Harbin Rainbow Technology Co.,Ltd is one of the biggest fastener equipment dealer and manufacturer in China. We have invested one Cold former factory(Ningbo), one Thread rolling machine factory(Ningbo), one Heat treatment furnace factory(Suqian) and one Electro plating equipment factory(Wuxi). We have more than 30 years experiences in supplying all kinds of fastener equipment, such as Bolt Maker, Nut Maker, Cold Heading Machine, Thread Rolling Machine, Wire Drawing Machine, Heat Treatment Furnace and Zinc Plating line, etc. to customers all over the world, With our reputation increasing and our team becoming more professional, wehave experienced a significant growth in business during the recent years.Nowadays, more and more reputed companies compete in a long-termcooperation with us.We abide by the principles of honesty, credibility, and mutual-benefit. Our motto is “ONCE BUSINESS, FOREVER FRIENDS”, we will do our best to serve clients at home and abroad. Due to our top-notch professional knowledge and rich trad experience, we have seen our market developing ability and actual businessgrowth with an increasingly faster pace. We sincerely look forward to workingwith you. Let's build a great future together! https://www.fastenersmachine.com/

Don't wanna be here? Send us removal request.

Text

RNF Series 6 Station Nut Former

RNF Series 6 Station Nut Former

Nut making machine is a special cold forging equipment for producing hex nuts. It adopts the cold forging method to feed the material through the roller wheel, and then the feeding, cutting, pressing ball, pressing angle, punching and other processes are completed in one machine. This cold forging nut former machine automatically upsets all kinds of hex nuts and non-standard parts. Trust Rainbow for superior nut forming equipment.

Specifications of RNF Series 6 Station Nut Former Machine

MODEL

FORGING STATION

MAX.FORGING DIA.( mm)

CUT-OFF DIA.( mm)

PRODUCT SIZE

FORGING LENGTH (mm)

DIE PITCH (mm)

SLIDER STROKE (mm)

OUTPUT( per.min.)

MAIN MOTOR(HP )

WEIGHT(T)

DIMENSION(cm)

