#double sided pcb manufacturer

Explore tagged Tumblr posts

Text

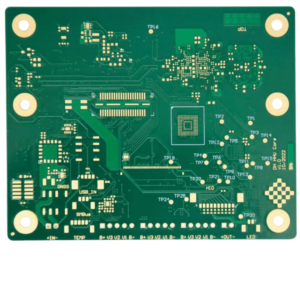

Double Sided PCB Manufacturers In Gujarat

Sb electronics is a manufacturer and supplier of double sided pcb, single sided pcb, aluminium pcb. it is widely used in various electronics applications in india.

#double sided pcb#double sided printed circuit board#double sided pcb manufacturer#double sided pcb supplier#double sided pcb manufacturer in gujarat

0 notes

Text

double sided pcb manufacturer

Techno Advance System is a largest PCB Assembly Company in India. We offer PCB Assembly, LED PCB Assembly, double sided pcb, and LED Assembly in Ahmedabad, India.

#double sided pcb#double sided pcb manufacturer#double sided pcb in india#pcb soldering manufacturer#double sided pcb manufacturing#double sided pcb in gandhinagar

0 notes

Text

Double Sided PCB Manufacturers in India: Your Trusted Partner for Excellence

In today’s fast-evolving electronics industry, double-sided printed circuit boards (PCBs) play a pivotal role in powering complex devices and technologies. Our PCBs, with conductive layers on both sides, provide enhanced design flexibility, higher circuit density, and improved performance. If you’re searching for double sided PCB manufacturers in India, Shree Ram Electronics is your ideal partner for high-quality, innovative, and cost-effective solutions.

Why Double-Sided PCBs?

Double-sided PCBs are widely used in applications requiring medium to high complexity. By utilizing both sides of the board, designers can achieve a compact yet efficient layout, essential for industries like telecommunications, automotive, consumer electronics, and industrial automation. With components mounted on both sides, our PCBs support more connections and functionalities, making we indispensable for modern devices.

Why Choose us?

We take pride in being a leader among double sided PCB manufacturers in India. With years of unparalleled manufacturing experience, we specialize in providing end-to-end solutions tailored to meet the diverse needs of our clients.

Here’s what sets us apart:

High-Quality Standards: Our PCBs are crafted with precision using state-of-the-art infrastructure to ensure durability and reliability.

Innovative Design Capabilities: Our expert team leverages cutting-edge technology to design PCBs that meet even the most demanding specifications.

Cost-Effective Solutions: We focus on delivering value without compromising on quality, making us a preferred choice for businesses seeking competitive pricing.

Comprehensive Support: From design to manufacturing and testing, we offer holistic services to streamline your project’s success.

Why Shree Ram Electronics Should Be Your Choice

Our company is committed to delivering high-quality, innovative, and cost-effective end-to-end electronics solutions to valuable customers. By leveraging our advanced manufacturing capabilities and design expertise, we ensure that every PCB we produce aligns with your exact needs.

Partnering with us means more than just procuring a product; it’s about building a relationship rooted in trust, reliability, and excellence.

Conclusion

When it comes to double sided PCB manufacturers in India, we stand out for its commitment to quality, innovation, and customer satisfaction. Reach out to us today and let us help you bring your electronic projects to life with precision-engineered PCBs designed for excellence.

0 notes

Text

As a top China PCB manufacturer, Hitech Circuits has a lot of experience and skill in every part of PCB production, from layout and design to manufacturing, testing, and after-sales support. All our work is done in our ISO-certified factory, ensuring high quality at every step. We focus on excellence, with each circuit board going through strict quality control before delivery. We make a wide range of printed circuit boards, including PCB prototypes, FR4 PCB, double-sided PCB, aluminum PCB, RF PCB, ceramic PCB, high-frequency PCB, and HDI PCB. If you need a reliable PCB manufacturer in China, contact us today! Just send email to [email protected] . For more information, please visit https://hitechcircuits.com/

#pcb manufacturer#pcb assembly#ceramic pcb#hdi pcb#PCB prototypes#fr4 pcb#double-sided PCB#multilayer pcb#aluminum PCB#pcb factory#pcb fabrication#RF PCB#high frequency

0 notes

Text

The Role of Double-Sided PCBs in Multilayered Circuitry

In the rapidly evolving world of electronics, staying abreast with design and architectural advancements is paramount for maintaining the edge in efficiency and performance. Among the various technological marvels that have graced the industry, double-sided Printed Circuit Boards (PCBs) stand out prominently. Acting as the backbone for many contemporary electronic applications, these components are particularly crucial when it comes to the construction of sophisticated multi-layered circuitry.

This era is marked by an insatiable thirst for electronic gadgets and devices. As this demand grows, so does the call for intricate, yet compact, device components. PCB technology, while rooted in time-tested principles, has had to adapt and morph to cater to these demands. In this transformational journey, double-sided PCBs have proven to be instrumental. Delving deep into their structure and functionality reveals their indispensable nature.

The Essential Components of Double-Sided PCBs

At a glance, a double-sided PCB might seem just like its single-sided counterpart but with components on both its sides. However, this seemingly simple design alteration serves a multitude of purposes:

Space Utilization: The quest for miniaturization in electronics is unending. As gadgets shrink, there's a pronounced emphasis on using every millimeter of space efficiently. Double-sided PCBs address this challenge head-on. By allowing components to be mounted on both sides, they drastically increase the potential for component placement, ensuring that devices remain compact.

Connectivity Enhancements: A remarkable feature of these PCBs is the capability to connect circuits on both faces through small holes known as 'vias'. This not only results in a more compact design but also leads to increased circuit density, fostering improved connectivity and signal transmission.

