#dairy butterfly valves

Text

0 notes

Text

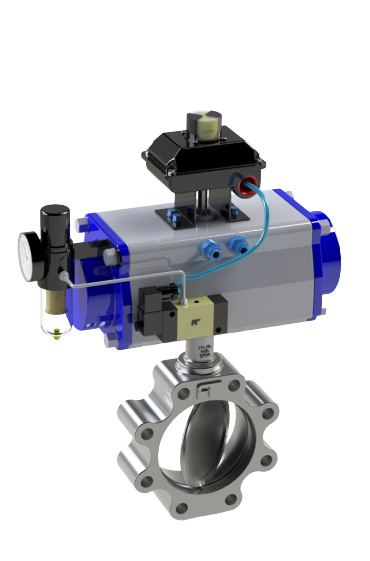

High-Quality Pumps and Valves by Aleader Company

In both industrial and civil engineering, pumps and valves play a critical role. As a leading company in this field, Aleader Company has earned widespread recognition and trust for its superior product quality and innovative technology. This article will provide an in-depth look at Aleader Company's pump and valve products and their applications across various industries.

Why Choose Aleader Company's Pump and Valve Products?

Durability Made from premium materials with excellent corrosion resistance, high-temperature resistance, and wear resistance.

High Efficiency Optimized internal structure design enhances fluid flow efficiency and reduces energy loss.

Intelligent Control Some pump and valve products are equipped with intelligent control systems for remote monitoring and automation, enhancing operational convenience and safety.

Diverse Range Comprehensive product range, including centrifugal pumps, gear pumps, diaphragm pumps, ball valves, butterfly valves, globe valves, and more, meeting various application scenarios.

Typical Application Cases

Petrochemical Industry In the petrochemical field, Aleader's pump and valve products are widely used for crude oil transportation and media control in refining processes. Their high corrosion resistance materials and intelligent control systems ensure safe and efficient production processes.

Water Treatment Industry In municipal and industrial water treatment systems, Aleader's pump and valve products are used for sewage treatment and potable water purification. Their high efficiency and durability ensure the long-term stable operation of water treatment systems.

Food Processing Industry In food processing, Aleader's sanitary-grade pump and valve products meet strict hygiene requirements and are widely used in dairy, beverage, and pharmaceutical industries, ensuring product safety and quality.

Installation and Maintenance

Installation Steps

1. Preparation:

Confirm the installation location and the size and specifications of the pipe interfaces.

Check the pump and valve products for any damage and ensure all accessories are complete.

2. Installation:

Follow the product manual for installation, ensuring all connections are tight and leak-free.

Connect and debug the intelligent control system to ensure normal operation.

3. Test Run:

After installation, perform system testing to check all parameters and ensure the pump and valve operate normally.

Maintenance Tips

Regular Inspections: Periodically inspect all connection points and seals to ensure there are no leaks or loose parts.

Cleaning and Lubrication: Regularly clean and lubricate the interior of long-running pumps and valves to maintain optimal working conditions.

Replace Worn Parts: Replace any worn or damaged parts promptly to avoid affecting system operation.

Conclusion

With its superior product quality and technological innovation, Aleader Company has become a leader in the pump and valve industry. Whether you need efficient and durable industrial pumps and valves or intelligent control systems, Aleader can provide professional solutions. For more information or to place an order, visit Aleader Company's official website or contact their customer service team. Enhance your installations with the trusted quality and reliability of Aleader Company's pumps and valves.

0 notes

Text

The Benefits of Using a Sanitary Butterfly Valve for Food Production

In the dynamic and meticulously regulated food production industry, maintaining high standards of hygiene, efficiency, and reliability is paramount. A critical component that significantly contributes to these standards is the sanitary butterfly valve. Designed specifically for hygienic applications, these valves offer numerous advantages over traditional valve types. Freture Techno Pvt. Ltd., a leading butterfly valve manufacturer based in Mumbai, India, excels in providing top-quality sanitary butterfly valves tailored to meet the stringent demands of the food industry.

Understanding Sanitary Butterfly Valves

Sanitary butterfly valves are a type of quarter-turn valve, designed with a disk that rotates to allow, regulate, or halt the flow of fluids. The “sanitary” aspect refers to their construction and materials, which ensure they meet the rigorous cleanliness standards required in food production. Typically made from stainless steel, these valves are designed to minimize crevices and cavities where contaminants could accumulate, making them easy to clean and maintain.

