trailer and camper businesses. In fact, normally there in 4, 500 rivets Atlanta divorce attorney’s airstream travelling trailer based on the company. Pointe are really dependable and extremely resistant to dislodging, producing all of them the perfect equipment for getting the kilometres on.

Electric and magnetic motors

At the time you turn the main element in the combustion or drive the switch on the food blender, you anticipate the equipment to perform just like a well-oiled machine. Pointes help to make that happen keeping every element in place. Created from tough supplies, like metal and aluminium, rivets are designed to previous and stay in place.

Military equipment

Not prevalent for the common Joe, and better fitted to G. We. Joe, rivets certainly are an important element found in high- overall performance ammunition managing systems to operate a vehicle efficiency. Pointe are found in the building of the string that bears ammunition throughout the weaponry.

Sound system

We’ve almost all noticed the word “communication is usually key”. Intended for modes of transport want airplanes, vessels, and vehicles, that is accurate which explains why having speakers happen to be crucial to safe and hanging around, in the event that you will. Pointe possess the all-important work of keeping these essential devices in position.

Vacation decorations and wall structure indicators

Christmas and Halloween adornments, picture structures, and art work can most quickly become installed on wall space and ceiling with captivating. Because you just get access to 1 part in the wall structure or perhaps ceiling, rivets will be the best way to effectively improve a space.

To know more about rivets click here.

1 note

·

View note

Text

Basic Types of Rivets & Their Applications

The overall types of pointe are sturdy, blind, tube, and metallic piercing (including split rivets). From a structural style aspect, the most crucial rivets will be the solid and blind rivets.

Sturdy Rivets: Many solid cheville are made from aluminium to ensure that the shop mind could be chilly shaped simply by bucking this with a pneumatic hammer. Therefore, solid pointe will need to have cold-forming ability with out cracking. An agent report on sound rivets is usually provided in desk IX (ref. 2). Various other stable rivet components are metal, SAE 1006 to WEATHER RESISTANT 1035, 1108 and 1109 steels, A286 stainless, and titanium.

Remember that the cheville in desk IX will be included in armed service standard specs, which are plentiful. Although the majority of the sturdy rivets outlined in desk IX possess common mind, there are additional common mind types, because demonstrated in figure thirty-four. Nevertheless, since the “experts” usually do not necessarily acknowledge the names, additional titles have already been put into the figure. Notice also that the countersunk mind angle may differ from 60° to 120° although 82° and 100° will be the prevalent angles.

The sharp advantage of the countersunk head can be removed in some instances, as in the Briles BRFZ “fast” rivet (fig. 35), to boost the shear and fatigue power while nonetheless keeping a flush match.

Blind Rivets: Sightless rivets obtain name from the actual fact they can become completely set up in one part. They have the next significant positive aspects over sound rivets:

1 ) Only 1 owner is necessary intended for installation.

instalment payments on your The set up device is definitely portable ( much like a great electrical exercise in proportions ).

3. They will can be utilized exactly where only one aspect of the workpiece is obtainable.

four. A given- size rivet can be utilized to get a variety of fabric thicknesses.

five. Installation period is quicker than with stable rivets.

six. Clamping pressure is even more uniform compared to solid pointe.

7. Much less training is necessary for the operator.

Impaired rivets happen to be classified based on the methods utilized to set up all of them:

1 . Draw mandrel

installment payments on your Threaded originate

3. Travel pin

Pull-Mandrel Rivets: This rivet is mounted with an instrument that is applicable force towards the rivet mind even though tugging a prenotched serrated mandrel to increase the much part from the tubular rivet. When the correct load is usually reached, the mandrel fractures at the level. A common pull-mandrel rivet is proven in determine 36.

Standard Types of Rivets & Their Applications

The overall designs of cheville are sturdy, blind, tube, and steel piercing (including split rivets). From a good structural style aspect, the most crucial rivets will be the solid and blind rivets.

Sound Rivets: Many solid pointes are constructed with lightweight alloy to ensure that the shop brain could be chilly shaped by simply bucking that with a pneumatic hammer. Hence, solid pointe will need to have cold-forming capacity with no cracking. An agent report on sound rivets is definitely provided found in desk IX (ref. 2). Various other stable rivet components are instruments, SAE 1006 to HIGHLY RESISTANT TO WEATHER CHANGES 1035, 1108 and 1109 steels, A286 stainless, and titanium.

