#fertilizer granulator machine

Explore tagged Tumblr posts

Text

In the pursuit of sustainable agricultural development today, organic fertilizer production is not only the key to improve soil health, but also an important way to achieve green agriculture. In order to achieve this goal, we need to integrate the concept of energy conservation and green production in the production process of organic fertilizer, and modern organic fertilizer equipment is the practitioner of this concept.

First, let's focus on the New Type Organic Fertilizer Granulator and Hydraulic Type Roller Granulator. These two granulators lead the energy saving trend of organic fertilizer production with their efficient energy utilization and excellent granulation effect. By optimizing the granulation process, they reduce energy consumption while ensuring uniform particles and nutrient stability, providing great convenience for subsequent packaging, transportation and use.

In raw material treatment, the application of Chain Crusher and Straw Crusher has effectively reduced the crushing energy consumption of raw materials, reduced dust pollution, and realized the resource utilization of waste. With its strong crushing capacity and stable performance, these shredders provide a high-quality raw material base for organic fertilizer production.

In terms of mixing uniformity, the Double Shafts Mixer, with its efficient mixing capacity, ensures full mixing of raw materials and additives, improving the overall quality of the fertilizer. At the same time, these mixers are designed to pay attention to energy saving and consumption reduction, contributing to green production.

As an important link in the production of organic fertilizer, Drum screener machine accurately separates different particle sizes of fertilizer particles with its continuous and efficient working mode, which not only ensures the uniformity of products, but also avoids the waste of energy. The flexible application of Vibrating Screen further improves the screening efficiency and reduces the energy consumption.

In the Fertilizer drying and cooling stage, Drum Fertilizer Dryer and Drum Fertilizer Cooler achieve low temperature drying and rapid cooling by optimizing thermal efficiency, effectively reducing energy consumption and emissions. These devices not only improve the quality of the finished fertilizer, but also meet the requirements of green production.

Finally, the application of Coating Machine puts on a protective film for organic fertilizer, extends the shelf life of fertilizer and improves the utilization rate of nutrients. Although this link seems simple, it is yet another interpretation of the concept of green production, because it reduces the waste of fertilizer and improves the economic and environmental benefits of agricultural production.

#organic fertilizer machine#organic fertilizer#organic fertilizer production line#fertilizer machine#fertilizer production line#fertilizer granulator machine#fertilizer granulator#fertilizer

0 notes

Text

In the wave of agricultural modernization, organic fertilizers play an important role in nourishing the earth and promoting crop growth, and the improvement of their quality has become the focus of the industry. So, how is the new organic fertilizer granulator to play a key role in this quality upgrade war?

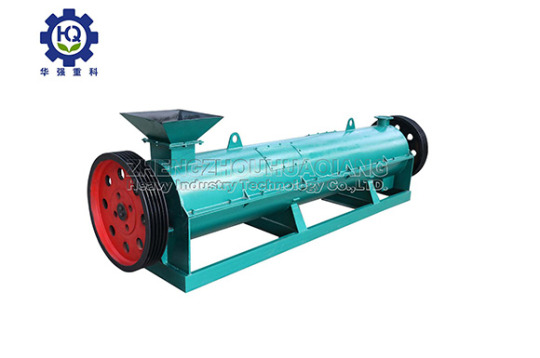

Double Roller Press Granulator is like a skilled craftsman, through precision roller design, apply just the right amount of pressure to the raw material, so that the fibers and nutrients are closely combined to form a strong and uniform particle. This process not only improves the physical strength of the fertilizer, but also ensures the steady release of nutrients, providing lasting nutritional support for the crop.

The Hydraulic Type Roller Granulator is the essence of roller technology to the extreme. It introduces an advanced hydraulic system to achieve accurate control and dynamic adjustment of roll clearance. This means that regardless of the type of raw material, how the humidity changes, the machine can react quickly to maintain the best pelletizing effect. This high degree of flexibility and adaptability makes the Hydraulic Roller Granulator more flexible in dealing with complex and changeable production environments.