Key Benefits of Sanitary Butterfly Valves in Food Production

Hygiene and Cleanability

The primary advantage of sanitary butterfly valves is their superior hygiene. Made from high-grade stainless steel, these valves are resistant to corrosion and are designed with smooth surfaces that prevent the buildup of bacteria, mold, and other contaminants. The absence of internal pockets and crevices ensures thorough cleaning, reducing the risk of contamination in food products. This cleanability is essential for maintaining the safety and quality of food products, complying with food safety regulations, and achieving certifications such as HACCP (Hazard Analysis and Critical Control Points) and ISO 22000.

Ease of Maintenance

Sanitary butterfly valves are known for their simplicity in design, which translates to easier maintenance and lower downtime. The disk and seal design allows for quick disassembly, inspection, and cleaning without the need for specialized tools or extensive training. This ease of maintenance ensures that production lines can be quickly brought back online after routine checks or unexpected issues, maintaining consistent productivity and minimizing operational costs.

Efficient Flow Control

These valves offer precise flow control, essential for processes requiring exact dosing and mixing of ingredients. The ability to finely adjust the flow rate ensures consistent product quality and optimizes the use of raw materials. Sanitary butterfly valves provide a reliable seal in both the open and closed positions, reducing the risk of leaks and ensuring the integrity of the production process.

Durability and Longevity

Constructed from robust materials like stainless steel, sanitary butterfly valves are designed to withstand the demanding conditions of food production, including exposure to various temperatures, pressures, and cleaning agents. This durability translates to a longer lifespan, reducing the frequency of valve replacements and providing a better return on investment over time.

Cost-Effectiveness

Despite their high performance, sanitary butterfly valves are often more cost-effective than other types of valves. Their straightforward design and minimal moving parts mean they are less expensive to manufacture, purchase, and maintain. This cost-efficiency makes them an attractive option for food producers looking to optimize their budget without compromising on quality or performance.

Versatility

Sanitary butterfly valves are highly versatile and can be used in a wide range of applications within the food industry. Whether it's for the production of beverages, dairy products, or processed foods, these valves can handle various types of liquids and semi-liquids. Their adaptability to different production processes makes them an indispensable component in a modern food manufacturing facility.

Applications in Food Production

Sanitary butterfly valves are used across various stages of food production:

Ingredient Handling: Ensuring precise control over the addition of liquids and semi-liquids.

Mixing and Blending: Providing consistent flow rates for uniform mixing.

Pasteurization: Withstanding high temperatures and maintaining sterility.

Bottling and Packaging: Ensuring clean and efficient transfer of products into packaging.

Compliance with Industry Standards

Freture Techno Pvt. Ltd. manufactures sanitary butterfly valves that comply with international standards, including FDA, 3A, and EHEDG. This compliance ensures that their valves meet the highest quality and safety requirements, providing peace of mind to food producers.

Innovation and Customization

Freture Techno Pvt. Ltd. stands out not only for its adherence to quality standards but also for its innovative approach and customization capabilities. Recognizing that each food production facility may have unique requirements, the company offers customized solutions tailored to specific needs. This bespoke approach ensures that their sanitary butterfly valves integrate seamlessly into existing systems, enhancing efficiency and performance.

Sustainable Manufacturing

In addition to their functional benefits, sanitary butterfly valves from Freture Techno Pvt. Ltd. are manufactured with a focus on sustainability. The company employs eco-friendly manufacturing processes and materials, reflecting a commitment to environmental responsibility. By choosing these valves, food producers can align their operational practices with broader sustainability goals, appealing to eco-conscious consumers and stakeholders.

Real-World Success Stories

Numerous food production companies have experienced significant improvements in their operations after integrating sanitary butterfly valves from Freture Techno Pvt. Ltd. These success stories highlight reduced contamination risks, lower maintenance costs, and enhanced product quality. For instance, a dairy processing plant reported a 20% increase in productivity and a notable reduction in product recalls due to improved hygiene and reliability of the valves.

Conclusion

The role of sanitary butterfly valves in food production cannot be overstated. Their benefits, ranging from superior hygiene and ease of maintenance to precise flow control and cost-effectiveness, make them an indispensable component in the industry. Companies like Freture Techno Pvt. Ltd. are at the forefront of manufacturing these essential valves, providing high-quality, reliable solutions that meet the rigorous demands of modern food production.

As the food industry continues to evolve, the importance of maintaining stringent hygiene standards and operational efficiency remains paramount. Sanitary butterfly valves offer a robust solution to these challenges, ensuring that food products are safe, high-quality, and produced efficiently. By investing in these valves, food producers can not only enhance their production processes but also ensure compliance with international standards, ultimately leading to greater consumer trust and satisfaction.

