#crusher parts suppliers in India

Explore tagged Tumblr posts

Text

crusher parts suppliers

Vishal Engi �� Chem specialized in manufacturing crusher spares, which includes parts made from high-quality manganese steel Jaw plates, cheek plates, Hammers for Hammer mills, shredder spares, cone crusher mantles, concaves, liners for ball mill, gyratory crusher parts, Eccentric bush from non-ferrous alloy castings. We are capable enough to produce a casting of steel products weighing 10 to 2000 kg for a single piece. Our firm ensures the quality expectations of our customer’s requirements as per national and international standards.

0 notes

Text

Rockstar 400 Plate

In industrial environments, wear and abrasion are common challenges that can significantly impact the longevity and efficiency of machinery and components. This is where Rockstar 400 Plate comes into play. With its superior hardness and durability, the Rockstar 400 Plate offers exceptional resistance to abrasion, making it a top choice for industries seeking to extend the service life of their equipment. In this article, we will explore what Rockstar 400 Plate is, its key properties, specifications, benefits, and applications. We will also explain why Vandan Steel & Engg. Co. is the go-to choice for all your Rockstar 400 Plate needs.

What is Rockstar 400 Plate? The Rockstar 400 Plate is a type of abrasion-resistant steel plate known for its high hardness and strength. Made from high-quality wear-resistant steel, the plate is designed to withstand harsh conditions where abrasion and impact are significant concerns. Rockstar 400 Plates are commonly used in industries where heavy wear and tear are common, such as mining, construction, and metallurgy.

Specifications of Rockstar 400 Plate Item: Abrasion Resistant Plate Thickness: 6mm to 75mm Length: 6,000mm to 12,000mm Width: 1,500mm to 2,500mm Production: Hot-Rolled (HR) / Cold-Rolled (CR) Heat Treatment: N (Normalizing), Q+T (Quenching and Tempering) Material Options: Rockstar 400 Abrasion Resistant Steel Plates, Rockstar 400 Wear Resistant Plates

Benefits of Using Rockstar 400 Plate Extended Equipment Lifespan: The high abrasion resistance of the Rockstar 400 Plate helps reduce wear and tear on equipment, thus extending the lifespan of machinery components. Reduced Maintenance Costs: Less frequent maintenance and replacement of parts lead to significant cost savings over time. Improved Operational Efficiency: By minimizing downtime associated with maintenance, businesses can maintain higher productivity levels. Versatile Applications: The plate's machinability and fabricability make it suitable for various applications across different industries. Enhanced Safety: With its toughness and resistance to cracking, the Rockstar 400 Plate contributes to the structural safety of machinery and equipment.

Applications of Rockstar 400 Plate Rockstar 400 Plate is used in a wide range of industries where abrasion resistance is crucial. Some of the common applications include:

Mining Machinery: The plate is ideal for use in chutes, hoppers, crushers, and conveyor systems, where wear is a frequent issue. Construction Machinery: Used in bulldozers, loaders, excavators, and dump trucks to protect against abrasion. Concrete Industry: Suitable for concrete mixers, molds, and equipment exposed to abrasive materials. Coal Industry: Used in the manufacturing of coal handling equipment to resist wear from coal particles. Metallurgy: Applied in blast furnaces, steel plants, and other equipment exposed to high temperatures and abrasive materials. Fan Industry: Protects fan blades and housings from erosion caused by dust and particles.

Why Choose Vandan Steel & Engg. Co. for Rockstar 400 Plates? When it comes to acquiring the highest quality Rockstar 400 Plate, Vandan Steel & Engg. Co. stands out as a leading choice. Here's why:

Expertise in the Industry: Vandan Steel & Engg. Co. has years of experience in manufacturing, exporting, and supplying high-quality abrasion-resistant plates. Their expertise ensures that you receive products that meet stringent industry standards. Wide Product Range: As stockists of a variety of abrasion-resistant steel plates, they provide a range of thicknesses, sizes, and specifications to suit different industrial requirements. Quality Assurance: All products go through rigorous quality checks to ensure they meet international standards for abrasion resistance, hardness, and mechanical properties. Global Reach: Vandan Steel & Engg. Co. caters to clients not only in India but also around the world, making them a trusted global supplier. Customer-Centric Approach: Their dedicated team offers technical support and guidance to help you choose the right plate for your application.

