#fasteners for concrete board

Explore tagged Tumblr posts

Text

⟁ PLUMMET. ft BOOTHILL.

⠀ — “swoopin’ in to save me again, sugar plum?”

⚠︎ mechanic!reader (but it isn’t really relevant), i saw boothill trailer and ran to google docs, gn reader (ma’am used once at the end) wc 1k.

“your bounty has been completed!”

boothill could feel the explosion of the ship, even from the distance he was and against the strong winds from his high speed fall. a rush of heat slapped him in the face, leaving a thorough hunger in his gut temporarily quelled.

“how would you like to land?”

the cyborg kept his hat fastened to his head with his palm against the top, eyes briefly glancing down to the city below he was slowly getting closer to plumetting down into.

“…good question.”

the ground was steadily approaching, even if it was gonna take him a solid second or two to actually reach it. he’d never tested if his body could withstand smacking against concrete from— give or take— six thousand feet in the air, but he had a small hunch today wasn’t the day to try his luck. becoming a blue splat on the pavement wasn’t exactly in the cards of his itinerary.

boothill’s eyes looked left, looked right, fingers twirling the rope on his belt. he doubted it’d do much to really help, but it was a start nonetheless.

he eventually came up with an idea— a totally foolproof idea. loop his rope around one of the street lights when he got close enough, avoid hitting the ground, swing himself back up into the air, and land safe and sound on…wherever the hell he managed to land. hopefully on his feet.

super simple, super easy. lightwork.

and so he eyed the ground, wrapping one end of his rope taught around his right palm, his left getting the momentum of the other end ready in a smooth swinging motion.

“c’mon now boothill,” he muttered to himself, voice thoroughly drowned out by the wind. “ain’t nothin’ but a lil’ repositionin’.”

he kept falling, getting closer,

closer…

closer…

almost there…

boothill readied his hand to swing, but the motion quickly became unnecessary when something— or rather, someone— grabbed his wrist, and he was pulled upward with a shocked ‘muddle—!’ before he could test the success rate of his plan.

the cowboy snapped his head up, hat nearly tipping off his head. he was hung like a ragdoll from his arm, feet dangling down below him as his eyes met his apparent saviours—

of course.

boothill’s sharp teeth slowly shone in a wide grin, loud and scruffy laugh echoing into the still rather open air around him. because who else would it have been besides you, your brows slightly furrowed at him from the safety of your little hoverboard he remembered you tinkering with just a couple days ago.

“well fudge me!” he’d slap his knee if the position allowed. “look who it is— ain’t you a sight for sore eyes!”

boothill reached up for your other hand, you wordlessly met him halfway reaching down, leaving both of your fingers locking around the others wrist.

“swoopin’ in to save me again, sugar plum?”

you shake your head with a sigh, hoverboard beginning a steady descent down. it was a little harder to balance with boothill weighing it down, but nothing you couldn’t handle.

“you’re lucky,” you half scoff. “i’ve got a sixth sense for you being an idiot.”

boothill’s hearty laugh echoed out again, the wind whipping around you leaving his hair tousled and a little tangled.

“ain’t that the fudgin’ truth,” he jostled your hand a little. he doubted he could really get adrenaline rushes anymore, but this was pretty damn close. “reckon i’d be flatter than a darn hotcake if it weren’t for yer timely intervention!”

his feet touching the ground were a welcome stabilisation, though the cyborg made no move to release your hand— instead he actually broke into a quick sprint, barely giving you the time to pick up your board as he tugged you along.

“you got somewhere to be or somethin’?”

you asked, stumbling a bit before you got your footing to keep up. you were just so cute when you pretended to be all sore with him.

“you bet i do— somewhere that ain’t swarmin’ with those sorry IPC shirtbags!”

it was a fair point— a giant explosion in the sky of one of their own ships made quite the beacon for attention.

running with him wasn’t so bad, at least. his grip around your wrist was surprisingly gentle, and the smell of him filled your nose in the wind as you trailed behind. some citrus, maybe cedar, and an unmistakable lingering of those phosphorus tracer bullets he chewed on so often.

you two dipped around a corner, backed against an old brick wall as some heavy footsteps kept running the other way.

“say, remind me to get’cha a drink later,” boothill gave a small tug to your wrist again, bringing you just a little closer. “as a thanks for all them times y’saved my sorry behind.”

boothill smiled when you chuckled rather than shooing his hand away or giving a smart response.

“you’re gonna have quite the tab going.” you carefully repositioned your hand with his, your fingers lacing together rather than him just holding your wrist. boothill’s eyes could have turned into cartoonish hearts.

“tell ya what,” his hand gave yours a squeeze. “i know a place. it ain’t too far from here, won’t have to worry about no one botherin’ us,” it was quite endearing, the way his voice still held that gentle rasp even as it softened. “i start workin’ off that tab, get a night with you, and heck we’re both winnin’ ain’t we?”

you hummed at that. it didn’t sound so bad.

“alright,” you nodded. “but let’s focus on you not having to gun down another dozen IPC workers first.”

it was your turn to pull him along with a swift tug of his wrist, resuming your sprint just in time to avoid some more heavy footsteps heading in your direction.

“you weren’t pullin’ my leg about that sixth sense, were ya sweetheart?” boothill fell into a natural step behind you.

“consider this added to your tab.”

“yes ma’am!”

⠀ MASTERLIST / GOT A REQUEST ?

#boothill#boothill x reader#boothill hsr#honkai star rail x reader#honkai star rail#hsr#honkai star rail headcanons#boothill honkai star rail#hsr boothill#boothill headcanons#boothill x you#star rail x reader#UNEARTHLY

2K notes

·

View notes

Note

Hello 🖤 I love seeing your blog pop up in my feed, simply exquisite 🖤

I have a request. What would older Terry Silver do with an adult student who is rather boisterous in class, she listens but only when she wants, she's a smarty pants. Terry so wishes to teach her a lesson after many months of class passing, learning her mannerisms, learning HER. Ever the voyeur, finding her home, seeing what lies within when she's not home, Terry plans a little 'private lesson,' specifically for her at his home dojo. Ending with his gi sloppy on him, his hair a mess like the slut he is with his student underneath him with no mercy being shown. His student definitely listens to HIS wants and desires, eager to please.

Breaking Stone.

(Terry Silver x Reader)

---

-"How safe is this, Sensei? I mean, it’s solid rock."-

Your voice speaks up from the gathered crowd and Terry Silver, he knew you’d have something to say without having to turn his back towards the mass of students keenly eyeing his demonstration in silence, standing jam packed in a circle around the erected board with a concrete block fastened to the center of the scaffolding propped up on iron legs, following his every word like a mantra only for him predict that your mouth will eventually move to utter something and dare interrupt him. Class fifty eight. A lesson on Brick Breaking. Tools necessary; pretty straightforward. A slab of rock and a fist. Additional spices; your usual commentary in the midst of it all. Happened almost daily. Happened to the degree it was a constant he could count on. -"We’ll break our hands on that."- You add with a sense of urgency and worry once the entirety of the exercise’s participants turn their eyes towards you, scrutinizing, weighing and accessing what you just blurted out and you tended to blurt out stuff frequently. Terry joins them in their quiet staring, finding a twitch of satisfaction stir through him once he realized you were jittery and stuttering, made self aware through the fact you were the sudden center of attention. Needing to justify yourself for placing the spotlight unto yourself, you blurt out some more bullshit. Nerves, was it? You deserved that. Deserved much worse for stepping out of line. -"What do we do in case we tear our ligaments punching the board?"- You ask, scratching the back of your head. Ligaments? Were you frightened of getting a boo-boo? At that point, Terry allows himself to turn his entire body towards you, taking his time, slowly --- painfully slowly --- looking straight ahead, towards you. You shift, from one bare foot on the mat to the other, like the stillness of everything around you gave you a sense of discomfort.

Stew in it. He hoped you'd stew in it.

-"Seems a bit extreme. Sorry."-

You chuckle, apologizing, looking down. Then back up.

Terry has to chuckle with you, neatly folding his hands in front of him.

A bit extreme? It was meant to be extreme.