The Integration in Multilayered Circuitry

In the realm of PCBs, multi-layered designs are the epitome of complexity and innovation. Comprising more than two layers of conductive tracks, these PCBs have each layer meticulously isolated by an insulating substrate. Here's where double-sided PCBs become integral:

Enhanced Functionality: The multi-layered architecture can often seem daunting. However, with double-sided PCBs serving as a foundational layer, the process of integrating multiple layers becomes more systematic. This invariably results in devices that can perform a wider range of functions efficiently.

Complexity Management: Handling intricate circuits is no easy feat. But, thanks to the double-sided PCB's ability to manage connections on both of its surfaces, this complexity is significantly tamed, leading to devices that are both reliable and efficient.

Thermal Management: Electronic devices generate heat, and multi-layered circuitry, due to its dense component placement, exacerbates this challenge. Double-sided PCBs, with their dual-faced design, facilitate better heat distribution and dissipation, ensuring the devices remain cool and function optimally.

Advantages of Modern Electronics

The benefits of incorporating double-sided PCBs in multi-layered circuitry are manifold. While some advantages are immediately apparent, others become evident over prolonged use:

Reduced Size: Their ability to house components on both sides plays a significant role in achieving device miniaturization. This not only meets the consumer demand for smaller gadgets but also paves the way for innovative device designs.

Cost Efficiency: It's a common misconception that more advanced components invariably lead to escalated costs. While the upfront expenditure on double-sided PCBs might be marginally higher, the long-term gains in terms of device durability, reduced maintenance, and enhanced functionalities translate to substantial cost savings.

Reliability: Entities like Vishal International are a testament to the unparalleled quality and longevity that double-sided PCBs offer. Their meticulous construction and design, coupled with stringent quality checks, ensure that devices have fewer system glitches, ensuring minimal downtimes and extended device life.

To say that double-sided PCBs play a pivotal role in the realm of multi-layered circuitry would be an understatement.Double sided PCB manufacturers in Bangalore such as Vishal International silently power the seamless operations of a myriad of modern electronic devices. As the technological landscape marches forward, PCBs' significance is poised to grow exponentially. Designers, manufacturers, and tech aficionados must recognize and leverage the unmatched potential of double-sided PCBs in the intricate world of multi-layered circuitry.

#double sided pcb manufacturers in bangalore#double sided pcb manufacturers in India#pcb manufacturers in bangalore

0 notes

Text

Circuit Board, PCB assembly & electronics manufacturing service provider from China (hitechcircuits.com)

What is a prototype PCB assembly?

PCB prototyping is the experimentation pilot stage of the product which is to be mass produced at a later stage. This is more of an experiment which is done after the initial discussions and the design. This offers a pre-production analysis of the boards that are to be manufactured, reducing the possible number of errors in the PCB design. PCB prototypes help the manufacturer analyze the strengths as well as weak areas of their proposed circuit boards. Prototypes also serve as a reference point for future versions of the same product. At Hitechpcba, we handle PCB prototype assembly in quantities from one to hundred printed circuit boards.

We have acquired capabilities that enable us to serve our clients better. All these years, we have worked on many complex prototype PCB assembly projects, and we believe the following capabilities have helped us serve our clients better.

Prototype PCB Assembly Services: We specialize in the following prototype printed circuit board assembly services.

SMT: We can provide single-sided and double-sided surface mount PCB assemblies in different specifications.

Plated Through Hole: We offer plated through hole assembly with selective soldering.

Mixed Assemblies: We often work on projects involving mixed assemblies – through-hole and SMT and electromechanical assemblies.

PCBA Testing: All the PCBA functional testing is performed in-house. Over the years, we have invested in various test fixtures and equipment, which helps us ensure the quality of PCBA. Currently, we provide the following types of PCBA testing services:

Flying probe testing for PCB

Functional testing including system and board-level testing

General PCB Assembly Capabilities: Our general PCB assembly capabilities are not limited to these:

RoHS, leaded or lead free, clean and no chemistries

PCB components including various types of QFNs, BGAs, 0105, 0201, 0804, and press fit components in small quantities.

What are the benefits of a prototype PCB assembly?

Prototype PCB assembly comes with several advantages. These benefits play a major role in the facilitation of your PCB manufacturing. Some of these benefits include:

Detection of Flaws Early

With prototype PCB, you will easily detect whatever flaws are present during the product’s development stages. This will allow you to solve the issues thereby saving you some money if you had gone ahead to make the production having the flaws in them.

If you go ahead to make changes during the production, there may be a need for more technicalities, and this may be expensive.

Testing of Each Component

With a prototype, you will be able to test all your system’s elements individually before you go ahead to set it up. You should do this because it is important especially for very complex projects composed of several parts that are PCB based.

When you validate each of these components, you will be able to identify those areas having issues that you should look into. This is the only way the project can function the right way.

Reduction in Total Costs

Utilizing the prototype bare PCB for any of your projects could go a long way in reducing what you’ll have spent in total for the project. With prototyping, you will be able to notice those errors in your project and then make corrections before you start the real production.

As soon as these flaws have been checked and rectified, then you may continue with the manufacturing of your Printed circuit boards in large quantities, thereby saving you unnecessary costs.

High-Quality PCBs

Why prototyping your PCB is important is to help you test if your project will function effectively. When we talk of testing, it involves the identification of errors present and then rectifying and making corrections to them.

Therefore, the eventual PCB after the prototyping will be of high quality that surely meets standards set internationally.

Less Turnaround Time

With prototype PCB assembly, you will be able to reduce the total time used in producing your printed circuit board. While making use of prototype printed circuit boards, you’ll be able to see the errors and then make corrections before you start the actual production.

