#mobile jaw crusher for sale

Explore tagged Tumblr posts

Text

#equipments for sale#construction equipment#industrial equipment#recycling equipment#waste management#mobile shredders#mobile screeners#mobile crushers#shredders for sale#crushers for sale#screeners for sale#tracked shredders#tracked crushers#recycling shredders#industrial shredders#mobile jaw crushers#jaw crushers for sale#stone crushers#rock crushers#crushing and screening#screening equipments#komplet australia

0 notes

Text

How Much Does It Cost to Invest? Situation Analysis

Investing in stone crushing equipment is a pivotal decision for businesses in construction, mining, and aggregate production. The costs involved can vary significantly depending on various factors, from the type of crusher to the size of the plant. This article will provide a detailed breakdown of the factors influencing the stone crusher price and the overall cost of establishing a crusher plant.

Understanding the Stone Crusher Price

1. Types of Stone Crushers

The type of stone crusher you choose plays a critical role in determining the price(chancadora de piedra precio). Different crushers are designed for specific applications:

Jaw Crushers: Known for their ability to handle large stones, jaw crushers are cost-effective for primary crushing but may not provide the fine output needed for some projects.

Cone Crushers: These are more expensive but offer precision in secondary and tertiary crushing stages.

Impact Crushers: While moderately priced, they are ideal for shaping materials and creating uniform output.

Mobile Crushers: Offering convenience and flexibility, these units are typically more expensive than their stationary counterparts.

2. Capacity and Output

The production capacity of the stone crusher significantly impacts its price. Crushers designed to process larger volumes of material or produce finer outputs are generally more expensive. For example, a crusher with a capacity of 200 tons per hour will cost more than one designed for 50 tons per hour.

3. Material and Build Quality

High-quality materials, such as wear-resistant steel and advanced engineering, contribute to the durability and efficiency of the crusher. While these features may increase the upfront cost, they reduce long-term maintenance expenses.

4. Brand Reputation

Well-established brands often charge higher prices due to their reliability, innovation, and strong after-sales support. AIMIX, for example, is renowned for its high-performance crushers that balance quality and affordability.

youtube

Cost Breakdown for Setting Up a Crusher Plant

1. Initial Investment

Setting up a crusher plant(planta chancadora) involves multiple components, each contributing to the overall cost:

Primary Equipment: Crushers, screens, feeders, and conveyors form the core of the plant. Depending on the scale of the operation, these can range from $100,000 to over $1 million.

Land Acquisition: The cost of land varies based on location and size, with rural areas generally being more affordable.

Construction and Installation: Building the necessary infrastructure and installing the equipment requires significant investment.

2. Operational Costs

Once operational, the crusher plant incurs ongoing expenses, including:

Energy Costs: Crushers are energy-intensive, making electricity or fuel a major recurring expense.

Labor Costs: Skilled operators and maintenance personnel are essential for smooth operations.

Spare Parts and Maintenance: Regular servicing and replacement of wear parts are necessary to maintain efficiency.

3. Compliance and Legal Costs

Operating a crusher plant requires permits and adherence to local environmental and safety regulations. Obtaining these can add to the initial investment.

4. Transportation and Logistics

The cost of transporting heavy equipment to the site and moving raw materials and finished products also contributes to the overall investment.

Analyzing the Market Situation

1. Growing Demand for Crushed Stone

The rising demand for crushed stone in construction, road building, and infrastructure projects is driving the market. This makes investing in a crusher plant a potentially lucrative opportunity.

2. Regional Market Variations

The cost of stone crushers and the demand for their output vary significantly across regions. Conducting a regional market analysis helps identify the most profitable locations for investment.

3. Advancements in Technology

Modern crusher plants are equipped with advanced features such as automation, energy efficiency, and real-time monitoring. These innovations can reduce operational costs and improve productivity, offsetting the higher initial investment.

