#development of dyes product laboratory

Explore tagged Tumblr posts

Text

RK Industries | Innovating High-Grade Dyes

RK Industries: Baroda’s dependable name in industrial valves and fittings, providing durable products with excellent customer-focused solutions.

Visit :

#development of dyes product laboratory#dyes Product Testing Laboratory#dyes Product quality Testing Laboratory#Best quality dyes product in India#Vietnam#Brazil

0 notes

Text

Cristae Clear

When colour TV first arrived, it added a whole new depth to the viewing experience, revealing details previously hidden in shades of grey. A similar revolution of colour is bringing new insights to niche areas of microscopy. The latest addition is a dye that brings colours to the imaging of mitochondria – the energy-generating powerhouse of human cells – in living cells. Structures within the mitochondria can then be labelled in order to highlight how their shape and behaviour changes over time. In this example, cristae – the densely folded inner membranes that provide a large surface area for energy production – are green while DNA are pink. Observing the mitochondria over time, the team saw that even as the shape and layout changed, closely-packed cristae acted as barriers to compartmentalise different sections and lock the DNA in voids between them. Understanding these dynamics could help explain mitochondria’s role in development and disease.

Written by Anthony Lewis

Image from work by Tianyan Liu and Till Stephan, and colleagues

College of Future Technology, Institute of Molecular Medicine, National Biomedical Imaging Center, Beijing Key Laboratory of Cardiometabolic Molecular Medicine, Peking University, Beijing, China

Image originally published with a Creative Commons Attribution 4.0 International (CC BY 4.0)

Published in Proceedings of the National Academy of Science (PNAS), December 2022

You can also follow BPoD on Instagram, Twitter and Facebook

6 notes

·

View notes

Text

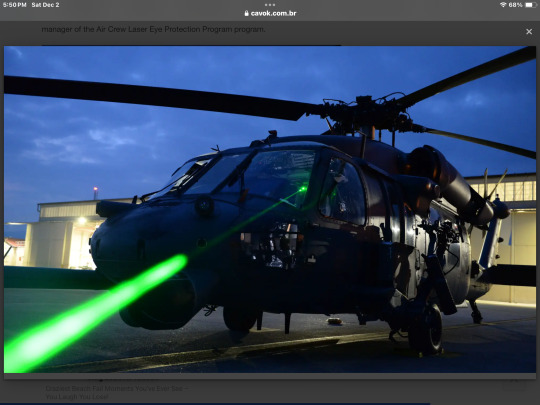

To combat laser weapons, USAF improves pilots' eye protection

Fernando Valduga By Fernando Valduga 12/02/2023 - 13:00 in Military

The Human Systems Division of the U.S. Air Force Lifecycle Management Center is in the process of updating goggles for crews operating several USAF aircraft around the world.

Composed of eight different devices and known as the Block 3 product family, the glasses will provide protection against laser threats and introduce for the first time a combined capacity of ballistic and laser protection. Eyewear devices include separate day and night glasses, ballistic glasses and visors designed for integration with night vision glasses. The devices will be available to all crews, except those operating U-2 and F-35 Lightning II aircraft. The type of eye protection the crew will receive will depend on the mission.

“If you are flying low and slow or hovering like a helicopter or CV-22 Osprey, the crew would prefer to have ballistic protection, as well as laser protection. However, if you are on a fighter or flying a bomber at high altitude, the chances of needing ballistic protection are not so high. We also worked with the U.S. intelligence community, which provided an assessment of the threats faced by air crew members,” Beer said. “We used this information to determine what we needed to protect ourselves against and what eye protection technologies we needed to adopt,” said Mark Beer, deputy manager of the Air Crew Laser Eye Protection Program program.

Cases of "lazing" - laser pointers pointed at aircraft pilots - have increased in recent years, according to the Federal Aviation Administration (FAA) and the U.S. Air Force Office of Special Investigations. In 2022 alone, there were 9,500 incidents throughout the country.

"Eye health is very important for our pilots. The consequences of being hit by a laser without adequate protection can not only prevent the pilot from flying and landing an aircraft safely, but can also cost them their career. Therefore, our goal is to ensure that the right glasses are available to everyone. We work closely with the Air Force Research Laboratory (AFRL) in this effort. AFRL researchers were instrumental in the pre-engineering phase of manufacturing and development and in experiments with dye and filter technologies," said Captain Pete Coats, chief manager of the laser eye protection program for crews of the Human Systems Division.

Along with improved protection, night glasses will allow more natural light through the lenses, increasing the visibility of crew members. A key part of the development of glasses has been partnerships with stakeholders. More than 42,000 devices will be fielded for Air Force units by 2027.

The Air Force Life Cycle Management Center (AFLCMC), based at Wright-Patterson Air Base, is designed to provide a single face and voice to customers, manage weapon systems throughout their life cycles, and simplify and consolidate personnel functions and processes to reduce redundancy and increase efficiency. In addition, the operational structure of the AFLCMC provides a framework for decision-making and process optimization throughout the life cycle of the weapons system.

Tags: Military AviationLaserUSAF - United States Air Force / U.S. Air Force

Sharing

tweet

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, has participated in several events and air operations, such as Cruzex, AirVenture, Dayton Airshow and FIDAE. He has work published in specialized aviation magazines in Brazil and abroad. Uses Canon equipment during his photographic work in the world of aviation.

Related news

Turkish Aerospace Industries developed the Anka-3 unmanned aerial combat vehicle to operate alongside its new national KAAN fighter. Anka will make its first flight in mid-December, while the first KAAN flight is scheduled for December 27.

MILITARY

Turkey prepares the first flights of the ANKA-3 drone and KAAN poaching for this month

02/12/2023 - 12:00

MILITARY

Russia destroys Ukrainian Su-25 jet and then discovers that it attacked a model used as bait

02/12/2023 - 09:00

MILITARY

Venezuelan military aircraft present painting clamoring for the Essequibo region

01/12/2023 - 23:15

MILITARY

Czechs have already raised 500,000 euros to offer Black Hawk helicopter to Ukrainian intelligence

01/12/2023 - 21:46

The new helicopters delivered to the Indonesian military.

HELICOPTERS

Indonesia receives eight new Airbus H225M helicopters assembled in the country

01/12/2023 - 18:30

BRAZILIAN AIR FORCE

Brazil has its first wife promoted to Major-Brigadeiro

01/12/2023 - 17:53

4 notes

·

View notes

Text

Garg Chemical Industry is a one of the eminent name in the chemical industry, known for its exceptional quality and diverse range of chemical products. With decades of experience and expertise, Garg Chemical Industry has established itself as one of the leading chemical manufacturers in Delhi, catering to a wide array of industries.

Wide Range of Chemical Products: Garg Chemical Industry offers an extensive range of chemical products that find applications across various sectors. The company specialises in the manufacturing of industrial chemicals, laboratory chemicals, pharmaceutical chemicals, and specialty chemicals. Whether it's acids, solvents, dyes, pigments, or any other chemical, Garg Chemical Industry ensures that every product is manufactured with precision and adheres to the highest quality standards.

Quality Assurance: At Garg Chemical Industry, quality is given utmost priority. The company follows stringent quality control measures at every stage of the manufacturing process to ensure that the final products meet or exceed customer expectations. The raw materials used are carefully sourced from trusted suppliers, and rigorous quality tests are conducted to ensure their purity and effectiveness. Garg Chemical Industry has earned various certifications and accolades for its commitment to quality and continuous improvement.

Industry Expertise: With its extensive industry experience, Garg Chemical Industry has developed in-depth knowledge and expertise in understanding the unique requirements of different sectors. The company's team of experts works closely with customers to provide tailored solutions and develop customized chemical formulations that meet specific industry needs. From manufacturing to packaging and timely delivery, Garg Chemical Industry ensures a seamless experience for its customers.

