#denim fibre innovation

Text

DENIM FIBER SUSTAINABILITY & INNOVATION

If you’re a denim aficionado who cares about the environment, you’ve always wondered about the sustainability of denim fiber. There has never been a better time to commit to sustainable fashion than now, with climate change on the horizon. The garment industry is constantly being scrutinized, with organic cotton and denim being examined to determine how natural they are…The origin of the fibers used in denim cloth, whether natural, organic, or synthetic, will determine its long-term viability.

Read More:-https://jdinstitute.co/denim-fiber-sustainability-innovation/

#denim fibre innovation#denim industry#denim and sustainability#innovative denim designs#denim fibre sustainability report 22

0 notes

Text

Called Infinna, the fibre is already being used by global brands including Patagonia, H&M and Inditex, which owns Zara. "It's a premium quality textile fibre, which looks and feels natural - like cotton," says Mr Alava, rubbing his own navy blue tee between his fingers. "And it is solving a major waste problem."

Around the world, an estimated 92 million tonnes of textiles waste is created each year, according to non-profit Global Fashion Agenda, and this figure is set to rise to more than 134 million tonnes by 2030, if clothing production continues along its current track.

To the untrained eye, samples of Infinited Fiber's recycled fibre resemble lambswool; soft, fluffy and cream coloured. Mr Alava explains that the product is produced through a complex, multi-step process which starts with shredding old textiles and removing synthetic materials and dyes, and ends with a new fibre, regenerated from extracted cellulose.

This finished fibre can then simply "hop into the traditional production processes" used by High Street brands, replacing cotton and synthetic fibres, to produce everything from shirts and dresses to denim jeans.

Much of the science involved in making the fibre has been around since the 1980s, says Mr Alava, but rapid technological advancements in the last few years have finally made large-scale production a more realistic possibility.

In parallel, he believes High Street brands have become more focused on "really honestly looking for changing their material usage", while millennial and Gen Z consumers are increasingly concerned about shopping sustainably. "They are different animals, different consumers, to people my age," he laughs.

The company has already attracted so much interest in its technology that it recently announced it was investing €400m (£345m; $400m) to build its first commercial-scale factory at a disused paper mill in Lapland.

The goal is to produce 30,000 tonnes of fibre a year once it's operating at full capacity in 2025. That is equivalent to the fibre needed for approximately 100 million T-shirts.

"I think the impact could be quite big, if you think about the whole textile system, what exists currently and how much textile waste that we have," argues Kirsi Niinimäki, an associate professor in fashion research at Aalto University, a few blocks away from Infinited Fiber's headquarters.

"It's a really good example of actually how we can 'close the loop'… really begin to move to a circular economy."

Infinited Fiber's growth is tied into a wider vision in Finland, which wants to become Europe's leading circular economy, with a focus on reusing and saving resources. In 2016, it became the first government in the world to create a national road map designed to help reach its goal.

Several other Finnish start-ups are looking at ways to produce new textile fibres on a big scale, while also cutting down on harmful emissions and chemicals. These include Spinnova which, from its textiles factory in Jyväskylä, central Finland, transforms cellulose from raw wood pulp into ready-to-spin fibres.

Spinnova's yarn is attracting plenty of global attention and has so far been used by brands including upmarket Finnish clothing label Marimekko, and outdoor wear firms North Face, Bergans and Adidas, which recently used it in a limited edition midlayer hoodie designed for hikers.

Elsewhere in Europe, there are a range of other companies developing technologies to create more circular yarns, including Swedish startup Renewcell, and Bright.fiber Textiles, which plans to open its first factory in the Netherlands in 2023.

But experts say there are a range of challenges facing these new fibre brands as they plot their expansions.

Ms Niinimäki underlines that the clothing manufacturing sector has, until recently, been slower than many other industries when it comes to embracing sustainability, which could set the tone for a slower transformation than companies like Spinnova and Infinited Fiber hope.

"It has been so easy to produce the way that we have been producing, and just to move towards more effective industrial manufacturing on an increasingly bigger scale," she says.

"There hasn't been a big pressure to change the already existing system." However, she is hopeful that, in the European Union at least, new rules aimed at ensuring clothing manufacturers focus on more sustainable and durable products will speed up "a change in mindsets".

Another issue is whether clothing brands will be able to pass on the additional costs of their new high-tech production techniques on to consumers, especially at a time when the cost of living is spiralling globally.

Adidas' latest limited edition hoodie produced with Spinnova fabric costs €160 (£137; $160) to buy online in Finland, at least €40 more than most of its other technical hoodies.

"Fashion is a complicated area, because even if people are saying that they are environmentally aware, they don't always act rationally," says Ms Niinimäki. "There's also this kind of emotional side when you talk about fashion consumption, and of course, the price is also linked to that."

While both Infinited Fiber and Spinnova insist their business plans look holistically at all aspects of production - for example using renewable technologies to power their factories - climate campaigners argue it is still too early to accurately estimate the net effect of these new techniques on carbon emissions.

"Pulp and other alternative fibres can provide diversity for sourcing textile materials and therefore lessen the burden caused by production of more traditional textile raw materials such as cotton," says Mai Suominen, a leading forest expert for WWF. "However it depends on the use of energy, all the processes they use and how they use waste materials."

Most importantly, she argues, simply slotting more sustainable fibres into the multibillion dollar fashion industry won't be enough to combat climate change, if we keep making and buying clothes at the current rate.

There is no sustainable development unless the overall natural resource consumption is radically decreased to a level that fits within planetary boundaries," she argues.

But within the Finnish fibres industry there is a sense of boomtown optimism that the increased use of recycled or reimagined fibres could be an important part of the jigsaw in the battle to limit climate change.

"The fast-fashion companies who have been kind of creating certain parts of the problem are highly interested in new technologies," says Infinited Fibers chief executive Petri Alva. He believes that if investment continues, the recycled fibres could become mainstream within ten to 15 years.

#textiles#fashion#fashion industry#sustainable fashion#recycled textiles#closed loop economy#artificial fibres

100 notes

·

View notes

Text

I've been thinking about old railway uniforms, and come to the conclusion that the textiles could be INTERESTING in a steampunk world.

If steam power is widespread and commonplace, that means that there's going to be plenty of steam piping and/or boilers around. A lot of it would probably be insulated for safety and efficiency, but that still probably means that a significant part of the population has to work around HOT steam-powered equipment fairly often. I don't think that EVERYONE would necessarily be going around in protective double denim, but I think there'd just be less demand for fabrics with worse heat resistance.