Tips for a Successful Investment

1. Conduct Thorough Research

Compare the prices and features of stone crushers from various manufacturers. Look for models that meet your specific needs without overextending your budget.

2. Choose Reliable Manufacturers

Opt for manufacturers with a strong reputation for quality and service. AIMIX, for example, offers robust and efficient stone crushers, along with excellent after-sales support.

3. Plan for Future Growth

Select equipment that can handle increased production demands. This ensures that your investment remains viable as your business scales.

4. Consider Total Cost of Ownership

While the upfront cost is important, consider the long-term costs of energy, maintenance, and spare parts. A slightly higher initial investment in a durable, energy-efficient crusher can save money over time.

Conclusion

Investing in a stone crusher or crusher plant requires careful planning and analysis. Factors such as equipment type, capacity, material quality, and market conditions play a vital role in determining the overall cost. By understanding these elements and working with reliable manufacturers like AIMIX, businesses can maximize their return on investment.

Whether you are looking to expand your operations or enter the market, the growing demand for crushed stone offers promising opportunities. Take the time to research, plan, and choose wisely for a successful and profitable investment.

For expert advice and high-quality stone crushing equipment, contact AIMIX today!

#aimix#aimixgroup#construction#equipments#machinelearning#machinery#mining#crusher#stone crusher#Youtube

0 notes

Text

We have this 2024 Rubble Crusher RC150T Mobile Jaw Crusher for Rental or for Sale, this crusher has the biggest jaw size in its class,650x350 jaw opening and can produce up to 50 tonne per hour depending on material, the crusher only weighs 3700KG and can easily be transported and can crush concrete, rock ,bricks and tiles etc down to a size of 15mm up to 100mm.

**THIS UNIT ADVERTISED IS AVAILABLE FOR RENTAL OR FOR SALE**

Contact me for Rental details & availability.

"Finance Available if Wanting to Purchase”

***Contact me for details***

"We are based on the Gold Coast QLD"

0 notes

Text

Selecting the Right Mobile Crusher Plant for Quartz: An In-Depth Guide

Quartz, renowned for its hardness and durability, is a prevalent mineral used in various industries, including construction, electronics, and manufacturing. As quartz deposits are mined and processed, the selection of a suitable crusher plant becomes crucial. In this article, we explore the considerations and factors that guide the selection of a mobile crusher plant for quartz, catering to the needs of different stakeholders involved in quartz processing.

Understanding the Significance of Mobile Crusher Plants for Quartz

Mobile crusher plants offer unparalleled advantages in the processing of quartz deposits, especially in scenarios where mobility, flexibility, and efficiency are paramount. Unlike stationary crusher plants, mobile crushing plant for sale can be easily transported to different sites, facilitating on-the-go processing of quartz materials without compromising productivity or quality.

Factors Influencing the Selection of a Mobile Crusher Plant for Quartz

Choosing the right mobile crusher plant for quartz involves considering various factors, including production requirements, operational constraints, environmental considerations, and budget constraints. Here are the key factors to consider:

1. Production Requirements:

The production requirements dictate the capacity, output size, and throughput of the mobile quartz stone crusher. Contractors must assess the anticipated production volumes and material specifications to ensure that the selected plant can meet the project's demands effectively.

2. Mobility and Site Accessibility:

The mobility of the crusher plant is critical, especially for projects located in remote or challenging terrain. Mobile concrete crusher plants with robust chassis and versatile configurations can navigate through narrow roads, rough terrain, and confined spaces, ensuring accessibility to different quartz deposits and construction sites.

3. Crushing Technology and Equipment:

Different types of mobile crushers, such as jaw crushers, impact crushers, cone crushers, and vertical shaft impactors (VSIs), offer distinct advantages and capabilities for crushing quartz. Contractors must evaluate the crushing technology and equipment features to determine the most suitable option for their specific application requirements.

