#conveyor plant manufacturer

Explore tagged Tumblr posts

Text

Advantages Of Foundation-Free Mixing Station

The foundation-free mixing station adopts modular splicing design, equipped with main structure, mixer, belt conveyor, batching machine, cement silo, line system, control room. The system is complex and the investment cost is high, but it has good production capacity, good coordination ability, strong anti-interference stability, and is installed on a solid foundation. If the construction period is tight, the foundation-free mixing station can also exert its strong production capacity and provide a stable and efficient supply of concrete for the project. At the same time, the foundation-free mixing station can withstand a large workload and is suitable for large-scale engineering projects.

We FOCUS MECHINERY stand for new product ideas and courageous vision of the future, we stand for our never-stopping dedication and devotion to your construction equipment solutions, we focus on your project needs.If you're looking for a particular supplier or specific configurations, I can provide more details or recommendations!

#concrete manufacturer#foundstion-free concrete plant#belt conveyor concrete mixer#concrete plant customization#foundstion-free

0 notes

Text

The Role of Bagasse Dryers in Modern Biomass Energy Production

Bagasse dryers are essential to the generation of modern biomass energy because they effectively lower the moisture content of bagasse, improving its combustion characteristics. By increasing energy output and decreasing emissions, this approach improves the sustainability and economic viability of biomass energy generation. For more information, you can read our blog: https://methodsindia.com/achieving-excellence-exploring-sugar-elevators/

#Bagasse Dryers#Bulk Reception Unit (BRU)#Cross Country Conveyors#Sugar Elevators#Mineral Beneficiation plant manufacturers in India

0 notes

Text

Intech Bulk Handling Systems Pvt. Ltd. provides high-quality material handling solutions, such as coal and ash handling plants, dust collectors, vibrating screens, chain conveyors, and belt conveyors. Trusted globally, we offer competitive prices and superior products. Whether you require coal handling plant manufacturers or vibrating screen manufacturers in India, count on Intech Engineers for efficient solutions!

#Dust Collector Manufacturers#Vibrating Screen Manufacturers#Belt Conveyor manufacturers#Chain Conveyor Manufacturers#Coal Handling Plant Manufacturers#Ash Handling Plant Manufacturers#Coal Handling Plant#Ash Handling Plant#Belt Conveyor#Chain Conveyor#Vibrating Screen#Dust Collector

0 notes

Text

In this blog you will get complete information on the chevron conveyor belt that tells in detail about its key features, versatile applications and potential benefits. Call us for any other information required.

#chevron conveyor belt#chevron conveyor belt manufacturers#chevron conveyor belt suppliers#chevron conveyor belt exporters#conveyor belt#industrial plants

0 notes

Text

0 notes

Text

Conveyorized Liquid Painting Plant Manufacturer

New Touch Technology is a manufacturer of conveyorized liquid painting plant in Ghaziabad, Utter Pradesh, India. For more details contact us!

0 notes

Text

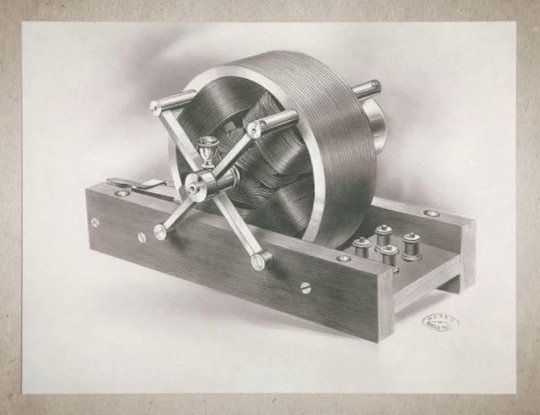

One of the Greatest Inventions of All Time

Nikola Tesla has many revolutionary inventions to his credit, but he is best known for his pioneering work in the development and promotion of alternating current (AC) electrical systems. Tesla's innovations in AC technology revolutionized the generation, transmission, and distribution of electrical power, becoming the foundation for the modern electrical power systems that we use today.

