#electrical box roll forming machine

Explore tagged Tumblr posts

Text

Hexbug TM

Once again blame the server. I have no excuses for this one.

(Arcane lore + LOL Machine Herald)

Title: Hexbug TM

WC: 2029w

Summary: Jayce's constant need for revenge manifests itself into ingenuity. Very unfortunately for Viktor, Jayce has his sights set dead square on him.

--------------

Ever since setting up shop with the Machine Herald, Jayce had been getting in a few more fights. Not to the extent of his previous position as the Defender of Tomorrow (who according to the Piltover Press was on sabbatical) but more petty spats with chempunks. He had to admit that a couple of these had been started on purpose, much to Viktor’s chagrin. Viktor, in his high and mighty Herald-ness, thought petty fights were beneath him. Which is why it was such a surprise for Jayce when he walked with his arm half torn off and a hole in his side.

“Hey, V- holy fuck! What happened?” Jayce rushed over, taking some of the weight off Viktor’s dead arm from him.

“Some idiot decided to try and scam a child. I stepped in.”

“What’s this I hear from Mr No Unnecessary Fighting?” Jayce couldn’t help but tease, even if the hexclaw singed his hair for it.

“This fight was necessary. Are you going to help, or stand there?”

Jayce rolled his eyes. “Yeah, yeah, don’t get pissy. Wow, they really did a number on you huh?”

He poked into the mess of wiring that was the cavern in Viktor’s side and he squirmed away.

“Stop that. Get me over to the table.”

The table was the one in the corner, kept clear and reserved for when one of them fucked up so badly they had to be put back together. Normally it was Jayce on the table. Viktor hauled himself up onto the table and unclasped his mask, tossing it to the side. His face was contorted in discomfort - while his modifications dulled pain, it could not remove it completely.

“How does it look?” He asked Jayce, his tone betraying his anxiety. Jayce peered at the arm, and then into his side.

“Hmm. The arm is only torn at the hinge, and none of the wiring broke so that will be an easy enough fix. You’ve demolished some plates on your ribs and the wiring is a mess so that will need a little more time. Jeez, what did they hit you with?”

“Death ray.”

Jayce gave Viktor a deadpan look and Viktor raised his eyebrows. “It was purple.”

“Sure. Anyway, let's get this armour off and get you fixed.”

Once the armour was off and Viktor had laid down, Jayce pulled out a box lovingly labelled as ‘Vik’s Robo Parts’ and got to work. They kept up conversation the whole time, and Viktor admitted it took him longer to get back because he wanted to make sure the kid was looked after. Jayce should have expected as much - for the stubborn front he put up, Viktor sure had a soft spot for children.

It took about an hour and a half of work to fix everything back up, not without complaints from Viktor.

“You’re soldering that wrong, I can feel it.”

“No, I’m not. I’m soldering it my way, which is the correct way and not your weird version.”

“Mine is superior and holds stronger. Redo it.”

Jayce sat back and put the soldering iron in its stand. “Do you want me to get the cattle prod while you're immobile here?”

Viktor glared, but couldn’t help the flush that rose to his cheeks. They had recently discovered that powerful electricity had a very different effect on Viktor than it did Jayce. It turns out that when you shock someone who has partially metal nerves, it tickles like hell. Jayce had used this incessantly when Viktor was being annoying and it pissed him off to no end, never mind the fact that Viktor himself had a bad habit of using the hexclaw to torment Jayce. When he was the victim, it was a hate crime in his eyes.

“If you do, I will put that fun powder I made in a random set of your socks and wait for you to put them on.”

Now it was Jayce’s turn to blush. The powder referenced was an accidental concoction of Viktor’s that made the victim ridiculously sensitive to any form of touch. Getting the stuff off was bad enough, but the fastest way to dissolve the effects was to provide… certain stimulation. This war between the two had been going on for months, and at this point Viktor was winning.

Viktor huffed out a smug laugh. “That’s what I thought.”

Jayce gave him a weary look and went back to screwing the plates into Viktor’s side. He kept his face schooled as he carefully slipped a small disc under the panel without Viktor’s knowledge before screwing it closed.

“Well, there you go. Good as new.” Jayce stood and wiped his greasy hands on a rag.

Viktor powered half his body back on with an audible whirr, flexing his arm and feeling hte plating on his ribs.

“Decent.”

“Just decent?”

Viktor groaned. “What do you want from me? ‘Oh Jayce, it’s the most wonderful repair ever! However may I thank you, big strong beefcake who has come to save me?’”

Jayce couldn’t help but laugh at Viktor’s ridiculous impression of himself. “Well I don’t know, that could be nice. Being called a beefcake is a plus.”

Jayce flexed his arms in jest and Viktor recoiled.

“Forget it, I am never speaking to you again.”

“You don’t mean that.”

“This time, I do.”

In the week following life went on as usual, and while Viktor did have to stitch up Jayce’s leg after someone decided to run at him with a knife it was uneventful. Which is the perfect environment for them to start pissing each other off. This time Viktor had left blueprints all over Jayce’s workstation.

“Viktor, is it seriously that difficult to pick up after yourself?”

Viktor shrugged, not even looking at him. “My lab, my space.”

“Which you are currently sharing.”

“What did I just say? My lab.”

Jayce huffed, stashing the blueprints into the box they came out of. “You are a problem.”

“Oh, I’m a problem now? I wasn’t a problem when you ran into a knife two days ago. I even gave you lidocaine.”

“You’re like if a tin can could speak and it was bad.”

Viktor turned to throw a piece of chalk at his head. It missed, so he turned back to his board with a grumble and realised he had in fact just thrown his last piece of chalk. Jayce could almost see the steam rising off his shoulders.

“Jayce. My chalk, if you please.”

“Hmm… no.”

“What?”

Jayce laughed at the slightly dumbfounded look on Viktor’s face. “You chuck chalk at my face and expect me to give it back?”

Viktor started striding across the room towards him. “Motherfucker I am going to strap you down to a table and make you feel torture like you’ve never known.”

“Not if I get there first.”

Jayce jammed a hand in his pocket and closed it around a small remote, flicking the switch on the side and turning the knob up three clicks of the seven that were on it. Viktor stopped in his tracks and shrieked, falling to his knees and clawing at his side as a loud zapping noise started. He tried to speak, but Jayce turned the dial up another level and Viktor keeled over on his side, laughing.

“JAHAYCE!”

Jayce turned the dial down to one, watching Viktor giggle and catch his breath.

“Whahat did you dohoho?”

“Hexbug.” Jayce said, turning the dial up and down again and making Viktor cackle.

“Ehehe… elaborahate!”

“I made it! I took a cattle prod apart and made a little bug out of it. It can emit the same shocks that the prod does. Cool, right?”

“NohohOT COOL! Why- ahaha! Why is it insihide me?”

“I put it there.” Jayce played with the dial, turning it up and down for fun. “And it means I can do this.”

Jayce placed his thumb on a joystick and Viktor felt something inside him move. The awful ticklish feeling was centred over a spot on his ribs, but that was now rapidly crawling down his side. The current stopped and Viktor felt tiny legs latching onto the wiring in his chest and crawling around. Viktor barely held back a yell as he fell backward onto the floor, kicking uncontrollably. Jayce knew the wires he was messing with connected to his nerves. At least if it was maintenance he could smack away his hands but this? He couldn’t exactly rip apart his own chest, no matter how badly it tickled.

“JAHAYCE YOHOU AHAHASSHOLE!”

“Aw, does that tickle?”

The bug burrowed into a section of wiring near his spine and zapped again, making Viktor jolt. Jayce noticed the reaction and sent the bug on a fast paced adventure of his internal wiring, zapping at random intervals. This very quickly dissolved Viktor into a squirmy, hysterical mess.

Jayce watched the carnage with a grin, turning down the voltage and piloting the little bug up Viktor’s spine until it was sitting near his central nervous controls. Viktor’s eyes widened when he felt the bug step onto the motherboard.

“Jayce- Jahayce I don’t think you realise what this will do to me-”

“Really? Cause I think it’s gonna tickle really badly.”

The bug walked fully onto the board and Viktor made a choked noise, half a laugh in his throat already.

“I wanna see what each voltage does here.”

“Jayce, no!”

“Why? Is it gonna tickle?”