Commitment to Sustainability: Garg Chemical Industry is not only focused on delivering quality products but also committed to sustainable manufacturing practices. The company strives to minimize its environmental impact by implementing eco-friendly processes and adhering to all relevant environmental regulations. Garg Chemical Industry actively invests in research and development to develop greener alternatives and promote the efficient use of resources.Customer Satisfaction:Customer satisfaction is at the core of Garg Chemical Industry's business philosophy. The company believes in building long-term relationships with its clients by delivering superior products and exceptional service. The dedicated customer support team at Garg Chemical Industry is always ready to assist customers with their queries and provide technical assistance whenever needed.

Conclusion: As one of the leading chemical suppliers in Delhi , Garg Chemical Industry has earned a reputation for its commitment to quality, extensive product range, and customer satisfaction. With a strong focus on sustainability, industry expertise, and continuous innovation, the company is well-positioned to meet the evolving needs of various sectors. As Garg Chemical Industry expands its footprint and embraces new technologies, it continues to be a trusted partner for businesses seeking reliable and high-quality chemical products. Chemical Industries in Delhi

Contact:- +91 9953507979

Address:- 2950/220, Vishram Nagar, Tri Nagar, DELHI 110035

Thanks for Scrolling…

#chemical industries in delhi#chemical company in delhi#chemical manufacturers in delhi#chemical company in India#best chemical company in India#top chemical company in india

2 notes

·

View notes

Text

Why Saber Test Certification is Essential for Exporting Products from Ajman to the UAE? | +971 554747210

The UAE is one of the largest and most dynamic markets in the Middle East, offering lucrative opportunities for businesses across various industries. Whether you're involved in manufacturing electronics, food products, apparel, or building materials, securing access to this market is crucial for the growth and success of your business. For exporters in Ajman, one key step toward achieving this is ensuring that your products meet the safety and quality standards set by the UAE government. This is where the Saber Test certification becomes essential.

In this blog, we’ll explore why Saber Test certification is indispensable for businesses in Ajman looking to export products to the UAE, how the certification process works, and how it can benefit your business in the competitive UAE market.

What is the Saber Test Certification?

The Saber Test is a product certification system developed by the Emirates Authority for Standardization and Metrology (ESMA) to ensure the safety, quality, and regulatory compliance of products being imported into the UAE. The system applies to a wide range of consumer goods, including electronics, textiles, food products, and construction materials.

Before a product can be imported, distributed, or sold in the UAE, it must undergo testing and obtain certification from an accredited testing laboratory. The Saber Test ensures that the product meets the UAE's stringent safety and quality standards, as well as any applicable international regulations. The Saber Test is mandatory for many products, and without it, businesses cannot legally sell their goods in the UAE market.

The Importance of Saber Test Certification for Exporters in Ajman

Ajman is home to a growing number of manufacturers and exporters, making it a key player in the UAE’s industrial landscape. As the demand for high-quality, safe products continues to increase, businesses in Ajman must adhere to regulatory requirements in order to successfully enter and compete in the UAE market. Here's why Saber Test certification is essential for businesses looking to export their products to the UAE:

1. Compliance with UAE Regulatory Standards

The UAE has strict regulations in place to ensure that all imported products meet specific safety and quality standards. These regulations are designed to protect consumers, promote fair competition, and align with global safety norms. Without Saber Test certification, products cannot be legally imported into the UAE or sold in the local market.

For exporters in Ajman, this means that obtaining Saber Test certification is a crucial step in ensuring that their products comply with these regulations. This compliance not only helps businesses avoid potential fines or penalties but also streamlines the customs clearance process, enabling faster access to the UAE market.

2. Ensuring Consumer Safety and Quality Assurance

Saber Test certification is primarily focused on ensuring consumer safety. It helps verify that products do not contain harmful chemicals, are durable, and meet the necessary performance standards. This is particularly important for industries like electronics, toys, food products, and textiles, where safety is paramount.

For example, electronic products need to pass safety tests to ensure they do not pose electrical hazards or fire risks, while food products must meet health standards to prevent contamination. Apparel manufacturers must ensure that textiles do not contain harmful substances such as formaldehyde, lead, or azo dyes, which can cause allergic reactions or skin irritation.

By obtaining Saber Test certification, businesses in Ajman can ensure their products are safe for use, offering peace of mind to consumers and helping to build a positive reputation in the market.

3. Boosting Brand Credibility and Consumer Confidence

In today’s highly competitive market, consumer trust is essential for business success. Products that are Saber-certified carry a seal of quality and safety, which enhances the credibility of a brand. When consumers see that a product has passed the Saber Test, they know it meets the necessary quality standards and is safe for use.

For exporters in Ajman, Saber Test certification is a powerful marketing tool that can help differentiate their products from competitors. This certification demonstrates a commitment to quality, making it easier for businesses to build consumer loyalty and trust.

4. Facilitating Smooth Market Access in the UAE

One of the major benefits of Saber Test certification is the streamlined access it provides to the UAE market. The Saber Test ensures that products meet the technical regulations required for import, which simplifies the customs clearance process. Without Saber certification, products may be delayed or rejected at the border, causing costly disruptions and delays in delivery.

For businesses in Ajman looking to export products to the UAE, obtaining Saber Test certification is essential for ensuring a smooth, hassle-free entry into the market. This certification allows businesses to avoid unnecessary delays and ensures that their products can be quickly distributed to retailers, wholesalers, and consumers across the UAE.

5. Meeting International Standards and Global Trade Requirements

The UAE is not only a hub for local commerce but also a gateway to global markets. Many countries, particularly in the GCC region, recognize the Saber Test certification as a benchmark for product safety and compliance. This means that businesses in Ajman that obtain Saber certification can also meet international standards, facilitating export opportunities beyond the UAE.

For example, products certified by the Saber Test can often be exported to other countries in the GCC and the Middle East with fewer regulatory hurdles. Saber certification thus serves as a valuable passport for Ajman-based exporters to tap into regional and global markets.

6. Minimizing Risk and Reducing Liabilities

Failure to comply with UAE regulations can result in costly consequences, including fines, penalties, and even product recalls. For manufacturers and exporters in Ajman, the Saber Test helps mitigate these risks by ensuring that products meet the necessary safety, quality, and compliance standards.

The certification process also reduces the likelihood of product liability claims or customer complaints. By passing the Saber Test, businesses can minimize the risk of recalls and legal issues, which could otherwise harm their brand reputation and profitability.

7. Improving Product Design and Manufacturing Processes

The Saber Test process requires businesses to assess the safety, quality, and performance of their products. This not only helps ensure compliance with regulations but also encourages manufacturers to improve their product design and manufacturing processes.

For businesses in Ajman, the Saber certification process provides valuable feedback that can help identify areas for improvement in product quality and performance. This continuous improvement cycle can lead to better-designed products that are more durable, reliable, and appealing to consumers.

8. Supporting Sustainable Practices

The UAE is increasingly focusing on sustainability, and Saber Test certification also ensures that products meet environmental standards. For exporters in Ajman, this means that their products must be manufactured in a way that minimizes environmental impact, such as using eco-friendly materials and production methods.

Saber certification can help businesses align with the UAE's green initiatives and appeal to environmentally conscious consumers. By ensuring that their products are environmentally friendly and meet sustainability standards, Ajman-based exporters can gain a competitive edge in the marketplace.

How the Saber Test Certification Process Works

The process for obtaining Saber Test certification typically involves the following steps:

Product Registration: Businesses must register their products on the Saber platform, providing detailed information about the product's specifications and compliance with relevant safety and quality standards.

Product Testing: After registration, the product is tested by an accredited laboratory to assess its compliance with UAE regulations. Testing focuses on safety, quality, and environmental standards, depending on the product category.