-"Our student here thinks our methods are strange, but these classes aren’t mandatory."-

He simply shrugs matter-of-factly, addressing the people around him, all eyes leave you and pinning themselves in his direction instead, encircling him like a tightly closed ring, listening attentively, leaving you even more isolated in your folly. The great mother hen and the ducklings. The one, solitary ugly black duck that talked too much. -"Nobody’s here by force."- He explains, and contrary to popular belief, everyone here gave their signature of consent on a written contract. Terms. Conditions. Price rates. Health insurances. They showed up to daily classes because they wanted to, giving their hard earned money out of their own volition. He didn't go kidnapping people off of the streets of LA and harassing them into black Gi, in spite of what the likes of Larusso tried to accuse him of, same way not even Larusso himself was harassed into this, decades ago. -"Or are you all here by force?"- Terry purses his lips, looking around, enjoying this far too much to stop. In unison, they all speak up, one voice, stemming from one collective lung. -"No, Sensei!"- The dojo resonates with their shout. He tries again, spreading his arms, envisioning himself like Pontius Pilate about to wash his hands clean of you and let the crowds make their decisions. -"Why are you here for then?"- He inquires, raising his voice, encouraging them. Spurring them on. -"To learn, Sensei!"- Obeying, they repeat the motion, letting out a united cry and content, Terry squeezes his fingers into a fist once they all fall silent, all but an echo remaining, his other free hand caressing the concrete block in front of him, never taking his eyes off of you. At this point, with a mouth standing agape, forgetting you should've joined everyone in their jubilant war cry, you were as pale as a ghost. Not quite so chatty or smart anymore.

Perfect.

-"The lesson is —"- He begins. -"A true artist of the craft spends years, even decades just hitting things. Sand. Wood. Stone. Metal. Flesh."-

Terry coos, confessing, that he did, on occasion, imagine hitting you.

The sweetest thing he'd ever strike. Purely to shut you up, get you the way you were right now; As quiet as the dead; all gulps and anxious little eyes darting left and right. Preferably having you bent over his knee like an unruly child and taking the bamboo stick to you bare buttocks until they were rendered crimson red with punishment. After it was all done, he'd have you thanking him for the honor too. He smiles, just at the notion; an expression he doesn't bother hiding.

-"Having been broken so many times, it makes their bones so dense that when it comes in contact with solid rock, the rock breaks first."-

Terry digs his teeth into his lower lip, taking his stance and lunging forward suddenly, knuckles breaking through the barrier of the rock and crumbling, his fingers pushing through the crack he made on the other side. It was as simple as that. -"Asaa!"- He bellows and if the dojo was collectively holding it's breath, once he's done, the remains of sharp jagged tiny pebbles spilling on the mat under around his feet like so many rolling marbles, he senses an equally collective exhale. He can swear you weren't blinking at that point. What were you shocked by? The fact that he just smashed through a brick that weighed ten pounds like it was nothing or the implication he's broken his hand by choice so many times that he could pull shit like this in the first place? Maybe it wasn't smart to backtalk or question the methods of a person who could crush your windpipes in with merely just his thumbs. -"So, you see — breaking our fists, it’s part of the curriculum."- He shakes his head, staring you down, taking a couple of steps forward, until it was undeniable he was addressing you in particular; his infuriatingly Doubting Thomas, ignoring the students that wordlessly volunteered to clean up, scooting down to pick up the unfortunate remains of the rock slab, chirping away at the remains like a handful of chicks. -"This is part of what you signed up for when you came to this dojo. When you came to Cobra Kai."- He assesses firmly. -"You came to break with the old so the new and the improved could take its place."- He adds. Eventually, you'd have to bruise and break in those pretty little hands much like everyone else would and if you didn't have the guts to do that, you'd advance nowhere and your here would become fairly obsolete. Someone might as well tell you that upfront.

Even though, he confessed. The idea of a piece of rock breaking your hands?

Something shoots through him, like a radioactive phantasm of jealousy.

He wanted to do the breaking instead.

Not leave it up to an inanimate piece of training gear.

-"And if you can't imagine yourself doing that, you can always take up a knitting class."-

He adds, finally, earning himself a couple of amused chuckles.

Blood rushes into your cheeks.

Were you angry? Ashamed? Humiliated? Good.

—

Looking through your files was child's game after that.

He pretty much had everything he needed to know about you, printed in black and white in his own two hands, on the very exact form you filled the day you signed up for adulted classes six months ago; your home address, bank statement, contact number, email, age, place of employment, blood type in case an accident took place mid-training and a transfusion was needed on short notice. And yes, he's broken into your home before. Terry did it the first time you ever ran your mouth to backtalk him, asking if doing fifty consecutive push ups as warm was a smart decision because it was bound to leave everyone too exhausted to hold proper form and too distracted with tiredness to properly follow the class. He checked every drawer, every shelf, every nook, every cranny, supposing he wanted to find something he could spit on in indignation and discovering nothing more fitting but what he could only deduce was your framed graduation photograph, pursuing his lips and letting the saliva build up right before he hurled the spittle out of his mouth and right unto the glass inside of the frame, watching it trickle down your face, smearing it with his finger in retaliation, deciding the gesture was fitting punishment. If only he had a chance to do it with your actual face next. Spit in your mouth too, for refusing to shut up as it did. Spit in your mouth for missing three of your classes this week, like that was a thing you were allowed to do when you weren't. Did he tear into you verbally too hard last time? Was that it? Undoubtedly, but that still didn't give you permission to leave. He wanted you to come back so he could harass you some more, like you deserved to be harassed.

He knocks on your door, freshly having concluded this week's teaching.

Still in his Gi, jacket slung over his shoulders.

He did that on purpose, to make it seem like him coming here wasn't premeditated or something he tactically prepared for in advance, but rather, like a last minute decision he made in the utmost rush to the degree he didn't even have time to change out of his training attire, forgetful, overworked old man that he is. -"Who’s there!?"- Your concerned, slightly confused voice calls from the other end and he hears the keyhole clicking, only for your uncertain face to show up in the precipice of the doorframe illuminated by the warm light of your apartment's foyer looming like a halo behind you, brows practically jumping once you recognized him, appearing relieved. -"Sensei Silver!?"- You state in surprise, opening the door entirely, letting him step over the threshold, moving out of the way to usher him inside from the corridor. He tries not to seem too familiar with the territory, pretending not to know exactly where to stand; next to the shoe rack or the coat hanger. -"God. I’m so sorry. Got scared halfway to death!"- You place your hand over your chest, exhaling and smiling. Way too fidgety for someone who took Tang Soo Do classes. What were you afraid of? Of someone barging in and subduing you? -"What do I owe the honor of the visit! I didn’t expect anyone."- You shake your head, all charm. Of course he prepared an excuse for him being here and it comes in a form of a sleek pamphlet he produces from inside of his jacket, handing it to you. He had it printed, in bulk and giving out to everyone at the dojo solely so he could have a reason to give you one to you as well. -"The curriculum. For our future classes. I thought you might wanna look through it. Freshly printed."- Terry explains. He hoped you would've continued showing up, smart mouth you always were, but there you went, disappearing. If Muhammad wouldn't come to the mountain, the mountain would have to come to Muhammad.

-"You missed the last session so I brought it over personally. Where'd you go?"-

Terry feigns concern. He knew where you went. You were pegged down a notch.

Proceeded retreating with your tail behind your legs.

That's what you get for questioning him.

But, he didn't expect you to retreat quite so definitely.

Who'd you ask if you can do that? Did you ask anyone? Him?

You eyelashes flutter, like you were about to come up with an excuse.

