#chemical manufacturing company in chennai

Explore tagged Tumblr posts

Text

Chemical Manufacturing Company in Chennai: A Growing Industrial Hub

Chennai emerges as a major industrial centre in India where chemical manufacturing activities have become prominent. The increasing number of chemical manufacturing company in Chennai benefits from a strong infrastructure base and experienced workers and advantageous port access. Industry players supply premium chemicals that serve pharmaceuticals as well as agriculture and textiles and construction activities.

Importance of Chemical Manufacturing in Chennai

The chemical industry supports various national industries through its production of fundamental raw materials and special-purpose chemical blends. The chemical industry in Chennai thrives due to public backing combined with research facilities and dependable logistics systems which make it an ideal place for chemical manufacturing.

Types of Chemicals Manufactured in Chennai

The production sector employs industrial chemicals which serves both manufacturing operations and industrial cleaning procedures and industrial coverings.

Pharmaceutical Chemicals: Active pharmaceutical ingredients (APIs) and excipients for drug formulation.

Agrochemicals: Fertilizers, pesticides, and soil conditioners for enhanced agricultural productivity.

Specialty Chemicals: Customized solutions for industries such as textiles, paper, and water treatment.

Petrochemicals serve as important raw materials to create plastics while providing base materials for rubber manufacturing together with synthetic fibres production.

Construction Chemicals provide sealants and adhesives with waterproofing solutions which extend the longevity of buildings.

Advantages of Choosing a Chemical Manufacturing Company in Chennai

Quality Assurance: Companies adhere to stringent quality control measures and global standards.

Buyers profit from cost-efficient solutions because pricing remains competitive along with manufacturing processes that deliver high efficiency.

Research and development innovations are driven through advanced laboratories which operate with skilled researchers.

The adoption of environmentally friendly manufacturing approaches has become common practice among multiple production facilities.

The logical backbone of Chennai consists of meticulously developed transportation facilities that deliver chemicals promptly.

Industries Benefiting from Chemical Manufacturing in Chennai

The Pharmaceutical Industry demands bulk chemicals as fundamental ingredients to create medications along with their medical applications.

Agrochemicals in agriculture provide farmers with two benefits that include higher crop yields and pest defense capabilities.

Automobile and Aerospace Industry: Relies on high-performance coatings and lubricants.

Specialty chemicals enable fabric treatment while performing dyeing operations in the Textile and Dyeing industry.

Food and Beverage industry applies food-grade chemicals and preservatives which increase shelf life of their products.

How to Choose the Right Chemical Manufacturing Company in Chennai

Verify that the business abides by regulatory guidelines as well as safety standards.

The availability of many chemical products provides evidence of a company's expertise level and product reliability.

A thorough evaluation must be made to assess research and development capabilities since formulations need innovative approaches and customization features.

A company must offer competitive prices along with efficient distribution services to excel in the market.

Technical support together with strong after-sales services creates additional value which strengthens an association between businesses.

Conclusion

Industrial growth in the Chennai area receives substantial support from the local chemical manufacturing operations. High-quality chemical solutions delivered by these companies serve various industries by meeting industry standards for efficiency and sustainability. The increasing demand keeps Chennai as the main choice for chemical manufacturing and supply activities which strengthens industrial development and economic expansion.

0 notes

Text

Round Pet Bottle Labeling Machine Manufacturer in Ahmedabad

Company Overview: Shiv Shakti Machtech is a Round Pet Bottle Labeling Machine Manufacturer in Ahmedabad, Gujarat, India. A round PET bottle labeling machine is a specialized equipment designed to apply labels accurately and efficiently onto cylindrical PET (Polyethylene Terephthalate) bottles. It ensures consistent placement of labels, enhancing product aesthetics, branding, and compliance with regulatory standards. Why Choose Our Round PET Bottle Labeling Machines? Precision Labeling: Accurate application of labels on round PET bottles, ensuring uniformity and aesthetic appeal. High-Speed Performance: Capable of labeling bottles at high speeds, maximizing production output and efficiency. Versatility: Compatible with various bottle sizes and shapes, accommodating diverse packaging requirements. User-Friendly Design: Intuitive controls and easy adjustments for quick setup and minimal downtime. Durable Construction: Built with robust materials for long-term reliability and minimal maintenance. Applications: Beverage Industry Pharmaceuticals Cosmetics and Personal Care Food Products Chemicals and Household Products Distillery Dairy Agrochemicals Paint Shiv Shakti Machtech is Round Pet Bottle Labeling Machine Manufacturer in Ahmedabad, Gujarat, India, Including Kathwada, Vadodara, Changodar, Gota, Naroda, Nikol, Mehsana, Palanpur, Deesa, Patan, Vapi, Surendranagar, Bhavnagar, Jamnagar, Junagadh, Rajkot, Amreli, Mahuva, Surat, Navsari, Valsad, Silvassa, Porbandar, Mumbai, Vasai, Andheri, Dadar, Maharashtra, Aurangabad, Kolhapur, Pune, Rajasthan, Jaipur, Udaipur, Kota, Bharatpur, Ankleshwar, Bharuch, Ajmer, Delhi, Noida, Baddi, Solan, Himachal Pradesh, Una, Jammu Kashmir, Haryana, Hisar, Gurgaon, Gurugram, Madhya Pradesh, Indore, Bhopal, Ratlam, Jabalpur, Satna, New Delhi, Kolkata, West Bengal, Assam, Asansol, Siliguri, Durgapur, Bhubaneswar, Odisha, Brahmapur, Puri, Goa, Amaravati, Andhra Pradesh, Visakhapatna, Hyderabad, Guntur, Chittoor, Kurnool, Vizianagaram, Srikakulam, Karimnagar, Ramagundam, Suryapet, Telangana, Medak, Bengaluru, Bangalore, Mangaluru, Hubballi, Vijayapura, Davanagere, Kalaburagi, Chitradurga, Ballari, Kolar, Chennai, Coimbatore, Madurai, Tiruchirapalli, Tiruppur, Salem, Erode, Tirunelveli, Tamil Nadu, Kerala, Kochi, Thiruvananthapuram, Kozhikode, Thrissur, Kollam, Alappuzha, Kottayam, Kannur, Malappuram, Bharatpur, Jodhpur, Bikaner, Alwar, Bhilwara, Nagpur, Amravati, Solapur, Malegaon, Navi Mumbai, Thane, Wardha, Vasai-Virar, Gondia, Hinganghat, Barshi, Ulhasnagar, Nandurbar, Bhusawal, Pimpri-Chinchwad, Kalyan, Satara, Yamuna Nagar, Chhachhrauli. For further details or inquiries, feel free to reach out to us. View Product: Click Here Read the full article

#Ahmedabad#Ajmer#Alappuzha#Alwar#Amaravati#Amravati#Amreli#Andheri#AndhraPradesh#Ankleshwar#Asansol#Assam#Aurangabad#Baddi#Ballari#Bangalore#Barshi#Bengaluru#Bharatpur#Bharuch#Bhavnagar#Bhilwara#Bhopal#Bhubaneswar#Bhusawal#Bikaner#Brahmapur#Changodar#Chennai#Chhachhrauli

3 notes

·

View notes

Text

Warehouse Services in India

Warehouse services play a crucial role in supply chain management, ensuring the safe storage, handling, and distribution of goods. Whether for manufacturers, e-commerce businesses, or retailers, efficient warehousing helps optimize inventory management and reduce operational costs. With the growing demand for seamless logistics, Warehouse Services in India have evolved to offer advanced solutions, including temperature-controlled storage, automation, and real-time inventory tracking.