Conclusion The Rockstar 400 Plate is an essential material for industries dealing with high abrasion environments. Its exceptional hardness, toughness, and wear resistance make it a preferred choice for applications in mining, construction, and more. Choosing the right supplier is crucial, and Vandan Steel & Engg. Co. has proven expertise in providing top-notch Rockstar 400 Plates to meet various industrial needs. With a focus on quality, customer service, and a wide range of options, Vandan Steel & Engg. Co. ensures you get the best abrasion-resistant plates to enhance your operations.

Contact Vandan Steel & Engg. Co. For more information on Rockstar 400 Plates and other abrasion-resistant materials, get in touch with Vandan Steel & Engg. Co.

Contact Number: +91-8828813630 Email: [email protected] Website: www.wearplates.co.in Ensure your equipment stays protected and operates efficiently by choosing high-quality Rockstar 400 Plates from Vandan Steel & Engg. Co.

#Rockstar 400#Rockstar 400 Plate#Rockstar 400 Plate Manufacturers#Rockstar 400 Plate Suppliers#Rockstar 400 Plate Stockists#Rockstar 400 Plate Exporters#Rockstar 400 Plate Manufacturers in India#Rockstar 400 Plate Suppliers in India#Rockstar 400 Plate Stockists in India#Rockstar 400 Plate Exporters in India#stockists#exporters#suppliers#manufacturers#innovation#metalwork#manufacturer#wear plates#wearplates#india#mumbai#maharashtra#punjab#delhi#vandan steel

1 note

·

View note

Text

How to Choose the Right Cattle Feed Making Machine?

Best Cattle Feed Making Machine Manufacturers

Raising healthy, productive cattle requires providing them with nutritious feed tailored to their specific needs. While buying pre-made feed is certainly an option, many farmers are turning to Cattle Feed Making Machine, offering greater control over ingredients, costs, and nutritional content. But with so many options available, choosing the right machine can be overwhelming. This guide will walk you through the essential factors to consider, highlight top features, and even introduce you to reputable Cattle Feed Making Machine Manufacturers like Keyul Enterprise in Mumbai, India.

Understanding Your Needs of Cattle Feed Making Machine

Before diving into the world of Cattle Feed Making Machines, it's crucial to understand your specific requirements. Consider the following:

Herd Size: Smaller herds might be well-served by compact machines, while larger operations necessitate higher capacity models.

Desired Feed Type: Machines differ in their ability to process various ingredients like grains, hay, silage, and even Wood Sawdust (processed and used responsibly).

Power Source: Choose between electric, diesel, or gasoline options based on your farm's infrastructure and energy costs.

Budget: Set a realistic budget and compare prices from different Cattle Feed Making Machine Suppliers and Exporters in Mumbai, India, and beyond.

Key Features to Look For: Cattle Feed Making Machines

Now that you know your needs, let's explore the features that make a Cattle Feed Making Machine exceptional:

Durability: Invest in a machine built to last, using high-quality materials and robust construction. Look for warranties and service support offered by the manufacturer.

Ease of Use: Simple operation is key, especially for those new to feed making. Intuitive controls, clear instructions, and readily available spare parts are crucial.

Versatility: Some machines offer additional functionalities like grinding, mixing, and pelleting, allowing you to create a wider range of feed options.

Safety: Prioritize features like emergency shut-offs, proper guards, and noise reduction for a safe working environment.

Cleaning and Maintenance: Choose a machine designed for easy cleaning and regular maintenance to ensure optimal performance and longevity.

Exploring Best Cattle Feed Making Machine Options

With a clearer understanding of your needs and desired features, delve into the exciting world of Cattle Feed Making Machines. Here are some specific types to consider:

Chaff Cutter Machine: Ideal for chopping hay, silage, and other roughage into manageable sizes for easier digestion.

Wood Pellet Making Machine: Turns processed wood waste into a sustainable and cost-effective feed ingredient (when used responsibly).

Wood Crusher Machine: Reduces wood into smaller particles before processing into pellets or using in feed mixes.

Cow Dung Dewatering Machine: Extracts valuable nutrients from cow dung and concentrates them for inclusion in feed, promoting sustainability and waste reduction.

Finding the Right Cattle Feed Making Machines Supplier and Exporters

Choosing the right Cattle Feed Making Machine Manufacturers and Exporters is crucial for a smooth experience. Look for companies with:

A proven track record: Extensive experience and positive customer reviews speak volumes about their quality and reliability.

Wide range of options: Find a supplier offering various machine types and capacities to match your specific needs.

Competitive pricing: Compare prices and offerings from multiple suppliers to ensure you get the best value.