-"I think you're right, Sensei. I mean, the whole Cobra Kai dojo scene, ---"-

You begin, looking away from him, vehemently staring at the pattern on the corridor carpet, holding the flyer with a sense of unease, like you weren't certain what to do with it. If you crumpled it up, he'd make you eat it. -"It ain't for me. I'm not cut out for it."- You confess, finally meeting his gaze, appearing a bit shy at the notion. He knew a tangent was incoming. Decides to let you have it. And knowing you, you wouldn't shut up any time soon in the next five minutes. -"I can't do any of those things you demonstrated last week. Break my bones on purpose? Smash through rocks? Ignore pain? I know when I'm out of my depth and there's no shame in admitting something ain't for me and gracefully moving on. What you said the last time --- you helped me see that. You really did."- You utter, in one solitary breath, and it takes everything within Terry not to laugh at you. So, humiliating in front of the whole class for interrupting him for the umpteenth time with some inane observation, you thought it was for your own good and that it made you see things more clearly? What? Was that why you left his dojo like it was a bus station? Did you really take up knitting as a hobby in the meantime as well? -"I had a great time studying these past few months under you, but I just can't continue."- You visibly gulp once he says nothing and you feel incentivized to further explain. You never had a problem with that before. Go ahead. He was giving you center stage to speak. So speak. -"I talk back. I interrupt. I question. I worry. I'm so sorry. I can't just let go and do it. Do what I'm supposed to do on the mat."- You add, your eyes widening, perhaps in anxiety, pupils dilating, looking back and forth between the surrounding furniture and the wall --- anywhere but at him. Why should he let you go? When it was so fun pushing your buttons? In fact, he decides you could use some more of that.

-"Do you like me?'-

He asks, bluntly. You take a step back, stammering.

-"Excuse me, sir?"-

-"I said, do you like me?"- He repeats himself, firmer.

Your mouth wordlessly forms a shape, but no sound comes forth.

You weren't certain what to say.

Finally.

You were speechless for once. That was a welcoming novelty.

-"Because, if you like me, you won't leave me here stranded, with one student less and waltz out impulsively, on such a short notice. That's not how things work. There's a price for that."-

He winds you up, deciding to stoke a fire and then immediately extinguish it, intending to fluster you for thinking what he led you to think, watching the abject shame settle into your expression like a newly formed wrinkle just because for a mere second, you thought this was a confession of something more than it was instead of a cleverly phrased and deliberately misguiding segway intended to put you on the spot and make you feel like an idiot with no listening comprehension. -"I'll pay everything I still own and ---"- You practically stumble over your words, clutching the pamphlet to your chest vigorously, like a shield, referencing unpaid lesson, trying to regain what little balance you had, visibly sweating bullets. Stoke the fire. Extinguish the fire. Stoke the fire. Extinguish the fire. Terry steps forward, shutting you up. Commanding you to stay silent. -"Don't talk."- He orders, flatly, putting up his hand alongside his finger as a warning and then coming closer still, until the tip of it is practically pushing against your mouth. You appeared flaggerbasted. Like you weren't sure what was going on, too shocked to actually move. This was why confusing people into a state of paralytic awkwardness was paramount in verbal warfare. He pushed his index finger between your lips and you still didn't move, letting him get away with it, too stunned for words. -"For once, listen. Don't speak."- He murmurs, staring at your mouth, pushing his nail inside, feeling your wetness and finding your tongue, frozen stiff, clasping it with his thumb and index finger and holding it, pulling on it, until you groaned, trying to mutely gibber and failing. -"This is the thing that always talked back. Can't talk back anymore, can it?"- He taunts and you shake your head with an expression that would place deer in headlights to shame, shivering vigorously.

You've seen what his hands could do. What his fists could do.

He could rip your tongue out of your skull and it would pose little issue.

He felt you knew that right about now.

Practically dangled by the tip of your mouth's organ. Your head slumping back.

Unable to release yourself, you slowly lower yourself, to your knees.

-"That's good."- Terry coos, pleased, watching you drool all over his hand.

-"Open that pretty little mouth of yours and use it for something really valuable for a change."-

He purrs, even as his fingers go fidgeting, lower his Gi's trousers, loosening the obi around his waist, pulling his cock out of his briefs, showcasing it to you so the state of the situation would settle in. He'd hatefuck your mouth. He was already hard. Already dripping precum. Almost like the very act of coming here and pestering you served to do it for him as he, without much deliberation, pushed himself inside of your lips, taking in the sloppy, receptive moisture, enjoying the symbolism of the flyer he's given you falling next to you on the floorboard until you were practically kneeling atop of it. -"Perfect."- He hums, praising. -"You've been badgering and badgering and I can't tell you how many times I thought about interrupting class and just giving it to you, in front of everyone, right there, in the middle of the dojo. Let them all see what happens when someone questions Terry Silver and his methods."- Now it was his turn to make some confessions, fingers tangling into your hair, coiling into a fist, making you look at him with your watering, teary eyes. He amps up his pace, bobbing your head back and forth for you, using your tresses as reins. Look how you've infected him. Now he was the one rambling and loving it. -"But, I wanted the occasion to be something special. Someplace I could really savor it --- and what better place than right under your very own roof."- He closes his eyes, smiling, enjoying the sensation of tense pleasure building up in his gut, right before looking down at you with your brows furrowed. You were just now realizing this was premeditated. Poor you. -"Oh, don't look at me like that. Don't think I haven't been in here before. Been here a thousand times."- He chuckles into his own chin, moaning. Of course he's desecrated something miniscule every time you talked back as an elaborate form of revenge and violation, like wiping his cock on the curtain after masturbating on your bed. Nothing was for free. Disrespect certainly wasn't.

-"And you'll be seeing a lot more of me just yet. Don't think this is over. Don't think you can disassociating with Cobra Kai and me on a whim. You can't."-

He flat out threatens, his hips rutting vigorously against your head.

You thought this was a game?

You sign up to his dojo for like six months and call it quits when things get hard?

Cobra Kai was a brotherhood. A society. Not an extracurricular pastime or a hobby.

That's what people weren't getting. He didn't want them to just yet.

But you? He'd was breaking the news to you hard and fast in the flesh.

-"You belonged to me from the moment you met me and put on the Gi and you'll belong to me until your dying breath."-

He grits his teeth, shaking, seething, feeling his tresses slide out of his ponytail and unto his forehead in an unruly mess, satisfaction coiling in his groin imaging you returning to the dojo on Monday, dressed in your uniform, all neat and proper, your attitude curbed and kept only for special occasions, releasing suddenly, just at the thought that he owned you, hearing you gurgle from the floor, droplets of his cum trickling down your chin and leaking unto the Cobra Kai pamphlet on the parquet in front of you. No, no. That wouldn't do. Not a single ounce wasted. -"Swallow."- Terry orders, catching his breath, scrutinizing you as you did so, still holding your hair, yanking forward suddenly, his cock falling out of your mouth, giving you leeway to breathe again and you do, gasping with sharp inhales of breath, a bubble of saliva popping between your lips as you rolled back to sob and cough. Pathetic. Eager to serve. So you were capable of shutting the fuck up, letting go and getting lost in an action after all? You were teachable. He knew you would be. Much like the rock slab on the training dummy, though, you needed to be broken in first. Terry slides his hand across the top of his head, slicking loose hair strands back, lifting up his finger to threaten and warn once again. Remind, in case you've forgotten. Had your brains scrambled in all sorts of awkward and unlikely directions. -"So, you better not miss out on any of my classes ever again or I'll have a reason to hold a very, very big grudge. Especially if you don't show up and break that stone like I've taught everyone to do. Understood?"-

-"Yes, Sensei."- You manage desperately, drooling, nodding your head.

#terry silver#old man terry#kk3#cobra kai#terry silver x reader#terry silver x beloved#tw; dubious consent#tw; teacher and student#tw; facefucking#tw; hatefucking#tw; stalking#tw; manipulating#tw; mind games#tw; all the warnings

99 notes

·

View notes

Note

Tech/Crosshair for the Kiss Roulette? Not picking any kisses, am leaving that for the RNG. :3

:D One day I'll write something not mer au for you today is not that day lol

Set in the Melna Gaisma AU

The air felt thick. The one who wore yellow tape under his eyes- Bly had said it meant ran was coming. Crosshair hadn’t believed the human until he saw the thick clouds move in to blot out the sun into a more tolerable gloom. The sanctuary had tried their best on such short notice, but the hastily strung well-worn tarp only provided minimal relief from the sun baring down on him. He had his eye on several wooden boards fastened together that food had been brought in on, but retrieving them from the dumpster had proved difficult. Especially with the few other mer constantly trying to check in on him. Surface mer where so damn nosy.