Therefore, the eventual prototype will be free of defects. This implies that your PCBs will be produced quickly by your manufacturer.

What are the different types of prototype PCB assembly services you offer?

With years of market presence and experience, we specializes in the following prototype PCB assembly services.

Plated through-hole (PTH): We can provide the through-hole assembly with selective soldering.

Surface mount technology (SMT): We offer single-sided as well as double-sided SMT board assemblies in varied specifications.

Mixed Assemblies: Our experts often work on projects involving both PTH and SMT assemblies.

What are the types of testing Hitechpcba use for prototype PCB assembly?

Automated Optical Inspection (AOI): This is performed before and after the soldering to identify the component placement, presence, and solder quality.

X-ray Testing: In this type of testing, the operator relies on the X-ray images of the PCB to check the solder joints and lead-less components such as Quad Flat Packs and ball grid arrays, which are generally not visible to naked eyes.

In-Circuit Testing (ICT): This method is used to detect manufacturing defects by testing the electrical properties in the SMT Assembly.

These techniques help us ensure the reliability and accuracy of the circuit boards. In addition to this, it ensures a long operational life of equipment, minimal production losses, streamlined processes, and much more.

What are the capabilities Hitechpcba offer for prototype PCB assemblies?

We specialize in offering IPC compliant, and quick turn PCB assemblies. We are very particular about our scheduled deliveries and timelines, and we deliver without compromising the quality. Our PCBA capabilities are not limited to these. Here are some capabilities we offer through prototype PCB assemblies.

RoHS compliance

Stringent testing procedures

Device encapsulation

Full turnkey, partial turnkey, and kitted/consigned services

Assemblies using Surface Mount (SMT), Thru-hole, Mixed Technology (SMT/Thru-hole), Single and double-sided SMT/PTH, Large parts on both sides, BGA on both sides.

Do you perform a component analysis for prototype PCB assemblies?

Yes, we check the quality and performance of components before mounting them on the circuit boards. This is because a malfunctioning component can affect the performance of the entire circuit board assembly and also pose risks.

What is your standard turnaround time for a prototype PCB assembly?

Our turnaround time for standard applications is two weeks. This timeframe varies depending on the complexity of the applications. However, we are committed to offering quick turnaround times without compromising on quality, functionality, and accuracy, which offers our client a competitive advantage and reduced time to market. You can also request any emergency assistance or queries related to any type of PCB assembly. Our experts will assist you in all possible ways.

How is the cost of prototype PCB assembly estimated?

PCBA costing varies based on the different factors, such as PCBA parts, type of materials to be used, order quantity, and much more. We can also offer quotes and customization options once you share the detailed requirement with us.

We focus on quality and customer satisfaction over anything else. This has helped us build a long list of happy and satisfied customers. So, if you wish to partner with a manufacturer of prototype PCB assembly in China, then don’t hesitate to reach us. Our experts will assist you through all the phases of the prototype PCB assembly process. We look forward to making your experience with us better and memorable.

How to choose prototype pcb assembly manufacturer?

Our pcb prototype assembly service includes the sourcing of components. This allows you to concentrate on what you do best: layout design. We have a dedicated sourcing staff that coordinates with multiple suppliers and distributors to purchase electronic parts as per client requirements, and our staff completes these purchasing particulars in a most efficient manner. We have advanced processes for optimal selection of packaging (cut tape, tube, bulk, etc.) to reduce the total cost. Furthermore, we are capable of cross-referencing parts and even locating hard-to-find and obsolete parts. Customers can be rest assured that when Hitech Circuits substitutes components that they are high quality: we only use the electronic component numbers and manufacturers specified in the BOM. We will not modify your original layout design. Part substitutions take place only with your permission.

The final pcb prototype assembly service cost includes assembly labor charges, bare circuit board rates, and part costs. We understand the importance of prompt delivery. The sooner the components are sourced, the sooner we can begin circuit board fabrication. We thoroughly evaluate engineering inquiries and concerns related to the related parts with our clients before commencing circuit board assembly. The average time taken for pcb manufacturing assembly is about two weeks, which can be further reduced if there are no hard-to-locate components or documentation mistakes.

We have specialized experts to deliver fast turnarounds for prototype circuit board assembly with surface-mount (SMT), through-hole (THT) and mixed-technology components.

Anyone interested in electronics and electronic circuit boards needs to understand the various stages of developing and producing a printed circuit board. It can come in handy when you are seeking a top prototype smt assembly provider. The various production stages of printed circuit boards entail design, prototyping (prototype PCB development and rapid prototyping pcb assembly), and PCB high volume production. Different entities will always seek part of the whole production process depending on their electronic circuit board needs.

However, this article seeks to help you understand everything about prototype PCB assembly, a fundamental aspect of the PCB production process.

Rapid prototyping pcb assembly represents a fundamental phase of the printed circuit production process. It is also inferred as PCBA prototype assembly, SMT or surface-mount technology PCB prototype, PCB sample assembly, etc. From these alternative names, the meaning of prototype assembly regarding printed circuit boards becomes apparent. So what is assembly prototype?

PCB prototype assembly service is a fast prototype printed circuit board assembly primarily used to test fresh or new electronic designs. Consequently, it assists with checking and ensuring quality assurance of the PCB. For instance, it verifies that no bug exists in the test PCB, updates the design, and finds bugs. In most instances, prototype assembly of an electronic project will require two or three iterations to ensure everything is perfect.

Why Choose Hitech Circuits PCB Assembly for Your Prototype PCB Assembly Projects?