Certification Issuance: If the product passes the required tests, the business is granted a Saber Certificate, which authorizes the product for import and sale in the UAE market.

Market Access: With the Saber Certificate, businesses can export and distribute their products in the UAE and other GCC countries, gaining access to a broader customer base.

Conclusion

Saber Test certification is a critical requirement for businesses in Ajman looking to export their products to the UAE. By ensuring compliance with safety, quality, and environmental standards, Saber certification helps businesses gain access to the competitive UAE market, build consumer trust, and boost brand credibility. It also opens doors for international trade, reduces risks, and supports sustainable manufacturing practices. For Ajman-based manufacturers and exporters, obtaining Saber Test certification is not just a regulatory requirement—it’s a strategic move that can pave the way for long-term success in the UAE and beyond.

0 notes

Text

Chemical Reagents: Driving Innovation in Modern Industries

Chemical reagents are essential compounds or mixtures that facilitate chemical reactions, playing a pivotal role across various scientific and industrial applications. From pharmaceuticals to environmental testing, these substances are the backbone of countless innovations. At Sunlight Active Drug Ingredients Pvt. Ltd (Sun Light ADI), we specialize in producing high-quality chemical reagents that meet the diverse needs of modern industries.

What Are Chemical Reagents?

Chemical reagents are substances used to detect, measure, examine, or produce other substances through chemical reactions. They are classified based on their application, such as analytical reagents, organic reagents, and inorganic reagents. These reagents are crucial in laboratories for experiments and analyses, ensuring precise and reliable results.

Applications of Chemical Reagents

Pharmaceutical Industry: Reagents are indispensable in drug formulation, quality control, and research. Sun Light ADI's specialized reagents support the synthesis of Active Pharmaceutical Ingredients (APIs) and intermediates.

Environmental Testing: Chemical reagents help in monitoring pollutants and ensuring environmental compliance. Our high-purity reagents facilitate accurate environmental assessments.

Agriculture: Reagents play a role in soil testing and the development of fertilizers and pesticides, promoting sustainable agricultural practices.

Food and Beverage Industry: Ensuring food safety and quality involves rigorous testing using chemical reagents. Sun Light ADI provides reagents that meet stringent food safety standards.

Chemical Manufacturing: Reagents are the building blocks of various chemical products, including polymers, dyes, and coatings.

Why Choose Sun Light ADI for Chemical Reagents?

High-Quality Standards: At Sun Light ADI, we adhere to strict quality control measures to ensure our reagents meet international standards.

Diverse Range of Products: We offer a comprehensive selection of chemical reagents tailored to various industries.

Innovative Solutions: Our team of experts continually develops new reagents to meet evolving industry demands.

Sustainability Commitment: We focus on environmentally friendly production processes, minimizing the ecological impact of our operations.

Conclusion

Chemical reagents are fundamental to scientific progress and industrial innovation. With Sun Light ADI’s commitment to quality and sustainability, industries can rely on our products to drive their research and production forward. Whether you're in pharmaceuticals, environmental science, or chemical manufacturing, our reagents are designed to meet your specific needs with precision and reliability.

0 notes

Text

Chemical Manufacturing Company in Chennai: A Growing Industrial Hub

Chennai emerges as a major industrial centre in India where chemical manufacturing activities have become prominent. The increasing number of chemical manufacturing company in Chennai benefits from a strong infrastructure base and experienced workers and advantageous port access. Industry players supply premium chemicals that serve pharmaceuticals as well as agriculture and textiles and construction activities.

Importance of Chemical Manufacturing in Chennai

The chemical industry supports various national industries through its production of fundamental raw materials and special-purpose chemical blends. The chemical industry in Chennai thrives due to public backing combined with research facilities and dependable logistics systems which make it an ideal place for chemical manufacturing.

Types of Chemicals Manufactured in Chennai

The production sector employs industrial chemicals which serves both manufacturing operations and industrial cleaning procedures and industrial coverings.

Pharmaceutical Chemicals: Active pharmaceutical ingredients (APIs) and excipients for drug formulation.

Agrochemicals: Fertilizers, pesticides, and soil conditioners for enhanced agricultural productivity.

Specialty Chemicals: Customized solutions for industries such as textiles, paper, and water treatment.

Petrochemicals serve as important raw materials to create plastics while providing base materials for rubber manufacturing together with synthetic fibres production.

Construction Chemicals provide sealants and adhesives with waterproofing solutions which extend the longevity of buildings.

Advantages of Choosing a Chemical Manufacturing Company in Chennai

Quality Assurance: Companies adhere to stringent quality control measures and global standards.

Buyers profit from cost-efficient solutions because pricing remains competitive along with manufacturing processes that deliver high efficiency.

Research and development innovations are driven through advanced laboratories which operate with skilled researchers.

The adoption of environmentally friendly manufacturing approaches has become common practice among multiple production facilities.

The logical backbone of Chennai consists of meticulously developed transportation facilities that deliver chemicals promptly.

Industries Benefiting from Chemical Manufacturing in Chennai

The Pharmaceutical Industry demands bulk chemicals as fundamental ingredients to create medications along with their medical applications.

Agrochemicals in agriculture provide farmers with two benefits that include higher crop yields and pest defense capabilities.

Automobile and Aerospace Industry: Relies on high-performance coatings and lubricants.

Specialty chemicals enable fabric treatment while performing dyeing operations in the Textile and Dyeing industry.

Food and Beverage industry applies food-grade chemicals and preservatives which increase shelf life of their products.

How to Choose the Right Chemical Manufacturing Company in Chennai

Verify that the business abides by regulatory guidelines as well as safety standards.

The availability of many chemical products provides evidence of a company's expertise level and product reliability.

A thorough evaluation must be made to assess research and development capabilities since formulations need innovative approaches and customization features.

A company must offer competitive prices along with efficient distribution services to excel in the market.

Technical support together with strong after-sales services creates additional value which strengthens an association between businesses.

Conclusion

Industrial growth in the Chennai area receives substantial support from the local chemical manufacturing operations. High-quality chemical solutions delivered by these companies serve various industries by meeting industry standards for efficiency and sustainability. The increasing demand keeps Chennai as the main choice for chemical manufacturing and supply activities which strengthens industrial development and economic expansion.

0 notes

Text

Ammonium Chloride (AMCL)

Ammonium Chloride (AMCL): Properties, Uses, and Applications

Ammonium chloride (NH₄Cl), often abbreviated as AMCL, is a white crystalline salt that is commonly used across various industries due to its versatility and wide range of applications. Whether in agriculture, medicine, or the production of chemicals, this compound has proven essential in a variety of sectors. Let’s explore its properties, uses, and significant applications in today’s world.

What is Ammonium Chloride (AMCL)?

Ammonium chloride is an inorganic compound made from the combination of ammonia (NH₃) and hydrochloric acid (HCl). It is a highly soluble salt that forms colorless, crystalline structures under standard conditions. The salt is commonly found as a byproduct in several industrial processes, but it can also be produced synthetically by neutralizing ammonia with hydrochloric acid.

The molecular formula for ammonium chloride is NH₄Cl, and it has a relatively low melting point of about 338°C. It is highly soluble in water, where it dissociates into ammonium (NH₄⁺) and chloride ions (Cl⁻), making it an ideal candidate for use in liquid formulations or solutions.

Key Properties of Ammonium Chloride (AMCL)

Physical Characteristics:

Color: White crystalline solid.

Solubility: Easily dissolves in water and forms an acidic solution.

Melting Point: Approximately 338°C.

Density: 1.53 g/cm³.

Chemical Characteristics:

Slightly acidic when dissolved in water.

Can undergo sublimation when heated.

Reacts with bases to form ammonia gas, and with metals, it can create ammonium salts.