Customer support: A responsive and knowledgeable support team is invaluable for troubleshooting and maintenance assistance.

Keyul Enterprise: Your Partner in Animal Feed Making Machine

Located in Mumbai, India, Keyul Enterprise stands out as a leading Cattle Feed Making Machine Manufacturer. They offer a diverse range of high-quality machines, from Chaff Cutter Machines to Wood Pellet Making Machines, all catering to the specific needs of Indian farmers. Their commitment to innovation, affordability, and excellent customer service makes them a trusted partner for your feed-making journey.

Conclusion: Cow Feed Making Machine

Choosing the right Cattle Feed Making Machine empowers you to provide your cattle with optimal nutrition, control costs, and even embrace sustainable practices. By considering your needs, prioritizing key features, and exploring reputable suppliers like Keyul Enterprise, you can make an informed decision and unlock the benefits of customized feed production for your herd. Remember, with the right machine and knowledge, you can transform your cattle farming operation and pave the way for a healthier, more productive future.

#Cattle Feed Making Machine#Best Cattle Feed Making Machine#Top Cattle Feed Making Machine#Quality Cattle Feed Making Machine

1 note

·

View note

Text

Apollo Paver Parts in India, Paver Solid Rubber Tyre in India, Solid Rubber Tyre in India

The Apollo Paver is a prominent piece of construction equipment utilised in projects all throughout India. It is well-known for its toughness, dependability, and great performance. However, Apollo Paver Parts, like any heavy gear, require regular maintenance and replacement to ensure optimal performance Apollo Paver Parts in India.

There are numerous Apollo Paver Parts providers in India, but it is critical to select a reputable supplier who can deliver high-quality parts that are built to last. These components include screed plates, auger blades, conveyor chains, and other key components required for the paver to operate well Kishan Industries.

One of the primary benefits of using high-quality Apollo Paver Parts is that they can assist extends the paver's lifespan. By employing high-quality parts, the paver can work at its best, lowering the likelihood of problems and assuring efficient operation.

We specialise in delivering high-quality Apollo Paver Parts in India at [business name]. Our parts are intended to suit the paver's exact specifications, guaranteeing that they fit perfectly and perform optimally. We make our parts with high-quality materials and innovative technologies to ensure that they are long-lasting, dependable, and work well.

Solid rubber tyres are a popular choice for Indian pavers since they have various advantages over typical pneumatic tyres. Pneumatic tyres are prone to punctures and necessitate routine maintenance, which can be expensive and time-consuming. Solid rubber tyres, on the other hand, require no maintenance and can give higher traction and stability, making them an excellent choice for Paver Solid Rubber Tyre in India.

We specialise in delivering high-quality Paver Solid Rubber Tyres in India at [business name]. Our tyres are comprised of high-quality rubber compounds that are intended to endure big loads while also providing outstanding traction and stability on a variety of surfaces.

Our solid rubber tyres have a longer lifespan than conventional pneumatic tyres, which is one of their key benefits. Customers will benefit from lower maintenance and replacement expenses as well as longer paver lifespans and more effective operation.

Our Paver Solid Rubber Tyres are also made to offer superior stability, lowering the risk of accidents and enhancing worker safety. Additionally, they can be used in a variety of weather conditions, guaranteeing that the paver will function properly in any setting.

Traditional pneumatic tyres used to be the only option for large machinery like crushers and other equipment. But they might be expensive and time-consuming to maintain regularly because they were prone to punctures. That is, up to the introduction of Solid Rubber Tyre in India.

Solid rubber tyres are more resilient and long-lasting than conventional compressor tyres because they are comprised of high-quality rubber compounds. Additionally, because they don't require any maintenance, clients may end up saving money over time.

Solid Rubber Tyres of the highest calibre are our area of expertise at [business name] in India. Our tyres are perfect for use in pavers since they have been constructed to handle big loads and offer outstanding grip and stability on a variety of terrain.

Solid rubber tyres have superior stability, which lowers the risk of accidents and increases workplace safety. This is one of its key benefits. Additionally, they may be used in a variety of weather situations, making pavers effective in any setting.

Solid rubber tyres are not only stable and long-lasting, but also ecologically benign. They are an environmentally responsible replacement for conventional tyres since they are created from recycled materials.

https://www.kishanindustries.in/paver-parts-products-details.html

1 note

·

View note

Text

What types of industries require hearing protection?

Hearing protection is an essential part of workplace safety in many industries. Exposure to loud noises over a prolonged period can result in hearing damage and loss, which can be irreversible. Therefore, it's important to understand which industries require hearing protection and how safety product equipment suppliers in India can help provide adequate safety products.