There are several PCB manufacturers specializing in prototype PCB assembly services. However, Hitech Circuits stands out owing to the following:

1.Strong Supply Chain: Over the years, we have built strong supply chain relationships in the industry, which helps us fulfill the requirements of turnkey prototype assembly services easily.

2.Fastest Turnaround Times: Our engineering expertise coupled with our understanding of industry requirements and a well-equipped facility enables us to assure the fastest turnaround times of 24-48 hours.

3.Reliability: All the printed circuit boards that we produce are IPC compliant, which helps us assure reliability.

4.Competitive Pricing and Quick Quote: Our supply chain relationships enable us to assure competitive prices. The cost of the PCB prototype assembly will be made available within 24-48 hours.

2 notes

·

View notes

Text

How to identify multilayer pcb?

Multilayer printed circuit boards and double-sided PCB boards are similar in appearance. Ordinary people can’t see the difference between them without paying attention, or you can’t tell whether it is a double-sided PCB board or multilayer PCB board. So, how to distinguish between ordinary double-sided PCB boards and multi-layer PCB boards?

First of all, we must have an understanding of the number of layers of the circuit board. The number of layers of the PCB board is the inner layer. 1 layer is referred to as single layer PCB, and 2 layers is referred to as double sided PCB. Multilayer PCB board refers to 4-48 layers; the higher the number of layers, the higher the unit price. Because the inner layer of the circuit is to be pressed, the technical content is high, and the machine cost is relatively high.

Generally speaking, you can identify multilayer pcb by following:

The more layers, the larger the shadow in the sheet;

Dim shadows can be seen in the multi-layer PCB circuit board, if the shadow is light then you can see a little dim, and if the shadow is deep you can see the circuit clearly;

Multilayer PCB circuit boards generally have a smooth surface, especially when they are cleaned after forming and processing;

If you want to know how many layers of the PCB board are, and the precise data, you can only check through the IM inspection of the manufacturer or the PCB drawing of the development engineer.

0 notes

Text

Ceramic PCB Fabrication

Ceramic PCB and Substrate: Alumina PCB, Aluminum Nitride Base, Copper Clad

Ceramic PCB (ceramic substrate) refers to a special process board in which a copper foil is directly bonded to a surface of an alumina (Al2O3 ) or aluminum nitride (AlN) ceramic substrate (single or double-sided or multilayer Ceramic PCB) at a high temperature. The ultra-thin composite substrate produced has excellent electrical insulation properties, high thermal conductivity, excellent solderability, and high adhesion strength, and can etch various patterns like a PCB board, and has a large current carrying current ability.

Hitech Circuits is a professional ceramic pcb manufacturer, supplier from China, we mainly supply high quality Alumina (Al2O3) Ceramic PCB, Aluminum Nitride (AIN) Ceramic PCB board and IGBT Ceramic PCB. Our ceramic printed circuit boards features of high pressure, high insulation, high temperature, and high reliable and minor volume electronic products, Hitech is your best choice for ceramic PCB boards and needs.

Ceramic PCB Parameter

Ceramic PCB in high pressure, high insulation, high frequency, high temperature, and high reliable and minor volume electronic products, then Ceramic PCB will be your best choice.

Why Ceramic PCB has such excellent performance?

96% or 98% Alumina (Al2O3), Aluminum Nitride (ALN), or Beryllium Oxide (BeO) PCB

Conductors material: For thin film technology, thick film technology, it’ll be silver palladium (AgPd), gold pllladium (AuPd); For DCB (Direct Copper Bonded) it’ll be copper only

Application temp: -55~850℃

Thermal conductivity value: 16W~28W/m-K (Al2O3); 150W~240W/m-K for ALN , 220~250W/m-K for BeO;

Max compression strength: >7,000 N/cm2

Breakdown Voltage (KV/mm): 15/20/28 for 0.25mm/0.63mm/1.0mm respectively

Thermal expansion conefficient(ppm/K): 7.4 (under 50~200℃)

Why Purchase Your Ceramic PCBs from HITECH CIRCUITS?

At HITECH CIRCUITS, we are dedicated to producing and selling quality PCBs to all of our customers. With over 15 years of experience in the electronic industry we are committed to producing custom ceramic PCBs that meet up with the various electronic devices at hand. Our professionals manufacture nothing but top-notch ceramic PCBs that are developed to tackle your demands. In addition, we assure that you will get nothing but the best and affordable prices for all the quality ceramic PCB we manufacture. Regardless of the quality of the printed circuit boards that you want, it will be gotten at a decent price.

Ceramic PCB Classification

1. According to the material Alumina (Al2O3) Ceramic PCB Beryllium Oxide (BeO) Ceramic PCB Aluminum Nitride (ALN) Ceramic PCB

2. According to the manufacturing process HTCC (High-Temperature Co-fired Ceramic) LTCC (Low-Temperature Co-fired Ceramic) DBC (Direct Bonded Copper) DPC (Direct Plate Copper) Ceramic PCB is a thermal conductive organic ceramic circuit board with high thermal conductivity and prepared at a temperature below 250°C using thermally conductive ceramic powder and organic adhesive, ceramic PCB types by material including alumina pcb, Aluminum nitride ceramic PCB, Copper clad ceramic PCB, Zirconia ceramic base PCB.

Four types: HTCC, LTCC, DBC, and DPC

1. The HTCC (high temperature co-fired) preparation method requires a temperature above 1300°C, but due to the choice of the electrode, the preparation cost is quite expensive.

2. The LTCC (low temperature co-firing) requires a calcination process of about 850°C, but circuit precision is poor, and the thermal conductivity is low.