Freture Techno Pvt. Ltd., with its expertise and commitment to quality, stands as a trusted partner for food producers seeking reliable and innovative sanitary butterfly valves. Based in Mumbai, India, the company continues to lead the way in delivering exceptional products that drive the success of food production facilities worldwide.

1 note

·

View note

Text

Hygienic Pumps and Valves Market Set to Witness Robust Expansion, Fueled by Increasing Emphasis on Food Safety and Quality Standards

Overview and Scope

Hygienic pumps and valves are designed to satisfy unique requirements for industrial production processes for purity and hygiene. These smooth pumps are used for regular cleaning with acids and bases. A hygienic centrifugal pump is also a type of centrifugal pump used to maintain the purity of the product without the risk of contamination.

Sizing and Forecast

The hygienic pumps and valves market size has grown strongly in recent years. It will grow from $2.22 billion in 2023 to $2.36 billion in 2024 at a compound annual growth rate (CAGR) of 6.1%.

The hygienic pumps and valves market size is expected to see strong growth in the next few years. It will grow to $3.02 billion in 2028 at a compound annual growth rate (CAGR) of 6.4%.

To access more details regarding this report, visit the link:

https://www.thebusinessresearchcompany.com/report/hygienic-pumps-and-valves-global-market-report

Segmentation & Regional Insights

The hygienic pumps and valves market covered in this report is segmented –

1) By Pump Type: Centrifugal Pump, Positive Displacement Pump, Other Pump Types

2) By Valve Type: Single-Seat Valves, Double-Seat Valves, Butterfly Valves, Diaphragm Valves, Control Valves, Other Valve Types

3) By Material Type: Stainless Steel, Copper, Bronze

4) By Hygiene Class: Aseptic, Standard, Ultraclean

5) By Application: Pharmaceutical, Food, Cosmetics, Fine Chemistry, Other Applications

North America was the largest region in the hygienic pumps and valves market in 2023. The regions covered in the hygienic pumps and valves market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa.

Intrigued to explore the contents? Secure your hands-on sample copy of the report:

https://www.thebusinessresearchcompany.com/sample.aspx?id=8028&type=smp

Major Driver Impacting Market Growth

The rising demand for dairy products is expected to propel the growth of the hygienic pumps and valves market. Dairy products refer to milk products that include foods produced from the milk of mammals. Hygienic pumps and valves help manufacture dairy products by regulating and controlling flow and pressure in pumping systems.

Key Industry Players

Major companies operating in the hygienic pumps and valves market report are Alfa Laval AB, Lone Star Fund, Group Aktiengesellschaft, ITT Inc., Evoguard GmbH, KSB SE & Co. KGaA

The hygienic pumps and valves market report table of contents includes:

1. Executive Summary

2. Market Characteristics

3. Market Trends And Strategies

4. Impact Of COVID-19

5. Market Size And Growth

6. Segmentation

7. Regional And Country Analysis

.

.

.

27. Competitive Landscape And Company Profiles

28. Key Mergers And Acquisitions

29. Future Outlook and Potential Analysis

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

Supplier of SS Dairy Valves and Fittings in Punjab

Meghmani Metal Industries is one of the leading Manufacturer and Supplier of SS Dairy Valves and Fittings in Punjab, India.

Established in 2011, Meghmani Metal Industries is dedicated to providing exceptional products to the metal industry, emphasizing customer satisfaction and environmental responsibility.

We provide an extensive selection of stainless steel products such as plates, coils, bars, pipes, tubes, flanges, valves, fittings, fasteners, channels, and flats.

We supply SS dairy valves and fittings, specially crafted for dairy processing equipment, guaranteeing sanitary and effective performance. Our products are manufactured using premium materials and advanced technology for superior quality.

SS dairy valves and fittings feature user-friendly operation, high tensile strength, corrosion resistance, durability, and excellent weldability, ensuring dependable performance and extended service life.

Types of SS Dairy Valves and Fittings:

Sanitary ball valves

Butterfly valves

Diaphragm valves

Elbows and tees

Reducers and adapters

Sight glasses

Applications:

Paper & Pulp Industry

Structural Pipe

Food Processing Industry

Chemical Industry

Fabrication Industry

Water Supply Systems

Meghmani Metal Industries is one of the leading Manufacturers and Supplier of SS Dairy Valves and Fittings in Punjab and locations such as Firozpur, Dhilwan, Dasuya, Dinanagar, Sham Churasi, Karoran, Samrala, Amritsar, Raikot, Pathankot, Malaut, Kurali, Mandi Gobindgarh, Jaitu, Nabha, Payal, Balachaur, Muktsar, Moonak, Khamanon, Batala, Phagwara, Machhiwara, Ajnala, Sultanpur Lodhi, Tarn Taran, Maur, Zira, Alawalpur, Patiala, Ghagga, Kot Kapura, Gobindgarh, Kapurthala, Pattran, Jalalabad, Bagh Purana, Bathinda, Nawashahr, Budhlada, Dhanaula, Banur.

