#dairy valves in india

Text

https://www.linkedin.com/pulse/our-superior-quality-valves-lead-industry-avc-valves

Our Superior Quality Valves Lead the Industry

Check Valves Manufacturer, Gate Valves India, and Pneumatic Valves India are the epitome of quality, dependability, and innovation in the world of industrial valve production. AVC Valves India Pvt Ltd have carved out a niche in the business by providing a diverse selection of high-quality valves that meet a variety of industrial requirements.

0 notes

Text

Premium Quality Dairy Fittings Manufacturers in India

Piping Projects.in is a renowned Dairy Fittings Manufacturers in India. A sanitary fitting is a device for regulating dry and bulky materials. These fittings are simple to install, disassemble, and meet stringent hygiene standards. Sanitary pipe fittings are made to endure various environments, including chemical exposure, processing, and cleaning regimens.

The SMS fittings offer a smooth surface finish and highly resist corrosive agents in severe situations. Sanitary tube fittings include many ports, reducing the connections necessary for fluid flow. This capability is helpful in tight places when SMS union fittings are placed. These fittings are easy to clean and maintain over time. Our products come in various sizes to suit various usefulness and intended applications. We are also a leading Fastener Manufacturer in Chennai.

The adaptable sanitary tee allows flow in many directions, guaranteeing a smooth media flow throughout the system. Sanitary elbows serve an essential function in increasing machinery efficiency across various sectors. These dairy fittings meet various industrial standards. We have a large variety of Dairy Fittings, making us the major Dairy Fittings Supplier in India. Besides dairy fittings, we have various products like Pipe Fitting Manufacturers, Tube Fittings Manufacturers, and Valve Manufacturers.

Product source: Dairy Fittings Manufacturers

Also Visit: Pipe Fittings Weight Chart in kg pdf in India

#Dairy Fittings Manufacturers in India#Dairy Fittings Supplier in India#Dairy Fittings Manufacturers#Pipe Fitting Manufacturers#Tube Fittings Manufacturers#Valve Manufacturers#Dairy Fittings#Fastener Manufacturer in Chennai#Pipe Fittings Weight Chart in kg pdf in India

0 notes

Text

Top SS Dairy Valve & Fittings Supplier in India

Top SS Dairy Valve & Fittings Supplier in India:

Meghmani Metal:

With more than 30 years of experience in the Indian stainless steel market, we have been in operation since 2011. We are quite knowledgeable about the market. We pledge to deliver premium goods on schedule.

We Are a Well-Known Manufacturer And Supplier Of All Ferrous And Non-Ferrous Metal Products Like Stainless Steel Pipes,…

View On WordPress

0 notes

Text

Top-notch Round Bar Manufacturer in India - Piping Project.in

PipingProject.in is a well-known Round Bar Manufacturer in India. Our Round Bar is renowned for its exceptional resistance to corrosion and versatility in a variety of applications. It provides stability and support to a variety of equipment in high-temperature and high-pressure settings. Pump shafts, valves, dairy equipment, surgical components, machine tools, and other related applications use round bar stock extensively. Additionally, we are a significant Valves Supplier in India.

We stand out in the Indian market as a reliable and customer-centric round bar manufacturer. The firm has gained a reputation for prompt deliveries and cheap prices due to its strong distribution network and emphasis on client happiness.

We have a verified Round Bar Weight Chart in kg,mm,PDF that provides measurements in both kilos and millimeters. The weights of our round bars for different diameters and wall thicknesses are displayed in kilograms per meter (kg/m) in the table below. It is crucial to remember that the weights in this table are approximations that might change depending on the kind of steel and the manufacturing techniques employed.

Product source: Round Bar

#RoundBarManufacturerinIndia#ValvesSupplierinIndia#RoundBarSupplierinIndia#roundbarmanufacturer#RoundBarWeightChartinkgmmPDF

0 notes

Text

Exporter of Spray Dryer in Ghana

Drytech Engineering Systems is an Exporter of Spray Dryer in Ghana.

Drytech Engineering Systems is Based in Ahmedabad, Gujarat, India.

We are a Manufacturer, Supplier, Stockiest, and Exporter of Flash Dryers, Spray Dryers, Spin Flash Dryers,

Fluid Bed Dryers, and Evaporator Dryers, Rotary Valves, Rotary Atomizers, Hot Air Generators,

Centrifugal Blowers, and Dust Collector Systems.

we adhere to international standards, ensuring top-notch performance and reliability across

various industries.

Spray dryers are broadly classified into two types based on the method of atomization.

Nozzle Spray Dryers

Rotary Atomiser Spray Dryers

Our team of experts is dedicated to providing you with the best spray-drying solutions,

ensuring your complete satisfaction.

We stand by the quality of our products and offer comprehensive support and maintenance services.

Why Choose Our Spray Dryers?

Innovative Technology

Our spray dryers utilize cutting-edge technology to ensure uniform drying, high efficiency, and consistent product quality.

