#essential ecm

Explore tagged Tumblr posts

Text

Terje Rypdal — After The Rain. 1976 : ECM 1083.

#jazz#jazz guitar#Terje Rypdal#1976#ecm#jazz rock#manfred eicher#1970s#1970s jazz#essential ecm#essential jazz#essential album

8 notes

·

View notes

Text

The electric countermeasures that were in the SR 71 were able to blind North Vietnam’s radar.

THE SR-71 PLAYED A MAJOR PART IN LINEBACKER II

The bombing of the supply channels of Vietnam, which led to the ending of the war (Jan. 1973) Linebacker II, an SR 71, was flying with the B-52 shielding them with their electric countermeasures.. ⭐️by blinding the North Vietnamese radar.⭐️

The following story was sent to me by Chris Cobb, who is my neighbor and went to high school with me, about his father, Colonel Darrel Cobb, and Reg Blackwell, “My Dad passed away four years ago. . . .but boy, did we hear some of the stories in the latter years. For example, in this mission, my Dad said that he was watching the SAMs coming toward him and took his eye off the speed. He checked with Reg, the RSO, what speed he showed, and he replied 2150 KTAS (which translates to 2474 MPR).”

Essentially, this mission blinded the North Vietnamese radar by the SR ECM. And within one month, the Paris peace talks were held, and the was over.

An hour before midnight on 27 December 1972, Giant Scale mission GS663 got underway when SR-71 975 lifted off Kadena runway on what would prove to be the only Habu night sortie of the entire Vietnam War.

Col. Darrel Cobb and RSO Capt Reggie Blackwell's mission objective was to conduct a coordinated EMR/HRR sortie to determine if the North Vietnamese had acquired new equipment or employed updated procedures for the SA-2s that were responsible for generating such high B-52 losses. To achieve this, the SR-71’s arrival over the Haiphong/Hanoi areas was timed at precisely the exact moment that 60 B-52s were to begin dropping their bombs on the rail yards at Lang Dang, Duc Noi, and Trung Quant, the Van Dien supply center, and three missile sites.

With the North's defensive radar systems running at full stretch to cope with the raid, intelligence planners reasoned that this would be an ideal time for such a sortie. In addition, the SR-71, with its unmatched ECM suite, would provide additional electronic support for the bombers.

As they arrived at the collection area on schedule, Cobb and Blackwell observed numerous SA-2 firings. During the fleeting moments when they were crossing the immediate target area, they were able to radiate a blinding ECM blanket. During the raid, only one Guam-based B-52 was lost. Darrel and Reggie landed back at Kadena at 0239 hours. The next day they learned that their mission had produced a wealth of intelligence data.

The two 60-bomber raids launched on the final two nights of Linebacker II saw all B-52s arrive back at their bases safely. Following the action on the night of 29/30 December, the North Vietnamese government expressed a willingness to return to the negotiating table.

The Habus had faithfully recorded a record of Linebacker's enormous level of destruction. The conflict in Vietnam ended for the United States when the Paris Agreement was enacted on 27 January 1973.

Lockheed Blackbird: Beyond the Secret Missions by Paul Crickmore

Post~Linda Sheffield

Thank you, Chris Cobb

@Habubrats71 via X

14 notes

·

View notes

Text

I like that, if you look at the way the new ship classes are described in mostly LotF but also FotJ a little, you can just tell that Allston was imagining these things as if they were to be put to screen, and he puts a lot of effort into making them connect to the established visual language while still being distinct in their own right.

The Eta-5 is basically a crossbreed of the Eta-2 Actis and the RZ-1 A-Wing. Alephs have a TIE-style cockpit ball (though the dual viewport thing is what makes me actually agree with Syal on its ugliness) and also big engine nacelles that probably are evocative of Y-Wings, depending on the exact proportions. Shrieks are literally YT series freighter parts kitbashed into a bomber. The Blur is very explicitly compared to a TIE/SA bomber with the cockpit and the ECM equipment in side-by-side pods, but the solar array radiator wings are curved instead of sharply angled.

He doesn't give as many larger designs, but the Galactic-class destroyer is essentially a fatter Imperator. Not that visually distinct, but at least there are in-universe reasons for that not to vary much.

8 notes

·

View notes

Text

Urs Leimgruber — AIR Vol. 1 (Creative Works)

When confronted with a four CD set of freely improvised music, basic may not be the first word that comes to mind. But check out the title. What’s more essential to a saxophonist than air? It’s what they project through a horn. If they can’t gather it and blow it through that metal tube in sufficient volume and with enough control, no sound comes out. Urs Leimgruber has been making records using different members of the saxophone family for fifty years, and been playing longer than that. Originally known outside of Switzerland as a member of Om, which recorded for ECM back in the 1970s, he’s operated in completely composed and totally free settings, as well as many creative nodal points on the line between them.

In recent years, he seems to have narrowed his focus to the soprano saxophone. Each disc of AIR Vol. 1 presents an improvisation with a long-term collaborator in The Space, the rehearsal-performance-recording room where Leimgruber works when he’s at home in Lucerne. Hans-Peter Pfammatter plays a prepared upright piano; Jacques Demmierre, an amplified spinet (an antique keyboard that sounds like a harpsichord); Thomas Lehn, analogue synthesizer; and Gerry Hemingway, drums. The accompanists differ in instrument and aesthetic, but each has an individual and deeply considered approach to his instrument. By performing with each in a sequence, Leimgruber invites one to listen for his essential character as a player and improviser.