Remember that the pointe in desk IX will be included in army standard specs, which are plentiful. Although the majority of the sturdy rivets detailed in desk IX possess general mind, there are various other common mind types, while demonstrated in figure thirty four. Nevertheless, as the “experts” usually do not necessarily acknowledge the names, various other brands had been put into the figure. Take note also that the countersunk mind angle may differ from 60° to 120° although 82° and 100° will be the prevalent angles.

The sharp border of the countersunk head can be removed in some instances, as in the Briles BRFZ “fast” rivet (fig. 35), to raise the shear and fatigue power while even now preserving a flush match.

Blind Rivets: Window blind rivets obtain name from the actual fact they can become completely set up in one aspect. They have the next significant positive aspects over sound rivets:

1. Only 1 user is necessary pertaining to installation.

installment payments on your The unit installation device can be portable ( much like a great electrical routine in proportions ).

2. That they can be utilized wherever only one part of the workpiece is obtainable.

3. A given- duration rivet can be utilized meant for a variety of fabric thicknesses. Installation period is quicker than with stable rivets.

six. Clamping push is even more uniform compared to solid cheville.

4. Much less training is necessary for the operator.

Sightless rivets happen to be classified based on the methods applied to set up these people:

1 . Take mandrel

instalment payments on your Threaded come

2. Travel pin

Pull-Mandrel Rivets: This rivet is mounted with an instrument that can be applied force for the rivet mind even though tugging a prenotched serrated mandrel to broaden the much aspect in the tubular rivet. When the correct load is certainly reached, the mandrel fractures at the level. A universal pull-mandrel rivet is proven in physique 36.

Threaded-Stem Rivets: The threaded-stem rivet (fig. 37(a)) includes a threaded inner mandrel (stem) with all the exterior part machined smooth on two sides designed for the device to hold and turn. The top is normally normally hexagonal to avoid rotable of the tube body as the mandrel has been torqued and damaged away.

Drive-Pin Rivets: This kind of rivet includes a travel pin number that advances the much side with the rivet to create a mind, as demonstrated in physique 38. Even though drive-pin pointes could be set up quickly, they will are often not really found in aeronautical applications. They may be utilized mainly for industrial sheet metallic applications.

Tubular Rivets: Tubular pointes are partly hollow and can be found in a number of configurations. The generic type includes a produced at once 1 part and a empty end that sticks throughout the items becoming became a member of. The hollow end is usually cool created into a field mind.

Since considerable cold developing is necessary upon these pointe, they need to end up being incredibly ductile and so are as a result manufactured from low strength components. They are usually used for industrial applications instead of in the tail wind market.

A few specific types of tube rivets will be

1 . Compression

2 . Partial tubular

Compression Tubular Rivets: A compression tube rivet (fig. 39) includes two parts which have a great interference in shape when powered together. These types of rivets happen to be utilized in a commercial sense in smooth materials and in which a great appearance is necessary on both equally sides of the component.

Semi tubular Rivets: The semi tube rivet (fig. 40) includes a hole during a call end (hole depth to at least one 1 . doze of shank size ) in a way that the rivet methods a good rivet when the discipline mind is.

Full Tubular Rivets: The entire tubular rivet (fig. 41) includes a much deeper hole compared to the semi tube rivet. It really is a less strong rivet compared to the semi tube rivet, nonetheless it can touch softer components such as for example plastic material or cloth.

Metal-Piercing Rivets: Metallic piercing cheville (fig. 42) act like semitubular rivets, other than they have higher column power. Section of the meal materials isn't drilled, as well as the rivet pierces completely or perhaps most of just how through whilst mushrooming to be able to a locked placement.

Split Rivets: Split (bifurcated) rivets (fig. 43) will be the standard “home restoration ” rivets. They will possess sawed or divided bodies with razor-sharp ends to create their particular personal openings through leather-based, dietary fiber, plastic material, or gentle metals. That they aren't found in critical applications: The threaded-stem rivet (fig. 37(a)) includes a threaded inner mandrel (stem) together with the exterior section machined toned on two sides just for the device to grasp and move. The top is definitely normally hexagonal to avoid rotable of the tube body as the mandrel has been torqued and damaged away.

Drive-Pin Rivets: This kind of rivet includes a get flag that propagates the much side on the rivet to create a brain, as proven in number 38. Though drive-pin cheville could be set up quickly, that they are often certainly not found in tail wind applications. They can be utilized mainly for business sheet steel applications.