Precision Control

Achieve precise control over the drying process with our advanced systems, ensuring optimal moisture content and particle size.

Energy Efficiency

Designed to minimize energy consumption, our spray dryers offer cost-effective solutions while maintaining superior performance.

Customizable Solutions

We provide customizable spray drying solutions tailored to meet your specific production requirements, ensuring maximum flexibility and productivity.

Versatile Applications

Suitable for a wide range of applications, our spray dryers are perfect for the food, pharmaceutical, chemical, and dairy industries.

Drytech Engineering Systems is an Exporter of Spray Dryer in Ghana including locations like Kumasi, Tamale, Sekondi-Takoradi, Ashaiman, Sunyani, Cape Coast, Obuasi, Teshie, Tema, Madina, Koforidua, Wa, Techiman, Ho, Nungua, Lashibi, Dome, Tema New Town, Gbawe, Oduponkpehe, Ejura, Taifa, Bawku, Aflao, Agona Swedru, Bolgatanga, Tafo, Berekum, Nkawkaw, Akim Oda, Winneba, Hohoe, Yendi, Suhum, Kintampo, Adenta East, Nsawam, Mampong, Konongo, Asamankese, Wenchi, Savelugu, Agogo, Anloga, Prestea, Effiakuma, Tarkwa, Elmina, Dunkwa-on-Offin, Begoro, Kpandu, Kintampo, Navrongo, Axim, Apam, Salaga, Saltpond, Akwatia, Shama, Keta, Nyakrom, Bibiani, Somanya.

For detailed information and inquiries, please feel free to contact us.

0 notes

Text

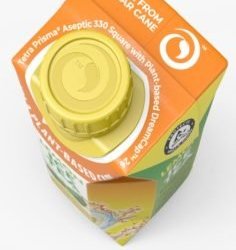

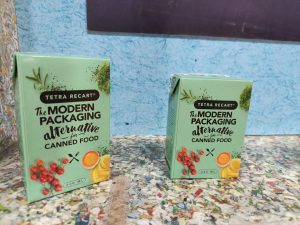

Tetra Pak's new filling machine, closure & barrier solutions, processing tech

In its nearly four-decade journey in India, Tetra Pak, a provider of food processing and packaging solutions, has expanded its offerings with solutions for both brand owners and consumers. Its recent innovations include a high-speed filling machine, plant-based closure solutions, paper-based barrier solutions for beverage cartons, and OneStep technology for the heat-treatment processing of milk.

According to a biennial trend report of the company, Trendipedia 2023, consumers are becoming more value-, health-, and environment-conscious. There's also a growing demand for personalized experiences, with consumers demanding products tailored to their needs. In such a scenario, the market presence of aseptic liquid packaging cartons has grown significantly in recent years and is expected to continue in the foreseeable future.

The E3 Speed Hyper is a filling machine with a capacity to fill 40,000 carton packs per hour—the company claims it is the world's fastest filling machine in the aseptic carton industry. It features eBeam sterilization, allowing for a 10% reduction in operational costs. The machine uses less power (up to 30% reduction), water (up to 45% reduction), and chemicals (up to 99% reduction).

The latest additions include the Tetra Brik Aseptic 200 Edge, featuring a plant-based cap, made out of sugarcane pulp. It is deployed with the beverage brand Maaza for its foray into the dairy category with the launch of Maaza Magic lassi. The introduction of these caps has helped increase renewable content in packaging by 11% and decreased the CO2 impact by approximately 24% when compared to the fossil-based cap solution, the company says.

According to Tripurari, Tetra Pak has been working on categories such as ice cream with large-size chunks or inclusions, mayonnaise, sweetened condensed milk, and more. In the dairy sector, it can supply everything from a single valve to a complete greenfield factory. On the processing side, the company can provide equipment and solutions for a wide range of products – from whey powder to ice cream.

“As demand in the ice cream sector grows, we introduced the Tetra Pak Extrusion Wheel,” he adds. “It enables brands to produce uniform, premium-quality ice cream with inclusions of up to 25 mm in size at the highest capacity in the industry and the lowest cost. This equipment can produce up to 200 products per minute and 12,000 products per lane, per hour. Adaptability to changing markets is crucial, particularly within the dairy industry."

Tetra Pak believes in investing ahead of the curve to support its customers' ambitions while meeting evolving consumer expectations. “From packaging support to technological innovations that minimize production downtime, disruption, and costs, we are more than just a solution provider—we are a partner for growth. Importantly, we have been in India for nearly 40 years, manufacturing high-quality products, and this extensive experience helps us stand out in the market,” he concludes.