Certain musical rudiments do not make the grade. While melody and rhythm can be handy, neither is essential. One might expect one or the other to assert their necessity when playing with a drummer, but while occasionally present, both players abstract them into expressions of line, sometimes drawn quite faintly, and other times with force. Likewise, one might look for harmony in encounters with keyboards, but shape and space seem to be more important. With Lehn, mercurial shifts between proximate and distant timbres come into play. But with all of his partners, Leimgruber sounds absolutely like himself. He alternates exquisitely pure tones with bold, lacerating ones, fashioning them into shapes that complement what his partners play, but could be complete on their own.

Bill Meyer

#Urs Leimgruber#AIR Vol. 1#creative works#bill meyer#albumreview#dusted magazine#saxophone#improvised music#the space#Peter Pfammatter#Jacques Demmierre#Thomas Lehn#Gerry Hemingway

3 notes

·

View notes

Text

EMS and ODM, Global Market Size Forecast, Top 8 Players Rank and Market Share

EMS and ODM Market Summary

Electronics manufacturing services (EMS) is a term used for companies that test, manufacture, distribute, and provide return/repair services for electronic components and assemblies for original equipment manufacturers (OEMs).

The concept is also referred to as electronics contract manufacturing (ECM).

An original design manufacturer (ODM) is a company that designs and manufactures a product as specified and eventually rebranded by another firm for sale. Such companies allow the firm that owns or licenses the Company to produce products (either as a supplement or solely) without having to engage in the organization or running of a factory.

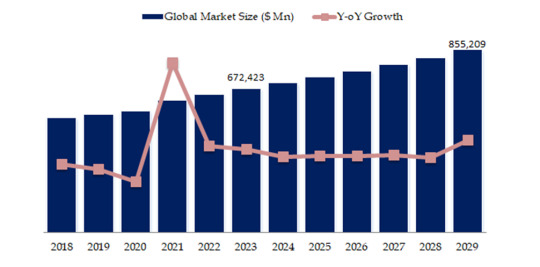

According to the new market research report “Global EMS and ODM Market Report 2023-2029”, published by QYResearch, the global EMS and ODM market size is projected to reach USD 855210 million by 2029, at a CAGR of 4.1% during the forecast period.

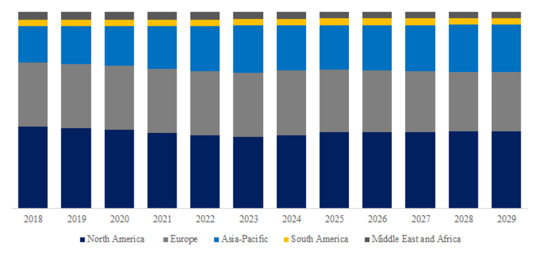

Figure. Global EMS and ODM Market Size (US$ Million), 2018-2029

Based on or includes research from QYResearch: Global EMS and ODM Market Report 2023-2029.

Market Trends:

In a short period of time, markets and consumers’ behaviours have undergone drastic changes due to the outbreak of the coronavirus (COVID-19). From people raiding grocery store aisles to the cancelation of the world’s most significant events and mandates for “non-essential” businesses to temporarily close, this pandemic is having a substantial impact on the economy and society as we knew it.

1. Despite all of the negatives that have come from the COVID-19 pandemic, it has led to several positive outcomes. For example if your product or service can be marketed to coronavirus patients, it is most likely doing well. With the development of the epidemic, there will still be considerable development in the medical industry in 2021.

2. Most of the traditional EMS centres in Southeast Asia will see above trend growth from 2021 – 2025 in response to both trade tensions, and real and perceived excess concentration of manufacturing in China by some leading western OEMs.

3. Over the next 5 years, a number of low-cost Asian countries will see new investments in their nascent tech manufacturing industries. This likely includes Laos, Cambodia, Myanmar, and Bangladesh. Much of this investment will be based on the size of existing labor force, as well as growth rates of the labor force and the burgeoning local consumer markets. EMS and ODM companies from Foxconn to Flex realize that these large investments in new manufacturing centers often take 15 years or more before they really become a competitive force at meaningful scale.

4. A new breed of mid-sized, China based/China only EMS providers will find their wings and expand outside of China to compete with larger multi-national EMS providers from Taiwan and the US.

Market Drivers:

The key driver for the electronics contract manufacturing industry (EMS and ODM) is costs.

High-volume manufacturing in the form of EMS / ODM can be attracted to countries by offering low-cost labor and availability of components

The critical success factors for an EMS / ODM model able to offer real outsourcing cost reductions and benefits that actually help OEMs reduce costs and save money, include:

Low cost geographic destinations

Component costs

Intellectual property (IP) protection

Government tax incentives

Figure. EMS and ODM, Global Market Size, Ranking of Major Manufacturers 2022

Based on or includes research from QYResearch: Global EMS and ODM Market Report 2023-2029.

The global key manufacturers of EMS and ODM include HONHAI, Compal, Pegatron, Quanta, Jabil, Flextronics, Luxshare, Wistron, Inventec, BYD Electronics, etc. In 2022, the share of top 5 players exceeds 52.68%.