RNF08B-6S-12

6

8

8

M4-M5

12

38

40

175/350

l0

3.5

195X135X130

RNF11B-6S-14

6

11

10

M5-M6

14

50

60

120/240

15

4.3

230X155X135

RNF11B-6SL-20

6

11

10

M5-M6

20

50

65

110/200

20

4.5

230X155X135

RNF11B-6SL-35

6

11

10

M5-M6

35

50

125

110

20

4.5

230X155X135

RNF14B-6S-18

6

15

14

M6-M8

18

60

70

75/160

20

8

300X195X175

RNF14B-6SL-30

6

15

14

M6-M8

30

60

100

85/160

30

8

300X198X175

RNF14B-6SL-50

6

15

14

M6-M8

50

60

160

85

30

8.5

300X198X175

RNF17B-6S-20

6

17

17

M8-M10

20

70

80

65/130

20

10

350X220X185

RNF17B-6SL-50

6

17

17

M8-M10

50

70

160

80

40

10.5

360X220X185

RNF17B-6SL-70

6

17

17

M8-M10

70

70

220

80

50

10.5

360X220X185

RNF19B-6S-25

6

20

19

M10-M12

25

80

95

95

40

10.5

360X220X185

RNF19B-6SL-50

6

20

19

M10-M12

50

80

160

75

50

16

380X245X196

RNF19B-6SL-70

6

20

19

M10-M12

70

80

220

65

60

16

380X235X196

RNF22B-6S-30

6

22

22

M12-M14

30

80

160

80

60

18

380X235X196

RNF22B-6SL-60

6

22

22

M12-M14

60

80

220

75

60

18

380X235X196

RNF24B-6S-35

6

24

24

M14-M16

35

100

160

75

75

27.5

550X248X270

RNF24B-6SL-70

6

24

24

M14M16

70

100

210

65

75

27.5

550X248X270

RNF27B-6S-40

6

27

29

M16-M18

35

100

160

75

100

30

550X248X270

RNF27B-6SL-70

6

27

29

M16-M18

70

100

210

65

150

30

550X248X270

RNF30B-6S 40

6

30

28

M16-M20

40

120

150

60-90

100

40

550X280X200

RNF30B-6SL-80

6

32

28

M16-M20

80

120

200

50-65

125

45

650X280X200

RNF33B-6S-40

6

33

30

M18-M22

40

140

150

60-80

125

55

600X300X200

RNF33B-6SL-80

6

33

30

M18-M20

80

140

280

60

200

50

650X300X280

RNF36B-6S-45

6

35

32

M18-M24

45

150

160

60-80

125

60

650X300X200

RNF36B-6SL-100

6

35

32

M18-M24

100

150

260

50-60

150

70

750X300X200

RNF41B-6S-50

6

40

40

M20-M27

50

165

200

55-70

150

68

700X350X240

RNF41B-6SL-100

6

40

40

M20-M27

100

165

260

50-60

200

80

750X350X280

RNF45B-6S-55

6

45

42

M20-M30

50

180

210

50-60

180

85

750X300X280

RNF45B-6SL-100

6

45

42

M20-M30

100

180

260

50-60

270

100

800X350X300

All specifications are subject to changes without prior notice

Advantages of the RNF Series 6 Station Nut Former Machine

1. High productivity: Like the automatic nut bolt manufacturing machine, this cold forging machine equipped with six stations that can efficiently produce a large volume of nuts in a short amount of time, increasing overall productivity.

2. Precision and accuracy: The RNF Series nut former machine ensures precise and consistent nut forming, resulting in high-quality nuts with tight tolerances and excellent dimensional accuracy.

3. Versatility: This cold forging nut former machine is designed to handle various nut types and sizes, providing flexibility to meet diverse customer requirements.

4. Advanced technology: Equipped with state-of-the-art features, the RNF Series cold forging nut former machine incorporates advanced controls and automation, reducing the chances of errors and enhancing operational efficiency.

5. Cost-effectiveness: By streamlining the nut forming process and minimizing material waste, the RNF Series nut former machine helps to reduce production costs and increase profitability.

0 notes

Text

QLBF Series 3 Station Bolt Former

QLBF Series 3 Station Bolt Former

The QLBF Series 3 Station Bolt Former is a cutting-edge equipment designed for the efficient and precise production of bolts. Equipped with three stations, it enables essential operations like heading, thread rolling, and trimming in a single machine. As one of the professional cold forming machine manufacturers, Rainbow offers fully automatic nut bolt making machine that has high productivity, exceptional precision, and flexibility for manufacturers in need of medium to large scale bolt production. The QLBF Series 3 Station Bolt Former is an ideal choice for achieving optimal efficiency and superior quality in bolt manufacturing processes.

Specifications of QLBF Series 3 Station Bolt Former

Main Technical Data of RBF Series 3-station High Speed and Fully Automatic Cold Heading and Forming Machine

Model

Unit

RBF-63S

RBF 83S

RBF 83L

RBF-103S

RBF-103L

RBF-133S

RBF-133L

Forging station

No.

3

3

3

3

3

3

3

Forging force

Kgs

38,000

65,000

65,000

85,000

85,000

120,000

120,000

Max cut-off dia.

mm

Ф8

Ф10

Ф10

Ф12

Ф12

Ф15

Ф15

Max cut-off length

mm

80

75

135

100

190

140

250

Speed Range

pcs/min

160-260

140-240

110-180

120-200

85-140

100-160

60-100

P.K.O Stroke

mm

12

12

16

15

15

26

25

K.O Stroke

mm

65

50

115

80

160

100

230

Main slide stroke

mm

110

106

193

150

280

200

350

Main motor

kw

11

18.5

18.5

18.5.

22

30

30

Cut-off-die size

mm

Ф30*45L

Ф53*56L

Ф30*50L

Ф45*59L

Ф45*59L

Ф63*69L

Ф55*70L

Punch die size

mm

Ф40*90L

Ф45*95L

Ф45*140L

Ф53*115L

Ф53*112L

Ф60*130L

Ф60*179L

Main die size

mm

Ф50*85L

Ф60*80L

Ф60*150L

Ф75*108L

Ф75*200L

Ф86*135L

Ф86*265L

Die pitch

mm

60

70

70

90

90

98

110

Machine Weight(Approx)

Kgs

8,000

11,000

14,000

14,000

20,000

23,000

32,000

Normal bolt size

mm

3-6

5-8

5-8

6-10

6-10

8-12.7

8-12.7

Shank length of blank

mm

10-65

15-55

25-105

15-70

30-150

20-100

70-210

Mechanical Dimensions(cm)

cm

380*212*147

420*220*173

455*235*208

410*250*180

570*240*230

455*260*196

780*260*270

REMARKS

The company keeps the right to revise above parameters. If there is any alterations , advance notice won't be given then.

The products' most applicable production speed is decided by the product shape, size and material.

Maximum material shearing diameter and product size listed in the table can be calculated according to medium carbon alloy steel. It is equal to 10.9 grade high Intensity screw.