Reactivity: Ammonium chloride has mild reactivity. It is stable under normal conditions but can react under specific circumstances, such as heating or when in contact with strong alkalis.

Uses and Applications of Ammonium Chloride (AMCL)

Ammonium chloride’s unique properties make it a highly versatile compound in both industrial and domestic applications. Below are some of the key areas where AMCL plays an important role:

1. Agriculture

Ammonium chloride is widely used in the agricultural sector as a nitrogen fertilizer. It provides plants with a readily available form of nitrogen, which is essential for their growth. Nitrogen is a critical nutrient in the photosynthesis process and helps in the development of leaves and stems. AMCL is especially beneficial for crops that require acidic soils and is commonly used for rice, corn, and wheat farming.

2. Industrial Manufacturing

In the industrial sector, ammonium chloride is employed in various processes, including:

Flux for Soldering: Ammonium chloride is used as a flux in the soldering process, particularly for metals like copper and iron. The compound helps in cleaning the metal surfaces by removing oxidation layers, improving the quality of the soldered joints.

Textile Industry: AMCL is also used in the textile industry as a dyeing agent and in the production of certain chemicals.

Metal Treatment: It is used in the production of metal products, such as galvanizing iron and steel, to prevent rust formation and improve corrosion resistance.

3. Pharmaceuticals and Medicine

Ammonium chloride is a key ingredient in several medicinal products. It is used as an expectorant in cough syrups and other over-the-counter medicines. In this context, AMCL helps to thin mucus in the airways, making it easier to expel.

Urinary Alkalinization: Ammonium chloride is also used to acidify the urine for patients undergoing certain medical treatments. The acidifying effect can help to dissolve kidney stones, or in some cases, enhance the elimination of certain drugs from the body.

Antiseptic Solutions: It can also be found in various antiseptic and disinfectant solutions.

4. Laboratory Reagents

In laboratories, ammonium chloride is used as a reagent in various chemical reactions and experiments. It is especially useful in the synthesis of chemicals like ammonium salts and can be used as a buffer in some biochemical studies.

5. Food Industry

Although not as widely used as in other sectors, ammonium chloride can sometimes be found in food products as an additive. It is employed in the production of baking powder and as a leavening agent. In some cultures, it is used as a flavoring agent in salted licorice.

6. Fire Extinguishers

In the production of fire extinguishers, ammonium chloride plays a role in the formation of a compound used to create fire-suppressing aerosols. It is especially effective in extinguishing metal fires.

Environmental Impact and Safety

While ammonium chloride is generally safe for use in various applications, it is important to handle it with care due to its acidic nature. Ingestion of large amounts can lead to gastrointestinal distress, and prolonged exposure to high concentrations can irritate the respiratory tract.

From an environmental perspective, AMCL is considered biodegradable and does not typically accumulate in ecosystems. However, like many chemicals, it should be disposed of properly to avoid any potential harm to water bodies or soil.

Conclusion

Ammonium chloride (AMCL) is a multifaceted compound that plays a significant role in several industries, including agriculture, pharmaceuticals, manufacturing, and food processing. Its ability to serve as a fertilizer, a chemical reagent, and an industrial material has made it an essential part of modern society. As with any industrial chemical, it is crucial to handle ammonium chloride with care to ensure safety and minimize environmental impact.

With its broad range of uses, AMCL will continue to be a valuable compound in various sectors for years to come.

URL: For more information, visit connex pharma : Ammonium Chloride (AMCL)

0 notes

Text

The Evolving Flow Cytometry Market: Key Trends and Opportunities in 2025

The global flow cytometry market size is expected to reach USD 7.01 billion by 2030, registering a CAGR of 6.96% over the forecast period, according to a new report by Grand View Research, Inc. Technological advancements in the technique are introducing new and improved analytical tools, which include the development of microfluidic flow cytometry for Point-of-Care (PoC) testing. Furthermore, the rising prevalence of cancer, immunodeficiency disorders, and infectious diseases is driving the industry. In addition, increasing R&D investments in biopharmaceutical, life science, and biotechnology research activities have led to high demand for flow cytometry instruments. In recent years, a key focus has been on the development of portable microfluidic flow cytometry devices for PoC testing.

Microfluidics and flow cytometry together make a useful tool to measure multiple characteristics of biological samples. For instance, the easy availability of several microfluidics and miniaturized detectors have enabled the creation of microchip-based cytometers, such as optofluidic cytometer, imaging cytometer, and impedance cytometer. The development of microfluidic flow cytometry devices, which are cost-effective, portable, and compact, is beneficial. They are affordable in developing economies, such as Asia & Africa, and are enabling rapid growth in PoC testing applications. Furthermore, improvements in fluorescent dyes and the increasing utility of benchtop cytometers for academic research settings are expected to drive the industry.

Developments in multicolor flow cytometry are accelerating the adoption of the technique in novel drug development activities. For instance, in January 2020, DxFLEX, CE-IVD, a 13-colour clinical flow cytometry system was launched by Beckman Coulter Life Sciences in Europe. Similarly, easy cellular analysis by simultaneous evaluation of several parameters allows extensive use of such devices for contract research purposes. The COVID-19 pandemic also spurred innovations in the technique, as evidenced by the launch of new products in this domain. For instance, in July 2021, Metropolis Healthcare Ltd. launched CoviRisk-TBNK, a simple blood test to detect the risk status of a COVID-19 hospitalized patient.

It helps analyze patients’ need for ICU facilities or ventilation and aids in the reduction of stress on healthcare resources. The test is a flow cytometry-based lymphocyte subset assay and is IVD-approved. Such innovations are anticipated to fuel industry growth in the near future. Moreover, flow cytometry is a significant tool in listing and characterizing immune cells, and is also helpful in recognizing and validating underlying genetic defects. The technique is also used to observe and monitor the immune response of patients after stem cell transplantation, and hence, organ transplantation plays an important role in boosting industry growth. According to the WHO, around 50,000 stem cell transplantations are performed globally every year, and this number is expected to grow in the near future, broadening the scope of applications for the technique.

On the other hand, instruments are highly expensive, and hence, buyers in several developing countries may not be able to afford technologically advanced flow cytometry equipment. These instruments may cost over USD 100,000 and pose significant budgetary constraints for small- & mid-sized hospitals and clinical laboratories. However, some manufacturers, such as Sony, are trying to launch newer instruments using software to automate a number of processes. Such developments would not only improve the usability of the technique but also help bring down the average instrumentation cost-under USD 100,000-in the near future.

Flow Cytometry Market Report Highlights

The instrument product segment held the largest share in 2023 due to technical advancements, as well as increased prevalence of chronic conditions

The cell-based flow cytometry technology dominated the industry in 2023 due to the high demand for early diagnosis and rising awareness about the associated benefits of cell-based assays

By application, the clinical segment accounted for the largest revenue share in 2023 owing to increased activities pertaining to infectious diseases, such as influenza, HIV, and COVID-19, among others

The academic institutes end-user segment led the market in 2023 owing to increased R&D activities by academic institutes & research centers

North America was the leading region in 2023 due to the high implementation of scientifically advanced flow cytometry solutions, high healthcare expenditure, and well-established healthcare infrastructure in the region

Asia Pacific is expected to register the fastest CAGR from 2022 to 2030 owing to the extensive growth in the pharmaceutical and biotechnology industries in emerging economies, such as China and India

Flow Cytometry Market Segmentation

Grand View Research has segmented the global flow cytometry market report based on product, technology, application, end-use, and region:

Flow Cytometry Technology Outlook (Revenue, USD Million, 2018 - 2030)

Instruments

Cell Analyzers

Cell Sorters

Reagents & Consumables

Software

Accessories

Services

Flow Cytometry Technology Outlook (Revenue, USD Million, 2018 - 2030)

Cell-based

Bead-based

Flow Cytometry Application Type Outlook (Revenue, USD Million, 2018 - 2030)

Research

PharmaceuticalApoptosis

Drug Discovery

Stem Cell

In Vitro Toxicity

Cell Sorting

Cell Cycle Analysis

Immunology

Cell Viability

Others

Industrial

Clinical

Cancer

Organ Transplantation

Immunodeficiency

Hematology

Autoimmune Disorders

Flow Cytometry End-use Outlook (Revenue, USD Million, 2018 - 2030)

Commercial Organizations

Biotechnology Companies

Pharmaceutical Companies

CROs

Hospitals

Academic Institutes

Clinical Testing Labs

Flow Cytometry Regional Outlook (Revenue, USD Million, 2018 - 2030)

North America

US

Canada

Europe

UK

Germany

France

Italy

Spain

Denmark

Sweden

Norway

Asia Pacific

Japan

China

India

Australia

Thailand

South Korea

Singapore

Latin America

Brazil

Mexico

Argentina

Middle East & Africa

South Africa

Saudi Arabia

UAE

Kuwait

List of Key Players

Danaher

BD

Sysmex Corporation

Agilent Technologies, Inc.