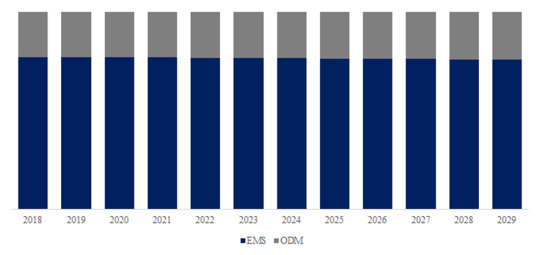

Figure. EMS and ODM, Global Market Size, Split by Product Segment

Based on or includes research from QYResearch: Global EMS and ODM Market Report 2023-2029.

In 2022, EMS accounted US$ 493771 million in the global EMS and ODM market. And this type segment is poised to reach US$ 646661 million by 2029.

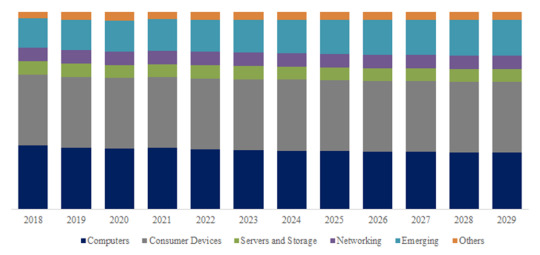

Figure. EMS and ODM, Global Market Size, Split by Application Segment

Based on or includes research from QYResearch: Global EMS and ODM Market Report 2023-2029.

In 2022, Consumer Devices accounted US$ 231053 million in the global EMS and ODM market, share the largest. And this type segment is poised to reach US$ 306990 million by 2029.

Figure. EMS and ODM, Global Market Size, Split by Region

Based on or includes research from QYResearch: Global EMS and ODM Market Report 2023-2029.

In EMS and ODM market, North America occupies an important share, with a market share of 36% in 2022, and the market size is expected to reach US$ 191775 million by 2029.

About The Authors

ShiYuanyuan - Lead Author

Email: [email protected]

Shi Yuanyuan is a senior technology and market analyst, specializing in chemical industry, agriculture, consumer goods, etc. Analyst Shi Yuanyuan has 3 years of experience in the chemical industry and consumer goods industry, focusing on APIs, chemical intermediates, household appliances, wearable devices, 3C products, etc. She can provide the development of technical and market reports and also participate in custom projects.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

3 notes

·

View notes

Text

Ariel Kalma, Jeremiah Chiu & Marta Sofia Honer - The Closest Thing to Silence

In August 2022, Australia-based, French born fourth-world music legend Ariel Kalma was invited to participate in BBC Radio 3’s Late Junction series of special collaborations. The program pairs artists who have not previously worked together to create new music cooperatively. Kalma was quick to suggest working with two musicians whom he had never met – International Anthem recording artists Jeremiah Chiu & Marta Sofia Honer, whose critically-acclaimed duo debut 'Recordings from the Åland Islands' had been released just a few months earlier. An invitation was sent to Chiu and Honer, which was received with great enthusiasm, as Chiu had long been a fan of Kalma’s work, even citing him as a major influence on his approach to electronic music composition. The essential structure of the Late Junction collaboration was that the artists would work together to create around twenty minutes of music. They began passing music back and forth, some that Kalma had started, and some that Honer & Chiu had started, with each adding to or editing the track before returning it to the other. The music would only go back and forth a few times before being finalized. After meeting their twenty minute goal for the program (four pieces total), the three musicians were satisfied in what they would present and sent along their work to the producers of Late Junction. However, there was a nagging suspicion that this wasn’t the end of the story. There were several pieces that they had nearly completed but that weren’t sent for inclusion in the radio program, and there were many ideas for refining those pieces that had. With this in mind Kalma, Chiu and Honer agreed that they would continue to work together to try to push the music further. The freshly minted trio felt like there was much more to be said and more work to be done. The Late Junction program was broadcast in September of 2022. Simultaneously, Kalma, Chiu and Honer began expanding upon the music they had started for the purpose of the broadcast, working diligently on the music for several months. Their collective approach to this work was born in improvisation and realized via collage-based editing. The end result brings several distinct musical moments — recorded sometimes decades apart — into conversation with one another, forming new narratives from building blocks of old ones. There are snippets of improvised playing from each musician, edited together with recordings that Kalma had made in the 70s at GRM, and even moments of audio notes — like Kalma explaining his ideas — that would make it into the final mixes. Ultimately, the collection of music highlights the work of all three musicians, intertwining the contextual immersion heard on Chiu & Honer’s 'Recordings from the Åland Islands' with an intergenerational reverence for (and the undeniable presence of) Kalma’s decades-spanning body of work. It is work that has definitively enshrined him as one of the true, transcendent pioneers and sages of new age and fourth-world music. That reverence is affirmed by the album title chosen by the group — "The Closest Thing to Silence" — which is taken from a quote by Kalma included in a documentary by RVNG Intl (as part of their release of the 2014 compendium/retrospective An Evolutionary Music). Perhaps coincidental, Kalma’s quote was a slight modulation of a legendary ECM Records motto, as he said: “Music is the closest thing to silence.” All Compositions by Ariel Kalma, Jeremiah Chiu, and Marta Sofia Honer. Design and layout by Will Work for Good & Some All None. Photography by Alejandro Ayala & Ama Kalma.

#ariel kalma#jeremiah chiu#marta sofia honer#electronic#ambient#jazz#new age#fourth world#2024#international anthem#Bandcamp

4 notes

·

View notes

Text

What Are The Best Performance Upgrades For Dodge RAM 1500?