If you have any questions or require further information, please feel free to contact us.

Read the full article

#Ajnala#Alawalpur#Amritsar#BaghPurana#Balachaur#Banur#bars#Batala#Bathinda#Budhlada#Butterflyvalves#channels#coils#Dasuya#Dhanaula#Dhilwan#Diaphragmvalves#Dinanagar#Elbowsandtees#fasteners#Firozpur#fittings#Flanges#Ghagga#Gobindgarh#Jaitu#Jalalabad#Kapurthala#Karoran#Khamanon

0 notes

Text

https://www.linkedin.com/pulse/our-superior-quality-valves-lead-industry-avc-valves

Our Superior Quality Valves Lead the Industry

Check Valves Manufacturer, Gate Valves India, and Pneumatic Valves India are the epitome of quality, dependability, and innovation in the world of industrial valve production. AVC Valves India Pvt Ltd have carved out a niche in the business by providing a diverse selection of high-quality valves that meet a variety of industrial requirements.

0 notes

Text

What is ball vs butterfly valve?

When it comes to controlling the flow of fluids in pipelines and industrial processes, two types of valves often come into play: ball valves and butterfly valves. Both have their unique features and applications, making them suitable for various scenarios. In this guide, we will explore the differences between ball valves and butterfly valves, helping you make an informed decision based on your specific requirements. Additionally, we'll understand BU-LOK, a leading ball valve manufacturer of Tube Clamps and Dairy Pharma Fittings, providing a wide range of industrial solutions.

Ball Valves: Robust and Reliable

What Are Ball Valves?

Ball valves are quarter-turn valves that use a hollow, perforated, and pivoting ball (often made of metal or plastic) to control the flow of fluids. They are known for their simplicity and reliability. Here are some key characteristics of ball valves:

1. Design: Ball valves consist of a spherical ball with a hole in the center. When the ball's hole aligns with the flow path, the valve is open, allowing fluid to pass through. When the ball is rotated 90 degrees, the hole is perpendicular to the flow, blocking it completely.

2. Operation: Ball valves are easy to operate with a simple lever or handle. They provide quick and precise control of fluid flow, making them suitable for applications where on/off control is critical.

3. Durability: Ball valves are robust and can handle a wide range of pressures and temperatures. They are also less prone to wear and tear compared to other valve types.

4. Sealing: The sealing mechanism in ball valves ensures a tight closure, minimizing the risk of leaks.

5. Applications: Ball valves are commonly used in a variety of industries, including oil and gas, water treatment, chemical processing, and HVAC systems.

Butterfly Valves: Versatile and Economical

What Are Butterfly Valves?

Butterfly valves are rotary valves that use a circular disc (the "butterfly") with a pivot in the center to control flow. They are known for their versatility and cost-effectiveness. Here are some key characteristics of butterfly valves:

1. Design: Butterfly valves consist of a circular disc positioned perpendicular to the flow path. When the disc is parallel to the flow, the valve is open, allowing fluid to pass. When the disc is turned 90 degrees, it blocks the flow.

2. Operation: Butterfly valves are operated using a lever, gear, or actuator. They provide relatively quick control of fluid flow, but not as precise as ball valves.

3. Compactness: Butterfly valves have a compact design, making them suitable for applications with limited space.

4. Economical: They are often more cost-effective than ball valves, making them a popular choice for large-diameter pipelines and low-pressure systems.

5. Applications: Butterfly valves find use in a wide range of industries, including water distribution, HVAC, wastewater treatment, and food processing.

Choosing the Right Valve

The choice between ball valves and butterfly valves depends on several factors:

1. Flow Control Precision: If precise flow control is essential, ball valves are the better choice due to their quarter-turn operation and tight sealing.

2. Space Constraints: In applications with limited space, butterfly valves' compact design may be advantageous.

3. Cost Considerations: For cost-conscious projects or larger-diameter pipelines, butterfly valves offer a more economical solution.

4. Durability: Ball valves are generally more durable and suitable for higher-pressure and temperature applications.

5. Application Specifics: Consider the specific requirements of your application, including the type of fluid, pressure, temperature, and environmental conditions.