Construction and manufacturing industries are among the top industries that require hearing protection. These industries often involve the use of heavy machinery and power tools, which can generate high levels of noise. Without proper hearing protection, workers in these industries are at risk of hearing damage and loss.

Mining is another industry where hearing protection is crucial. Underground mining equipment, such as drills and rock crushers, can generate intense noise levels that can damage workers' hearing. Additionally, surface mining operations, such as blasting, can create loud, concussive noises that require hearing protection.

The transportation industry also needs Safety product equipment suppliers distributors in India. Workers who operate or work around airplanes, helicopters, and other heavy equipment may be exposed to high levels of noise. Airports and other transportation hubs may also have a noisy environment, which necessitates the use of hearing protection.

In the entertainment industry, hearing protection is required for musicians, sound technicians, and others who work in concert venues and studios. Exposure to loud music and sound equipment can result in permanent hearing loss, which can have severe consequences for those working in the industry. Therefore, it's essential to have safety products supplier in India that can provide suitable hearing protection for these workers.

Apart from these industries, workers in agriculture, forestry, and the military may also require hearing protection. In agricultural and forestry industries, loud machinery such as chainsaws and tractors can produce high levels of noise. Military personnel may be exposed to gunfire, explosions, and other loud noises, which can cause hearing damage.

Safety product equipment suppliers distributors in India play a vital role in providing hearing protection products for workers in these industries. They offer a wide range of safety products, including earplugs, earmuffs, and custom-molded hearing protection devices. By working with a reliable supplier, employers can ensure that their workers have access to the right hearing protection products.

In conclusion, hearing protection is necessary in several industries to prevent hearing damage and loss among workers. Employers in these industries should prioritize worker safety by providing adequate hearing protection. Safety product equipment suppliers in India can help ensure that employers have access to high-quality safety products that meet the needs of their workers. By working together, we can create a safer working environment for everyone.

#industrial hand gloves supplier in india#industrial safety products supplier#industrial safety hand gloves supplier in india#safety products supplier in india

0 notes

Link

#r ring#r rings#piston ring#piston ring gaps#piston ring exporters#piston ring suppliers#Cone Crusher Spare Parts#Cone Crusher Piston Rings in India

0 notes

Text

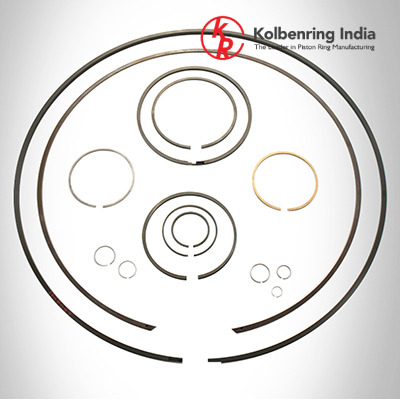

Piston Rings Supplier in India | Custom Piston Ring Manufacturers in India

We are leading Custom Piston Ring Supplier in India with highest quality piston rings with low rates. Browse our custom piston ring photo gallery here.

For More Details Kolbenring India

Contact no: +91 79 22870742 Mail id: [email protected] URL: www.kolbenringindia.com

#Piston Rings Supplier in India#Cone Crusher Spare Parts#Piston Ring Set in India#Piston Seals#Seal Rings

0 notes

Text

Best Franchise options in Bangalore

If you are looking for the best m sand Franchise Options in Bangalore, then you don’t need to be worry about option of franchise in Bangalore India related sand suppliers in Bangalore. Stona Sand is one of the best company for the option of Plastering Sand Suppliers in Bangalore as well as for the concrete sand supplier in Bangalore and many more for fast growing construction industry. We offer best franchise options in Bangalore in various construction materials which you can browse through based on the category.

Demand for franchise in Bangalore for m-sand

Buy quality construction sand online at best prices in Bangalore. There is great demand for m sand Bangalore. M sand is an alternative for river sand. Due to fast growing construction industry, the demand for sand has increased tremendously, causing deficiency of suitable river sand in most part of the word. Manufactured sand (M Sand) is a substitute of river sand for concrete construction. Manufactured sand is produced from hard granite stone by crushing. The m sand has required gradation of fines, physical properties such as shape, smooth surface textures and consistency which makes it the best sand suitable for construction.