The Dodge RAM 1500 is the vehicle of choice for many when it comes to off-roading… From 3.0- liter EcoDiesel V-6 engine to 5.7- liter HEMI V-8 engine; Dodge RAM 1500 has a robust engine line up. And, guess what??? With a few simple performance upgrades, you can unlock its real potential that the manufacturer had left on the table.

Interested in learning more about these performance upgrades??? Well, read this blog post all the way through…

Improve Your Dodge RAM 1500 Performance with These Upgrades

Before we begin… let’s us clarify a few things. This article has a generalized explanation of Dodge RAM 1500 performance upgrades. No particular Dodge RAM engine type is being discussed here. Therefore, if you need specific information on 5.7L HEMI V-8 engine performance upgrades, or information about other engine types for that matter, contact a qualified expert.

It's time to move on to our main topic now that the disclaimer has been concluded.

Upgrade #1- Cold air intake

Installing a cold air intake system is one upgrade you can make to improve the performance of your Dodge RAM 1500. Cold air intake, as is evident from the name as well, is a system designed to feed the engine with cold dense air. More air promotes fuel burning inside the combustion chamber, which produces more power.

But, before you install a cold air intake system, you should understand about its benefits and drawbacks, such as how it will affect your vehicle's fuel consumption, torque output, etc…

Upgrade #2- Performance tuner chip

Plugging in a performance tuner chip to your Dodge RAM 1500 is another option to improve its performance. For those who don’t know, the performance tuner chip is a computer unit that can make a few tweaks to your RAM's engine control module, or ECM, to improve engine performance.

Plus, it has been found that the use of performance tuner chip can significantly improve a vehicle’s gas mileage. But, but, but… using such technologies to boost engine performance has several downsides that you should be aware of.

Upgrade #3- Throttle body spacer

Adding a throttle body spacer to your Dodge RAM 1500 engine is one more change you can make to bring out its full potential. The RAM's throttle body and upper intake manifold is where you must put them. The part will significantly enhance your RAM’s air intake capacity. It will funnel more air into the combustion chamber of the engine.

And, as we just explained in the above paragraph, more air would result in effective fuel combustion and increased torque production. But, again… do some research before installing it.

Upgrade #4- Exhaust modification

The exhaust system can also be upgraded for greater engine performance. The combustion gases are essentially vented to the outside air by the exhaust system. The exhaust system installed on your Dodge Ram has limits on how fast it can discharge engine emissions. You may improve the exhaust fume flow rate of your Dodge RAM by upgrading the exhaust pipes.

Increased exhaust flow can dramatically improve your vehicle's torque production. But… you should only have qualified technicians modify the exhaust system on your Dodge RAM.

Upgrade #5- Cooling system upgradation

The torque output of your Dodge RAM will not be directly affected by cooling system upgrades, but the durability of its engine most certainly will be. The cooling system essentially keeps the engine temperature within the permissible range; thereby preventing it from overheating.

Off-road vehicles' engines, like the one in the Dodge RAM 1500, occasionally have to work harder and produce a lot of excess heat. You'll need a performance water pump, a multi-core radiator, and a heavy-duty electric fan in these circumstances to dissipate extra engine heat.

Key Takeaways

These performance upgrades can help your Dodge RAM 1500 unlock its full potential and transform it into a real off-roader. There are numerous other things that you can also do to get the most out of your Dodge RAM 1500.

In any case, before you start upgrading your vehicle, you must do some research on the pros and cons of using those technologies to unleash the power that you are not supposed to. That’s all for today’s blog post. We hope this had added value to your knowledge.

3 notes

·

View notes

Text

Why You Should Consider Buying a Used Rear Axle and ECM for Your Car

When it comes to maintaining or repairing your vehicle, there are certain components that are crucial for its overall performance and safety. Two such important parts are the rear axle and the ECM (Engine Control Module). Both of these components play a significant role in your car’s functionality, and replacing them can often be costly when purchasing new. However, buying used rear axles and ECMs can be an affordable and reliable alternative. Here’s why you should consider going for used options for these vital parts.

Used Rear Axles: and ecm for cars An Essential Part of Vehicle Performance The rear axle is a critical component of your car’s drivetrain. It transfers the power from the engine to the wheels, allowing your vehicle to move. In vehicles with rear-wheel drive or four-wheel drive, the rear axle is essential for distributing torque to the wheels. Over time, rear axles can wear out, and replacing them can be expensive.

Benefits of Choosing a Used Rear Axle:

Cost Savings: A new rear axle can be pricey, and if you're driving an older model or one that's no longer in production, finding a replacement part can be difficult and costly. Used rear axles are often much more affordable and provide significant savings compared to new ones.

Environmentally Friendly: Opting for a used part helps reduce waste and the demand for new parts. This contributes to a more sustainable approach to car repairs.

Reliability: Used rear axles are often taken from vehicles with relatively low mileage and are thoroughly inspected to ensure they are in good working condition. Many sellers provide warranties or guarantees for used axles, offering peace of mind.

Availability for Older Models: For older cars or discontinued models, new parts may be hard to find. Used rear axles are often available for cars that are no longer in production, making it easier to maintain and repair these vehicles.

When purchasing a used rear axle, it’s important to ensure compatibility with your vehicle’s make, model, and year. Reputable suppliers will provide you with the necessary details and help you find a part that fits your car perfectly.