0 notes

Text

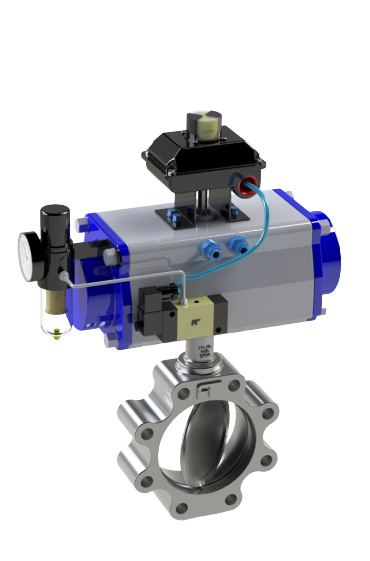

The Benefits of Using a Sanitary Butterfly Valve for Food Production

In the dynamic and meticulously regulated food production industry, maintaining high standards of hygiene, efficiency, and reliability is paramount. A critical component that significantly contributes to these standards is the sanitary butterfly valve. Designed specifically for hygienic applications, these valves offer numerous advantages over traditional valve types. Freture Techno Pvt. Ltd., a leading butterfly valve manufacturer based in Mumbai, India, excels in providing top-quality sanitary butterfly valves tailored to meet the stringent demands of the food industry.

Understanding Sanitary Butterfly Valves

Sanitary butterfly valves are a type of quarter-turn valve, designed with a disk that rotates to allow, regulate, or halt the flow of fluids. The “sanitary” aspect refers to their construction and materials, which ensure they meet the rigorous cleanliness standards required in food production. Typically made from stainless steel, these valves are designed to minimize crevices and cavities where contaminants could accumulate, making them easy to clean and maintain.

Key Benefits of Sanitary Butterfly Valves in Food Production

Hygiene and Cleanability

The primary advantage of sanitary butterfly valves is their superior hygiene. Made from high-grade stainless steel, these valves are resistant to corrosion and are designed with smooth surfaces that prevent the buildup of bacteria, mold, and other contaminants. The absence of internal pockets and crevices ensures thorough cleaning, reducing the risk of contamination in food products. This cleanability is essential for maintaining the safety and quality of food products, complying with food safety regulations, and achieving certifications such as HACCP (Hazard Analysis and Critical Control Points) and ISO 22000.

Ease of Maintenance

Sanitary butterfly valves are known for their simplicity in design, which translates to easier maintenance and lower downtime. The disk and seal design allows for quick disassembly, inspection, and cleaning without the need for specialized tools or extensive training. This ease of maintenance ensures that production lines can be quickly brought back online after routine checks or unexpected issues, maintaining consistent productivity and minimizing operational costs.

Efficient Flow Control

These valves offer precise flow control, essential for processes requiring exact dosing and mixing of ingredients. The ability to finely adjust the flow rate ensures consistent product quality and optimizes the use of raw materials. Sanitary butterfly valves provide a reliable seal in both the open and closed positions, reducing the risk of leaks and ensuring the integrity of the production process.

Durability and Longevity

Constructed from robust materials like stainless steel, sanitary butterfly valves are designed to withstand the demanding conditions of food production, including exposure to various temperatures, pressures, and cleaning agents. This durability translates to a longer lifespan, reducing the frequency of valve replacements and providing a better return on investment over time.

Cost-Effectiveness

Despite their high performance, sanitary butterfly valves are often more cost-effective than other types of valves. Their straightforward design and minimal moving parts mean they are less expensive to manufacture, purchase, and maintain. This cost-efficiency makes them an attractive option for food producers looking to optimize their budget without compromising on quality or performance.

Versatility

Sanitary butterfly valves are highly versatile and can be used in a wide range of applications within the food industry. Whether it's for the production of beverages, dairy products, or processed foods, these valves can handle various types of liquids and semi-liquids. Their adaptability to different production processes makes them an indispensable component in a modern food manufacturing facility.

Applications in Food Production

Sanitary butterfly valves are used across various stages of food production:

Ingredient Handling: Ensuring precise control over the addition of liquids and semi-liquids.

Mixing and Blending: Providing consistent flow rates for uniform mixing.

Pasteurization: Withstanding high temperatures and maintaining sterility.

Bottling and Packaging: Ensuring clean and efficient transfer of products into packaging.

Compliance with Industry Standards

Freture Techno Pvt. Ltd. manufactures sanitary butterfly valves that comply with international standards, including FDA, 3A, and EHEDG. This compliance ensures that their valves meet the highest quality and safety requirements, providing peace of mind to food producers.

Innovation and Customization

Freture Techno Pvt. Ltd. stands out not only for its adherence to quality standards but also for its innovative approach and customization capabilities. Recognizing that each food production facility may have unique requirements, the company offers customized solutions tailored to specific needs. This bespoke approach ensures that their sanitary butterfly valves integrate seamlessly into existing systems, enhancing efficiency and performance.

Sustainable Manufacturing

In addition to their functional benefits, sanitary butterfly valves from Freture Techno Pvt. Ltd. are manufactured with a focus on sustainability. The company employs eco-friendly manufacturing processes and materials, reflecting a commitment to environmental responsibility. By choosing these valves, food producers can align their operational practices with broader sustainability goals, appealing to eco-conscious consumers and stakeholders.