Features of QLBF Series 3 Station Bolt Former

01

Compatible Reversible Nuts and Fixed Bolt Clips

Reversible nuts and fixed bolt clips that match with RBF serial multi-station parts forming machine.

02

Swing Transfer Conveyance

Transfer conveyance of rotary swing mode and transfer force of adjustable pneumatic mode ensures stable and reliable work-piece conveyance and high speed operation of the machine. The first station clip can automatically loose short dimension feeding, stop and alarm.

03

Coordinated Reciprocating Movement

Reciprocating movement of clipping table and opening/closing actions of the clips are both driven by a jpint intermediate shaft to ensure the coordinated actions.

04

Optional CNC Type Adjusting Mechanism

Is rear knock-out mechanism. Rear knock-out mechanism of various stations can be respectively and independently adjusted. Last station can. Before being kicked out, dead - point position of all models keeps the same. Some models can choose to add hand - wheel type or CNC type rear knock-out threaded pipe adjusting mechanism.

05

Independent Adjustment and Overload Protection

Is punch knock - out mechanism of RBF serial model. Punch knock - out coincides with back action of machine slider. After the work piece is shaped, it stays in the mould and then being kicked out by rear knock - out mechanism. It avoids being talken away by the punch and then get deformed, Various stations of front knock - out positions can be independently adjusted. All the front lead - out mechanism have knock - out force over- load protection devices.

06

Automatic Pawl Lifting and Noise Reduction

Is electric feeding mechanism, In return stroke, pawl can be automatically raised by air cylinder and be separated from ratchet wheel. It not only removes friction and noise, but also prevents ratchet wheel from reversal operation.

0 notes

Text

RBF Series 6 Station Bolt Former

RBF Series 6 Station Bolt Former

The RBF Series 6 Station Bolt Former is an advanced piece of equipment designed for the efficient and precise production of bolts. With its six stations, it offers a comprehensive bolt manufacturing process including heading, threading, and trimming. This automatic nut bolt manufacturing machine ensures high productivity, accuracy, and versatility, making it suitable for manufacturers requiring large-scale bolt production with a wide range of specifications. The RBF Series 6 Station Bolt Former is an excellent choice for achieving optimum efficiency and quality in bolt manufacturing operations.

Specifications of RBF Series 6 Station Bolt Former

Main Technical Data of RBF Series 6-station High Speed and Fully Automatic Cold Heading and Forming Machine

Model

Unit

RBF 46S

RBF -66S

RBF 86S

RBF-106S

RBF-136S

RBF-136L

Forging station

No.

6

6

6

6

6

6

Forging force

Kgs

24,000

50,000

90,000

110,000

140,000

140,000

Max cut-off dia.

mm

Ф7

Ф10

Ф13

Ф16

Ф18

Ф18

Max cut-off length

mm

66

100

100

133

140

185

Speed Range

pcs/min

125-210

110-180

90-150

85-140

65-105

60-100

P.K.O Stroke

mm

10

26

26

26

26

30

K.O Stroke

mm .

51

85

85

110

110

160

Main slide stroke

mm

114

140

140

190

206

270

Main motor

kw

7.5

15

22

30

45

45

Cut-off-die size

mm

Ф24*35L

Ф35*45L

Ф42*60L

Ф52*75L

Ф58*80L

Ф58*80L

Punch die size

mm

Ф31*65L

Ф40*90L

Ф45*115L

Ф53*115L

Ф60*130L

Ф60*130L

Main die size

mm

Ф38*85L

Ф50*120L

Ф60*120L

Ф75*135L

Ф94*135L

Ф94*190L

Die pitch

mm

46

64

80

94

110

110

Machine Weight(Approx)

Kgs

9,000

16,000

20,000

24,000

31 ,000

35,000

Normal bolt size

mm

2-4

3-6

5-8

6-10

8-12.7

8-12.7

Shank length of blank

mm

6-50

15-75

15-77

15-102

20-100

20-150

REMARKS

The company keeps the right to revise above parameters. If there is any alterations, advance notice won't be given then.

The products' most applicable production speed is decided by the product shape, size and material.

Maximum material shearing diameter and product size listed in the table can be calculated according to medium carbon alloy steel. It is equal to 10.9 grade high Intensity screw.

At Rainbow, we understand the dynamic nature of manufacturing processes. Our commitment to innovation and reliability shines through in every aspect of our fastener equipment. Experience precision and efficiency with our state-of-the-art Nut Bolt Manufacturing Machine. Trust Rainbow for excellence in manufacturing technology.