That probably means that textile innovation wouldn't focus so hard on inventing New materials; but rather on improving natural fabrics. With a focus on mechanical innovation, I think your steampunk inventor would have an ENORMOUS array of linkages available to them - for converting a continuous mechanical input to various complicated and adjustable movement patterns. I think that having a lot more workers in hot environments would also lead to wide-spread use of mechanical refrigeration.

I've seen a few videos of industrial fabric-handling machines - they seem to have a Lot spiky metal fingers making repetitive movements. I think a steampunk world would be GREAT at making those little fingers do different, interesting patterns of movement! I recently saw a Matt Parker video about a continuous lattice of 7 different directions of pencil, and there was a cool animation of its cross-section. Imagine the funky patterns you could weave with thread going in more than 2 directions - either coplanar with eachother or in 3d space. All the cool decorative patterns woodworkers can do with plywood and veneer - imagine that with thread!

One of the reasons that a lot of tradespeople wore denim was because the pattern of the fabric obscured oil and grease stains. Could you achieve the same effect with the above funky patterns if they were dense enough? SO many workwear fashion options. And if you've got hot steam on tap as well as decent refrigeration - heat treatment would be easy to incorporate. What sort of interesting features would they be heat-setting into their clothes?

And if you want to build any sort of articulated machine/robot with steam as the power source; you need something to carry that steam - a flexible, high-pressure, heat resistant pipe. That sounds like a braided hose to me - and if you're using more colourful metals than stainless steel, your steam plumbing could get COLOURFUL! You know how we have braided hoses with a red or blue strand for hot or cold water? JUST IMAGINE the industry standard colour coding schemes for different temperatures, pressures, and phases of various fluids they could have!

Colour coded flexible pressure hose reminds me of an electrical system - I wonder how a steampunk world would do mechanical calculation? Did someone say Convoluted Fluid Based Computers?? With advances in textiles, hoses, and ropes - surely at some point they'd invent wire or fibre-wrapped pressure vessels! (Just think what they'd do with carbon fibre!) A society with (admittedly probably building-sized) computers that's used to dealing with high-pressure fluids - SURELY they'd invent jet propulsion? Perhaps not for rockets or aircraft - imagine pressure-jet steampunk ships, submarines even.

Actually where I can see modern-ish chemical rocketry in a steampunk world is in miniature steam generators - either HO bipropellant (your choice of liquid or gaseous) or peroxide monopropellant. A vigorous chemical reaction with hot, fast H2O as the product - sounds like a (rather explosive) portable power source.

Anyways, TLDR i'd LOVE to see what technological innovations a steampunk world would have. What paths they'd go down for research.

2 notes

·

View notes

Text

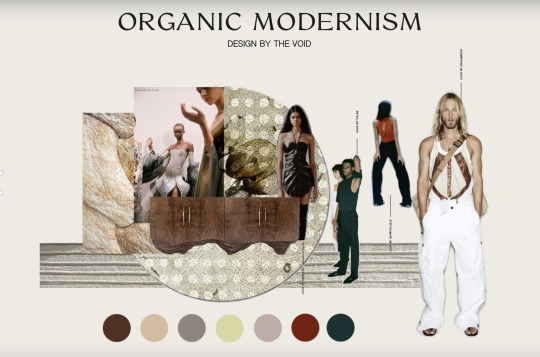

………..the future of fashion as we dive into the exciting world of trend forecasting for the upcoming Spring/Summer season of 2024-25……………..

"Get ready to embrace the future of fashion as we dive into the exciting world of trend forecasting for the upcoming Spring/Summer season of 2024-2025. In this blog, we'll explore the latest styles, colours, and patterns that are set to dominate the runways and inspire your wardrobe. From bold prints to innovative designs, join us as we uncover the hottest trends that will define the fashion landscape in the seasons to come. Let's embark on this stylish journey together!"

Get ready to add a pop of colour to your life! We'll dive into the exciting world of colour trends for the upcoming seasons. From vibrant hues to soothing pastels, we'll explore the shades that will dominate the fashion and design landscape. Whether you're looking to revamp your wardrobe or refresh your living space, join us as we uncover the hottest colour palettes that will inspire your style and elevate your surroundings. Let's embrace the power of colour together.For Spring/Summer 2024, WGSN and Coloro predict key colours to be Fondant Pink, Cyber Lime, Radiant Red, Elemental Blue, and Nutshell that are set to dominate the world of design and fashion, collective craving for equilibrium and steadiness, stability and need to nurture and care for each other in these difficult times, mentally and physically, raising our energy levels or grounding us back down, they connect to the evolving, fast paced and technologically driven world we live in.Care, connection and community underpin our five key colours for S/S 24.

Depiction of the colours

Fondant pink, Radiant Red - stimulating, sweet qualities nurturing a loving culture.

Elemental Blues and Nutshell - grounding and stable attributes

Cyber Limes - synthetic realism, connecting us to our ever-expanding digital lives.

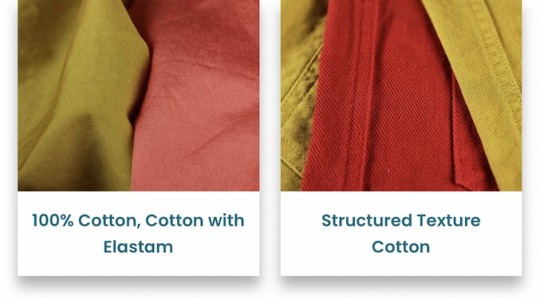

Get ready to indulge in the luxurious world of fabrics.We'll explore the latest trends in textiles and materials that are set to make a statement in the upcoming seasons. From soft and sustainable fabrics to bold and innovative textures, we'll uncover the materials that will define fashion, interior design, and beyond. Join us as we dive into the fascinating realm of fabrics and discover the perfect blend of style and comfort. Let's embrace the tactile wonders of fashion and design together.

The fabrics that we would see everywhere around would be :

Hemp

Chitin fibre - Chitin is a natural compound found in the shells of crabs and shellfish that protect them from their environment. Like cellulose from plant fibres, chitin is easy to process into textiles, because it has a soft texture and dyes easily.

Seaweed - made by using algae from the sea, absorb sweat faster than cotton

Banana fibre - fabric made from bananas

Pineapple leather + silk - Pineapple leather is an imitation leather called Pinatex. It is made from a blend of natural pineapple leaf fibres, thermoplastic polyester, and petroleum-based resin.