Tubular Rivets: Tubular pointe are somewhat hollow and can be found in a number of configurations. The generic type includes a made at once a single aspect and a hollowed out end that sticks throughout the parts becoming became a member of. The hollow end can be frosty shaped into a field mind.

Since intensive cold creating is necessary about these pointes, they need to always be incredibly ductile and so are therefore manufactured from low strength components. They are usually used for industrial applications instead of in the jetstream sector.

Several specific types of tube rivets will be

1 . Compression

2 . Partial tubular

Compression Tubular Rivets: A compression tube rivet (fig. 39) contains two parts which have a great interference in shape when motivated together. These kinds of rivets happen to be utilized from the commercial perspective in smooth materials and in which a great appearance is necessary on both equally sides of the component.

Semi tubular Rivets: The semi tube rivet (fig. 40) includes a hole during a call end (hole depth to at least one 1 . 12 of shank size ) in a way that the rivet techniques a good rivet when the discipline mind is created.

Full Tubular Rivets: The entire tubular rivet (fig. 41) includes a further hole compared to the semi tube rivet. It really is a weakened rivet compared to the semi tube rivet, nonetheless it can touch softer components such as for example plastic-type or textile.

Metal-Piercing Rivets: Steel piercing cheville (fig. 42) act like semitubular rivets, except for they have better column durability. Area of the hoagie materials isn't drilled, plus the rivet pierces completely or perhaps most of just how through even though mushrooming to be able to a locked placement.

Split Rivets: Split (bifurcated) rivets (fig. 43) will be the standard “home fix ” rivets. They will possess sawed or break up bodies with sharpened ceases to create their very own very own slots through set, fibers, plastic-type material, or gentle metals. That they aren't found in critical applications

1 note

·

View note

Text

Pop Rivet Supplier in Mumbai

Pop Rivet Supplier in Mumbai. Although we’re proven to many companies being a pop rivet supplier in Mumbai, Electronic digital Fasteners truly supplies a lot of different kinds of rivets in addition to being a pop rivet supplier.

The definition of “rivet” can be used by a go crazy rivet provider to describe many different fasteners which has a couple of prevalent traits. They are really pre-shaped for one end and have their very own other end reshaped when they are directly into use. Most have an easy shaft that passes throughout the materials getting bonded.

They are simply used to become a member of two or more supplies together and form a joint that is certainly stronger and tighter when compared to a screw of the identical diameter could possibly be. Let’s check out four of the very popular rivets a burst rivet dealer might have furthermore to put rivets and what applications they’re employed for:

As a come rivet distributor in Mumbai, we should get started with the impaired rivet -- also known as the pop rivet:

Semi-tubular rivets

Semi-tubular, or tube, rivets uses an indentation or perhaps hole in the long run opposite our factory head, making it simpler to deform, using fewer force. Semi-tubular rivets happen to be popular to get mass development applications.

Blind rivets from a pop rivet supplier certainly are a tubular rivet. Available in a set head, countersunk head, or perhaps modified even head, sightless rivets have a mandrel that may be drawn in the rivet, broadening the impaired end and after that snapping away to finish protecting the connection. Impaired rivets great applications when the joint may be accessed by only one aspect.

Solid/round brain rivets

The first rivet design and style, going back for the Bronze Era. Solid rivets can be deformed simply having a hammer, a crimping application, or a rivet gun, according to size and material real softness. One of the most trustworthy, safe, and fool proof rivets around.

Thus, even if you have known all of us as a Mumbai pop rivet supplier, you have to know that we as well carry these kinds of and many other rivet styles in many different metals use with a wide range of professional and professional applications and products.

Should you be looking for a soda rivet company in Mumbai, contact the pop rivet supplier professionals here at Digital Fasteners. They could be able guide you to one more rivet that is certainly more appropriate to your specific employ and that can save time and money.

1 note

·

View note

Text

"Fasteners"

https://en.wikipedia.org/wiki/Fastener

The most common types are the screw, nut and bolt, possibly involving washers. Other more specialized types of threaded fasteners include captive threaded fasteners, stud, threaded inserts, and threaded rods.