Main Technical Data of RBF Series 6-station High Speed and Fully Automatic Cold Heading and Forming Machine

Model

Unit

RBF-136LL

RBF-166S

RBF-206S

RBF-206L

RBF-256S

RBF-276S

Forging station

No.

6

6

6

6

6

6

Forging force

Kgs

140,000

230,000

390,000

390,000

500,000

730,000

Max cut-off dia.

mm

Ф18

Ф23

Ф30

Ф30

Ф34

Ф41

Max cut-off length

mm

240

190

195

240

320

320

Speed Range

pcs/ min

55-90

55-95

50-80

40-70

40-60

30-50

P.K.O Stroke

mm

40

35

46

45

50

50

K.O Stroke

mm

210

165

180

220

280

280

Main slide stroke

mm

320

280

280

346

446

450

Main motor

kw

45

75

90

90

132

200

Cut-off-die size

mm

Ф58*80L

Ф74*105L

Ф94*130L

Ф94*130L

Ф109*150L

Ф129*180L

Punch die size

mm

Ф60*130L

Ф75*185L

Ф90*215L

Ф90*215L

Ф120*270L

Ф180*270L

Main die size

mm

Ф94*240L

Ф108*200L

Ф125*200L

Ф125*240L

Ф148*300L

Ф178*300L

Die pitch

mm

110

129

140

140

160

190

Machine Weight(Approx)

Kgs

42,000

56,000

80,000

80,000

135,000

170,000

Normal bolt size

mm

8-12.7

10-16

12-20

12-20

16-25.5

20-28.5

Shank length of blank

mm

20-200

25-152

25- 160

25-200

50-250

50-250

REMARKS

The company keeps the right to revise above parameters. If there is any alterations, advance notice won't be given then.

The products' most applicable production speed is decided by the product shape, size and material.

Maximum material shearing diameter and product size listed in the table can be calculated according to medium carbon alloy steel. It is equal to 10.9 grade high Intensity screw.

For further details and to explore how Rainbow nut and bolt manufacturing machine can enhance your production capabilities, please reach out to us.

Features of RBF Series 6 Station Bolt Former

01

Coordinated Clipping Table Movement

To achieve synchronized movements, a j-pint intermediate shaft drives both the reciprocating movement of the clipping table and the opening/closing of the clips.

02

Adjustable Rear Knock-Out Mechanism

Rear knock-out mechanisms can be individually and separately adjusted for different stations. The last station is. All models' dead-point positions remain the same prior to being removed. Rear knock-out threaded pipe adjustment mechanisms can be added to some models using a hand wheel or a CNC machine.

03

Overload Protection

RBF serial model's punch knock-out mechanism. Punch knockout occurs at the same time as the machine slider's back movement. The work piece remains in the mold after being moulded before being knocked out by a rear knock-out mechanism. It avoids getting distracted by the punch and being malformed. The placements of different front knock-out stations can be individually changed. All of the front lead-out mechanisms feature provisions to protect against knock-out forces exceeding loads.

04

Quiet and Efficient Electric Feeding Mechanism

Is the feeding mechanism electric, During the return stroke, the air cylinder has the ability to lift the pawl and detach it from the ratchet wheel. In addition to removing friction and noise, this bolt forging machine also stops the ratchet wheel from turning in the other direction.

0 notes

Text

RBF Series 5 Station Bolt Former

RBF Series 5 Station Bolt Former

The RBF Series 5 Station Bolt Former is a specialized equipment used for the efficient and precise production of bolts. With its 5 stations, it offers multiple operations such as heading, threading, and trimming, allowing for a complete bolt manufacturing process in a single machine. This machine is designed for high productivity and accuracy, making it an ideal choice for manufacturers in need of large-scale bolt production.

Specifications of RBF Series 5 Station Bolt Former

Main Technical Data of RBF Series 5-station High Speed and Fully Automatic Cold Heading and Forming Machine

Model

Unit

RBF- 65S

RBF 85S

RBF-105S

RBF-135L

Forging station

No.