Feel free to Contact Us For Franchise Options in Bangalore India

A team of highly skilled and capable individuals at your disposal making the mining industry more organized and streamlined. A very well renowned and reputed sand manufacturing brand in the Southern part of the country. We suggest and optimize a crusher setup based on the targeted market and resources in hand.

1 note

·

View note

Text

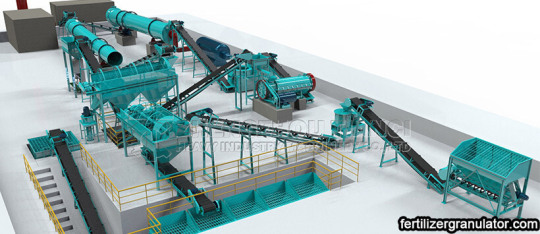

How to choose fertilizer manufacturing process plant

Fertilizer promotes the development of ecological agriculture, and the demand is huge. Investment in building fertilizer plants has become a popular project. Some investors want to build small-scale fertilizer manufacturing process to save costs, while some investors in fertilizer plants are going to build large-scale fertilizer plants to save unit production costs.

So what should we pay attention to when purchasing fertilizer manufacturing process plant? Here are some notes.

1. Determine the type of fertilizer and producton site. Determining whether to produce organic fertilizer or compound fertilizer affects the choice of site. If organic fertilizer is produced, it should not be too far from the farm where raw materials are provided. The type of fertilizer determines whether compound fertilizer equipment or organic fertilizer equipment is needed. Different types of fertilizer equipment also have differences.

2. Determine the fertilizer granulator machine. Granulation is the key link in fertilizer production and plays an important role in the quality of manufactured fertilizer. Fertilizer granules are cylindrical, spherical and flat spherical in shape. The granules produced by granulators of different shapes are different. The choice of granulator is related to the scale of fertilizer plant construction and local market. Fertilizer factories have different investment scales, different production processes, and different supporting equipment.

If a small fertilizer plant is to be built, it is suggested to configure simple machinery and equipment to reduce investment in equipment. The small fertilizer production line is composed of crusher, mixer, granulator, drum screener and automatic packing machine. If organic fertilizer fermentation is needed, it can be carried out with batten fermentation and windrow turning machine. The advantages are that they are more in line with the principle of aerobic fermentation. It is not easy to form anaerobic fermentation. The fermentation is full and complete, and the fermentation speed is fast. Forklift trucks can also be used instead of turner (the effect is not as good as turner), which can be adopted in terms of saving investment. According to the local environmental protection requirements, choose dust removal settings, where environmental protection requirements are high, choose heavy dust settings to meet the local emission quality standards.

Investment in large and medium-sized fertilizer plants, fertilizer production equipment can choose turning machine, automatic batching system, loader feeding hopper, crusher, mixer, granulator, dryer, hot stove, cooler, feeder, screener, cyclone dust collector, packing machine, etc. Increase mechanical automation, save manpower and cost. Organic fertilizer tank fermentation, can choose simple compost turning machine, double screws compost turning machine (suitable for large yield).

3. Determine the manufacturer of fertilizer manufacturing process plant. Several fertilizer machine manufacturers were inspected, and the strength, scale and reputation of the manufacturer of fertilizer equipment were fully understood. It is better to inspect the production workshop, finishing workshop and assembly workshop of the enterprise, to know the product quality, processing equipment, production process of the enterprise, and whether the fertilizer equipment produced by the manufacturer is professional. Referring to the customer cases that the manufacturer has completed, on-site test machine, the production site can best show the real operation of the equipment. Looking for fertilizer equipment suppliers with perfect after-sales service, suppliers provide professional technicians to guide customers to install and debug equipment, so that the equipment can operate normally, and provide corresponding training services.

4. Determine the safety performance of fertilizer manufacturing process plant. Safety is the first, before purchasing, we need to consider whether the production line has safety devices, whether the machine design is reasonable, whether safety factors are taken into account, whether the parts are not welded properly, whether the bolts are tightened, whether there is pollution, and so on. In addition, whether the overall operation of the equipment is smooth and whether the design of the production line is reasonable are also matters needing attention, because it relates to the efficiency and quality of the operation of the equipment. With the permission of the manufacturer, the operator can try to operate it in practice and feel its state conveniently.

Powerful organic fertilizer production equipment enterprises can customize their own equipment configurations for different customers according to their needs, and users can choose their own equipment according to their own needs. Zhengzhou Tianci Heavy Industry Machinery Co., Ltd. We provide customers with process design, equipment manufacturing, installation and commissioning, with full one-stop services. We are a leading agricultural equipment manufacturer in China, has strong technical strength in fertilizer machines. We have exported to many countries, India, Korea, Vietnam, Pakistan, Malaysia, Kenya, Sudan, Egypt, Algeria, Russia, Ukraine, Turkey, Spain, etc. Any question, welcome to contact us.