4. Operational Efficiency and Maintenance:

Operational efficiency and ease of maintenance are essential considerations when selecting a mobile crusher plant for quartz. Contractors should assess the plant's energy efficiency, automation features, and maintenance requirements to minimize downtime, optimize productivity, and reduce operational costs.

5. Environmental Impact and Regulatory Compliance:

Mobile crusher plants must comply with environmental regulations and sustainability standards to minimize their impact on the environment. Contractors should evaluate the plant's emissions, noise levels, and waste management practices to ensure compliance with local regulations and community expectations.

6. Cost Considerations:

Cost considerations, including capital investment, operating expenses, and lifecycle costs, play a significant role in the selection of a mobile crusher plant for quartz. Contractors must assess the total cost of ownership and weigh it against the anticipated benefits and returns to make informed investment decisions.

Conclusion

In conclusion, choosing a mobile crusher plant for quartz requires careful consideration of various factors, including production requirements, mobility, crushing technology, operational efficiency, environmental impact, and cost considerations. By evaluating these factors comprehensively, contractors can select the most suitable mobile crusher plant that meets their project needs effectively.

Mobile crusher plants offer unparalleled advantages in quartz processing, enabling contractors to enhance productivity, flexibility, and sustainability in their operations. As the demand for quartz products continues to rise, the selection of the right mobile crusher plant becomes increasingly critical for achieving operational success and delivering high-quality quartz materials for diverse applications. Embracing mobile crusher technology empowers contractors to overcome logistical challenges, optimize production processes, and capitalize on opportunities in the dynamic quartz processing industry.

0 notes

Text

Top 10 Crusher Manufacturers in India

India's crusher manufacturing industry has seen significant growth over the past few decades, with numerous companies emerging as leaders in the market. Among the top 10 crusher manufacturers in India, Craftsmencrusher has established itself as a prominent player. Known for its innovative engineering and robust machinery, Craftsmencrusher specialises in producing high-performance crushers designed for various industrial applications, including mining, construction, and recycling. The company's product range includes jaw crushers, cone crushers, impact crushers, and mobile crushing units, all of which are engineered to deliver optimal efficiency and reliability under the most demanding conditions.

Craftsmencrusher's commitment to both customer satisfaction and quality is evident in its state-of-the-art manufacturing facilities, which employ advanced technologies and stringent quality control measures to ensure each crusher meets international standards. Additionally, the company invests heavily in research and development to continually enhance the performance and durability of its equipment. This focus on innovation has allowed Craftsmencrusher to introduce several industry-first features, such as automated control systems and energy-efficient designs, setting new benchmarks for performance and sustainability.

The company’s vast distribution system ensures timely delivery and exceptional after-sales support across India and beyond. Craftsmencrusher also offers customized solutions to meet the specific needs of its clients, providing comprehensive consulting services, from site evaluation to equipment selection and maintenance planning. This customer-centric approach has earned the company a loyal clientele and a strong reputation in the market.

Overall, Craftsmencrusher stands out among the top 10 crusher manufacturers in India due to its unwavering focus on quality, innovation, and customer service. With a proven track record and a forward-looking approach, the company is well-positioned to continue leading the industry and contributing to the growth of India's infrastructure and industrial sectors.

0 notes

Text

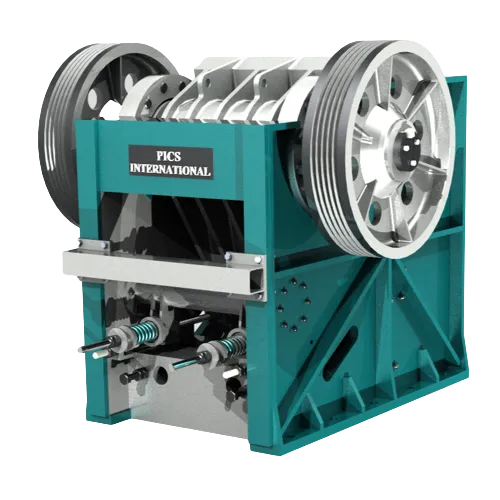

Pics International We Engineer, We Manufacture, We Deliver..... Worldwide

Picson Construction Equipments Pvt. Ltd.

