#Double sided PCB manufacturers in India

Explore tagged Tumblr posts

Text

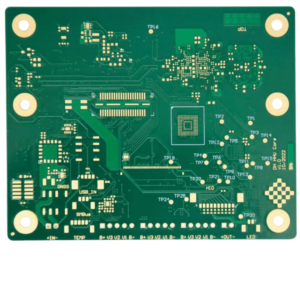

Double Sided PCB Manufacturers in India: Your Trusted Partner for Excellence

In today’s fast-evolving electronics industry, double-sided printed circuit boards (PCBs) play a pivotal role in powering complex devices and technologies. Our PCBs, with conductive layers on both sides, provide enhanced design flexibility, higher circuit density, and improved performance. If you’re searching for double sided PCB manufacturers in India, Shree Ram Electronics is your ideal partner for high-quality, innovative, and cost-effective solutions.

Why Double-Sided PCBs?

Double-sided PCBs are widely used in applications requiring medium to high complexity. By utilizing both sides of the board, designers can achieve a compact yet efficient layout, essential for industries like telecommunications, automotive, consumer electronics, and industrial automation. With components mounted on both sides, our PCBs support more connections and functionalities, making we indispensable for modern devices.

Why Choose us?

We take pride in being a leader among double sided PCB manufacturers in India. With years of unparalleled manufacturing experience, we specialize in providing end-to-end solutions tailored to meet the diverse needs of our clients.

Here’s what sets us apart:

High-Quality Standards: Our PCBs are crafted with precision using state-of-the-art infrastructure to ensure durability and reliability.

Innovative Design Capabilities: Our expert team leverages cutting-edge technology to design PCBs that meet even the most demanding specifications.

Cost-Effective Solutions: We focus on delivering value without compromising on quality, making us a preferred choice for businesses seeking competitive pricing.

Comprehensive Support: From design to manufacturing and testing, we offer holistic services to streamline your project’s success.

Why Shree Ram Electronics Should Be Your Choice

Our company is committed to delivering high-quality, innovative, and cost-effective end-to-end electronics solutions to valuable customers. By leveraging our advanced manufacturing capabilities and design expertise, we ensure that every PCB we produce aligns with your exact needs.

Partnering with us means more than just procuring a product; it’s about building a relationship rooted in trust, reliability, and excellence.

Conclusion

When it comes to double sided PCB manufacturers in India, we stand out for its commitment to quality, innovation, and customer satisfaction. Reach out to us today and let us help you bring your electronic projects to life with precision-engineered PCBs designed for excellence.

0 notes

Text

The Role of Double-Sided PCBs in Multilayered Circuitry

In the rapidly evolving world of electronics, staying abreast with design and architectural advancements is paramount for maintaining the edge in efficiency and performance. Among the various technological marvels that have graced the industry, double-sided Printed Circuit Boards (PCBs) stand out prominently. Acting as the backbone for many contemporary electronic applications, these components are particularly crucial when it comes to the construction of sophisticated multi-layered circuitry.

This era is marked by an insatiable thirst for electronic gadgets and devices. As this demand grows, so does the call for intricate, yet compact, device components. PCB technology, while rooted in time-tested principles, has had to adapt and morph to cater to these demands. In this transformational journey, double-sided PCBs have proven to be instrumental. Delving deep into their structure and functionality reveals their indispensable nature.

The Essential Components of Double-Sided PCBs

At a glance, a double-sided PCB might seem just like its single-sided counterpart but with components on both its sides. However, this seemingly simple design alteration serves a multitude of purposes:

Space Utilization: The quest for miniaturization in electronics is unending. As gadgets shrink, there's a pronounced emphasis on using every millimeter of space efficiently. Double-sided PCBs address this challenge head-on. By allowing components to be mounted on both sides, they drastically increase the potential for component placement, ensuring that devices remain compact.

Connectivity Enhancements: A remarkable feature of these PCBs is the capability to connect circuits on both faces through small holes known as 'vias'. This not only results in a more compact design but also leads to increased circuit density, fostering improved connectivity and signal transmission.

The Integration in Multilayered Circuitry

In the realm of PCBs, multi-layered designs are the epitome of complexity and innovation. Comprising more than two layers of conductive tracks, these PCBs have each layer meticulously isolated by an insulating substrate. Here's where double-sided PCBs become integral:

Enhanced Functionality: The multi-layered architecture can often seem daunting. However, with double-sided PCBs serving as a foundational layer, the process of integrating multiple layers becomes more systematic. This invariably results in devices that can perform a wider range of functions efficiently.