Other types of fastener include:

anchor bolt

batten

bolt (fastener)Screw

brass fastener

buckle

button

cable tie

cam

captive fastener

Chain

clamp (or cramp)hose clamp

claspslobster clasp

cleco

clips

circlip

hairpin clip

paper clip

terry clip

clutch

drawing pin (thumbtack)

flange

frog

grommet

hook-and-eye closure

hook and loop fastenerVelcro

latch

nail

pegs

clothespin

tent peg

PEM nut

pins

bowtie cotter pin

circle cotter

clevis fastener

cotter

dowel

linchpin

R-clip

split pin

spring pin

tapered pin

retaining rings

circlip

e-ring

rivet

Solid/round head rivets

semi-tubular rivets

blind (pop) rivet

rock bolt

rubber band (or bands of other materials)

screw anchor

snap fastener

snap-fit

staple

stitches

strap

tie

toggle bolt

treasury tag

twist tie

wedge anchor

zipper

1 note

·

View note

Photo

This 12-foot stepladder is made of superior quality, non-conductive fiberglass.

Extra heavy-duty and ready for professional use, capable of supporting 375 pounds on each step.

Double rivet step construction, each step secured with six, large headed, semi-tubular steel rivets for maximum strength.

Industrial quality Type 1AA Ladders are non-conductive, lightweight, strong, and stable.

1 note

·

View note

Text

Usha Precision

We possess well-equipped production units with skilled employees, which are backed by latest technology and sophisticated machinery.

#U-Pins#Semi Tubular Rivets#precision turned components#stainless steel suppliers#metal manufacturing#stainless steel fabricators near me#stainless steel manufacturers#stainless steel fabricators

0 notes

Text

Steel Button Head Blind Rivet

Material:

Steel/Steel

Certification:

ISO, GS, RoHS, CE

Package :

box+Carton

Payment Terms:

L/C, T/T, Western Union

Origin:

WUXI China

Item:

Steel Button Head Blind Rivet

Company profile

We provide the product and service to the customers worldwide and are greatly appreciated in a variety of different markets.

We are quite welcome customized orders which involve different standard blind rivets, structural blind rivets, peel-type blind rivets, multi-grip blind rivets ,rivet nuts ,semi-tubular rivets, drawer locks, cabinet locks, panel locks, cam locks, sliding glass door locks, Nd-Fe-B magnet products and other hardware , and also are able to help you to develop new products based on your given requirements at competitive quotes and good service .

We can also provide you Aluminium/steel open color blind rivet, stainless steel bilnd rivet open type, close type blind rivet.

If you want get more information about our products please contact me!

Read the full article

#BlindRivetNutThreadedInsertRivetGun#ClosedEndDomeHeadBlindRivet#DinStandardFlatHeadFullHexBodyBlindRivetNut#FlatHeadFullHexagonBlindHoleRivetNut#FlatHeadOpenEndBlindRivetNutHeadType#KnurledCountersunkHeadBlindRivetNut#MetricBlindInsertRivetNutRivnut#StainlessSteelFlangeHeadBlindRivetNutInsertNutsert#StainlessSteelFlatHeadOpenEndBlindRivetNut#SteelButtonHeadBlindRivet

0 notes

Text

Tips for Blind Rivets

Materials - An excellent guideline of thumb when choosing a oblivious rivet is by using the same materials rivet while the essence into which usually it's getting installed. If you are riveting bedding of stainless steel collectively, make use of a metal rivet. The same applies to aluminum and stainless. This is important because using dissimilar metals might lead to galvanic corrosion, based on the application's Blind Cheville Weblog a couple of environment.

Unit installation Tooling -- What function specifically really does installation tooling enjoy in what sort of shades rivet functions? It's straightforward. An set up tool has got one work … to draw the stem in the blind rivet up throughout the rivet physique before take drive with the device triumphs over the tensile power on the rivet control, leading to the stem cigarette smoking off in its predetermined breakpoint. There is nothing much, much more to it than that. All strength parameters and application requirements of a installed blind rivet reside within the rivet itself properly. In case the installation device breaks off of the blind rivet stem, really completed their job. Therefore, this means that the principal account designed for blind rivet set up tooling is ease of access. Can the tool match the particular area around where in fact the rivet must go? Thankfully, there are various types and configurations of tooling available.

Therefore , generally, you will discover an assembly device that quite actually "fits" your preferences. The stipulation to the access requirement is based on the fact that one types of blind strength rivets need special nose area techniques for the installation application to set up the rivet effectively. That's not the truth for non-structural blind rivets. We'll go over structural rivets in greater detail in component three of the series.