Viktor felt the bug electrify and the popping noise started, along with what felt like a gentle, unbearable tickle throughout all the metal parts of his body.

“Shihit! Ihit’s everywhehere!”

Jayce lit up like the sun, and Viktor knew he shouldn’t have opened his mouth. “Wait, that translates to all the augmentations?”

Viktor didn’t confirm, and he didn’t need to.

“So what you’re saying is if I turn this up here it’s going to tickle all over?”

Jayce turned the dial up to level two, and he broke.

“YEHES!”

Jayce leaned in with a grin. “Good.”

The dial turned up to three, and then four. Viktor screamed.

“Four… five…”

“PLEHEHEASE AHAHAHA!”

“Six…”

“IHIT TIHIHICKLES!”

“Aaaand seven!” Jayce counted through all the levels, paying close attention to how Viktor reacted with each one. At the highest level he could see the electricity arcing over Viktor’s body while the man thrashed on the floor, completely lost in his own frenzied laughter. Jayce let him sit through the torture for a few seconds before turning the dial back to zero and switching the remote off.

Viktor curled into a ball on the ground, still giggling at the last zaps of the current.

“How are you feeling?”

“...how do you THINK?” Viktor spat, sitting up. His hair was a tousled mess and his face was flushed adorably. “You just tickled me from the inside! I didn’t even know that could be fucking done!”

Jayce felt a little bad. Just a little. “If you hop on the table I’ll remove the bug.”

Viktor heaved for breath and held out a hand to stop. “No, no, just leave it. I can’t be bothered going through the rigmarole. I do ask that you don’t leave it directly over my nervous system though.”

“Oh!” Jayce started, turning on the remote again. The bug took a step and Viktor arched his back, squeaking.

“Ah, sorry. Heh. This will tickle.”

He carefully drove the bug down to Viktor’s side while his partner tittered, placing it somewhere he could easily access the next time Viktor took himself apart. Jayce turned off the remote and placed it on his desk.

“You deserved that.”

Jayce got a hexclaw middle finger in response. Viktor stood and brushed himself off.

“I hate to admit it, but I do have to hand it to you. I did not see that one coming.”

Jayce beamed with pride, and Viktor caught his expression with narrowed eyes.

“This is not something to celebrate, Jayce. See, now I must one up you. Prepare yourself.”

Viktor picked up his thrown chalk and went back to his equation, leaving Jayce sweating by the desk. He had just hammered in the final nail of his own coffin.

#tickling#arcane tickling#jayce talis#viktor arcane#lee!viktor#jayvik#arcane tickles#arcane jayce#vikjayce#machine herald viktor#machine herald tickling#hexclaw

47 notes

·

View notes

Text

Woven Wheel

Pairing: Hobie Brown x fem! Reader/ Spider-Punk x fem! Reader

Word count: 4.3k

Tags: use of Y/N sparingly, no specific physical description of the reader (except for her clothing), Hobie is taller than the reader, CW food, FLUFF.

My Navigation

Thread the Needle Masterlist

CHAPTER 5 >>> CHAPTER 6

You sit on Hobie's rickety chair, on your lap is his emerald bed sheet, your hands expertly stitch together the large hole on the side of the cloth. Eyes glued to what you're doing, you don't notice Hobie's piercing gaze.

He's crouched over to the other side of the room, fixing the wiring of his answering machine. Hobie watches your cherry earrings sway as you move your head to the side to inspect your handiwork. The bags under your eyes are more prominent than the last time he saw you. He sighs, fingers wrapping around the wiring of his answering machine.

Hobie should've been more persuasive at telling you to stay home and get some much needed rest. But you being you, you won the argument, telling him that it'll be your place too once you graduate so you should come over and help with the cleaning and fixing. With that you already won, but then you added the fact that he already used a ticket from your favour card. Rolling your eyes through the payphone's receiver as if he can see you, you tell him that you always keep to your word. He relents, the only thing he can do now is to make sure you don't get too tired, opting to give you the easiest job, even if he means he has to do more.

So here you are sitting in his sparse living room, mending his bedsheet, watching as James walks over to you. You smile politely to the blonde, making small talk.

"You're gonna burn a hole right through her" Ned appears out of nowhere, whispering right in Hobie's ear.

Hobie pushes him off, Ned cackles at his annoyed reaction. "Fucker"

"You look like a lovesick teen, just go fuckin' tell her, you idiot" Ned sits down to Hobie's level, whispering to him. "Seriously, go do it before someone else does" as Ned says this, you laugh at something James said, the blonde smiles sheepishly at you. "Also I need to see you two finally get together before I leave. I deserve that much after watching you two yearn for each other the entire time I've known you lot"

Hobie frowns at what Ned says, fingers twisting the wiring in his hands faster, he jumps when a sudden jolt of electricity shocks him, the wiring falling from his hand "Fuck!" He yells, holding and shaking his hands.

You perk up, attuned to his scream of pain, stopping mid conversation. "You okay, Hobs?" Handing the linen to James, speed walking the small distance towards Hobie's crouched form. "The hell did you do?" Crouching down, you hold his hands gingerly, massaging his calloused fingers. Probably the opposite of what you should do when somebody gets electrocuted.

"I'm okay, just a shock is all" Hobie stares at your hands gingerly holding his. You nod, still a little concerned.

Ned chuckles, Hobie stares daggers at his friend, shutting him up, a faint smirk staying on his lips. "Maybe you should let Yuri do that, she's good with that kind of stuff" Ned teases Hobie more.

"Let me do what?" Yuri enters the boat, a large box in her hands.

"I have it," Hobie grumbles.

You stand up, dropping Hobie's hands on his side, "oh, let me help you with that"

Ned stops you before you could get your hands over to the box. "Got it, y/n"

"I got it" Yuri lightly shoves Ned away, "I'm not a damsel in distress" she walks towards the pile of boxes on the side of the boat, dropping the large box next to the pile, "see, no sweat"

"When's lunch?" James pipes up, still holding Hobie's bedsheet.

"Mate, you barely did anything" Ned scrunches his nose, "you're right though, when's lunch, Hobie?"

You laugh, Yuri rolls her eyes, a ghost of a smile on her red lips.

"Bunch of leeches, the lot of you" he murmurs. Tapping you on your arm, "what do you want?" Hobie asks you.

"Pizza or fish and chips" Ned says before you could answer, a teasing smile on his lips.

"I asked her not you" Hobie huffs.

"I second that," James agrees, pointing at Ned.

"A coke too," Yuri adds.

"Christ" Hobie places his hands over his hips, "you good with either?" He turns his head towards you.

"A large coke for me, please" you add to the teasing.

"I expected better from you" Hobie narrows his eyes, you giggle at his expression.

—

The chair creaks from under you, finishing the last stitches on the bed sheet, you try to make conversation with Yuri. She sorts through the various boxes for some utensils to eat with. The men left a few minutes ago to buy lunch, leaving you and Yuri inside the Houseboat.

"So what are you gonna study?" You break the silence.

"Getting right to the point, huh?" Yuri teases but you take it too seriously, eyes widening, afraid that you might've offended her.

"Sorry, I didn't mean–"

"I was joking," Yuri stops her perusal of boxes, now looking straight at you with her piercing gaze, "you can ask" she chuckles, "seriously, don't apologize"

"Oh, okay, sorr–" Yuri raises a sharp brow, you backtrack, suddenly nervous from her stare, "right, so um, what are you gonna study?"

Yuri smiles, "Architecture, I know, it's a surprise, huh?" She gestures towards her dark clothes, combat boots and spiked denim jacket.

"Kind of? I mean look at me, do I look like a fashion student?" Gesturing towards your not so plain clothes, but still pretty tame from what you used to wear back in the day. You opted for a pair of bell bottomed jeans instead of your usual straight cut denim, your long sleeved blouse rustles slightly when a draft blows in. The detailed design of hummingbirds stitched on the collar of your shirt practically comes alive every time you turn your head. You're slowly trying to ease back to your usual self, following Danny's advice. And it actually works since you had a major breakthrough with your design a few nights ago. You're keeping it a secret, a little surprise for your model.

"You're a fashion student?!" She feigns surprise.

Chuckling, you see why her and Hobie are friends.