Complexity Management: Handling intricate circuits is no easy feat. But, thanks to the double-sided PCB's ability to manage connections on both of its surfaces, this complexity is significantly tamed, leading to devices that are both reliable and efficient.

Thermal Management: Electronic devices generate heat, and multi-layered circuitry, due to its dense component placement, exacerbates this challenge. Double-sided PCBs, with their dual-faced design, facilitate better heat distribution and dissipation, ensuring the devices remain cool and function optimally.

Advantages of Modern Electronics

The benefits of incorporating double-sided PCBs in multi-layered circuitry are manifold. While some advantages are immediately apparent, others become evident over prolonged use:

Reduced Size: Their ability to house components on both sides plays a significant role in achieving device miniaturization. This not only meets the consumer demand for smaller gadgets but also paves the way for innovative device designs.

Cost Efficiency: It's a common misconception that more advanced components invariably lead to escalated costs. While the upfront expenditure on double-sided PCBs might be marginally higher, the long-term gains in terms of device durability, reduced maintenance, and enhanced functionalities translate to substantial cost savings.

Reliability: Entities like Vishal International are a testament to the unparalleled quality and longevity that double-sided PCBs offer. Their meticulous construction and design, coupled with stringent quality checks, ensure that devices have fewer system glitches, ensuring minimal downtimes and extended device life.

To say that double-sided PCBs play a pivotal role in the realm of multi-layered circuitry would be an understatement.Double sided PCB manufacturers in Bangalore such as Vishal International silently power the seamless operations of a myriad of modern electronic devices. As the technological landscape marches forward, PCBs' significance is poised to grow exponentially. Designers, manufacturers, and tech aficionados must recognize and leverage the unmatched potential of double-sided PCBs in the intricate world of multi-layered circuitry.

#double sided pcb manufacturers in bangalore#double sided pcb manufacturers in India#pcb manufacturers in bangalore

0 notes

Text

double-sided PCB manufacturer in india

sb electronics is one of the best manufacturer of double sided pcb in gandhinagar, gujarat. Our Double-Sided PCBs offer the perfect balance between complexity and versatility, making them suitable for a wide range of applications where space and functionality are critical.

#double sided pcb#double sided pcb manufactures#double sided pcb supplier#double sided pcb in gujarat#double sided pcb in gandhinagar#double sided pcb in india

0 notes

Text

double sided pcb manufacturer

Techno Advance System is a largest PCB Assembly Company in India. We offer PCB Assembly, LED PCB Assembly, double sided pcb, and LED Assembly in Ahmedabad, India.

#double sided pcb#double sided pcb manufacturer#double sided pcb in india#pcb soldering manufacturer#double sided pcb manufacturing#double sided pcb in gandhinagar

0 notes

Text

Double-Sided Masking Tapes Market 2024-2033 : Demand, Trend, Segmentation, Forecast, Overview And Top Companies

The double-sided masking tapes global market report 2024 from The Business Research Company provides comprehensive market statistics, including global market size, regional shares, competitor market share, detailed segments, trends, and opportunities. This report offers an in-depth analysis of current and future industry scenarios, delivering a complete perspective for thriving in the industrial automation software market.

Double-Sided Masking Tapes Market, 2024 report by The Business Research Company offers comprehensive insights into the current state of the market and highlights future growth opportunities.

Market Size - The double-sided masking tapes market size has grown strongly in recent years. It will grow from $12.33 billion in 2023 to $13.1 billion in 2024 at a compound annual growth rate (CAGR) of 6.2%. The growth in the historic period can be attributed to automotive industry demand, electronics and pcb manufacturing, construction and building applications, industrial and manufacturing needs, and efficient bonding solutions

The double-sided masking tapes market size is expected to see strong growth in the next few years. It will grow to $17.25 billion in 2028 at a compound annual growth rate (CAGR) of 7.1%. The growth in the forecast period can be attributed to increased automation in manufacturing, e-commerce and online sales, regulatory compliance, medical and healthcare applications, and renewable energy and solar panel assembly. Major trends in the forecast period include advanced materials and composites, automation in manufacturing, technological innovations, innovative solutions, and strategic partnerships.