Given that we've mentioned how exactly to boost joint dependability, we are able to switch our focus on the rivets themselves. You will discover four simple components with each blind rivet (you'll take note three of these speak right to the joint integrity factors as well).

BR SITE 2 -- 3Rivet variety involves picking:

Material

Size

Grip Selection

Head Design A wide selection of grip and diameters ranges are available, enabling blind rivets to be utilized in a significant selection of applications. Some prevalent blind rivets can be found in lightweight aluminum, metal, and stainless, they're also obtainable in copper, instruments, and plastic-type material. These smoother rivets have grown to be more prevalent together with the increased utilization of composite materials. Collection of head design isn't only very important to the cosmetic of the done piece, but with consideration to the effectiveness of the components being joined also. The three most obtainable head designs are Dome Head typically, Countersunk, BR BLOG PAGE 2 -4 and Huge Flange.

Dome brain rivets are the most adaptable and so are employed most frequently due to their very low upvc profile and clean aesthetic overall look. Remember that several manufacturers utilize the terms "button" mind and "low-profile" mind rather than curve head. Equally key and low-profile minds are extremely like the standard curve mind. Countersunk rivets are used whenever a flush surface is necessary or desired. Different sides of countersunk heads can be found. The most typical design for regular countersunk sightless rivets is definitely 120- level countersunk. 82-degree and 100-degree countersunk heads can be found for some military spec and structural applications also. Large flange blind rivets are usually utilized to greatly help spread the strain insert when among the mating components can be ductile, such as for example composite, wooden, fiber-glass, and materials. There are several common window blind rivet types:

Drive-Pin and Break-Stem.

Drive-pin blind rivets have got a partial hole in the physical body and a mating pin that protrudes, situated in the opening. The installation technician hammers the pin in to the rivet human body to ensure that they have flush with the very best of this rivet mind. Among the significant advantages of a drive-pin rivet is certainly that no particular tools happen to be necessary for set up. You may use a hammer if you want literally. Drive-pin rivets may also be utilized with nearly every material and don't need a hole to end up being drilled completely to put in. A drive-pin rivet's drawback in accordance with other styles of blind rivets is a backing block out could be necessary for set up depending on materials and program, which in turn mitigates the advantage of shutter installation. They provide less clamping force than almost every other rivet styles also.Since Assemblage magazine points out, "Increased usage of composite components, such as plastic material, fiberglass, and plywood, comes with BR WEB LOG 3 -2increased demand for impaired rivets based on a upset designs to fasten individuals components. inches These rivets are well-known in the market seeing that Trifurcating window blind rivets. Perhaps you have ever applied what's referred to as a "molly" fastener to hold something in drywall? It is the same idea. The trifurcating blind rivet body provides slot machine games inside the shank which will type "legs" during set up. These hip and legs provide clamping pressure although spreading the clamp download of the rivet, which is vital when working with these people in ductile components such as for example plastics. That they prevent pull-through of the set-up rivet in applications in which regular shades rivets will fail. Will be certainly a different type of shutter rivet referred to as a "peel rivet. very well A Remove rivet uses an identical idea as the trifurcating rivet, BR BLOG 3-3 with a different system slightly. With Peel rivets, the mandrel is manufactured with "knife factors " beneath its brain, made to break up the rivet body in four portions upon set up. Those segments then broaden and peel from the lime back similar to the petals of any floral. These kinds of "petals" within the backside of your rivet offer clamping push, which is disseminate to the trifurcating rivet similarly. Attention ought to be considered when working with stem rivets, seeing that sharpened ends are area of the formation. Preferably, there must be little usage of the backside of a credit card application just where peel rivets are installed.Plastic blind rivets work exactly like their metallic cousins essentially. They might need their particular set up tooling and have a tendency to dry and get fragile as time passes, thus careful consideration ought to be taken when choosing them just for the application.