He sighed, long tail slapping restlessly on the concrete surrounding his new enclosure. It wasn’t big enough by a long shot, but they had jury rigged something called a yoga mat between two pools. He could toss water on it and stretch out between them. The one called Aayla had promised to look into joining the two ponds somehow, but even after staying here a brief time Crosshair could tell they were short on the money humans used for trade.

This wasn’t anything like what he’d been dreaming of. There was no substitute for the comforting pressure of the ocean. Where he could swim down deep enough to drown out the giant ball of light that tried to burn his scales every day, but it was better than the “recuse”. His new care takers kept a wide breath and didn’t seem to realize their newest volunteer spent his breaks visiting the off limits area that was Crosshair’s new domain.

Softly a faint pitter-patter bounced off the make shift sun shade as water began to fall from the sky. He heard Bly yelp in the distance, calling to someone to get inside if they wanted to stay dry. A few mer called to each other cheerfully, the opportunity to talk with out drying a welcome change. Amidst the chatter and soothing drum beat of the rain beating against the shade, then echoing the patter as it fell through to land in the pool he stretched out with another sigh.

He’d seen rain a few times. Mostly on rare visits to the surface when he’d wanted to see the stars or search for floating debris. It had always felt odd on his scales and skin. Like the ocean was trying to coax him back down to the depths, but unable to move through the air of the surface world. As the rain leaked through the thread bare tarp he settled to rest along the edge of the enclosure, arms crossed to support his head as he stared at the sky through the tinted glasses Tech had given him. Rain had been a novelty, but now he supposed it would become common to him.

A soft splash out of rhythm with the rain drew his attention. His ear fins shot up as he tried to hone in on the sound as it speed up towards him. Higher pitched pitter-patters followed the splashes as they rounded the corner and he couldn’t help the small smile at the sight of his mate jogging towards him in the rain. The white and red umbrella was a little worse for wear, but kept Tech mostly dry. Thankfully it looked like his mate had worn a more practical shoe then his normal one. Something that gripped to the concrete better than the shoes that had led to them meeting in the first place.

Still he couldn’t resist teasing him. “Careful little scholar, you’ll slip again.”

Tech grinned as he knelt down, ignoring the water soaking into his slacks. “I am being cautious, but I know that there is nothing to fear from this tank.”

“The sign says I’m a bite risk.” He flashed sharp fangs as he rose to meet Tech, their breath mingling with the fresh water filling his senses.

“Only when requested.” Tech bantered back drily, his smiled shifting to a quirk of his eyebrow and lips.

Crosshair chuckled, reaching up to cup Tech’s jaw and down him closer. The umbrella shifted, letting a few raindrops fall between them as Tech knelt under the makeshift awning without realizing it wasn’t very water proof. The falling water beaded beautifully on Tech’s skin, tempting Crosshair to dart a tongue out to lick it away. “Only for you.”

Before Tech could retort or retrieve his umbrella Crosshair sealed their lips together to taste the water falling on their skin properly. Not nearly salty enough, but the taste of Tech’s soft gasp more than made up for it. As did the warmth of the skin under his hand. His partner melted into the kiss, eager to return it even as water soaked through his clothing. Clever fingers ran through Crosshair’s short hair, blunt nails dragged against his scalp as Tech tried to find purchase in the slick strands.

Perhaps the rain would keep it’s novelty, if it kept the other humans away.

#clone shipping#cloneshipping#clone/clone#clone ship#cloneship#crosstech#crosshair x tech#crosshair/tech#mer au#melna gaisma#fishieswrites

8 notes

·

View notes

Text

Day 199: Tuesday July 18, 2023 - "Office Bar"

With Audrie's help, we got the iron cast shelf brackets attached with drywall anchors. "These might be heavier than the board itself! Very cool Etsy find, now installed, brought us to one last final task... attaching the bar and locking it down.

Over the weekend I did the finishing sanding and stain coats, polishing this to perfection, after grinding away on it all week in the heat. Now I lay across the brackets to see it all together for the first time; its soft to the touch and so beautiful to look at. The bar itself is a piece of art, and I am happy with it - exactly as I envisioned. Opens my office up a lot to get the full table out of there and I get all the same utility in this artful piece that I crafted myself. Nailed it.

Just one final task! I went to Home Depot after dinner and pondered over fasteners that would work best to finish the job. I brought home a few options that should hopefully work, preferring to use the lag screws and bolt them down with the impact (Mesquite is like drilling into concrete). I got ten bolts, needing 9, Just in case. I ended up breaking 6 of the 10 bolts in various stages of stress. Its a complete mess under the hood, though I managed to cobble together somewhat of a good solution with what I had left. Not quite a professional yet!

Song: Zach Bryan - Coffee Cups

Quote: “Show us a man who never makes a mistake and we will show a man who never makes anything. The capacity for occasional blundering is inseparable from the capacity to bring things to pass.” ~Herman Lincoln Wayland

2 notes

·

View notes

Text

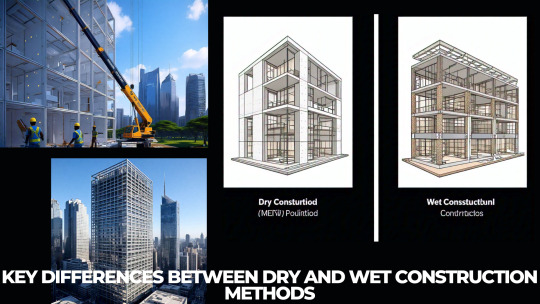

Construction methods have evolved over time, offering solutions that cater to varying project demands, climates, and timelines. The choice between dry construction and wet construction is fundamental, as each method comes with distinct processes, materials, and outcomes. Understanding these differences is essential for professionals, technicians, and aspiring engineers in Nigeria and across Africa, especially as the continent embraces modernization and sustainability in building practices.

At Jered Engineering & Designs Limited, we specialize in dry construction and its transformative potential. This article delves into the key differences between dry and wet construction methods, offering insights into their applications and advantages.

1. Definition and Processes

Dry Construction Dry construction involves assembling pre-manufactured components such as gypsum boards, aluminum panels, and steel frameworks. These materials are fixed using screws, adhesives, or fasteners without requiring water.

Wet Construction Wet construction relies on traditional materials like concrete, cement, and mortar, which are mixed with water and applied on-site. The curing process depends heavily on water availability and environmental conditions.

2. Materials Used

Dry Construction Materials:

Gypsum boards

Aluminum and steel frames

Pre-fabricated panels

Fiber cement boards

Glass panels

Wet Construction Materials:

Cement, sand, and aggregate

Bricks and blocks

Concrete mixes

Plaster and mortar

3. Construction Speed

Dry Construction:

Rapid installation since materials are prefabricated.

Reduced dependency on curing time.

Ideal for projects with tight deadlines, such as office spaces and retail fit-outs.

Wet Construction:

Time-consuming due to curing and drying processes.

Subject to delays caused by weather conditions, especially heavy rains common in parts of Nigeria and Africa.

4. Labor and Skill Requirements

Dry Construction:

Requires specialized skills for assembling prefabricated components.

Training in tools like screw guns and precision measurement devices is essential.

Jered Engineering invests in workforce training to empower local communities with these skills.

Wet Construction:

Relies on manual labor for tasks like bricklaying, plastering, and concrete mixing.

Skills required are often traditional and widely available.

5. Environmental Impact

Dry Construction:

Minimal water usage, making it suitable for areas with limited water resources.

Less on-site waste as components are prefabricated.

Recyclable materials like aluminum and steel contribute to sustainability.

Wet Construction:

High water consumption during material preparation and curing.

Significant waste generation from excess materials and construction debris.

Contributes to environmental degradation if not managed properly.

6. Structural Applications

Dry Construction:

Best suited for interiors, partitions, ceilings, and lightweight façades.

Growing use in modular buildings and prefabricated housing in Nigeria’s urban centers.

Wet Construction:

Preferred for load-bearing structures like foundations, columns, and beams.

Common in areas with traditional construction practices.

7. Cost Implications

Dry Construction:

Higher upfront costs for prefabrication and specialized materials.

Long-term savings due to faster project timelines, reduced labor costs, and lower maintenance expenses.

Wet Construction:

Generally lower initial costs, making it attractive for small-scale projects.