Apogee Flow Systems Ltd.

Bio-Rad Laboratories, Inc.

Thermo Fisher Scientific, Inc.

Stratedigm, Inc.

Miltenyi Biotec

Cytek Biosciences

Sony Group Corporation (Sony Biotechnology Inc.)

Order a free sample PDF of the Flow Cytometry Market Intelligence Study, published by Grand View Research.

0 notes

Text

AATCC announces 2025-2026 board of directors

This fall, AATCC individual members elected their 2025-2026 President and Interest Group Board of Directors representatives. Election results were announced at the AATCC Annual Meeting, preceding the Technical Committee on Research (TCR) meeting on November 13, 2024. All officers began their term on January 1, 2025

President

Christina Rapa, W.L. Gore and Associates, will serve two years as President before continuing to Immediate Past President for two years.

Rapa has been an advocate for AATCC for over 23 years. Starting as a Textile Engineering student at both Jefferson University and NC State and continuing through the formation of the Northwest chapter in Portland/Seattle in the early 2000s, she now serves as the Delaware Valley chapter Chair.

As the Material Interest Group chair for the last 3.5 years, she has invited members via webinar to hear diverse speaker topics such as “Space Textiles”, “Biobased leather”, “Advances in regenerated cellulose” and “Seaweed fiber”. As an engineer in the Fabrics division at W.L. Gore and Associates, she focuses on digital transformation, including 3D material creation and PLM software implementation.

Rapa will be a member of the Board for all four years, providing continuity and guidance to the Association. When Rapa became President, John Crocker, SDL Atlas, became Immediate Past President.

Interest Groups

AATCC members participate in one or more interest groups to network, learn, and share ideas with like-minded colleagues. Each member may select one “voting” interest group from which they elect representatives to the AATCC Board.

The Chemical Applications Interest Group re-elected Sabyasachi Gaan, as Chair. Sabyasachi Gaan received his PhD in chemistry from UC Davis in 2007. He has been working at Empa in Switzerland since 2007 and is currently head of the Additives and Chemistry group in the Laboratory of Advanced Fibers. His group specializes in the development of functional polymer and metal additives, synthesis and modification of sustainable thermoset and thermoplastic polymers, and recycling of polymers. He has been a member of AATCC since 2016, served on the AATCC Journal of Research Committee, and currently serves as the AATCC Chemical Applications Interest Group Chair.

The Concept 2 Consumer Interest Group elected Chris Hipps as Chair. Chris Hipps is the Global Director of the Color Management business at Archroma. He has been with Archroma since 2014. Prior to this, from 1998 to 2014, he was with Datacolor, Oxco, and CAE Simuflite in various technical, sales, and marketing positions. Beginning his career as a process engineer and shift dyeing manager at Dixie Yarns’ Caroknit division, he graduated from NC State University with a Bachelor of Science degree in Textile Science and then earned his Master of Business Administration degree from the University of North Carolina at Charlotte. Hipps has been a member of AATCC since 1992 and was the interim Chair for the Concept to Consumer Interest Group.

The Materials interest group has elected Apurba Banerjee as Chair and Yongxin Wang as Vice-Chair. Banerjee has served as the At-large Member since 2021.

Apurba Banerjee is a Textile Research Scientist at Standard Textile Corporation (STC). As a key member of the Research and Development department, she plays a pivotal role in bringing sustainable, value-added products to life in the realms of Hospitality, Healthcare, and Interiors. Banerjee is a proud alumna of the University of Georgia, where she earned her Ph.D. in Polymer, Fiber, and Textile Science in 2017. Prior to that, she honed her craft at Colorado State University, graduating with a master’s degree in Apparel and Merchandising in 2013. Banerjee has a passion for advancing industry benchmarks through her multiple voluntary leadership roles in organizations like AATCC and ASTM International.

Yongxin Wang is a Materials Manager at W.L. Gore & Associates, Inc. She has been with W.L. Gore & Associates, Inc. since 2018. Prior to this, Wang worked at VF Corporation as a Materials Research Manager, where she worked as a project lead, and gaining extensive experience on raw materials and their properties, textile manufacturing/processing/structure, and their relationship with apparel performance. Wang received her Master’s in Textile Materials and Product Design from Donghua University, Shanghai China in 2010, and went on to receive her Ph.D. in Fiber and Polymer Science from North Carolina State University in 2013. Her experience in textiles is demonstrated in her numerous publications throughout her career. Wang has been a member of AATCC 2021.

In 2023, AATCC newly established the Rising Professionals Interest Group. The group is focused on supporting individuals as they embark on a career in textiles. Members include recent graduates as well as seasoned professionals transitioning from other industries and those who just want to learn more about navigating opportunities for growth.

The Rising Professionals interest group re-elected Jessica Brooks as Chair and Monét Freeman as Vice-Chair.

Jessica Brooks is the Colorist for the Vertical Business Units for W. L. Gore & Associates. She has been with Gore since 2021. In addition, Brooks is an adjunct faculty at Thomas Jefferson University and teaches the Color, Dyeing & Finishing course. Prior to this, she was the Dye Lab & Technical Manager for Darlington Fabrics. Brooks has been a member of AATCC since 2013 and is currently the Vice Chair of the AATCC Delaware Valley Section and the Chair of the RISE Interest Group. She is a member of the RA36 Color Measurement Test Methods committee and on the AATCC Board of Directors. She feels very strongly in helping push future generations into taking active roles within AATCC and promoting a mentorship space within the association.

Monét Freeman serves as a Physical Testing Specialist at the Textile Technology Center at Gaston College, with six years of professional experience steering all facets of manufacturing, quality and testing, operations management, and coordinating industry training. Originally from Charlotte, North Carolina, Freeman completed her studies in Textile Technology at North Carolina State University’s Wilson College of Textiles. Freeman is a strong believer that, no matter what, there is always room for improvement and perfecting your craft. Her interest in the Rising Professionals Interest Group stems from her own personal experience of not feeling fully equipped with the tools for career development or networking right out of school.

Opportunities

While AATCC Board elections only occur every two years, there are many ways to get involved. Taking a leadership role on a committee or task group is an excellent way to make connections and gain valuable experience. To learn more about available opportunities, contact Gregg Woodcock, AATCC Executive Director ([email protected]) or any Board or staff member.

0 notes

Text

RK Industries | Lab Tools for Dye Testing

RK Industries uses advanced lab equipment to create high-quality color dyes, ensuring reliable, precise production that meets industry standards.

#development of dyes product laboratory#dyes Product Testing Laboratory#dyes Product quality Testing Laboratory#Best quality dyes product in India#Brazil

0 notes

Text

Breaking News Business, Economy, Multimedia, Web Development, Science, World

EnvatoMarket: Centaurus - Creative Multi-Purpose WordPress Theme. Just sign in to download it for free.