Closed-end oblivious rivets make use of a solid-core rivet body, hence eliminating wetness or gases' capability to go through the rivet body alone, which takes place with open-end blind rivets. Self-plugging sightless rivets direct mostly to "multi- hold " types. These different types of the typical open-end window blind rivet hire a somewhat distinct mandrel mind and rivet body style that outcomes in the mandrel stem insert the empty body primary with a greater part of the stem. An interference fit outcome between rivet and mandrel body, preventing moisture and gases from permeating through the rivet body essentially. Yet, like open-end blind rivets, the bigger stored stem isn't going to normally enhance the rivet's strength integrity. A blind rivet is regarded as to get "structural" mainly because it meets the next requirements: the stem need to break remove with the rivet flange (or mind) in the minimal and optimum of it has the grasp selection, and the base should be by artificial means locked to ensure that are unable to vibrate from the rivet body system after set up. The locked stem provides more structural integrity to the rivet thus, with considerably higher shear values primarily paired rivets could be installed from aspect for the application, they provide a major advantage over other installed fasteners permanently, such as for example semi-tubular or solid rivets, clinch fasteners, and traditional bolts and nuts. This is critical when access to the backside of an application is nonexistent or limited. Mainly because blind rivets are set up from only 1 side, this kind of frequently causes them to be more cost effective and flexible than other styles of nails.

When working with impaired rivets, there are many key components to consider to be able to take full advantage of joint reliability.

The two most significant factors are Grip Hole and Range Size.

Grasp Range -- This is actually the total material fullness where the rivet is made to function. When indicating a shades rivet, Blind Rivets Cross Sections imply stick to the manufacturer's suggestions for the whole materials size that the rivet is made to batten. You will have a maximum and minimal thickness, in increments of around typically. 060". Noises simple, correct? It really is, nevertheless, it's also among the most typical faults made. Utilizing a blind rivet out of its mentioned grip selection could cause on your degradation leading to looseness or perhaps malformation from the rivet.

Gap Size -- All shutter rivets possess a recommended pit size in to that they can easily become mounted. This is essential because shade rivets are created to broaden and pull-up of their suggested ditch. If the pit is usually too big, the rivet can't increase enough effectively " fill up the hole, inch leading to fewer pull-up and loose bones. If the ditch is definitely also little, likely to either have got difficulty installation the rivet through, or perhaps lead to a "shear stage " creating in the rivet body, that could result in the rivet shearing off and failing on the application form.

1 note

·

View note

Text

Types of bolts

Materials can be kept intact by stray pieces, welding or rivets. Introducing a bolt requires a touch of information to observe the right bolt measurement, length and head type. Your decision of bolt relies upon how and where it will be utilized. Peruse on to track down the right bolt for your work.

Significant highlights

Sorts of rivets

Employments

Establishment

Adornments

Shop our rivets

What is a bolt?

A bolt is a latch intended to keep two bits of material intact through a solitary penetrated opening. The tail of the bolt is disfigured which holds it safely set up. By and large introduced utilizing a bolt weapon, rivets are generally utilized in mechanics and auto body fixes, yet that is not all - a few kinds of rivets are even utilized in materials.

A bolt is comprised of three sections:

A head (which can be level, domed, subset).

A body or shaft.

The tail which is upsetted to fix the bolt set up.

Rivets

Principle kinds of rivets and employments

Solid rivets

Solid rivets were once chiefly used to shape hot bolted joints, yet have to a great extent been supplanted by different kinds of rivets which are faster to introduce. Be that as it may, hot riveting is as yet utilized today to repair old joints and for embellishing purposes (in modern plan, for instance). For this situation, the tail of a steel bolt is warmed with a gas welding light prior to being annoyed with a bolt firearm or setter.

Tubular rivets

Tubular rivets include a shallow opening at the tip which makes them more straightforward to introduce without warming. With cautious establishment, these rivets can be utilized as turn focuses and can demonstrate exceptionally helpful for moving joints.

Semi tubular rivets

Semi tubular rivets are great for undertakings like fixing belts and are comprised of a couple of parts. Generally made of metal, these rivets are not difficult to fit with least exertion.

Contingent upon the kind of bolt, you could have to involve a punch for a flawless completion. These rivets may likewise be known as empty rivets.

All you really want is a couple of rotating punch pincers to make an opening in the calfskin or texture prior to utilizing a particular hand driver to match the distance across of the bolt to introduce the bolt and keep the components set up.

Hammer drive rivets

Hammer drive rivets are solid rivets with a round or domed head, and a helical strung body. They can likewise be called U drive screws. These latches are set in blind openings utilizing a sledge or press.

Hammer drive rivets are frequently utilized for introducing divider signs, tags and vehicle maker plates. They can likewise be utilized to introduce signs on modern machines or gear like siphons or valves.

