#drum mix plant

Explore tagged Tumblr posts

Text

Why Should We Choose Mobile Drum Mix Asphalt Plant ?

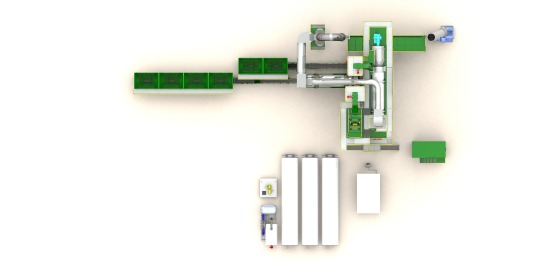

One Trailer Mounted Mobile Drum Mix Asphalt Plant Realizes the High Integration of Asphalt Plant.

One transport trailer can realize all the functional requirements of the asphalt mixing station (filling, drying, mixing, storage of finished products, operation), which meets the user's requirements for fast installation, fast transition, and rapid production.

Mobile Asphalt Plant is asphalt mix manufacturing equipment in the form of one or some mobile modules mounted on chassis, so it features fast relocation and rapid reassembly, and pre-production preparation time can be saved greatly.

#asphalt mixing plant#asphalt plant#mobile drum plant#asphalt drum mix plant#mobile asphalt drum mix plant#mobile asphalt plant#drum mix plant#asphaltplant#heavy equipment#concrete#road construction#bitumen#construction#mobile hot mix plant

2 notes

·

View notes

Text

The Importance of Drum Mix Plants in Large-Scale Infrastructure Projects

Large-scale infrastructure projects demand precision, efficiency, and consistency in asphalt production. Drum mix plants play a crucial role in ensuring these requirements are met, making them indispensable for modern construction. From highways to airports, these plants streamline the production process while maintaining superior asphalt quality. Let’s delve into the various reasons why drum mix plants are pivotal in large-scale infrastructure projects.

Essential Role in Large-Scale Asphalt Production

Drum mix plants are engineered to produce large volumes of asphalt with ease. Their continuous production capabilities allow contractors to meet the demands of extensive infrastructure projects. By combining aggregates and bitumen in a single drum, these plants ensure a seamless and efficient production process, minimizing delays and maximizing output.

Consistency and Quality Control in Complex Projects

Infrastructure projects require uniform asphalt quality to ensure durability and performance. Drum mix plants deliver unmatched consistency by using automated controls and advanced mixing technologies. These plants maintain precise temperature control and accurate mixing ratios, ensuring that the asphalt meets stringent quality standards.

Speed and Efficiency in Large-Scale Operations

Time is a critical factor in infrastructure projects. Drum mix plants are designed for high-speed operations, enabling contractors to complete projects within tight deadlines. Their continuous mixing process eliminates interruptions, boosting overall productivity and ensuring timely project completion.

Impact on Cost-Effectiveness

Cost management is a major concern in large-scale construction. Drum mix plants offer significant savings by optimizing material usage and reducing wastage. Their efficient operations lower energy consumption and operational costs, making them a cost-effective solution for asphalt production.

Meeting Environmental Regulations and Sustainability Goals

Modern drum mix plants are equipped with features that minimize their environmental impact. Advanced dust collection systems and energy-efficient burners reduce emissions, helping contractors meet environmental regulations. Additionally, many plants support the use of recycled asphalt, contributing to sustainability goals.

Adaptability for Diverse Infrastructure Projects

From urban roadways to remote airstrips, drum mix plants can adapt to various project requirements. Their modular designs make them easy to transport and assemble at project sites, ensuring flexibility and convenience. This adaptability allows contractors to tackle diverse infrastructure challenges with confidence.

Technological Advancements Enhancing Project Success

Innovations in drum mix plant technology have revolutionized asphalt production. Modern plants feature user-friendly interfaces, real-time monitoring, and automated controls. These advancements enhance operational efficiency, improve asphalt quality, and provide contractors with valuable data insights for better decision-making.

Choose the Right Drum Mix Plant Manufacturer for Your Next Project

The success of your infrastructure project depends on selecting the right drum mix plant manufacturer. Reliable manufacturers, such as Kaushik Engineering Works, offer state-of-the-art plants designed to meet the unique demands of large-scale projects. They also provide after-sales support, ensuring smooth operations throughout the project lifecycle.

Conclusion

Drum mix plants are an integral part of large-scale infrastructure projects, offering unmatched efficiency, quality, and cost-effectiveness. By choosing the right plant and manufacturer, contractors can streamline operations, meet environmental standards, and achieve project success. Explore the possibilities with drum mix plants and elevate the quality of your construction projects.