Coconut fibre

Corn fibre

Recycled polyester

Lab grown cotton

Tencel

Organic linen

100% biodegradable fabric

Hemp

Recycled denims

Polyester blend

Thin cardigans

Delve into the fascinating world of design details and uncover the trends that will elevate your style game. From intricate embroidery to eye-catching embellishments, we'll explore the small yet impactful elements that will make a big statement in the upcoming seasons. Get ready to embrace the artistry and attention to detail as we discover the hottest design details that will set your fashion choices apart. Let's embark on this stylish journey together.

Sweet necklines

Puff sleeves

Ruffles

3D design

Patch pocket

colour blocking and mock layers develop more vibrant items.

The use of Butterfly in patterns is mostly focused on floral and striped designs, which feature repetitive and regular shapes. Knit fabrics with heart-shaped cut-outs and hand-crocheted textures effectively display the sweet visual effect.

Wrap Waist X-line

Ruched Waist A-line

Slim-fit High Neck

Cuffed ankles of tapered pants

Twisted knots

Exposed stitches

Smocking and flared sleeves

Flared pants with slit

Let's explore the captivating world of trend forecast themes. From futuristic minimalism to nostalgic retro vibes, we'll dive into the overarching concepts and inspirations that will shape the upcoming seasons. Get ready to immerse yourself in a world of creativity and imagination as we uncover the themes that will influence fashion, design, and beyond. Let's embark on this trendsetting journey together and discover the themes that resonate with your personal style.

It's been a thrilling journey exploring the trend forecast for 2024-2025. From vibrant colours and luxurious fabrics to captivating design details and inspiring themes, we've uncovered the key elements that will shape the fashion and design landscape. Now, armed with this knowledge, you're ready to embrace the upcoming seasons with confidence and style. So go ahead, express yourself, and let your fashion choices reflect the trends that resonate with you. Remember, fashion is all about self-expression and embracing your unique sense of style. Stay trendy and keep rocking those fabulous looks.

0 notes

Text

From 10,000 litres of water to zero: the denim industry is transforming

Nanobubbles, ozone or laser. The future of denim fashion is already present thanks to disruptive technologies and more efficient production models aimed at making its manufacturing a more environmentally friendly process.

Jeans are the most democratic and iconic garment in our wardrobe: each year, according to the UN, around 5 billion jeans are made. A fad that needs no explanation: they are comfortable, resistant and so agile that they have managed to evade all borders, slipping into the strict codes of the office or, judging by the latest catwalks, also of Haute Couture. But is sustainability among its benefits? The industry has spent years focused on its transformation, developing more efficient technologies and processes to take advantage of the properties of denim fabric and minimise the use of water and chemicals in its manufacture and finishing. Its big challenges.

«Among the main actions of the industry to avoid these impacts is the use of organic cotton. Many brands are even joining the wave of regenerative cotton and, of course, one type of material”, says Gema Gómez, director and founder of the Slow Fashion Next[1], a fashion and sustainability training platform, highlighting the weight that fabric has in its environmental footprint. Studies, such as the one prepared by the French Agency for the Environment and Energy Control (Ademe)[2], calculate that around 10,000 litres of water are used to obtain 1 jeans, of which close to 60% comes from the high water footprint of conventional cotton crops. «Here it is important to make a distinction: when we talk about sustainability it is not only about what we do, but how we do it. It is true that cotton is a thirsty fibre, but it is not the same if it is grown with irrigation, as it happens with other crops, if it is grown with rainwater, if it is mixed with other types of food crops, or if it is sold It is destined to financially support the farming communities” [3], points out the expert.

Recycled fibres are also beginning to be the norm in its composition. As the environmentalist Núria Nubiola, founder of Infinit Denim[4], points out: "The good thing about denim is that it is a strong and durable material that works very well for recycling." This small Barcelona firm reinvents garments through upcycling and, with the remains of the redesign process, they create a new biodegradable thread. Committing to use this, they have managed to reduce carbon emissions by 70% and amortize the water footprint of the fabric. " We take advantage of the remains of that cut to make the shredded, but the resulting thread is not 100% denim," warns the expert who, through innovation projects, has studied its benefits together with cellulosic fibres such as kapok (from a tree whose large fruits contain soft, light and silky fibres that look like cotton), EcoVero[5] (a type of viscose made with sustainable wood from controlled sources) or hemp. The result is a resistant and versatile yarn that allows you to make both denim and knitted or knitted garments.

From water consumption to the age of air

Although much of the environmental impact of a garment depends on the choice of fabric, the industry has been working for some time to completely change the way jeans are manufactured with disruptive technologies and more efficient models, focused on reducing the consumption of water and chemical substances. Since its founding in 1994, the Valencian software company Jeanologia[6] has focused on inefficient finishing processes, developing a laser marking system that removes the indigo dye from jeans through evaporation. "It replaces the sandblasting technique, potassium permanganate spraying and other manual applications that are harmful to health and the environment," says its marketing director, Carmen Silla, such as pumice-stone washing, which jeopardises the durability of the tissue. She assures that with this technology they have managed to considerably reduce both their water footprint and operating costs. Designers can create a digital file with the desired styles, enter it into the system, and within seconds, the laser transfers it onto the garment. "We make sustainable production scalable, without losing the quality and appearance of the product, obtaining an authentic replica of vintage looks." In fact, they have more than 3,000 lasers installed around the world, 30% of the world's denim production.

From the Valencian company they usually joke that they inaugurated the era of air in the finishing of garments. The explanation can be found inside their famous washing machines, which use ozone instead of water. "Our G2 ozone technology, instead of carrying out a traditional wash with water, washes into the atmosphere. In other words, this technology takes the air from the atmosphere, extracts the oxygen and transforms it into ozone gas, which acts as an oxidant to age the garments naturally”. Silla assures that this method, together with E-Flow technology, has managed to reduce water by 80% and chemicals by 70%. "Until then, the traditional method of transporting chemicals to the garment was through water. However, E-Flow creates nano-air bubbles, a cloud of moisture that transports the chemicals into the textile material without any waste and with a minimal amount of water." Yet another example of how technological innovation can become a great ally of sustainability.