As for the New Type Organic Fertilizer Granulator, it is a comprehensive integration of a variety of innovative technologies. It not only integrates the advantages of the above two pelletizing machines, but also integrates the concept of intelligent and automated control. Through advanced sensors and control systems, the New Type Organic Fertilizer Granulator can monitor the parameters in the production process in real time and automatically adjust them according to the actual situation. This intelligent production method not only greatly improves production efficiency and product quality, but also significantly reduces labor costs and energy consumption.

New Type Organic Fertilizer Granulator series Roller Press Granulator, Hydraulic Type Roller Granulator and New Type Organic Fertilizer Granulator, with its excellent performance and advanced technology, provide strong support for the quality upgrade of organic fertilizer. They not only improve the physical properties and nutrient stability of fertilizers, but also promote the development of agricultural production in a greener, more efficient and sustainable direction.

#fertilizer granulator machine#granulator machine for fertilizer#fertilizer#Organic fertilizer granulator#organic fertilizer production line

0 notes

Text

Pan Granulator | Fertilizer Granulator Machine

The Art of Fertilizer Granulation: Mastering Pan and Disc Granulator Machines

Fertilizer production is a critical component of modern agriculture, ensuring that crops receive the essential nutrients they need for optimal growth. Among the various methods of fertilizer production, granulation stands out as a highly effective technique. Within the realm of granulation machinery, Pan Granulators and Disc Granulator Machines have gained prominence, thanks to their versatility and efficiency.

Pan Granulators:

Pan granulators, also known as pan pelletizers, are renowned for their simplicity and versatility in fertilizer production. These machines feature a rotating disc with a shallow, circular pan. Raw materials, such as powdered or fine-grained components, are fed into the pan. As the disc rotates, the materials adhere together due to the combination of gravity, friction, and moisture, forming uniformly sized granules.

The advantages of Pan Granulators are multifaceted. They can handle a wide range of raw materials, including organic and inorganic substances. Additionally, they offer precise control over granule size and density, making it possible to customize fertilizer formulations to meet specific crop requirements. Their relatively low energy consumption and minimal maintenance requirements make them a cost-effective choice for fertilizer manufacturers.

Disc Granulator Machines:

Disc granulator machines, also known as disc pelletizers, share some similarities with pan granulators but have distinct differences. These machines employ a rotating disc with multiple inclined or curved blades. Raw materials are fed into the disc, where the blades agitate and compress them into round granules. The addition of binding agents or liquid solutions helps facilitate the granulation process.

Disc granulators are favored for their efficiency in producing spherical granules, which have improved flowability and are less prone to dust formation. They excel in creating high-density granules, making them suitable for producing compact, slow-release fertilizers. Moreover, they are adaptable to both small-scale and large-scale fertilizer production operations.

Experience Matters:

With over four years of experience in the field of Pan Granulators and Disc Granulator Machines, one gains valuable insights into optimizing granulation processes. Expertise is developed in selecting the right materials, adjusting machine parameters, and understanding the intricacies of granule formation.

In conclusion, Pan Granulators and Disc Granulator Machines are invaluable tools in the fertilizer production industry. Their ability to efficiently convert raw materials into uniform granules with precise control over properties ensures that crops receive the nutrients they need for healthy growth. For those with experience in this field, mastering these machines is a testament to their commitment to advancing agriculture through effective fertilization.

1 note

·

View note

Text

ट्राईकोडर्मा विरिडी एक उच्च गुणवत्ता वाला जैविक एजेंट है। Tricoderma viride की तेजी से विकास होती है, और यह मिट्टी में पोषक तत्वों और ऑक्सीजन को जल्दी से उपयोग कर सकता है, जिससे पौधों की बीमारी के रहने का वातावरण बिगड़ जाता है और फफूंद को नष्ट कर्ता हेl

#biopesticide#fertilizer granules compaction machine#fertilization#organic fertilizer production line#organic fertilizer equipment

2 notes

·

View notes

Text

Key considerations for choosing energy-saving equipment in NPK fertilizer production line upgrades

When selecting energy-saving equipment to upgrade an NPK fertilizer production line, multiple factors need evaluation. Here’s a straightforward breakdown:

1.Energy Efficiency

Focus on equipment energy ratings. For machinery like fertilizer mixer machines and fertilizer granulators, prioritize models with higher efficiency. For example, modern high-efficiency mixers achieve the same blending quality while using less power. Compare energy performance data from suppliers to identify the best options.