5

5

5

5

Forging force

Kgs

43,000

85,000

98,000

145,000

Max cut-off dia.

mm

Ф8

Ф10

Ф12

Ф15

Max cut-off length

mm

95

100

133

185

Speed Range

pcs /min

120-200

95-160

90-150

60-105

P.K.O Stroke

mm

15

26

20

30

K.O Stroke

mm

80

85

110

160

Main slide stroke

mm

136

140

190

270

Main motor

kw

15

22

30

37

Cut-off-die size

mm

Ф30*45L

Ф35*62L

Ф45*59L

Ф63*69L

Punch die size

mm

Ф40*90L

Ф45*115L

Ф53*115L

Ф60*130L

Main die size

mm

Ф50*110L

Ф60*120L

Ф75*135L

Ф86*190L

Die pitch

mm

60

80

94

110

Machine Weight(Approx)

Kgs

11T

17,000

20T

32,000

Normal bolt size

mm

3-6

5-8

6-10

8-12.7

Shank length of blank

mm

10-75

15-75

15-100

20-150

Mechanical Dimensions(cm)

cm

350*220*170

420*250*190

455*275*230

560*300*225

REMARKS

The company keeps the right to revise above parameters. If there is any alterations, advance notice won't be given then.

The products' most applicable production speed is decided by the product shape, size and materia.

Maximum material shearing diameter and product size listed in the table can be calculated according to medium carbon alloy steel. It is equal to 10.9 grade high Intensity screw.

Main Technical Data of RBF Series 5-station High Speed and Fully Automatic Cold Heading and Forming Machine

Model

Unit

RBF-165S

RBF-205L

RBF-255L

RBF-255LL

RBF-305L

Forging station

No.

5

5

5

5

5

Forging force

Kgs

236,000

380,000

480,000

480,000

600,000

Max cut-off dia.

mm

Ф18

Ф23

Ф30

Ф32

Ф36

Max cut-off length

mm

190

240

370

450

420

Speed Range

pcs /min

55-95

45-75

35 55

30-50

25 45

P.K.O Stroke

mm

30

45

45

60

60

K.O Stroke

mm

165

220

315

400

380

Main slide stroke

mm

274

346

500

620

580

Main motor

kw

55

75

110

110

132

Cut-off-die size

mm

Ф75*100L

Ф75*120L

Ф99*150L

Ф99*150L

Ф118*150L .

Punch die size

mm

Ф75*185L

Ф90*215L

Ф120*270L

Ф120*270L

Ф140*300L

Main die size

mm

Ф108*200L

Ф125*240L

Ф148*355L

Ф148*450L

Ф168*420L

Die pitch

mm

129

140

160

160

180

Machine Weight(Approx)

Kgs

52,000

72,000

130,000

160,000

200,000

Normal bolt size

mm

10-16

12-20

16-25.4

16-25.4

24-30

Shank length of blank

mm

20-150

25-200

60-300

120-400

100-350

Mechanical Dimensions(cm)

cm

600*317*272.5

830*430*320

935*460*339.5

1200*470*500

1100*490*480

REMARKS

The company keeps the right to revise above parameters. If there is any alterations, advance notice won't be given then.

The products' most applicable production speed is decided by the product shape, size and material.

Maximum material shearing diameter and product size listed in the table can be calculated according to medium carbon alloy steel. It is equal to 10.9 grade high Intensity screw.

Features of RBF Series 5 Station Bolt Former

01

Enhanced productivity

The RBF Series 5 Station Bolt Former is designed to provide even higher productivity compared to its predecessor. Its five-station design enables the simultaneous formation of multiple bolts, allowing for faster production.

02

User-friendly interface

The RBF Series 5 Station Bolt Former features a user-friendly interface, making it easy to program and operate. It allows for quick and simple setup, minimizing downtime and streamlining production processes.

03

Robust construction

Built with sturdy materials and components, this bolt former offers excellent durability and reliability. It can withstand heavy-duty use and is designed for long-lasting performance.

04

Low maintenance requirements

The machine requires minimal maintenance, reducing maintenance costs and downtime. Routine cleaning and servicing can be easily carried out by the user, ensuring smooth operation.

0 notes

Text

RBF Series 4 Station Bolt Former

RBF Series 4 Station Bolt Former

The RBF Series 4 Station Bolt Former is a high-performance machine designed for efficient production of bolts. With its four stations, it offers multi-stage processing capabilities, including heading, threading, and pointing. It provides precise and consistent results, ensuring reliable bolt production. Ideal for use in industries such as automotive, construction, and fastener manufacturing.

Specifications of RBF Series 4 Station Bolt Former

Main Technical Data of RBF Series 4- station High Speed and Fully Automatic Cold Heading and Forming Machine

Model

Unit

RBF 44S

RBF-64S

RBF-64L

RBF-84S

RBF-104S

RBF-104L

RBF-134L

Forging station

No.