Used ECM (Engine Control Module): The Brain of Your Car’s Engine The ECM (Engine Control Module) is like the brain of your vehicle’s engine management system. It monitors and controls the engine’s functions, including fuel injection, ignition timing, and emissions control. If the ECM fails, it can lead to poor engine performance, stalling, or even complete engine failure.

Why Buy a Used ECM?

Cost-Effective Solution: A new ECM can be expensive, with prices often reaching hundreds or even thousands of dollars, depending on the make and model of your car. Used ECMs are significantly cheaper, allowing you to repair your car without the hefty price tag.

Programming and Compatibility: Some vehicles require specialized programming or specific ECM models to function correctly. Used ECMs from reputable sellers often come pre-programmed for specific vehicles, ensuring a quick installation process. Some ECM sellers also offer reprogramming services for an additional fee.

Availability for Older Cars: Like with rear axles, if you own an older or discontinued vehicle, finding a new ECM can be challenging. Used ECMs are a great option for these vehicles, as they’re often easier to source and can be less expensive than purchasing a new one.

Environmental Impact: By choosing to use a recycled ECM, you're helping to reduce the overall waste generated by the automotive industry. It’s a small but meaningful step toward sustainability.

How to Choose a Quality Used Rear Axle or ECM When purchasing used car parts, it’s crucial to choose a trustworthy seller to ensure the quality and compatibility of the part. Here are some tips for buying used rear axles and ECMs:

Work with Reputable Suppliers: Choose suppliers that specialize in used car parts and have good customer reviews. They should offer warranties or guarantees on the parts they sell to provide you with peace of mind in case something goes wrong.

Ensure Compatibility: Make sure the part you're buying is compatible with your vehicle. When it comes to ECMs, this is particularly important since different models and years require specific units. For rear axles, compatibility also depends on the make and model, especially for vehicles with different drivetrain configurations.

Inspect the Part: Request a detailed description of the part's condition. For rear axles, request whether it has been inspected for wear and tear; for ECMs, request that the unit be tested for functionality and free from electrical damage.

Warranty or Return Policy: Always check for a warranty or return policy when buying used parts. This ensures that if there are any issues with the part after installation, you have options for replacement or a refund.

Final Thoughts Replacing critical components like the rear axle and ECM with used parts can be a great way to save money on car repairs while ensuring that your vehicle continues to perform reliably. Used parts, when sourced from reputable suppliers, offer a cost-effective solution without sacrificing quality. Whether you’re dealing with axle failure or an ECM issue, choosing used parts can help extend the life of your vehicle and keep your repair costs low.

0 notes

Text

Pat Metheny — Bright Size Life. 1976 : ECM 1073.

! listen @ Apple Music ★ buy me a coffee !

#jazz#jazz guitar#jazz trio#guitar trio#pat metheny#1976#ecm#jaco pastorius#bob moses#manfred eicher#jazz fusion#1970s#1970s jazz#essential jazz#essential album#essential ecm

7 notes

·

View notes

Text

FIFTIETH Anniversary Of Operation LINEBACKER II

December 27, 1972

THE SR-71 PLAYED A MAJOR PART IN LINEBACKER II

The bombing of the supply channels of Vietnam, which led to the ending of the war (Jan. 1973) Linebacker II, an SR 71, was flying with the B-52’s shielding them with their electric countermeasures.. ⭐️by blinding the North Vietnamese radar.⭐️

The following story was sent to me by Chris Cobb, who is my neighbor and went to high school with me, about his father, Colonel Darrel Cobb and Reg Blackwell, “My Dad passed away four years ago. . . .but boy, did we hear some of the stories in the latter years. For example, in this mission, my Dad said that he was watching the SAMs coming toward him and took his eye off the speed. He checked with Reg, the RSO, what speed he showed, and he replied 2150 KTAS (which translates to 2474 MPR).”

Essentially, this mission blinded the North Vietnamese radar by the SR ECM. And within one month, the Paris peace talks were held, and the was over.

An hour before midnight on 27 December 1972, Giant Scale mission GS663 got underway when SR-71 975 lifted off Kadena runway on what would prove to be the only Habu night sortie of the entire Vietnam War.

Col. Darrel Cobb and RSO Capt Reggie Blackwell's mission objective was to conduct a coordinated EMR/HRR sortie to determine if the North Vietnamese had acquired new equipment or employed updated procedures for the SA-2s that was responsible for generating such high B-52 losses. To achieve this, the SR-71’s arrival over the Haiphong/Hanoi areas was timed at precisely the exact moment that 60 B-52s were to begin dropping their bombs on the rail yards at Lang Dang, Duc Noi, and Trung Quant, the Van Dien supply center, and three missile sites.

With the Norths defensive radar systems running at full stretch to cope with the raid, intelligence planners reasoned that this would be an ideal time for such a sortie. In addition, the SR-71, with its unmatched ECM suite, would provide additional electronic support for the bombers.

As they arrived at the collection area on schedule, Cobb and Blackwell observed numerous SA-2 firings. During the fleeting moments when they were crossing the immediate target area, they were able to radiate a blinding ECM blanket. During the course of the raid, only one Guam-based B-52 was lost. Darrel and Reggie landed back at Kadena at 0239 hours. The next day they learned that their mission had produced a wealth of intelligence data.

The two 60-bomber raids launched on the final two nights of Linebacker II saw all B-52s arrive back at their bases safely. Following the action on the night of 29/30 December, the North Vietnamese government expressed a willingness to return to the negotiating table.