Read More: The Importance of Drum Mix Plants in Large-Scale Infrastructure Projects

0 notes

Text

Advantages Of The Drum Mixers - Atlas Technologies

Explore the advantages of drum mixers for continuous asphalt production. With seamless operation, experience uninterrupted production and enhanced efficiency for your paving projects. Read More: https://www.atlastechnologiesindia.com/blog/asphalt-batch-plant-vs-drum-plant/

0 notes

Text

Decisions While Buying An Asphalt Plant - Atlas Industries

Deciding on the right asphalt plant buying decision can be tricky. They key advantage and disadvantages of drum mix plant basic process to product hot mix asphalt.Once you have decided to have your own asphalt plant you are now going to make important decisions.

0 notes

Text

Asphalt Plant | Bitumen Sprayer Manufacturer in India - S.P. Enterprise

S.P. Enterprise is a manufacturer of road construction machinery like asphalt plant, hot mix plant, asphalt drum mix plant, bitumen sprayer in India. We are exporter and supplier of road construction equipments. Call us on +91-9712583240.

#asphalt plant#bitumen sprayer#mobile asphalt plant#asphalt drum mix plant#asphalt mixing plant#asphalt hot mix plant#bitumen pressure distributor

2 notes

·

View notes

Text

Asphalt Drum Mix Plant for Best Road Construction Equipment

The Asphalt Drum Mix Plant is essential for producing high-quality asphalt used in road construction. Designed for efficiency and durability, it ensures consistent mixing at optimal temperatures. This advanced equipment, trusted by professionals, delivers superior performance, making it the best choice for infrastructure projects. It is the Best Road Construction Equipment for reliable, cost-effective operations.

#asphalt drum mix plant#road construction equipment#best road construction equipment#asphalt mixing plant#durable asphalt plant#efficient road construction equipment#high-quality asphalt production#cost-effective road equipment#infrastructure projects equipment#asphalt plant manufacturers

0 notes

Text

Top Asphalt Drum Mixing Plant Manufacturer in Delhi

Vishwakarma Engineering Works stands out as a top Asphalt Drum Mixing Plant Manufacturer in Delhi, offering efficient and robust solutions for the asphalt industry. Our equipment is engineered to support the creation of world-class roads, ensuring superior performance and reliability for every project.

Contact Us :- Phone:-9811821123 Email :[email protected] Website :-https://vishwakarmaengworks.com/asphalt-drum-mixing-plant-manufacturer/

0 notes

Text

Hot Drum Mix Plant Introduction

ot drum mix plant, also known as continuous drum asphalt mixing plant or drum mix asphalt plant, is a kind of asphalt plant that produces asphalt concrete using a continuous process. It realizes the continuous process of heating and drying of aggregate and mixing of mixture through a series of continuous working units. Hot drum mix asphalt plant occupies an important position in road construction projects with its high efficiency and continuous production.

The output of hot drum mix plant varies depending on the model and configuration. Generally speaking, the output of small hot drum mix plant may range from tens of tons/hour to hundreds of tons/hour, while the output of large hot drum mix plant can reach thousands of tons/hour. The specific output needs to be determined according to the model of the hot drum mix plant, production capacity and actual production demand.

Asphalt hot drum mix plant is mainly composed of the following parts: - Batching system: responsible for feeding all kinds of aggregates into the mixing system according to the proportion. - Drying System: Usually consists of drums which are used to heat and dry the aggregates. - Combustion system: Provides heat, which is used to heat the aggregate in the drum. - Mixing system: carried out in the drum to mix the heated aggregate with binder materials such as asphalt. - Hot Aggregate Lifting and Storage System: Lifts the dried hot aggregate to the storage bin for subsequent metering and mixing. - Weighing System: Accurately measures various raw materials to ensure the quality of the mix. - Dedusting system: used to reduce the dust generated during the production process and protect the environment. - Control system: automated control of the whole mixing plant to ensure the stability and efficiency of the production process.

Characteristics of hot drum mix asphalt plant: - Continuous production: The drum hot mix asphalt plant adopts continuous process, which can realize continuous heating and drying of aggregate and continuous mixing of mixture, and improve the production efficiency. - Simple process: Compared with intermittent mixing plant, the process of drum mix asphalt plant is simpler and the structure of the plant is relatively compact. - High degree of automation: modern drum hot mix asphalt plant generally adopts PLC programmable centralized control, touch screen operation, automatic and manual switch freely, which greatly improves the degree of automation of production. - Good environmental performance: Equipped with dust removal system, it can effectively reduce the dust emission in the production process and protect the environment.