4

4

4

4

4

4

4

Forging force

Kgs

20,000

45,000

45,000

65,000

85,000

85,000

130,000

Max cut-off dia.

mm

Φ5

Φ8

Φ8

Φ10

Φ12

Φ12

Φ15

Max cut-off length

mm

55

90

125

100

130

185

190

Speed Range

pcs/min

300

140-240

100-180

120-200

95-160

90-150

75-120

P.K.O Stroke

mm

10

12

20

19

20

30

30

K.O Stroke

mm

45

85

110

85

110

160

160

Main slide stroke

mm

100

136

172

140

190

280

270

Main motor

kw

7.5

15

15

22

30

30

37

Cut-off-die size

mm

Φ20*30L

Φ30*45L

Φ30*45L

Φ35*50L

Φ45*59L

Φ45*59L

Φ63*69L

Punch die size

mm

Φ32*60L

Φ40*90L

Φ45*110L

Φ45*115L

Φ53*115L

Φ53*115L

Φ60*130L

Main die size

mm

Φ38*60L

Φ50*110L

Φ50*130L

Φ60*120L

Φ75*135L

Φ75*200L

Φ86*190L

Die pitch

mm

48

60

60

80

94

94

110

Machine Weight(Approx)

Kgs

45,00

10,000

12,000

14,000

18,000

24T

26,000

Normal bolt size

mm

2-4

3-6

3-6

5-8

6-10

6-10

8-12.7

Shank length of blank

mm

10-40

10-75

35-100

15-75

15-100

20-150

25-150

Mechanical Dimensions(cm)

cm

250*150*125

400*203*169

440*200*165

430*230*185

450*250*195

570*277*219

500*277*219

REMARKS:

The company keeps the right to revise above parameters. If there is any alterations, advance notice won't be given then.

The products' most applicable production speed is decided by the product shape, size and material.

Maximum material shearing diameter and product size listed in the table can be calculated according to medium carbon alloy steel. It is equal to 10.9 grade high Intensity screw.

Main Technical Data of RBF Series 4- station High Speed and Fully Automatic Cold Heading and Forming Machine

Model

Unit

RBF-134LL

RBF-164S

RBF-164LL

RBF-204L

RBF-204LL

RBF-254SL

RBF-254L

Forging station

No.

4

4

4

4

4

4

4

Forging force

Kgs

130,000

220,000

220,000

380,000

380,000

450,000

450,000

Max cut-off dia.

mm

Φ15

Φ18

Φ18

Φ23

Φ23

Φ26

Φ30

Max cut-off length

mm

285

195

325

240

360

255

320

Speed Range

pcs/min

50-80

70-110

40-70

50-80

40-65

40-70

35-62

P.K.O Stroke

mm

30

30

45

45

46

35

46

K.O Stroke

mm

280

170

320

220

325

215

280

Main slide stroke

mm

380

260

490

346

496

330

446

Main motor

kw

37

55

55

75

75

110

110

Cut-off-die size

mm

Φ55*70L

Φ60*90L

Φ64*100L

Φ75*120L

Φ75*120L

Φ80*130L

Φ99*150L

Punch die size

mm

Φ60*229L

Φ75*185L

Φ75*185L

Φ90*215L

Φ90*215L

Φ120*270L

Φ120*270L

Main die size

mm

Φ86*305L

Φ100*190L

Φ100*345L

Φ125*240L

Φ125*345L

Φ140*250L

Φ148*300

Die pitch

mm

110

120

120

140

140

160

160

Machine Weight(Approx)

Kgs

38,000

40,000

60,000

62,000

76,000

103,000

120,000

Normal bolt size

mm

8-12.7

10-16

10-16

12-20

12-20

14-25.4

16-25.4.

Shank length of blank

mm

75-260

20-150

100-300

25-200

100-300

35-200

60-260

Mechanical Dimensions(cm)

cm

720*300*250

610*326*265

900*350*320

730*320*300

870*320*320

830*430*320

-

REMARKS:

The company keeps the right to revise above parameters. If there is any alterations, advance notice won't be given then.

The products' most applicable production speed is decided by the product shape, size and material.

Maximum material shearing diameter and product size listed in the table can be calculated according to medium carbon alloy steel. It is equal to 10.9 grade high Intensity screw.

Features of RBF Series 4 Station bolt former

01

High precision

The RBF Series 4 Station bolt former is designed to provide high precision in forming bolts. It ensures consistent and accurate results in every operation.

02

Versatile operation

This bolt former is capable of forming bolts with various specifications and dimensions. It can handle different sizes of bolts and provide flexibility in production.

03

Efficient production

With its four-station design, the RBF Series bolt former allows for high-speed production. It can quickly and efficiently form multiple bolts simultaneously, increasing productivity.

04

Easy setup and operation

The machine is designed with user-friendly features, making it easy to set up and operate. It reduces the downtime involved in changing the production setup, ensuring smooth operation.