The Habus had faithfully recorded a record of Linebacker's enormous level of destruction. The conflict in Vietnam ended for the United States when the Paris Agreement was enacted on 27 January 1973.

Lockheed Blackbird: Beyond the Secret Missions by Paul Crickmore

Post~Linda Sheffield Miller

Thank you, Chris Cobb

@Habubrats71 via X

12 notes

·

View notes

Text

Traction Control Systems and Chassis Control Logic

Introduction

The two most important pillars in the field of automotive engineering are performance and safety. Automakers have always tried to find a balance between these crucial elements as technology has developed.

To achieve that balance and ensure that cars provide the best possible performance while upholding the highest standards of safety and stability, contemporary developments like Traction Control Systems (TCS) and Chassis Control Logic (CCL) are essential. Modern cars now come equipped with these technologies, which increase their dependability and efficiency in a variety of driving scenarios.

The fundamentals of these technologies, their constituent parts, their interactions, and the numerous advantages they offer to the driving experience are all examined in this blog. We can understand TCS and CCL’s function in modern car dynamics by comprehending how they operate.

Traction Control Systems (TCS)

The purpose of Traction Control Systems (TCS), a crucial part of an automobile’s electronic stability control system, is to preserve the best possible wheel traction when accelerating.

The chance of losing traction in difficult driving situations rises as cars get stronger and can accelerate more quickly. TCS mitigates this risk by limiting excessive wheel spin, particularly when the car accelerates on slick terrain like snow, ice, or wet roads.

Crucial Elements and Roles of Traction Control Systems

Wheel-Speed Sensors: To track the wheels’ rotational speed, TCS installs sensors on each wheel. The system receives real-time data from these sensors and uses it to identify any variations in wheel speed, which are a sign that one or more wheels are sliding or spinning more quickly than the others.

Engine Control Module (ECM): The engine control module, or ECM, is in charge of regulating engine power to stop wheel spin. To minimize slide, the ECM can temporarily lower engine power to a tire that begins to lose traction by adjusting ignition timing or reducing throttle input.

Brake Actuation: TCS can apply brake pressure to particular wheels in addition to managing engine power. By slowing down the spinning wheel and redistributing torque, this aids in the vehicle’s traction recovery.

Intelligent Control Logic: Smart control algorithms in advanced TCS systems evaluate sensor data to identify the optimal strategy for traction maintenance without sacrificing performance. By limiting excessive wheel spin, these technologies help to maintain the best possible vehicle stability.

How TCS Works in Practice

The technology continuously tracks each wheel’s speed when the driver accelerates. The system kicks off when one or more wheels start spinning more quickly than the others, which is a sign of a loss of traction.

Either either lowering engine power or by selectively applying the brakes to one or more wheels, TCS can step in. Without requiring any input from the driver, the intervention is mild yet effective, enabling the car to restore traction swiftly and safely.

CCL, or chassis control logic

A collection of advanced technologies and control systems known as chassis control logic (CCL) maximizes a car’s handling, stability, and general driving characteristics. By combining several vehicle control technologies, this system improves performance and offers a controlled, balanced, and smooth driving experience.

The car can adjust to a variety of driving circumstances thanks to the interaction between CCL and other systems including TCS, ABS (Anti-lock Braking System), and ESC (Electronic Stability Control).

Essential Elements and Purposes of Chassis Control

Electronic Stability Control (ESC): ESC stands for Logic Electronic Stability Control. An essential component of CCL is ESC. Using the brakes selectively and, in certain situations, lowering engine power to steady the vehicle, helps avoid skidding and losing control. It works especially well when there are abrupt turns or when a car starts to oversteer or understeer.

Anti-lock Braking System (ABS): ABS keeps the wheels from locking up when applying severe braking, preserving steering control. By distributing braking forces evenly among the wheels, ABS makes it possible for the car to stop swiftly and safely without losing stability.

Electronic Brake-force Distribution (EBD): EBD modifies the brake force distribution between the front and back wheels to maximize braking. Road conditions, speed, and vehicle load are some of the variables that affect this adjustment. ABS and EBD combine to enhance total braking performance.

Adaptive Suspension Systems: Adaptive suspension systems, which automatically modify shock absorber settings, are a characteristic of certain cars with CCL. Through improved cornering stability, a smoother ride, and road condition adaptation, these systems can improve handling.

How CCL Works in Practice?

CCL collects information from a variety of sensors that track the activity of the car. These sensors, which identify any changes in the dynamics of the vehicle, include wheel-speed sensors, gyroscopes, and accelerometers.

To guarantee the best handling and stability, the CCL system continuously modifies the suspension, steering, braking, and other vital components based on this data. To restore stability, the system might, for example, alter engine power, change the suspension, or apply brakes to particular wheels if it notices a loss of traction during a turn.

The Advantages of Chassis and Traction Control Systems (TCS)

Logic of Control (CCL)

Numerous benefits that greatly enhance vehicle performance, safety, and stability are provided by both TCS and CCL. These technologies make modern cars more reliable and flexible for the driver by improving their performance in a variety of driving situations.

Traction control systems (TCS) advantages

Enhanced Traction: Even in slick weather like rain or snow, TCS makes sure the car keeps its maximum traction by minimizing wheel spin. As a result, the driver can continue to steer the car without fear of losing control.

Better Acceleration: TCS helps to make acceleration more controlled and smooth. TCS ensures that power is delivered to the road effectively during rapid acceleration by preventing wheel spin, which improves vehicle performance.