Real-World Success Stories

Numerous food production companies have experienced significant improvements in their operations after integrating sanitary butterfly valves from Freture Techno Pvt. Ltd. These success stories highlight reduced contamination risks, lower maintenance costs, and enhanced product quality. For instance, a dairy processing plant reported a 20% increase in productivity and a notable reduction in product recalls due to improved hygiene and reliability of the valves.

Conclusion

The role of sanitary butterfly valves in food production cannot be overstated. Their benefits, ranging from superior hygiene and ease of maintenance to precise flow control and cost-effectiveness, make them an indispensable component in the industry. Companies like Freture Techno Pvt. Ltd. are at the forefront of manufacturing these essential valves, providing high-quality, reliable solutions that meet the rigorous demands of modern food production.

As the food industry continues to evolve, the importance of maintaining stringent hygiene standards and operational efficiency remains paramount. Sanitary butterfly valves offer a robust solution to these challenges, ensuring that food products are safe, high-quality, and produced efficiently. By investing in these valves, food producers can not only enhance their production processes but also ensure compliance with international standards, ultimately leading to greater consumer trust and satisfaction.

Freture Techno Pvt. Ltd., with its expertise and commitment to quality, stands as a trusted partner for food producers seeking reliable and innovative sanitary butterfly valves. Based in Mumbai, India, the company continues to lead the way in delivering exceptional products that drive the success of food production facilities worldwide.

1 note

·

View note

Text

0 notes

Text

Industrial Boilers and Parts Manufacturer & Supplier in Pune, India

Industrial Boilers and Parts Manufacturer & Supplier in Pune, India.

Sterling Engineers and Boilers Pvt. Ltd.

Top Industrial Boiler Pressure Parts Manufacturers in Pune

Founded in the year 2012, Sterling Engineers & Boilers Private Limited has admirable position in manufacturing and service providing of Industrial MFG, Pressure Vessel Tank, Industrial Tanks, Industrial BoilersCharcoal Filter, Regeneration Oxidation Plant, Industrial Piping Service Ducting Service. These products are extremely admired owing to their top nominal costs. Our products are developed employing the industry permitted and advanced technique. We Are Manufacturer Industrial MS Chimney Manufacturers in Pune | Boiler Pressure Parts In Pune | Industrial Pressure Vessel In Pune | Industrial Storage Tank In Pune | Industrial Bending Service In Pune | Industrial Fire Fighting System In Pune | Hot and cold insulation industrial piping service In Pune | Structural Fabrication Services In Pune | Industrial MS Chimney Suppliers in Pune.

Quality Assurance

Client Satisfaction

Mass Man Power

+91-968-901-1211 CALL US

Popular Products

Our company is committed to design, manufacture, supply, erect and commission Boiler Pressure Parts and its equipments in scheduled time as per the quality norms to the utmost satisfaction of our clients.

Pressure Vessel Tank:Fabricated chimneys manufactured with /without flanges or readymade pipes with all accessories used to discharge gases.

Industrial Chimney:Capacity from 1 KL to 10000000 Kl for Steam,water,molasses, Liquids, Petrol, Diesel, Chemical and all forms of semi liquids, liquids with or without lining

Industrial Tanks:While engrossing on varied demands of many industries, we have been offering SS Pressure Vessel Tank that is used for specific purposes.

OUR PRODUCTS

Industrial Chimney:

India’s Best manufacture company of Industrial MS Chimney In Pune

One of India’s premier manufacturers of Industrial MS Chimneys in Pune is renowned for its excellence in designing and fabricating high-quality chimney solutions for industrial applications. With a rich history of delivering reliable and efficient chimneys, this company combines cutting-edge technology with skilled craftsmanship. Their chimneys are built to withstand harsh industrial environments, ensuring durability and safety. They offer custom design and engineering services to meet specific client requirements, adhering to stringent quality standards and regulatory compliance. With a commitment to innovation and customer satisfaction, this company is a trusted partner for industrial chimney solutions in Pune and beyond.(https://www.sterlingengineers.in/industrial-ms-chimney-pune

2. Piping Services:

Supply, Fabrication, Welding, Laying & Testing of Pipelines (AG & UG) along with supply of pipe, pipe fittings, valves etc. We have capable supplier chain with us for supply of required pipe material along with fittings as per client spec. We execute pipe fabrication & laying projects for water reagent steam process in chemical plants, pharma plants, refineries, fertilizer plants, dairy plants, food processing units, sugar plants etc.Pune hosts India’s foremost manufacturer of diverse industrial piping solutions. Renowned for their expertise, they provide a wide range of high-quality piping products tailored to meet the rigorous demands of industrial applications. Trusted for their precision engineering and reliability, they are the industry leader in Pune.(https://www.sterlingengineers.in/industrial-piping-service-pune)

