#crankshaft types

Explore tagged Tumblr posts

Text

Exploring Different Types of Crankshafts and Their Applications

Welcome to our blog post on the fascinating world of crankshafts and their diverse applications in various engines. A crankshaft is a vital component of any engine, responsible for converting reciprocating motion into rotational motion. It serves as the backbone of an engine, facilitating the transfer of power from the pistons to the drivetrain. The world of crankshafts is incredibly vast, encompassing different types and functions tailored to specific engine requirements. Engine builders and enthusiasts alike recognize the significance of choosing the right crankshaft type for optimal performance. In this article, we will delve into the realm of crankshafts, exploring the different types available and shedding light on their applications.

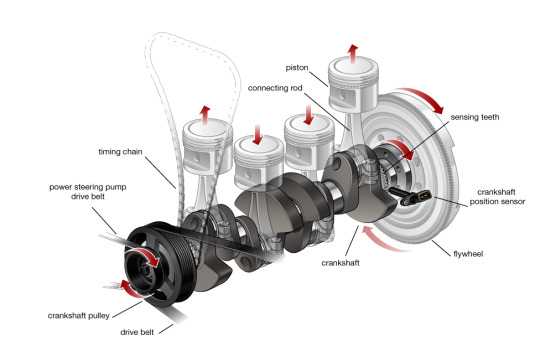

Crankshafts come in a range of designs, each serving a distinct purpose based on the engine’s intended use. Understanding the various crankshaft types is crucial for engine builders, as it allows them to tailor the engine’s characteristics to meet specific performance goals. The primary function of a crankshaft is to convert the reciprocating motion of the pistons into rotational motion, which drives the vehicle or powers machinery. Achieving this transformation involves the collaboration of multiple components, including the connecting rod and crank pin, which play crucial roles in the overall system.

Engine builders often opt for fully-built crankshafts or those with specific modifications to suit the engine’s needs. These crankshafts undergo meticulous design and engineering processes to ensure optimal performance, durability, and efficiency. The selection of the appropriate crankshaft type depends on factors such as the engine’s intended application, desired power output, and the desired torque curve. With the vast array of crankshaft types available, from cast iron to forged steel, it’s essential to understand their strengths, limitations, and specific applications.

In this article, we will explore different types of crankshafts and their applications across various engines. We will discuss the distinguishing features of each crankshaft type, highlighting their advantages and disadvantages. Whether you are an engine enthusiast seeking to expand your knowledge or an engine builder aiming to optimize performance, this comprehensive guide will provide valuable insights into the world of crankshafts and help you make informed decisions when it comes to selecting the most suitable crankshaft for your specific needs. Let’s dive into the intricacies of crankshaft types and uncover the secrets behind their incredible functionality in the realm of engines.

Exploring Different Types of Crankshafts and Their Applications

Crankshafts are a vital component of engines, responsible for converting the reciprocating motion of the pistons into rotational motion. They serve as the backbone of an engine, facilitating the transfer of power from the pistons to the drivetrain. The world of crankshafts is incredibly diverse, with different types and functions tailored to specific engine requirements. Engine builders and enthusiasts recognize the significance of choosing the right crankshaft type for optimal performance. In this article, we will explore the various types of crankshafts and shed light on their applications across different engine

#1 Understanding Crankshaft Types and Functions

Crankshafts come in a range of designs, each serving a distinct purpose based on the engine’s intended use. The primary function of a crankshaft is to convert the reciprocating motion of the pistons into rotational motion. This conversion is essential for driving the vehicle or powering machinery. Achieving this transformation involves the collaboration of multiple components, including the connecting rod and crank pin, which play crucial roles in the overall system.

Engine builders often have the option of choosing fully built crankshafts or those with specific modifications to suit their engine’s needs. Fully built crankshafts undergo meticulous design and engineering processes to ensure optimal performance, durability, and efficiency. The selection of the appropriate crankshaft type depends on factors such as the engine’s intended application, desired power output, and the desired torque curve.

#2 Different Types of Crankshafts

Cast Iron Crankshafts

Cast iron crankshafts are commonly found in older engines or engines designed for heavy-duty applications. Cast iron provides excellent strength and durability, making it suitable for engines that experience high stress and loads. However, cast iron crankshafts can be heavier than other types, which may affect the engine’s overall weight and performance.