0 notes

Text

Bolt Forging Machine

Bolt Forging Machine

Rainbow's Bolt Forging Machine is a robust, adaptable equipment for bolt forging processes, transforming metal blanks into components such as bolts, screws, and fasteners. Its cutting-edge technology and meticulous engineering guarantee uniform outcomes, high production speed, and remarkable longevity, making it a perfect choice for manufacturers in diverse sectors.

Types of Bolt Forging Machine

RBF Series 4 Station Bolt Former

This advanced machine is designed for efficient and precise production of bolts, offering four stations for versatile and high-quality bolt manufacturing.

RBF Series 5 Station Bolt Former

This state-of-the-art machine is designed for precise and efficient production of bolts, offering five stations for enhanced versatility and high-quality bolt manufacturing results.

RBF Series 6 Station Bolt Former

Rainbow's RBF Series 6 Station Bolt Former offers versatile and precise bolt production. With six stations, it ensures high-quality results and seamless operation for fastener manufacturers.

QLBF Series 3 Station Bolt Former

This state-of-the-art machine is designed for efficient and precise production of bolts, offering three stations for versatile and high-quality bolt manufacturing results.

Benefits of Bolt Forging Machine

1

Increased productivity: Bolt forging machine can produce bolts at a much faster rate compared to traditional methods. This leads to higher production capacity and improved efficiency.

2

Improved bolt quality: Bolt forging machines ensure consistent and precise manufacturing, resulting in bolts that meet strict quality standards. This reduces the risk of defects or failures in the bolts, enhancing overall product reliability.

3

Cost savings: By automating the bolt forging process, companies can save on labor costs as fewer operators are required. Additionally, the increased productivity and improved bolt quality contribute to lower production costs in the long run.

0 notes

Text

Rainbow Fastener Manufacturing Machinery Display

Bolt Forging Machine

Rainbow's Bolt Forging Machine is a robust, adaptable equipment for bolt forging processes, transforming metal blanks into components such as bolts, screws, and fasteners.

RBF Series 4 Station Bolt Former

RBF Series 5 Station Bolt Former

RBF Series 6 Station Bolt Former

QLBF Series 3 Station Bolt Former

Nut Forging Machine

Rainbow' s Nut Forging Machine is a powerful, flexible tool for nut forging processes, converting metal blanks into components such as nuts, couplings, and connectors.

RNF Series 6 Station Nut Former

RNF Series 7 Station Nut Former

Cold Heading Machine

Rainbow's Cold Heading Machine is a specialized equipment used for cold forming and heading processes. It efficiently and accurately shapes metal materials, producing high-quality and reliable fasteners.

RSH Series 1 Die 2 Blow Cold Heading Machine

RSR Series Semi-Tubular Rivet Cold Heading Machine

RB Series 2 Die 4 Blow Cold Heading Machine

Nut Tapping Machine

Rainbow Nut Tapping Machine: Achieve precise and efficient nut tapping with our reliable equipment. Ensuring high-quality results, our machine is designed for versatility and ease of use.

4 Spindle Nut Tapping Machine

2 Spindle Nut Tapping Machine

Cold Heading Machine

Rainbow's Cold Heading Machine is a specialized equipment used for cold forming and heading processes. It efficiently and accurately shapes metal materials, producing high-quality and reliable fasteners.

RSH Series 1 Die 2 Blow Cold Heading Machine

RSR Series Semi-Tubular Rivet Cold Heading Machine

RB Series 2 Die 4 Blow Cold Heading Machine

Thread Rolling Machine

Offering precision and efficiency for seamless metal rolling. Achieve high-quality results with our reliable and versatile equipment.

CY Series Flat Die Thread Rolling Machine

ZP Series Round Die Thread Rolling Machine

Nut Tapping Machine

Rainbow Nut Tapping Machine: Achieve precise and efficient nut tapping with our reliable equipment. Ensuring high-quality results, our machine is designed for versatility and ease of use.

4 Spindle Nut Tapping Machine

2 Spindle Nut Tapping Machine

Screw Washer Assembly Machine

Washer assembling machine is a specialized machine with high speed, to assemble bolt, plain washer, spring washer, then thread. The machine has stable performance and strong practicality.

Nut Bolt Assembly Machine

The Nut Bolt Assembly Machine is a specialized equipment used for efficiently and accurately assembling nuts and bolts. It automates the assembly process, reducing labor requirements and ensuring precise and consistent results. This machine is ideal for manufacturers in need of high-volume nut and bolt assembly capabilities.