3. Boiler Pressure Parts:

Best manufacturers company of 80 TPH High pressure boiler in Pune

In Pune, one of the standout manufacturers for 80 TPH high-pressure boilers is renowned for its exceptional expertise and quality offerings. With a rich history of engineering excellence, this company specializes in crafting cutting-edge, high-capacity boilers capable of withstanding extreme pressures. These 80 TPH boilers are designed for industries that demand substantial steam generation, like power plants and large manufacturing units. The company’s commitment to innovation, precision engineering, and adherence to stringent quality standards make it a trusted provider in Pune. They ensure reliable and energy-efficient solutions, reflecting their dedication to meeting the demanding requirements of high-pressure industrial applications.(https://www.sterlingengineers.in/80-tph-high-pressure-boiler-pune)

4. Pressure Vessel:Best manufacturers company of industrial pressure vessels in Pune

Spherical or cylindrical subjected to internal pressure of steam or liquids. In Pune, a leading manufacturer stands out as the go-to provider for industrial pressure vessels. Renowned for their exceptional craftsmanship and precision engineering, this company specializes in designing and fabricating top-quality pressure vessels for a wide range of industrial applications. Their vessels are built to meet stringent safety and performance standards, catering to the unique needs of various industries such as petrochemical, pharmaceutical, and manufacturing. With a strong commitment to innovation and quality, they offer customized solutions, ensuring reliability and durability in the most demanding environments. Trusted for their expertise and reliability, they are the preferred choice for industrial pressure vessels in Pune.(https://www.sterlingengineers.in/industrial-pressure-vessel-pune)

GET QUOTE

5. Storage Tank:Stainless Steel Storage Tanks Manufacturers in Pune

Pune boasts reputable manufacturers specializing in Stainless Steel Storage Tanks. These companies are known for their expertise in crafting high-quality, corrosion-resistant storage solutions. Utilizing premium stainless steel materials and advanced fabrication techniques, they create tanks that excel in durability and hygiene. These tanks find applications across various industries such as food and beverage, pharmaceuticals, and chemical processing, ensuring the safe and efficient storage of liquids and materials. With a commitment to precision engineering, regulatory compliance, and customization options, these manufacturers are trusted partners in Pune’s industrial landscape, delivering reliable stainless steel storage solutions that meet the stringent demands of diverse industries.(https://www.sterlingengineers.in/ss-storage-tank-pune)

6. Fire Fighting System:

Industrial Fire Protection Systems and Service in Pune

Following safety norms and industry standards, we offer highly proficient Fire Fighting Services. Fire Fighting Services are important for providing utmost protection to people in a building in case of a fire hazard. Our highly skilled and experienced professionals are equipped with the latest tools required during such scenario. They execute the service as per industrial norms, and regarded for their flexibility, effectiveness and timely implementation in any environment. Customers from across the country can avail our Fire Fighting Services at nominal rates.(https://www.sterlingengineers.in/industrial-fire-fighting-service-system-pune

7. Insulation:India’s leading manufacturer company for hot & cold insulation in Pune

All insulations (cold and hot) as required at projects along with acoustic insulation. Pune is home to India’s leading manufacturer company specializing in hot and cold insulation solutions. With a stellar reputation for excellence, this company offers top-tier insulation materials and services for a wide range of industries. Their insulation solutions are designed to enhance energy efficiency, reduce heat transfer, and maintain temperature control in industrial processes. Using cutting-edge technology and adhering to rigorous quality standards, they provide custom-tailored insulation solutions that meet the specific needs of clients across Pune and beyond. Trusted for their expertise, commitment to sustainability, and impeccable service, they are the preferred choice for hot and cold insulation solutions in India’s industrial landscape.(https://www.sterlingengineers.in/hot-cold-insulation-service-pune)

Useful Links

Projects

Our People

Resources

Our Clients

Gallery

Contact Us

Sitemap

Contact Us

+91-968-901-1211

T-71/1-A/7, General Block

MIDC, Bhosari, Pune - 411026

#Industrial MS Chimney#Boiler Pressure Parts#Industrial Pressure Vessel#Industrial Storage Tank#Industrial Bending Service#Industrial Fire Fighting System#Hot and cold insulation industrial piping service#Various Structural Fabrication Services In Pune#Maharashtra.

0 notes

Text

Supplier of SS Dairy Valves & Fittings in India

Supplier of SS Dairy Valves & Fittings in India:

About Us:

Meghmani Metal is dedicated to offering outstanding products and services to India’s dairy industry. We specialize in Supplier high-quality stainless steel valves and fittings for dairy and food processing firms and have over 5 years of expertise in the field.

Our goods are made to the highest standards and come in a variety of sizes and…

View On WordPress

#Ahmedabad#Gujarat#India#SS Dairy Valves & Fittings#Stainless Steel Dairy Valves & Fittings#Stockiest#Suppliers

0 notes

Text

India's leading manufacturer of round bars

Piping Project.in is a well-known Round Bar Manufacturer in India. Our Round Bar is known for its great corrosion resistance and ability to perform well in a variety of environments. It works effectively in high-temperature and high-pressure situations, providing stability and support to a variety of equipment. Round bar stock is widely utilized in pump shafts, valves, dairy equipment, surgical components, machine tools, and other applications. In addition, we are asignificant Valves Supplier in India.