"I joke" Yuri winks, "I stopped tryin' to blend in a looong time ago" she crosses the small threshold, sitting in front of you on an equally rickety chair, "you look different, they stare, you look plain, they whisper. You can't bloody win. Might as well be myself out of spite, right?" she lifts her leg to cross it over the other. "Così va il mondo'' she sighs.

"Such is life" you translate, Yuri smirks, eyes twinkling.

"I see why Hobie likes you so much," she leans on the wooden table, elbows propped up, hand holding her chin. "You're not just pretty, but smart too, huh?"

Smiling genuinely at her, you take note of her freckles, dotting her face like stars, her septum piercing glinting in the low light of the lamp you've placed on the table.

The door to the houseboat swings open, the boys' bickering slices the silence inside the boat.

"Fuckin' told you to hold it on its side!" Hobie argues with James.

"I did! It slid down! I can't control gravity, Hobie!" James retaliates.

Ned enters the space first, he looks so out of it, face frowning, exasperated at his two companions. He holds a liter of coke in his hand, the other a plastic bag of something hot inside.

Yuri side eyes you, shaking her head at the men arguing, you chuckle. She stands up reluctantly, going towards the pile of boxes to take out the utensils.

You follow her lead, walking to meet halfway with the tired Ned. He hands you the bottle of coke.

"I feel like I've aged ten bloody years"

You chuckle, helping Ned place the food on the wobbly table.

"Wait, place it on the floor, that table's not stable enough" Hobie stops you, grabbing the soda bottle from your hands, he juggles it in between the paper bag he's carrying.

"I got it, Hobie" you take the bottle from his hand, " 's not that heavy, you're already carrying too much"

"Where do we eat then, doofus?" Yuri asks the question that's on everyone's mind, she holds plates of various sizes in her hands, mismatched spoons and forks placed on top of the ceramic, in her other hand are mugs, hanging precariously on her ring clad fingers.

"Well, idiot," Hobie retaliates, "the floor is your best friend" He sits down on the newly polished floor, the wood gleaming in all its glory. The paper bag almost spills over when he sits down, grabbing the top of the bag before the contents decorate the clean floors.

"The chips!" James dramatically yells.

"They're fine!" Hobie clicks his tongue, he taps the floor next to him. "Right here, y/n" he softened up when he said your name.

You don't waste a second to cross the space, dropping down next to him. You sit criss crossed, cradling the liter bottle like a baby.

"You need a dining table or at least a settee that doesn't give you tetanus when the spring pokes you" Ned unceremoniously sits down, adjacent to you, he yelps when hot oil singes his finger. "Where else are we gonna sit?" He licks the oil off his red fingertip.

"You gonna buy me one, Neddy?" Hobie gives you a box full of chips, you give him a small 'thank you'.

"I'll buy you one if you actually do what we discussed earlier" Ned replies. Hobie narrows his eyes, non-verbally telling him to shut up.

You look at Ned quizzically, he shrugs, handing everyone their share of fried fish. Your stomach grumbles at the sight. Everyone sits in a circle, the pizza box and soda lays in the middle of the group.

Yuri snorts, knowing what he meant. James opens the pizza box, the savory smell coating the small space. He quickly grabs a slice, gobbling it down.

"Bloody hell, use a plate at least. Were you raised in a barn?" Yuri grimaces, handing James a plate. He nods a thank you, mouth full of dough. "Here you go, love" she hands you a couple of plates and utensils.

"Thanks,Yuri" You hand the spare utensils to Hobie, Leaning forward to grab a slice.

"What's all this? You two best mates now?" Hobie asks, biting off a chip.

"You jealous? We're just lookin' out for each other. Ain't that right, sweets?" Yuri winks at you. You stop chewing for a hot second.

Ned guffaws while James laughs with a mouthful of cheese and sauce. Hobie rolls his eyes, handing you his makeshift glass so you could pour him a drink.

You pour him one while Hobie casually rolls your sleeves up to your elbows so you don't splash soda on it. The fizz rises up towards the edge of the mug. "It's not that cold anymore"

"I'll manage" Hobie thanks you by tapping his mug towards yours, it clinks when they meet.

"Best fish and chips in town, fuck I'm gonna miss this" Ned says.

"They have fish and chips in Richmond," Yuri scoffs, biting into the doughy pizza.

"I know they have fish and chips! But not this fish and chips" he shows his plate like a commercial, hand gesturing around his plate.

"They literally all taste the same" James quips, hand reaching for tissues.

"They would taste the same for you because you don't stop to actually taste it" Ned rebukes.

Their banter fades in the background as Hobie scooches next to you, legs kissing yours, "you want my slice?"

"Hmm? You don't like it?" You lean further into him, "is it the cheese?"

"Nah, I just don't like it" he leans towards you, further closing the already small distance, breath mixing in with yours. "It's too.." he tries to find the right word to describe it, "..gooey for me"

You snort at his choice of word "hehehe say it again"

"What's so funny about 'gooey'?"

"You saying 'gooey', big punk Hobie saying gooey is funny" you take the pizza from his plate, taking a bite from it. "Oh, you're right, it is gooey"

"Doughy, fuck that's the word I was looking for"

You giggle, "I think 'doughy' has the same effect as 'gooey'"

"You're very funny" Hobie stops for a second, unabashedly staring at your lips, he brings his thumb over to it, wiping at the corner of your mouth. You don't have time to react, freezing into place. "Sorry, you got sauce on it" he continues wiping, thumb grazing your lower lip. You stare at him, eyes wide, breath hitching in your throat. "Got it"

You clear your throat, "Thanks"

"Oi lovebirds!" Ned whistles to get your attention, Hobie glares at Ned.

"We're not dogs, what the hell do you want?"

"Pass me the hot sauce" Ned points at the packets near your crossed legs.

Hobie scoffs, tossing Ned the packets. It bounces off Ned's mug, almost falling inside his drink. Ned flips Hobie the bird as a thank you. Hobie lovingly answers the same.

The group munches on their food quietly for a few minutes, you relish in the peace. Until James burps. Yuri scrunches her nose, you hide your giggle with a bite of your lip.

"So, what are you planning on doing after you graduate?" Yuri bravely asks, her utensils clinking on the plate as she finishes eating.

"Getting right to the point, huh?" You tilt your head at Yuri, copying the words she uttered a few minutes ago.

Yuri smiles, "aye, you got me there"

Hobie watches the interaction, glad that you made friends with Yuri.

"Well there's this fashion house where an old friend of mine works at, that would be nice working with him. And it's right here in London so I don't have to go far" you wipe your fingers with a napkin.

"Think big, y/n! What's your ultimate goal?" Yuri pats your knee.

"She's right, go big or go home, eh?" Ned chides in.

"You guys are laying it on me, huh?" You shyly say.

"My da applied to the biggest radio station in London when he was younger, he never thought he'd even get accepted! Now look at him, the most famous radio host in the country!" James adds in the conversation.

"Wait, who's your dad?" Hobie asks.

"JJJ" James answers, huffing his chest in pride.

You all look at him surprised, Hobie slowly turns to look at you, mirroring the same expression.

"What the fuck? You're just gonna drop that insane lore just like that?" Ned looks at James, shocked.

"Yeah, and you know what?" James shifts in his seat, hand curling around his drink. "I'm not even gonna elaborate" he snickers, drinking loudly from his mug.

"I see the resemblance" you lean a bit to look at James closely.

"Yeah, just tape a mustache on him and he's a carbon copy" Hobie agrees.

"Let's shut the fuck up about him, yeah?" Yuri cuts in, James softly mumbles out a 'hey'. "You don't even want to tell us" Yuri points a finger in James' direction. "Let's go back to the topic at hand, y/n, what do you want to do after graduation?"

"You don't have to answer if you don't want to," Hobie places his chin on your shoulder, comforting you.

"Aye, you don't have to answer if you don't feel comfortable telling us. I mean I am asking what your hopes and dreams are. It's a tall order." Yuri tells you.

"It's fine, really" you smile bashfully, "I– there's a fashion house in Paris, that I've been dreaming of working at since I was a kid. I guess that's what I want to do after." You fiddle with your thumbs.

Hobie watches the twinkle in your eyes, he smiles sadly at the prospect of you moving so far away from him, but he can't help but feel proud. He sighs, avoiding looking at your face, instead he stares at your discarded plate.