2.Automation Level

Smart automation matters. Automated systems (such as precision dosing equipment) reduce energy waste by minimizing human error and adjusting power usage based on real-time needs. This avoids rework from inaccurate ingredient ratios and optimizes energy consumption during low-demand periods.

3.Compatibility

Ensure new equipment works seamlessly with your existing setup. Mismatched systems might force extra energy use to compensate. For instance, a new heating unit must align with your line’s temperature controls without requiring workarounds.

4.Maintenance andDurability

Factor in long-term reliability. Frequent breakdowns in “energy-saving” gear can negate benefits through repair downtime and rushed production schedules. Choose robust, low-maintenance equipment that sustains performance over time.

5.Proven Success Cases

Learn from others. Study how similar facilities upgraded their NPK fertilizer production line-what equipment they used, what worked, and what didn’t. This practical insight helps avoid trial-and-error while balancing efficiency and savings.

0 notes

Text

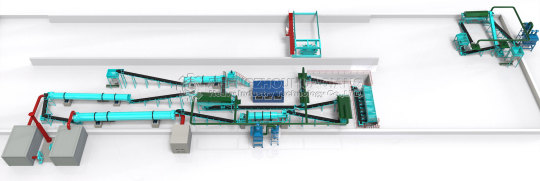

Analysis of process flow of pig manure organic fertilizer production line

The pig manure organic fertilizer production line is a systematic process that transforms raw pig waste into high-quality organic fertilizer.

1.Raw Material Collection and Pre-treatment

The process starts with collecting fresh pig manure while avoiding contamination. Since the collected manure usually contains high moisture and large chunks, it undergoes initial processing. A solid-liquid separator first removes liquid components (which can be used for liquid fertilizers), while the remaining solids get crushed into smaller particles using a grinder for easier handling.

2.Fermentation Stage

The pre-treated manure then enters fermentation facilities. Microbial agents like Bacillus subtilis are often added to speed up decomposition. Common composting methods involve controlled pile fermentation. Operators maintain temperatures between 50-65°C using regular turning with compost turning machines. This ensures proper aeration for efficient aerobic fermentation. The process typically takes 15-30 days until the manure fully decomposes – indicated by dark brown coloration and transformation from foul odor to earthy aroma.

3.Post-fermentation Processing

The matured compost requires further refinement. A crusher machines it into fine powder. For granular fertilizers, the powder enters a granulator (using disc granulators or press mathods) to form uniform pellets. These pellets then go through drying equipment to reduce moisture, followed by cooling machines.

4.Screening and Packing

Cooled pellets pass through vibrating screens to remove oversized particles and excess powder. The final product gets weighed and packed into bags of various sizes using automated packing machines, ready for distribution.

In short, the process flow of the pig manure organic fertilizer production line is rigorous and scientific, which can effectively turn pig manure into treasure and produce high-quality organic fertilizer.

0 notes

Text

Environmental measures in sheep manure organic fertilizer production lines

Sheep manure organic fertilizer production lines play a vital role in modern agriculture, and its environmental protection measures are equally critical. Here’s a breakdown of the key eco-friendly practices involved:

Raw Material Collection and Processing

1. Collection Systems: Automated manure scraping systems gather sheep waste into storage pits. Specialized vehicles then transport it mechanically, reducing labor costs and preventing pollution during handling.

2. Pre-treatment: Manure undergoes sorting and crushing to remove impurities, boosting efficiency and quality in later stages.

Fermentation and Decomposition

1. Fermentation Techniques: By adjusting moisture, pH, and carbon-to-nitrogen ratios—plus optimizing oxygen supply—the process heats up, reduces moisture, and neutralizes harmful elements. Aerobic or anaerobic fermentation uses microbes to break down organic matter into stable humus, eliminating pathogens and parasites.

2. Fermentation Equipment: Tanks or troughs with temperature control and ventilation systems ensure precise conditions, speeding up decomposition and improving fertilizer quality.