Split or bifurcated rivets

Split rivets include a domed or bracket head made of metal or steel, and a tail split into two wings that are collapsed back to get things like bicycle parts (mud watches, plates, and so forth) They can likewise be utilized for cowhide merchandise. It's essential to introduce these rivets accurately on your first attempt as the wings will snap effectively in the event that they must be bowed at least a few times. You can add on a washer to these rivets to get the securing.

Blind rivets

These rivets have truly reformed the modern world. They are fast and simple to introduce and offer faultless outcomes. Blind rivets can be utilized to supplant an entire scope of screws in long-lasting congregations. Indeed, this kind of bolt can be utilized to introduce miles of modern ducting right away.

They are comprised of two sections:

a mandrel;

a pin.

You just need a hand driver or a bolt firearm with the right sort of ability to match the breadth of the bolt to introduce these rivets. Essentially match the length and distance across of the bolt to the thickness of your materials.

Investigate the ManoMano list

Bolt weapons

Various sorts of blind rivets

Instructions to ascertain the length of a blind bolt

Here is a recipe to assist you with tracking down the right bolt to match the components you need to collect:

The absolute thickness of the materials you need to gather x 1.1 = Total 1

Breadth of the bolt x 1.5 = Total 2

All out 1 + Total 2 = right bolt length

Makers will for the most part demonstrate a grasp range for each sort of bolt. Make certain to really look at this before buy. If it's not too much trouble, note: pick a bolt that is excessively lengthy for your get together and the tail might project which can prompt wounds.

Various sorts of blind rivets

Standard blind rivets

Standard blind rivets are by and large the most generally utilized rivets. It's smart to have a scope of these economical rivets in your tool stash with a hand driver to cover an assortment of DIY occupations. These rivets are regularly used to introduce vehicle tags and come in all tones to match the actual plate.

Fixed blind rivets

The mandrel top of the bolt is held inside the bolt body which implies these rivets give an ideal seal much under tension. It's vital to follow the suggested opening sizes intimately with this kind of bolt. It's likewise conceivable to add a neoprene washer under the bolt head. These rivets can be utilized to collect metal and plastic.

Stripped blind rivets

As these rivets are set, the body separates into a few sections for a bigger bearing region which is great for securing metal to delicate materials. Remembered for this classification are what a few makers call 'T-style' blind rivets which have a special interior locking framework which upgrades shear strength.

Multi-grasp rivets

Multi-grasp rivets give an enormous bearing surface and can fill openings successfully which is convenient for managing lopsided, elliptical or distorted openings. They can be utilized to supplant a few standard blind rivets in various sizes which can make stockpiling simpler. The pin remains locked and is difficult to remove. These rivets are great for meager metal sheet and parts prone to manage vibrations.

Plastic blind rivets

These rivets are introduced very much like standard rivets. They arrive in a scope of shadings and are utilized for non-conductive materials. The body and pin are made of plastic (either polyamide or nylon) and the head is level. It's a given that these rivets must be utilized for lightweight applications.

Primary blind rivets

These blind rivets come enthusiastically prescribed on account of their high pliable and shear strength. They include a locking system to keep the mandrel set up and a wide cap to forestall pull-out. The actual mandrel is notched to permit hand drivers to improve hold.

Furrowed blind rivets

The furrowed groups of these rivets makes them simple to detect. This plan makes them ideal for securing in blind openings. It's critical to pick the right bolt material relying upon the materials you are collecting so as not to cause harm.

Rivets and eyelets for materials

Utilized for a scope of in everyday purposes, eyelets are regularly found close by rivets. Fitted to things like garments, shoes, canvas sheets, sails and leather work, these rivets should be introduced utilizing a unique kind of hardware or a punch and bite the dust.

Equivalent to tubular rivets, the thought is to make an edge for stringing bands or ropes through materials. A wide range of sorts of rivets and eyelets are utilized in garments making, the most well known being:

quick rivets;

rhinestone rivets;

oval or rectangular eyelets;

press studs;

pyramid studs.

These eyelets and rivets all require the utilization of unique setting devices.

Hand drivers

Bolt adornments

Assuming you are a stickler, you could find yourself disinterested with the last look of a bolt. A few kinds of rivets (like standard blind rivets) can be concealed by plastic or metal bolt covers. These covers are intended to work on the completion of clasp.

In any case, be cautious - some bolt covers accompany a part intended to be put between the head and the attaching material. Remember to represent this part while working out the length of the bolt.