Order your report now for swift delivery @ https://www.thebusinessresearchcompany.com/report/double-sided-masking-tapes-global-market-report

The Business Research Company's reports encompass a wide range of information, including:

1. Market Size (Historic and Forecast): Analysis of the market's historical performance and projections for future growth.

2. Drivers: Examination of the key factors propelling market growth.

3. Trends: Identification of emerging trends and patterns shaping the market landscape.

4. Key Segments: Breakdown of the market into its primary segments and their respective performance.

5. Focus Regions and Geographies: Insight into the most critical regions and geographical areas influencing the market.

6. Macro Economic Factors: Assessment of broader economic elements impacting the market.

Market Drivers - The growing penetration of the construction sector is expected to propel the growth of double-sided masking tapes. Double-sided masking tapes are used to resist the material from corrosion and keep the material surfaces clean and smooth and provide sealing function protection against environmental elements during construction. Due to these characteristics, the construction industry has gradually used double-sided masking tape for outdoor and indoor applications. For instance, in September 2021, according to the Global Construction Outlook report by Marsh, a UK-based Insurance company stated that between 2020 and 2030, the global construction market is expected to grow by $4.5 trillion, reaching $15.2 trillion, with emerging markets accounting for $8.9 trillion. Furthermore, China, India, the United States, and Indonesia will account for 58.3% of global construction growth. Therefore, the rise in construction activities is expected to boost demand for double-sided masking tapes market during the forecast period.

The double-sided masking tapes market covered in this report is segmented –

1) By Product Type: Silicon-based Adhesive, Acrylic-based Adhesive, Rubber-based Adhesive 2) By Application: Painting, Plating, Abrasive Blasting, High-Temperature Applications, Other Applications 3) By End-User: Automotive, Building and Construction, Healthcare, Electrical and Electronics, Packaging, Aerospace, Other End-users

Get an inside scoop of the double-sided masking tapes market, Request now for Sample Report @ https://www.thebusinessresearchcompany.com/sample.aspx?id=7204&type=smp

Regional Insights - North America was the largest region in the double-sided masking tapes market in 2023. Asia-Pacific is expected to be the fastest-growing region in the double-sided masking tapes market share during the forecast period. The regions covered in the double-sided masking tapes market report include Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East and Africa.

Key Companies - Major companies operating in the double-sided masking tapes market include 3M, Intertapes Polymer Group, Shurtape Technologies LLC, TesaTapes Private Ltd., Nitto Denko Corp, Lintec Corporation, Avery Dennison Corporation, Yem Chio Co Ltd., SEKISUI Chemical Co Ltd., Lohmann GmbH & Co. Kg, Guangzhou Broadya Adhesive Products Co Ltd., Scapa Group plc, Berry Global Inc., Saint-Gobain Performance Plastics, L&L Products, Adchem Corp, Adhesive Applications Inc., Adhesives Research Inc., Advanced Flexible Composites Inc., Adhesive Systems Inc., American Biltrite Inc., Arkema Group, Ashland Inc., Bostik Findley SA, Collano Adhesives AG, Dow Inc., Drytac Corp, Franklin International Group Ltd., H.B. Fuller India Adhesives Pvt Ltd.

Table of Contents 1. Executive Summary 2. Double-Sided Masking Tapes Market Report Structure 3. Double-Sided Masking Tapes Market Trends And Strategies 4. Double-Sided Masking Tapes Market – Macro Economic Scenario 5. Double-Sided Masking Tapes Market Size And Growth ….. 27. Double-Sided Masking Tapes Market Competitor Landscape And Company Profiles 28. Key Mergers And Acquisitions 29. Future Outlook and Potential Analysis 30. Appendix

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

Find the best PCB manufacturing companies in Gujarat

Gujarat has also become the most suitable location for the manufacturing of PCBs owing to its rapid industrial development and utmost infrastructural facilities. The state has a solid industrial nature, and the government encourages further development by providing stimulus for electronics and PCB manufacturing. This makes it easy for the PCB manufacturing companies in Gujarat to find a suitable environment to operate from. These PCB manufacturing companies have highly developed technologically enabled capabilities and expertise in Gujarat.

Top PCB Manufacturing Companies in Gujarat

Epsilon Electronics

Epsilon Electronics is one of the leading PCB Manufacturing companies in Gujarat, operating in the fields of embedded systems and product engineering in India. From embedded software development services to industrial products and projects development, PCB manufacturing, and 3D design printing, Epsilon Electronics can be categorized as a one-stop-shop. The company has earned a reputation for quickly translating ideas into practicable solutions, which has led businesses to consider it as their preferred provider as PCB manufacturing companies in Gujarat.