What Are Warehouse Services?

Warehouse services involve the storage and management of goods before they are distributed to customers or retailers. These services include inventory control, order fulfillment, packaging, and transportation coordination, helping businesses streamline their supply chain operations.

Types of Warehouse Services

Public Warehousing – Shared storage facilities available to multiple businesses, offering cost-effective solutions.

Private Warehousing – Dedicated storage facilities owned or leased by a company for exclusive use.

Bonded Warehousing – Secure storage for imported goods before customs clearance, delaying duty payments until needed.

Cold Storage Warehousing – Temperature-controlled facilities for perishable items like food, pharmaceuticals, and chemicals.

Fulfillment Warehousing – Specialized storage and order processing centers for e-commerce and retail businesses.

Automated Warehousing – Facilities equipped with robotics, AI, and IoT for efficient inventory management and faster processing.

Benefits of Warehouse Services

Improved Inventory Management – Ensures accurate stock control, reducing losses due to overstocking or shortages.

Cost Efficiency – Reduces logistics costs by consolidating shipments and optimizing distribution.

Faster Order Fulfillment – Ensures quick processing and dispatch of goods, enhancing customer satisfaction.

Risk Management – Provides secure storage to protect goods from damage, theft, and environmental factors.

Scalability – Allows businesses to expand operations without immediate investments in storage infrastructure.

Challenges in Warehousing

Space & Capacity Constraints – Growing demand for storage can lead to space shortages.

High Operational Costs – Maintenance, labor, and security expenses can add up.

Inventory Loss & Damage – Poor handling or inadequate security can lead to product losses.

Regulatory Compliance – Warehouses must adhere to safety, taxation, and environmental regulations.

Supply Chain Disruptions – Delays in transportation or stock shortages can impact business efficiency.

Warehouse Services in India: A Growing Market

With the rise of e-commerce, retail expansion, and global trade, Top Warehouse Services in India have seen significant growth. Modern warehousing solutions now include smart tracking systems, automated sorting, and strategically located distribution centers to ensure fast and cost-effective deliveries. Key logistics hubs like Delhi, Mumbai, Chennai, and Bangalore have state-of-the-art warehousing facilities to support various industries.

Conclusion

Warehousing is an essential component of modern supply chains, offering businesses the ability to store, manage, and distribute goods efficiently. With advancements in technology and logistics infrastructure, Warehouse Services in India continue to evolve, providing reliable and cost-effective solutions for businesses of all sizes. Partnering with an experienced warehousing provider ensures seamless inventory management, reduced operational costs, and enhanced customer satisfaction.

0 notes

Text

Fire Extinguisher Supplier in chennai

When it comes to safeguarding your property, business, and loved ones from the devastating effects of fire, having a reliable fire extinguisher is crucial. Based in the heart of Chennai, Manximpex is a leading supplier of high-quality fire extinguishers, catering to the diverse needs of both residential and commercial clients. With years of expertise in the field, the company is dedicated to providing fire safety solutions that ensure peace of mind and protection against unforeseen fire hazards.

Why Choose Manximpex for Fire Extinguishers in Chennai?

At Manximpex, fire safety isn't just a business – it's a commitment to quality, reliability, and customer satisfaction. Here's why Manximpex stands out in the competitive market of fire extinguisher suppliers in Chennai:

1. Wide Range of Fire Extinguishers

Manximpex offers a comprehensive range of fire extinguishers designed to tackle different types of fires. Whether it's a kitchen fire, electrical fire, or industrial fire, they have the right solution for you. Their inventory includes:

ABC Dry Powder Extinguishers: Ideal for general fire hazards including wood, paper, and electrical fires.

CO2 Extinguishers: Best suited for electrical fires and flammable liquid fires.

Water and Foam Extinguishers: Perfect for Class A fires involving wood, paper, textiles, and other common materials.

Specialized Fire Extinguishers: Manximpex also provides specialized extinguishers for high-risk industries, including gas-based and wet chemical extinguishers.

2. Expert Consultation and Installation

Understanding which fire extinguisher is best for your specific needs can be challenging. That’s where the expertise of Manximpex shines through. Their team of trained professionals provides expert consultation to assess your premises and recommend the most suitable fire extinguishers. Furthermore, they also offer installation services to ensure that your fire safety equipment is correctly placed and ready for use.

3. Quality Assurance

Manximpex takes pride in offering products that meet international safety standards. All their fire extinguishers are sourced from reputed manufacturers, ensuring durability and effectiveness when you need them most. They perform rigorous quality checks on every product before it reaches the customer, giving you confidence in the reliability of your purchase.

4. Maintenance and Refilling Services

Fire extinguishers need regular maintenance and refilling to ensure they function properly in an emergency. Manximpex offers maintenance services to inspect, refill, and repair extinguishers, ensuring they remain in optimal working condition. They also provide a reminder system for servicing, so you never miss an important maintenance date.

5. Competitive Pricing

As a customer-centric company, Manximpex strives to provide the best products at competitive prices. Whether you’re outfitting a single office or an entire industrial complex, their pricing remains affordable without compromising on quality. They also offer flexible payment options to suit every budget.

6. Fast and Reliable Delivery

Manximpex understands that fire safety cannot wait. That’s why they offer quick and reliable delivery across Chennai, ensuring that your fire extinguishers arrive on time and are ready to be put to use immediately. Whether you're a business or homeowner, they make sure that your fire safety needs are addressed swiftly and efficiently.

Industries Served by Manximpex

Manximpex is not limited to residential customers – their products and services cater to a wide variety of industries, including:

Commercial Buildings: Providing fire extinguishers for office spaces, shopping malls, and public venues.

Industrial Facilities: Supplying fire extinguishers for factories, warehouses, and production units with high-risk environments.

Hotels and Restaurants: Ensuring fire safety in kitchens and dining areas.

Schools, Hospitals, and Institutions: Installing fire safety systems for educational and healthcare environments.

Residential Complexes: Ensuring that homes and apartments are equipped with the best fire safety products.

Customer Satisfaction: Manximpex’s Priority

At Manximpex, customer satisfaction is a top priority. Their team is always available to answer any queries, provide product demonstrations, and assist with any concerns regarding fire safety. From the first point of contact to post-purchase support, they ensure that every client is treated with the utmost professionalism and care.

Contact Manximpex Today for Your Fire Safety Needs

For residents and businesses in Chennai looking for top-quality fire extinguishers and expert fire safety solutions, Manximpex is the name you can trust. With their wide range of products, excellent customer service, and commitment to safety, they are your reliable partner in fire protection.

Contact Manximpex today at:

Phone: +91-7428115550 | +91-7065192900 |

Email: https://manximpex.com/fire-extinguisher-2/

Website: [email protected]

Ensure your safety today with Manximpex – because when it comes to fire protection, you can never be too prepared!