PICS INTERNATIONAL is a leading global engineering and manufacturing unit engaged in supplying cutting-edge crushing and screening equipment for applications in mining, quarrying, and infrastructure projects, Construction and Demolition and waste recycling.

We have more than three decades of experience in supplying a robust range of crushing, screening and washing equipment, including varying sizes of stationary and mobile jaw, cone and impact crushers; heavy duty screens and mobile plants for recycling construction and demolition waste. These high-quality industrial equipments ensures a fine and precise performance promises an end result which is nothing less than the best.

Our Quality Products

1.CRUSHER

2.IMPACTORS

3.WASHING SYSYTEM

4.SCREENS

5.FEEDERS

6.MIXING

OUR PRODUCTS

1.Single Toggle Jaw Crusher

2 Double Toggle Jaw Crusher

3 Cone Crusher HC Series

4 Cone Crusher GC Series

Our Products

Crusher

Sand Making Machine

C & D Waste Recycling Plant

Washing System

Semi Mobile Series

Applications

Quarrying & Aggregate

Sand Processing

C & D Waste Recycling

Mining

Industrial Sand

Supports

Parts

Service

Operator Training

Dealer Portal

Manuals

Get In Touch

986, 986/1, Near Getco Substation, GIDC, Por Ramangamdi, Por, Vadodara - 391243, Gujarat, India.

9081777945

https://www.picsinternational.com/

#Stone Crusher#Cone Crusher#Jaw Crusher#C&D Waste#C&D Waste Recycling#C&D Waste Recycling Plant#C&D Waste Recycling Plant Manufacturer#C&D Waste Recycling Plant Manufacturer in India#Construction & Demolition Waste Recycling#Construction & Demolition Waste#Stone Crusher Manufacturers

0 notes

Text

Mobile Stone Crusher for Sale

Mobile Stone Crusher for Sale

Available used and fully refurbished portable mobile stone crushing plant. We are supplier and exporters of mobile crushers from India. The crushers we supply are sourced from auctions and complete sevicing and reconditioning is done at our yard by qualified engineers. We also supply spare parts for Mobile Stone Crushers. The Spare parts we supply are genuine OEM, Remake and used reconditioned,…

View On WordPress

#Business#crusher for sale#mobile cone crusher for sale#mobile crushers#mobile crushers for rock#mobile impact crusher for sale#mobile jaw crusher for sale#used mobile crusher for sale

1 note

·

View note

Video

youtube

Small Mobile stone crusher for start-up companies and small business activites.

#diesel jaw crusher#mobile jaw crusher#stone crusher mobile#mobile crusher for stone#mobile stone crushr small#mobile stone crusher for sale#mobile rock crusher#mobile mini rock crusher for sale

0 notes

Text

On Corporate Desperation

I'd love to tell someone at one of the major manufacturers that wagging a 1% rebate for the interest rate in a pandemic and during a chip shortage does not send particularly kind "Hey, I know you're struggling, so here's a bit of a leg-up" vibes.

This is more the manufacturers saying "Yeah, we know you're struggling, but - guess what? Our profit margin matters more, and our workers can't respec out of the automotive industry. So fuck your feelings, screw your budget, and pay the fuck up."

I'd maybe have an easier time sitting with it if I hadn't argued against this with regional sales reps personally, but most Canadian offices are dead-set on meeting sales quotas for the end of the fiscal year.

Guess what: they won't.

I'm also likely to be shelved for the rest of the week, starting tomorrow. My colleagues and I keep telling the sales directors that any blitzes, big-top sales, private events and mail-in offers are generally perceived as being inappropriate by the general public in times like these, and their response usually amounts to "Welp, it's that or we send all of 2021 and 2022's lineups to the crusher..."