It's feasible to fit a neoprene washer under the top of a fixed blind bolt.

Hand drivers

Rivets: a short history

Before the time of circular segment or gas welding, metal developments were gathered by hot riveting. The Eiffel tower, for instance, involves 1,051,000 rivets. Spans, steel water stockpiling tanks and a considerable number boats were made solid, safe and watertight utilizing hot rivets.

A group of laborers hence needed to depend on heat delivered by heaters to get the rivets intensely hot. On the opposite end, laborers would utilize a sledge or handheld pneumatic riveting weapon to shape the finish of the bolt into a vault shape.

As the rivets chilled off, they would contract, for all time locking the gathered parts. Solid rivets can in any case be utilized for a few little congregations yet more present day sorts of rivets in all actuality do will generally make life simpler.

The Second Great War was a period of mechanical advancement and blind rivets showed up during this chance to stay aware of the interest for fast creation on the two sides.

1 note

·

View note

Text

11 Types of rivets & Basic uses with Diagram

Want to know about Types of rivets?

Then you landed in the right place. Here you will get a complete guide on types of rivets and their uses, from scratch to end.

⇒Here are some basics of Rivets, Have a look first-

Rivets are fasteners used for joining metal sheets and plates in fabrication work such as bridges, ships, cranes, structural steelwork, boilers, aircraft etc.

The rivet is often inserted and close by force so that it completely fills the holes and forms rigid rivets joint.

And, Riveting is the method of making permanent joints for riveting the plates to be joined are drilled or punched.

Now, let’s dig into the mainstream of the article, Where you will know types of rivets with diagram–

Types of Rivets-

Here are the most common 11 types of rivets-

Solid rivets

Split rivets

Blind rivets

Tubular rivets

Snap head rivets

Pan head rivets

Mushroom head rivets

Countersunk rivets

Flathead

Conical head rivets

Pan head with tapered neck rivets

Solid Rivet-

Solid rivet’s shank is solid and is used for general purposes. This rivet is the strongest of all kinds.

It is the simplest and reliable rivet founded in the Bronze age and can be fitted through a hammer or rivet gun.

The material used in manufacturing can be aluminium, brass, copper, stainless steel etc and comes in many colours and sizes.

Split Rivet-

Split’s shank is divided into parts and identified by pairs of legs on their tails which are folded back on themselves after installation.

it is used in small and light works like tin plates, textiles, leather, plastics and use in bicycle seats.

As the name suggests, It is split into two parts from the body side and having a single head at the top. It is also known as a Bifurcated rivet.

Blind Rivet-

As the name suggests, Blind rivets are actually used where you can not access the other side of the surface like something hollow.

Metal sheets and other hard materials are fastening through blind rivets with the help of the rivet-gun.

The common uses of these rivets refer to brittle and soft materials, electrical parts, automobiles, hand tools, locks, and home appliances etc.

Commonly, It is also known as POP and Break stem rivet.

Tubular Rivet-

Tubular’s shank is hollow in nature and the rest is just similar to the solid rivet. It is used to drill in shoes and file covers etc.

This can also be used to fastening aluminium, thin metals sheets, plastics, leather and on the pivot points where movement is required.

This is also known as Hollow rivet, due to the hollow shape at the body end.

This is classified into two categories-

(I) Full Tubular

(II) Semi Tubular

Snap Head Rivet-

Snap head or cup head rivet is the most commonly used rivet and it gives a very strong joint.

These rivets are widely used and meet the requirement of various industries like the manufacturing and construction industries to provide maximum strength in general.

The diameter of Shank is approx 1.6d and the length of the head is 0.7d.

Pan Head Rivet-

It has the unique design of a slightly rounded head and slopping down from the top of the head(see diagram) to provide a tighter grip during the fastening process.

This can be made up of carbon steel, brass, copper, aluminium and stainless steel with a length range from 6mm to 100mm in general.

Pan heads are used in Heavy structural work to provide maximum strength and grip.

Mushroom Head Rivets-

A mushroom head is used to deduce the rivet head height on the metal surface and provides the locking needed for maximum strength.

As the name suggests, these rivets are mushroom-like heads and have a lower profile than standard rivets.

Materials are used to manufacture these rivets aluminium alloys, titanium, and nickel alloys.

To read the rest of the article content including diagrams- Types of rivets

0 notes