The strengths that help Epsilon Electronics stand out from the other competitors are its sophistication in its tools and people to do the job. Their skills in quickly translating concepts into deliverables and their excellent customer relations make them a valued supplier in the PCB manufacturing sector. For specific requirements or for faster deliveries, Epsilon Electronics has the experience and capability that clients require when dealing with this company.

SB Electronics

SB Electronics is one of the pioneer organizations in PCB manufacturing companies in Gujarat having experience in this sector more than 25 years. The company deals in manufacturing multi-layer PCBs such as Single Side, Double Side P. T. H. (through-hole plating) and Double Side NON- PTH PCBs using high-end materials such as FR2, FR4, CEM. SB Electronics has always been committed to providing quality and innovative printed circuit boards making it a reliable supplier to diverse industries.

Using the information provided above, you can make a list of the best companies for pcb manufacturing in Gujarat for your next electronic project. For more details or to discuss your specific case, please do not hesitate to contact Epsilon Electronics. We are here to assist you in achieving your goal of having the finest PCB solutions in the industry. Click on the following link to visit our website now.

#PCB manufacturing companies in Gujarat#pcb manufacturing#pcb design company in india#PCB manufacturing companies#PCB manufacturing company#printed circuit board

0 notes

Text

Printed Circuit Boards Manufacturers — How To Choose The Right One

1. Industry Proficiency and Abilities

You will have to select a PCB manufacturer who provides the types of PCB you need. Other parameters to be kept in mind like proficiency, abilities, facilities, highly equipped technology and another instrument, human resources, standards/certification, location, testing lab with R & D set up, etc.

You wouldn’t search for a shop that initially does single-sided, double-sided, and low-layer count PCBs to manufacture your 24-layer backplane PCB manufacturer!

Be assured that your need match up with the supplier.

2. Products with Quality / Standard Certifications

Qualitative product is one of the most essential parameters to keep in mind when selecting a PCB manufacturer. First, you must review the PCB manufacturer’s Quality Management System (QMS).Depending upon your need assessment; you can look forward to your manufacturer to be ISO 9001 certified at least.ISO Certification primarily indicates that a basic QMS exists. Some examples are quality policy, SOP implementation, effective and preventive actions, continuous assessment, and employee re training.

3. On-time Delivery

Be assured that the PCB manufacturer you finalize has a performance data record and they can convey precise lead time and dispatch within that lead time. The accomplishment of your project is highly dependent on those results.

4. Cost

The cost of PCB manufacturing is dependent on many different parameters.

Source: India or abroad

Abroad sources are supposed to be cheaper but come with other parameters considered like longer delivery time, high logistic costs, linguistic problem for communication..

An Indian source is high – priced but if you find a suitable source locally, you could have the benefit of the least delivery time and minimum transportation cost, and you may visit the source also.

0 notes

Text

Roots EMS

PCB Assembly & Electronics Manufacturing Services Company in India

Our Services

PCB Design and Engineering

PCB Assembly & SMT

Vapor phase soldering

Conformal Coating

Box Build Assembly

Our PCB Designing Services

Schematic capture

Layout

Fabrication

Testing

PCB Assembly & SMT

CAPABILITIES

Hi complex double-sided PCB assembly

High mix, medium volume assemblies

Fine Pitch SMT, Through-hole and Box Build Assemblies

Automated optical inspection

In-circuit test

X-ray inspection

Full functional testing, automatic testing equipment and End of Line (EOL) testing

Conformal coating

IPC 610 standards class 2 and class 3

Design for manufacturing (DFM), Design for Assembly (DFA) & Design for Test (DFT) analysis

End to End manufacturing traceability

Rapid prototyping

https://rootsems.com/

Group of Companies

ROOTS INUSTRIES INDIA LIMITED

ROOTS MULTICLEAN LIMITED

ROOTS AUTO PRODUCTS PRIVATE LIMITED

ROOTS CAST PRIVATE LIMITED

ROOTS POLYCRAFT

ROOTS PRECISION PRODUCTS PRIVATE LIMITED

SATCHIDANANDA JOTHI NIKETHAN INTERNATIONAL SCHOOL

RK NATURE CURE HOME

roohttps://rootsems.com/about-us/

#printedcircuitboard#roots#PCB Design and Engineering#PCB Assembly & SMT#Vapor phase soldering#Conformal Coating#Box Build Assembly