Conclusion

For those seeking reliable components like Tube Clamps and Dairy Pharma Fittings, BU-Lok Valves & Fitting India Pvt Ltd stands out as a top manufacturer. Their range of Tube Clamps, including Hydraulic Pipe Tube Clamps, Heavy Duty Tube Clamps, and Light Duty Tube Clamps, caters to various industrial needs. BU-Lok Valves & Fitting India Pvt Ltd has earned a reputation for delivering quality solutions in the field of fluid control systems.

Whether you opt for ball valves or butterfly valves, having dependable Tube Clamps and fittings from BU-Lok Valves & Fitting India Pvt Ltd can enhance the efficiency and reliability of your fluid control systems. Their commitment to quality and innovation makes them a trusted choice for industrial solutions.

In the debate of ball valves vs. butterfly valves, there is no one-size-fits-all answer. Both types of valves have their advantages and are suitable for different applications. Your choice should be guided by your specific requirements, including precision, space, cost, and durability considerations. Additionally, partnering with trusted ball valve manufacturers or ball valve supplier like BU-Lok Valves & Fitting India Pvt Ltd for complementary components ensures that your fluid control systems operate at peak performance, regardless of the valve type you choose.

0 notes

Text

What Pipe Fittings Are Commonly Required In Dairy Production Lines

Pipe Fittings Commonly Required in Dairy Production Lines

In dairy production lines, various pipe fittings play a crucial role in ensuring the smooth operation of processes and maintaining the quality and safety of dairy products. These fittings are designed to meet specific requirements related to hygiene, durability, and ease of cleaning. In this response, we will explore some of the commonly required pipe fittings in dairy production lines.

Overview of Essential Pipe Fittings for Dairy Production

Tri-Clamp Fittings: Tri-clamp fittings, also known as sanitary fittings, are extensively used in the dairy industry. They feature a three-part assembly comprising a clamp, gasket, and ferrule, providing a secure and leak-free connection between pipes and equipment. Tri-clamp fittings are easy to install, dismantle, and clean, making them ideal for maintaining strict hygiene standards in dairy production.

Dairy Valves: Different types of valves are employed in dairy production lines to control the flow of liquids and gases. These include ball valves, butterfly valves, and diaphragm valves. Valves are crucial for regulating the movement of milk, cream, and other dairy products through the production line, ensuring precise control and preventing contamination.

Elbows: Elbows are fittings that enable changes in the direction of fluid flow. In dairy production lines, 90-degree and 45-degree elbows are commonly used to navigate around equipment, corners, and obstacles. They facilitate smooth flow without causing excessive pressure drops or disruptions, thereby optimising the efficiency of the production process.

Tees: Tee fittings are employed to create branches in the piping system, allowing the distribution of fluid to multiple destinations. In dairy production lines, tees are utilised to divert flow to different equipment or parallel processing lines. They help in maintaining uniform pressure and balanced distribution of dairy products.

Reducers: Reducer fittings are used when there is a need to connect pipes of different sizes. In dairy production, reducers are often required to transition between large diameter pipes and smaller diameter pipes, accommodating variations in equipment or process requirements. They ensure a smooth and efficient flow of dairy products between different sections of the production line.

Clamps and Hangers: Clamps and hangers are essential for providing support and stability to the piping system. They help in preventing sagging or excessive movement of pipes, reducing stress on the fittings and ensuring the integrity of the system. Stainless steel clamps and hangers are commonly used in dairy production due to their corrosion resistance and ease of cleaning.

Sight Glasses: Sight glasses are transparent or translucent fittings installed in pipelines to visually inspect the flow of fluids. In dairy production, sight glasses allow operators to monitor the product flow, detect any abnormalities, and ensure the absence of contaminants. They are typically made from food-grade materials that are resistant to chemical reactions and can withstand frequent cleaning and sanitization.

Unions: Unions are fittings that enable the quick and convenient disconnection of pipes or equipment for maintenance or cleaning purposes. They consist of two threaded ends and a nut that allows for easy joining or separation. Unions are particularly useful in dairy production lines where regular cleaning and inspection are essential to maintain sanitary conditions.

Check Valves: Check valves, also known as non-return valves, are designed to allow the flow of fluids in one direction while preventing backflow. In dairy production, check valves are crucial for maintaining the integrity of the process and preventing cross-contamination between different sections of the production line.

Tube Fittings: Tube fittings, such as compression fittings and push-in fittings, are commonly used in dairy production lines for connecting and sealing tubes. These fittings provide a secure and leak-free connection, ensuring the integrity of the fluid flow.