Advantages of asphalt hot drum mix plant: - Efficient production: the continuous production process makes the drum hot mix asphalt plant have high production efficiency, which can meet the demand of large-scale road construction projects. - Stable quality: Through precise measurement and continuous mixing, the quality of the asphalt mixture is stable and reliable. - Energy saving and environmental protection: modern drum hot mix asphalt plant emphasizes on energy saving and environmental protection design, and adopts high-efficiency combustion system and dust removal system to reduce energy consumption and emission. - Strong adaptability: can be flexibly configured and adjusted according to the needs of different projects to meet the needs of different types and specifications of asphalt mixture production.

In summary, the hot drum mix plant plays an important role in road construction projects with its high efficiency, continuous and stable production characteristics. With the continuous development of science and technology, the technology and performance of the drum hot mix asphalt plant will be constantly upgraded and improved.

This resource is from http://www.asphalt-mixing-plants.net/industry-news/hot-drum-mix-plant.html Should you be interested in, please contact us at: Haomei Machinery Equipment Co.,ltd Whatsapp/Wechat: 0086 181 3788 9531 Email: [email protected]

0 notes

Text

0 notes

Text

What is Asphalt Recycling Plant?

The use of reclaimed asphalt, or recycling, has become a necessity. Governments increasingly want the reclaimed asphalt from old roads re-used in an effort to be more environmentally friendly. Recycled asphalt also can provide you with cost savings on several fronts.

To use this valuable secondary resource, ZOOMLINE offers the Asphalt Recycling Plants to help your recycling and cost-saving efforts. Regardless of the system you choose, modern ZOOMLINE plant technology will provide a quality recycling process and product.

Asphalt Recycling Plant | Hot & Cold RAP Recycling, RAPpro 100% Recycled Asphalt Hot Mix Plant, Recycled asphalt hot mix plant, RAPpro 100% Recycled Hot Mix Asphalt Production Plant.

#asphalt mixing plant#bitumen#road construction#asphalt drum mix plant#asphalt plant#concrete#heavy equipment#asphaltplant#construction#mobile asphalt drum mix plant#recycling asphalt plant#asphalt recycling plant#recycled asphalt plant#RAP Recycling#recycled asphalt hot mix plant#recycled hot mix asphalt production plant#asphalt production plant

3 notes

·

View notes

Text

Batch Mix or Drum Mix Plant? A Comparison for Your Project

When choosing the right asphalt plant for your construction project, understanding the differences between drum mix and batch mix plants is crucial. Each type of plant has its unique features, benefits, and limitations that can significantly impact your project’s efficiency, cost, and quality. In this blog, we’ll dive into the details of each plant type, compare them, and offer tips to help you make an informed decision.

Asphalt Mixing Plants

Asphalt mixing plants are essential in road construction, providing the asphalt needed for paving. There are two primary types of asphalt mixing plants: drum mix plants and batch mix plants. Each has its own operational mechanisms and use cases.

Asphalt Drum Mix Plant

How It Operates

An asphalt drum mix plant continuously produces asphalt by combining aggregates, bitumen, and additives in a drum. The materials are fed into the drum where they are heated and mixed in a continuous flow process. The mixture is then discharged from the drum and can be used immediately.

Key Components

Drum Mixer: The core component where mixing takes place.

Cold Aggregate Feeder: Feeds aggregates into the drum.

Burner: Heats the aggregates and bitumen.

Control Panel: Manages the operation and quality control.

Bitumen Tank: Stores and supplies bitumen to the mixer.

Advantages

Continuous Production: Allows for constant operation and high output.

Lower Operating Costs: Less fuel and labor compared to batch plants.

Simple Design: Easier to operate and maintain.

Disadvantages

Lower Quality Control: Less precise control over mix quality compared to batch plants.

Limited Flexibility: Harder to adjust mix designs and proportions.

Higher Emissions: Can have a greater environmental impact due to continuous operation.

Ideal Use Cases

Large-Scale Projects: Suitable for projects requiring high production volumes.

Road Paving: Efficient for continuous paving jobs where consistent quality is less critical.

Asphalt Batch Mix Plant

Description and Functionality

An asphalt batch mix plant produces asphalt in batches rather than continuously. The plant mixes a predetermined quantity of aggregates and bitumen at a time, allowing for precise control over the mix.