We stand out in the Indian market as a reliable and customer-centric round bar manufacturer. With a robust distribution network and a focus on customer satisfaction, the company has earned a reputation for timely deliveries and competitive pricing.

We have a verified Round Bar Weight Chart in kg,mm,PDF that provides measurements in both kilos and millimeters.

The table below displays the weights of our round bars in kilograms per metre (kg/m) for various diameters and wall thicknesses. It is crucial to note that the weights in this table are estimations and may differ depending on the steel variety and manufacturing techniques employed.

Product source: Round Bar

#Round Bar Manufacturer in India#Valves Supplier in India#Round Bar Supplier in India#round bar manufacturer#Round Bar Weight Chart in kg#mm#PDF

0 notes

Text

Exporter of Spray Dryer in Ghana

Drytech Engineering Systems is an Exporter of Spray Dryer in Ghana.

Drytech Engineering Systems is Based in Ahmedabad, Gujarat, India.

We are a Manufacturer, Supplier, Stockiest, and Exporter of Flash Dryers, Spray Dryers, Spin Flash Dryers,

Fluid Bed Dryers, and Evaporator Dryers, Rotary Valves, Rotary Atomizers, Hot Air Generators,

Centrifugal Blowers, and Dust Collector Systems.

we adhere to international standards, ensuring top-notch performance and reliability across

various industries.

Spray dryers are broadly classified into two types based on the method of atomization.

Nozzle Spray Dryers

Rotary Atomiser Spray Dryers

Our team of experts is dedicated to providing you with the best spray-drying solutions,

ensuring your complete satisfaction.

We stand by the quality of our products and offer comprehensive support and maintenance services.

Why Choose Our Spray Dryers?

1. Innovative Technology

Our spray dryers utilize cutting-edge technology to ensure uniform drying, high efficiency, and consistent product quality.

2. Precision Control

Achieve precise control over the drying process with our advanced systems, ensuring optimal moisture content and particle size.

3. Energy Efficiency

Designed to minimize energy consumption, our spray dryers offer cost-effective solutions while maintaining superior performance.

4. Customizable Solutions

We provide customizable spray drying solutions tailored to meet your specific production requirements, ensuring maximum flexibility and productivity.

5. Versatile Applications

Suitable for a wide range of applications, our spray dryers are perfect for the food, pharmaceutical, chemical, and dairy industries.

Drytech Engineering Systems is an Exporter of Spray Dryer in Ghana including locations like Kumasi, Tamale, Sekondi-Takoradi, Ashaiman, Sunyani, Cape Coast, Obuasi, Teshie, Tema, Madina, Koforidua, Wa, Techiman, Ho, Nungua, Lashibi, Dome, Tema New Town, Gbawe, Oduponkpehe, Ejura, Taifa, Bawku, Aflao, Agona Swedru, Bolgatanga, Tafo, Berekum, Nkawkaw, Akim Oda, Winneba, Hohoe, Yendi, Suhum, Kintampo, Adenta East, Nsawam, Mampong, Konongo, Asamankese, Wenchi, Savelugu, Agogo, Anloga, Prestea, Effiakuma, Tarkwa, Elmina, Dunkwa-on-Offin, Begoro, Kpandu, Kintampo, Navrongo, Axim, Apam, Salaga, Saltpond, Akwatia, Shama, Keta, Nyakrom, Bibiani, Somanya.

For detailed information and inquiries, please feel free to contact us.

View Product: Click Here

Read the full article

0 notes

Text

Why Modular Cold Rooms are the Future of Cold Storage?

Modular Cold Rooms serve as a vital link in meeting the evolving demands for improved storage and transportation facilities, particularly for small and medium-sized enterprises. These on-site cold storage spaces are customisable in size and capacity, catering to the diverse requirements of various industries like:

Hospitality

Supermarket and retail

Plant cultivation and floriculture

Medications

Seafood and dairy products

Facilities for preparing meat, ripening and processing food

Additional specialised applications

Modular Cold Room is the future of Cold Storage because of the following reasons:

Adaptability - Versatility is the hallmark of Modular Cold Rooms, allowing businesses to tailor the storage space according to their specific needs. Whether it's adjusting refrigeration types, storage capacity, size and thickness, or implementing strip curtains, these rooms offer flexibility for future scalability or expansion.

Simple and Fast Installation - In the building sector, speed is crucial and prefabricated structures can expedite the installation process. With parts prepared in the production facility, assembly is swift and labour is utilised efficiently. This enables you to promptly establish and start utilising modular cold storage facilities.

Mobility - In contrast to traditional construction methods, modular cold rooms offer the advantage of easy assembly, disassembly, and relocation. This makes them beneficial for businesses with fluctuating trade volumes, allowing flexibility to adapt to varying needs over time.