Decreased Skidding Risk: TCS improves overall vehicle stability by reducing the chance of skidding during abrupt turns by enhancing traction and managing wheel spin.

Enhanced Off-Road Capability: TCS makes sure the car maintains traction when driving off-road or on uneven terrain, assisting drivers in navigating difficult situations.

Enhanced Safety: By reducing traction loss, particularly during fast twists or emergency maneuvers, TCS greatly increases safety. This facilitates drivers’ ability to keep control, especially under challenging circumstances.

Easy to use: TCS is a completely automated system that doesn’t require any input from drivers, thus drivers of all experience levels can use it. Overall driving safety and confidence are raised as a result.

Chassis Control Logic’s (CCL) advantages

Better Management: CCL improves a car’s handling and cornering skills by modifying the steering and suspension. This makes driving more responsive and smooth, especially when negotiating tight curves or difficult road conditions.

Enhanced Stability: CCL enhances stability, especially when navigating curves or performing fast turns, by coordinating with other systems like ESC and ABS. This lessens the chance of skidding or rollover, particularly in higher cars like trucks and SUVs.

Optimal Braking: By ensuring that the vehicle’s braking power is distributed evenly across all wheels, ABS and EBD work together to improve brake efficiency and shorten stopping distances.

Customized Driving Modes: Certain cars with CCL include driving modes that can be changed, such as sport, comfort, and eco. To suit the driver’s preferences and the state of the road, these modes modify the throttle sensitivity, steering response, and suspension firmness.

Improved Vehicle Control: By enhancing vehicle control, features like torque vectoring and variable steering assistance make it simpler to handle challenging driving situations.

Decreased Tire Wear: CCL helps avoid uneven tire wear by more uniformly transmitting forces over all four wheels, which extends tire life.

The disadvantages of chassis control logic (CCL) and traction control systems (TCS)

Although TCS and CCL have many benefits, these systems do have certain disadvantages.

Traction control systems (TCS) disadvantages

Diminished Power Output: TCS may briefly lower engine power or apply braking force when it steps in to limit wheel spin. This may cause a brief drop in acceleration performance, which in some circumstances — particularly for high-performance cars — may not be acceptable.

Loss of Driver Control: For seasoned drivers who would rather manually control traction, TCS intervention may occasionally feel excessively harsh. A sense of lost control may result from this.

Limited Off-Road Effectiveness: Although TCS works well on paved roads, it may not operate as well off-road, especially when negotiating obstacles that need wheel spin for traction.

False Activation: On rare occasions, TCS may mistakenly identify wheel slips in traffic or under mild acceleration, resulting in needless interventions that could irritate drivers.

Cost and Complexity: Production costs and vehicle complexity are raised by the incorporation of TCS systems. Over time, this may lead to increased maintenance expenses.

Chassis Control Logic (CCL) drawbacks

Enhanced Intricacy: The combination of many control systems, such as adaptive suspension, ABS, and ESC, can result in a complicated configuration that can be expensive and challenging to fix.

Dependency on Sensors: Electronic components and sensors are crucial to CCL. The whole functionality of the system may be impacted if any of these parts malfunction, raising safety issues.

Driver Adaptation: When the system modifies the handling or responsiveness of a vehicle, some drivers may find it difficult to become used to the new behavior.

Restricted Off-Road Capability: Although CCL improves handling and stability on roads, it might not provide the same advantages off-road, where other factors are in work.

Environmental Impact: Non-electric vehicles may use less fuel due to the increased energy consumption caused by the additional electronic components needed for CCL systems.

Conclusion:

To sum up, modern cars have been transformed by revolutionary technology like Chassis Control Logic (CCL) and Traction Control Systems (TCS).

Together, these systems enhance vehicle performance, safety, and stability, enabling cars to confidently traverse a variety of road conditions.

Although there are certain disadvantages, these technologies’ advantages in improving driving comfort and safety greatly exceed any possible difficulties. We may anticipate that these systems will grow even more as car technology develops, improving everyone’s driving experience.

We at Dorleco are at the forefront of automotive technology, offering state-of-the-art VCU, CAN Keypads, and CAN Display products suppliers and E/E Software services that improve the performance, stability, and safety of automobiles.

Our cutting-edge Chassis Control Logic (CCL) and Traction Control Systems (TCS) are made to provide exceptional driving control, smooth handling, and maximum traction in any situation.

The TCS and CCL technologies from Dorleco guarantee a more responsive, safe, and comfortable driving experience by controlling slick surfaces, boosting acceleration, and improving overall vehicle stability.

Every step of the way, Dorleco gives drivers performance, confidence, and peace of mind because of our dedication to innovation and quality. For the future of superior automobiles, rely on Dorleco.

#TractionControl#ChassisControl#Autonomous Vehicle#Dorleco#CANKeypads#CANDisplays#VCUs#Vehiclecontrolunit#EVSoftwareServices#E/Earchitectures

0 notes

Text

Immobilizer and ECM Repair Training Institute in India

Hi-Tech Skill Development Academy offers comprehensive Immobilizer Repair Training in India, providing specialized courses to help you master key immobilizer repairs and ECM (Electronic Control Module) diagnostics. Our Car ECM Training Institute offers expert training across India, teaching students how to troubleshoot and repair immobilizers and ECMs. With a curriculum designed for beginners and professionals, our courses cover essential skills such as diagnosing key immobilizer issues, understanding ECM systems, and repairing automotive control units. Whether you're pursuing a career in automotive technology or seeking advanced skills, Hi-Tech ensures hands-on experience and industry-relevant knowledge. Gain the expertise needed to succeed in this rapidly evolving sector and boost your career with Hi-Tech’s training programs in immobilizer and ECM repair.