0 notes

Text

Turnkey Projects Solution in Tamil Nadu

Amma En-Fab is a reliable Turnkey Projects Solution in Tamil Nadu, India. Our Registered Office and Manufacturing Unit is in Ahmedabad, Gujarat, India. A Turnkey Project Solution is a comprehensive service where a single contractor handles every aspect of a project from start to finish. This includes planning, designing, construction, procurement, installation, testing, and commissioning of the complete system or facility. Turnkey projects are particularly useful for companies that require a single point of responsibility for the successful completion of their projects. With our years of experience and a strong reputation for delivering high-quality projects, we are the trusted partner for businesses looking to execute their industrial projects with precision and efficiency. Why Choose Amma En-Fab's Turnkey Project Solutions? End-to-End Expertise: We manage every stage of your project from design to commissioning, ensuring consistency and high standards throughout the process. Single Point of Contact: Our turnkey solutions provide a single contact for all project needs, reducing communication gaps and ensuring efficiency. Customized Solutions: We understand that every business has unique requirements. We provide tailored solutions that meet your specific needs in terms of scale, functionality, and budget. Timely Project Delivery: Our experienced team completes your project on time, within budget, and without compromising on quality. Cost-Effectiveness: We provide competitive pricing without sacrificing quality, ensuring that your investment yields maximum returns. Quality Assurance: We follow strict quality control from material procurement to final handover, ensuring the highest project standards. Applications: Food Processing Plants Pharmaceuticals Chemical Manufacturing Packaging Industry Water Treatment Textile Industry Waste Management Automotive Manufacturing FAQs: Can you handle large-scale industrial projects? Yes, we have the expertise and resources to manage large-scale industrial projects, including factory setups, automation lines, and infrastructure systems. What is the typical timeline for a turnkey project? The timeline depends on the scope and complexity of the project. We work closely with you to establish realistic deadlines and ensure on-time delivery. How do you ensure the quality of a turnkey project? We ensure strict quality control from design to installation, guaranteeing all components meet international standards. Amma En-Fab is a reliable Turnkey Projects Solution in Tamil Nadu, India including locations in Chennai, Coimbatore, Madurai, Tiruchirappalli, Salem, Ambattur, Tirunelveli, Tiruppur, Avadi, Tiruvottiyur, Thoothukkudi, Nagercoil, Thanjavur, Pallavaram, Dindigul, Vellore, Tambaram, Cuddalore, Kancheepuram, Alandur, Erode, Tiruvannamalai, Kumbakonam, Rajapalayam, Kurichi, Madavaram, Pudukkottai, Hosur, Ambur, Karaikkudi, Neyveli, Nagapattinam. Contact us today for more information or to request a quote. View Product: Click Here Read the full article

#Ahmedabad#Alandur#Ambattur#Ambur#AmmaEn-fab#Avadi#Chennai#Coimbatore#Cuddalore#Dindigul#Erode#Hosur#India#Kancheepuram#Karaikkudi#Kumbakonam#Kurichi#Madavaram#Madurai#Manufacturer#Nagapattinam#Nagercoil#Neyveli#Pallavaram#Pudukkottai#Rajapalayam#Salem#Supplier#Tambaram#TamilNadu

0 notes

Text

Top Exporters of Pipe Flanges in India – Leading Suppliers & Manufacturers

India is home to some of the top exporters of pipe flanges, catering to various industries worldwide. These companies provide high-quality flanges that meet international standards.

Leading Pipe Flange Exporters in India

1. XYZ Flanges Pvt. Ltd.

Location: Mumbai, India

Products: Weld Neck, Slip-On, Blind, Threaded Flanges

Certifications: ISO 9001, ANSI, ASTM

Key Markets: USA, UK, UAE, Germany

2. ABC Industries

Location: Chennai, India

Products: Stainless Steel, Carbon Steel, Alloy Steel Flanges

Certifications: API, ISO 14001

Key Markets: Europe, Middle East, South East Asia

3. DEF Engineering Works

Location: Gujarat, India

Products: Forged, Plate, Lap Joint, Socket Weld Flanges

Certifications: ASME, ISO 45001

Key Markets: Canada, Africa, Australia

Why Choose Indian Pipe Flange Exporters?

High-quality manufacturing following global standards

Cost-effective pricing compared to other regions

Wide material selection including stainless steel, carbon steel, and alloy steel

Strong global network ensuring timely deliveries

Common Applications of Pipe Flanges

Oil & Gas Industry

Power Plants

Chemical Processing

Water Treatment Plants

Marine & Offshore Engineering

FAQs

1. What are the standard certifications for pipe flange exporters?

Most reputed exporters hold ISO, ANSI, ASTM, and ASME certifications, ensuring quality and compliance with global standards.

2. Which materials are commonly used for pipe flanges?

Pipe flanges are made from stainless steel, carbon steel, and alloy steel, chosen based on the application and industry requirements.

3. How to choose the best exporter of pipe flanges?

Consider certifications, export markets, pricing, material quality, and industry experience before selecting a supplier.

#PipeFlanges#FlangeExporters#IndustrialFlanges#IndiaManufacturing#FlangeSuppliers#StainlessSteelFlanges#OilAndGas#GlobalTrade#EngineeringSolutions

0 notes

Text

Pressure Safety Valves Manufacturer in India

Safety valves are crucial components in industrial systems, designed to protect equipment, personnel, and the environment by preventing overpressure situations. These valves automatically release pressure when it exceeds a certain limit, ensuring that systems operate safely. From steam boilers to chemical plants, safety valves are essential for maintaining operational integrity.

A pivotal role in ensuring the reliability and effectiveness of safety valves manufacturers in Mumbai, Chennai, Ahmedabad, Ghaziabad, Delhi, Bangalore, Vadodara, Gujarat, Rajasthan in India. When choosing a manufacturer, it's essential to consider factors like quality, compliance with international standards, and customer support. The right manufacturer will offer durable, high-performance products that meet the specific needs of various industries.

Pedlock Valve is a well-established name in the safety valve industry. With decades of experience, Pedlock Valve has built a reputation for delivering high-quality safety valves that meet stringent industry standards. The company’s commitment to innovation and customer satisfaction has made it a preferred choice for industries around the world.

A Leading Safety Valve Manufacturer

What makes Pedlock Valves stand out in the competitive landscape of safety valve manufacturers? The answer lies in its unwavering dedication to quality and excellence. Pedlock Valve is certified by leading industry bodies, ensuring that every product is manufactured to the highest standards. Their safety valves are known for their reliability, durability, and performance under pressure.

Product Range

Pedlock Valve offers a wide range of safety valves to cater to various industrial applications. Whether you need pressure relief valves, safety shut-off valves, or thermal relief valves, Pedlock Valves has the expertise and products to meet your needs. These valves are designed to work in extreme conditions, providing consistent performance in critical situations.

Innovation and Technology

In today’s fast-paced world, staying ahead requires constant innovation. Pedlock Valve invests heavily in research and development to incorporate the latest technological advancements into their products. From using cutting-edge materials to implementing advanced manufacturing processes, Pedlock Valve ensures that their safety valves manufacturer in Chennai, Mumbai, Ahmedabad, Vadodara, Delhi, Bangalore, Rajasthan, Ghaziabad, Delhi in India is at the forefront of technology.

Quality Assurance

Quality is at the heart of everything Pedlock Valve does. The company employs rigorous testing and quality control processes to ensure that each valve meets the highest standards. From material selection to final inspection, every step is meticulously monitored to guarantee the safety and reliability of their products.

Customer Centric Approach

Pedlock Valve believes in putting the customer first. Their customer service team is always ready to assist with product selection, technical support, and after-sales service. Additionally, our company offers customization options to meet the unique requirements of different industries, ensuring that clients get the perfect solution for their needs.

Industries Served

Our company serves a wide range of industries, including oil and gas, petrochemical, power generation, and pharmaceuticals. Their safety valves are trusted by leading companies around the world to protect their critical systems. For example, in the oil and gas industry, Pedlock Valve’s products are used to ensure the safe operation of pipelines and processing plants.

Global Reach and Distribution

We have a global presence, with a robust distribution network that ensures timely delivery of products to customers around the world. Their strategic partnerships with distributors and service centers allow them to provide prompt support and service, no matter where their clients are located.