Production Process Control

1. Equipment Setup: Automated tools like compost turning machines, crushers, screening machines, and disc granulators streamline production, cutting waste and environmental impact.

2. Dust and Odor Management: Dust and fumes are controlled through pipelines, spray systems, and biofilters to meet national emission standards.

Resource Recycling

1. Biogas Production: Manure is used for biogas fermentation. The resulting gas serves as clean energy for lighting or cooking, while biogas residue and liquid become nutrient-rich fertilizers for crops.

2. Organic Fertilizer Conversion: After dehydration, fermentation, crushing, and granulation, sheep manure is transformed into organic fertilizer. This closes the waste loop, reduces pollution, and conserves resources.

By integrating these measures, the sheep manure organic fertilizer production lines turn waste into value while protecting ecosystems—a win-win for farming and the environment.

0 notes

Text

Why can our conveying machine reduce material loss?

In the field of fertilizer production, material loss is not only related to cost control, but also affects production efficiency and product quality. As a professional manufacturer of fertilizer production machine, we know the importance of reducing material loss, especially in key production links such as organic fertilizer production lines and fertilizer production lines. And our fertilizer transport aircraft is the right assistant to achieve this goal.

Our fertilizer conveyors use advanced design concepts and manufacturing processes to ensure minimal loss of materials during transportation. Our fertilizer conveyors offer higher accuracy and stability than conventional conveyors. Through the precise control system, it can automatically adjust the conveying speed and flow rate according to the characteristics of the material and the production needs, avoiding the overflow and accumulation of the material caused by the speed is too fast or too slow, thus effectively reducing the waste of the material.

In the organic fertilizer production line, our fertilizer conveyors show their unique advantages. Because organic fertilizers usually contain high moisture and fragility, traditional conveying machine is often prone to damage and scattering of materials during conveying. Our fertilizer conveyor adopts a soft transportation method, with a special conveyor belt or pipeline, to ensure the integrity of the material in the transportation process, which greatly improves the utilization rate of organic fertilizer.

In addition, our fertilizer conveyors also have excellent sealing performance, which effectively prevents dust and volatilization of materials during transportation. This not only protects the production environment, but also reduces the loss caused by volatilization of materials. In the fertilizer production line, this is particularly important, because it is directly related to the quality and yield of fertilizer products.

To sum up, our fertilizer conveyors successfully reduce the loss of materials during transportation with their advanced design, precise control, gentle delivery and excellent sealing performance. This not only saves costs for customers, improves production efficiency, but also contributes to the sustainable development of the fertilizer production industry. When you choose our fertilizer conveyor, you choose an efficient, environmentally friendly and intelligent fertilizer production solution.

#organic fertilizer production line#fertilizer granules compaction machine#disc granulator#flat-die pellet machine

0 notes

Text

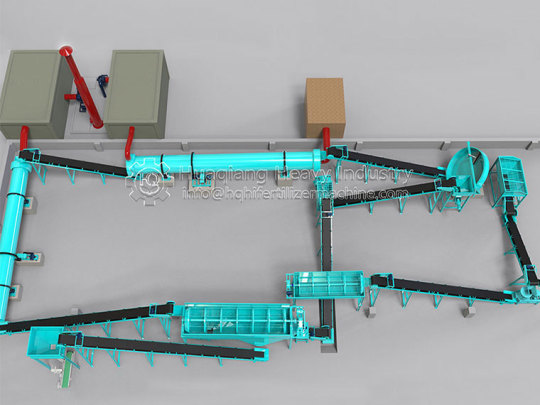

Briefly describe the process of organic fertilizer production line

Organic fertilizer production is to harmlessly treat and recycle organic raw materials such as agricultural waste and livestock and poultry manure, and finally produce fertilizers rich in organic matter and nutrients. The process of organic fertilizer production includes composting fermentation of organic matter and post-fermentation treatment.

The first step is composting fermentation. The organic waste should be mixed evenly in a certain proportion, then placed in a fermentation tank, and then fermentation agents should be added. During the fermentation process, environmental factors should be strictly controlled, and the compost should be regularly turned and oxygenated by a Compost Turning Machine The high temperature stage lasts for several weeks to allow microorganisms to fully decompose organic matter.