NameCheap: SEO in the age of GEO: Local search optimization

[One dead and 104 sick from McDonald's Burger - Violations at the onion factory, Taylor Farms, are public]

TyposThes: The historic company that collapsed like a paper tower - How it ended up in lockdown

ProNews: Zuckerberg (Facebook): "Biden forced us to take down posts against deadly Covid-19 vaccines" And Kamala Harris is an accomplice in the crime. [So, he says they were forced or was it something else?]

NDTV: erberg Orders Removal Of Tampons From Men's Bathrooms At Meta Offices Meta discontinued its diversity, equity, and inclusion (DEI) programs and removed transgender and non-binary themes from its Messenger app and removes tampons from men's bathrooms. [I do not wonder why, I know exactly why!]

[Shrimp Puffs Recalled - Increased Risk to Consumers, Wegmans Jalapeno Baked Cheese Puffs]

Deluxe: 40% off 1st order of business checks, deposit tickets, forms & envelopes. More deals from Deluxe.

AIOSEO: How to Improve Readability Score on WordPress (Step by Step)

[Class I recall for 5 contaminated yogurt and tzatziki products, The recalling company is Grecian Delight/Kronos of Elk Grove Village, Illinois]

100PercentFedUp: Costco Hit With Another Major Product Recall … This Time It’s A Popular Medication

[The guy who said Facebook was not suppressing free speech announces that FB will stop suppressing free speech - Is Zuckerberg still the same guy? look closely]

[Potato chips: Popular brand compensates class action beneficiaries – Had misleading information on the bag for 7 years, Deep River brand]

[Recall of cold cuts and meats from supermarket shelves, Kampanos salami]

Reuters: Apple to pay $95 million to settle Siri privacy lawsuit

[Pesticide industry sues city for implementing EU directive that protects citizens, Brussels was immediately sued by the pesticide industry lobby organization Belplant.]

[Cake recall – poison with 4 undeclared allergens and 3 carcinogenic dyes, Lithuanian Bakery Inc., based in Nebraska, recalled Napoleonas chocolate and raspberry tortes]

[EFET: Recall of chocolate with hazelnuts – Worms detected, VEGAN CHOCOLATE WITH HAZELNUTS, VEMONDO - Ludwig Weinrich GmbH]

[European alert for women's perfume - Contains a prohibited substance that affects reproduction, Eau de toilette by Arcobaleno parfumes under the brand name Sara 30]

HubSpot: The Top 27 AI Marketing Tools

ToEdolio5: Mammoth profits for insurance companies amounting to 21 billion with the government's gift for mandatory insurance against natural disasters, but they forget to pay their obligations (Hellas).

iEfimerida: Germany is the "world champion of sick leave" - Workers are absent for 20 days a year

ZeroHedge: Why Property Tax Is Illegal !

CanadaFreePress: “The CDC is now saying there have been enough cases of people who have had the vaccine, received the vaccine & then suffered a stroke”

[Vegan sausages in mineral oil, salt and iodine – Disappointing laboratory results]

Best Quotes

If a physical object or event can evoke an emotion, that emotion can equally create that object or event. This happens because your psychological state shapes your physical reality.

Holiday/New Year Sales

Enjoy the offers from the WMS network 🙂

Huge discounts, early-bird prices, amazing prizes, epic announcements, and hot deals from WebMarketSupport and its network.

Business-related, multimedia, and more.

Update Dec 29: Fresh deals for New Year’s season. My bonuses are valid throughout the duration of these deals.

WebMarketSupport News:

Business Storytelling: Don't Sell, Take People On a Journey. Latest article. Comprehensive analysis and a sneak peek into the innovative storytelling framework "7ID StoryX". The "Story Odyssey" experience unlocked (inside the member's area). Just signup with your email to get access to all the upcoming releases.

Knowledge Economy: Workshop #12 incoming, the date set for Tuesday, Jan 14. Be there, secret prizes.

Look out for the freebie before the workshop (done)

Info product #1 Landing page development with the powerful 7ID StoryX (storytelling framework)

Stay tuned for more!

news #BusinessNews #EconomyNews

0 notes

Text

Hydrochloric Acid Suppliers in Mumbai — Maruti Fine Chemicals

Hydrochloric Acid Suppliers in Mumbai — Maruti Fine Chemicals serves customers across Mumbai and Maharashtra, making it a trusted name in the chemical industry. Hydrochloric acid is one of the most important chemicals used in various industries. From cleaning and metal processing to food production and pharmaceuticals, hydrochloric acid plays a vital role in numerous applications. Maruti Fine Chemicals is well-known for hydrochloric acid manufacturers in Maharashtra.

Why Choose Maruti Fine Chemicals?

When it comes to buying hydrochloric acid, businesses need a supplier they can trust. Maruti Fine Chemicals stands out for several reasons:

High-Quality Products

Maruti Fine Chemicals ensures that hydrochloric acid meets the highest quality standards. The company uses advanced manufacturing processes to produce acid with consistent purity and strength.

Reliable Supply

Timely delivery is critical for industrial operations. Maruti Fine Chemicals has a robust distribution network that ensures prompt delivery of hydrochloric acid to customers in Mumbai and across Maharashtra.It is the best hydrochloric acid supplier in Mumbai.

Affordable Prices

Despite offering top-notch quality, Maruti Fine Chemicals provides competitive pricing. We strive to make high-quality hydrochloric acid accessible to businesses of all sizes.

Expertise in Manufacturing

With years of experience in hydrochloric acid manufacturing in Maharashtra, Maruti Fine Chemicals has developed expertise in producing hydrochloric acid efficiently and safely. Our commitment to innovation and quality has earned them the trust of customers.

Customer Support

Applications of Hydrochloric Acid

Hydrochloric acid has a wide range of applications across various industries. Here are some of the key uses:

Industrial Cleaning

Hydrochloric acid is widely used for cleaning metal surfaces and removing rust, scale, and other impurities. It is commonly used in the maintenance of industrial equipment and pipelines.

Chemical Processing

In the chemical industry, hydrochloric acid is a key raw material for producing a variety of chemicals, including PVC (polyvinyl chloride), fertilizers, and dyes.

Food Industry

Hydrochloric acid is used in the food industry for processing and refining food products. It is often used to adjust the pH levels in food and beverage production.

Pharmaceuticals

In the pharmaceutical industry, hydrochloric acid is used to produce medicines and as a reagent in laboratory testing.

Water Treatment

Hydrochloric acid is used in water treatment plants to control pH levels and remove impurities from water.

Construction

In the construction industry, hydrochloric acid is used to clean and prepare surfaces before painting or coating.

Maruti Fine Chemicals: Hydrochloric Acid Supplier in Mumbai

Mumbai is a bustling industrial hub with a high demand for chemicals like hydrochloric acid. Maruti Fine Chemicals caters to the needs of various industries in Mumbai by providing top-quality hydrochloric acid. The company’s strong presence in hydrochloric acid suppliers in Mumbai ensures that businesses in the city have access to reliable and affordable chemical supplies.

Hydrochloric Acid Manufacturer in Maharashtra

As one of the leading hydrochloric acid manufacturers in Maharashtra, Maruti Fine Chemicals serves customers across the state. Our manufacturing facility is equipped with modern technology, ensuring the production of high-quality hydrochloric acid that meets industry standards. The company’s commitment to quality and customer satisfaction has made us a preferred choice for businesses in Maharashtra.

Packaging and Delivery

Maruti Fine Chemicals understands the importance of safe and efficient packaging for hydrochloric acid. The company offers a variety of packaging options to suit the needs of different customers. From small containers for laboratory use to bulk packaging for industrial applications, we have solutions for all requirements. Our efficient delivery system ensures that customers receive their orders on time and in perfect condition.