More sustainable dyes

In this search to eradicate the most polluting processes in the manufacture of our clothes, the other aspect in which great advances have been realised, has been in the garment dyeing process. As Gema Gómez explains, in the 70s the composition of denim underwent several changes. On the one hand, natural fibres were mixed with synthetic fibres such as elastane, which, although they improve their elasticity, also put the recycling of the garment to the test. On the other, "they went from natural indigo dye to synthetic, whose ingredients come from petroleum," says the expert, who is committed to the recovery of dyes of vegetable origin. This is the case of the American company Stony Greek Colours,[7] which works with local farms in the production of regenerative rotating crops of indigo, the plant from which the iconic blue of jeans is obtained; or the company Colorifix[8], which manufactures dyes from molasses, a by-product of sugar, with which they make the most of the exploitation of this crop.

Also the image of those blue water tanks is beginning to be a thing of the past. Contrary to the conventional method, which consists of immersing the threads in a series of chemical dyes that give it colour while preventing oxidation, the Valencian company Tejidos Royo[9] presented Dry Indigo dyeing technology in 2018. It is a foam formula, with a nitrogen cover that protects the colour, dyeing the yarn without using a drop of water in the process, reducing the amount of chemicals by 89%, energy consumption by 65% and, consequently, reducing wastewater to zero. Every year the company donates one million litres of drinking water to an NGO, the amount that it has managed to save with this innovative tool.

Counted washes

At this point, we only have to answer what we can do for our jeans. The firms appeal to take advantage of the properties of denim – it is an antibacterial fabric, quite resistant to stains and odours – and limit its washing to only when strictly necessary. "Not only does it help to preserve them, since each wash wears out the fabrics and dyes," says Núria Nubiola, from Infinit denim. «Studies have been carried out on the environmental footprint of jeans and, based on their useful life, which was around eight years, if you washed them every time you put them on, there was more impact on that consumption than on the production". We can reduce visits to the washing machine, airing them after use or cleaning only the stains with a brush and soap. Because sustainability is a shared duty and time is the most sustainable way to give our jeans a personal and unique finish.

Choosing more sustainable jeans

Focus on its composition. Choose jeans with natural fibres from certified organic crops or from recycling, in this way you will ensure that the fabrics have been developed in a more respectful way with the environment. Bet on circular designs. It is increasingly easy to find mono-material jeans on the market – the closer it is to 100%, the greater its recyclability – and circular designs, with minimal trimmings and fibre-friendly finishes, which make it easier to make the most of the fabric. Yes to timeless jeans. The chosen colour and the right fit are two important elements to take into account when looking for a piece that ends up being a good basic that will mock the passage of time in our wardrobe. Also allow time to give it that vintage and worn finish. Fix and reinvent. Thanks to its resistance, denim is upcycling's best friend: a way of turning old jeans into the most groundbreaking item in the wardrobe.

Source

S-Moda, De 10.000 litros de agua a cero: la industria del denim se transforma (como la Rosalía), in: El País,21-7-2023, -

https://smoda.elpais.com/moda/de-10-000-litros-de-agua-a-cero-la-industria-del-denim-se-transforma-como-la-rosalia/

[1] Since 2011 we have been helping Fashion professionals and companies to become the solution that the sector needs as a strategic challenge through training and consulting. https://slowfashionnext.com/

[2] The Agence de la transition écologique. (ADEME, Agency for ecological transition) is a public agency under the joint authority of the Ministry for an Ecological Transition and the Ministry for Higher Education, Research and Innovation. At ADEME - The French Agency for Ecological Transition’s role is to mobilise citizens, economic actors and territories towards a fairer, more harmonious, low carbon and resource-efficient society. At every level, their expertise and forecasting capacities serve to guide and inform public policies. https://www.ademe.fr/en/about-ademe

[3] Read also : https://www.tumblr.com/earaercircular/715379082096951296/the-type-of-cotton-matters-betting-on-more?source=share

[4] Infinit Denim was born out of a need. An internal call to transform the fashion industry and to do it from its origin: the material. A team of women united to do what appears to be the most reasonable thing: to take advantage of the fibers and fabrics contained in the garments we have already worn to create them an ew. It is as simple as imitating what nature has been doing since its beginnings: introducing "dead" materials into a new cycle, transforming them into "nutrients". https://infinitdenim.com/en/sobre-nosotras/

[5] EcoVero is the sustainable version of viscose. Conventional viscose is very harmful to the environment: the wood for the fibers is often planted as a monoculture (e.g. eucalyptus), which requires a lot of water. Many toxic chemicals are used in the processing. EcoVero is the most environmentally friendly viscose available. EcoVero is certified with the EU Ecolabel because it meets high environmental standards throughout its life cycle: from raw material extraction to production, distribution and waste disposal.

[6] https://www.jeanologia.com/about-us/

[7] Natural indigo has an established history in textiles and its traditional production methods went largely unchallenged until roughly 100 years ago with the introduction of unsafe synthetic dyes. Synthetic indigo, derived from harmful chemicals (like Benzene, Formaldehyde, and Cyanide), began replacing the natural dyes that had been in use for centuries. Until now, plant-based alternatives could not provide consistent performance to remain the primary market color solution. Today, customers can use Stony Creek Colors' completely plant-based solutions to harness the restorative beauty of nature and combat persistent industry challenges. https://www.stonycreekcolors.com/pages/who-we-are

[8] Colorifix minimises the environmental impact of industrial dyeing by replacing chemistry with biology at every step in the process, from the creation of the dyes to their fixation into fabrics. https://colorifix.com/colorifix-solutions/

[9] Tejidos Royo is a Spanish company founded in 1903 and leader in the textile industry in Europe. Our international calling and vast marketing network allows us to export fabrics to clients in over 30 countries. Vertical business model: Spinning, Indigo dyeing, Weaving, Piece dyeing, Special finishes. https://www.tejidosroyo.com/en/aboutus

0 notes

Text

Unleash Your Comfort: Embrace the Freedom of Men's Stretchable Jeans

n the fast-paced world of men's fashion, staying comfortable without compromising on style has become a top priority. Stretchable jeans by us have emerged as a game-changer, providing men with the perfect blend of comfort and fashion-forward design. Among the diverse array of brands offering stretchable jeans, our brand stands out as a true innovator. With its commitment to exceptional quality, cutting-edge technology, and trend-setting styles, this brand has redefined the concept of men's stretchable jeans. In this article, we explore the features, benefits, and unique elements that make these jeans a must-have for the modern man.