Pipe Fittings Suppliers in Saudi Arabia

Petromet Flange Inc is a world-class producer, supplier, and exporter of flanges, fittings, and other piping components. By providing them with our goods and services, we consider our customers as partners. Pipe Fittings Suppliers in Saudi Arabia offer a wide range of fittings.

Pipe Fittings Manufacturers in Saudi Arabia also offer competitive pricing, due to the country’s low labour costs & access to raw materials. We are a Pipe Fittings Manufacturers in India, Pipe Fittings Manufacturer in Sri Lanka

It is important to note that the specific requirements for pipe fittings in dairy production may vary based on the scale and complexity of the production line, as well as regional regulations. Consulting with industry experts

0 notes

Text

SS Butterfly Valve by Ronak overseas

Use Of butterfly valve

.Butterfly valves are used where space is limited. Unlike gate valves, butterfly valves can be used for throttling or regulating flow as well as in the full open and fully closed position. The pressure loss through a butterfly valve is small in comparison with the gate valve.

ABOUT US

The company is headquartered in Mumbai and is a market leader in the piping and related products segment under the RONAK OVERSEAS brand name. Ronak Overseas was established in 1989 in Mumbai. Which offers a wide range of stainless steel products for the food processing, beverage, dairy, brewing, cosmetic, pharmaceutical and chemical industries. Today, we cater to the needs of millions of homes. Ronak Pipes has management and industrial skills, ranging from basic pipe connections and excellent contracts for large construction projects.

As a manufacturer of RONAK OVERSEAS of Stainless Steel Sanitary Valves, Fittings, Tubing, we manufacture and supply the widest line of Stainless Steel Sanitary Valves, Fittings, Tubing. We are a company aimed at developing and improving hygiene equipment for the dairy, food, cosmetic, beverage, beverage and pharmaceutical industries. To enhance brand equity in all parts of India, we are constantly expanding our distribution and service network across India. We are also dedicated to increasing the value and efficiency of our excellent products and services to meet the needs of a constantly changing consumer market.

One of the known brand in the market since 1997

You can visit our website for more information

www.ronakoverseas.co.in

0 notes

Text

Supplier of SS Dairy Valves and Fitting in Maharashtra

Meghmani Metal:

Meghmani Metal is an ISO 9001:2015 certified Supplier of SS Dairy Valves and Fitting in Maharashtra, India.

The company offers a diverse range of stainless steel products, including steel flanges, SS fasteners, steel butt welding, steel pipe fittings, steel rods, wires, coils, and flats.

Industrial valves offered include gate valves, globe valves, ball valves, butterfly valves, check valves, pressure valves, and diaphragm valves.

Meghmani Metal provides stainless steel dairy valves in various ranges, specifications, types, forms, sizes, shapes, wall consistencies, standards, and lengths tailored to customer requirements.

Dairy valves are constructed precisely from high-quality raw materials to ensure flawless dimensional precision and strong construction.

The company's SS dairy fittings include dairy bends, tees, reducers, clamps, pipe holder clamps, ferrules, hose clamps, tri-clamp tees, elbows, reducers, and more, offering customization options for sizes and shapes as per customer requirements.

Features:

Corrosion Resistant

High Tensile Strength

Temperature Resistant

Easy Formability and Fabrication

Low Maintenance (Long-lasting)

Attractive Appearance

Environmentally Friendly

Meghmani Metal is Supplier of SS Dairy Valves and Fitting in Maharashtra, India Including Mumbai, Pune, Nagpur, Nashik, Vasai-Virar, Solapur, Bhiwandi, Amravati, Kolhapur, Akola, Latur, Jalna, Panvel, Navi Mumbai, Parbhani, Dhule, Nanded, Jalgaon, Ahmadnagar, Chandrapur Etc.

For detailed information, kindly contact us.

Read the full article

#Ahmadnagar#Akola#Amravati#Bhiwandi#Chandrapur#Dhule#Exporter#India#Jalgaon#Jalna#Kolhapur#Latur#Maharashtra#Manufacturer#Mumbai#Nagpur#Nanded#Nashik#NaviMumbai#Panvel#Parbhani#Pune#Solapur#SSDairyValvesandFitting#supplier#Vasai-Virar

0 notes

Text

Looking for ball valves? We are your trusted stockists, offering a diverse selection of top-notch ball valves for various applications. Explore our collection of industrial ball valves. We are your trusted stockists, offering reliable solutions for fluid control. For more details visit here: https://avcvalves.in/ball-valve/