There is a common misconception made that Tesla was the first to invent, or discover, AC, but this is not true. It is well-known that Hippolyte Pixii was the first to discover AC in 1832. Pixii was an instrument maker from Paris who built an early form of an alternating current electrical generator (based on the principle of electromagnetic induction discovered by Michael Faraday), and thus started a new industry in power transmission. Tesla was not the first to discover or invent an AC motor, but he was the first to invent a practical AC induction motor with commercial value that could outperform all other motors. It must be noted that Italian inventor Galileo Ferraris also invented an induction motor similar to Tesla's, but it had no commercial value, and he even admitted himself that it was useless. Tesla's induction motor operates on the principle of electromagnetic induction, properly utilizing a rotating magnetic field that induces a current in a stationary conductor, resulting in rotational motion. The utilization of the rotating magnetic field makes the motor more simple, robust, versatile, efficient, and cost effective in that it has less moving parts reducing the likelihood of mechanical failure (as was common in other motors).

Tesla's induction motor became a fundamental component in the field of electrical engineering and is used today in various applications, being one of the most widely used devices in the world. The motors play a crucial role in transmitting electrical power to homes and businesses. They are commonly used in power generation plants to convert mechanical energy into electrical energy, which is then transmitted through the power grid for distribution to various locations. Induction motors are also widely employed in appliances and machinery within homes and businesses for various applications. These applications include conveyor systems, hoists, cranes, lifts, pumps, fans, ventilation systems, compressors, manufacturing machinery, wind turbines, washing machines, refrigerators, garbage disposals, microwaves, dishwashers, vacuums, air conditioners, robotics, electric vehicles, trains, power tools, printers, etc. Basically, anything that requires a spinning action for power.

The induction motor is widely considered one of the most important inventions in the history of electrical engineering. Its importance lies in its transformative impact on industries, its efficiency and reliability, and its role in the broader electrification of society.

#nikola tesla#science#history#invention#discovery#induction motor#electricity#power#goat#ahead of his time#ahead of our time

152 notes

·

View notes

Text

365 Promises of God

Day 306 – We Are Presented Holy, Blameless, Above Reproach

in the body of His flesh through death, to present you holy, and blameless, and above reproach in His sight-- (Col 1:22 NKJV)

Read: Colossians 1:21-23

Many years ago, I worked for a company that made air conditioner registers, the very common variety that exist in almost every home with central heat and air. The plant that made these registers was located in Mexico, and I was sent there to train them how to use our computer system to properly plan to forecast. When I got there, I was given a tour of their seven million dollar production line. It was a simply amazing and complicated process of stamping and spot-welding metal parts, and a paint line that painted the finished products. They were sparkly when they were carefully set on a conveyor system after being professionally painted and dried. Beautiful parts moving back to back along a conveyor.

We followed the conveyor for what was about 50 yards, to a packaging station where 7 workers were packaging the parts. Each register was put in a fancy individual box buy guy #1, which was quickly folded and taped by guy#2, and guy #3 would take the completed individual boxes, and put six of them in a carton. Guy #4 would tape the cartons up and stack them on a pallet. Guy #5 would drive off with a full pallet, once complete, and guy #6 would place a fresh pallet in that place. Guy #7 was frantically forming cartons and individual boxes, and was always behind.

Since Guy #7 couldn’t keep up with demand, shiny registers passed everyone by, one by one, and fell on the concrete floor, getting marked and dented as a pile of finished not-so-new registers built up on the floor. I pointed at the guy waiting to put a pallet on the floor. “You should help that guy make boxes! He can’t keep up!”

His response was, “No, I’m the guy who places the pallet.”

I looked at guy #5. “You’re not doing anything while waiting for that pallet to fill up. You need to help that guy make boxes!”

He said, “No, I’m the guy that takes the pallets away.”

I spied a shiny red button by the end of the conveyor. I pointed to it and asked guy #7, “Why don’t you press that button and stop the production line until you can catch up?”

Everyone there started shaking their heads frantically, “NO NO NO NO! Only the plant manager can stop the production line!”

I then asked guys 5 and 6 to help guy 7, again, pointing at the stack of damaged registers. They repeated to me what their jobs were. I just shook my head as we walked away from that travesty in manufacturing.

I asked one of the supervisors why they were destroying expensive and perfectly good parts and why the workers couldn’t shift to fill the bottlenecks in the process. He said everyone had a specific job to do, and that they would get blamed if that job didn’t get done. Helping somebody else would expose them to getting blamed if that job wasn’t done right, and they were not required to do it anyway.