1 note

·

View note

Text

Abrex 400 Manufacturers in India

Introduction

In industries where machinery and equipment are subjected to intense conditions, the need for robust materials is paramount. Abrex 400 stands out as a premier choice for such applications, offering superior abrasion resistance and toughness. Manufactured using advanced metallurgical processes, this steel grade ensures that equipment remains operational for extended periods, reducing maintenance costs and downtime.

Overview

Abrex 400 is part of a family of abrasion-resistant (AR) steels known for their high hardness and excellent mechanical properties. These steels are designed to provide long-lasting performance in environments characterized by severe mechanical wear and impact. The unique composition and heat treatment processes used in the production of Abrex 400 contribute to its outstanding performance, making it a preferred material in several demanding applications.

Specifications

The specifications of Abrex 400 make it suitable for a wide range of industrial uses:

Hardness: 400 HBW (Brinell Hardness)

Tensile Strength: Typically ranges from 1250 to 1400 MPa

Yield Strength: Approximately 1000 MPa

Elongation: 10% in 50mm

Thickness: Available in various thicknesses, generally ranging from 6mm to 100mm

Chemical Composition: Primarily consists of carbon, manganese, chromium, and nickel, which contribute to its high hardness and strength

Advantages

Using Abrex 400 steel plates offers numerous benefits in industrial applications:

Superior Abrasion Resistance: The primary advantage of Abrex 400 is its high resistance to abrasion, which extends the life of machinery and components exposed to harsh environments.

High Strength: Its impressive tensile and yield strength make it suitable for heavy-duty applications, ensuring structural integrity under significant loads.

Enhanced Toughness: Abrex 400 maintains its toughness even in cold conditions, making it versatile for use in various climates.

Cost Efficiency: By reducing the frequency of replacements and maintenance, Abrex 400 helps in lowering overall operational costs.

Ease of Fabrication: Despite its high hardness, Abrex 400 can be cut, welded, and machined using conventional methods, allowing for easy fabrication into complex shapes and designs.

Major Industry Uses

Abrex 400 is integral to numerous industrial sectors, providing durability and reliability where they are needed most:

Mining and Quarrying: Equipment such as crushers, hoppers, conveyors, and dump truck bodies are regularly exposed to abrasive materials. Abrex 400 enhances the lifespan and performance of these components.

Construction: In construction machinery like bulldozers, excavators, and loaders, Abrex 400 is used in blades, buckets, and wear plates, ensuring these machines can handle tough tasks efficiently.

Material Handling: Sectors involving bulk material handling, such as ports and logistics centers, use Abrex 400 in chutes, feeders, and transfer points to maintain smooth and continuous operations.

Agriculture: Agricultural equipment, including plows, tillers, and harvesters, benefit from Abrex 400’s abrasion resistance, ensuring prolonged functionality in challenging environments.

Recycling: In recycling plants, where materials like glass and metal are processed, Abrex 400 is used in shredder parts, ensuring longevity despite constant abrasion.

Conclusion

Abrex 400 steel plates are crucial for industries that demand high durability and abrasion resistance in their equipment and components. By offering superior hardness, strength, and toughness, Abrex 400 ensures that machinery operates efficiently and with minimal downtime. Its wide range of industrial applications, from mining to construction, highlights its versatility and importance. Sourcing Abrex 400 from reputable suppliers ensures quality and performance, making it a vital asset in modern industrial practices. Embracing Abrex 400 means investing in enhanced productivity, reduced maintenance costs, and improved operational efficiency, solidifying its role as a critical material in today's demanding industrial landscape.

0 notes

Text

crusher parts suppliers

Vishal Engi – Chem specialized in manufacturing crusher spares, which includes parts made from high-quality manganese steel Jaw plates, cheek plates, Hammers for Hammer mills, shredder spares, cone crusher mantles, concaves, liners for ball mill, gyratory crusher parts, Eccentric bush from non-ferrous alloy castings. We are capable enough to produce a casting of steel products weighing 10 to 2000 kg for a single piece. Our firm ensures the quality expectations of our customer’s requirements as per national and international standards.

0 notes

Text

Grow your business with best jaw crusher Machine

What is Jaw Crusher?