Higher long-term costs due to frequent maintenance and repairs.

8. Durability and Longevity

Dry Construction:

Resistant to moisture, pests, and fire when using high-quality materials like gypsum boards and fiber cement panels.

Durability depends on proper installation and material quality.

Wet Construction:

Known for its strength and ability to support heavy loads.

Susceptible to cracks, water damage, and wear over time if not maintained.

Practical Implications for Nigeria and Africa

Dry Construction Advantages:

Urbanization Demands: Rapid urbanization in cities like Lagos and Abuja calls for faster, scalable solutions that dry construction provides.

Water Scarcity: In arid regions like northern Nigeria, minimal water use in dry construction is a critical advantage.

Sustainability Goals: Governments across Africa are pushing for eco-friendly construction methods to combat climate change.

Wet Construction Suitability:

Traditional Applications: Rural areas still rely on wet construction for cost-effective housing.

Load-Bearing Needs: Essential for projects requiring heavy-duty foundations and structural support.

Why Jered Engineering Chooses Dry Construction

At Jered Engineering & Designs Limited, we believe dry construction is the future of sustainable building in Nigeria and beyond. Here’s why:

Efficiency: Faster project delivery allows us to meet the demands of a growing population.

Sustainability: By minimizing waste and water usage, we align with global environmental standards.

Quality: Our focus on precision ensures every project stands out for its durability and aesthetic appeal.

Conclusion

The choice between dry and wet construction methods depends on the project’s requirements, budget, and location. However, as the world leans towards sustainable and efficient building practices, dry construction is rapidly gaining prominence.

For professionals and aspiring technicians, understanding these methods is crucial to staying ahead in a competitive industry. With Jered Engineering & Designs Limited, you’re not just choosing a construction partner; you’re embracing a vision for the future of building in Nigeria and Africa.

#JeredEngineering

#JED

#FacadeDesign

#Dryconstruction

www.jeredengineering.com

0 notes

Text

Bolts: The Essential Fasteners for Strong and Secure Connections

Jinnox Bolt is one of the leading Bolt Manufacturers in India. Bolts are one of the most commonly used fasteners in construction, machinery, and many other industries. These versatile, threaded metal components play a vital role in holding parts together securely, ensuring the structural integrity and functionality of countless applications. Whether you're building a skyscraper, assembling furniture, or constructing a vehicle, bolts are essential for creating strong, durable connections. In this blog, we will explore what bolts are, their types, common applications, and why they are such an integral part of various industries.

What Are Bolts?

A bolt is a type of fastener that consists of a threaded shaft, a head, and sometimes a washer. The head of the bolt is typically hexagonal (though it can also be square, round, or other shapes) to allow for easy gripping with a wrench or socket. Bolts are designed to be inserted into a hole and fastened using a nut, which fits onto the threaded shaft. The combination of the bolt and nut forms a strong, secure connection, and the threading ensures that the bolt stays in place even under heavy loads.

Bolts come in a variety of sizes, materials, and strengths, depending on the specific application. The materials commonly used for bolts include steel, stainless steel, titanium, brass, and aluminum, each providing different levels of corrosion resistance, strength, and durability.

Types of Bolts

There are numerous types of bolts, each designed to serve a specific purpose or function. Some of the most common types include:

Hex Bolts: These bolts have a hexagonal head and are widely used in construction and automotive industries. Their versatility makes them suitable for a variety of applications.

Allen Cap Bolt: As a top Allen Cap Bolt Supplier, we take immense pride in manufacturing and supplying premium quality bolts.

Anchor Bolts: These bolts are used to secure structures to concrete or masonry, providing stability in heavy-duty applications.

Square Bolt: every Square Bolt is subjected to thorough testing and inspection, giving you confidence in the dependability and performance of our goods.

U-Bolts: Shaped like the letter "U," these bolts are used to secure pipes, tubes, or round objects to flat surfaces.

Eye Bolts: With a loop at one end, eye bolts are ideal for lifting or securing loads with ropes or cables.

Common Applications of Bolts

Bolt Manufacturer are used in a vast array of applications across multiple industries, from construction to automotive to aerospace. Some of the most common uses include:

Construction: In the construction industry, bolts are used to secure steel beams, reinforce structural elements, and fasten concrete to steel structures. Bolts are crucial for ensuring the safety and stability of buildings, bridges, and other large structures.

Machinery and Equipment: Bolts are used in the assembly of machines, vehicles, and industrial equipment. They help hold parts together, ensuring that machines function smoothly and safely. Automotive engines, for example, rely on bolts to hold components like the cylinder heads, transmission, and exhaust system in place.

Furniture Assembly: Many types of furniture, from bookshelves to office chairs, are assembled using bolts. Carriage bolts and hex bolts are commonly used for securing various parts, providing strong and durable connections.

Electrical and Electronics: Bolts supplier in India are often used in electrical applications to secure components within electrical cabinets, devices, and circuit boards. They are also used to attach electrical panels to walls or ceilings.

Aerospace and Aviation: In the aerospace industry, bolts play a critical role in securing aircraft parts, such as wings, engines, and landing gear. Given the safety and performance demands of the aviation industry, high-strength bolts made from materials like titanium or high-grade steel are used extensively.

Advantages of Using Bolts

Strength and Durability: Bolts suppliers are designed to handle high loads and stresses. Their threaded design ensures a tight, secure hold, making them ideal for applications that require long-term durability.

Easy to Install and Remove: Unlike some other fasteners, bolts can be easily installed and removed with standard tools like wrenches or sockets. This makes them ideal for applications that require periodic maintenance or repairs.

Versatility: Bolts come in a wide variety of sizes, materials, and types, making them suitable for a vast range of applications, from light-duty to heavy-duty tasks.

Corrosion Resistance: Bolts made from stainless steel or coated with anti-corrosion materials can withstand exposure to moisture, chemicals, and harsh environments. This makes them perfect for use in industries like marine, automotive, and construction.

We are supplier in various cities

Bolt Supplier in Mumbai

Bolt Supplier in Pune

Bolt Supplier in Ludhiana

Bolt Supplier in Rajkot

Bolt Supplier in Ahmedabad

0 notes

Text

Common Mistakes to Avoid When Using Drywall Screw in India

When using drywall Screw in India, several common mistakes should be avoided to ensure a secure and long-lasting installation. First, not using the correct screw length can lead to weak or improper fastening. Screw that are too short may not anchor properly, while those too long could damage the drywall or underlying structure. Another mistake is over-driving the screw, which can cause the drywall to crack or weaken the hold. It's also important to use Screw specifically designed for drywall, as regular Screw may not provide the necessary grip. Lastly, neglecting to pre-drill holes in thicker drywall can result in splitting or uneven placement. Avoiding these mistakes will lead to more durable and secure installations.

Using the Wrong Type of Drywall Screw for Indian Conditions

One of the most significant mistakes when using drywall Screw in India is choosing the wrong type of screw for the specific needs of your drywall installation. Drywall Screw come in different lengths, diameters, and types of coatings. It's essential to choose Screw that are designed for dry climates or specific wall types commonly used in Indian construction. In areas where high humidity is a concern, consider opting for corrosion-resistant Screw with a zinc or phosphate coating. Using regular steel Screw in such environments can lead to rusting and premature failure, which is common in coastal regions like Mumbai, Goa, or Kerala.

Over-tightening the Drywall Screw

Over-tightening drywall Screw is a widespread mistake, particularly for beginners. When you drive the screw too deep into the drywall, it can damage the material and cause it to break. This can create holes in the wall, making it harder to finish the wall properly. In India, where drywall is still relatively new in certain regions, it's easy to make this mistake. Ensure you tighten the screw just enough to secure the drywall in place without pushing it too far in. The screw should sit slightly below the surface of the drywall, but it should not break through the paper layer.

Not Pre-drilling Holes for Drywall Screw

In many instances, drywall installers in India may skip the step of pre-drilling holes for Screw, assuming that the drywall can handle direct screwing. However, pre-drilling is essential when working with thicker drywall or when securing the Screw into wooden studs or metal framing. Not pre-drilling can cause the drywall to crack or split, especially when working with thicker drywall boards commonly found in commercial and residential buildings in India. A pre-drilled hole ensures that the screw goes in straight and without excessive force, preventing damage to the drywall.