1 note

·

View note

Text

Double Sided PCB Manufacturers in India - Shree Ram Electronics

Double sided PCB manufacturers in India play a crucial role in providing innovative solutions for various electronic applications. Shree Ram Electronics excels in this domain, offering high-quality, cost-effective double-sided PCBs that meet industry standards. With our extensive manufacturing experience and cutting-edge infrastructure, we ensure that each PCB is designed and produced to the highest level of precision and durability. Our commitment to innovation and excellence guarantees that we deliver solutions that cater to the unique needs of our valuable customers, making us a trusted partner in the electronics industry.

0 notes

Text

The Rise of Sustainable Circuitry: Exploring Eco-Friendly Practices in PCB Manufacturing

In recent years, there has been a growing global concern regarding the environmental impact of various industries. One sector that has gained significant attention is the electronics industry, particularly in the manufacturing of printed circuit boards (PCBs). PCBs are integral components of electronic devices, ranging from smartphones and laptops to industrial machinery and medical equipment. As the demand for electronics continues to rise, it becomes crucial to explore eco-friendly practices in PCB manufacturing. This article delves into the emerging trend of sustainable circuitry and highlights the importance of adopting environmentally conscious approaches in the production of PCBs.

I. The Environmental Impact of Traditional PCB Manufacturing:

The conventional methods of PCB manufacturing have significant environmental consequences. The production processes involve the use of hazardous chemicals, such as lead, mercury, and brominated flame retardants (BFRs), which pose risks to human health and the ecosystem. Additionally, the energy consumption and carbon emissions associated with PCB manufacturing contribute to climate change. These factors have spurred the need for alternative practices that prioritize sustainability.

II. The Principles of Sustainable Circuitry:

Sustainable circuitry aims to minimize the environmental impact of PCB manufacturing through various principles:

a) Material Selection: One of the fundamental aspects of sustainable circuitry is choosing eco-friendly materials for PCB production. Opting for lead-free solder, recyclable substrates, and non-toxic coatings reduces the ecological footprint of the manufacturing process.

b) Waste Reduction: Sustainable circuitry emphasizes the reduction of waste generated during PCB manufacturing. Implementing efficient production techniques, recycling solder and unused materials, and proper disposal of hazardous waste are crucial steps in achieving this objective.

c) Energy Efficiency: Energy consumption plays a significant role in the environmental impact of PCB manufacturing. Sustainable practices focus on optimizing energy efficiency through process improvements, equipment upgrades, and the utilization of renewable energy sources.

d) Lifecycle Considerations: Sustainable circuitry takes into account the entire lifecycle of PCBs, including their disposal. Designing for disassembly and recyclability ensures that the materials used in PCBs can be recovered and reused, reducing the need for virgin resources.

III. Innovations in Sustainable Circuitry:

The pursuit of sustainable circuitry has driven innovations in PCB manufacturing. These advancements not only reduce environmental impact but also enhance the performance and longevity of electronic devices.

a) Green Chemistry: Green chemistry principles are being applied to develop eco-friendly alternatives to traditional PCB manufacturing chemicals. This includes the use of water-based fluxes and solder masks, as well as the development of halogen-free flame retardants.

b) Renewable Materials: Researchers are exploring the use of renewable materials, such as bioplastics and bio-based resins, as substitutes for conventional PCB substrates. These materials offer reduced environmental impact and can be derived from renewable resources.

c) Closed-Loop Manufacturing: Closed-loop manufacturing systems aim to minimize waste and resource consumption by recycling materials within the production process. This approach reduces the reliance on virgin materials and contributes to a more circular economy.

d) Life Cycle Assessment (LCA): LCA is a methodology used to evaluate the environmental impact of a product throughout its entire lifecycle. Applying LCA to PCB manufacturing allows for the identification of areas with the highest environmental impact, enabling targeted improvements and informed decision-making.