Forged Steel Crankshafts

Forged steel crankshafts are a popular choice for high-performance engines. They are created through a forging process that involves shaping the crankshaft under extreme heat and pressure. This manufacturing technique enhances the strength and durability of the crankshaft, making it capable of withstanding higher RPMs and torque. Forged steel crankshafts are often found in sports cars, racing engines, and performance-oriented applications.

Billet Crankshafts

Billet crankshafts are machined from a solid block of high-quality steel or aluminium alloy. This manufacturing method allows for precise customization and optimization of the crankshaft’s design. Billet crankshafts are commonly used in custom-built engines, where specific performance requirements need to be met. They offer excellent strength, reliability, and flexibility to achieve desired engine characteristics.

Nitrided Crankshafts

Nitriding is a surface-hardening process that involves diffusing nitrogen into the outer layer of the crankshaft. This treatment improves the crankshaft's wear resistance and reduces the risk of surface fatigue. Nitrided crankshafts are commonly used in engines that operate under high temperatures and experience high combustion pressures, such as turbocharged or supercharged engines.

#3 Applications of Different Crankshaft Types

Automotive Engines

Automotive engines vary in their requirements, depending on factors such as vehicle type, intended use, and desired performance characteristics. Cast iron crankshafts are often found in heavy-duty trucks, where strength and durability are crucial. Forged steel crankshafts are commonly used in sports cars and high-performance vehicles, where the engine needs to withstand high RPMs and torque. Billet crankshafts find their place in custom-built engines, allowing engine builders to achieve specific performance goals.

Racing Engines

Racing engines demand exceptional performance and reliability. They require crankshafts capable of withstanding extreme stresses and high RPMs. Forged steel crankshafts are a popular choice in racing engines due to their strength and durability. Billet crankshafts are also highly sought after in professional racing, as they offer precise customization options to meet the specific requirements of different racing disciplines.

Industrial Engines

Industrial engines power a wide range of machinery, including generators, pumps, and heavy equipment. These engines often operate under heavy loads and prolonged periods of use. Crankshafts for industrial engines are typically chosen based on their strength, durability, and resistance to wear. Cast iron or forged steel crankshafts are commonly used in industrial applications, depending on the engine’s power requirements and expected workload.

Conclusion

Crankshafts are a crucial component in the world of engines, facilitating the conversion of reciprocating motion to rotational motion. The choice of the right crankshaft type is essential for achieving optimal performance, durability, and efficiency in different engine applications. Cast iron, forged steel, billet, and nitrided crankshafts each have their advantages and are tailored to specific engine requirements. Whether it’s for automotive, racing, or industrial engines, understanding the different crankshaft types and their applications allows engine builders to make informed decisions and achieve the desired engine characteristics. By delving into the intricacies of crankshafts, we uncover the secrets behind their incredible functionality and their significant role in powering our world.

#Crankshafts#crankshaft types#reciprocating motion#engine builder#crank pin#fully built#connecting rod

0 notes

Text

Can a Bad Crankshaft Bearing Cause an Engine Seizure?

When it comes to the health of an engine, the crankshaft bearing plays a crucial role. This small yet vital component ensures the smooth operation of the crankshaft, which is responsible for converting the linear motion of the pistons into rotational motion. But what happens if the crankshaft bearing goes bad? Can it lead to an engine seizure? The answer is yes. A bad crankshaft bearing can indeed cause an engine to seize, and in this blog, we'll explore how and why this happens.

What is a Crankshaft Bearing?

A crankshaft bearing is a part of the engine that supports the crankshaft, allowing it to rotate within the engine block with minimal friction. These bearings are designed to withstand high pressure and extreme temperatures, ensuring the crankshaft operates smoothly. There are usually two types of bearings in an engine: main bearings and rod bearings. The main bearings support the crankshaft’s rotation, while the rod bearings connect the crankshaft to the connecting rods of the pistons.

How Does a Crankshaft Bearing Go Bad?

Over time, crankshaft bearings can wear out due to various factors. Some common causes include:

Lack of Lubrication: Engine oil is essential for reducing friction between moving parts. If the oil supply is inadequate or if the oil becomes contaminated, the crankshaft bearings can wear down quickly.

Overheating: Excessive heat can cause the bearings to expand and lose their proper fit, leading to increased wear and potential failure.

Contamination: Dirt, debris, or metal shavings in the oil can scratch and damage the bearing surfaces, leading to premature wear.

Improper Installation: If the bearings are not installed correctly during engine assembly, they may fail prematurely.