Then there is post-fermentation processing. The fermented organic fertilizer includes two types: powdered organic fertilizer production line and granular organic fertilizer production line.

1. The processing technology of powdered organic fertilizer production line is relatively simple, which is divided into three stages: crushing, screening and packing. Crushing: Crushing large or agglomerated fermented materials to produce uniform powdered organic fertilizer. Screening: Screen out organic fertilizer that meet the requirements to ensure product quality. Packing: Final packing of the screened organic fertilizer for easy storage and transportation.

2. The production line of granular organic fertilizer is relatively more complicated, with the following steps: Ingredient mixing: Add humic acid or other elements of fertilizer to the fermented organic fertilizer, and then mix them evenly through a mixer to facilitate subsequent processing. Granulation: Use Granulators (such as Disc Granulator)to make the organic fertilizer into uniform granules. This is not only conducive to storage and transportation, but also improves the convenience of fertilization. Drying and cooling: Reduce the moisture content of organic fertilizer to prevent mold and deterioration, and increase the hardness of fertilizer particles. Screening: Use a Drum Screener Machine to screen out broken particles and select particles of appropriate size for subsequent processing. Coating: Use a Coating Machine to coat the fertilizer particles to prevent the particles from sticking. Packing: Packing is the last step. Generally, an automatic packing machine is used. Our Granular Fertilizer Packing Machine is controlled by a computer to ensure the accuracy of fertilizer packing.

This completes the entire production process of organic fertilizer from raw materials to finished products. This production method achieves efficient transformation of waste and provides high-quality organic fertilizer for agricultural production.

0 notes

Text

In modern agriculture, large-scale composting production has become an important means to improve soil fertility and promote sustainable agricultural development. In this green revolution, the compost turning machine has become an indispensable equipment in the compost fermentation process with its unique advantages. So, why do we use a flip machine for large-scale composting? Let's unravel the mystery of it.

First, the Turning Machine, especially the Windrow Compost Turning Machine, ensures an even distribution of oxygen during the composting process through its powerful turning capacity. In large-scale composting production, the volume of the material pile is huge, and if the lack of effective turning, the internal anaerobic environment is easy to form, affecting the microbial activity and reducing the fermentation efficiency.

The use of flipping machine not only solves this problem, but also promotes the uniform propagation of microorganisms, accelerates the decomposition and transformation of organic matter, and lays a solid foundation for the production of high-quality organic fertilizer. Naturally, this is closely related to the Organic Fertilizer Production Line, because high-quality compost is a prerequisite for subsequent granulation, screening and other processes.

Secondly, the turning machine also helps to regulate the humidity and temperature of the compost. In the early stage of compost fermentation, the material humidity is high and the temperature rises rapidly. Regular operation of the tilting machine can effectively reduce the temperature of the pile, prevent excessive evaporation of water, and maintain a suitable fermentation environment. With the deepening of the fermentation process, the tilting machine can also mix the partially decomposed material in the outer layer with the insufficiently fermented material inside to further improve the uniformity of fermentation. This process, echoing the working principle of the Disc Granulator or Rotary Drum Granulator in the Fertilizer Granulating Production Line, both emphasize the importance of material uniformity to the quality of the finished product.

Moreover, the use of the turning machine has greatly improved the efficiency and automation level of composting production. Compared with the traditional manual turning method, the turning machine not only saves the labor cost, but also reduces the influence of human factors on the quality of compost. Especially when dealing with a large amount of organic waste, such as urban sludge, agricultural straw, etc., the application of the rollover machine is indispensable. It not only speeds up the conversion of waste to Fertilizer, but also provides a reliable guarantee for the production of Organic-Inorganic Fertilizer Compound Fertilizer.

Finally, it is worth noting that the selection and operation of the rollover machine also need to be adjusted according to the characteristics of the compost raw materials, production scale and expected objectives. Whether it is a bar type, wheel type or large wheel disk overturning machine, it has its applicable scenes and advantages. The correct selection and rational use of turning machine will bring greater economic and ecological benefits for large-scale composting production.