Sustainability Practices

Pedlock is committed to sustainability. The company actively seeks to reduce its environmental impact through eco friendly manufacturing practices and the development of products that help industries minimize waste and energy consumption. Sustainability is not just a buzzword at Pedlock Valve; it’s a core part of their business philosophy.

Why Choose Pedlock Valve for Your Safety Valve Needs?

Choosing Pedlock Valve means choosing a company that is dedicated to safety, quality, and customer satisfaction. With a proven track record, a wide range of products and a commitment to innovation, our company is the ideal partner for all your safety valve needs.

Conclusion

In conclusion, Pedlock Valves stands out as a pressure safety valves manufacturer in Ahmedabad, Mumbai, Delhi, Chennai, Vadodara, Gujarat, Rajasthan, Bangalore, Ghaziabad in India that prioritizes quality, innovation, and customer service. Whether you’re in the market for standard safety valves or customized solutions, we have the expertise and products to meet your needs. Trust Pedlock Valve to protect your systems and ensure safe operations in even the most challenging environments.

#Safety Valves Manufacturer in Mumbai#Safety Valves Manufacturer in Ahmedabad#Safety Valves Manufacturer in Vadodara#Safety Valves Manufacturer in Rajasthan#Safety Valves Manufacturer in Bangalore#Safety Valves Manufacturer in Ghaziabad#Safety Valves Manufacturer in Gujarat#Safety Valves Manufacturer in delhi

0 notes

Text

Why Partnering with a Reliable Chemical Manufacturing Company in Chennai Makes Business Sense

Chennai is one of the prominent industrial centers in India, and the capital city of Tamil Nadu is an abuzz city. The city offers a gamut of services to businesses from different sectors. One of the most critical industries thriving in the city is chemical manufacturing. As the need for specialized chemicals continues to increase across sectors like pharmaceuticals, textiles, automobiles, and agriculture, the necessity of collaborating with a chemical manufacturing company in Chennai has never been more evident.

Whether you want bulk chemicals, specialty formulations, or raw materials to be used for the development of products, a supplier can literally be the make or break point of efficiency, quality, and scale for your business. In this blog, we talk about why Chennai is home to some of the best chemical manufacturing companies and what to look for in the right partner for your business.

Importance of Chemical Manufacture to Various Industries

Chemicals form the base of many industries; from industrial purposes to consumer commodities. Pharmaceuticals are impossible without chemicals since these are life-saving drugs. For textiles, it is not possible to manufacture dyes, anti-wrinkle finishes, or water-repellent materials without chemicals. Similarly, chemicals also play an integral role in automotive industries. This is because manufacturing coatings, adhesives, lubricants, and plastics in automotive industries relies entirely on chemicals that ensure the performance, safety, and aesthetics of a vehicle.

The requirement for a good chemical manufacturing company in Chennai is increasing because the industries are becoming more demanding, and more advanced solutions are needed.

Customization, meeting quality standards, and providing on-time delivery will help businesses maintain production schedules without compromising on quality.

Why Chennai is a Hub for Chemical Manufacturing

Being located on the southeaster coast of India, Chennai is an ideal place for domestic as well as international trade. The good transportation network in the city, including the Chennai Port, makes it easy to import raw materials and finished chemicals for exportation. This implies that it is easy for companies to source raw chemicals and distribute their products all over the world.

Several companies in Chennai, including established and new chemical manufacturers, cater to numerous industries. With easy access to skilled labour and robust industrial infrastructure, these cities also offer close proximity to key petrochemical plants, contributing to efficient production of high quality.

Key Selection Factors for Choosing a Chemical Manufacturing Company in Chennai

With so many options, it is sometimes challenging to determine which one is best suited for your business needs. Some of the key factors are described below:

1. Quality Assurance

The quality of chemicals produced by a manufacturing company is paramount. A good company follows the strict standards and certifications within the industry and ensures that all chemicals meet the needed regulatory and safety norms. This ranges from ISO certification, GMP (Good Manufacturing Practice), to environmental standards. Quality assurance is never a compromise.

2. Customization Capabilities

Each business is unique and one-size-fits-all rarely works for the chemical industry. The top-end chemical manufacturer in Chennai is unique because it is capable of manufacturing products according to specific needs; this could be on a unique formulation or packaging.

3. Scalability

As your business grows, your chemical supply needs may change. Choose a manufacturer that can adjust production volumes according to your growth needs, which will ensure continuity and reliability when your business grows. Scalability also means that it can change with new technologies and market trends.

4. Logistics and Delivery

Timely delivery is important in any industry where downtime leads to massive loss of money. An effective chemical manufacturing company in Chennai would be one that provides good logistics and inventory management, ensuring that chemicals get delivered on time and in the right quantities.

5. Sustainability Practices

In today's eco-friendly world, it is of paramount importance to work with a manufacturer who engages in sustainable practices. Seek manufacturers that are engaged in eco-friendly chemical production processes, waste reduction, and follow environmental regulations.

Conclusion

The chemical manufacturing industry in Chennai is booming, and great opportunities are there for businesses from various industries. Partnering with a company that focuses on quality, customization, scalability, and sustainability is sure to meet the chemicals you need for your products while ensuring efficiency in operations.

For large companies or start-ups, the selection of the best manufacturing partner is key in maintaining the competitive advantages in their respective markets. The right chemical supplier contributes to improving the quality of products, reducing associated operational risks, and building a sustainable future for business.

0 notes

Text

Free Job Alert Vacancy in Gummidipundi, Andhra Pradesh

Gummidipundi, a small yet vibrant industrial town located on the border of Tamil Nadu and Andhra Pradesh, has been emerging as a hub for employment opportunities. With its proximity to Chennai and its growing industrial base, this region is witnessing an increase in job openings across various sectors. If you're searching for a Free Job Alert Vacancy in Gummidipundi, Andhra Pradesh, this blog is your comprehensive guide to exploring opportunities in this area without being overwhelmed by the dominance of large corporations.

Why Gummidipundi is a Promising Location for Job Seekers Gummidipundi's strategic location has made it a hotspot for industries like manufacturing, logistics, warehousing, and small-scale enterprises. The town is well-connected by rail and road, ensuring easy access for workers commuting from nearby regions. Additionally, the availability of affordable housing and a relatively low cost of living makes it a practical choice for job seekers looking to settle down or start their careers.

Unlike metropolitan cities where competition is fierce, Gummidipundi offers a balanced environment where individuals can find meaningful work without the added stress of urban living.

Key Sectors Offering Job Opportunities

Manufacturing and Production Gummidipundi has a flourishing manufacturing sector with small and medium-scale enterprises producing a variety of goods, including textiles, chemicals, and fabricated materials. Job roles in this sector often include:

Machine operators Quality assurance inspectors Assembly line workers Maintenance technicians Skilled and unskilled workers alike can find plenty of opportunities in these industries. The town's industries often prioritize hiring locally, offering numerous entry-level positions that require minimal qualifications.

Logistics and Warehousing The growth of e-commerce and supply chain activities has led to the establishment of logistics hubs in and around Gummidipundi. Job seekers with skills in inventory management, transportation, and data entry will find this sector particularly lucrative. Common vacancies include:

Warehouse supervisors Forklift operators Inventory clerks Delivery personnel This sector is especially attractive for individuals looking for flexible working hours and opportunities for career advancement.

Agriculture and Agro-Based Industries Given its semi-rural setup, agriculture still plays a significant role in the local economy. Agro-based industries such as food processing units and cold storage facilities are growing steadily. Jobs in this sector range from farming and packaging to roles in quality control and equipment operation.