A jaw crusher is a large piece of equipment used to crush rock in mines and ore processing plants. The device was first introduced in 1858 by inventor Eli Whitey Black, who primarily developed stone crushing machines. From there, jaw crushers have seen a lot of activity in mining and quarries, as well as in recycling processes where large materials need to be reduced.

There are Two types of Jaw Crusher:-

Single Toggle Jaw Crusher

Double Toggle Jaw Crusher

Single Toggle Vs Double Toggle

A single-toggle jaw crusher has a fixed working jaw, while a double-lever jaw crusher has two. A double toggle jaw crusher is more efficient because it has two shafts and can crush more materials at the same time. In addition, the double toggle jaw crusher is more efficient in terms of energy saving. In a single toggle jaw crusher, the pivot point is located at the bottom of the chamber. This means that the greatest movement occurs in the upper part of the chamber, where the largest stones are crushed. As the jaw moves forward, the clutch plate moves with it, pushing the material against the stationary plate. This results in crushing that is more efficient than with a double crusher. In a double toggle jaw crusher, the pivot point is located at the top of the chamber. This means that the greatest movement occurs in the lower part of the chamber, where the smallest stones break. The clamp plate is also positioned differently in the double toggle crusher, with the pivot point located behind the rocker arm. This results in smoother crushing as the material is crushed evenly throughout the chamber

Best Jaw Crusher Manufacturers & Suppliers in India

K.V.Metal Works is a well-known name in the production and marketing of industrial and construction machinery.

These machines are made with high-quality raw materials and are matched according to quality standards.

#stonecrushermachinemanufacturer#stonecrushermachine#singletogglejawcrusher#doubletogglejawcrusher#BeststonecrushermachineIndore#1singletogglejawcrusheratthebestprice#singletogglejawcrusherinIndore

0 notes

Text

CDE Asia introduces sustainable sand with the installation of Combo X70 in Omerga, Maharashtra

08 September 2022

Balaji Construction commissioned CDE Asia’s Combo X70 plant as their first sand washing unit

Balaji Construction has been catering to the construction industry for more than 2 decades and has been a pioneer in this field. They are renowned suppliers of sand & aggregates for various infrastructure projects.

On shifting from a limited feed capacity crusher to an advanced one, Mr. Sunil Mane, Owner, Balaji Construction, decided to explore the burgeoning market for M-Sand in their area by installing a sand washing plant. After extensive research, Mr. Mane resolved to commission CDE Asia’s bestseller i.e., Combo X70. For the same, he visited our Chikhli plant in Gujarat and minutely examined and discussed output quality, delivery aspects, spare parts availability, service assistance, and so on before making investments in the CDE Asia plant.

The plant has the potential to convert stone dust to industry-grade concrete sand (Zone II) and plaster sand (Zone III) which are ready for commercial use. The 70 TPH plant works at a rated power capacity of 110 KW. The key attributes of Combo X70 are its 95% water recycling capacity and limited water usage which is perfectly aligned to address the issue of water shortage in the western parts of India.

A few months later, the client also availed our Annual Maintenance Contract (AMC) for uninterrupted hassle-free service. The plant was officially launched in May 2020.

“CDE Asia has fulfilled its promise of supplying consistent and high-quality output. We are impressed by Combo X70’s design compactness, automation capabilities, eco-friendly processes, and minimal maintenance requirements. Hence, we are extremely satisfied to be associated with CDE Asia and benefit from their futuristic technology.”, said Mr. Sunil Mane, Owner, Balaji Construction.

According to Mr. Neeraj Jain, Vice President Sales, CDE Asia, “We are pleased to have been able to introduce Balaji Construction to the promising world of M-Sand through Combo X70. We are confident that superior sand washing technology from CDE Asia will give our client an edge above the competition and fulfill his marketing goals.”

The installed plant has the capacity to function at 100 KW for about 12 hours and produce an average of 20,000 tonnes of sand on a monthly basis.For more information please visit us : https://cdeasia.com/news/2022/september/cde-asia-introduces-sustainable-sand-with-the-installation-of-combo-x70-in-omerga-maharashtra .