Security & Safety - Reputable suppliers always prioritise the security and safety of modular cold storage. They ensure this by providing control valves and safety switches, along with features that guarantee smooth operation and employee safety.

Trustworthiness - Modular Cold Rooms provide extensive solutions for cold storage needs. They outperform fixed cold rooms in terms of operations, refrigeration capacity, and energy efficiency, regardless of size or modular features.

Total command - Many companies are concerned that the ease of modular cold rooms come at the expense of maintaining proper temperature. However this is not the case every time, instead Cold rooms typically feature microprocessor based electrical control panels for maintaining the proper temperature.

The Efficiency of Energy - Various factors such as the compressor, evaporator, condenser fan motors, type of refrigerator, and insulation materials in walls, doors, and flooring contribute to the energy efficiency of a cold room. To ensure efficient temperature control and overall energy savings, modular rooms are constructed using food-safe, high-density insulated sandwich panels with optimal thermal insulation and fire ratings.

Minimal upkeep - In the long run, regular check-ups are far simpler and less expensive than fixing problems as they arise. Opting for a regular cold room installation from a trusted supplier can simplify routine maintenance tasks and extend the cold room’s lifespan.

Mechair Industries is one of the leading modular cold room manufacturers in India. To get more details about our products, visit our website https://www.mechair.in/

0 notes

Text

Why Modular Cold Rooms Are The Future Of Cold Storage?

According to a Colliers analysis, India's cold storage capacity is predicted to increase by 8.2% from 2020 to 40.7 million metric tons by 2023. Modular cold rooms can assist bridge the gap in the market for small and medium-sized cold rooms as attention moves toward improved storage and transportation facilities. Thus, here are some explanations for why modular cold rooms are the way of the future for cold storage in case you're still not sure if you should install one for your company.

The Modular Cold Rooms

Modular cold rooms are on-site, small to medium-sized cold storage spaces that may be customized in size and capacity to meet your company's requirements. Modular cold rooms are able to accommodate different needs for cold storage.

Hospitality

Supermarkets and retail

Plant cultivation and floriculture

Medications

Seafood and dairy products

Facilities for preparing meat, ripening food, and processing food

Additional specialized applications

Modular Cold Rooms: The Future of Cold Storage for Nine Reasons

Due to their numerous demonstrated advantages, modular cold rooms are increasingly being chosen by a large number of businesses. Now let's go more specific.

1.Adaptability

Modular cold rooms are renowned for their outstanding versatility because they are made to accommodate the various needs of enterprises. You can select based on your storage needs, whether it's on the type of refrigeration system, storage capacity, size and thickness, or use of strip curtains. As a matter of fact, their modular design allows for easy future scalability or expansion.

2.Simple Installation and fast

In the building sector, speed is crucial, and prefabricated structures can facilitate simple and rapid installation. When the parts are prepared in the production facility, they may be quickly and labor-efficiently assembled on site. This implies that you can quickly set up and begin using your modular cold storage!

3.Mobility

Unlike traditional construction, modular cold rooms are readily erected, disassembled, and transferred to new locations. Thus, you may get the most out of these small to medium-sized modular cool rooms if your trade volumes are higher at a particular period of the year.

4.Security and Safety

The security and safety of the modular cold storage will be guaranteed by a reputable supplier of cold storage systems. In addition to control valves and safety switches, they have features that guarantee trouble-free operation and employee safety.

5.Trustworthiness

Without a doubt, modular cold rooms offer comprehensive cold storage solutions. When compared to fixed cool rooms, their performance in terms of operations, refrigeration capacity, and energy efficiency is unmatched, regardless of their size and modular features.

6.Total command

Many companies could be concerned that the ease of use of modular cold rooms could come at the expense of maintaining proper temperature. This is not at all the case, though. Indeed, these cold rooms typically have microprocessor-based electrical control panels installed.

7.The efficiency of energy

The compressor, evaporator, and condenser fan motors, the kind of refrigerant used, the insulation in the walls, doors, and flooring, and other elements all affect how energy-efficient a cold room is. For efficient temperature control and overall energy economy, the walls, doors, and ceilings of modular cold rooms, for example, are constructed from food-safe, high-density insulated sandwiched panels with an ideal thermal insulation and fire rating.

8.Minimal upkeep

In the long run, regular checkups are far simpler and less expensive than fixing problems as they arise. Having said that, installing a modular cold room from a reputable supplier can make routine maintenance easier and prolong the cold room's useful life.

9.Adaptability

Modular cold rooms are a flexible option, even though they are often utilized for small to medium-sized cold storage needs. Customizing the panel material and thickness as well as the refrigeration system to maintain the necessary temperatures for an extended period of time will allow these cold rooms to be utilized as freezers or chillers under ambient settings.

Modular Cold Room Features That Provide Extra Benefit

These BLUEICE modular cold room features and specs will provide you with the much-needed operating edge.