Construction and Infrastructure As Gummidipundi continues to grow, infrastructure development is creating employment in construction-related fields. From manual labor to supervisory roles, there’s a constant demand for skilled workers like masons, carpenters, and electricians.

How to Stay Updated with Free Job Alerts Getting timely updates about job vacancies in Gummidipundi is crucial for job seekers. Here are some effective ways to stay informed:

Online Job Portals Websites like Naukri.com, Indeed, and local job boards often list vacancies specific to smaller towns and industrial hubs. Set up email alerts for terms like Free Job Alert Vacancy in Gummidipundi, Andhra Pradesh to receive instant updates.

Social Media Platforms Many small-scale companies and recruitment agencies post job openings on platforms like Facebook and LinkedIn. Join local groups and forums to connect with potential employers and fellow job seekers.

Networking Local networks, word-of-mouth referrals, and community gatherings can also be valuable sources of job information. Residents and workers often share leads on open positions within their industries.

Employment Exchanges and NGOs Government employment exchanges and non-governmental organizations in the region can help you find suitable job openings. These organizations often organize job fairs and skill training programs to bridge the gap between employers and job seekers.

Tips for Securing a Job in Gummidipundi Polish Your Resume Highlight relevant skills and experience that match the job description. For entry-level roles, emphasize your willingness to learn and adapt.

Be Proactive Visit industries, warehouses, and offices in person to inquire about vacancies. Employers often appreciate candidates who take the initiative to approach them directly.

Upskill Yourself Take up short-term certification programs in areas like machine operations, safety training, or basic computer skills. Many local training institutes offer affordable courses tailored to the needs of Gummidipundi’s industries.

Follow Up After applying for a job, follow up with a polite email or call to show your interest in the position. This simple step can set you apart from other candidates.

A Word of Encouragement The job market in Gummidipundi, Andhra Pradesh, holds immense potential for those willing to explore it with dedication and an open mind. Whether you're a fresh graduate looking to kickstart your career or an experienced professional seeking stability, this region offers diverse opportunities to match your aspirations.

By staying vigilant and leveraging resources like free job alerts, you can secure a rewarding position in one of Gummidipundi’s thriving sectors. Remember, persistence and preparedness are your biggest allies in any job hunt.

Embrace the possibilities that Gummidipundi has to offer, and take the first step toward a fulfilling career today!

0 notes

Text

What's a Gasket?and How They Work

Gasco INC. is one of the Top Gasket Companies in India.We produce the best gasket available on the market. A gasket, like a spring, is an item that stores energy by closing two opposing sides which do not meet completely. "Fills the space between two objects, generally to prevent leakage between the two objects while under compression.

Gaskets Are Universal

Gaskets may be found everywhere. They're in the air, in your car, and at work! Any grommet or seal that binds two objects together is referred to as a gasket. Rubber, plastic, metal, and other materials can all be used to make gaskets. The material choice depends on why you need to use a Gasket.Gasket Manufacturers in India supply gaskets to the Pulp and Paper Industry.

However, as you will see, gaskets are more than just a way to stop leaks. Let us do the dirty work and tell you all you need to know about gaskets before you blow a gasket trying to figure out the differences between each one!

What Are Some Examples of Gasket Applications?

There are several industrial uses for gaskets. These include gas, plumbing, petrochemicals, food processing, and equipment.

Examples include gaskets around windows and in water taps. For instance, gaskets maintain cold air inside refrigerators. Workplace gaskets include those found in pumps, valves, pipelines, and equipment.

Gasco INC is one of the leading Gasket Manufacturers, Suppliers, & Stockists in India.The following are the various industries that employ gaskets in their day to day process :

Gasket Manufacturers in India use it in Process industry

Gaskets is used in Petrochemical industry

Gaskets is used in Chemical industry

Gaskets is used in Pharmaceutical industry

Spiral Wound Gasket Manufacturers in Mumbai use Gaskets is used in Pulp and paper industry

Gaskets is used in Food and beverage industry

Gaskets is used in Sugar industry

Spiral Wound Gasket Manufacturers in Chennai use Gaskets is used in Flange connections

Gaskets is used in Pipe connections

Specific Gasket Functions:

Gaskets are used to seal closed containers like boilers and fuel tanks. When developing a gasket for these closed vessel applications, certain shapes, pressures, and temperatures must be met.

A closed vessel gasket, for example, may need to be spherical with a single stud bolt and designed to resist pressures ranging from a normal fuel tank to a steam pressure vessel.

Premium Quality Gasket Manufacturer In India.

Gasco INC is one of the leading Gasket manufacturer in India. Gaskets have been designed in accordance with national and international industry standards, using high-quality raw materials and cutting-edge technology. We supply different types of Gaskets in Mumbai India.

we also distribute gaskets, O rings, seal rings, & gland packings with their types. we have the best quality with ISO-certified products. We are a Gasket manufacturer for industrial usage that works even in the most stringent conditions.

Gaskets are widely used in a variety of fields and applications such as vehicle engines, pipelines and plumbing, industrial equipment, and home appliances. They are essential in establishing a solid seal between parts that keeps fluids and gases from escaping or entering. We are also gasket supplier in india.

Website: gascogaskets.com

Our Products: Gasket Supplier

Other Products: EPDM O Ring Manufacturers in India

0 notes

Text

3D Monotech introduces Markforged FX10

Monotech Systems, a prominent provider of 3D printing and advanced manufacturing solutions, has launched the Markforged FX10, a cutting-edge industrial 3D printer, in India. The unveiling event took place on 19 December 2024, at the Radisson Blu Hotel Chennai, attracting industry leaders and dignitaries from diverse sectors.

The company claims that Markforged FX10 stands out as the world’s first industrial 3D printer to offer both metal and composite printing capabilities. Its modular print system enables seamless switching between metal and composite print engines, providing unparalleled flexibility for users. Boasting a large build volume of 375 mm x 300 mm x 300 mm, the FX10 is designed to enhance productivity by delivering robust, precise tools and fixtures.

Chief guest Gaurav Sarda, regional head – East Coast region, emerging corporate group, HDFC Bank, hailed the FX10’s launch as a milestone for India’s manufacturing industry. He also highlighted Monotech’s R&D facility in Ambattur, Chennai, as a symbol of the company’s innovation-driven approach.

Advanced features and material support

The FX10 offers several advanced features, including:

Printhead-Mounted Optical Sensors: For verifying dimensional accuracy and monitoring device health.

Automatic Calibration and Material Changeover: Ensuring efficient operations and minimal downtime.

Wide Material Compatibility:

Composite Materials: Onyx, Onyx FR, Onyx ESD, Continuous Carbon Fiber, and Nylon variants.

Metal Materials: 17-4PH Stainless Steel v2 and 316L Stainless Steel.

Insights from industry leaders

The event commenced with introductory remarks from Rajesh Mrithyunjayan, VP – 3D Products and Solutions at 3D Monotech, and Prashant Sinha, Markforged country manager, India. Both emphasized the strong partnership between Monotech Systems and Markforged in driving innovation.

Richard Elving, VP sales for Markforged in the APAC region, highlighted India’s growing prominence as a global manufacturing hub. “India is emerging as a leading manufacturing destination as the world explores alternatives,” he said.

Tej Prakash Jain, managing director of Monotech Systems, reflected on the company’s growth since its inception in 1999, expanding from a small six-person team to a 600-strong workforce. “The launch of the FX10 marks another milestone in our journey, mirroring India’s expanding capabilities in manufacturing,” he adds.