I mentioned that no matter how good a job they all did at their own pieces, they were all at fault if we shipped boxes of bent registers to our customers. He shrugged and said that the blame for that would go to the plant manager, who was the only one allowed to shut down a production line for any reason.

Less than a year later, the plant manager took the fall for this and many other manufacturing issues they discovered. He really did get the blame for them, and in a lot of respects, he deserved it. Compare this to the company I now work for, where workers freely move from position to position on a production line, helping each of them complete a production run. If anything is wrong with the parts at any stage, they can and do shut the production line down, because they all know that it’s better to fix an issue that caused 10 bad parts than to continue letting it run, producing a thousand bad parts.

You can bet that if we produce an entire run of mislabeled product, somebody is going to catch the blame for it, possibly losing their job. Blame is a painful thing to be on the receiving end of. I’ve gotten blamed for many things I didn’t do, and many other things I did. If you stacked those things I earned blame for, if each were an inch that blame train would be a thousand miles long. It might be the same for you too.

Isn’t it comforting to have a promise like this in the Bible, that we are going to be presented by Christ to God as holy, and blameless, and above reproach? All those things we did? The mistakes we made, the errors in judgement, even the willful sins we’re sorry about now, the ones we regret and hope nobody finds out about? Those have all been nailed to the cross, dear Christian, and you will NEVER have to get shouted at about them again.

Prayer:

Lord, thank you for this beautiful promise, that I won’t have to get blamed for what I’ve done, when I get to heaven. I can hardly wait. Help me, Lord, to keep short accounts with you, today. Amen

3 notes

·

View notes

Text

[In front of Paint 2!]

MY DREAM!!!!

AT LONG LAST and multiple thwarted attempts (pandemic and chip shortage) I have finally managed a successful field trip to Subaru of Indiana for their manufacturing tour!!!!

17 years ago, my baby car was born right there!!

We got to see—EVERYTHING, from the steel and aluminum coils to them being stamped into thin sheets to the tool and die process to the welding to the drivetrain, suspension assemblies, brakes, front consoles, trim and finish, paint, quality testing (various points), tires on conveyor belts like little doughnuts, cars on doing brake tests, cars on dynos, cars being pressure-tested for leaks… And also Subaru NICU, where all the cars that don’t pass their tests go for diagnosis and repair (ope).

You weren’t allowed to bring anything into the plant, so my highlights from memory:

One of the transfer presses that stamps out body pieces was, when the plant was constructed in the 1980s, the largest piece of industrial machinery ever imported into the United States. It came via the Panama Canal, up the Mississippi, up the Ohio River, and then they had to built an entire port in order to get it out of the water. It then took three days to drive all the pieces up to Lafayette, Indiana. We got to see it punching out interior door panels!

There are various buffer zones in line production so that if one part of the process gets slowed down it won’t automatically cause a slowdown in the entire plant. The place where extra engines are stored when they’re in buffer status is called an “engine hotel.”

The USDM 2.0 and 2.5L engines are built at SIA, though transmissions come from Japan fully-assembled.

There are different musical chimes for each part of the line, and it chimes when there’s a slowdown in a particular area so people can keep track of what’s going on and where the bottlenecks are.

SIA currently manufactures USDM Legacy, Outback, Ascent, and Crosstrek models. USDM Forester, Impreza, WRX, BRZ, and Solterra are built in Japan and shipped.

The SIA test tack is the second largest oval track in the state of Indiana, second only to the Indianapolis Motor Speedway—SIA also has an off-road test track.

The paint process interacts poorly with silicone-based products, so painters cannot use a long list of shampoos, soaps, chapsticks, lotions, etc. They also can’t eat popcorn, because the oils stay on human fingers for 2-3 days?!

They don’t batch paint—so instead of painting 20 red cars, say, you’ll see different colors coming out right after each other. All the Subarus they built are made to order, which means each already has a customer who triggered the construction of this vehicle.