Signs of a Bad Crankshaft Bearing

Identifying the symptoms of a failing crankshaft bearing early can save you from a potential engine seizure. Some of the common signs include:

Knocking Noise: A worn crankshaft bearing may produce a knocking or rumbling noise, especially when the engine is under load. This sound is often referred to as "rod knock."

Low Oil Pressure: Damaged bearings can cause a drop in oil pressure, as the gap between the bearing and crankshaft increases, allowing oil to leak out.

Metal Shavings in Oil: If you notice metal particles in the engine oil, it could be a sign that the bearings are deteriorating.

How a Bad Crankshaft Bearing Leads to Engine Seizure

When a crankshaft bearing fails, it can lead to several severe issues that may cause the engine to seize. Here’s how it happens:

Increased Friction: As the bearing wears out, the friction between the crankshaft and bearing increases. This added friction generates more heat, which can lead to the crankshaft welding itself to the bearing surface. When this happens, the crankshaft can no longer rotate, resulting in an engine seizure.

Oil Starvation: A failing bearing can disrupt the flow of oil to the crankshaft, leading to oil starvation. Without proper lubrication, the crankshaft can overheat and seize.

Misalignment: A worn bearing can cause the crankshaft to become misaligned. This misalignment can place undue stress on other engine components, leading to catastrophic failure and engine seizure.

Preventing Engine Seizure Due to Bad Crankshaft Bearings

To prevent engine seizure caused by a bad crankshaft bearing, it’s essential to maintain your engine properly. Regular oil changes, using the correct oil type, and monitoring oil pressure can help keep your bearings in good condition. Additionally, addressing any unusual noises or low oil pressure readings promptly can prevent further damage.

If you suspect your crankshaft bearings are failing, it's crucial to have your engine inspected by a professional mechanic as soon as possible. Early detection and repair can save you from a costly engine rebuild or replacement.

Conclusion: Trust Aftermarket Aviation Spares for Quality Engine Parts

In conclusion, a bad crankshaft bearing can indeed cause an engine seizure, leading to severe damage and costly repairs. Ensuring proper engine maintenance and addressing any issues early on can help prevent such catastrophic failures. When it comes to sourcing high-quality engine parts, including crankshaft bearings, trust Aftermarket Aviation Spares. They offer a wide range of reliable and durable components to keep your engine running smoothly. Whether you're in aviation or any other industry, Aftermarket Aviation Spares is your go-to supplier for top-notch engine parts.

0 notes

Video

youtube

Ford Fiesta 1.25 - Capteur PMH Crankshaft Position Sensor Ford -حساس ال...

#youtube#Crankshaft Position Sensor The crankshaft position sensor also known as CKP sensor is a type of sensor used in internal combustion engines t

0 notes

Note

If you feel like info dumping or if you even know.

The trucks with the crank in the front of them. How does that work? What is being cranked?

Or is that some made up movie nonsense that I fell victim too because I’ve never seen one in real life I just know of their existence.

No, they're real. Here's a video of a 1978 Land Rover S3 being cranked. Older ones (depending on how long they've been sitting) you'd have to spin the handcrank multiple times to get them started (just don't do what that fella did—only use your left hand, never your right and never both, otherwise it's a good way to shatter every bone in your hand when the engine turns over). The fella with the Land Rover was taking chances if you ask me because he could've broken his ankle if the handcrank whipped back over. They do that sometimes.

Anyway...

Basically what happens is the handcrank is pushed into the front of the vehicle below the radiator to connect to the crankshaft (that's this thing in the engine):

The crankshaft is what spins and connects to the pistons. The pistons is what causes pressurisation in the engine. Piston goes up, it pushes a petrol and air mixture upward to touch the sparkplug above it. Sparkplug ignites the petrol when it makes contact, a (contained) explosion happens, that pushes the piston back down and makes the crankshaft rotate. The pistons keep the crankshaft moving, and the crankshaft provides power (in this case rotational force—"torque") to the clutch and transmission, which then provides that power to the driveshaft, which is a spinning rod that connects to the differentials (the part that lets your wheels spin independently of each other). The differential(s) connectes to your axles, and the axles makes the wheels spin, which makes your car go forward.

Normally that first "push" of the crankshaft (the initial overturn of it—this is "turning over" an engine) is done by the starter. Some old cars didn't have starters, so you were required to manually crank the crankshaft to build pressure in the cylinder, and the magneto (a now-defunct type of ignition system) would create the spark (along with a small transformer) that would spark to combust the engine and turn the engine over.