Screw Sorting Machine

The Screw Sorting Machine is a specialized equipment used for automated sorting of screws based on size, shape, and other specified criteria, increasing efficiency in assembly processes.

U Shape Bolt Equipment

Rainbow U Shape Bolt Equipment: Delivering precise and efficient U-shaped bolt production. Our reliable machine ensures high-quality results and is designed for versatility and ease of use.

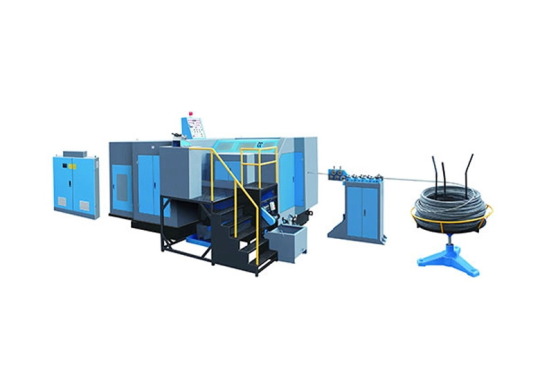

W58 Straightening & Cutting Machine

XM-B38NC Spline Head Hydraulic Pipe Bending Machine

ZD-3-B Thread Bar Automatic Receiving Machine

ZD-3 Thread Bar Automatic Feeding Maching

Maintenance Tips for Fastener Making Machinery

Regular Cleaning and Lubrication

Keep the fastener making machinery clean and free from debris. Regularly lubricate moving parts to reduce friction and ensure smooth operation.

Inspection and Replacement of Wear Parts

Periodically inspect the cold forging machine for any signs of wear or damage. Replace worn-out parts, such as belts, bearings, or cutting tools, to prevent breakdowns and maintain optimal performance.

Calibration and Alignment

Check the alignment of the machine components, such as guides, rollers, and cutter heads, to ensure accurate operation. Calibrate the machine according to manufacturer specifications to maintain precise dimensions and tolerances in the produced fasteners.

Importance of Automation in Fastener Production Processes

Automation plays a crucial role in fastener production processes, offering numerous benefits and advantages.

Firstly, automation improves productivity and efficiency. Automated machines can perform tasks at a much faster pace than manual labor, resulting in increased production rates and throughput. This allows manufacturers to meet higher demand and achieve greater output with fewer resources.

Secondly, automation ensures consistent quality and precision. Automated machines perform tasks with high accuracy and repeatability, reducing human error. This results in the production of fasteners that meet stringent quality standards and have consistent dimensions, ensuring a reliable and consistent end product.

Thirdly, automation enhances worker safety. By automating repetitive and hazardous tasks, workers are protected from potential injuries and risks associated with manual labor. This creates a safer working environment and reduces the occurrence of work-related accidents.

Moreover, automation enables real-time monitoring and data collection. Automated machines can gather data on production rates, quality metrics, and machine performance. This data can be analyzed to identify bottlenecks, optimize processes, and make data-driven decisions for improving overall efficiency and quality.

Ultimately, the implementation of automation in fastener production processes helps manufacturers stay competitive in the global market by increasing productivity, improving quality, enhancing worker safety, and driving overall operational excellence.

Different Types of Fastener Making Machinery

1. Heading Machines: Used to create the head of fasteners, such as screws and bolts, by applying pressure to a metal blank.

2. Thread Rolling Machines: Used to create threads on fasteners through a rolling process, ensuring strong and precise threading.

3. Nut Tapping Machines: Designed specifically for tapping threads into nuts, providing efficient and accurate threading operations.

4. Wire Drawing Machines: Used to reduce the diameter of metal wire by pulling it through a series of dies. This process creates the basic material used in fastener manufacturing.

5. Bolt Making Machines: Purpose-built machines that form bolts by cutting and shaping metal blanks, creating the desired dimensions and shapes for specific applications.

6. Screw Making Machines: Similar to bolt making machines, but specifically designed to manufacture screws, including self-tapping and machine screws, with various thread types.

7. Rivet Making Machines: These machines are used to form rivets by cutting and shaping metal blanks, enabling the production of different types and sizes of rivets.

8. Washer Making Machines: Designed for producing washers, these machines enable the cutting and shaping of metal blanks into washers of various shapes and sizes.

9. Nut Formers: Specialized machines that shape metal blanks into nuts by applying pressure and forming the desired dimensions and threading.

10. Fastener Packaging Machines: Used for automated packaging and labeling of fasteners, improving efficiency and ensuring proper packaging for shipment and distribution.

1 note

·

View note