Revolutionary Comfort:

The hallmark of our stretchable jeans lies in their revolutionary comfort. Our brand has harnessed the power of advanced fabric technology to create jeans that offer exceptional stretch and flexibility. The incorporation of elastane fibres into the denim fabric allows for maximum freedom of movement without compromising the jeans' structure or durability. Whether you're running errands, going for a bike ride, or simply relaxing with friends, these jeans provide unparalleled comfort that adapts to your every move.

Superior Fit and Silhouette:

Alongside remarkable comfort, these stretchable jeans offer a superior fit and silhouette. The fabric's stretch properties ensure a sleek and tailored appearance, contouring to your body shape without feeling restrictive. With a range of styles and cuts available, from slim and tapered to relaxed and straight, you can find the perfect fit that flatters your physique. These jeans accentuate your best features while maintaining a modern and stylish aesthetic.

Unmatched Versatility:

One of the key advantages of our men's stretchable jeans is their versatility. Whether you're aiming for a casual or semi-formal look, these jeans seamlessly adapt to any occasion. We offers a diverse range of washes, finishes, and colours, allowing you to effortlessly match your jeans with different outfits and styles. From classic indigo to contemporary black or even unique distressed patterns, there is a pair of stretchable jeans to suit every taste and preference.

Durability and Resilience:

Despite their incredible stretch properties, these jeans do not compromise on durability. Our brand's commitment to exceptional quality ensures that each pair of stretchable jeans is built to last. The fabric is carefully selected to withstand the rigours of everyday wear, maintaining its shape, colour, and elasticity over time. Whether you're constantly on the move or simply looking for jeans that will endure years of use, these stretchable jeans provide the perfect combination of comfort and longevity.

Fashion-Forward Designs:

These stretchable jeans are not only comfortable and durable but also fashion-forward. We keeps a finger on the pulse of the latest trends, offering innovative designs that keep you ahead of the curve. From subtle detailing and unique washes to contemporary cuts and finishes, these jeans allow you to express your personal style with confidence. Whether you prefer a minimalist look or bold statement pieces, the brand's collection of stretchable jeans caters to a wide range of fashion preferences.

Conclusion:

Therefore whether it is Men's stretchable jeans,Mens Jeans, MensDenims Jeans and Mens Fancy Jeans have revolutionised the fashion landscape by combining comfort and style in an unprecedented way. With their revolutionary comfort, superior fit, unmatched versatility, durability, and fashion-forward designs, they have become an essential wardrobe staple for the modern man. By choosing us. We excels in the art of stretchable jeans, you can embrace the freedom of movement without compromising on your personal style. Experience a new level of comfort and style with these extraordinary jeans that embody the perfect fusion of innovation and fashion.

0 notes

Text

Unleashing Versatility: Coats Epic Thread - The Go-To Choice for Leading Brands and Manufacturers Worldwide

India, 9th May ’23: Epic thread, a unique blend of polyester and cotton fibres for exceptional strength and softness. Coats, the manufacturer of Epic Thread, lists its features and why it is the best choice for world manufacturers.

In the fast-paced and demanding world of garment manufacturing, choosing the right sewing thread is crucial. It needs to be strong, durable, and versatile enough to meet the demands of different fabrics and designs. That's why leading brands and manufacturers worldwide rely on Coats Epic Thread, the high-quality polyester corespun sewing thread that has earned a reputation for its versatility and exceptional performance.

" Coats Epic Thread is made from a blend of polyester and cotton fibres, which gives it a unique combination of strength and softness. This blend allows the thread to withstand high levels of abrasion and tension while maintaining its shape and integrity. The thread is available in a range of colours, sizes, and finishes, making it suitable for a variety of sewing applications, from denim and workwear to activewear and intimate apparel.

One of the key advantages of Coats Epic Thread is its exceptional colour fastness. The thread is resistant to fading and discolouration, even when exposed to harsh environmental conditions and repeated washing. This feature ensures that the garment's seams remain vibrant and consistent, enhancing its overall appearance and longevity.

Another benefit of Coats Epic Thread is its sustainability credentials. The thread is Oeko-Tex® certified, meaning it is free from harmful substances and safe for human use. Additionally, Coats is committed to reducing its environmental impact and has set ambitious targets to achieve zero waste and reduce greenhouse gas emissions.

If you're looking for a high-quality and versatile sewing thread, look no further than Coats Epic Thread. Its exceptional performance, sustainability credentials, and worldwide reputation make it the go-to choice for leading brands and manufacturers. Check out this awesome thread from here - https://www.coats.com/en/products/threads/epic/epic

About the Author:

Coats is the world’s leading industrial thread company. They are headquartered in the UK, with a workforce of 17,000 in 50 countries across six continents around the world. Coats provide complementary and value-adding products, services and software solutions to the Apparel & Footwear industries. Coats apply innovative techniques to develop high technology Performance Materials threads, yarns and fabrics in areas such as Transportation, Telecoms and Energy, and Personal Protection.

0 notes

Text

Global Apparel Product Development and Innovations Report 2022: Chemical Recycling, Denim, Dyes, Fibres, Leisure Wear, Materials for Footwear, Traceability, Treatments, and Yarns - ResearchAndMarkets.com

New Post has been published on https://petn.ws/QdAT

Global Apparel Product Development and Innovations Report 2022: Chemical Recycling, Denim, Dyes, Fibres, Leisure Wear, Materials for Footwear, Traceability, Treatments, and Yarns - ResearchAndMarkets.com

DUBLIN–(BUSINESS WIRE)–The “Global Apparel Markets: Product Development and Innovations, 2022” report from Textiles Intelligence Ltd. has been added to ResearchAndMarkets.com’s offering. This report analyses some of the latest developments, innovations and new products in the global apparel industry, including: chemical recycling; denim; dyes; fibres; leisure wear; materials for footwear; traceability; treatments; and yarns. The report […]

See full article at https://petn.ws/QdAT

#PetTravelNews

0 notes

Text

Consumer and Fabric Innovation Trends Impacting The Fashion Industry In 2022

Gone are the days when companies and businesses had the power to steer people’s choices with what they communicated and sold – today’s consumer is taking the onus back as they become increasingly aware of the power they have to drive change when it comes to brand philosophies and what they offer, supported by a wave of radical activism.

Consumers are setting this in motion by consciously going for the products they choose to support, to which brands are responding by building customer feedback loops.

In terms of digitization – which is the current buzzword across industries and around the world – younger generations, especially Gen Z, have already started giving shape to the new digital dialogue of the future. Now more than ever before, it is important for fashion and beauty businesses to keep up with the times and place their products where the buck is – i.e. in the metaverse.