Cranking cars is something that was very common back in old cars (especially those in extreme weather conditions). For example crank-engines were very common up until around the 80s in Slavic cars due to cars being harder to ignite in cold weather (petrol is harder to vaporise when it's cold and it needs to be vaporised to be combusted, additionally batteries don't operate well in the cold so often the car batteries couldn't output enough power to work the start and crank the engine).

Other cars, like Land Rovers for example, were designed for use in "remote" terrain. Car batteries recharge by the alternator, but what do you do if you're in the middle of nowhere with a dead battery and no way to jump it or recharge the battery? That's when a hand crank comes in handy—your car battery will probably have enough juice to provide a spark to the sparkplugs, but not enough juice to power the starter motor (which connects to the flywheel to turn the crankshaft). In that scenario you can hand-crank the engine yourself to turn it over and your car battery will charge as the engine idles.

If you ask me, I really wish that hand-crank engines were still something commonly produced, especially in cars designed to be used for off-roading. They'd be a life-saver in some of the situations I get myself into.

5 notes

·

View notes

Text

SCIENCE SATURDAY!

All month, I have been teaching y'all bits and pieces about the minerals known as feldspars. They are the most common minerals in earth's crust. Today, we are going to learn some of the basic chemistry behind feldspar crystallization and erosion.

FELDSPAR CHEMISTRY

Feldspars are formed as a precipitate as magmas cool. As a result, there are many different kinds. Below is a phase diagram:

Ignore B, all we care about it the colorful triangle. All right, so we have 3 endmembers: Orthoclase (kspar), Albite (sodium plag), and Anorthite (calcium plag). Then, there are all the minerals in between which have different mixed percentages of sodium, calcium and/or potassium. For example, Bytownite is 70-90% calcium and 30-10% sodium. See why there are so many types?

All right, now magma. Magmas cool at different rates for various reasons I really don't want to go into because I am a paleontologist, not an igneous petrologist and that research I don't feel like doing.

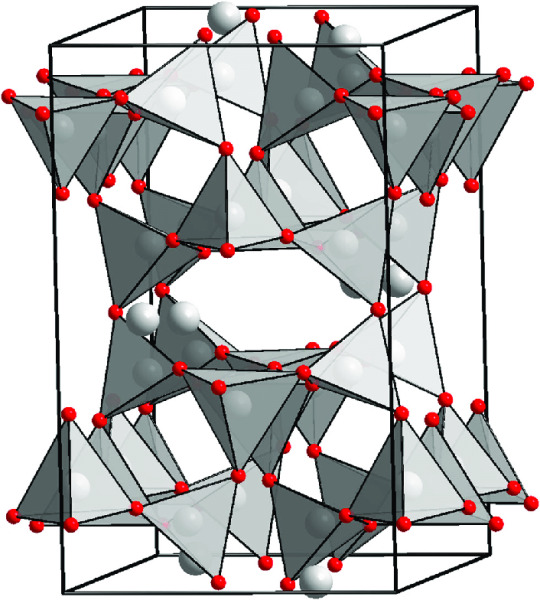

Feldspar structure: feldspars have what is called a "crankshaft" structure. We have a bunch of tetrahedrons linked by shared oxygen molecules and we make these fun hexagons.

Now, the basic chemical formula is (X)AlSi3O8. What we are essentially seeing is an Al 3+ substituted in for an Si 4+ causing a charge imbalance because 3 does not equal 4. This requires additional cations (called coupled substitutions).

EXAMPLE: Al 3+ and Na+ or K+ OR 2Al 3+ and 1 Ca 2+

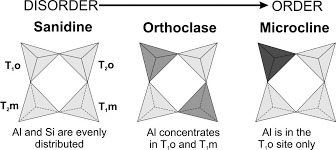

Where is the aluminum? That depends on the temperature of our magma! High temperatures make the position more random while low temps make it more ordered.

If we look at kspar (geologists are lazy and potassium feldspar is a lot to say) we have a K-Al coupled substitution with three polymorphs controlled by temperature and ordering. If we set up a graph where the y-axis is cooling rate and the x-axis is order, we would see the feldspar Sanidine has the lowest order and the fastest cooling and Microcline has the highest order and the slowest cooling while Orthoclase is somewhere in the middle.

Plagioclase has a complete solid solution between the endmembers Albite and Anorthite as I described earlier. Things to note are temperature (once again) plays an important role. Albite forms in low temp magma (800 degrees Celsius) and Anorthite forms in high temp magmas (1100 degrees Celsius). Yes, I know, 800 is a lot but not as mush as 1100 so deal.