Environmental Responsibility

As a responsible hydrochloric acid manufacturers in Maharashtra, Maruti Fine Chemicals is committed to minimizing the environmental impact of their operations. We follow strict safety and environmental guidelines during the production and handling of hydrochloric acid. The company also invests in sustainable practices to reduce waste and conserve resources.

Testimonials from Satisfied Customers

Over the years, Maruti Fine Chemicals has built strong relationships with their customers. Here are some testimonials:

“We have been sourcing hydrochloric acid from Maruti Fine Chemicals for several years. Their product quality and timely delivery have always impressed us.” — Industrial Cleaning Company, Mumbai

“Maruti Fine Chemicals provides excellent customer service. Their team is always helpful and ensures that we get what we need on time.” — Chemical Manufacturer, Maharashtra

“The hydrochloric acid from Maruti Fine Chemicals is of top-notch quality. It’s perfect for our food processing operations.” — Food Industry Client, Mumbai

How to Contact Maruti Fine Chemicals

If you are looking for a reliable supplier or hydrochloric acid manufacturers in Maharashtra Maruti Fine Chemicals is the name you can trust. Here’s how you can reach them:

Visit our office: You can visit their office to discuss your requirements and learn more about their products.

Call or Email: Our friendly staff is available to answer your queries and assist with orders.

Website: Check our website for detailed information about our products and services.

Conclusion

Maruti Fine Chemicals has established itself as the best hydrochloric acid suppliers in Mumbai and hydrochloric acid manufacturers in Maharashtra. With a focus on quality, reliability, and customer satisfaction, we cater to the needs of various industries. Whether you need hydrochloric acid for industrial cleaning, chemical processing, or any other application, Maruti Fine Chemicals ensures that you get the best product at an affordable price. Trust Maruti Fine Chemicals for all your hydrochloric acid needs and experience unparalleled service and quality.

Visit here for more information — https://goo.gl/maps/CzTRuLaAi5h1Mxe39 Reference link is here -https://www.google.com/maps/d/u/0/edit?mid=1GIW70x3XByOjG0uPT0P6RsMXTnb7LK4&ll=18.99462153159404%2C82.75998700000001&z=4

0 notes

Text

What Are the Key Standards for Textile Testing in the Global Market?

In today’s global textile industry, manufacturers face increasing pressure to produce fabrics that not only meet consumer expectations but also comply with various international standards. Textile testing plays a crucial role in ensuring that fabrics meet the required quality, safety, and performance criteria before they are brought to market. With textiles being traded worldwide, adherence to global standards is paramount for manufacturers aiming to maintain competitiveness, comply with regulations, and ensure consumer safety.

This blog will explore the key standards for textile testing lab in the global market, shedding light on why they are essential and how they help manufacturers navigate international trade.

The Importance of Textile Testing Standards

Textile testing standards are guidelines or criteria that manufacturers must follow to ensure that their fabrics meet the quality, safety, and performance requirements specific to various markets. These standards are developed by organizations such as ISO (International Organization for Standardization), ASTM (American Society for Testing and Materials), and OEKO-TEX®. Testing ensures that textiles meet requirements for a wide range of factors, including durability, comfort, safety, and environmental impact.

For textile manufacturers, compliance with these standards not only ensures product quality but also helps in gaining consumer trust, meeting regulatory demands, and avoiding costly recalls or penalties. Additionally, it enables easier access to global markets by meeting the requirements of importing countries.

Key Textile Testing Standards

Here are some of the most widely recognized and influential textile testing standards that shape the global textile market:

1. ISO 9001 – Quality Management Systems

ISO 9001 is a widely accepted standard for quality management systems (QMS) across various industries, including textiles. While it is not specific to textile testing, adherence to ISO 9001 ensures that manufacturers maintain consistent quality in their processes, products, and services.

Textile manufacturers who comply with ISO 9001 implement quality management principles that focus on customer satisfaction, process optimization, and continuous improvement. For textile products, this standard helps ensure that materials are tested for reliability, uniformity, and performance, ensuring high-quality end products.

2. ISO 17025 – General Requirements for the Competence of Testing and Calibration Laboratories

ISO 17025 is a globally recognized standard that applies to testing and calibration laboratories. It ensures that testing laboratories are competent and capable of delivering reliable and accurate results. In the context of textile testing, this standard guarantees that laboratories adhere to consistent, scientifically validated methods to evaluate various textile properties such as durability, colorfastness, and strength.

Compliance with ISO 17025 is crucial for testing laboratories that work with textile manufacturers, as it ensures that their testing results meet the necessary accuracy and reliability for product certification and compliance with international regulations.

3. OEKO-TEX® Standard 100 – Testing for Harmful Substances

The OEKO-TEX® Standard 100 is one of the most important textile testing certifications, particularly in the European and North American markets. This standard tests textiles for harmful substances, including chemicals, dyes, and finishing agents, that may be harmful to human health.

Under the OEKO-TEX® certification, textiles are evaluated for the presence of substances like:

Pesticides

Heavy metals (e.g., lead, cadmium)

Formaldehyde (a carcinogenic substance)

Phthalates (harmful plasticizers)

For textiles to earn the OEKO-TEX® Standard 100 certification, they must pass a series of tests that confirm they are free from harmful substances at levels that might pose a risk to consumer health. This certification has become essential for manufacturers aiming to cater to the eco-conscious consumer and comply with stricter regulations in many global markets.

4. REACH Compliance – Registration, Evaluation, Authorisation, and Restriction of Chemicals

The REACH regulation, implemented by the European Union, governs the use of chemicals in textiles and other products. This regulation requires textile manufacturers to ensure that their products do not contain harmful chemicals that could negatively impact human health or the environment. The regulation applies to all substances used in the manufacturing, treatment, and finishing processes of textiles.

REACH compliance involves testing textiles for the presence of restricted substances, ensuring that they do not contain chemicals that exceed the limits established by the European Union. For manufacturers exporting textiles to the EU, complying with REACH is essential to avoid fines, recalls, or being barred from the market.

5. ASTM D4966 – Abrasion Resistance of Textile Fabrics

The ASTM D4966 standard evaluates the abrasion resistance of textile fabrics, particularly those used in products that undergo frequent wear, such as upholstery, clothing, and industrial fabrics. This test involves rubbing the fabric against an abrasive surface to simulate wear over time, measuring the fabric’s durability and performance.

Abrasion resistance is a key factor for textiles used in everyday wear or furniture, and manufacturers rely on ASTM D4966 to ensure that their fabrics can withstand friction without breaking down. Meeting this standard helps ensure the longevity of the fabric and consumer satisfaction.

6. ISO 105-C06 – Colorfastness to Washing

ISO 105-C06 is one of the standards used to test the colorfastness of textiles, particularly to washing. This standard evaluates how well a fabric retains its color when subjected to multiple washes, assessing whether the dye used in the fabric is stable and whether it will bleed or fade over time.

Colorfastness testing is especially important for clothing and household textiles, as consumers expect fabrics to maintain their appearance even after several washes. For manufacturers, passing this test is a crucial step in demonstrating the durability and quality of their fabrics.

7. ISO 13934 – Tensile Strength and Elongation of Fabrics

The ISO 13934 standard measures the tensile strength and elongation of fabrics, which are key indicators of fabric durability. Tensile strength refers to the amount of force required to break the fabric, while elongation refers to the fabric’s ability to stretch before breaking. This testing is critical for determining how fabrics will perform under pressure or stress, especially for textiles used in apparel, upholstery, and industrial applications.

Adherence to ISO 13934 ensures that the fabrics manufactured are strong and will perform as expected, even under challenging conditions.