Keynote Highlights and Industry Applications

The event featured presentations from distinguished speakers, showcasing the transformative potential of 3D printing across industries:

Dr G Saravana Kumar from IIT Madras shared insights into 3D and 4D printing advancements in healthcare.

Aravind Udupi, head of engineering at Nordex Group, demonstrated how Markforged printers reduced their design-to-production cycle to just 18 months.

Dr Winstone Deaver, research engineer at 3D GRAPHYLLP, presented a case study where 3D printing reduced an Indian Navy impeller’s weight from 8 kg to 1 kg.

Sr scientist Ravi Babu from CSIR discussed applications in batteries, bioprinting, and the chemical industry.

Prashant Sinha concluded the event by showcasing the FX10’s capabilities and highlighting successful implementations of Markforged printers across aerospace, marine, energy, research laboratories, drones, and more. Attendees left with valuable insights into the FX10’s potential to revolutionize manufacturing and its role in advancing India’s industrial landscape.

0 notes

Text

The Unique Needs and Benefits of Glass Bottle Washers: Why Seppa Solutions is Your Best Choice

Haven't you ever wondered how crucial it is to wash glass bottles? From the cola you drink to the pill you swallow or the lotion you apply, the cleanliness of the package matters in a major way. But how do these bottles get so spotless? But why should companies care about investing in specialized equipment, like glass bottle cleaner? Let’s dive into the answers.

Why Is Glass Bottle Cleaning So Important?

Just like you might drink a cooling drink or take a drug to make you feel better. What if the bottle wasn't quite clean? Would you use it with confidence? Most likely not!

That’s why glass bottle cleaning is critical. It's not only about appearance; it's health, safety, and quality. Clean bottles guarantee escape from toxins, microbes, and other contaminants reaching the food we eat. It is also the business aspect of building a rock-solid reputation and customer credibility.

Fields such as beverages, pharmaceuticals, and cosmetics all have deep needs for the use of clean bottles. An unsanitary bottle can result in complaints, product loss, or more severe bad effects on customers.

How Glass Bottle Washers Get the Job Done

Glass bottle washers are special machines that provide cleaning to the next level. Here’s how they typically work:

Pre-Washing: This is the pre rinse to remove anything that may shake loose in the nuts/molds.

Deep Cleaning with Detergents: With high-pressure water jets and cleaning solutions, the bottle is cleaned from top to bottom, inside and out.

Sterilization: Most washers clean bottles using high-temperature water or steam to kill bacteria and to provide them in a germ-free state.

Final Rinse: A thorough rinse removes any leftover cleaning agents.

Drying and Inspection: Bottles are desiccated and typically checked to make sure that they are free of dirt and clean for use.

This method isn’t just thorough—it’s efficient. It guarantees every bottle is as clean as possible, without wasting time or resources.

What Makes Glass Bottle Washing Unique?

Cleaning glass bottles is no child's play washing dishes at home. They have unique needs that require careful handling:

Fragility and Strength: Glass bottles must be very carefully handled to prevent breakage, yet they also have to be subjected to strong cleaning to get rid of tough residues.

Different Sizes and Shapes: Imagine all the bottles in existence—from miniscule drug ampules to large fluid containers. A great washer can respond to any shape or size.

Chemical Residues: Some bottles hold sticky substances like oils or syrups. Cleaners of washing loads must contain cleaning agents powerful enough to overcome them without damaging the glass.

Eco-Friendliness: Water and energy are saved while cleaning bottles which has relevance particularly in refinancing.

Why Choose Seppa Solutions’ Glass Bottle Washers?

Search for a solution that satisfies all of the above needs and others and Seppa Solutions will take care of it. Here’s what makes their glass bottle washers stand out:

Tailored to Your Needs: Irrespective of beverage, pharmaceuticals, or cosmetics industry, their washers can also be tailored to fit your individual needs.

Environmentally Friendly: Seppa Solutions machines are used as a way to save water and energy but there is no sacrifice in cleaning quality.

Built to Last: Using high-quality materials, these washers are designed for strength and dependability, even when heavily used.

Advanced Automation: Their washing machines are equipped with smart functions, such as automatable settings and automatable inspection, which enables efficient and uniform cleaning.

When you choose Seppa Solutions, you’re not just buying a machine—you’re investing in quality, innovation, and long-term success.

Industries That Rely on Glass Bottle Washers

Uncontaminated glass containers are not only of interest for a specific sector of the economy. Lot of industries take advantage of having a state-of-the-art bottle washer such as:

Beverages: Clean bottles preserve the taste and freshness of beverages, from soda, to beer and wine.

Pharmaceuticals: Sterile bottles are crucial for storing medicines and vaccines.

Cosmetics: A sterilized receptacle can represent the top grade of the product in it.

Food Producers: Clean packaging is essential for products such as sauces, oils, and syrups to maintain freshness and safety.

No matter your field, clear bottles tell your customers you care about the customer on the receiving end of your product, and the quality of that product.

Why Seppa Solutions Is the Right Choice

When it comes to glass bottle washing, Seppa Solutions has set the gold standard. Their washers are designed to meet the highest levels of cleanliness while being cost-effective and eco-friendly.

Choosing Seppa Solutions means choosing:

Better product quality.

Streamlined operations.

A stronger reputation with your customers.

Ready to Make the Switch?

Why settle for anything less than the best? Your customers deserve clean, safe, and high-quality packaging. By investing in Seppa Solutions’ Glass Bottle Washer, you’re ensuring every bottle you use is up to the mark.

Don’t wait—contact Seppa Solutions today and discover how their innovative solutions can elevate your business. Because every little detail counts when it comes to cleanliness.

#glass bottle washers#glass bottle cleaner#glass bottle cleaning machine#industrial glass bottle washer#glass bottle washer machine

0 notes

Text

Industrial Manifold Valves Manufacturer in India

India has become a hub for high quality industrial equipment manufacturing, and manifold valves play a critical role in industrial applications across multiple sectors. As a leading manifold valves manufacturer in Mumbai, Chennai, Ahmedabad, Vadodara, Bengalore, Gujarat, Rajasthan, Ghaziabad and Delhi in India, Pedlock has carved a niche in providing reliable, durable, and precision engineered solutions.

Manifold valves are essential components in fluid control systems. These devices consolidate multiple functions into a single compact unit, allowing for easier installation, maintenance, and operation. Their versatility makes them indispensable in industries like oil and gas, petrochemicals, power generation, and pharmaceuticals.

Key Features of Manifold Valves

Precision Engineering: Manifold valves are crafted to ensure leak-proof performance and seamless operation under high pressure and temperature.

Corrosion Resistance: With materials like stainless steel and exotic alloys, they resist harsh environmental conditions.

Compact Design: Space-saving designs ensure easy integration into complex systems.

Long Lifespan: Engineered for durability, these valves withstand rigorous usage.

A Trusted Name in Manifold Valves Manufacturer in Across India

Why Choose Pedlock?

Pedlock is synonymous with excellence in manifold valves manufacturer in Delhi, Ahmedabad, Gujarat, Chennai, Bengalore, Mumbai, Rajasthan, Vadodara and Ghaziabad, India. Here are the reasons why industries trust:

Superior Quality Control: Our Company ensures every valve meets stringent quality standards through rigorous testing.

Innovative Design: The Company’s engineering team focuses on creating innovative solutions tailored to client needs.

Global Standards Compliance: Pedlock’s valves adhere to international standards like ISO, ASME, and ASTM.