20 notes

·

View notes

Text

Crown Equipment Corporation a Major Forklift Manufacturer Hacked

Key Takeaways

- Crown Equipment Corporation, a major forklift manufacturer, faces a suspected cyberattack and global IT outage. - Production plants have been shut down, and employees report unpaid due to IT issues. - While the company remains tight-lipped, employees and online discussions suggest a potential ransomware attack. - The lack of official communication has fueled speculation and criticism of Crown's incident handling. - The situation highlights the importance of cybersecurity preparedness and transparent communication during data breaches or cyberattacks.According to reports, Crown Equipment Corporation, one of the world's largest manufacturers of forklift trucks and industrial equipment, has been the victim of a suspected cyberattack. The incident has resulted in a global IT outage, forcing the company to shut down production plants worldwide and leaving employees without access to critical systems. About Crown Equipment CorporationCrown Equipment Corporation, headquartered in New Bremen, Ohio, United States, is the fifth-largest manufacturer of forklift trucks, industrial trucks, and high-rack conveyors globally. The company has regional headquarters in Australia, China, Germany, and Singapore, with its European headquarters located in Feldkirchen near Munich, Germany. Crown also operates a production facility in Roding, Bavaria, Germany. Worldwide IT Systems Down and Production HaltedSince Monday, June 10, 2024, production at Crown's sites in Roding, Germany, has been at a standstill due to a reported IT system outage. The company's websites (crown.com) are inaccessible, with attempts to visit resulting in an error message stating "crown.com is temporarily unavailable." Additionally, the company's phone lines appear to be down, making it challenging to reach them. Suspicions of a Cyberattack and Ransomware InvolvementWhile Crown Equipment Corporation's management remains tight-lipped about the situation, reports from employees and online discussions suggest a potential cyberattack, possibly involving ransomware. Employees have taken to social media platforms like Twitter and Reddit to express their frustrations, claiming they have not been paid due to the IT issues One Twitter user, allegedly a Crown employee, stated, "thanks for letting your servers be hacked and not paying your employees. It's not like we have bills or anything. I thought I worked for a better company." Another tweet from a purported employee read, "Hey Jon, I work for Crown Equipment, a billion-dollar company with 19,000 plus employees. We were hit with a cyberattack and are currently not working. Now they tell us no pay! This after bragging about being an employee-first company, have to love corporate America." A Reddit thread was started to discuss the hack:https://www.reddit.com/r/LinusTechTips/comments/1denozy/crown_lift_trucks_experiencing_phishing_hack/ Lack of Official Communication and SpeculationCrown Equipment Corporation has yet to release an official statement regarding the nature of the incident or the extent of the impact. This lack of communication has fueled speculation and rumors within the cybersecurity community and among employees. Reports indicate that the company has advised employees not to clear data from their tablets and has implemented additional security measures, such as reducing the timeout function for multi-factor authentication (MFA) and restricting access to Office 365 applications like email, Teams, SharePoint, and OneDrive to company devices only. Handling of the Incident CriticizedThe way Crown Equipment Corporation has handled this incident has drawn criticism from cybersecurity experts and observers. The lack of transparency and clear communication has left customers and employees in the dark, leading to widespread speculation and concerns about the potential data breach and its implications. Read the full article

3 notes

·

View notes

Text

Discover the Magic of Geared Electric Motors: Transforming Industries

In the realm of modern industry, geared electric motors are nothing short of magical. These powerful machines are quietly revolutionizing countless sectors and transforming the way we do business.

Geared electric motors combine the raw power of electricity with the precision and control of gears. This unique combination allows them to deliver exceptional torque and speed, making them ideal for a wide range of applications. From heavy machinery in manufacturing plants to conveyor systems in warehouses, these motors are the driving force behind many of our most essential operations.

2 notes

·

View notes

Text

Efficient Bagasse Dryers: Methods India Leading the Way in Eco-Friendly Solutions

Methods India introduces advanced bagasse dryers intended to effectively transform drying procedures. Their innovative technique guarantees effective moisture extraction from bagasse, supporting efforts to preserve the environment. The dependable and effective bagasse dryers from Methods are dedicated to both sustainability and quality, meeting industrial demands and encouraging environmentally friendly behaviors at the same time. Trust Methods India for advanced drying solutions that prioritize efficiency and environmental responsibility, setting new standards in the industry. For more information visit: https://methodsindia.com/cross-country-conveyors-changing-the-way-things-are-moved/

#Bagasse Dryers#Bulk Reception Unit (BRU)#Cross Country Conveyors#Sugar Elevators#Mineral Beneficiation plant manufacturers in India