IV. The Role of Vishal International in Sustainable Circuitry:

Vishal International is at the forefront of promoting sustainable circuitry in PCB manufacturing. The company recognizes the importance of minimizing environmental impact and has implemented several eco-friendly practices.

a) Lead-Free Manufacturing: Vishal International utilizes lead-free solder in its PCB manufacturing processes. This eliminates the use of toxic materials and reduces the potential harm to both human health and the environment.

b) Energy Efficiency Measures: The company has invested in energy-efficient machinery and production techniques, reducing energy consumption and greenhouse gas emissions.

c) Waste Management: Vishal International emphasizes proper waste management, ensuring that hazardous materials are disposed of in compliance with environmental regulations. Additionally, the company actively promotes recycling and reuse of materials whenever possible.

d) Sustainable Material Choices: Vishal International prioritizes the use of eco-friendly materials in PCB manufacturing, such as recyclable substrates and non-toxic coatings. These choices contribute to the overall sustainability of their products.

Conclusion

As the demand for eco-friendly electronics grows, Vishal International's dedication to sustainable practices positions it as largest multilayer pcb manufcturers in India. By supporting companies like Vishal International, we can drive the transition toward a more sustainable and greener future in the electronics industry.

#multilayer pcb manufacturers in India#double sided pcb manufacturers in india#pcb suppliers in India

0 notes

Text

Double Sided PCB Manufacturers In Gujarat

Sb electronics is a manufacturer and supplier of double sided pcb, single sided pcb, aluminium pcb. it is widely used in various electronics applications in india.

#double sided pcb#double sided printed circuit board#double sided pcb manufacturer#double sided pcb supplier#double sided pcb manufacturer in gujarat

0 notes

Link

Multilayer PCB Manufacturer in India, Multilayer PCB Manufacturer Delhi, Multilayer PCB, Multilayer PCB Circuit Board Delhi, Multilayer PTH PCBs Delhi. Double Sided PCB Manufacturers in India, PCB Manufacturer in Delhi

1 note

·

View note

Text

Techno Advance System is one of the Leading Box Build Assembly Service Provider and Single Sided PCB Manufacturer and Supplier in India. We also Manufacturer Double Sided PCB in Ahmedabad.

0 notes

Text

Power Capacitor — BCH Electric Limited

What is Power Capacitor?

Power capacitor are passive electronic components that provide a static source of reactive power in electrical distribution systems. They consist of two conducting plates separated by an insulating material called the dielectric. Power capacitors are used in the aerospace and automotive industries.

BCH India Power capacitors are aloof electronic parts that give responsive power Contactors static wellspring in electrical dispersion frameworks. They comprise two directing plates isolated by a protecting material called the dielectric. Multi-facet dielectrics give exceptional temperature dependability and recurrence attributes. Single-layer dielectrics are likewise accessible. Capacitance, a proportion of energy stockpiling capacity, is regularly communicated as C = K A/D, where An is the space of the terminals, D is their division, and K is a dielectric component between them the cathodes.

BCH Electric Limited Power capacitors are manufactured using Zn-Al metalized polypropylene film. These modules are provided with pressure interrupter arrangement for safety against bursting due to internal pressure arised due to prolonged high voltage/current. The modules are assembled in an aluminum case or CRCA container.

Non self healing APP capacitors manufactured using double hazy and double thick Polypropylene films between two electrodes of thick Aluminium foil have extended foil construction to ensure low watt losses.

Detail and Provisions of Power capacitor

Reach 1KVAR to 50KVAR

Type :

'MPP' Tube-shaped sort – Typical and Hardcore.

'MPP' Box type – Typical and Uncompromising

'Application' Box type – Single layer

'SHDLL' Box type-Very Hard core Long Life

Evaluated Voltage ( Vn): 440V/480V/525V

Recurrence : 50(+/ - 3%) Hz

Protection Voltage : 3 kV AC

Evaluated Temperature: 50°C

Future : 80000-1,25,000 Hrs

Components of Power Capacitor

BCH Electric Limited Power capacitors can utilize hub, outspread, flying, tab, screw, gull wing, or J-leads. A few gadgets bolt into the right spot, while others require or incorporate mounting sections. Shaft-mounted capacitors are likewise accessible. Surface mount innovation (SMT) adds power capacitors to a printed circuit board (PCB) by embedding part leads through openings in the board and afterward binding the leads set up on the contrary side of the board. Through-opening innovation (THT) mounts parts on a PCB by embedding part leads through openings in the board and afterward binding the leads set up on the contrary side of the board.