They also contain different amounts of silica (SiO2). Albite is 75% silica while Anorthite only has 50%. Anorthite is also the first felspar mineral to crystallize in cooling magma.

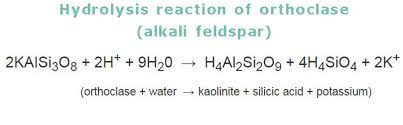

HYDROLYSIS

This is the chemical weathering of feldspars into clays such as illite, kaolinite, and smectite.

(That last one overlooks the dinosaur site I work at).

Due to the high temps that feldspars form at, they are not very stable at the surface. Therefore, they weather extraordinarily easily. Hydrolysis happens when water reacts with feldspar minerals (basic or acidic water works best because IONS). The feldspars are dissolved and then produce new ions in solution (K+, Ca2+, Na+).

Here is an example:

And now you know a little bit about the chemistry of feldspars!

36 notes

·

View notes

Text

The Convoluted Mess of Revavroom's Anatomy

"If we were going to make a Pokémon based on the motif of a car, for example, what would it eat? Would you make it able to suck up gasoline? How would it use the energy it got from that—how would it use that source of power? Even if the design is based on a car, a Pokémon is a living creature, so we would work over and over how to express its "car-ness" and what its source of energy should be."

Does this sound familiar? Probably not. This is a quote by Ken Sugimori, illustrator for Pokémon. In an interview for Pokémon Ultra Sun & Pokémon Ultra Moon Edition: The Official National Pokédex (yes, that is a mouthful), Ken was discussing the process of designing a Pokémon. Nearly 5 years after the guide was published, Pokémon Scarlet and Violet for the Nintendo Switch were released, and among the 102 new Pokémon first spotted in the vast Paldea region, we got two Pokémon that live up to Ken's point.

Varoom, the Single-Cyl Pokémon, and Revavroom, the Multi-Cyl Pokémon.

As you can tell by their designs, Varoom and Revavroom... certainly are genetic anomalies. A lot of people may be confused as to their digestive biology, but no fear, trainers! After having to rewrite this entire post after accidentally deleting it, I, Professor Athena, am here to tell you all about these mechanical marvels.

#0965 - Varoom

Before we can properly dissect what Varoom's diet consists of, we must first ask an important question regarding it...

..what is it exactly?

Well, in terms of origins, Varoom seems to be based on an internal combustion engine, a heat engine used in gasoline and diesel vehicles to convert gasoline into fuel for the car to run.

This actually ties into a small tidbit that we know about Varoom from Pokémon. According to Varoom's Pokédex entry in Pokémon Violet, the metallic part of Varoom is its actual body, the part that controls Varoom's movement and thought patterns. Meanwhile, the deep purple rocks that it carries around are supposedly its source of energy, converting the minerals of said rocks into energy.

While it may seem preposterous for a biotic creature such as Varoom to feed off of abiotic materials, this is an actual behavior present in numerous species of microorganisms. These microorganisms, often referred to as lithotrophs, use the energy of inorganic substrates to feed. Varoom does the same thing, but generalized to the rocks it will carry around with it

Although, while this does answer one question, it raises another all the same:

If Varoom feeds solely off the rocks that lay on its underbelly, then why does it have a "mouth" (which is truthfully a crankshaft)? It can't speak, and it's easy to assume that Varoom as a species doesn't rely too heavily on emotions for communication.

Well, there is a simple explanation for this: It does. The way that lithotrophs turn inorganic materials into energy isn't an evolutionary choice based on effectiveness, but rather necessity. What I mean is, lipotrophic means of consumption are much less practical than the things you and I are able to consume. While this low energy intake works for the sessile microorganisms, there are much better methods of intaking energy, rendering lipotrophy useless for more complex organisms, let alone Varoom. Despite what its in-game mechanics may suggest, Varoom is capable of long-term levitation and floats around the player at impeccable speeds. In order for a 35-kilogram-heavy being to be able to levitate at such speeds, it would require much more than occasional lithotrophy to rely on.

That begs the question of what Varoom actually eats with its "mouth". Since Varoom is devoid of teeth (thank Arceus for that decision), there are one of two reasonable conclusions that we can draw.

Varoom feeds exclusively off liquids and the energy it absorbs from rocks. Seeing as it's a car engine, while animalian in biology, it's still likely that it possesses some traits of IC engines. Given its Poison-typing, it's likely that poisonous/energetic liquids (slime, mucus, gasoline, fuel, etc.) are its main source of energy, leaving it motile for hours on end if it consumes enough.