Using Drywall Screw on Improper Substrates

Drywall Screw are designed to be used on specific materials such as drywall or plasterboard. Using them on improper substrates, such as concrete, brick, or stone, is a mistake that can lead to unsuccessful installation. The Screw might not grip properly, and the drywall will fail to stay in place. In India, where construction materials vary greatly between regions, it's essential to ensure that drywall Screw are only used with the appropriate framing materials. When working with concrete or brick walls, you’ll need to use masonry anchors or Screw designed specifically for these surfaces.

Not Using Enough Screw for Proper Support

One mistake many installers in India make is not using enough Screw to provide adequate support for the drywall. While it’s easy to think that fewer Screw will save time and effort, this mistake leads to weak, unstable drywall that may sag or even detach from the wall over time. The general recommendation is to place Screw about 12 to 16 inches apart along the studs. If you’re installing heavier drywall panels, you may need to use even more Screw to ensure the wall stays intact. Always follow the manufacturer's guidelines on spacing to prevent unnecessary stress on the material.

Ignoring the Quality of the Drywall Screw

Another common mistake when using drywall Screw in India is overlooking the quality of the Screw. Many people choose the most affordable option without considering the quality of the Screw they’re purchasing. Cheap Screw may not be strong enough to support the weight of the drywall, leading to Screw snapping or pulling out over time. Investing in high-quality Screw from reliable brands ensures that the Screw will stay intact and perform well over time. Look for Screw that are specifically designed for drywall use and ensure that they have the correct coating to resist corrosion.

Not Checking the Screw Placement Before Installation

Before installing your drywall, it’s crucial to mark the locations of the studs and other framing elements on the wall. Not checking for the correct placement of Screw can lead to drywall being installed incorrectly or Screw missing the studs altogether, resulting in an unstable and poorly installed wall. In India, where building standards may vary, it’s important to thoroughly inspect the stud spacing and framing type before screwing in drywall. For best results, use a stud finder to locate studs accurately and mark their positions clearly on the drywall before installation.

Conclusion

Using drywall Screw in India may seem simple, but small mistakes can lead to significant issues, such as drywall failure or an unprofessional finish. By avoiding the common errors listed above choosing the wrong type of Screw, over-tightening, failing to pre-drill, and more you can ensure a long-lasting and secure drywall installation. Taking the time to understand the specific requirements for drywall Screw in Indian conditions and using the right tools and techniques will help you achieve a smooth, durable, and professionally finished wall. Whether you are working on a residential or commercial project, keeping these tips in mind will prevent costly mistakes and ensure that your drywall installation is both efficient and successful.

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Garden 4 you Coffee Table Rustic Brown Nesting Table for Small Place 2 Sets Modern Furniture Living Room Sets End Side Table Night Stand for Bed Room Dining Room ✔FOR SMALL PLACE: A unique design nesting coffee table, with a large table (Φ 23.6 × 17.7 inch) and small one (Φ 15.7 × 15.7 inch). The small table is a two-tier design, it can be placed under the large table. ✔ELEGANCE & RETRO STYLE:Designed in vintage style, the nesting coffee table set is elegant and minimalist, bringing charm to your living room and giving your visitors a good impression of your home. ✔DETAIL-ORIENTED: A non-slip table feet with a adjustable foot pads make the table stand firm and stable. It can fits neatly into the wooden floor,tile floor even the concrete. ✔INTIMATE DESIGN: The size of the moderate, the contour novel, completely accord with human body engineering principle. Pass one or two afternoon hours leisurely with a peaceful cup of coffee. ✔STRONG AND DURABLE: A sturdy metal frame, fastened with double screws make the table firm and strong. Besides, the tabletop is a denser and scratch-resistant MDF board. It's your choice with high quality, good stability and cost-effective. [ad_2]

0 notes

Text

10 Common Deck-Building Mistakes and How to Avoid Them

Building a deck can be an exciting project that transforms your outdoor space into a functional and beautiful area. However, it’s also a project that requires careful planning and execution. Mistakes made during the process can compromise the deck’s safety, durability, and aesthetics. Here are 10 common deck-building mistakes and tips on how to avoid them.

1. Ignoring Local Building Codes

One of the most critical mistakes is failing to check and adhere to local building codes. These codes ensure that your deck is safe and compliant with legal requirements. Skipping this step can result in fines, failed inspections, or even having to tear down your deck.

How to Avoid It: Before starting, research your local building codes and obtain the necessary permits. Consult with your local building authority if you’re unsure about specific regulations.

2. Poor Planning and Design

A deck without a clear plan can lead to issues like wasted materials, poor layout, or an unbalanced structure.

How to Avoid It: Spend time planning your deck’s size, shape, and function. Use design software or hire a professional to create detailed plans that include measurements, materials, and structural elements.

3. Choosing the Wrong Materials

Using materials that aren’t suitable for your climate or intended deck use can lead to premature wear and tear.

How to Avoid It: Research materials that work well in your region’s climate. For example, pressure-treated wood is great for durability, while composite decking requires less maintenance.

4. Improper Post Placement

Deck posts that are uneven or poorly anchored can compromise the deck’s stability and safety.

How to Avoid It: Use a string line and level to ensure posts are aligned and at the correct height. Secure them with concrete footings to prevent shifting over time.

5. Inadequate Fasteners and Hardware

Using the wrong type or insufficient quantity of fasteners can weaken your deck’s structure.

How to Avoid It: Choose corrosion-resistant screws, bolts, and joist hangers specifically designed for outdoor use. Follow the manufacturer’s guidelines for spacing and installation.

6. Skipping the Ledger Board Flashing

The ledger board connects your deck to your home. Without proper flashing, water can seep into your home’s structure, causing rot and damage.

How to Avoid It: Install flashing between the ledger board and your home to divert water away. Use durable, corrosion-resistant materials like aluminum or vinyl.

7. Improper Spacing of Joists

If joists are spaced too far apart, your deck boards may sag or feel unstable.

How to Avoid It: Follow the decking material manufacturer’s recommendations for joist spacing. Typically, joists are spaced 12 to 16 inches apart, depending on the material.

8. Overlooking Drainage and Ventilation

Poor drainage and ventilation can lead to water pooling and wood rot, shortening your deck’s lifespan.

How to Avoid It: Ensure there is adequate spacing between deck boards for water to drain. Use spacers to maintain consistent gaps, and design the deck with proper airflow to prevent moisture buildup.

9. Rushing the Construction Process

Cutting corners to save time can lead to mistakes that compromise safety and quality.

How to Avoid It: Take your time to follow the plans and double-check your work at each step. Measure twice, cut once, and don’t skip essential steps like leveling or securing fasteners.

10. Neglecting Maintenance After Completion

Once your deck is built, neglecting regular maintenance can result in damage and reduce its lifespan.

How to Avoid It: Clean your deck regularly to remove dirt and debris. Inspect it annually for loose fasteners, rotting wood, or other signs of wear. Reapply sealant or stain every few years to protect the wood from the elements.

Final Thoughts

Building a deck is a rewarding project, but it requires careful planning and attention to detail. By avoiding these common mistakes, you can create a deck that is safe, durable, and enjoyable for years to come. If you’re unsure about any aspect of the process, consider hiring a professional to ensure the job is done correctly.

0 notes

Text

Fancy Commercial Plywood With Sapele Teak Ash Oak Walnut Birch Natural Wood Veneer

We cherish every opinion and suggestion of new and old customers, and constantly improve and enhance ourselves accordingly, so as to achieve the goal of providing customers with more perfect service and better Okoume Door Skin Plywood, Shuttering Board For Concrete Formwork, Ordinary Particle Board. We are committed to continuing to provide excellent products and services to create a smarter, healthier and more prosperous life for people. Our foreign trade principle is based on common development with customers. Over the years, we have continued to break through technical bottlenecks and improve the production and sales service system. We continue to meet the needs and optimize the quality of our services, thus achieving mutual growth and sustainable development with our customers.

Product Specifications

Size:600x1000mm, 610x2440mm, 1220x2440mm, 915x2135mm.