"Now that's the answer I was lookin' for"

"Thought you wanted to model?" James asks, looking confused in your direction. You tilt your head to ask him what he meant. "You two did go to a runway show, I thought it's because you wanted to model or something"

"Oh, that was for research" you answer.

Ned snorts "can't imagine Hobie at a runway show, especially him walking down on it" Ned shields his face with his arms when Hobie throws him another packet of sauce, this time aiming right for his face. It bounces off harmlessly, Ned sticks his tongue out. Hobie mumbles out a 'child', glaring at his friend.

"Mate, show us your runway walk!" James stands up, posing exaggeratedly.

"You first" Hobie lifts his head off your shoulder.

"I asked you first!"

"You asked for jack shit, fuck off" Hobie says flatly. You laugh at them both.

"Yeah, Hobie he did ask you first" Yuri grabs her plate to put in the sink.

"Why don't you do it then?" Hobie raises a pierced brow.

"Sure, If everyone does it" she leans casually on the kitchen island, a towel over her shoulder. "What do you say? You up for a little modeling?" Yuri smirks at you.

"Uh, no thank you" you stand up grabbing yours and Hobie's plates.

"I'll do it, I've got the physic for it" Ned stands up, cleaning up his station. "Let's clean this up, so we have the space"

"Let's goooo!" James grabs his dirty plates, quickly putting it in the sink.

"I've never seen him clean that fast" Hobie whispers to you, taking the plates from your hands. You smile at him, crouching down to take the empty mugs from the floor.

Once the floor gets cleaned (again) James hypes himself up, getting ready to walk. You grab your digital camera from your bag. Maybe if you assign yourself as the photographer they wouldn't notice you not walking with them.

You don't know if it's the sugar high from the soda or James' instigation but whatever it is they all comply. Yuri has a rare grin on her face, Ned punches Hobie's arm while he laughs loudly. James jumps up and down excitedly.

Hobie chuckles when you show him the camera, "go get a good angle of me"

"That's going to be hard" you tease. Hobie elbows your side lightly. Walking to the front of the 'runway', you crouch down for the best angle to take their pictures.

"Alright James! Go" Ned pats James' back.

James walks dramatically, hips swaying from side to side. Once he reaches you, he pouts, exaggerated. Pointing at the camera.

The flash goes off, James nods appreciatively, walking back to the rest of the group. Ned is up next, walking casually. He flips the bird at the camera. You laugh loudly, music to Hobie's ears. He's glad their shenanigans are making you laugh.

Yuri walks like she owns the place, hand on her waist, striking a pose at the end. She pauses for a second so you could take her picture, Yuri throws you a 'rock on sign' with her hand, it shows clearly in the grainy screen. She walks back to the laughing group.

Yuri grabs Hobie's shoulders, shaking him. "Your turn, Hobart!" She chuckles deeply, pushing him towards the starting position, "you better strike a bloody pose or you'll have to do it again!" The other two laugh at Yuri's teasing.

Hobie huffs, walking normally towards you. The instigators yell at him to do it properly.

"Hobie, you fucker! That's not how a proper model walks!" Ned exclaims.

He stops in front of you, the flash goes off, as you laugh at the picture you've taken. Hobie lifts you easily by your arm. You stand up, grinning at him.

"What are you doing?" You say, chuckling.

"You think you could escape? You gotta walk with me" Hobie throws his arm around your shoulder, cackling loudly.

You try to wiggle out of his hold. "Nooo!" Your smile betrays you as you try to hopelessly push him away. Yuri takes the camera from your hand, angling it to take numerous pictures of you two.

You laugh loudly as Hobie imitates (as best as he could) how a model walks, with you in his arms. The flash goes off in tandem with your strides, making it look like you're on an actual runway.

"Love it!" James cheers you on.

"Work it!" Ned adds, clapping his hands.

You stop at the end, grinning from ear to ear. Yuri keeps taking pictures, you're sure it's gonna run out of space soon enough, but it's well worth it. Hobie bends at his waist, grabbing the back of your knees, his other hand slides to your back, looping his arm across it, pulling you to his chest, lifting you off the ground. You yelp, quickly looping your arms to his neck.

"Hobie! What the fu–" click! Yuri captures the moment.

"That one's for the front page!" Yuri laughs, checking the picture on the small screen. James and Ned scooch closer to Yuri, peeking at the pictures. They laugh and smile at the pictures you've taken.

Hobie still holds you up, hands warm against your jeans. "You come here often?" He smiles down at you, eyes twinkling at your flustered face.

"I could strangle you right now" you quip.

"You're not tall enough" Hobie scoffs even though he has a smile on his lips.

"I literally have my arms around your neck"

"Kinky" he narrows his eyes at you, a smirk playing on his lips.

You chuckle nervously, "you can let me go now" you say despite not actually wanting him to let go.

"Nah, you look great in this angle" heat rises in your cheeks when he winks at you.

"Well you don't, you've got a bit of a double chin in this angle" you tease back, almost not getting the sentence out completely because of your laughs.

"I could just drop you, y'know"

"But you won't" you lean up slightly, pinching the back of his neck.

"You sure 'bout that?" He pretends to drop you, you gasp a bit, smacking your palm on his chest. He chuckles at your reaction. "I'm not gonna drop you" he fixes his hold on you.

"Yeah, but I'm getting heavy aren't I?" You grin at how he's trying really hard at carrying you.

"No" he lies, slowly putting you back on the ground.

"Mm-hmm, told you so"

—

You hum as Yuri gives you an unexpected hug goodbye, reciprocating the embrace, you pull away, holding her at arm's length.

"Watch us play at the concert?" Yuri asks you.

"Of course, I'll be there"

"Ohh, we'll definitely win then" Yuri goes in for another hug, squeezing you.

You and Hobie stand on the boat, watching them drive off in Yuri's beetle.

The sun slowly sets in the horizon, bathing the boat in its orange light. A breeze rushes past, hugging your coat tighter around you.

"You want a ride?"

"Ride?" You got distracted by the rays hitting his face just right, accentuating his sculpted face.

"Yeah, ride y'know, vroom vroom?" He acts as if he's revving his motorcycle's engine.

You laugh again, face hurting from all the smiling. "Are you trying to get rid of me already?"

"Never" he holds the crook of your elbow. "You're not too tired?" Concern on his face.

"A bit, but I'm not done yet with your bed sheet" you stand closer to him, the tips of your shoes kissing his. "Why do you have so many holes in them? I think I know what to get you for your birthday"

"I'm genuinely excited for new bed sheets" he rubs your arm, warming you.

"That's a sign you're getting old"

"Fuck off, I'm only a year older than you" he scoffs with no ounce of malice in it.

"Mm-hmm you're a homeowner now, how does it feel Mr. Hobart Brown" you lift an imaginary microphone to him. He finds your playfulness endearing, smiling softly at your good mood.

He plays along, leaning towards the invisible mic. "It'll be better once you've moved in"

You bite your lip, bashfully looking at him through your eyelashes. Moving the mic back to you "You've gone soft, can you tell us about that?"

Hobie sighs loudly, almost blurting out exactly why he's gone soft around the edges. He holds your wrist, pretending to talk into the imaginary mic "Well Ms. L/n, it comes with age" he surrenders just so he can hear you laugh wholeheartedly again.

"Knew it" You poke his chest. "Now, let me help you set up your bed. I can't let you sleep on the floor"

He bites his tongue at the innuendo that appears in his mind, "I'm not gonna sleep on the floor, I have a mattress"

"Yeah, a mattress that's on the floor!" You put your hands on your hips.

Hobie surrenders to you once again, at least he gets to hangout with you more. He's already getting ready for the screaming match when you two get frustrated with building the complicated bed frame.

—

You run from the metro station, legs straining, huffing, trying to regulate your breathing. Maybe it's a mistake to wear your new boots to the show, your heels clack against the hard pavement, increasing your chance of stumbling and breaking your ankle.

Fuck, fuck, fuck! You internally curse. You promised the band you'll be there for their final show, I can't believe I overslept! Please tell me they're not on yet! Regretting sleeping late because of your project. You shouldn't have made that complicated embroidery.

You skid to a stop, holding up your ticket to show the security guard. He nods stiffly, you practically run towards the side of the stage, dodging the growing crowd. You quickly gaze over the large stage, finding the staff still setting it all up. Yes! They haven't started yet! Smiling victoriously.