Furthermore, the demand for authenticity and transparency is at an all-time high, which will allow consumers to embrace ‘rawness’ and ‘clean’ products following the fashion trend.

Let’s take a closer look at the trends shaping the future –

The Rise of Bast Fibres

Bast fibres, which essentially include flax (linen), hemp, ramie and jute, are essentially fibres that support regenerative agricultural practices that can help the soil sequester carbon. Farmed regeneratively, we will be seeing bast fibres rise in importance as the fashion industry looks to diversify away from cotton to embrace alternative materials that don’t require as much dependence on natural resources (which in the case of cotton, is major water).

Being a biodegradable natural fibre, pure linen requires a fifth of the fertiliser required for cotton, less water to grow and draws carbon into the soil, making it a much-lower-impact crop.

Linen, on the other hand, is already growing in popularity in the fashion industry due to its natural performance and eco-friendly associations. It is also cooling, moisture-wicking, absorbent, breathable and durable, with inherent antibacterial, moth and stain-resistant properties.

Bast Fibres are the future of fashion, and very soon we will see every single brand and designer moving towards more conscious consumption and changing their business internally to do whatever is in their power to help make their businesses more environmentally friendly. Right from brands incorporating certain fabrics that are made from recycled pet bottles, to using innovative fabric alternatives… There is so much scope to look forward to.

The denim industry is also undertaking many explorations with hemp, while jute is also expected to make an impact in the footwear and accessories market – a trend we have already seen booming in the vacation-led resort wear and cruise segments.

This article is Authored by Mr. Samarth Bajaj, Co-Founder & CEO, The Designer’s Class

https://ift.tt/dI4Egak

https://ift.tt/qR4xEzS

#Saas#softwaresystems#productdevelopment#software#practice#optimization#accuracy#efficiency#productivity#softwareprojects#cracksthecode

0 notes

Text

Best China Fabric supplier of BD

CT Impex International, proud to offer artistic and novel contribution to the lifestyle with quality fabrics for the home and living which make one claim pride as an asset worth living for.

As a fabrics supplier CT Impex International Started its January on 2002 craftmanship with innovation and experience and adds extra value to satisfy the everyday user.

Our aim is to build long lasting relationships with our customers by providing high quality and best services at a reasonable price. We are also searching emerging markets and developing business scopes. Our intention is to give you the best value for your hand earned money; therefore, we offer imported Fabrics as your needs and budgets, innovative marketing concepts, quality products and state-of-the-art manufacturing methods have always been driven by the demands for customer satisfaction.

Our product line includes:

Nylon & polyester, Cotton Woven & Knitted Fabrics Taffeta, Taslon Tussor, Oxford, Satin, Ribstop, Twill, Canvas, Doddy, Micro fibre, Moss-skin, Suede, Denim, corduroy, popline, Bonding/ Lamination, Polar Fleece, Mesh & Tricot, Pique, PU/PVC Leather, Sherpa, Fur, on 100% cotton, 100% Polyester, 100% Nylon, 100% Rayon, T/R, CVC, T/C, N/C C/N Remie, Linen, Linen/Cotton, Remie/Cotton, Acrylic and so no

Special finish Fabrics

Breathable, Waterproof, Anti- weathering, Downproof, Anti-bacteria, Wrinkle Free, Wicking, (Quick Dry), High Visibility (passed EN471), Anti flammability, Crinkle, Teflon, Supplex, UV,

1 note

·

View note

Text

DENIM FIBER SUSTAINABILITY & INNOVATION

If you’re a denim aficionado who cares about the environment, you’ve always wondered about the sustainability of denim fibre.

Read More:- https://jdinstitute.co/denim-fiber-sustainability-innovation/

0 notes

Photo

WHAT DO YOU THINK THIS DENIM IS MADE FROM? IT’S LYOCELL HEMP! AND WHAT IS LYOCELL HEMP YOU ASK? WELL, SIMPLY PUT IT’S A BLEND OF HEMP, TENCEL AND COTTON. THIS IS PART OF A SUSTAINABLE DENIM CAPSULE COLLECTION LED BY LENZING, CREATED IN COLLABORATION WITH SOME OF THE MOST INNOVATIVE MINDS IN THE DENIM INDUSTRY. THE PROJECT EXPLORES HEMP, TENCEL AND COTTON AS BLENDING PARTNERS TO SHOWCASE AND INSPIRE ITS COMPATIBILITY FOR THE DENIM INDUSTRY. PROJECTS LIKE THIS ENABLE CONSUMERS LIKE ME AND YOU TO LEARN ABOUT DEVELOPMENTS IN THE INDUSTRY THAT COULD MAKE POSITIVE CHANGES FOR OUR PLANET. CONSUMER DEMAND AND AWARENESS IS KEY TO BEING ABLE TO MAKE THESE NEW INNOVATIONS PART OF OUR EVERYDAY LIVES. WHAT’S SO GOOD ABOUT HEMP? WELL HEMP IS A PLANET FRIENDLY FIBRE WHICH IS WHY WE ARE SEEING SO MUCH DISCUSSION AROUND THE USE OF HEMP WITHIN FASHION RIGHT NOW, PARTICULARLY HOW IT HAS MANY BENEFITS OVER COTTON. HEMP NEEDS VERY LITTLE WATER TO GROW AND HAS AN EXTREMELY FAST GROWTH RATE FROM SEED TO HARVEST (AROUND 90 DAYS). HEMP ALSO REQUIRES NO PESTICIDES AND HAS EXTREMELY STRONG PROPERTIES. PROJECT COLLABORATORS : PROJECT @tencel_usa HEMP FIBERS AND YARNS @kingdom DENIM CREATION @ndl.naveenadenim.ltd DESIGN, PATTERN CUTTING, SEWING & CREATIVE DIRECTION @endrime LAUNDRY & WASHING @jeanologia DYESTUFF @officina39 HANGTAGS & LABELS @warp_face THREADS CRAFIL SEWING THREADS THE PROJECT WAS SHOT BY @nick.clements (PHOTOGRAPHY) AND @oscaroldershaw (VIDEOGRAPHY) TALENT : KELLY HARRINGTON @kellouhar , SASKIA AT @presentmodelmanagement AND ALEX @d1models SHOES : @grensonshoes @grensongirlsofficial (at Brighton and Hove) https://www.instagram.com/p/CObLmd0jP68/?igshid=1qey1lusslu29

1 note

·

View note

Text

Saree Innovations in To the south India

silk saree

Think of Southern India and man made fiber sarees invariably one thinks of. The South Native american bride still likes to wear the original silk saree to the occasion of the girl wedding. With switching times, trends within sarees are also altering. Retailers in Southern area India are popular for their innovations around sarees. This article endeavours to throw brightness on the latest inventions in the silk in addition to temple area of Towards the south India.