3. The DBC requires formingan alloy between the copper foil and the ceramic, and the calcination temperature needs to be strictly controlled within the temperature range of 1065-1085°C. Because the DBC requires the thickness of the copper foil, generally, it cannot be less than 150-300 microns. Therefore, the wire width to depth ratio of such ceramic circuit boards is limited.

4. The preparation methods of DPC include vacuum coating, wet coating, exposure and development, etching, and other process links, so the price of its products is relatively high. In addition, in terms of shape processing, DPC 1800 ceramic fiber board plates need to be laser cut. Traditional drilling and milling machines and punching machines cannot accurately process them, so the bonding force and line width are more precise.

Hitech manufactures Ceramic PCB (printed circuit board) using the latest materials and technology, that has worked with thousands of electronic engineers to get their products into market, we have full technical knowledge and Ceramic PCB manufacturing experience in Ceramic PCB fabrication (also called Ceramic printed circuit board manufacturing or rigid Ceramic printed circuit board fabrication).

0 notes

Text

double-sided PCB manufacturer in india

sb electronics is one of the best manufacturer of double sided pcb in gandhinagar, gujarat. Our Double-Sided PCBs offer the perfect balance between complexity and versatility, making them suitable for a wide range of applications where space and functionality are critical.

#double sided pcb#double sided pcb manufactures#double sided pcb supplier#double sided pcb in gujarat#double sided pcb in gandhinagar#double sided pcb in india

0 notes

Text

Best Quality Single Side PCB Manufacturers

Single-Sided PCB Manufacturers: A Reference to Vaishno Electronics

Single-sided printed circuit boards (PCBs) are a fundamental component in modern electronics, used to connect and support various electronic components. These PCBs are designed with copper traces on just one side of the board, making them simpler to design and manufacture compared to their double-sided counterparts. Manufacturers specializing in single-sided PCB manufacturers, such as Vaishno Electronics, play a crucial role in ensuring these boards meet industry standards for quality, efficiency, and performance.

What is a Single-Sided PCB?

A single-sided PCB, or single-layer PCB, is the simplest type of printed circuit board. As the name suggests, it has a single layer of conductive copper, which forms the electrical connections for the components. The board typically includes components like resistors, capacitors, diodes, and integrated circuits (ICs), all of which are mounted on one side of the board.

These boards are generally used in simpler, less complex electronic devices where circuit density is lower, and cost-effectiveness is a priority. Despite their simplicity, single-sided PCBs are highly reliable and widely used in a variety of industries.

The Manufacturing Process for Single-Sided PCBs

Design & Layout: The manufacturing process starts with creating a detailed design of the PCB layout. The circuit design ensures that the components are placed in an optimal way, and the copper traces are routed to create electrical connections.

Material Selection: The most commonly used material for single-sided PCBs is FR4, a type of fiberglass. However, manufacturers may also use other materials like polyimide or paper phenolic based on the application’s requirements. The choice of material affects the board’s performance and cost.

Copper Clad Laminate (CCL) Preparation: Copper-clad laminates are used as the base material. The copper layer is bonded to the substrate (usually a fiberglass material), creating the foundation for the PCB.

Etching: After the design is transferred onto the copper layer, the unwanted copper is etched away using a chemical process, leaving only the necessary conductive pathways.

Drilling: Holes are drilled into the PCB to accommodate components and create vias (if needed). However, in single-sided PCBs, vias are not typically required unless the design includes additional functionality.

Solder Mask and Silkscreen: A solder mask is applied to protect the copper traces and prevent accidental shorts. The silkscreen layer adds text labels for components, helping during the assembly process.

Assembly and Testing: Once the PCB is fabricated, components are soldered onto the board. After assembly, rigorous testing ensures that the board functions as expected, without any defects.

Advantages of Single-Sided PCBs

Cost-Effectiveness: Single-sided PCBs are relatively less expensive to manufacture than multi-layered or double-sided boards. The simplified design and fewer materials required result in a lower production cost.

Ease of Manufacturing: The design and manufacturing processes for single-sided PCBs are simpler, leading to faster production times and fewer chances for errors.

Compact Design: Although single-sided PCBs are typically used for less complex designs, they still allow for efficient and compact circuit arrangements, making them ideal for basic consumer electronics and small-scale devices.

Reliability: Despite their simplicity, single-sided PCBs offer reliable performance and are durable enough for use in a wide range of applications.

Simplicity in Assembly: Single-sided boards are easier to assemble since all components are on one side, reducing the need for complex placement and orientation during assembly.

Applications of Single-Sided PCBs

Single-sided PCBs are used in a variety of industries, including:

Consumer Electronics: Common devices such as household appliances, toys, and basic gadgets often use single-sided PCBs because of their cost-effectiveness and straightforward design.

Automotive: Single-sided PCBs are frequently found in automotive applications, where they are used in simpler electronics like lights, sensors, and basic control systems.

Industrial Equipment: Many industrial control systems, sensors, and machinery rely on single-sided PCBs for their simple and efficient designs.

Medical Devices: Certain medical instruments, especially non-complex diagnostic equipment, use single-sided PCBs due to their reliability and ease of manufacture.

Communication Devices: Simple communication devices like radio transmitters and receivers often use single-sided PCBs for their basic circuit requirements.

Why Choose a Reliable Manufacturer like Vaishno Electronics?

When selecting a manufacturer for your single-sided PCB needs, it is essential to partner with a company that has the expertise, equipment, and quality control processes to ensure the highest quality product. Vaishno Electronics is one such manufacturer that stands out for its commitment to producing high-quality single-sided PCBs.