In summary, the use of large-scale composting machine is not only an inevitable choice to improve fermentation efficiency and ensure fertilizer quality, but also an important measure to promote the green transformation of agriculture and achieve sustainable development. In the future development of agriculture, the turning machine will continue to play its irreplaceable role, leading the composting production to a more efficient and environmentally friendly new chapter.

#Windrow Compost Turning Machine#Organic Fertilizer Production Line#Disc Granulator#Rotary Drum Granulator

0 notes

Text

In the green transformation of modern agriculture, the automatic control and intelligent monitoring technology of organic fertilizer production line is gradually becoming the key to improve production efficiency and ensure product quality. The wide application of this technology not only realizes the precise regulation of the production process, but also significantly reduces labor costs and energy consumption, and injected a strong impetus for the intelligent upgrading of the organic fertilizer industry.

Automation control technology:

In the organic fertilizer production line, the core equipment such as the New Type Organic Fertilizer Granulator and Hydraulic Type Roller Press Granulator realizes the fully automated operation from raw material delivery to finished product output through the integrated PLC control system. According to the preset parameters, the system automatically adjusts the speed, pressure and other key indicators of the granulator to ensure uniform particle size and regular shape. At the same time, mixing equipment such as Horizontal Mixer and Vertical Mixer have also joined the ranks of automatic control, which improves the mixing efficiency of raw materials and the quality of finished products through accurate matching and uniform mixing.

Intelligent monitoring technology:

In order to monitor the running status and product quality of the production line in real time, key equipment such as Drum Fertilizer Dryer and Drum Fertilizer Cooler are equipped with intelligent sensors and monitoring systems. These systems can monitor equipment temperature, humidity, speed and other key parameters in real time, once found abnormal immediately alarm and automatically adjust to the safety state, effectively avoid the occurrence of production accidents. Through intelligent identification technology, screening equipment such as Drum screener machine and Vibrating Screen can accurately screen finished products to ensure the consistency of product particle size and improve screening efficiency and accuracy.

More advanced is that the intelligent monitoring technology is also applied to post-processing equipment such as the Coating Machine , which ensures that the fertilizer has good slow release and anti-caking by monitoring the thickness and uniformity of the coating layer in real time. Combined with big data analysis technology, the operation data of the whole production line is collected and analyzed, which provides a scientific basis for production optimization and decision-making.

The automatic control and intelligent monitoring technology of organic fertilizer production line is leading the industry to develop in a more efficient and intelligent direction. With the continuous progress of technology and the in-depth promotion of application, it is believed that the organic fertilizer industry will usher in a broader development prospect.

#organic fertilizer machine#fertilizer machine#organic fertilizer#fertilizer production line#fertilizer granulator machine#fertilizer granulator

0 notes

Text

In modern agriculture, the application of organic fertilizers is increasingly widespread, which not only improves soil quality, but also promotes the healthy growth of crops. The fermentation process of organic fertilizer is a crucial part of the entire production process. By introducing and optimizing the use of the above organic fertilizer equipment, not only can significantly improve the fermentation efficiency and product quality of organic fertilizer, but also reduce energy consumption and labor costs, and contribute to the sustainable development of modern agriculture.

Detailed explanation of organic fertilizer fermentation process

The fermentation process of organic fertilizer is mainly divided into several stages: raw material preparation, compost fermentation, maturation stabilization and post-treatment. Raw materials need to be processed by equipment such as Straw Crusher to ensure uniform particle size and facilitate microbial decomposition. Subsequently, the compost fermentation is carried out under the appropriate temperature, humidity and ventilation conditions. At this stage, a Horizontal Mixer can be introduced to turn the pile regularly to ensure sufficient oxygen and accelerate the fermentation process.

Efficiency improvement strategy

Efficient granulation: The use of New Type Organic Fertilizer Granulator or Hydraulic Roller Granulator, through physical extrusion molding, improve the uniformity of particles and yield, reduce the follow-up screening workload, significantly improve production efficiency.