You stop, heels skidding to a halt, smile fading away when you see an unknown woman right next to Hobie, whispering closely to his ear, bare arms around his neck, fingers fiddling with the metal chain he always wears.

Oh

A/N: This chapter made me miss my chaotic OCs 🥺 Thank you for reading! Consider reblogging if you enjoyed it ❤️

(please tell me if I missed any asterisks, they're placeholders for me during drafting. I feel like I missed some lol)

*pictures above are from pinterest*

#thread the needle chapter 5#thread the needle series#thread the needle#hobie brown x reader#spider punk x reader#the kr8tor's creations#hobie brown#spider punk#spider man across the spider verse#x reader#atsv fanfiction#atsv fluff#atsv fanfic#atsv x reader#atsv hobie#hobie brown x fem!reader#hobie brown x you#hobie brown x y/n#spider punk x fem!reader#spider punk x you#hobie brown fluff#cw food#cw food mention#fanfic

340 notes

·

View notes

Text

The Consequences Of Genius

SO! On stream today, I decided to follow the example of Harlan Ellison (Who used to write short stories off of passerby suggestions in bookshop windows) And I took a suggestion and wrote a short story! Here's the completed story, started from the prompt: "A person doing research going crazy" from Crazycrazyfox, written in full by me on stream today. Genre: Horror

It had been years. When he first became obsessed with the idea in college, he was heralded as a genius of his generation. Capable of making the next incredible breakthrough. But now? After so much time had passed? He stayed in a dark, dim room, leaned against a desk covered in papers on a floor flooded with more papers, with only the dim desk-lamp to provide him light in the darkness. He had to be on to something. He must be!

After all this time, with all this equipment and all the money he’d spent, there had to be something to this madness. His eyes scrolled the pages of research and notes, at least the relevant ones on his desk, and he made further notations about this latest experiment. He stood, the motion causing many papers to billow away from him, and he marched towards his machine. His grand invention. The great signal flare with which he will usher in a new era of humanity.

He adjusted the amperage, re-arranged the antennas on the second pod, and triple-checked that they were powered. He stepped over the frayed and mangled corpse of the failed experiment as he wandered his way to the fuse box. It was important, of course, now that he wasn’t making his coffee, to re-divert the power back to his machine.

An unfortunate groan came from the floor. He glanced, with an expression of disinterest, at the almost-human on the floor. One arm failed to defuse from its torso, the other reaching out for a supportive hand, the entire creature red with blood.

He ignored it. It would mean nothing in his new realm, in his perfect future. It cost him nothing to repeat the experiment, save perhaps an electricity bill at the end of the month. But it was fine, he was so close now. When that time came he would be able to pay it in spades, and they would probably pay him for having made such a profound discovery in their building. Yes, yes, he would be beloved.

In school, his research had been heralded as brilliant and incredible. But his critics, they were vicious and unrelenting. They called him mad, they said he’d lost his mind, they could not fathom the possibilities that would be ushered forth by his great invention!

The whirling of the machine was like music to his ears with each booting sequence. Watching the DOS prompts on the little jerry-rigged laptop was like watching Picasso paint, and he was sure the world would agree! But, it had begun to grate. After fifteen failed runs, fifteen unpleasant corpses to clean up, fifteen groans and nightmarish forms, he was not without a few doubts and frustrations. He still had neglected to clean up the sixteenth experiment, and so it lay malformed on his floor.

It was a source of much frustration. On his next go around the desk, he stomped his foot down on its skull, the unfortunate squelch and squeals of pain and compounded flesh filled the room. As its final scream hollered out in an unpleasantly familiar deep voice, he pushed harder until there was no life left in the failed experiment. The hideous thing simply lay dead and slightly oozish upon the ground, whereupon he grabbed its unpleasantly fleshy and grotesque form where one might have a shoulder, and dragged it, slowly, uncomfortably, across the room leaving a trail of blood as the aged wooden floor left splinters in its hide. He pulled another trash bag from the roll he kept in the corner, and wrapped the foul and lost beast in it. He then heaved the squishy and liquidy bag of garbage out of his apartment into the elevator.

Out in the snow at the bottom of his building, he walked out into the uncovered parking lot, trailing the uncomfortable fleshy bag behind him, bringing it out to the now slightly full dumpster which smelled uncomfortably of rotting flesh and looked misshapen in all the worst ways. He threw the bag over his shoulder, comforted slightly by the idea that if it were not already dead, it soon would be. He then marched his way back in the door, into the elevator, and back to his damp, cramped, and paper-covered room. He re-examined his notes once more and re-drew the drapes to be sure that none would witness his genius before himself.

He knew that everything was ready, and so, more confidant than ever in his project, he readied for the seventeenth test. He adjusted both capsules, huge silver chambers which stood on opposite sides of the room, connected both by cables and the invisible power of radio waves. He brought the second one to life by connecting the circuit with the breaker on the far side. He considered, slightly, the idea that his project would be rejected. No, NO, that is impossible. He has worked so hard, and made such progress. There is nothing but success which awaits him. If not now, then soon enough. He brought the first chamber to life with another flip of the respective breaker. He waited for the coils and gears to find their place before the grand bronze doors opened. Immense quantities of steam poured out from the machine and flooded the floor of the little room, making what discarded papers that had come close into piles of literary mulch, and warmed the little room.

Out of habit, he checked his notes one more time. The calculations were excellent. The machinations worked beautifully. As a way to provide a new variable to this test, he connected a little samplette of gelatin to the machine. If all went well, he’d have a very lovely snack on the other side. If not- Well, nothing wrong with a seventeenth mess to clean up. He nodded his head, almost involuntarily. He was exhausted. It had been a long day, with hours of work behind him.

He stepped into the machine, flicking the switch as he went. The bronze doors closed and he heard the gears whir and the coils spark the air with loose bolts of plasma. The electricity in the air sparked and crackled, until eventually the chamber was filled with steam, and there was a bright light.

At first, there was nothing. Slowly, his senses came to him. The bronze doors before him opened. He was on the other side of the room. His heart quickened in an unnatural beat. He tried to raise his arms but failed. They were held in place. He tried to step forward, he fell. The contact with the metal of the chamber and wood of the floor against his incomplete visage caused searing pain along his body. He tried to call out, but his voice was nothing but a gurgle. It was strained, limited, he was naught but an unpleasant and lost slug of a person on the ground, one viable arm and one viable leg, both which stung immensely to move about his form. His vision was blurry but functional, which he counted among his successes. He thought to himself, it will be better for the-

“It will be better for the eighteenth test, I suppose.”

The voice came from above him. He looked up, and saw himself. Dirty from the days work, with an unbuttoned collared shirt and plaid pants, wholly unharmed, staring down at him with nothing but contempt and disappointment.

“I suppose you will have to go with the others.”

A boot was raised well above his head.

There was pain. There was screaming.

And then there was nothing. (P.S. You can see the entire stream where I wrote the story on my channel, Mys_Mistree on Twitch! Thank you for reading!)

4 notes

·

View notes

Text

X-1: Meet the Cast, and the Roll-A-Dance, and this here new, modified engagement function!

If there's a lot of engagement on this, this post is liable to get real long, beware before you expand. (This accidentally went live on the wrong blog for a sec, I bet I'll do that a lot!)

Welcome to the Engagement Lounge, for Meet the Roll-A-Dance (X-1) an extra! Short comments can go in the replies, but there's a character limit. Longer ones will need a reblog. Remember to @asksoldieron if you're reblogging someone else's reblog, so I can see it too!

This was a cute way to reintroduce the cast and transition into the timeskip after finishing up Tin Soldier and taking a long break. Erik's almost twelve in this one. When we see him again, he'll be nineteen, but he doesn't know it yet.

Barnaby's gone and there are a few new main characters who aren't there yet, but the plot goes on! If you wanted to check and see if you like this world, these people, and how I write about 'em, this is a good place to start.

I posted this February 17th, after being more-or-less absent for a year, as proof of life! Tin Soldier's actual anniversary is on April 9th. Technically, I started Tin Soldier very late on the 8th, but the clock switched over while I was putting the pilot up. I tried to stick to 12:01 AM from then on, but I screwed up a few times. (I simplified the time codes and cleaned up some mistakes after moving the site. Shh! Don't tell!) We'll call October 3rd Soldier On's birthday. Three excuses to put up extra content and party!