0 notes

Text

Mustard Oil / Edible Oil Bottle Filling Line

Company Overview: Shiv Shakti Machtech is a Manufacturer, Exporter, and Supplier of Mustard Oil / Edible Oil Bottle Filling Line in Ahmedabad, Gujarat, India. Shiv Shakti Machtech's Mustard Oil Bottle Filling Machine is crafted from top-notch materials, adhering to hygiene standards and facilitating easy cleaning. A Mustard Oil or Edible Oil Bottle Filling Line comprises a series of machines designed for filling, capping, and labeling bottles containing mustard oil or other edible oils. Filling Machine: Equipped to precisely fill bottles with desired quantities of mustard oil or edible oil. Features a conveyor belt system for bottle transportation, precision filling nozzles, and volume adjustment controls. Ensures uniform filling levels and reduces spillage or wastage of oil. Capping Machine: Responsible for securely sealing filled bottles with caps or lids. Utilizes various capping mechanisms (e.g., screw caps, press-on caps, snap-on caps) based on bottle and cap types. Ensures tight and consistent sealing to prevent oil leakage or contamination. Labeling Machine: Applies labels onto filled and capped bottles, providing product information, branding, and regulatory details. Operates with precision and consistency, even at high production speeds. Features may include label applicators, sensors, and controls for accurate label placement and alignment. Application: Food and beverage industry: Used in edible oil processing plants, bottling facilities, and packaging operations for Cooking Oil, Mustard Oil, Soybean Oil, Cottonseed Oil, Vanaspati Ghee, Rice Bran Oil, Sesame Oil, Palm Oil, Mustard Oil, Kachi Ghani Mustard Oil, Refined Oil, Coconut Oil, Sunflower Oil, Corn Oil, Olive Oil, Soya Oil, Canola Oil, Safflower Oil, Oil Spray, Avocado Oil, Rapeseed Oil, Nut Oils, Organic Safflower Oil, Palm Oil, Groundnut Oil, Edible Oil, Vegetable Oil. Geographical Coverage: Shiv Shakti Machtech serves as the Manufacturer and Supplier of Mustard Oil / Edible Oil Bottle Filling Line in Ahmedabad, Gujarat, India, and various locations across the country, including Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chandigarh, Chhattisgarh, Dadra and Nagar Haveli and Daman and Diu, Delhi, Goa, Gujarat, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Ladakh, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Nagaland, Odisha, Puducherry, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, and West Bengal. For further details, interested parties can contact Shiv Shakti Machtech. Read the full article

#Ahmedabad#AndhraPradesh#ArunachalPradesh#Assam#Bihar#Chandigarh#Chhattisgarh#DadraandNagarHaveliandDamanandDiu#Delhi#Exporter#Goa#Gujarat#Haryana#HimachalPradesh#India#JammuandKashmir#Jharkhand#Karnataka#Kerala#Ladakh#MadhyaPradesh#Maharashtra#Manipur#Manufacturer#Meghalaya#MustardOil/EdibleOilBottleFillingLine#MustardOil/EdibleOilBottleFillingLineinGujarat#MustardOil/EdibleOilBottleFillingLineinIndia#Nagaland#Odisha

2 notes

·

View notes

Text

Industrial Applications of Mild Steel Pipes

Mild Steel (MS) pipes are widely used in industrial applications due to their exceptional strength, durability, and affordability. As a reliable MS Pipe dealer in Gujarat, Tube Trading Co., understands the importance of these versatile pipes in a range of sectors. In this article, we will explore the industrial applications of MS pipes and highlight their significance as a Square pipe distributor in Vadodara.

Construction Industry:

The construction industry heavily relies on the utilization of mild steel pipes for various applications. These pipes are commonly employed in plumbing systems, water distribution networks, and sewage lines. The corrosion resistance and durability of MS pipes make them particularly suitable for underground installations. Moreover, they are extensively used for structural purposes in the construction of frameworks for buildings, bridges, and other infrastructure projects. The square-shaped MS pipes supplied by Tube Trading Co. - an excellent Square pipe distributor in Vadodara, make them highly suitable for creating sturdy supports, columns, and frames, enhancing the overall strength and stability of structures.