Here are a few reasons why Vaishno Electronics is a trusted choice:

Proven Expertise: With years of experience in the PCB manufacturing industry, Vaishno Electronics has developed the technical know-how to produce high-quality single-sided PCBs that meet industry standards.

Custom Solutions: Vaishno Electronics offers customized PCB manufacturing services, tailoring their designs to meet specific client requirements. Whether it's a simple consumer product or an industrial application, they provide bespoke solutions for various needs.

Advanced Manufacturing Capabilities: The company uses state-of-the-art technology and equipment for PCB fabrication, ensuring precision and efficiency in every batch. This allows them to produce PCBs in high volumes while maintaining excellent quality.

Cost-Effectiveness: Vaishno Electronics understands the importance of cost-effective solutions, especially for large-scale production. Their manufacturing processes are designed to optimize cost while maintaining quality, making them an ideal choice for businesses looking for affordable yet reliable PCBs.

Quality Assurance: Rigorous testing procedures are implemented at every stage of the manufacturing process to ensure that the final product meets the highest standards of performance and durability.

Timely Delivery: Vaishno Electronics ensures that products are delivered on time, making them a reliable partner for businesses with strict timelines and production schedules.

Conclusion

Single-sided PCBs are a critical component in many electronics applications, providing a simple and cost-effective solution for circuit connections. Manufacturers like Vaishno Electronics specialize in the production of high-quality single-sided PCBs, ensuring that customers receive products that meet the highest standards of performance, reliability, and cost-efficiency. Whether you're working on consumer electronics, automotive systems, or industrial machinery, choosing a trusted manufacturer like Vaishno Electronics will help ensure the success of your project.

Visit:- https://www.vaishnavielectronics.co.in/single-side-pcb.html

0 notes

Text

Double Sided PCB Manufacturers in India - Shree Ram Electronics

Double sided PCB manufacturers in India play a crucial role in providing innovative solutions for various electronic applications. Shree Ram Electronics excels in this domain, offering high-quality, cost-effective double-sided PCBs that meet industry standards. With our extensive manufacturing experience and cutting-edge infrastructure, we ensure that each PCB is designed and produced to the highest level of precision and durability. Our commitment to innovation and excellence guarantees that we deliver solutions that cater to the unique needs of our valuable customers, making us a trusted partner in the electronics industry.

0 notes

Text

The difference between copper base PCB, fake double-sided copper base PCB and true double-sided copper base PCB

Copper base PCB is the best heat dissipation and the most expensive circuit board among metal-based PCBs. Generally, copper base PCB include single-sided copper PCB, double-sided copper base PCB, and fake double-sided copper base PCB. The specific advantages of copper base PCB make them widely used in areas with large changes in high and low temperatures, as well as in the precision communication equipment and LED car light markets. The pad production processes of copper substrate manufacturers generally include immersion gold, OSP, HASL, immersion silver, etc.

Authenticity of true and false double-sided copper base PCB

Fake double-sided copper base PCB are generally designed by customers with two layers of circuits, but they are not connected to each other. The real double-sided copper base PCB is the double-sided circuit layer designed by the customer with vias connecting the two-sided circuits.

The copper base PCB, circuit layer requires a large current carrying capacity, so a thicker copper foil should be used, with a thickness of generally 35μm~280μm; the thermal conductive insulation layer is the core technology of the copper substrate. The core thermal conductive component is composed of aluminum oxide and silicon powder and a polymer filled with epoxy resin. It has a small thermal resistance (0.15), excellent viscoelastic properties, and is resistant to thermal aging and can withstand mechanical and thermal stress.

The copper substrate metal base is the supporting component of the copper substrate. It is required to have high thermal conductivity. It is generally a copper plate. Copper plates can also be used (copper plates can provide better thermal conductivity). It is suitable for conventional mechanical processing such as drilling, punching and cutting.

The structure of the real and fake double-sided copper substrate can be divided into 5 layers: 1 layer is the top copper foil, 2 layers are thermal conductive insulation materials, 3 layers are aluminum plates, 4 layers are bottom insulation materials, and 5 layers are bottom copper foil. Their functions are as follows:

The 1st layer of copper foil is used as the top circuit pattern (conductive).

The 2nd insulating layer is also the key layer to reflect the thermal conductivity, also known as the thermal conductive layer, which plays a dual role of thermal conductivity and insulation. Whether the heat generated by the LED lamp can be quickly transferred to the aluminum plate, it is necessary to know the thermal resistance of the thermal conductive insulating material.

The function of the 3rd layer is to transfer the heat conducted by the thermal conductive insulating material to the lamp cup again. There is also an installation function.

The functions of the 4th and 5th layers are the same as those of the 2nd and 1st layers above.

Through the above structure, we can easily understand the thermal conductivity and heat dissipation principle of the copper base PCB. In addition, the special process of copper base PCB processing and the thermoelectric separation production technology have improved the thermal conductivity of the copper base PCB by several times. Therefore, most designers who make LED copper base PCB now design a thermoelectric separation thermal conductivity method to make the heat dissipation performance of the copper base PCB better.

Email us Cynthia<[email protected]> if you are interested in PCB and PCBA service.

0 notes

Text

Reliable PCB Manufacturers in Jaipur: Innovation and Precision

Many PCB manufacturers in Jaipur use the latest technologies and machinery to produce high-precision, high-performance PCBs. With cutting-edge facilities and automated processes, you can expect reliable and high-quality products every time. Whether you're in need of single-sided, double-sided, or multi-layer PCBs, Jaipur boasts numerous manufacturers that deliver advanced, durable, and cost-effective solutions to meet the needs of a wide variety of industries.