Some of the critical innovations in a silk filled duvet sarees by To the south Indian retailers had been described below. A lot of the saree innovations tend to be by Sri Kumaran Silks in Chennai.

The saree-shirt appliance

Sri Kumaran Silks has launched the very idea of a saree-shirt mix, which is known as 'Jodi Pattu'. They have specially designed sarees with a corresponding shirt piece, which happens to be meant for the female's husband. Both the saree and the shirt are constructed with pure handloom egypt. The saree incorporates a beautiful embroidered pallu and matching embelleshment is done on the t shirt piece too.

This color-changing saree

Sri Kumaran Silks in addition has come up with the concept of some silk saree of which changes color. Should the wearer of the saree moves out of your girlfriend home, the color for the saree changes. Your retailer claims this is the first possibly color-changing saree to get developed in the world.

A Durbar Krishna Saree

The Durbar Krishna saree has been produced by RMKV. This saree depicts a prominent picture of Jesus Krishna in the pallu, in which Swarowski uric acid have also been used. That image is shown to bring good luck for the owner.

The zip-n-wear saree

This is one other innovative concept inside silk sarees by way of Sri Kumaran Silks. They have designed your saree with 3 different but complementing pallus. Each of these pallus have an attached scoot. The wearer within the saree can easily detachment one pallu along with attach another. This approach saree is popularly known as Zip-n-wear saree.

The pocket saree

This is yet another ground breaking concept by Sri Kumaran Silks. This particular saree has a bank account, which can hold a good cell phone and other modest items.

The landscaping saree

Sri Kumaran Silks has also formulated a new type of saree called the Landscaping Saree. This saree is made of pure man made fibre and the design to a rural landscape can be woven into the pallu.

The denim saree

The denim saree has been designed by Sri Kumaran Silks. It's actually a pure silk saree that gives the look from denim, at the same time holding onto the soft look of silk.

References

Kanchipuram silk sari

https://en.wikipedia.org/wiki/Kanchipuram_silk_sari

1 note

·

View note

Text

Nine change makers in the Netherlands making fashion more sustainable

The fashion industry is the second biggest polluter on the planet, responsible for around 10% of all global carbon emissions and tarnished by a reputation for sweatshops – but it doesn’t have to be this way. DutchNews.nl shines a light on nine innovators in the Netherlands helping to make the sector more sustainable.

Consumers in the Netherlands discard about 210 tons of unwanted clothing and textiles each year, two-thirds of which is incinerated; while the Dutch fashion industry has an annual surplus of around 21.5 million items of unsold clothing, often produced by poorly treated workers and not built to last. Each garment produced has an average carbon footprint of 20kg. Changing practices in the clothing industry is crucial to meeting the country’s emission targets and improving the industry’s human rights record. Here are nine change makers in the Netherlands leading the way.

Loop.a life

Knitwear brand Loop.a life has abandoned the wasteful model of regularly changing, seasonal collections and focuses instead on creating long-lasting essentials for men and women. The cotton and wool garments are created from recycled knitwear and denim using an entirely circular, closed-loop process. Removing the need to cultivate the raw materials saves around 500 litres of water per sweater for wool and between 5000 and 15,000 litres for cotton. Founded in 2016 by Ellen Mensink, Loop.a life were the first Dutch company to use 100% recycled yarn, most of it sourced in the Netherlands. Similar colours are carefully selected and combined with industrial waste and Eucalyptus wood fibres, which means no dye is needed.

Arch & Hook

It’s not just textiles that the fashion industry wastes. When garments are transported from factories to stores and hung on branded hangers, the plastic placeholders are discarded, condemning an estimated 85 billion single-use hangers to landfill each year. Since 2015, Amsterdam-based Arch & Hook has sought to change this by producing high-quality hangers made from sustainable materials. Previous collections have included bespoke hangers for clients such as Karen Millen and Harrods made out of FSC® certified wood, and last year, supported by Roland Mouret and the British Fashion Council, the company launched BLUE®, the first ever hanger made of upcycled ocean bound thermoplastic. ‘At Arch & Hook, we strongly believe that we are in the early stages of a new industrial revolution,’ says CEO and founder Sjoerd Fauser. ‘Cleaning up what humanity has caused is crucial before eliminating plastics entirely.’

Amsterdam-based &Wider

Examining the whole chain of production is crucial to making fashion more ethical. Amsterdam-based &Wider has been helping businesses bridge the data gap on working conditions in the clothing industry since 2014 by providing actionable results to drive material improvements in workers’ lives and in the businesses that employ them. Through their online platform, buyers and employers can gather anonymous data direct from workers, and use this information to implement changes in labour practices along the supply chain. ‘The fashion industry cannot work ethically without hearing from workers themselves,’ spokesperson Sesihle Manzini told DutchNews.nl. ‘The design of our system allows us to hear from vulnerable workers: those who we often hear about, but rarely hear from.’

MUD jeans

Mud, a natural, endlessly recycled material, inspired the name behind this sustainable jeans company headquartered in Laren. Founded in 2013 by industry-insider Bert van Son, who had seen first-hand the unethical practices in the sector, MUD has taken a different tack by producing garments made from up to 40% recycled materials and coloured with Cradle2Cradle dyes. 95% of the water used is recycled through reverse osmosis, reducing water use to about one third of the industry standard. Clients can rent or buy jeans, repairs are free, and they can get reductions on loans or purchases by cashing in any brand of old jeans with at least 96% cotton content.

The Fabricant

Thanks to Amsterdam-based digital fashion house The Fabricant, the digital dress is now a fact – and sold last year for $9500. The assertion that the clothes with the least environmental impact are those which do not exist is hard to argue with – even if it requires a total rethinking of how we promote fashion. The Fabricant specialises in 3D fashion design and animation, offering an alternative to physical concepts such as runway shows, sample sizes and photo shoots. The potential to try clothes on our digital selves, or create a digital advertising campaign can only cut carbon costs.