This one has a lot of band organ music in it, which I love. Those things make old school digital music. Music boxes are even older, and I love them too, but band organs are way more fun to watch.

On the way up from the States, I got to visit the Musee Mechanique in San Francisco and see a lot of both, and player-pianos, too! They had a BIG band organ behind glass that played the Beatles. I was in heaven.

I also got to see a transitional machine. Band organs and player pianos run ye olde MIDI files on punched paper rolls. Music boxes have a metal roll with itty-bitty bumps that plucks a tiny metal harp. How did we get from one to the other? A punched roll made of either very tough paper or wood that physically lifted the keys that play the instruments as it scrolled! Each key had a hook on it that would catch the holes in the roll and strike a note or an instrument. From metal harp to wooden keys to a pneumatic pump system that blows air through the holes!

Unlike the DDR we know, Roll-A-Dances have a mechanical dance pad instead of a digital one. They're slower, with nothing faster than 1/8 steps, so you don't foul the typewriter-like keys. I bet the early ones had the pneumatic input hooked up to the dance pad, and that would've been even slower. The one the household is playing with has a bellows in there, and needs magic and electricity. It's faster, but it's finicky!

We'll see the Roll-A-Dance again. Milo just loves it. You can't tell from his expression, but I gave you his joy in the coloured "light". I decided Milo should not be required to smile for you readers at home to know he's happy.

My music references, available on YouTube, are: A fairground organ playing ABBA; A fairground organ playing Bohemian Rhapsody; and of course you know Toccata. Butterfly and Captain Jack are DDR references, but they - and the other songs - are not, to the best of my knowledge, available in organ form. Yet. They do have Caramelldansen! Band organs give less than a shit about copyright and I agree with them!

[Back to the Site?]

#tin soldier and soldier on#band organs#fairground organs#ddr#ye olde digital music#a little piracy never hurt anyone#extra#instalment#engagement lounge

4 notes

·

View notes

Text

Despite the ambient cold , and damp air around him . He could feel his biceps burning as he slammed the front , blunt end of his hammer against the metal bolt jutting out against the rocks in front of him . Repeating the motions over , and over again . Only stopping once the metal bolt was fixed securely in place . Embedded into the earth . Setting up the foundations for future expansions , areas , and excursions . But for now ? with his breath hot against the cold air , lightly adjusting the system of pulleys , and ropes situated around his worker's harness to pull himself up a bit . The flashlight embedded into the chest area of the harness shining light over his work , lingering pebbles , debris wiped away by his gloved hands to inspect what he'd done .

Setting his hammer securely into place along his waist , he'd loosen the rope around his harness . Lowering himself down slowly , but surely until his boots at last touched down on the smoothed stone surface below with a small thud .

Loosening the zippers , and undoing the safety straps of his harness but keeping his utility belt on with him the harness would be set aside on a nearby work bench as he moved to flip a switch . The portable electric generator next to him coming to life with a whir once it was turned on , the overhanging lights above him switching on , illuminating more over the cavernous space around him .

Revealing more of what he'd expected to see . Large complex crystal structures that served as physical support beams for the crystal castle above him .

With a light smile of satisfaction with his hours of work coming to fruition he'd stop for a moment to breathe it in . Small beads of sweat trailing down from his chin to his shirt . The sound of roaring water , and the familiar chirp of bats overhead helping to center him as he regained his strength to continue .

He suspected that there was likely an exit point somewhere further on ahead , somewhere where the waters exited out to sea . Otherwise these area's would have been flooded when he'd first discovered them , the grand waterfall a ways ahead wouldn't have been possible otherwise .

Climbing up a metal ladder built into the side of the tall circular metal stand that held up a spacious platform overhead .

Upon reaching the top ? Mamoru would make his way over to a large interconnected display of monitors , computers , and multiple desk areas containing various machines as well as research equipment . All partially illuminated by the glow of the display screens that were now coming online as well as the other sets of overhanging lights situated far above him .

The symbol ... his symbol soon appearing over each monitor . An emblem in the form of a bat , wings spread wide .

" Begin recording session "

Pressing only a few keys on his keyboard as a small display box appeared on his monitor , showing soundwaves that measured the highs and lows of his voice with pixel perfect scrutiny as he spoke the order to verify that the voice it was recording belonged to him soon enough a recording icon began to blink in confirmation . Mounted CCTV cameras beginning to tilt towards his direction to record him as requested . Following his movements as he rose from his seat , and began to walk back towards another area with data racks that had yet to be installed .

" Recording session 25 . Encrypt file , standard protocols . Passkey required for access . Security level Omega "

Getting down , and situating his back unto a padded under car roller , Mamoru rolled himself underneath the set of data racks to begin to process of wiring the individual black boxes together from the bottom up to facilitate the transfer of all of his old files to his new computers .

" Progress on the new cave has been going well . All of my previous monitors , computers , data , localized server equipment , and other equipment was able to make the journey overseas from Gotham without any issues . All devices had been checked , and rechecked to ensure that they weren't tampered with upon arrival , or activated without my knowing . No contingency protocols were activated . By my own current estimates ? I should have everything up and running within a year . But ... I've been thinking on something . Usako ... Serenity , has become what the Batman , what I ... could never be . She's become a symbol of hope for all of planet Earth . Instead of what criminals fear once the sun goes down . She's brought people together , united them . Far better than I ever could as Mamoru Chiba . Even for a place like Gotham , that many once believed to be beyond saving . And she's done all of this without having to rely on the power of fear "

" But ... that doesn't mean that the Batman should disappear altogether . The Batcave in Gotham has been sealed , but I've decided to leave something behind , in case it's ever needed . When I think of the Earth now ... I see the happiness that Usako has brought to everyone . But , when I think of the future ? I still see the unknown , uncertainty . With the past serving as testament to why the mission remains as critical as ever . Even during these times of peace . The potential for future attacks by forces beyond our comprehension remains , and it will be for that purpose alone that Batman ... that I'll remain ready . Computer , create a new project file for me . Label title , Project Beyond "

As his hands moved about the different racks , unscrewing different panels , and examining them before moving unto the next . His work went on without confusion , accustomed to multitasking as he was .

" For now ... Earth needs King Endymion . So that's what I'll be . However , should there ever come a day where King Endymion isn't enough , where Usako , and the rest of our guardians aren't enough .. that will be when the Batman returns . To remind criminals , whether they be gods or mortal men , the reason why they fear the night . Light , however bright . Will always cast a shadow . And that's where the Batman will be , ready for whenever anyone attempts to take it out . Even if ... I won't be the one behind the mask on that day "

@starpwers

#ic. mamoru chiba ( Earth's Dark Night )#ic. sailor moon / batman verse#starpwers#ooc. hope you don't mind me tagging you in this !#ooc. I was hoping to write with you and I've been meaning to write a drable too for a while now#ooc. so please think of this as just a test of an idea with my muse !

1 note

·

View note

Text

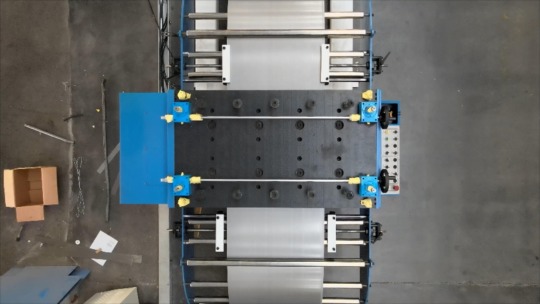

What is Heavy Gauge Thermoforming?

Thermoforming is a plastic processing technology, the main principle is to spread the hard plastic sheet heated to soften, the use of vacuum adsorption will be softened sheet adsorption on the surface of the mold, after cooling the molding technology.

Vacuum forming is widely used in plastic packaging, lighting, advertising, decoration and other industries.

With the continuous development of science and technology, the manufacturing industry is also constantly innovating and progressing. Among them, thermoforming plastics process, as an emerging manufacturing technology, is gradually becoming the new trend of the future manufacturing industry.

Vacuum forming according to the thickness of the sheet is divided into thin gauge thermoforming and heavy gauge thermoforming, this article we will focus on thick gauge thermoforming.