Considering how the demand for EVs is growing at an astonishing rate across Quebec, I'm actually in favor of shuttering SUV production lines and actually weaning the public off of the stereotypical suburban mommy-mobiles. Predictably enough, that line of thought makes shareholders piss their pants.

People got scared shitless, this summer. Forest fires, heat waves - I'm seeing more and more people effectively wake up, leaving their slack-jawed and half-hearted recycling attempts and going all-in on it, on reuse platforms or various rental services. I'm seeing community compost bins pop up everywhere.

What's baffling is that in the midst of all this, there's still fifty and sixtysomething guys in their second adolescence who really want that gas-guzzling V8 for the sake of fulfilling some boyhood fantasy...

There's a sales ban on gas vehicles being projected for seven or eight years from now - I don't remember when, exactly. I work in the fucking automotive industry and I can't wait for that to rear its head. It'll make Saudi Arabia's ballsack shrivel and it'll shake the Prairies into investing in something more sustainable than their black sands.

I'm just hoping recycling centers will be more adequately financed, by that point. I'd hate to see Canada get weaned off of gas and moving on to poisoning whole water tables with nickel-hydride runoffs...

1 note

·

View note

Link

Our company is a leading manufacturer and supplier of mining crushers in China. The main products are crushers for more than 160 types of stone and ore processing that can be used in mining, quarrying, construction, roads and other industries. Leading products include jaw crushers, impact crushers, cone crushers, mobile crushers, sand making machines, hammer crushers, roller crushers, etc.

1 note

·

View note

Text

Canadian Crusher Wear Parts - BDI

BDI Wear Parts is a dynamic, fast-growing company with years of experience in the production, application and supply of crusher wear parts, crusher parts, wear parts , spare parts, stone crusher, ball mill liners, bucket teeth, screen media, idler, and forged steel balls.We supply and ship parts across the globe to the USA, Canada, Europe, Australia, Africa and other countries.

BDI leverages its deep technical, industry and supply chain experience to help our customers improve their performance. Our service goes far beyond providing wear parts. We take great pride in helping our customers reduce costs, increase parts availability, minimize downtime and provide great after-sales service.

BDI’s experienced staff source and provide compatible quality crusher spares and wear parts for all leading mobile crushing and screening equipment at highly competitive prices.

Our very strong focus on providing high quality parts and applications advice enables BDI to help our customers continuously reduce capital and operational costs and improve production reliability. We take great pride in very positive feedback our customers provide us. This is the secret to our growth and our successful partnerships with our customers.

Product list by industries

Aggregates

Cone Crusher, Jaw Crusher, Gyratory Crusher, Horizontal Shaft Impactor, Vertical Shaft impactor, Hammer mill, Feeders, Grizzly Feeder, Dozer, Loader, Excavator.

Mining

Cone Crusher, Jaw Crusher, Gyratory Crusher, Feeders, Ball and SAG Mill, Roll Crusher, Grizzly Feeder, Loader, Excavator.

Cement

Cone Crusher, Jaw Crusher, Gyratory Crusher, Horizontal Shaft Impactor, Vertical Shaft impactor, Hammer mill, Feeders, Grizzly Feeder, Ball and SAG Mill, Kiln Parts.

Contact us and explore our wide range of products that we update daily. Our email: [email protected]

#CrusherWearParts#CrusherSpareParts#StoneCrusher#CrusherPart#JawCrusher#ConeCrusher#ImpactCrusher#WearParts#Quarry#Mining

1 note

·

View note

Text

HXJQ Intelligent Coal Crusher Contributes to the Green Coal Construction

In recent years, the coal industry has been sluggish. In response to the country's requirements for coal production, the production capacity has been reduced. According to statistics, in June, the domestic cumulative coal production capacity exceeded 400 million, and the target of 800 million tons was completed. 50%, with gratifying results, and a major change in the company's business conditions, the industry's development has been significantly improved and further optimized.