#ImmobilizerRepairTraining#ECMTrainingInstitute#CarECMTraining#AutomotiveRepairIndia#ECMRepairIndia#ImmobilizerRepairIndia#AutomotiveTechnologyTraining#AutomotiveRepair#KeyImmobilizerTraining#ECMRepairCourses#CarRepairCourses#AutomotiveTrainingIndia#AdvancedAutomotiveTraining#HiTechSkillAcademy#ECMRepair#ImmobilizerDiagnostics#AutomotiveRepairSkills#CarDiagnosticsTraining#IndiaAutomotiveTraining#CarECMRepair#ImmobilizerTrainingIndia#AutomotiveEngineeringIndia#VehicleECMTraining#CarMechanicTraining#AutomotiveTechnology#ImmobilizerCourses

0 notes

Text

Understanding Diesel Performance: Enhancing Efficiency and Power

Diesel engines have long been celebrated for their durability, fuel efficiency, and power. However, to truly unlock their potential, understanding diesel performance is essential. Whether you rely on diesel engines for commercial, agricultural, or personal use, improving performance can lead to better fuel economy, reduced emissions, and enhanced overall engine life.

What Is Diesel Performance?

Diesel performance refers to optimizing an engine's capability to deliver more power and efficiency without compromising its reliability. Achieving this balance often requires a combination of mechanical upgrades, electronic tuning, and regular maintenance.

Factors Influencing Diesel Performance

Airflow Efficiency: Diesel engines operate through compression ignition, which requires a precise air-to-fuel ratio. Improving airflow with high-performance intake systems and turbochargers can significantly enhance combustion.

Fuel Delivery Systems: Upgrading fuel injectors and using high-quality fuel ensures proper atomization and reduces engine strain.

Exhaust Optimization: Diesel particulate filters (DPFs) and performance exhaust systems improve exhaust flow, reducing backpressure and improving efficiency.

Engine Tuning: Modern diesel engines often come with electronic control modules (ECMs) that can be reprogrammed to optimize performance parameters like fuel timing and boost levels.

Benefits of Improving Diesel Performance

Investing in diesel performance upgrades benefits more than just engine power. Enhanced performance often translates to better fuel economy, reduced environmental impact, and extended engine life. Properly maintained diesel engines with optimized performance can also handle greater workloads, making them invaluable for industries like transportation and construction.

Understanding and improving diesel performance is not just about power it's about efficiency, reliability, and sustainability. By focusing on critical components and staying consistent with maintenance, you can ensure your diesel engine operates at its peak for years to come.

#1hz engine for sale#cars#classic car#luxury car#bmw#audi#engine rebuild kits#car engine repair#batman

0 notes

Text

Selecting the Right Enterprise Content Management Tool: Key Features to Consider

Choosing the appropriate Enterprise Content Management (ECM) tool is crucial for organizations aiming to optimize document handling and enhance collaboration. This guide outlines essential features to consider when selecting an ECM solution, including document management, version control, access control and security, workflow automation, integration capabilities, scalability, mobile accessibility, and analytics and reporting. By prioritizing these features, businesses can ensure the chosen enterprise content management tool aligns with their unique requirements, leading to improved efficiency and collaboration. Visit Us- https://www.quora.com/What-Are-the-Key-Features-to-Look-for-in-an-Enterprise-Content-Management-Tool/answer/Stock-Holding-DMS-1?prompt_topic_bio=1

#workflow management#shredding services#vdr in mumbai#document storage#paper shredding services#workflow management system#document shredding services#digitizing services#best document management system#best data room solution

0 notes

Text

Today organizations need to manage and migrate mission-critical documents, something essential to achieve efficiency as well as regulatory compliance. And since with the ever-advancing pace of enterprise content management (ECM) systems, organizations are now moving from Documentum migrations to cutting-edge cloud-based solutions like SharePoint. If you understand the detailed functioning of Documentum migration and would like to know the advantages this migration has concerning SharePoint, then this best guide would help you understand and make proper decisions.

0 notes

Text

ECM Diagnostics & Scanning - AutoWorx

Autoworx specializes in ECM diagnostics and scanning services to keep your vehicle running at its best. Your engine control module (ECM) is the brain of your car, managing essential systems like fuel injection, ignition timing, and emissions control. When something goes wrong, precise diagnostics are key to identifying and resolving the issue quickly.

Our team uses advanced scanning tools to read and interpret error codes from your vehicle’s ECM. Whether it’s a check engine light or subtle performance issues, we pinpoint the problem and recommend the right solution. This ensures accurate repairs and minimizes guesswork, saving you time and money.

At Autoworx, we don’t just scan and clear codes – we dig deeper. Our technicians are trained to identify the underlying causes of ECM errors, so you’re not stuck dealing with the same issue again. From sensor malfunctions to wiring problems, we ensure everything is working as it should.

With a focus on quality and efficiency, our ECM diagnostics service gives you confidence in your vehicle’s performance. If your car isn’t running quite right or warning lights are showing, trust Autoworx to get to the root of the problem. Reliable diagnostics, expert care – that’s the Autoworx way.

Visit: www.autoworxsp.com.au

0 notes