Oil and Gas Industry:

The oil and gas industry heavily relies on mild steel pipes for efficient resource transportation. These pipes are crucial for conveying petroleum products, natural gas, and various chemicals. The strength, reliability, and cost-effectiveness of MS pipes make them an excellent choice for pipelines in the industry. They possess the ability to withstand high-pressure applications, making them suitable for both onshore and offshore operations. The most trusted and noteworthy MS Pipe dealer in Gujarat - Tube Trading Co. caters to the demand for quality pipes in the oil and gas sector, ensuring the seamless flow of resources and contributing to the industry's overall productivity.

Automotive Manufacturing:

MS pipes are widely used in the automotive sector for manufacturing exhaust systems and chassis components. The excellent weldability of MS pipes allows for easy fabrication, enabling the production of customized exhaust systems that meet specific performance requirements. Additionally, the durability and strength of MS pipes make them suitable for creating sturdy chassis components, ensuring the safety and structural integrity of vehicles.

Agriculture and Irrigation:

Mild steel pipes are an integral part of irrigation systems in the agriculture sector. These pipes are used to transport water from sources such as wells, rivers, or reservoirs to fields for crop irrigation. MS pipes are durable and resistant to harsh environmental conditions, making them suitable for both above-ground and underground installations. They are also utilized in the construction of fencing structures, greenhouses, and enclosures for livestock. Square pipes, distributed by Tube Trading Co. - a reliable MS Pipe dealer in Gujarat, are commonly employed to create robust support frames for agricultural structures, ensuring their stability and longevity.

Manufacturing and Engineering:

Mild steel pipes are widely utilized in the manufacturing sector for diverse purposes. They play a crucial role in the fabrication of machinery, equipment, and conveyor systems. MS pipes are employed as conduits for the efficient transport of fluids, gases, and other materials within manufacturing plants. Due to their strength and ductility, these pipes are reliable for conveying compressed air, hydraulic fluids, and various chemicals. Furthermore, in the automotive industry, MS pipes find extensive usage in the production of exhaust systems, roll cages, and chassis components, thanks to their durability and affordability.

Infrastructure Development:

MS pipes play a significant role in infrastructure development projects. They are used for the construction of bridges, flyovers, and elevated highways, providing structural support and facilitating the transportation of people and goods. MS pipes are also employed in the installation of underground utility networks, including water supply, sewage, and gas pipelines.

Choosing the right-sized mild steel pipes for your project:

Choosing the right-sized mild steel pipes for your project is crucial to ensure proper functionality, structural integrity, and cost-effectiveness. Let’s explore some key factors to consider while choosing the right-sized MS pipes:

Flow Requirements: Determine the flow rate or volume of fluids or gases that will pass through the pipe. Calculate the required pipe diameter based on the desired flow velocity and pressure drop. This will help you choose a pipe size that can handle the anticipated flow without causing excessive pressure loss.

Load-Bearing Capacity: Assess the load-bearing requirements of your project. Consider the weight or load that the pipe will need to support, whether it's structural loads, machinery, or equipment. Larger-diameter pipes with thicker walls generally have a higher load-bearing capacity, providing greater strength and stability.

Material Compatibility: Ensure that the chosen mild steel pipe is compatible with the fluids or gases that will be conveyed. Consider factors such as corrosion resistance, chemical compatibility, and temperature limitations. Mild steel pipes are generally suitable for a wide range of applications, but if you anticipate exposure to corrosive environments, you may need to consider additional protective coatings or alternative materials.

Installation Considerations: Evaluate the available space and installation requirements. Consider factors such as the pipe's length, flexibility, and ease of joining. Determine whether you need straight lengths or require bends, fittings, or connectors to navigate through the project site. Ensure that the chosen pipe size can be accommodated within the available space without hindering the overall functionality of the system.

Standards and Regulations: Comply with industry standards and regulations governing pipe sizing for specific applications. Different industries and regions may have specific guidelines regarding pipe size selection. Familiarize yourself with relevant codes and standards to ensure compliance and to guarantee the safety and efficiency of your project.

Cost Considerations: Evaluate the cost implications associated with different pipe sizes. Larger-diameter pipes with thicker walls tend to be more expensive than smaller ones. Consider the balance between cost and performance to ensure that you select a pipe size that meets your project requirements while optimizing your budget.