How It Operates

The batch mix process involves heating and mixing aggregates and bitumen in discrete batches. The process ensures that each batch meets specific quality standards before being discharged for use.

Key Components

Batcher: Measures and batches the aggregates.

Drying Drum: Heats the aggregates before mixing.

Mixing Tower: Combines aggregates with bitumen in a controlled environment.

Control System: Provides precise control over mix formulations and quality.

Cold Aggregate Feeder: Delivers aggregates to the drying drum.

Advantages

Superior Quality Control: Provides more precise and consistent mix quality.

Flexibility: Easier to adjust mix designs and proportions for different projects.

Lower Emissions: Typically more environmentally friendly due to batch processing.

Disadvantages

Higher Initial Cost: More expensive to purchase and set up.

More Complex Operation: Requires more skilled labor and maintenance.

Lower Production Capacity: Generally produces less asphalt compared to drum mix plants.

Ideal Use Cases

High-Quality Pavements: Best for projects requiring stringent quality control and varied mix designs.

Smaller to Medium Projects: Suitable for projects where flexibility and mix quality are critical.

Comparative Analysis

Production Efficiency

Drum Mix Plants: Higher production efficiency due to continuous operation.

Batch Mix Plants: Lower production efficiency as it operates in batches but provides higher quality control.

Mix Quality

Drum Mix Plants: May have more variability in mix quality.

Batch Mix Plants: Offers superior control and consistency in mix quality.

Environmental Impact

Drum Mix Plants: Potentially higher emissions due to continuous operation.

Batch Mix Plants: Generally lower emissions and better adherence to environmental regulations.

Cost Considerations

Drum Mix Plants: Lower operational costs and initial investment but less flexibility.

Batch Mix Plants: Higher initial costs but can result in cost savings through improved quality and reduced waste.

Flexibility and Adaptability

Drum Mix Plants: Less flexible in terms of mix design changes.

Batch Mix Plants: More adaptable to different mix designs and requirements.

Factors to Consider When Choosing a Plant

Project Size and Scope

Consider the scale of your project. Larger projects with high asphalt demand may benefit from the continuous production of drum mix plants, while smaller or quality-focused projects may be better suited to batch mix plants.

Budget Constraints

Assess your budget for both initial investment and ongoing operational costs. Drum mix plants generally have lower initial costs, whereas batch mix plants, though more expensive upfront, can offer long-term savings through quality control.

Environmental Regulations

Ensure that the plant you choose complies with local environmental regulations. Batch mix plants often have an edge in meeting stringent environmental standards.

Quality Requirements

Evaluate the quality standards required for your project. If high-quality, consistent asphalt is critical, a batch mix plant may be the better choice.

Consult a Leading Construction Equipment Manufacturer Today!

Choosing the right asphalt plant can significantly impact the success of your project. For personalized advice and to explore the best options for your needs, consult with a leading construction equipment manufacturer. They can provide valuable insights and recommendations tailored to your specific project requirements.

For more information, read our detailed comparison and make an informed decision that ensures the best outcomes for your asphalt mixing needs.

Visit at: Batch Mix or Drum Mix Plant? A Comparison for Your Project

0 notes

Text

Drummed asphalt melting equipment - Atlas Technologies

See photos of quality drummed asphalt melting equiment from India. Capacity to heat 32 barrels in a batch of 70 minutes. For sale bitumen decanters

0 notes

Text

Combined asphalt drum mix and wet mix macadam plant in Libya

View case study of combined asphalt drum mix and wet mix macadam plant installed in Libya. Plant is with common feeder and with dust recycling system.The customer is a consultant for construction firms. Their requirement was for 90-120 tph drum mix plant and for a wet mix plant.

0 notes

Text

Asphalt Drum Mix Plant, Asphalt Mixing Plant, Asphalt Plant Manufacturers in India

S. P. Enterprise is India's reputed manufacturer and supplier of asphalt drum mix plant, asphalt mixing plant, asphalt plant, asphalt hot mix plant etc. Call us on +91-9712583240.

1 note

·

View note

Text

Best Manufacturers of Mobile Asphalt Drum Mix Plants in India

Alfa Omega India is recognized as one of the best manufacturers of mobile asphalt drum mix plants in India. We specialize in providing high-quality, durable, and efficient plants designed for superior performance in road construction. Explore our range now!

#construction equipment#mobile asphalt drum mix plant#mobile asphalt drum mix plant manufacturer#road construction equipment manufacturer

0 notes