BCH India Electric Limited Power capacitors are bundled in tape reels, plates, or rails, transporting cylinders or stick magazines and mass packs. Tape reel congregations incorporate transporter tape with emblazoned pits for putting away individual parts. A cover tape seals the transporter tape set up, and the composite tape is twisted on a reel that can be stacked into industry-standard, pick-and-spot board gathering hardware. Power capacitors with leads on four sides are frequently pressed in plate or rails made of carbon-powder or fiber materials and formed into rectangular blueprints containing frameworks of consistently divided pockets. Delivery cylinders or stick magazines are holders made of rigid polyvinylchloride (PVC) and expelled in industry-standard sizes. At long last, mass packs are utilized to appropriate parts as individual parts.

Visit our site now and get the detailed information about BCH Electric Limited Power capacitor now.

0 notes

Text

Soldering Equipment Market Ongoing Trends, Opportunities & Forecast To 2027

According to Market Research Future (MRFR), the global soldering equipment market is estimated to reach a value of USD 911.3 Million with a CAGR of 9.56% from 2018 to 2025 (forecast period). The report outlines the opportunities, strengths, threats, and possible business risks and offers a rigorous analysis of the market situation with the impact of COVID-19.

Soldering equipment links two or more electronic parts together by melting the solder around the gap. Solder is a molten mixture of lead, tin, brass, and silver. Soldering equipment is used in various end-use industries, such as automotive, energy & power, aerospace & defense, communication, and electrical & electronics. Soldering equipment techniques are known as infrared reflow, hot gas convection, or phase reflow. In double-sided PCBs, the reflow process is repeated either using the glue or the solder paste to hold the components in place.

Market Dynamics

Manufacturers focus on introducing equipment that will help the selective soldering process overcome the drawbacks of hand soldering. Focusing on developing small soldering equipment, with the increasing density of equipment, is expected to bolster the market's growth in the coming years. Selective soldering is becoming a widely known alternative to conventional hand soldering due to its merits, such as improved user interactions and simplified programming. As a result, manufacturers insist on increasing investment in the development of selective soldering equipment. This is predicted to further contribute to the development of the market in the coming years.

Get Free Sample PDF@ https://www.marketresearchfuture.com/sample_request/8330

Market Segmentation

The global market for soldering equipment has been segmented based on type and application.

Based on type, the global market for soldering equipment has been segmented into reflow soldering, induction soldering, hot-bar reflow, laser soldering, and mechanical and aluminum soldering. Among these, the reflow soldering segment led the market with a value of USD 151.2 million in 2019, and the segment is anticipated to register the highest CAGR of 11.10% during the review period.

Based on application, the global market for soldering equipment has been segmented into consumer electronics, networking & communication, automotive, aerospace & defense, and others. Among these applications, the consumer electronics segment is predicted to register the highest CAGR of 11% during the forecast period.

Regional Analysis

Depending on the region, the global market for soldering equipment has been segmented into North America, Europe, Asia Pacific and the rest of the world.

Asia Pacific is projected to hold the largest market share in soldering equipment over the forecast period due to a rise in foreign investment in the production of electric vehicle (EV) charging infrastructure due to the large population base and the increasing economies of China, India, Japan, and Thailand. China is anticipated to hold the largest share in the Asian Pacific soldering equipment market and is expected to proliferate over the review period due to increasing per capita disposable income and rising automotive and consumer electronics sectors. In addition, the growing attention of governments on expanding manufacturing facilities in emerging countries, such as India and China, is accelerating the region's dominance in the soldering equipment industry.

North America is the second-largest regional market for soldering equipment and is expected to see substantial growth as the demand for electronic equipment in the region is strong. The US dominated the North American market for soldering equipment, as the nation has a developed economy and rising industries such as consumer electronics and aerospace & defense.

Key Players

During the study, MRFR has analyzed some of the leading players in the global soldering equipment market who have contributed to market growth. These include Ersa GmbH, Pillarhouse International Ltd., RPS Automation LLC, FLASON ELECTRONIC CO. LIMITED, JBC S.L, SEHO Systems GmbH, ACE Production Technologies, Inc., Blundell Production Equipment Ltd, American Hakko Products, Inc., JUKI Automation, PACE Europe Ltd., The Harris Products Group, Inductelec Limited, JAPAN UNIX Co. Ltd, and RADYNE CORPORATION.

Browse Full Report Details @ https://www.marketresearchfuture.com/reports/soldering-equipment-market-8330

0 notes