United Wardrobe

Founded in 2014 by three students from Wageningen with a mission to make second-hand clothing the buyer’s default, this online marketplace has over 4 million subscribers. From its headquarters in Utrecht, United Wardrobe has now opened its doors to France, Germany and Belgium, allowing users to buy and sell everything from designer shoes to onesies for newborns. ‘People are way more conscious than six years ago,’ co-founder Thijs Verheul told DutchNews.nl. ‘We have already people of age 12 selling and buying secondhand clothes, not because it is cheap for them, but really because they love the sustainable factor.’

Renoon

‘I was so fed up with opening dozens of windows in my browser to find sustainable alternatives that matched my style,’ says Iris Skrami, who co-founded Renoon to fill a gap in the market for a curated one-stop online shop for eco-minded style seekers. The app and website, which launched in 2019, feature new and pre-owned items with emerging brands such as Fisch and PANGAIA listed alongside established designers such as Stella McCartney and Filippa K. ‘There are so many brands and products already in the market that we should have easier access to,’ says Skrami.

Fast Feet Grinded

Fast Feet Grinded are urban miners, seeking out wasted resources that gain new value when repurposed. In this case it’s our discarded trainers. Globally, an estimated 12 billion pairs of trainers are produced each year, of which at least 90% will end up in landfill. The Limburg-based company employs workers with a distance from the labour market to upcycle rubber, foam and fibre from unwanted trainers to make spongy surfaces for playgrounds, athletics tracks and sports fields – or materials for new trainers. This contribution to a more circular economy in sportswear has attracted partnerships with brands such as Decathlon, ASICS and Intersport.

RE LOVE FASHION by RE LOVE Foundation

Three-year-old creative agency RE LOVE FASHION is an anomaly in the sector: its mission is to reduce consumption. Fronted by the striking blue-haired Antoinette van den Berg, a trend-forecaster and stylist known in fashion circles as the Lady in Blu, the Amsterdam agency is forging a new path in a polluting industry by promoting what she describes as ‘joyful alternatives to enjoy fashion: reuse, retouch, restyle, repair and repeat’. ‘If we really want to reduce the pollution of the fashion industry, the most effective solution is to consume fewer new clothes,’ she told DutchNews.nl. ‘How nice is it to wear something that you know didn’t pollute?’

Source

Read the full article

2 notes

·

View notes

Text

I broke my word.

♡┊ It’s one of those rare instances when Blondie’s hands busy themselves with something other than anarchy and stitching materials together via needle. Today his weapon of choice is of the inky kind– a felt tip pen that’s petite in the hand and pigmented at the tip when he etches his deepest thoughts. Orange masking tape straps stationary to a book, he doesn’t want to deal with paper that shifts to one side as he writes. It could smudge, his ink could make an unsightly spray across the page, what good would that do?

Dearest halmoni!

I’m a wicked, disobedient grandson. Please find it in your heart to forgive me. I’ve read every text, no letters because I have a new address. If they bounced please send them back to me. My life has been changing rapidly.

I am now a regular attendee of fashion week. Do they talk about me at home? I hope not. I’m building my brand overtime. It’s called BLONDTIQUE. I’m making everything by hand like a real tailor! People seem to like my stuff... and, well, Blondenim will be turning two years old in April! I’ve met lots of new, nice friends. Wish you could meet them all. I’m not alone I’m Seoul.

The dogs are okay, I haven’t been in Seoul for so long. They’re behind on their courses. Once I’m back they’ll be consistent again. Truthfully I don’t always know what they want. Really difficult to care for animals. Andy’s helping me with them, he loves tteobo the most. Last summer bad things happened but they’re all good now.

♡┊ Which was clearly a sign that things would go very wrong, very fast. How? Blondie hasn’t decided, but he knows with every fibre of his being that it’s meant to be. Nothing in his life is ‘good’ for longer than a week. That’s when the poison works its black magic, making mountains out of molehills, marching ants up his spine, biting and biting and biting...

I don’t have a girlfriend, haven’t had one since I’ve been here. I do have many beautiful girl friends though. Not just pretty but smart too. Modern. Many of them remind me of you. The world is changing a lot halmoni, your ideas that were innovative are now the norm. It’s incredible how you saw the future and now we’re living it.

I want to ask about appa and umma, do they know anything about me now? I think I’m disciplined.

♡┊He draws their titles so hard they indent the paper. He’s still angry. And the proof is in unsightly script reading ‘appa’ and ‘umma’. None of his voice notes about the pair held any implications he understood why what was happening to him happened.

Please visit me in Seoul. I miss and love you very much. Please don’t send me anymore money, I want to take care of you instead.

♡ [Blondie]

♡┊The letter is shipped on February 3 with tokens from his travels: an Eiffel tower keychain from Paris, photos of his bowl cut from paris last July; a patch of denim from the first batch of BLONDENIM, a bottle cap from London’s alcoholic binge, stolen shoestrings from his skates courtesy of December’s bout of iceskating with Andy. He wraps the box on his own and tops it with a bow.

7 notes

·

View notes

Photo

“Towards a New Matter,”

Towards a New Matter is a material-based research project, in which denim fibers have been transformed through a recycling technique into a lightweight and sound absorbing panel material.

The textile industry’s production chains have been evolving into key waste and pollution generators over the last forty years. By 2018, from the 80 billion garments produced globally every year, 75% are discarded after being worn for a short time. The current gab between textile waste and design innovation poses an interesting challenge:

Could it be possible to turn textile waste into a new and sustainable material that can be integrated into our daily life? Through rudimentary material manipulation techniques and the development of manufacturing processes, the textile fibre could be transformed into a new panel material.

This biodegradable mono-material has been created without the need of adding a binding chemical, as it is entirely composed of natural resources and locally generated waste and scraps.

This manufacturing process has allowed recycled textile fibers to be converted into modular expandable elements that can be arranged within architectural spaces, into space-separating structures, thus generating spatial subdivisions or rooms within rooms, according to the user’s need.

The resulted elements have a high strengths and a stone-like aesthetics without loosing the warm and soft tactility of textiles. What began as a research of discarded textiles, became a production technique that can be contribute to apply the principles of reduction, reusing and recycling of textile.

Material-based Research Project from Milan Friedrich

#art#design#sustainable#sustainability#ecology#materials#biodegradable#denim#blue#milan friedrich#Architecture#walls#textile#recylcing#fibre#panel#acoustic#absorbing#minimal#minimalism#geometric#screen

41 notes

·

View notes