Fine grinding: The use of Chain Crusher and Half-Wet Material Crusher to fine raw materials, to ensure that the size of raw materials meet the requirements of fermentation, accelerate the microbial decomposition speed, shorten the fermentation cycle.

Intelligent mixing: The introduction of automatic control of the Double Axis Mixer or BB Fertilizer Mixer, to achieve accurate ratio and uniform mixing, reduce manual intervention, improve mixing efficiency and quality.

Optimization of drying and cooling: The Drum Fertilizer Dryer is combined with the Drum Fertilizer Cooler unit, which uses the heat exchange principle to quickly remove water, while controlling the temperature, protecting the activity of beneficial microorganisms, and laying a good foundation for subsequent granulation and packaging.

Screening and coating: Accurate screening by Rotary Screener Machine and Vibration Screener Machine ensures consistent product size. Subsequently, the Coating Machine is used for coating treatment to enhance the slow-release and anti-caking properties of the fertilizer and enhance the added value of the product.

#fertilizer granulator machine#granulator machine for fertilizer#fertilizer#drum granulator#roller granulator

0 notes

Text

In modern agriculture, animal manure, as a rich organic resource, can be transformed into efficient bio-organic fertilizer after scientific fermentation treatment. This paper will discuss an innovative bio-organic fertilizer fermentation process based on livestock and poultry manure, and incorporate the knowledge of relevant fertilizer production lines in the process.

First of all, the collection and treatment of livestock and poultry manure is the first step in the fermentation process. By means of equipment such as Windrow Compost Turning Machine, the manure is evenly stacked and turned regularly to ensure oxygen supply and temperature control during the fermentation process. This step not only helps to kill pathogenic bacteria and parasite eggs, but also promotes the decomposition of microorganisms, laying the foundation for the subsequent fermentation process.

During fermentation, microbes convert the organic matter in the manure into humus while releasing heat. This process requires precise control of fermentation conditions such as temperature, humidity and ventilation to ensure the quality and stability of the fermentation products. After fermentation, the resulting bio-organic fertilizer is rich in organic matter, microbial flora and various nutrient elements required by plants.

Next, in order to improve the utilization and convenience of bio-organic Fertilizer, it can be sent to the Organic Fertilizer Production Line for further processing.

By means of equipment such as Disc Granulator or Rotary Drum Granulator, the fermented organic fertilizer is granulated for easy storage, transportation, and use. This step not only improves the physical properties of the fertilizer, but also makes it more in line with market demands.

In addition, in the production process of bio-organic Fertilizer, an appropriate amount of inorganic nutrients such as nitrogen (N), phosphorus (P) and potassium (K) can be added according to the needs of crops to make Organic-Inorganic Fertilizer Compound Fertilizer. This fertilizer combines the advantages of organic and inorganic fertilizers to provide rich organic matter while quickly replenishing the nutrients needed by crops.

In summary, the fermentation process of bio-organic fertilizer based on livestock and poultry manure is a technology with broad application prospects. Through the scientific fermentation process and advanced production equipment, we can convert livestock and poultry manure into efficient and environmentally friendly organic fertilizer, contributing to the sustainable development of modern agriculture.

#Windrow Compost Turning Machine#Organic Fertilizer Production Line#Disc Granulator#Rotary Drum Granulator

0 notes

Text

It increases carbon, nitrogen ratio in the plant cell which leads to increase in number of productive flowers and buds. It fixes the nutrient imbalance in plants. It provides energy to the plant cell that helps for strong stem developments and increases vegetative growth of the plants. Thus, It helps for increasing the crop yield by 25 to 40 %.

#garden#flowers#nature#fertilizer granules compaction machine#agriculture#farming#fertilizer granulating produciton line#2024

1 note

·

View note

Text

Budget for the construction of organic fertilizer production lines in small breeding farms

Under growing environmental and sustainability demands, building organic fertilizer production lines has become a focus for small livestock farms. Budgets vary significantly depending on equipment and site configurations.

1.Equipment procurement

Fermentation equipment: A compact fermentation compost turning machines (core equipment) costs 5,000–15,000 yuan, depending on capacity and features.