#gate valves india#dairy butterfly valves#gate valves manufacturers#stainless steel valve manufacturer#dairy valves in india

0 notes

Text

Specially Designed Sanitary Butterfly Valves

Butterfly valves have been used because the invention of steam engines. The main reason they have been used for so long is they do not create a disturbance within the flow with the medium when compared with other types. It provides a simple structure consisting of a disc connected to a wheel away from valve. Turning the wheel opens or closes. Something else about butterfly faucets is that you could achieve a perfect closure, even with many years of obsolescence. Butterfly valves are also the most common ones on the market today and you will find them in different shapes, sizes, and materials. Sanitary butterfly faucets are also becoming more and more popular around the globe. This is because it is crucial to maintain hygiene in piping systems, especially for the pharmaceutical, food, chemical and beverage industries. Wish to consider talk about butterfly valve manufacturer with manual threading.

It really is basically a handbook valve with threaded ends. It really is mainly used for insulation and fluid control in piping systems. In addition, it works manually. Actually, some people prefer manual valves to automatic valves. Well, to some extent, it's nice as it's easier to control and regulate the flow of fluid in the piping system by using a manual valve. This gives you total treatments for what needs to be done and just how. Manual threaded butterfly valves are widely used in the chemical, food, beverage and brewery industries.

The real difference between this valve and other types of valves is that sanitary valves have been designed specifically for sanitary purposes. It is crucial to maintain hygiene inside the piping systems with the food, beverage and brewery industries and there's no better way rather than to obtain a valve that isn't only easy to clean but additionally designed for hygiene. It is important that you define environmental surroundings in which you make use of the valve before purchasing. However, there are many solutions, it is important that you get a valve that meets your requirements. As an example, if you are working with a high temperature and high-pressure piping system, you have to find a valve that may handle that.

Valves designers manufacture a wide range of sanitary fittings and valves in stainless steel such as sanitary butterfly valves, sanitary ball valves, sanitary check valves, sanitary indicator lights and sanitary fittings, etc. They're widely used in dairy food, foods, and beverages, pharmaceuticals, cosmetics, and other industrial markets. Manufactures use advanced CNC machine tools, processing and testing facilities to make certain our products meet your expectations for reliable performance and quality.

1 note

·

View note

Video

youtube

Bestl Discount : 20% Best Price bilge pump 12v 750gph MKBP-G750-12 12VDC rule water pump used in boat seaplane motor homes houseboat : https://ift.tt/2JFDXMG Big Sale bilge pump 12v 750gph MKBP-G750-12 12VDC rule water pump used in boat seaplane motor homes houseboat https://ift.tt/2JFDXMG Sale SS304 Stainless Steel Sanitary 1/2" to 4" Tri Clamp Butterfly Valve Homebrew Beer Dairy Product : https://youtu.be/elMJcYPcitw by Plumbing

1 note

·

View note

Text

SS Sanitary Ball Valve 3 way Tc End

What is a SS Sanitary Ball Valve 3 way Tc End?

ss sanitary Ball Valve 3 way Tc end is to shut off water flow in one pipe while opening water flow in another pipe, to mix water from two different pipes into one pipe, or to separate water from one pipe into two different pipes.A 3-way valve is normally provided with manual operation.They are often known as

tri-clover valves

and they use a ball valve or a butterfly valve to open and close the flow. They are polished to a flawless finish and have tri-clamp ends for a sanitary attachment. This includes the famous easy clean (EZ Clean) or fast clean ball valves used in breweries

SS Daiphragm Valve TC End

Used in different industries

Refineries

Gas Processing

Off-Shore Oil Drilling Companies

Petrochemicals

Hydro-Carbon

Fertilizers

Paper & Pulp Companies

Power Generation

Specialty Chemicals

Pharmaceuticals

Drugs

Steel

Cement

Water Pipe Line

Pesticides

General Piping

Construction

Engineering

Nuclear

Food Processing & Dairy

boiler & heatexchangers

0 notes

Text

SS Dairy Valves and Fittings Supplier in Mumbai

Meghmani Metal:

We Are a Well-Known Manufacturer and Supplier of All Ferrous And Non-Ferrous Metal Products,

Such As Stainless Steel Pipes, Stainless Steel Tubes, Steel Flanges, Steel Butt Welding, Steel Pipe Fittings,

Steel Rods, Wires, Colls, Flats, Structural, and so on.

We are a high-quality SS Dairy Valves and Fittings Supplier in Mumbai. India.

SS Dairy Valves & Fittings are an essential part of the dairy industry, ensuring the safe and hygienic handling of milk and other dairy products.