The recovery has a great impact on the coal market. The rebound in domestic coal prices has prompted coal companies to resume growth. As of June 2017, the investment in coal mining and washing industry reached 111.3 billion, a year-on-year increase of 0.2%.

The 13th Five-Year Plan for Coal Industry Development clearly states that by 2020, a low-energy, high-efficiency, green coal industrial system will be built, of which 85% of the requirements for mechanization of coal mine equipment will be developed in the direction of intelligence and informationization. The requirements of technology, mining machinery enterprises enter a new field of competition, facing the new situation after the reform of the coal industry, It means that the coal mining equipment business is gradually warming up.

As a well-known mining machine enterprise in China, HXJQ Machine has made breakthroughs in the technology of coal mine equipment in response to the requirements of this policy. Applying intelligent equipment to various fields is the main goal of HXJQ.

In order to promote the development of intelligent coal mines, HXJQ provides intelligent coal crushers for coal processing and production. The equipment is made of high-quality materials. Combined with modern intelligent control system, the equipment is more convenient and quick to operate, with high output and stable performance. The advantages of low energy consumption and green environmental protection have become one of the necessary equipments in the coal industry. They have made tremendous contributions to the coal industry and promoted the development of the domestic coal industry. They have been well received by customers in the coal industry.

Hongxing machine production and operation of intelligent coal crushing equipment: jaw crusher, mobile crusher, impact crusher, cone crusher, roller crusher and other equipment. Among them, the mobile crusher is one of the more popular equipments at present, and its performance advantage is very obvious. It is the demand of HXJQ combined with modern technology, learning advanced foreign technology, and designing advanced mobile crusher. According to the user's on-site production requirements, the user can choose a reasonable type of crushing equipment to match. The equipment has the advantages of high production efficiency, good running stability, remarkable energy-saving and environmental protection effects, and is one of the devices with good sales.

1 note

·

View note

Text

**URGENT FOR SALE | 2nd HAND CRUSHING PLANT * Mobile Jaw Crusher with 250 tons per hour production capacity: - 30 m3 loading bunker - 1100 x 4500 mm vibrating feeder - 1400 mm long bypass grizzly system - 2 x 7.5 kW vibrating drive motors * Secondary & tertiary impact crushers: - 1120 x 1250 mm secondary stage (after jaw)impact crusher - 1120 x 1000 mm secondary impact crusher (for the feedback processing) - Fixed chassis & walking platform are included * High stroke inclined vibrating screen: - 2000 x 6000 mm vibrating screen - 4 decks - 22 kW drive motor - Fixed chassis & walking platform are included

URGENT A VENDRE | USINE D'OCCASION DE CONCASSAGE ET CRIBLAGE

** Concasseur mobile à mâchoires d'une capacité de 250 tonnes par heure, en très bon état, et ayant été testé en usine:

- Tous les travaux d'entretien ont été effectués

- Inclure toutes les pièces nécessaires

- Ouvertures d'alimentation de 850 x 1100 mm et plaques de mâchoires à 95 %

- Trémie de chargement de 30 m3

- Alimentateur vibrant 1100 x 4500 mm

- Système de grizzly de dérivation de 1400 mm de long

- 2 moteurs d'entraînement vibrants de 7,5 kW

** Concasseurs à percussion secondaires et tertiaires:

- Concasseur à percussion 1120 x 1250 mm étage secondaire (après mâchoire)

- Concasseur à percussion secondaire 1120 x 1000 mm (pour le traitement de rétroaction)

- Le châssis fixe et la plate-forme de marche sont inclus

**Crible vibrant incliné à grande course:

- Tamis vibrant 2000 x 6000 mm

- 4 ponts

- Moteur d'entraînement de 22 kW

- Le châssis fixe et la plate-forme de marche sont inclus

عاجل للبيع | محطة تكسير و غربلة مستعملة *

كسارة فكية متنقلة بسعة 250 طن في الساعة بحالة جيدة جدا وتم اختبارها في المصنع: **