=====================================================

Company Name: CDE Asia

Address: Ecospace Business Park Block 4A/Floor 6, Action Area II New Town Rajarhat Kolkata 700 160 India

Phone: +91 33 3029 3800

Fax: +91 33 3029 3802

Url: https://cdeasia.com/

Email : [email protected]

0 notes

Text

Properties Of Hardened Steel

Steel, an alloy of carbon and the iron, was first invented in 1800 BC in an archaeological site in Anatolia. Since then, it has been the base material for some of the world's largest infrastructures and industries. Today, steel is used to make an extensive range of products starting from sewing needles to oil tankers and everything in between. Now, it is time to understand what hardened steel means. This is a term that is given to any steel that has medium or high carbon content and has undergone heat treatment, quenching, and tempering. Owing to these three consecutive steps, hardened steel becomes the apt choice for objects that endure high abuse or force, like automotive parts, drill bits, hand tools, etc. Following are some of the significant properties of hardened steel that set them apart from others.

1. Wear-resistant

One of the significant properties of hardened steel is its ability to resist wear and tear. Any steel with a high concentration of carbon will simultaneously have a high quantity of chromium. This, when going through heat treatment, creates chromium carbide particles that enhance wear resistance. Therefore a steel strip manufacturer in India is a perfect supplier for rough use products like shovels, nozzles, surgical equipment, fine cutlery, etc.

2. Abrasion-resistant

You can often find hardened steel used to create crushers, highway truck beds, conveyors, etc., prone to sliding. What hardened steel does is it provides unfathomable resistance against sliding abrasions. Not just that, it can also withstand heavy punching and drilling like the type that can be seen in hard-rock mining and quarries.

3. Durability

Another asset that is an advantage for hardened steel strip manufacturer is its extreme durability and toughness. This indicates how much force it can withstand before showing tiny cracks and fractures. When a strip of steel that comprises manganese, chromium, and carbon undergoes heat treatment, it becomes two times harder than untreated or oil-treated steel. This makes it perfect for equipment like knives and surgical items like scalpels that experience a lot of pressure on a regular basis.

4. Magnetized permanently

Being a hardened steel strip manufacturer means creating a demagnetized material. This is another one of the properties that are exhibited owing to the stress that is induced into the metal during the hardening transformation. However, this unique property is limited to a given grade of steel where the corrosive force elevates the hardness leaving the alloys permanently magnetic in nature.

5. Elasticity

Another astonishing characteristic of hardened steel is its elasticity situation. For instance, it will surely break if you try to bend an already hardened nail. The reason behind it is the iron carbide particles in the alloy prevent it from undergoing deformation and slipping. However, if you take the same nail, heat it red hot and then try to bend it, it definitely will like plastic. Once you have created the desired shape, let it cool down slowly, and it will retain the shape.

6. Corrosion-resistant

The last notable property of hardened steel is its strength to resist corrosive materials. In most parts of the world, metals are necessary for industrial purposes. However, not every type of metal can hold against chemicals. This corrosion often affects materials and metallic surfaces resulting in high costs. This is where hardened steel comes into play. Its corrosion-resistant coating help prevents damage by harmful chemicals, potable water, salt water, environmental changes, etc.

To sum it all up

In today's world, several types of steel are in the making. Nevertheless, owing to the many properties of hardened steel and its various utility, it is an absolute favorite by the famous steel strip manufacturer in India.

#manufacturer tempered steel strip#supplier of c75 steel in india#hardened spring steel strips#hardened steel strip manufacturer#cold rolled steel strips manufacturer#tempered steel strips exporter#en47 grades steel strips#annealed steel strips manufacturer#steel strips#steel strip manufacturer in india#c45 steel strip manufacturer#annealed steel strips

0 notes

Text

Mobile Stone Crusher for Sale

Mobile Stone Crusher for Sale

Available used and fully refurbished portable mobile stone crushing plant. We are supplier and exporters of mobile crushers from India. The crushers we supply are sourced from auctions and complete sevicing and reconditioning is done at our yard by qualified engineers. We also supply spare parts for Mobile Stone Crushers. The Spare parts we supply are genuine OEM, Remake and used reconditioned,…

View On WordPress

#Business#crusher for sale#mobile cone crusher for sale#mobile crushers#mobile crushers for rock#mobile impact crusher for sale#mobile jaw crusher for sale#used mobile crusher for sale

1 note

·

View note

Text

Spear Gear Manufacturer in India | Prakash Conveyor

High quality Spear Gear Manufacturer in Ahmedabad India. Prakash Engineering & Gear Co. believe in working effectively and efficiently to deliver products that fully satisfy our customer's need. Prakash Eng. & Gear company is manufacturer and suppliers of different type of Conveyor, Crusher Gears, Bolt, Stud, High light, Gear Box, Chain Wheel & Duplex, Concrete Mixer also any spare Parts of machine.

0 notes