It has an organ inside of its body that helps properly digest the food it eats once it swallows it. Avians (birds) have an organ for this purpose, being the gizzard. Once the avian swallows its food, the gizzard breaks the food down until it's safe enough for full consumption. A similar thing could be present within Varoom's anatomy, and there's a likely chance that this organ is Varoom's equivalent of a piston. In an IC engine, the pistons move up and down along the crankshaft, generating torque. This could be Varoom's "gizzard", breaking down the food it eats with its up-and-down movement. As for what it would digest if this was the answer, I suspect that its diet would consist of some of the many rock-like monsters that make up the vast world of Pokémon.

There is one more problem, with a plausible solution that could help to decipher the entire anatomical structure of Varoom as a whole, but we will focus on that as we talk briefly about Revavroom.

#0966 - Revaroom

Now, our discussion of Revavroom is going to be very brief, seeing as much of what we said with Varoom doubles for its evolution. However, there is one part of Revavroom that concerns me but will make the whole evolutionary family make a lot more sense.

Do you see anything off?

If you were pointing to the very ominous and out-of-place tongue that Revavroom has on its air filter mouth, you would be correct! This singular detail raises heaps of odd questions, all of which make the anatomy of this Pokémon an absolute mess.

Why is there a tongue in its air filter mouth?

Why does its actual "mouth" not have a tongue?

Why does it still consume energy from the rocks that are magnetically connected to it?

Does this mean that Revavroom could hypothetically eat three meals at once? And if so, why?

I almost gave up trying to decipher this, but then, in the throes of confusion, a paranormal answer spawned. I mentioned Varoom's Pokédex entry in Pokémon Violet but had completely neglected to look over its entry in Pokémon Scarlet; an entry that would explain everything.

Varoom's Pokédex entry in Pokémon Scarlet states that Varoom is said to be an inspirited car engine, with Varoom actually being an unnamed poisonous Pokémon controlling and powering the host, which is what we see.

This... explains it all! Sure, the wording does make it seem like nothing but conspiracy hokum that trainers use to gossip around the campfire with, but this could actually make perfect sense.

All Varoom are born from a parasitized mother, and many from a parasitized father as well. The parasite transfers to the offspring through their genetics (similar to some real-world examples). From there, Varoom is now fully controlled by the spirit possessing it, explaining the levitation and the ability to display lithotrophic traits despite being a complex organism (the spirit is sucking out the energy of the minerals).

Over time, the parasite grew stronger, thus growing a second, actual mouth. The spirit tries to grow past the confines of what we see with Revavroom. Revavroom, now having two mouths to feed, has to get as much energy as possible to sustain the energy it's consuming. Furthermore, tongues and ghosts in Pokémon are symbolic of each other, with the move Lick being one of the first Ghost-type Pokémon moves ever created.

This... was a lot. And yes, I did have to write most of this twice. But, trainers, I'm glad you enjoyed another lesson from Professor Athena! Tune in next time when they go over more burning scientific Pokémon questions! Ta ta!

#pokemon lore#pokemon theory#pokemon#pkmn#pokemon biology#pokemon headcanons#worldbuilding#revavroom#revaroompokemon#varoom#varoompokemon

26 notes

·

View notes

Photo

Volkswagen EA 48

The Volkswagen EA 48 was a very important car for Volkswagen, and it has not received the historical recognition it deserves. It was the first car designed entirely by Volkswagen, without engineering interference from the Porsche family. The Volkswagen Beetle had been a Porsche design, and Volkswagen wanted to experiment with an even smaller, cheaper, and even more logical vehicle. A rival for the Citroën 2CV, a Mini of German origin. It had to be a small car on the outside - it measured less than 3.5 meters, and its wheelbase was only 2,050 mm, 35 cm shorter than that of a Beetle - but to make enormous use of its interior space. Volkswagen decided to build a completely new platform for a project named EA 48, which would officially start in 1953. With the help of Gustav Mayer and Heinrich Siebt, development of a four-seater, front-engine, air-cooled, front-wheel drive utility began. At the time, quite a revolution. The Volkswagen EA 48 used a McPherson-type front suspension system, practically being a pioneer worldwide. This scheme freed up space for the engine and was simple to manufacture. In a car like the Volkswagen EA 48, the rationalization of space was one of the most important maxims. Extremely narrow 120 mm section tires were mounted, and instead of opting for a mechanics with four opposed cylinders like that of the Volkswagen Beetle, a two-cylinder mechanics was chosen. Two opposed cylinders, again creating a clear parallel with the Citroën 2CV. They tried to develop a 700 cc boxer, air-cooled, with a fan located on the crankshaft. The idea was soon discarded and a new 594 cc boxer was chosen, whose fan was driven by a belt, as in the Beetle. The engine barely developed 18 CV of power at 3,800 rpm, and although the behavior of the car was described As a sports car by its developers, the engine did not receive much praise. It was a very light car, and thanks to its 574 kg weight, it was capable of reaching almost 100 km/h top speed. The problem with the engine was its cooling: it overheated, and it wasn't until an original Porsche fan was attached to it that its temperature was manageable. This setback delayed its development.