Crushing equipment: A small crusher (3,000–10,000 yuan) processes materials into suitable sizes.

Granulation equipment: A disc granulator (8,000–20,000 yuan) shapes powdered materials into fertilizer pellets.

Drying equipment: A compact dryer (10,000–30,000 yuan) reduces moisture for better product quality.

Auxiliary tools: Conveyors, packaging machines, etc., add 5,000–20,000 yuan.

2.Site construction budget

Site rental: If you choose a more remote rural area, it is about 3-10 yuan per square meter per month. Calculated based on a 100-square-meter site, the monthly site rental fee is 300-1000 yuan.

Site construction: If you build a simple factory building, it is estimated to invest 20,000-50,000 yuan.

3.Raw material procurement budget

In the initial start-up, you need to purchase some auxiliary raw materials, such as fermentation agents, etc., which is about 500-2000 yuan.

4.Personnel cost budget

In the early stage, you may only need to hire 1-2 workers. According to the local wage level, the monthly wage expenditure is about 3000-6000 yuan.

5.Operating cost budget

Energy consumption cost: calculated based on equipment power and usage time, it is estimated to be 1000-3000 yuan per month.

Maintenance cost: regular equipment maintenance, fault repair, parts replacement, etc., estimated at 5,000-10,000 yuan per year.

In summary, the budget for a small farm’s organic fertilizer production line is about 80,000-150,000 yuan. Of course, this is only a preliminary budget range, and the actual cost will also be affected by factors such as equipment brand, raw material price fluctuations, and local labor cost differences.

0 notes

Text

Process analysis of bio-organic fertilizer production line

With the advancement of green agriculture and sustainable development, the problems of excessive use of chemical fertilizers in agriculture, such as environmental and soil compaction and fertility decline, have attracted attention. In this situation, bio-organic fertilizer has become a popular choice to replace traditional chemical fertilizers due to its environmental protection, safety and soil improvement characteristics. The main process of the bio-organic fertilizer production line includes the following steps:

1.Raw material collection and pretreatment

Collect various organic wastes, such as livestock and poultry manure, straw, kitchen waste, fungus residue, etc. Then strictly screen the raw materials to remove impurities such as plastics and metals. Finally, pre-process the raw materials by crushing and mixing. During this process, the moisture content of the raw materials should be controlled at 50%-60%. If it is too high, straw and other auxiliary materials should be added to balance it. At the same time, pay attention to adjusting the carbon-nitrogen ratio to ensure fermentation efficiency.

2.Composting and fermentation

Fermentation is the core link of bio-organic fertilizer production, which generates stable humus through the decomposition of organic matter by microorganisms. First, the raw materials are piled together, and then specific fermentation agents are added for aerobic fermentation. Then, in this process, the compost should be turned regularly by a Composting Turning Machine to increase oxygen, and the fermentation temperature should be controlled at around 65°C to kill parasite eggs and pathogens. Finally, the secondary fermentation is carried out, and after the temperature drops below 40°C, aging is carried out to promote the formation of humic acid, eliminate odor, and increase fertilizer efficiency.

3.Crushing and screening

The fermented fertilizer is passed through a Drum Screener Machine to remove undecomposed crude fibers, and the fermented bulk raw materials are crushed to remove debris.

4.Granulation

The fertilizer is granulated using a Disc Granulator or a Rotary Drum Granulator to improve the convenience of storage and application.

5.Drying, cooling and screening

The granulated organic fertilizer granules are dried to reduce the moisture content to less than 20%. The dried granules are then cooled to room temperature and screened to select granules that meet the particle size requirements.

6.Addition of microbial agents

The qualified particles after screening are evenly mixed with other additives (such as microbial agents, trace elements, etc.) to improve the nutritional comprehensiveness and biological activity of bio-organic fertilizer.

7.Finished product packing

The finished bio-organic fertilizer is packed into bags or boxes using an automatic packing machine, and then sold or stored.

The above are the key steps of the bio-organic fertilizer production line. If you want to know more about this process or related equipment, please feel free to contact us.

#bio-organic fertilizer production line#Composting Turning Machine#Disc Granulator#Rotary Drum Granulator

0 notes