Consultation and Expert Advice: If you are uncertain about the appropriate pipe size for your project, it is advisable to consult with experienced engineers, contractors, or MS pipe dealers. They can provide valuable insights and help you make an informed decision based on the specific needs and constraints of your project.

Final Thoughts:

Mild steel (MS) pipes have become indispensable in numerous industrial applications due to their versatility, reliability, and cost-effectiveness. In Gujarat, a state experiencing rapid industrial growth, Square pipe distributors in Vadodara serve as crucial suppliers, fulfilling the demand for quality pipes, including square pipes. The construction industry benefits from mild steel pipes for plumbing and structural applications, while the manufacturing sector relies on them for machinery fabrication. In agriculture, these pipes find extensive usage in irrigation systems and the construction of agricultural structures. Furthermore, the oil and gas industry heavily depends on MS pipes for efficient resource transportation. The widespread utilization of mild steel pipes underscores their importance in driving industrial development and infrastructure growth.

#distributor#Jindal pipes#steel industry#steel companies#industrial#seamless pipes#piping material#plumbing industry#construction structure#manufacturer#construction sites

7 notes

·

View notes

Text

Sand Belt Conveyors | Foundry Sand Plant Belt Conveyors In India | Industrial Belt Conveyor Manufacturer In India

Enhance Productivity With Our High-quality Sand Belt Conveyors In India. We Are A Leading Industrial Belt Conveyor Manufacturer In India, Specializing In Foundry Sand Plant Belt Conveyors. Experience Efficient Material Handling Today!

We are one of the leading Belt Conveyor Manufacturers, Suppliers, Exporters in India. Contact us for Belt Conveyors in India, Rubber Belt Conveyors in India

Fab India has opened up to a world of equipment meant for the foundry industry. The Belt conveyor is amongst the few unique and efficient systems of all. They constitute a seemingly continuous loop belt that runs on a couple of pulleys. The product proceeds along the belt between two locations

Varying Capacity: Belt conveyors bear a standard trough and even constitute a belting feature that runs on idlers that are backed by heavy-duty troughs. Placed on top of a structured frame composed of steel, the idlers come in varying angles between 20 and 45.

Troughed Walls Handling material worth a huge bulk gets easier due to high capacity performance conveyed by the troughed belt conveyors. A smooth stream of material is maintained by the unique design of the trough. It protects the material from external influences and prevents spilling. The operation of all equipment in the vicinity of the material doesn’t affect the material. Load Points Ensuring Dust Control All specific applications suggested by the client demand extra control from the exhaust ports and integrated skirt-boards. The placements of these features look appropriate at the far end of the conveyor. Besides retaining the dust, the belt can drive the material at the center owing to its favorable design. To ensure longevity, belt conveyors are developed by Fab India as an efficient solution that is highly engineered and tailored to meet all industry requirements.

#Sand Belt Conveyors#Foundry Sand Plant Belt Conveyors In India#Industrial Belt Conveyor Manufacturer In India

1 note

·

View note

Text

one of the things that’s been a little curiosity to me in games like factorio and satisfactory, is that they’ll have models for the energy usage of all these various machines, and how this energy usage is part of the fun of building the factories, providing a sort of base loop of having to get the materials for the power plant which requires you to get power to obtain the materials and so on... and both games just omit the power consumption of the conveyor belts, which, while there is variance in the ways you can set up your overall factory, i’d say pull the bulk of the weight. i mean, trains, inserters, trucks, drones... they’ve all got associated energy consumption demands that must be met in order to keep the factory going. i figured maybe the numbers are just so low that not only would it be tedious for players to have to keep them connected but that the low numbers would make it tedious to be constantly tacking on watts when your whole build is in the gigawatts.

but then i found this

Conveyor equipment, aside from gravity conveyors, requires motors and other equipment that use electricity for power. It is said that conveying equipment can consume up to 50% of a facility’s energy usage and account for nearly 70% of an electrical load in an industrial facility according to a representative from Rossi North America, a gear motor and gearbox manufacturer.

so probably not so insubstantial, especially when you consider that in these games you have kilometer spanning belts in some builds because some people don’t want to be hasseled with setting up trains. it’s not like these games really help people grasp how terrible real life industry is, it’s just a game afterall, but when apparently half of all energy consumption can just come from magical unseen space hampsters it certainly isn’t gonna help people get an idea of the true costs of these things.

5 notes

·

View notes