High-density PUR wall and ceiling panels that are safe for food and have a class O fire response rating in line with BS 476.

With an evaporator, two distinct refrigeration systems are used to keep cold room temperatures at +4°C and -18°C.

Air-cooled condenser unit using R407C/R404A refrigerant and a reciprocating compressor

integrated pressure safety switches

Regulators

Fully functional electrical control panel featuring temperature controller based on microprocessor

simpler to set up

Provide better insulation against heat.

Energy-efficient operations

Last Remarks

There is no going back to modular cold rooms! These cold storage facilities, which prioritize food safety and accessibility, can serve as a bridge for small to medium-sized cold rooms. Modular cool rooms are becoming a popular option because of their energy efficiency, ease of installation, and low maintenance requirements. They may also be used in a variety of sectors.

Get in touch with us and know how we can help you fulfil your cold storage needs in an effective and affordable way!

Cold Storage with Low Relative Humidity

You may need to store your seeds for a variety of reasons. Numerous items are made to maintain particular ratios of humidity and temperature, such as high humidity in germination chambers and medium temperature with low relative humidity for long-term seed storage. For the majority of seeds, these circumstances are ideal as they maximize germination rates.

Controlling temperature and humidity levels are essential for cold storage. Ideal conditions are essential for seed storage in particular to preserve viability and prevent discoloration, fungal development, and toxin generation. Ageing is the term for the metabolic processes that seeds go through even while they are dormant. A high humidity level can cause aging or degradation, yet too low humidity can lead to a decline in the viability.

Visit site

Contact us: 8866230337

Visit us: [email protected]

#Cold Storage Room Manufacturer in India#best cold room manufacturers in india#best cold storage manufacturers in india#cold storage manufacturing companies in india#cold storage room manufacturers#cold room supplier#cold storage supplier india#cold room manufacturers in india#cold storage manufacturers in india#cold storage manufacturers#cold room manufacturers#CA Cold Storage#controlled atmosphere chamber#cold storage room manufacturer#cold storage manufacturer in india#cold room manufacturer#cold storage manufacturer#cold room manufacturer in india#cold storage manufacturer in gujarat

0 notes

Text

AVC Valves India: ABC Valves India is a well-known producer of superior Globe Valves India. To satisfy the needs of various industries, they provide a wide variety of diameters, materials, and end connections. They are renowned for the strength, dependability, and exceptional flow control of their valves.Gate Valves Manufacturers in India and exporter of premium Ball Valves. They provide a wide variety of sizes, materials, and combinations to guarantee dependable performance and effective flow control.

0 notes

Text

MS Seamless Pipe in Uttar Pradesh

is a Manufacturer and Supplier of MS Seamless Pipe in Uttar Pradesh, India.

We established our company in 2011 in Ahmedabad, Gujarat, India.

An MS Seamless Pipe, also known as a Mild Steel Seamless Pipe, is a type of pipe that is made from mild steel, a type of carbon steel alloy.

we pride ourselves on delivering the highest quality seamless pipes that cater to diverse needs.

We specialize in manufacturing and supplying a wide range of stainless steel products, including SS sheets, plates, and coils, SS bars, wires, and rods, SS pipes and tubes, angles, channels, and flats, as well as industrial valves, dairy valves, and fittings.

Features of MS Seamless Pipes:

Seamless Construction: Manufactured without any welds, ensuring uniform strength and resistance to pressure.

Corrosion Resistance: Our pipes are treated to withstand harsh environmental conditions, minimizing maintenance needs.

High Tensile Strength: Designed to handle heavy loads and extreme pressures, making them ideal for demanding applications.

Versatile Sizes and Dimensions: Available in a range of sizes and wall thicknesses to suit various industrial needs.

Specifications:

Material: Mild steel (MS)

Size range: 1/2 inch to 24 inches

Wall thickness: 1.5 mm to 100 mm

Length: Up to 12 meters

Applications:

Oil and gas

Power generation

Construction

Automotive

Meghmani Metal Industries is a Supplier of MS Seamless Pipe in Uttar Pradesh, India including locations Kanpur, Lucknow, Ghaziabad, Agra, Meerut, Varanasi, Prayagraj, Bareilly, Aligarh, Moradabad, Saharanpur, Gorakhpur, Noida, Firozabad, Jhansi, Muzaffarnagar, Mathura-Vrindavan, Budaun, Rampur, Shahjahanpur, Farrukhabad-Fatehgarh, Ayodhya, Maunath Bhanjan, Hapur, Etawah, Mirzapur-Vindhyachal, Bulandshahr, Sambhal, Amroha, Hardoi, Fatehpur, Raebareli, Orai, Sitapur, Bahraich, Modinagar, Unnao, Jaunpur, Lakhimpur, Hathras, Banda, Pilibhit, Barabanki, Khurja, Gonda, Mainpuri, Lalitpur, Etah, Deoria, Ghazipur.

Feel free to contact us for more information and inquiries.

View Product: Click Here

Read the full article

0 notes