تم تنفيذ كافة أعمال الصيانة-

تشمل جميع الأجزاء الضرورية-

فتحات تغذية 850 × 1100 مم و ألواح فكية 95 ٪ -

قادوس تحميل 30 م 3-

مغذي اهتزازي 1100 × 4500 مم-

- نظام تجاوز طويل بطول 1400 مم

- وحدة تغذية هزازة 2 × 7.5 كيلو واط بمحركات اهتزازية

الكسارات التصادمية الثانوية والثلاثية:**

كسارة تصادمية 1120 × 1250 مم مرحلة ثانوية (بعد الفكية) -

كسارة تصادمية ثانوية 1120 × 1000 مم (لمعالجة التغذية الراجعة) -

يتم تضمين إطار ثابت ومنصة للمشي -

غربال اهتزازي مائل **

غربال اهتزازي 2000 × 6000 مم-

- 4 طوابق

محرك 22 كيلو واط - يتم تضمين إطار ثابت ومنصة للمشي

#crushing_plant#stone_crushing_plant#mobile_crusher#mobile_stone_crusher#mobile_washing_plant#mobile_sand_washing_plant#portable_crusher#portable_stone_crusher#mobile_jaw_crusher#mobile_impact_crusher#mobile_vsi_crusher#mobile_granite_crusher#mobile_basalt_crusher#semi_mobile_jaw_crusher#portable_jaw_crusher#stone_crusher#mobile_crushing_and_screening_plant#mobile_cone_crusher#mobile_cone_crushing_plant

0 notes

Text

BDI Equipment

BDI Wear Parts is a dynamically growing company with many years of experiences in production and supply Crusher wear parts, Crusher spare parts. We supply wear parts to USA, Canada, Europe, Australian, Africa etc. Drawing on the experience, expertise and financial stability of our highly successful organization, BDI aims to help customers reduce costs, increase parts availability, minimize downtime and provide an even greater after-sales services.

Through the recruitment of highly experienced staff, BDI is able to manufacture and provide compatible quality crusher spares and wear parts for all leading mobile crushing and screening equipment at highly competitive prices. Our focus on quality crafting, cost-effectiveness and customer satisfaction, together with our desire to continuously provide our customers with the best products has helped us succeed in the quarry and mining industry. PRODUCT LIST BY INDUSTRIES AGGREGATES Cone Crusher, Jaw Crusher,Gyratory Crusher, Horizontal Shaft Impactor, Vertical Shaft Impactor, Hammer mill, Feeders, Grizzly Feeder.

MINING Cone Crusher, Jaw Crusher,Gyratory Crusher, Feeders, Ball and SAG Mills, Roll Crusher, Grizzly Feeder. CEMENT Cone Crusher, Jaw Crusher,Gyratory Crusher, Horizontal Shaft Impactor, Hammer mill, Feeders, Grizzly Feeder, Ball and SAG Mills, Roller Mills. Kiln Parts.

For more information please visit our website:

0 notes

Photo

R.R. Machinery CO Rebel Mobile Crusher And Screener

JUST LISTED WITH NV REGISTRY FOR SALE IS THIS ONE OF A KIND MACHINE THAT'S LITERALLY LIKE A ROCK QUARRY THAT'S ON TRACKS YOU CAN MOVE AND FOLD UP AND TRANSPORT THAT IS A JAW CRUSHER OR AN IMPACT CRUSHER ALL IN ONE UNIT AND THIS ONE IS SUPER LOW MILED AND ALMOST NEW STILL. CALL TODAY!!!

Manufacturer: R.R. EQUIPMENT Model: REBEL Hours: 1,140 Serial Number: 7312 Condition: Used Description: Excellent condition, everything running, no leaks Has Remote Control, Comes with NEW set of Jaws! 35,000lb weight w/ additional jaws, New jaw wedges, Additional stationary magnet also included. If you have any questions and/or are interested, please call

FOR MORE INFORMATION PLEASE CALL 531 242 5963 OR 531 242 5960 OR 712 395 1116

0 notes

Text

How to find the ideal cone crusher parts supplier?