Wide Product Range: From simple two-valve manifolds to complex five-valve manifolds, our company offers it all.

Types of Instrument Manifold Valves

1. Two Valves Manifolds

Two valve manifolds are used for isolating and bleeding applications. They typically consist of an isolation valve and a bleed valve.

Features

Compact and lightweight design

Suitable for pressure instruments

High-pressure rating compatibility

2. Three Valves Manifolds

Three valve manifolds are widely used in differential pressure transmitters. They include two isolation valves and one equalizing valve.

Applications

Differential pressure measurement in process systems

Minimizing pressure fluctuations during maintenance

3. Five Valves Manifolds

These advanced manifolds are ideal for applications requiring high accuracy and reliability.

Advantages

Enhanced functionality with two isolation valves, two equalizing valves, and a vent valve

Designed for high-pressure and high-temperature environments

4. Instrument Manifolds Valves

Instrument manifolds valves integrate multiple connections, ensuring efficient monitoring and control.

Industries Served

Oil and gas exploration

Petrochemical processing

Power plants

Applications of Manifold Valves

Manifold valves serve diverse industries and applications, including:

Oil and Gas: Used in upstream, midstream, and downstream operations for pressure and flow control.

Petrochemicals: Ensure precise control and measurement in chemical processing units.

Power Generation: Monitor and manage steam and gas flows in power plants.

Pharmaceuticals: Enable sterile and controlled environments for drug manufacturing.

Water Treatment: Facilitate efficient flow management in desalination and purification plants.

Advantages of Choosing Pedlock’s Manifold Valves

Customization Options: our company offers customized solutions to meet specific industrial requirements.

Durability: High-quality materials ensure longevity and reliability even in challenging environments.

Cost-Effectiveness: Competitive pricing without compromising on quality.

Quick Delivery: An extensive distribution network ensures timely delivery.

Expert Support: Dedicated customer support for pre-sales and post-sales queries.

Our Commitment to Sustainability

Our company not only focuses on delivering top manifold valves but also emphasizes sustainability. The company employs eco-friendly practices in its manufacturing processes, reducing its carbon footprint while ensuring high product quality.

Conclusion

Pedlock stands out as a premier manifold valves manufacturer in Chennai, Ahmedabad, Gujarat, Vadodara, Delhi, Mumbai, Rajasthan, Ghaziabad and Bengalore, India, offering unparalleled quality, a wide range of products, and exceptional customer service. Whether you need two-valve, three-valve, or five-valve manifolds, our company has the expertise and resources to deliver tailored solutions.

#manifold valves manufacturer#manifold valves manufacturer in Mumbai#manifold valves manufacturer in Chennai#manifold valves manufacturer in Ahmedabad#manifold valves manufacturer in Gujarat#manifold valves manufacturer in Bengalore#manifold valves manufacturer in Rajasthan#manifold valves manufacturer in Delhi#manifold valves manufacturer in Ghaziabad#manifold valves manufacturer in Vadodara

1 note

·

View note

Text

What is the Career Potential After Completing a Piping Design Engineering Course in Chennai?

Introduction:

The Piping Design Engineering Course is an excellent choice for individuals aspiring to build a career in piping design, which is crucial in industries like oil & gas, chemical manufacturing, power generation, and construction. The Piping Design Certification Course in Chennai at Conserve Academy equips students with essential skills in designing and drafting piping systems, managing projects, and using advanced CAD software. With the growing demand for skilled piping designers globally, completing this course offers substantial career potential and job opportunities.

Career Opportunities After the Course:Graduates can explore various roles in the piping design industry, including:

Piping Design Engineer:Responsible for designing and optimizing piping systems for safety and efficiency.

Project Engineer:Manages piping design projects, ensuring they are completed within timelines and budgets.

CAD Designer:Creates accurate technical drawings of piping systems using CAD software.

Piping Drafter:Drafts detailed plans for piping installations under the guidance of design engineers.

Stress Analysis Engineer:Assesses the strength of piping systems through stress and strain analysis to ensure structural integrity.

Piping Material Specialist:Selects materials for piping systems, considering environmental conditions and industry standards.

Industry Demand and Job Market:With industries like oil & gas, chemical manufacturing, and power generation expanding globally, the demand for skilled piping design engineers is on the rise. Graduates from this course have numerous opportunities with top engineering firms, construction companies, and energy corporations. The course’s placement assistance gives graduates a strong advantage in the competitive job market.

Conclusion:

Choosing to pursue a career in piping design opens doors to a rewarding future in a high-demand field. With the right combination of practical skills and industry knowledge, graduates are poised for success. The Piping Design Engineering Course in Chennai at Conserve Academy equips students with the expertise needed to excel in this field. As the need for skilled professionals grows, this course offers a strong foundation for long-term career advancement in the engineering industry.

#piping course in chennai in chennai#piping design and drafting course in chennai#piping design certification course in chennai#piping design courses in chennai

0 notes

Text

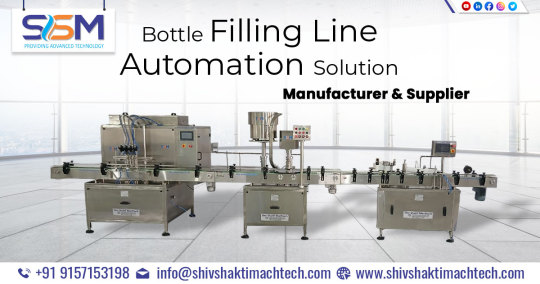

Bottle Filling Line Automation Solution

Company Overview: Shiv Shakti Machtech is a Manufacturer, Exporter, and Supplier of Bottle Filling Line Automation Solution in Ahmedabad, Gujarat, India Our Manufacturer Unit is in Ahmedabad, Gujarat, India. The Bottle Filling Line Automation Solution offers a state-of-the-art, automated system for filling, capping, labeling, and packaging bottles across various industries. How Does Bottle Filling Line Automation Work? A typical bottle-filling line automation system consists of several key components that work in synergy: Bottle Feeding System: Bottles are automatically fed into the filling station from the conveyor belt. Filling Machine: This part of the system fills each bottle to the desired level based on preset parameters. Capping and Sealing: After filling, caps are automatically placed and sealed to ensure the bottle is ready for distribution. Labeling: A labeling machine attaches labels to each bottle, ensuring correct branding and product information. Packaging: Finally, we package the filled and labeled bottles for distribution, making them ready to reach consumers. Applications: Food and Beverage Pharmaceuticals Cosmetics and Personal Care Chemicals Agricultural Products What types of liquids can be filled using this automation system? Our automation solutions can fill a wide range of liquids, from thin solutions like water and beverages to thicker liquids such as oils, syrups, and pharmaceutical medicines. Can the filling line handle different bottle sizes? Yes, Shiv Shakti Machtech’s automated bottle-filling lines are highly customizable and can handle various bottle sizes and types, ensuring versatility in your production process. Shiv Shakti Machtech is a Supplier of Bottle Filling Line Automation Solution in Ahmedabad, Gujarat, India Including Kathwada, Vadodara, Changodar, Gota, Naroda, Nikol, Mehsana, Palanpur, Deesa, Patan, Vapi, Surendranagar, Bhavnagar, Jamnagar, Junagadh, Rajkot, Amreli, Mahuva, Surat, Navsari, Valsad, Silvassa, Porbandar, Mumbai, Vasai, Andheri, Dadar, Maharashtra, Aurangabad, Kolhapur, Pune, Rajasthan, Jaipur, Udaipur, Kota, Bharatpur, Ankleshwar, Bharuch, Ajmer, Delhi, Noida, Baddi, Solan, Himachal Pradesh, Una, Jammu Kashmir, Haryana, Hisar, Gurgaon, Gurugram, Madhya Pradesh, Indore, Bhopal, Ratlam, Jabalpur, Satna, New Delhi, Kolkata, West Bengal, Assam, Asansol, Siliguri, Durgapur, Bhubaneswar, Odisha, Brahmapur, Puri, Goa, Amaravati, Andhra Pradesh, Visakhapatna, Hyderabad, Guntur, Chittoor, Kurnool, Vizianagaram, Srikakulam, Karimnagar, Ramagundam, Suryapet, Telangana, Medak, Bengaluru, Bangalore, Mangaluru, Hubballi, Vijayapura, Davanagere, Kalaburagi, Chitradurga, Ballari, Kolar, Chennai, Coimbatore, Madurai, Tiruchirapalli, Tiruppur, Salem, Erode, Tirunelveli, Tamil Nadu, Kerala, Kochi, Thiruvananthapuram, Kozhikode, Thrissur, Kollam, Alappuzha, Kottayam, Kannur, Malappuram, Bharatpur, Jodhpur, Bikaner, Alwar, Bhilwara, Nagpur, Amravati, Solapur, Malegaon, Navi Mumbai, Thane, Wardha, Vasai-Virar, Gondia, Hinganghat, Barshi, Ulhasnagar, Nandurbar, Bhusawal, Pimpri-Chinchwad, Kalyan, Satara, Yamuna Nagar, Chhachhrauli. For more information or to request a quote, please reach out to us. Read the full article