Its interior was the most spartan of the moment. Its four seats were practically beach chairs, a cloth hung between metal supports, again seeking the highest space-cost ratio. Only one of the two prototypes built is still in existence, and by now you may be wondering why it doesn't have a window or tailgate. The absence of a window is due to its status as a prototype, but curiously, Volkswagen was thinking of offering the openable boot hatch as an option.

The project seemed to be prospering, but after two years of development, the president of Volkswagen decided to hastily cancel the project. Heinz Nordhoff thought that the Volkswagen 600 would snatch sales from the Beetle, which, after a difficult market launch, was beginning to take off commercially. In the late 1950s Morris would launch the Mini, with similar ideas to the EA 48 - albeit a more modern liquid-cooled transverse engine - and huge commercial success. Possibly someone at Volkswagen regretted canceling its development.

42 notes

·

View notes

Text

The 1935 Monaco-Trossi race car had several features that set it apart from everything else on the grid. Its design drew inspiration from aircraft, featuring a front-mounted radial engine and an overall shape reminiscent of a wingless plane.

The power plant was an air-cooled, 2-row 16-cylinder engine boosted by 2 Zoller superchargers from behind.

An unconventional feature was its 2-stroke cycle with a split-cylinder design. The rear cylinders were fed by air, and the combustion remains were then flushed through two 4-to-1 exhaust headers out of the front cylinders. With a displacement of 4 liters, it had undersquared cylinders (65 × 75 mm). The crankshaft was a 3-piece unit placed inside a duralumin crankcase. Connecting rods were of a master-and-slave type and the two superchargers provided a mild boost of 0.7 bar (10 psi), each fed by a Zenith carburetor. The final output of 250 hp at 6,000 rpm was nothing to write home about, as the competition had engines producing beyond 350 hp.

The gearbox was mounted right behind the power unit, and the driver sat in the middle of the car. This layout made the car massively front-heavy, with a weight distribution of 75:25. Its debut was meant to take place at the 1935 Monza GP, but during official testing, it exhibited dangerously imbalanced behavior. The car had an independent front axle with cockpit-adjustable oil dampers and wider front tires, but it suffered from extreme understeer nevertheless.

Moreover, the air-cooled engine had insufficient venting. Due to overheating and handling issues, the Monaco-Trossi car was never put on the starting grid. Even its top speed of 240 km/h (150 mph) was significantly lower than the figures upwards of 300 km/h (186 mph) achieved by German cars. The Italian car was lighter, but that was not enough to compensate for its other deficiencies.

The team did not attempt to fix the issues and abandoned the program immediately.

Fortunately, the single surviving example made it through wartime, and after Trossi's death in 1949, his widow donated the car to an automobile museum in Turin. It remains in perfect condition.

3 notes

·

View notes

Text

How does an engine contribute to a car's powertrain?

The powertrain in a vehicle is the system responsible for generating power and delivering it to the wheels to propel the vehicle forward. The operation of a powertrain can vary depending on whether the vehicle is powered by an internal combustion engine (ICE) or an electric motor (in the case of electric vehicles). Here's a general overview of how a powertrain works in both types of vehicles:

Internal Combustion Engine (ICE) Vehicle - Combustion Process: In an ICE vehicle, the powertrain starts with the combustion process in the engine. Fuel (gasoline or diesel) mixes with air in the combustion chamber and is ignited by spark plugs (in gasoline engines) or compression (in diesel engines).

Power Generation: The combustion process generates energy in the form of mechanical power, causing pistons to move up and down within the cylinders of the engine. This motion drives the crankshaft, converting linear motion into rotational motion.

Transmission: The rotational motion from the crankshaft is transmitted to the transmission, which consists of gears that allow the driver to select different ratios (speeds). This enables the engine to operate efficiently across a range of vehicle speeds.