Principle of Heavy Gauge Thermoforming

Heavy gauge thermoforming refers to the use of material thickness of more than 2mm, can not be in the fully automatic tool on the thermoforming machine, must be used in heavy gauge thermoforming semi-automatic thermoforming machine for processing and production. light gauge thermoforming, the thickness of the plastic is 1.5 mm or less and is usually roll fed into the thermoforming machine.

Thick piece of pressure forming machine is a plastic sheet as raw material, through the vacuum forming process to produce plastic parts of the key process equipment, it is a thermoplastic material plastic sheet as raw material, through the oven heated to a softening temperature, and then through the plastic sheet and the mold between the plastic sheet and the key process equipment.

It takes thermoplastic plastic flat sheet as raw material, heated to softening temperature by oven, and then through the negative pressure of vacuum between plastic sheet and mold, the plastic sheet in thermoplastic state is adsorbed on the working surface of the mold and then cooled to form.

Difference Between Heavy Gauge Thermoforming and Thin Gauge Thermoforming

Different Materials

Heavy gauge thermoforming is generally used ABS, HIPS, etc.. Thin gauge thermoforming commonly used materials for PVC, PET, PP, PS, PETG, etc..

Material thickness is different, heavy gauge thermoforming industry need to use the material is sheet, that is, plate, 1-15mm thick, and light gauge thermoforming used in the material is coil 0.2-1mm thick.

Different Uses

Heavy gauge thermoforming is commonly used in machine shells, display racks, advertisements, bases, image boards, sports equipment shells, beauty equipment shells, medical equipment shells, golf cart shells, toy car shells, turnover trays, game machine shells, refrigerator liners, light boxes and other vacuum forming products. The product thickness 1-10mm or even thicker.

Thin gauge thermoforming is generally used in electronic products, cosmetics, food, health care products, toys, daily necessities and other pressure forming products. The thickness of the product is 10-100 silk.

Different Processes

Heavy gauge thermoforming than thingauge thermoforming is more complex, on the basis of the process, heavy gauge thermoforming than thin gauge thermoforming more than a few milling edges, skeleton washing, grinding and other processing procedures.

Heavy gauge thermoforming industry cut edges and holes are CNC engraved, while the thin gauge thermoforming industry is punched with a knife mold, so the price of thick gauge thermoforming than thin gauge thermoforming is a little more expensive.

Different Machines

The machines used in heavy gauge thermoforming industry are semi-automatic thermoforming machines, which have a slow production time, while those used for light gauge thermoforming are high-speed machines, which are very fast.

Application

Heavy gauge thermoforming products are mainly used in: electrical appliance shell, automobile body jacket, pet tray, advertising light box, automobile interior and exterior, transportation, building materials, packaging, medical equipment, household appliances, education and sanitary ware, sporting goods, medical equipment, food equipment, instrument shell, lighting, refrigerator industry, air conditioning industry and home appliance parts and other people's daily life in various fields.

Heavy gauge thermoforming products can not only replace the injection molding process, saving the cost of expensive injection molds, but also replace the traditional handmade, with the advantages of advanced production process, fast speed, reliable quality and so on.

Heavy Gauge Thermoforming Materials

A variety of thermoplastic materials are used in heavy gauge thermoforming, each with unique properties for specific applications. The main materials used in thick sheet blister molding are: various colors of ABS, acrylic, PETG, PVC, PC, PP, PE, PS, etc. and a variety of modified plastics such as glossy, skinned and transparent sheets. The thickness ranges from 3mm to 60mm.

ABS: ABS is a thermoplastic known for its strong and durable properties. It has good impact resistance and high temperature resistance, making it ideal for both interior and exterior applications. In the automotive industry, ABS is used to make interior panels and instrument panels because of its strength, elasticity and aesthetic flexibility. In consumer products, it is used to produce everything from toys to cell phone cases.

PE: Chemically resistant and highly durable and cost effective. PE is available in a wide range of densities and different properties with good elasticity and strength. PE is widely used in packaging due to its ability to effectively keep out moisture and other contaminants. Its chemical resistance makes it the material of choice for containers holding corrosive substances.

PS: PS has good rigidity and clarity and is easy to work with. It provides a cost-effective alternative for scenarios where clear, rigid plastic is required. Because of its transparency and rigidity, PS is often used to produce displays and models where a clear view of the product is critical.

PVC: prized for its versatility, strength and chemical resistance.

PC: prized for its transparency and impact resistance.

PMMA: prized for its optical transparency and UV resistance.

HIPS: tough and low cost.

Production Process

Heavy gauge thermoforming and thin gauge thermoforming principle is similar, is the positioning of the plate through the oven heated to a soft state, the vacuum forming mold and its periphery to form a closed space and will be the cavity air instantly pumped away, the plate is tightly covered in the surface of the mold, cooled and shaped to obtain the product of the process.

Vacuum forming is a cyclic process, each cycle mainly consists of: loading - heating softening - blowback pre-drawing - suction molding - cooling and shaping - demolding and taking out the parts. After removing the molded part, the sheet is placed again (either received or automatically) for the next cycle.

Mold Design and Making

Different customers have specifications for their products, so plastic molds must be made before production. In this case, the molds are made from plaster of plastic molds and the molds are produced using plastic. The lower cost is plaster molds, followed by electroplated copper molds, while aluminum molds are more expensive. When the molds are made, they are allowed to dry naturally or are dried and then treated according to the specific conditions of the product surface.

Mold Installation

When the mold is completely dry, it should be placed on the upper iron plate of the vacuum chamber, then the mold should be loaded to the applicable size according to the size of the mold then the paper should be placed in a hot wood cabinet to hold it in place and process it.

Forming

Fix the plastic sheets on the mold with fixing clips, heat the ends of the plastic sheet until they become soft, then use a vacuum pump to pump out the air between the material and the mold, so that the softened plastic sheet is adsorbed on the top of the mold, and then blow the air in the reverse direction to release the product from the mold when it cools down.

Finished Product

The finished plastic components is trimmed and integrated into a product that can be sold after sale packaging.

Agvantages

The advantage of heavy gauge thermoforming is its simplicity. For businesses or individuals looking to produce prototypes quickly, heavy gauge thermoforming stands out. The molds for heavy gauge thermoforming can be made from less durable materials such as wood or epoxy, so converting prototypes to physical form is both faster and cheaper.

Heavy gauge thermoforming is particularly cost-effective for low to medium volumes. Because tooling costs are typically lower than injection molding costs, small quantities can be produced without significant financial outlay. Another advantage is the relative ease of design changes. Because molds are less expensive, modifications can be made without incurring excessive costs.

Due to the large area and thick material of thick gauge thermoforming products, their strength and durability are high and they are able to protect the integrity of the goods. Secondly, heavy gauge thermoforming products can be customized to provide a wide range of features and shapes. In addition, the production process of heavy gauge thermoforming products is relatively simple and highly efficient, allowing them to meet the demands of mass production.

The automatic molding of heavy gauge thermoforming is particularly suitable for the production and processing of large products, because it realizes the automated operation from raw materials to finished products, so the efficiency is high and the quality is relatively stable.

In thick plate thermoforming technology, a variety of additional services can be performed, such as mold design, surface treatment, processing details and supporting assembly. Through these services, the appearance and performance of plastic products can be further enhanced.

Conclusion

In conclusion, as an emerging manufacturing technology with advantages of complex shape, high production efficiency and low cost, the plastic thermoforming process is gradually becoming a new trend in the future manufacturing industry. With the continuous progress of science and technology and the continuous expansion of the application, I believe that the pressure forming process will play a more important role in the future manufacturing industry.

Heavy gauge thermoforming technology plays an important role in creating a wide variety of plastic products, while also helping to improve product quality and customer satisfaction. The proper selection of plastic materials, proper control of the manufacturing process, and the provision of additional services are all important factors in the creation of high-quality and value-added thick gauge thermoforming products.

We also continue to explore and advance, pushing the limits of material capabilities and part complexity using advanced molding technologies such as thermoforming, vacuum forming, twin sheet forming, and pressure forming.