1 note

·

View note

Text

Best Conveyor Belt Manufacturers in Chennai - Cherry Belts

Chennai, the capital of Tamil Nadu, is a bustling industrial hub with a rich history in manufacturing and production. The city is home to some of India’s most significant automotive, electronics, textile, and manufacturing companies. For industries that rely heavily on efficient material handling, conveyor belts play an indispensable role in ensuring smooth, continuous production. In this blog, we will explore the rising demand for conveyor belt manufacturers in Chennai, how they are contributing to industrial growth, and why Cherry Belts stands out as a leading provider of conveyor solutions in the region. #

The Role of Conveyor Belts in Industrial GrowthIndustries in Chennai are experiencing significant growth, from automotive giants like Hyundai and Ford to electronics and textiles industries. This surge has fueled the need for efficient, automated systems to keep up with production demands. Conveyor belts are critical components in these systems, streamlining the movement of materials, reducing labor costs, and enhancing overall productivity.

Conveyor belts serve as the backbone of many industries, whether they are used to transport automotive components, electronics, or raw materials. They improve efficiency, speed up production, and enable companies to meet high production targets while maintaining quality and reducing human error. For industries in Chennai, where competition is intense, having the right conveyor system can make all the difference in staying ahead.

Different Types of Conveyor Belts Used in Chennai's IndustriesThe diversity of industries in Chennai means that conveyor belt requirements vary widely. Conveyor belt manufacturers in Chennai, like Cherry Belts, offer a broad range of conveyor belts designed to meet the specific needs of different sectors. Here are some of the most common types of conveyor belts used across industries in Chennai: Rubber Conveyor BeltsRubber conveyor belts are highly durable and can withstand harsh conditions, making them ideal for industries such as mining, steel, and construction. These belts are designed to handle heavy loads and resist wear and tear, ensuring long-lasting performance in demanding environments. PVC Conveyor BeltsPVC (polyvinyl chloride) conveyor belts are favored in industries such as food processing, pharmaceuticals, and packaging due to their hygienic and lightweight properties. They are resistant to moisture, oils, and chemicals, making them perfect for clean, safe material handling.

Heat-Resistant Conveyor BeltsHeat-resistant conveyor belts are essential for industries such as cement, steel, and glass manufacturing, where materials are transported at high temperatures. These belts are specially designed to withstand heat without degrading or losing their strength, ensuring smooth operations in extreme conditions.

Chevron Conveyor BeltsIndustries like agriculture, mining, and construction, where materials need to be transported at steep angles, rely on chevron conveyor belts. The unique patterns on the surface of these belts provide extra grip, preventing slippage and ensuring the safe and efficient transport of goods. Modular Conveyor BeltsModular conveyor belts are used in highly automated industries, such as automotive manufacturing, electronics assembly, and packaging. These belts are designed for flexibility, easy maintenance, and quick assembly, allowing industries to adapt to changing production needs.

Each of these conveyor belt types plays a crucial role in enhancing the efficiency and productivity of industries in Chennai. Choosing the right conveyor belt is vital to ensure the smooth flow of materials and avoid production delays.

Cherry Belts: Leading the Way as Conveyor Belt Manufacturers in ChennaiWhen it comes to choosing a reliable conveyor belt manufacturer in Chennai, Cherry Belts stands out as a top choice. As one of the leading conveyor belt manufacturers in Chennai, Cherry Belts has built a strong reputation for providing high-quality, durable, and cost-effective conveyor solutions. Here are some key reasons why Cherry Belts is a trusted partner for industries in Chennai:

Extensive Range of Conveyor BeltsCherry Belts offers a wide selection of conveyor belts tailored to the needs of different industries. Whether it’s for transporting heavy loads in manufacturing plants or ensuring hygiene in food processing units, Cherry Belts provides customized solutions to match specific industrial requirements.

Customization and FlexibilityEvery industry has its own set of challenges, and a one-size-fits-all approach rarely works. Cherry Belts excels in providing tailor-made conveyor belts that suit the unique requirements of its clients. From material selection to design features, Cherry Belts works closely with its customers to deliver solutions that improve efficiency and performance. Quality and DurabilityCherry Belts is committed to delivering products that are built to last. The company adheres to strict quality control measures, ensuring that each conveyor belt is tested for durability, strength, and flexibility. This focus on quality ensures that industries in Chennai receive conveyor belts that can withstand heavy usage and tough conditions. Innovative TechnologyBy continuously investing in research and development, Cherry Belts stays ahead of industry trends. The company uses state-of-the-art technology to manufacture conveyor belts that meet global standards. This focus on innovation allows Cherry Belts to offer cutting-edge solutions that boost productivity and minimize downtime for its clients. Environmental ResponsibilitySustainability is a growing concern in today’s industrial landscape, and Cherry Belts is dedicated to environmentally responsible manufacturing practices. By minimizing waste and reducing the environmental impact of its production processes, Cherry Belts contributes to the creation of eco-friendly conveyor belt solutions that align with the global shift towards sustainability.

Exceptional Customer ServiceAt Cherry Belts, customer satisfaction is a top priority. From helping clients choose the right conveyor belt to offering maintenance and support services, Cherry Belts ensures that every customer has a seamless experience. The company’s responsive after-sales service helps minimize downtime and ensures optimal performance. Conclusion: Conveyor Belt Manufacturers in Chennai Paving the Way for Industrial EfficiencyConveyor belts are an integral part of the industrial ecosystem in Chennai, where manufacturing, automotive, electronics, and other sectors drive the economy. With the right conveyor belt system, industries can significantly enhance their operational efficiency, reduce costs, and improve product quality.

As one of the top conveyor belt manufacturers in Chennai, Cherry Belts is a trusted partner for industries looking for reliable, high-performance conveyor solutions. With a strong focus on quality, innovation, and customer satisfaction, Cherry Belts continues to lead the way in delivering conveyor belt solutions that power industrial growth in Chennai.

0 notes