The manufacturer uses high-grade stainless steel to produce these valves and fittings, allowing them to withstand the harsh conditions of dairy processing.

Types of SS Dairy Valves

Ball Valves

Ball valves, known for their reliability and quick shut-off capabilities, find extensive use in dairy processing, providing control over the flow of liquids.

Butterfly Valves

Butterfly valves, with their simple yet effective design, are popular for regulating the flow in large pipelines, ensuring smooth operation in dairy plants.

Diaphragm Valves

Diaphragm valves, characterized by a flexible membrane, offer precise control over fluid flow, making them ideal for dairy applications where accuracy is crucial.

Meghmani Metal proudly SS Dairy Valves and Fittings Supplier in Mumbai, Maharashtra serving locations including Ahmednagar, Akola, Amravati, Aurangabad, Bhandara, Bhusawal, Buldhana, Chandrapur, Daulatabad, Dhule, Jalgaon, Kalyan, Karli, Kolhapur, Mahabaleshwar, Malegaon, Matheran, Mumbai, Nagpur, Nanded, Nashik, Osmanabad, Pandharpur, Parbhani, Pune, Ratnagiri, Sangli, Satara, Sevagram, Solapur, Thane, Ulhasnagar, Vasai-Virar, Wardha, Yavatmal.

Read the full article

#Ahmednagar#Akola#Amravati#Aurangabad#Bhandara#Bhusawal#Buldhana#Chandrapur#Daulatabad#Dhule#India#Jalgaon#Kalyan#Karli#Kolhapur#Mahabaleshwar#Maharashtra#Malegaon#Matheran#Mumbai#Nagpur#Nanded#Nashik#Osmanabad#Pandharpur#Parbhani#Pune#Ratnagiri#Sangli#Satara

0 notes

Text

Disc Valves

There are several names and uses for valves. Due to their low cost, simplicity of usage, and effectiveness, these technical components enable operators to safely regulate the flow of process fluids and have established themselves as standard technologies in most markets.

What Is a Disc Valve?

The Disc valve is not so much a unique valve as it is a closing device for a wide variety of valves. Disc valves can be actuated manually and automatically, and are made in various sizes to fit standard piping.

How Do Disc Valves Work?

A disc valve's functionality is determined by the particular device of which it is a component. All disc valves share the fact that the valve disc serves as the main pressure barrier, though. In order to hold back the entire power of the input flow pressure and depressurize the output, this disc will either allow fluid to flow around it or be fully perpendicular to the flow. To withstand this level of stress, the valve disc is normally forged from harder metals, and several actuation techniques are employed to put the disc in this position.

Types of Disc Valves

Butterfly valves

Butterfly valves use a disc to completely close the pipe. The most common designs are zero-eccentric, double-eccentric, and triple-eccentric butterfly valves. Zero offset valves employ a disc that revolves around the pipe's axis and are typically used for applications up to 200 psi and 400 degrees F. Double offset butterfly valves employ two offset stems to move the valve disc in a cam-like fashion, which can often withstand greater pressures. To provide a frictionless seal against the disc seat, triple offset valves use three offset stems.

Disc check valves

Disc Check Valves are specified for one-way/non-reverse flow. They provide some "check" to the system so that the operator knows that the process fluid is not moving in an undesired direction after passing the check point.

Sanitary disc valves

Although they are specifically designed to offer the working fluid abiotic, sanitary conditions, sanitary valves are functionally identical to earlier disc valves. To facilitate an uninterrupted product flow, the disc is often rounded. They often handle dairy, medications, drinks, cooking oils, and other foods and chemicals and are composed of inert metals like stainless steel.

Choose Disc Valves

Valve specifications are an important part of the design process as they affect efficiency, operating time and many other factors that can make or break a project.

Disc valves size

This question will give insight into how big your valve must be, the type of disc valve chosen, the flow rate for your project, and the force the disc valve must hold.

Pressure and temperature

These valves can be rated in many different ranges, so it is important to know the working pressure and temperature of the process fluid before looking for the right disc valve. Make sure the valve is also rated for the proper temperature. A valve that is not suitable for these two properties is sure to fail, so please specify your operating temperature and pressure.

Actuator type

There are many options to choose from: manual drive, automatic drive, motor drive, hydraulic/pneumatic and other methods to provide the right type of drive for your project.

AJA Technology is a hydraulic pumps and motors manufacturer. We meet the needs of users with continuous innovation, high-quality products and perfect services. If you have any questions about hydraulic pumps or hydraulic systems, please call or email us. We are more than happy to serve you.

0 notes