0 notes

Text

Bare punching machine brand (ranking of Xinjiang mother row processing machine)

The composition and working process of the fully automatic bus control system are usually controlled by CNC fully automatic bus. The two motor control systems are used. Two motors are used for dual -fly forks and one motor is used for division. The control system mainly uses pneumatic control. The pneumatic system is mainly achieved by the solenoid valve and the cylinder and the sensor. In order to facilitate program control and maintenance, the whole machine can be divided into two types: manual operation and automatic operation. Therefore, the corresponding input and output points are more. If the mechanical connection method is used, it will greatly increase the hardware module and electrical connection. The corresponding fault rate will It will also greatly increase. So we adopt a solution of PLC and touch screen. The system frame diagram is shown in Figure 1.

In the 1970s, Wuhan Iron and Steel Company, based on the introduction of digestion and absorption of Japanese cold -rolled silicon steel sheet manufacturing technology to produce cold -rolled silicon steel sheets, introduced Japanese high -guide magnetic crystal grains to cold -rolled silicon steel sheets in the 1990s ( Hi-B) manufacturing technology has created iron-hearted materials with better energy-saving effects. However, because the number of products cannot meet the problems of demand and production technology, it is still necessary to import some cold -rolled silicon steel sheets from Japan, Russia, and Western Europe. In terms of the use of amorphous alloy materials for the development of power distribution transformers, in the early 1990s, my country had formed a specialized work by the original Mechanical Department, the Ministry of Metallurgical Department, the former Electric Power Commission, the National Economic and Trade Commission, and the former National Science and Technology Commission. Group, in -depth research on the design and manufacturing process of amorphous alloy iron heart materials and amorphous alloy iron heart transformers. ~ 500kva's power distribution transformer, tried by electricity users, showed that it basically achieved practical requirements. Bare punching machine brand

The number of coil winding circles is reflected by the number of rotations rotated by the bus. The number of circles is then converted from a dry spring sensor to a pulse signal. After plastic surgery, it becomes a square wave, and the counter is triggered by a differential division. When the input given signal consisting of a single -knife two -digit switch is consistent with the count signal of the counter, that is, when the number of circles that need to be bypass in one person and the number of rings that have been winded in one year, Just turn on and send the signal to the controller to stop the winding motor immediately to ensure the accuracy of the number of circle control.

In the configuration of the bus component, the main axis motor determines the shape, weight and winding process of the device that can process the coil. Different types of spindle motors are used in different types of parent line machines to meet different coil winding processes.

The busbar machine brand thermal runway mold: This type of mold structure is roughly the same as the fine water outlet. The biggest difference is that the flow tract is in one or more thermal flow plates and hot pouting. The pouring mouth is directly on the product, so the runner does not need to be released. This system is also called the water -free system, which can save raw materials. It is suitable for the situation where the raw materials are more expensive and the product requirements are high. It is difficult to design and process. Essence The thermal flow system, also known as the hot lane system, is mainly composed of hot pouring mouth, hot watering panel, and temperature control electric box. Our common thermal flow system has two forms: single thermal pouring mouth and multi -point heat pouring mouth. Single -point heat pouring mouth is to shoot the melting plastic directly into the cavity with a single hot portal cover. It applies to a single cavity and single -pouring plastic mold; more hot pouring mouth is the branches of the melting material through the hot watering panel to each Divide the hot pouring socket and then enter the cavity, it is suitable for single cavity multiple points or multi -cavity molds. Maternal mold mold

When you use punching, please put the direction handle until the position of the punching word is marked; after using the perforation, the handle can be hit until the oil return sticker position.

The display screen uses a large screen (7 -inch) color screen to display the touch formula. It has a password protection function to modify unqualified data. If the customer uses not a standard workpiece, you can also set the data according to the requirements of the non -standard workpiece to set the data for the data. Processing, it is very convenient to operate. Bare punching machine brand

When the orbital surface and the rolling of the rolling surface form an ingredient, it also has the effect of reducing the contact stress caused by the load. Manageing the lubrication work, fully forming the reliability of the oil film is very important to ensure the reliability of the linear guide.

0 notes

Text

What Is a Hot Rolling Machine?

A hot rolling machine, also known as a hot rolling mill, is an industrial machine used to shape and form metal at high temperatures. It is a complex piece of equipment that consists of several components working together to process metal into desired shapes and dimensions.

The Main Components of a Hot Rolling Machine

Reheating Furnace

The metal is heated to a specific temperature in a reheating furnace before it enters the rolling mill. The furnace uses different heat sources, such as natural gas, electricity, or fuel oil, to raise the metal's temperature to its optimal rolling temperature.

Rolling Mill Stands

The rolling mill stands consist of a series of rolls that apply pressure to the metal to reduce its thickness and shape it. The number and arrangement of rolls vary depending on the type of rolling mill and the desired product.

Rollers

The rollers are the key components that apply pressure and deformation to the metal. They can be cylindrical or shaped rolls, depending on the desired shape of the final product. The rollers rotate in opposite directions to draw the metal between them and reduce its thickness.

Guides and Guides Boxes

Guides and guide boxes are used to direct the metal through the rolling mill. They ensure proper alignment and control of the entry and exit of the metal, maintaining its uniformity and preventing defects.

Cooling and Quenching Systems

Hot rolling generates a significant amount of heat in the metal. Cooling and quenching systems, such as water sprays or cooling beds, are used to rapidly cool the metal after it passes through the rolling mill. This helps to set its final shape and properties.

Coiling or Cutting Systems

Once the metal has been rolled to the desired shape and dimensions, it may be coiled into large rolls or cut into specific lengths, depending on the intended use and customer requirements.

Final Products of a Hot Rolling Machine

A hot rolling machine can roll a wide range of metal products. Some common products can be produced using a hot rolling machine.

Bars and Rods

Hot rolling machines are used to produce metal bars and rods with specific dimensions and surface finishes. The hot rolling machine rolling bars and rods is called the steel bar rolling mill production line. These bars and rods are widely used in construction, infrastructure projects, machinery manufacturing, and other applications.

Structural Shapes

Hot-rolling machines can roll metal into various structural shapes, such as I-beams, angles, channels, and rails. These shapes are commonly used in construction and structural engineering projects.

Wire

Hot rolling machines can also be used to produce metal wire of different diameters. The wire is rolled to reduce its thickness and improve its mechanical properties. Metal wire finds applications in industries such as construction, electrical wiring, and manufacturing.

Finally

Hot rolling machines are used to process a variety of metals, including steel, aluminum, copper, and alloys. They are essential in the automotive, construction, aerospace, and manufacturing industries, where high-quality metal products with precise dimensions and properties are required.

The specific configuration and features of a hot rolling machine can vary depending on the application and the type of metal being processed. Different rolling mills may have additional equipment to ensure efficient and precise production.

0 notes

Text

How To Maintain The Feed Machine Machine?

In the process of pellet feed production, if the user does not operate the feed pellet machine correctly, it will undoubtedly affect the service life of the feed pellet machine. How can we better reduce the wear of vulnerable parts of the feed pellet machine? Let's share with you the wear cause analysis and maintenance methods of vulnerable parts of the feed pellet machine.

1. Raw material particle size Because the crushing fineness of raw materials determines the surface area of pellet feed composition, the finer the particle size is, the larger the surface area is, the faster the material absorbs water in steam, and it is relatively easy to condition and particle forming; If the grain is too coarse, the die wear increases, the energy consumption increases, and the productivity decreases.

The requirements of animal feed equipment manufacturers are that the particle size of raw materials after crushing shall all pass through the 8-mesh screen, but the material on the 25-mesh screen shall not be greater than 35%. For materials with high crude fiber content, a certain amount of grease shall be added in the granulation process to reduce the friction between the material and the ring mold, and the appearance of formed feed particles shall be smooth.

2. Raw material impurity cleaning If there are too many iron impurities in the material, resulting in accelerated die wear, this should attract the attention of the pellet feed-making machine operator. Therefore, impurity removal before raw material processing is very important.

3. Add steam Adding steam during material granulation is conducive to material softening and lubrication, to reduce the wear of materials on the machine and improve the output. Generally, the pressure varies with the variety of pressed materials. After adding steam, the moisture content of materials should reach 16% ~ 17%, and the temperature of materials after quenching and tempering should be controlled at 78 ~ 87 ℃.

4. Clearance between ring die and press roll The unreasonable installation angle of the feeder will lead to uneven material distribution between the ring die and the press roll, and over time, it will lead to uneven wear distribution between the ring die and the press roll.