Thickness:2.5~30mm

Glue:MR, E1, E2, Melamine, WBP, Phenolic.

Core material:Poplar, birch, combi, hardwood, eucalyptus, etc.

Face & back:Teak, Eucalyptus, Beech, Maple, Walnut, Ash, White oak, Red oak, Mahogany, Cherry, Ebony, etc.

Surface veneer:Crown Cut, Quarter Cut, Rotary Cut, Sliced Cut, natural and engineer veneer.

Moisture content:8%--12%

Grade:AA/AA, BB/BB, BB/CC, CC/CC.

Density:500-630KG/BCM

Thickenss tolerance:Less than 6mm, ±0.2-0.3mmMore than 10mm, ±0.5mm

Modulus of rupture:≥30Mpa

Product application:For indoor furniture/cabinets/floor & decoration.

Packaging:Covered by plastic bag and carton /plywood board, fastened by steel belts with pallets, and are suitable to seaworthy transportation.

Certificate:FSC,CE,CARB,ISO9001:2000

Product Features1) High bending strength. 2) Strong nail holing. 3) Moisture resistant and easy work. 4) Tight construction and high strength. 5) No ratten or decay. 6) Low formaldehyde emission. 7) Suitable for indoor furniture & floor or decoration use. 8) Suitable for indoor construction of viaduct and tall frame building. 9) Various species of surface natural wood veneer are available

#Fancy Commercial Plywood With Sapele Teak Ash Oak Walnut Birch Natural Wood Veneer#plywood#Commercial Plywood

0 notes

Text

Exterior Insulation System: A Modern Approach to Energy Efficiency and Comfort

In today’s world of rising energy costs and an increasing focus on sustainability, homeowners and builders are looking for innovative ways to improve energy efficiency in buildings. One such solution gaining popularity is the Exterior Insulation System (EIS). This blog explores what an exterior insulation system is, its benefits, components, and why it’s becoming a key player in modern construction.

What is an Exterior Insulation System?

An Exterior Insulation System refers to a construction method where insulating materials are applied to the exterior walls of a building. Unlike traditional insulation methods that are installed within walls or attics, this system focuses on creating a thermal envelope around the entire building, minimizing energy loss through the structure.

These systems are commonly used in both residential and commercial buildings, offering a seamless way to improve energy performance while also enhancing aesthetic appeal.

Components of an Exterior Insulation System

An effective exterior insulation system typically consists of the following layers:

Substrate or Base Wall The existing structure, which could be concrete, brick, wood, or other materials, serves as the base for the insulation system.

Adhesive or Mechanical Fasteners These are used to attach the insulation panels securely to the substrate.

Insulation Boards Insulation boards made of materials like expanded polystyrene (EPS), extruded polystyrene (XPS), or mineral wool form the core of the system. These boards reduce heat transfer and improve energy efficiency.

Reinforcement Layer A layer of fiberglass mesh is embedded into a base coat, providing strength and resistance against cracking.

Finish Coat A weather-resistant, decorative finish, often made of acrylic or silicone-based materials, is applied. This layer protects the insulation and adds to the building’s visual appeal.

Benefits of Exterior Insulation Systems

Enhanced Energy Efficiency Exterior insulation reduces thermal bridging, a common problem where heat escapes through structural elements like studs and beams. By addressing these weak points, EIS significantly lowers heating and cooling costs.

Improved Comfort Buildings with EIS maintain more stable indoor temperatures, offering greater comfort for occupants throughout the year.

Increased Durability The system protects the building envelope from weather-related damage, including moisture, temperature fluctuations, and UV rays, extending the life of the structure.

Aesthetic Flexibility EIS allows for various finish options, giving architects and homeowners the freedom to choose colors and textures that match their vision.

Environmental Sustainability By reducing energy consumption, exterior insulation systems contribute to lower greenhouse gas emissions, aligning with global efforts to combat climate change.

Cost-Effectiveness While the upfront cost of EIS may be higher than traditional insulation methods, the long-term savings on energy bills and maintenance make it a smart investment.

Applications of Exterior Insulation Systems

Residential Homes: To enhance energy efficiency in single-family and multi-family homes.

Commercial Buildings: To meet stringent energy codes and create sustainable designs.

Renovation Projects: Ideal for retrofitting older buildings to meet modern energy standards.

Things to Consider Before Installation

Climate: The effectiveness of EIS may vary depending on the local climate. Ensure the system is designed to handle specific weather conditions.

Moisture Management: Proper drainage and vapor barriers are crucial to prevent water infiltration.

Professional Installation: Hiring skilled professionals ensures the system is installed correctly, maximizing its benefits.

Conclusion

The Exterior Insulation System is a game-changer in the construction industry, offering a holistic solution to improve energy efficiency, comfort, and aesthetics. Whether you’re constructing a new building or renovating an old one, investing in EIS can lead to significant savings and a smaller carbon footprint. As energy codes become stricter, exterior insulation systems will undoubtedly play a central role in shaping sustainable architecture for the future.

So, why wait? Upgrade to an exterior insulation system today and enjoy the benefits of a smarter, greener, and more comfortable building!

#stucco systems#eifs systems san antonio#stucco system texas#eifs systems texas#stucco san antonio#continuous insulation system#exterior insulation system#stucco system san antonio

0 notes

Text

The Complete Ipe Decking Installation Guide: From Planning to Perfection

If you're aiming to enhance your home's value with an outdoor area that combines durability with visual appeal, ipe decking installation might be just what you need. It is very durable, easy to maintain, and resistant to rot and decay. But before you start planning your ipe wood decking project, let's go over the basics.

Handling and storage

Ipe wood needs time to acclimate to its environment before installation. Since it's often delivered partially dried, it should be stored in a shaded area and allowed to adjust to the local humidity for at least 7 to 14 days. This helps prevent issues like warping, cupping, or excessive shrinking after the deck is installed.

Joint spacing

Follow the recommended spacing guidelines for boards: 16 inches for 1 x 4 and 1 x 6, and 32 inches for thicker boards like 2 x 6. This will allow for proper ventilation and prevent cupping or warping.

Pitch

To allow for proper water drainage, install your Ipe decking with a slight slope. Aim for a slope of at least 1/4 inch for every 10 feet of decking if you're using standard Ipe lumber. If you’re working with tongue and groove boards, increase the slope to 1/4 inch for each foot to ensure effective water runoff.

Placement

Do not install hardwood decking directly over concrete, as it can retain moisture and cause cupping or bending upwards.

Gap

Maintain a 3/32-inch gap between Ipe boards for ventilation and to account for expansion and contraction with temperature changes.

Airflow

Make sure there’s at least 18 inches of space below the deck to allow air to move through and help the wood stay stable. Cross-ventilation is important too, as it will reduce movement in the wood caused by moisture.

Water drainage

Prevent water from pooling under or on the deck by sloping the ground for drainage and avoiding construction over concrete slabs.

Sealing

Ipe wood usually comes with End Seal on the ends to keep it from cracking. If you cut the wood, make sure to seal the ends the same day to prevent end checking.

Fastening

Ipe wood is incredibly hard, so you’ll need to pre-drill holes before installing screws or fasteners to avoid splitting the wood. It’s also important to use only stainless steel fasteners for Ipe decking installation. If you use screws that are MCQ compliant, Ipe can develop tannin weep, which can cause unsightly stains on the deck's surface. Stainless steel prevents this issue and ensures a clean, long-lasting finish.

And that's it!Ipe decking installation is not a difficult process, but it does require careful planning and proper handling. For professional guidance and high-quality Ipe wood, always consult a reputable supplier or contractor.

ABS WOOD, for example, has been a trusted source of Ipe decking and other hardwood products for years. With their expertise and top-of-the-line materials, you can confidently create the perfect deck for your home. Visit their website today at www.abswood.com to learn more.

0 notes

Text

Preventing Storm Damage: Roofing Solutions for High-Risk Areas

Storms can cause significant damage to homes, especially in high-risk areas where severe weather is frequent. Your roof is the first line of defense against these powerful forces, and ensuring it is built to withstand such challenges is essential for the long-term safety of your home. At Flagstone Roofing & Exteriors, we offer expert advice and roofing solutions designed specifically for storm-prone regions. By taking proactive measures, you can minimize damage and protect your property.