Actually, cone crushers are one of one of the most commonly made use of forms of rock crushers. They are commonly used to reduce the size of big ores and also rocks into tinier granules as well as pieces as well. Additionally, they are made use of in a variety of sectors such as phosphate and also chemical industry, useful, metallurgical and mining. They might be used in the governmental or social jobs like road building and train remodelling as well as more. If you are looking to purchase the crusher components, after that you have to find the right cone crusher parts maker that supplies real products to the consumers. Basically, the cone crusher is a most challenging equipment as well as has more components, but its major structure stays the exact same. It typically consists of the adhering to such as:

• Manganese metal

• Principal shaft

• Springs.

• Counter shaft.

These cone crushers are one of one of the most reliable as well as sophisticated types of rock crushers. They provide a number of benefits, however not regulated to huge squashing percentage, finest grainy items, less power usage along with slim and also consistent product size. They also consist of energy conserving ultra-fine shattered elements of rock. They constantly use wrapped squashing principle and additionally include a substantial product variety. Their clearance of cavity is more convenient than any type of other type of crusher type maker. In addition, making use of diameter shaft, mass obligation rock as well as a separate lubrication system assures the sturdiness and dependability of a device. The functioning concept of cone crusher builds them a remarkable alternative for crushing the rock, lime stone, granite, non-ferrous metal as well as crushing iron ore.

Necessary points to think about before picking an ideal supplier.

Whether you are in mining market, roadway structure or in the building and construction, the inefficient equipment can slow down the manufacturing, take full advantage of downtime and also put unneeded stress on your earnings. In such case, you wish to use cone crushers, which can enhance your earnings by generating more than assured as well as quicker than expected. Actually, a cone crusher is much more important portion of your ore or rock processing process, considering that it squashes the product to preferred dimensions. Right initially, this procedure is usually additional in a squashing system. Now, there are lots of processes that rely on timely squashing, to make sure that the total chain of procedures the procedure as well-oiled equipment and one smooth.

youtube

Even the jaw crushers are various other types of crushing systems, however if your feature requires the cone crushers, after that you will call for a tough along with a trusted equipment that will not even permit you down in a center of your job. Prior to picking the right cone crusher components maker, first of all, you wish to know the producer's experience in making the cone crusher components. Next, you need QIMINGCASTING INC. to know the sorts of cone crusher components offered from them. According to your demands as well as needs, you can choose the best cone crusher parts and afterwards buy it for your very own functions. The company's mobile crusher can be lugged to any site as well as likewise makes use of a shut circuit squashing in addition to evaluating the process along with a belt conveyor to swiftly squash the stones to three diverse finishers.

Optimize your earnings with the cone crushers.

Because of the innovation of patented technology, the business's cone crusher equipment allows quicker squashing, which makes it possible for the quicker speed in addition to a lengthier toss. Thus, it gives a higher result than contrasted to the score of a crusher. Their vagrant also releases the safety and security system along with a continuous setup, which enables for good stability as well as marginal drift that guarantees the vagrant iron pieces are ejected without also any concerns while keeping the uniformity in an output of completed ore or rocks. Nonetheless, the technical attributes sported by numerous designs of cone crushers are built by Nordberg, which exchanges benefits in a sort of basic upkeep; because of simple accessibility to the whole adjustable components. Other advantages additionally consist of minimal downtime; as a result of its best tramp expeling capability and really much less maintenance costs; due to using optimal bronze bushings, labyrinth seals as well as several various other elements of each crusher are just changeable. Also, these crushers are more flexible in design. For your squashing requirements, you want a producer that not only builds energy efficient and also difficult crushing machines, yet likewise waits to give after sales solution in instance of any drawback.

0 notes