#pcb manufacturer in haryana#low-cost pcb manufacturer#multilayer pcb manufacturer#best pcb manufacturer#pcb manufacturer

0 notes

Text

The Rise of Sustainable Circuitry: Exploring Eco-Friendly Practices in PCB Manufacturing

In recent years, there has been a growing global concern regarding the environmental impact of various industries. One sector that has gained significant attention is the electronics industry, particularly in the manufacturing of printed circuit boards (PCBs). PCBs are integral components of electronic devices, ranging from smartphones and laptops to industrial machinery and medical equipment. As the demand for electronics continues to rise, it becomes crucial to explore eco-friendly practices in PCB manufacturing. This article delves into the emerging trend of sustainable circuitry and highlights the importance of adopting environmentally conscious approaches in the production of PCBs.

I. The Environmental Impact of Traditional PCB Manufacturing:

The conventional methods of PCB manufacturing have significant environmental consequences. The production processes involve the use of hazardous chemicals, such as lead, mercury, and brominated flame retardants (BFRs), which pose risks to human health and the ecosystem. Additionally, the energy consumption and carbon emissions associated with PCB manufacturing contribute to climate change. These factors have spurred the need for alternative practices that prioritize sustainability.

II. The Principles of Sustainable Circuitry:

Sustainable circuitry aims to minimize the environmental impact of PCB manufacturing through various principles:

a) Material Selection: One of the fundamental aspects of sustainable circuitry is choosing eco-friendly materials for PCB production. Opting for lead-free solder, recyclable substrates, and non-toxic coatings reduces the ecological footprint of the manufacturing process.

b) Waste Reduction: Sustainable circuitry emphasizes the reduction of waste generated during PCB manufacturing. Implementing efficient production techniques, recycling solder and unused materials, and proper disposal of hazardous waste are crucial steps in achieving this objective.

c) Energy Efficiency: Energy consumption plays a significant role in the environmental impact of PCB manufacturing. Sustainable practices focus on optimizing energy efficiency through process improvements, equipment upgrades, and the utilization of renewable energy sources.

d) Lifecycle Considerations: Sustainable circuitry takes into account the entire lifecycle of PCBs, including their disposal. Designing for disassembly and recyclability ensures that the materials used in PCBs can be recovered and reused, reducing the need for virgin resources.

III. Innovations in Sustainable Circuitry:

The pursuit of sustainable circuitry has driven innovations in PCB manufacturing. These advancements not only reduce environmental impact but also enhance the performance and longevity of electronic devices.

a) Green Chemistry: Green chemistry principles are being applied to develop eco-friendly alternatives to traditional PCB manufacturing chemicals. This includes the use of water-based fluxes and solder masks, as well as the development of halogen-free flame retardants.

b) Renewable Materials: Researchers are exploring the use of renewable materials, such as bioplastics and bio-based resins, as substitutes for conventional PCB substrates. These materials offer reduced environmental impact and can be derived from renewable resources.

c) Closed-Loop Manufacturing: Closed-loop manufacturing systems aim to minimize waste and resource consumption by recycling materials within the production process. This approach reduces the reliance on virgin materials and contributes to a more circular economy.

d) Life Cycle Assessment (LCA): LCA is a methodology used to evaluate the environmental impact of a product throughout its entire lifecycle. Applying LCA to PCB manufacturing allows for the identification of areas with the highest environmental impact, enabling targeted improvements and informed decision-making.

IV. The Role of Vishal International in Sustainable Circuitry:

Vishal International is at the forefront of promoting sustainable circuitry in PCB manufacturing. The company recognizes the importance of minimizing environmental impact and has implemented several eco-friendly practices.

a) Lead-Free Manufacturing: Vishal International utilizes lead-free solder in its PCB manufacturing processes. This eliminates the use of toxic materials and reduces the potential harm to both human health and the environment.

b) Energy Efficiency Measures: The company has invested in energy-efficient machinery and production techniques, reducing energy consumption and greenhouse gas emissions.

c) Waste Management: Vishal International emphasizes proper waste management, ensuring that hazardous materials are disposed of in compliance with environmental regulations. Additionally, the company actively promotes recycling and reuse of materials whenever possible.

d) Sustainable Material Choices: Vishal International prioritizes the use of eco-friendly materials in PCB manufacturing, such as recyclable substrates and non-toxic coatings. These choices contribute to the overall sustainability of their products.

Conclusion

As the demand for eco-friendly electronics grows, Vishal International's dedication to sustainable practices positions it as largest multilayer pcb manufcturers in India. By supporting companies like Vishal International, we can drive the transition toward a more sustainable and greener future in the electronics industry.

#multilayer pcb manufacturers in India#double sided pcb manufacturers in india#pcb suppliers in India

0 notes

Text

Double Sided Flexible PCB

A flexible PCB is a kind of printed circuit board, also called a flexible printed circuit, or FPC for short. FPC is made of adhesive material or non-adhesive material. The copper used in the FPC production process is divided into electrolytic copper and rolled copper, and non-stick rolled copper is more flexible and foldable. A double-layer flexible PCB consists of two conductive layers with an insulating layer in between. It is an ideal product that requires circuit density. https://www.hitechpcba.com/flexible-pcb-manufacturing

0 notes

Text

What Makes Aimtron Electronics a Leader in ESDM and PCB Assembly?

In today’s fast-paced world of electronics manufacturing, companies are constantly looking for ways to innovate, streamline operations, and improve the quality of their products. One company that stands out in this space is Aimtron Electronics, a leader in the field of Electronics System Design and Manufacturing (ESDM) and PCB (Printed Circuit Board) Assembly. But what sets AImtron apart from its competitors?