1. Choosing the Right Roofing Material

One of the most important steps in preventing storm damage is selecting the right roofing material. Not all materials are created equal when it comes to weather resistance. For areas prone to hurricanes, heavy rainfall, or high winds, the best options include:

Metal Roofing: Metal roofs are incredibly durable and can withstand winds up to 140 mph, making them ideal for storm-prone areas. They are also resistant to impact from debris and can last 50 years or more with proper maintenance.

Impact-Resistant Shingles: These specially designed shingles are built to endure hail, wind, and debris impact. They’re a cost-effective solution for homeowners looking to improve their roof’s durability without the price tag of metal roofing.

Clay or Concrete Tiles: For areas that experience high heat and wind, clay or concrete tiles are excellent. While they’re heavier, their resilience against harsh weather conditions makes them a long-lasting solution.

2. Reinforced Roof Decking

The roof decking is the foundation upon which all roofing materials are installed. In high-risk storm areas, reinforcing the roof decking is essential for preventing damage from strong winds and heavy rains. By using materials like plywood or OSB (oriented strand board) with additional fasteners, the roof’s structure will be more secure and less likely to fail under pressure.

At Flagstone Roofing & Exteriors, we recommend adding hurricane clips or straps that attach the roof decking to your home’s frame, ensuring a stronger hold during storms.

3. Storm-Resistant Flashing

Flashing protects the vulnerable areas of your roof, such as around chimneys, vents, and skylights, by keeping water from seeping in. In storm-prone regions, the quality and installation of flashing are crucial. Using storm-resistant flashing, made from materials like copper or stainless steel, ensures that your roof remains watertight even in the most challenging conditions.

4. Sealing and Waterproofing

Water infiltration is one of the leading causes of roof damage after a storm. Proper sealing and waterproofing prevent leaks and water damage by creating a barrier between your roof and the elements. Adding a waterproof underlayment beneath your roofing materials is a smart way to protect against water penetration during heavy rains and storms.

5. Gutter and Drainage Systems

A functional gutter and drainage system is essential for preventing stormwater from pooling on your roof, which can lead to leaks and structural damage. Regularly cleaning your gutters and ensuring they’re free from debris will help keep water flowing away from your home. For high-risk areas, consider installing larger gutters that can handle heavy rainfall, or a gutter guard system to keep leaves and debris from clogging your drainage system.

6. Proper Roof Ventilation

While it might not seem like a storm prevention measure, proper roof ventilation is crucial for protecting your roof from storm damage. A well-ventilated roof reduces heat and moisture buildup, preventing the materials from deteriorating over time. This ensures your roof stays in optimal condition, ready to withstand high winds and heavy rains.

7. Securing Roof Attachments

Any attachments on your roof, such as satellite dishes, solar panels, or HVAC units, should be securely fastened. During a storm, these items can become loose and cause damage not only to your roof but to the surrounding area. Properly securing roof attachments minimizes the risk of them being torn off by high winds.

8. Regular Roof Inspections

Preventing storm damage starts with regular roof inspections. Before storm season hits, it’s important to assess your roof for any potential weak spots. Look for damaged or missing shingles, cracks, or areas that may be prone to leaks. Professional inspections can identify issues that need immediate attention and provide you with the peace of mind that your roof is ready for whatever Mother Nature brings.

9. Roof Maintenance After a Storm

Even if your roof appears to have survived a storm unscathed, it’s essential to perform a post-storm inspection. High winds and flying debris can cause hidden damage that may not be immediately visible. Look for signs of damage such as cracked shingles, loose flashing, or clogged gutters. Prompt maintenance can prevent small problems from becoming major issues down the road.

10. Installing a Secondary Water Barrier

For homes in areas with a high risk of hurricanes or heavy storms, installing a secondary water barrier beneath your roofing materials can offer added protection. This additional layer helps prevent water from seeping through your roof in case the outer layer is damaged during a storm. It’s a great investment for homeowners who want extra security against severe weather.

Conclusion

Protecting your home from storm damage starts with a strong, durable roof. By selecting the right materials, reinforcing key areas, and ensuring proper maintenance, you can greatly reduce the risk of costly repairs after severe weather. At Flagstone Roofing & Exteriors, we specialize in roofing solutions designed to withstand the toughest storms. Whether you need an inspection, roof replacement, or storm-resistant upgrades, our team has the experience and expertise to help you safeguard your home.

Contact us today! Let Flagstone Roofing & Exteriors help you prepare your roof for the next storm and keep your home safe.

#roof storm damage#roofer#roofing#home water purification#residential solar services#roof repair#flagstoneroofing#justinledford

0 notes

Text

5 Ways to Build An Eco- Friendly Building Structure With Timber

In recent years, the construction industry has been increasingly turning towards sustainable practices to mitigate environmental impact. Timber is a renewable and adaptable resource that presents opportunity for environmentally beneficial building designs. Here are five innovative methods to harness timber for sustainable construction.

MASS TIMBER CONSTRUCTION:

Mass Timber Construction encompasses various techniques like cross-laminated timer (CLT), glue-laminated timber, and nail-laminated timber (NLT). Through the use of adhesives or fasteners, layers of timber board are bound together to create engineering wood products. Because mass timber is sourced responsibly and is manufactured using efficient methods, it has lower embodied carbon emissions than traditional materials like steel and concrete.

By using mass timber construction, you can lessen your dependency on energy-intensive materials like concrete, which is a major contributor to the world’s carbon emissions. Moreover, timber buildings help combat climate change by sequestering carbon over the course of their lifetime. Timber Frames Newcastle construction projects contribute to sustainable forestry practices and drastically reduce their carbon footprint by using mass timber in their building constructions.

PASSIVE DESIGN INTEGRATION:

Using natural resources like sunshine and airflow to their fullest potential can reduce the need for artificial heating, cooling and lighting systems. This is known as passive design integration. Because wood naturally has thermal characteristics, including wood parts into building structures helps to enable passive design solutions. Wood is a great insulator which lowers the need for energy intensive HVAC systems and helps to maintain acceptable indoor temperatures.

In addition to improving occupant comfort and lowering energy consumption, timber’s thermal mass helps buildings to efficiently control temperature swings. Energy efficiency and occupant well being can be given priority in eco friendly buildings designed by architects and designers through the strategic integration of timber features.

MODULAR CONSTRUCTION:

The process of prefabricating building components off site and assembling them on site is known as modular construction and it has several benefits in terms of sustainability and efficiency. Modular construction approaches work especially well with timber because of its lightweight and manageable nature. While improving quality control procedures, off site manufacturing reduces waste production and building time.

Additionally, Timber Frames Newcastle construction optimizes resources and makes effective use of materials which supports overall sustainability goals. Developers can minimize their impact on the environment, expedite the construction process and design eco friendly buildings by adopting this method.

INCORPORATING NATURAL ELEMENTS INTO THE BUILT ENVIRONMENT:

The goal of biophilic design is to reestablish the connection between inhabitants and the natural world. Biophilic design concepts are perfectly aligned with timber because it is an aesthetically beautiful and biodegradable material. Using exposed timber surfaces on walls, floors and ceilings encourages a feeling of coziness and connection to the outdoors in interior areas.

Furthermore, the natural textures and earthy hues of Timber Frames Newcastle promote a feeling of peace and wellbeing, which improves occupants’ entire experience. Architects can design sustainable buildings that enhance human well being, productivity and environmental conservation by adopting biophilic design concepts.

LIFECYLE ASSESSMEN AND MANAGEMENT:

In order to determine how wood based building constructions affect the environment, a thorough lifecycle assessment (LCA) and management strategy must be put in place. Lifecycle Assessments (LCA) examines the environmental impact of building materials and processes across their whole existence, from the extraction of raw materials to recycling or disposal at the end of their useful life.

When obtained ethically from forests that are responsibly managed, wood has better life cycle assessments (LCAs) than other common building materials. Through Life Cycle Assessment (LCAs) and the implementation of sustainable forest management techniques, interested parties can guarantee that constructions made of wood have a beneficial impact on conserving resources and preserving the environment.