8. Global Organic Textile Standard (GOTS)

For textiles that claim to be organic, GOTS certification ensures that they meet the highest environmental and social criteria throughout the entire production process. GOTS certification guarantees that the textile fibers used are organic, the manufacturing processes are sustainable, and the fabric does not contain any harmful chemicals.

Manufacturers that seek to produce eco-friendly textiles and appeal to environmentally conscious consumers often pursue GOTS certification. Compliance with GOTS provides confidence to customers that the textiles are produced using sustainable methods and meet stringent environmental standards.

9. ISO 10456 – Thermal Insulation and Breathability Testing

The ISO 10456 standard assesses the thermal insulation properties of fabrics. This test measures how well fabrics trap air and retain heat, which is especially important for textiles used in outerwear, insulation materials, and activewear.

Similarly, breathability testing under this standard evaluates how well a fabric allows moisture to escape, helping to keep the wearer comfortable and dry. Fabrics used in performance sportswear, activewear, and outdoor clothing often undergo these tests to ensure they provide adequate protection against weather conditions while maintaining comfort.

Conclusion

In the global textile market, textile testing standards are not just a regulatory requirement but a crucial step toward ensuring product quality, consumer safety, and environmental sustainability. From compliance with chemical safety regulations like REACH and OEKO-TEX® to performance tests like abrasion resistance and tensile strength, these standards guarantee that textiles meet the needs of diverse markets while maintaining high quality.

For textile manufacturers, adherence to these standards is essential for competing on the global stage, particularly in markets that demand high levels of product quality and environmental responsibility. By embracing textile testing standards, manufacturers can ensure their products are safe, durable, and ready for global trade, all while gaining the trust of consumers and regulatory bodies worldwide.

0 notes

Text

Acetyl Chloride: Uses, Benefits, and Safety Measures in Industrial Applications

Acetyl chloride is a vital chemical in many industrial processes, and it is known for its versatility and reactivity. A colourless, sharp-smelling liquid, it plays a crucial role in various manufacturing sectors. Understanding how Acetyl chloride works, its benefits and the essential safety precautions can help industries harness its potential effectively while keeping operations safe.

Uses of Acetyl Chloride in Industry

One of the primary applications of Acetyl Chloride is in the pharmaceutical industry. It’s used in the preparation of various active ingredients, particularly antibiotics. Many pharmaceutical companies rely on Acetyl Chloride to produce complex compounds that are essential for medications. Its reactivity enables it to help form specific chemical bonds, making it a valuable tool in synthesising pharmaceutical products.

In agriculture, Acetyl Chloride contributes to the creation of pesticides and herbicides. The chemical's reactive properties allow it to be transformed into components that protect crops, ensuring better yields and quality. Similarly, in the chemical industry, it is commonly used in the manufacture of dyes, fragrances, and other organic compounds. Here, it acts as a building block, helping to form essential structures in a wide range of products we use daily.

Acetyl Chloride is also used in laboratories for research purposes, often aiding in the study of chemical reactions and properties. Its reactive nature provides scientists with insights into chemical behaviours, supporting advancements in chemistry and related fields.

Benefits of Using Acetyl Chloride

The primary advantage of Acetyl Chloride is its efficiency. As a reactive agent, it helps speed up chemical reactions, which can make manufacturing processes faster and more efficient. For industries where time is money, this efficiency can translate to reduced production times and improved cost-effectiveness.

In addition to being efficient, Acetyl Chloride is also versatile. Its applications span across multiple industries, from pharmaceuticals to agriculture and research. This versatility makes it an invaluable asset for various sectors looking for reliable chemical agents that can help achieve specific results. Its ability to introduce acetyl groups in compounds enables the production of a diverse range of products, contributing to the development of items we use every day.

Safety Measures for Handling Acetyl Chloride

Despite its many benefits, handling Acetyl Chloride requires strict safety precautions. Due to its reactive nature, it can be hazardous if not managed properly. One major concern is its reaction with water, which can release hydrochloric acid fumes. These fumes can cause severe irritation to the skin, eyes, and respiratory system. Therefore, protective gear is essential when working with Acetyl Chloride, including gloves, goggles, and proper ventilation.

Conclusion

In conclusion, Acetyl Chloride is an essential chemical with significant applications across various industries. Its role in pharmaceuticals, agriculture, and research highlights its versatility and value. While it offers considerable benefits in efficiency and productivity, handling it requires strict adherence to safety protocols. Proper storage, protective equipment, and training are crucial in managing its risks effectively. By maintaining these safety standards, industries can continue to benefit from Acetyl Chloride’s unique properties without compromising workplace safety.

0 notes

Text

Custom Chemical Solutions Chennai: Excellence Tailored for Various Industries

With an ever burgeoning industrial landscape in Chennai, comes the need for innovative and bespoke solutions to meet particular operational requirements. The service, custom chemical solutions Chennai has been central to industries such as pharmaceuticals, manufacturing, agriculture and research. Custom chemical solutions provide necessary formulations and processes tailored to ensure that your business reaches its efficiency, sustainability and regulatory standards.

Custom Chemical Solutions describes the basics of what we offer.

Custom chemical solutions, may be the specialized formulation or the process, to fit a particular industry need. These solutions are unlike off the shelf chemicals developed in close cooperation with suppliers and clients, ensuring that all formulations are fully optimised for use in the application in question. Key features of custom chemical solutions include:

Personalized Formulations: Tailor made chemicals to deal with specific challenges/problems or processes.

Enhanced Efficiency: Solutions of operational performance, and waste reduction.

Regulatory Compliance: The formulated chemicals to meet industry and environmental specifications.

Scalability: Small and large scale production solutions.

Custom Chemical Solutions in Chennai Usage

Chennai’s diverse industries rely on custom chemical solutions for various applications, including:

Pharmaceuticals: Drug development, formulation for active pharmaceutical ingredients (APIs) and laboratory reagents.

Agriculture: With tailored fertilizers, pesticides and growth enhancers to help increase crop yield.

Manufacturing: Adhesives, coatings and plastics, specialised chemicals.

Textiles: Additional custom dyes and processing chemicals which enable more durable fabrics.

Research and Development: Experimental and analytical chemical innovation.

Custom Chemical Solutions have the following advantages.

The use of custom chemical solutions offers numerous benefits to businesses in Chennai, such as:

Optimized Performance: Customization guarantees that chemicals will address specific operational needs, resulting in better results and lower costs.

Eco-Friendly Practices: Design of formulations from a sustainability perspective is explored.

Cost Efficiency: With custom, exact, fit chemicals, businesses can avoid overbuy or undersell off-the-shelf products.

Improved Safety: Safety measures tend to be incorporated in custom solutions, to decrease the risk of injuries during handling and application.

Innovative Edge: Partnering with suppliers for bespoke solutions is intelligent, promotes innovation and keeps businesses one step ahead.

How to Pick The Right One?

In Chennai, partnering for high quality custom chemical solutions requires a good supplier. Here are some factors to consider:

Expertise and Experience: Suppliers should be looked for who’ve an excellent track file growing custom formulations.

Technical Support: Knowledgeable professionals can provide great guidance and troubleshoot your issues for a supplier.

Quality Assurance: Make sure the supplier has a quality control process in place, and is industry certified.

Sustainability Focus: Select suppliers who consider environmental practices and materials as top priority!

Timely Delivery: Prompt delivery to prevent production delays is ensured by reliable suppliers.

Conclusion

Access to custom chemical solutions Chennai has readily available, has been transforming the way industries work, with the provision of custom made & efficient customized chemicals compared to generic ones. Collaboration with trusted suppliers helps businesses to pursue new opportunities to innovate, comply, and be sustainable. Being the fastest growing industrial hub, the role of Chennai, in all sectors, will continue to be driven by custom chemical solutions as a pillar of success and excellence.

0 notes