Let’s explore the key factors that have helped Aimtron Electronics become a trailblazer in the ESDM and PCB assembly industries.

1. Comprehensive End-to-End ESDM Solutions

Aimtron Electronics offers a complete range of services that span the entire product lifecycle, from initial concept to final delivery. This end-to-end capability allows the company to provide tailored solutions that meet the unique needs of its clients. Whether it's designing a custom PCB, developing complex electronics systems, or providing full-scale manufacturing, Aimtron integrates each step seamlessly, ensuring quality and efficiency throughout the process.

This ability to handle every phase of the development cycle means clients don't have to manage multiple vendors, which can lead to miscommunication, delays, and inconsistencies. Aimtron’s holistic approach not only simplifies the process but also accelerates time-to-market, which is crucial in today’s competitive electronics landscape.

2. Cutting-Edge PCB Assembly Technology

Aimtron Electronics has built a reputation for using the latest technology and techniques in PCB assembly. The company invests heavily in advanced manufacturing equipment, including pick-and-place machines, automated optical inspection (AOI) systems, and reflow soldering technology. These innovations ensure that each PCB assembly is completed with the highest level of precision and reliability.

Moreover, Aimtron’s facilities are designed to handle a wide range of PCB assembly types, including single-sided, double-sided, and multi-layer boards. This versatility means that the company can meet the needs of a variety of industries, from consumer electronics to automotive and industrial applications.

3. Uncompromising Quality Control Standards

One of the hallmarks of AImtron Electronics is its commitment to quality. The company adheres to strict industry standards, such as ISO 9001 and IPC-2221, ensuring that its products meet or exceed the highest benchmarks in the ESDM and PCB assembly industries. AImtron integrates quality control (QC) at every stage of the production process, from design to final assembly.

To further ensure the reliability of its products, AImtron employs automated testing systems, in-circuit testing (ICT), and functional testing to detect any potential defects early in the process. These rigorous quality control measures reduce the likelihood of failure and improve the overall performance of the final product.

4. Design Expertise and Innovation

At Aimtron, the design team is at the heart of everything. The company’s engineers are experts in Electronics System Design (ESD), with deep knowledge in a wide variety of industries and applications. AImtron’s design capabilities cover a broad spectrum, including analog circuits, digital circuits, RF (Radio Frequency) designs, and power electronics.

The team works closely with clients to understand their unique needs and provide innovative solutions that align with their business goals. This collaborative approach ensures that each design is optimized for performance, manufacturability, and cost-efficiency. Additionally, Aimtron’s design team uses state-of-the-art CAD (Computer-Aided Design) software to create accurate and detailed schematics, reducing the likelihood of errors and streamlining the design-to-manufacturing transition.

5. Scalability and Flexibility

Aimtron Electronics excels in delivering scalable solutions. Whether a customer needs a small batch run for prototyping or high-volume production for large-scale manufacturing, Aimtron has the capacity and flexibility to meet diverse demands. The company’s manufacturing facilities are designed for scalability, enabling it to accommodate both small and large orders with equal efficiency and quality.

This flexibility is particularly beneficial for clients in industries such as medical devices, telecommunications, automotive, and aerospace, where demands can fluctuate based on market conditions, regulations, and technological advancements.

6. Commitment to Sustainability

As industries increasingly focus on reducing their environmental footprint, Aimtron Electronics has taken significant steps to ensure that its operations are both efficient and eco-friendly. The company actively embraces green manufacturing practices, such as reducing waste, recycling materials, and utilizing energy-efficient technologies in its PCB assembly process.

Aimtron also works with clients to develop environmentally friendly products, ensuring that their designs are not only high-performing but also sustainable. This commitment to sustainability resonates with clients who are looking to reduce their carbon footprint and meet global environmental standards.

7. Customer-Centric Approach

Aimtron’s customer-centric approach is one of the key factors that sets it apart from other companies in the ESDM and PCB assembly space. From the initial consultation to after-sales support, Aimtron places a strong emphasis on building lasting relationships with its clients.

The company offers personalized service, ensuring that each customer’s unique needs are met with tailored solutions. Aimtron’s engineering team works hand-in-hand with clients to refine designs, troubleshoot issues, and optimize product performance. Additionally, the company’s customer service team is always available to provide ongoing support, from product updates to maintenance and repair services.

8. Global Reach with Local Expertise

While Aimtron Electronics operates on a global scale, it combines this reach with local expertise to serve a diverse client base across multiple industries. The company’s team understands the nuances of different markets, from regional regulations and certifications to cultural considerations in manufacturing.

Aimtron’s ability to navigate these complexities while delivering top-tier ESDM and PCB assembly services has earned the company a strong reputation as a trusted partner in the global electronics supply chain.

Conclusion

Aimtron Electronics stands out as a leader in Electronics System Design and Manufacturing (ESDM) and PCB Assembly due to its combination of cutting-edge technology, rigorous quality standards, innovative design expertise, and a customer-focused approach. The company’s commitment to excellence, scalability, and sustainability has positioned it as a trusted partner for companies across a variety of industries.

With a strong emphasis on precision, efficiency, and reliability, Aimtron Electronics continues to push the boundaries of what’s possible in electronics manufacturing, ensuring that its clients remain competitive in an ever-evolving market.

If you're looking for a partner who can handle all your ESDM and PCB assembly needs, Amitron Electronics offers the experience, technology, and customer care you need to succeed.

#Electronics System Design and Manufacturing (ESDM)#PCB Assembly#Electronics System Design#functional testing#automated optical inspection#reflow soldering#ESDM Solutions

0 notes