Drivetrain: The transmission sends power to the drivetrain components, including the driveshaft, differential, and axles, which transfer power to the wheels. The differential allows the wheels to rotate at different speeds, enabling smooth turns.

Wheel Movement: The power transmitted through the drivetrain causes the wheels to rotate, propelling the vehicle forward or backward depending on the gear selection and throttle input from the driver.

Electric Vehicle (EV) -

Battery Pack: The primary source of power for the EV, storing electricity in chemical form.Powers the electric motor and provides electricity for all electronic devices within the EV.

Battery Management System (BMS): Monitors battery cell conditions, including voltage, current, temperature, and state of charge (SoC).It protects the battery against overcharging, deep discharging, and overheating and helps balance the charge across cells. Ensures optimal performance and longevity of the battery by regulating its environment.

Inverter: Converts DC from the battery pack into AC to drive the electric motor.Adjusts the frequency and amplitude of the AC output to control the motor’s speed and torque. Critical for translating electrical energy into mechanical energy efficiently.

Onboard Charger: Facilitates the conversion of external AC (from the grid) to DC to charge the battery pack. Integrated within the vehicle, allowing for charging from standard electrical outlets or specialized EV charging stations. Manages charging rate based on battery status to ensure safe and efficient charging.

DC-DC Converter: Steps down the high-voltage DC from the battery pack to the lower-voltage DC needed for the vehicle's auxiliary systems, such as lighting, infotainment, and climate control. Ensures compatibility between the high-voltage battery system and low-voltage electronic components.

Electric Motor: Converts electrical energy into mechanical energy to propel the vehicle. It can be of various types, such as induction motors or permanent magnet synchronous motors, each offering different efficiencies and characteristics. Typically provides instant torque, resulting in rapid acceleration.

Vehicle Control Unit (VCU): The central computer or electronic control unit (ECU) that governs the EV's systems. Processes inputs from the vehicle’s sensors and driver inputs to manage power delivery, regenerative braking, and vehicle dynamics. Ensures optimal performance, energy efficiency, and safety.

Power Distribution Unit (PDU): Manages electrical power distribution from the battery to the EV’s various systems. Ensures that components such as the electric motor, onboard charger, and DC-DC converter receive the power they need to operate efficiently. Protects the vehicle's electrical systems by regulating current flow and preventing electrical faults.

In both ICE vehicles and EVs, the powertrain's components work together to convert energy into motion, enabling the vehicle to move efficiently and effectively. However, the specific technologies and processes involved differ significantly between the two propulsion systems.

#electric powertrain technology#conventional powertrain#Electric vehicle components#revolo hybrid car kit#ev powertrain development services#software (SW) platforms for all Electric vehicles components#Battery Management Systems#Inverter#Smart Charger#VCU solutions

3 notes

·

View notes

Photo

Back in a former life, I had an addiction that I loved beyond sanity. Here’s the story of it. 2002 2003 2004 2005 2006 2007 2008 2009 pt1 2009 pt2 2009 Redux

This is the final spec list for my glorious, insane Brutal Truth.

Nissan Skyline BCNR33 GT-R (Type 2) manufactured in April 1996. JDM non V-Spec vehicle retailed through Osaka Nissan Prince in May/June 1996. Imported to the UK in June 1997. Remained in original JDM spec without speedometer conversion until August 2002. Only the steering wheel & white dial sets were fitted in Japan.

Nismo RB26N1 bare engine: [N1 water pump (improved flow & less cavitation)/Reinforced cylinder block head bolt boss/Increased sump capacity (6L 20w60)/1.2mm oil restrictor]

N1 head with 0.5mm overbore (2598cc)

Cryogenically hardened N1 crankshaft

Wossner forged & cryogenically hardened pistons

Abbey Motorsport reinforced & cryogenically hardened con-rods

ACL Race Series conrod & crankshaft bearings

Tomei sump baffle kit

Tomei high flow (larger drive gears) oil pump

HKS 1.2mm metal head gasket

Tomei Procam Spec 2 cam kit (270 degree inlet & outlet with 10.25mm lift)

HKS V-Cam System Step 1 Type B (variable 248-278 degree inlet; replaces Procam inlet camshaft)

HKS vernier cam pulleys

HKS kevlar reinforced timing belt

Trust metal intake & throttle gaskets

HKS front pipe & decat gaskets

GReddy Iridium 08 Racing sparkplugs

Mocal 19-row oil cooler & Abbey Motorsport remote oil filter assembly

Abbey Motorsport catch tank & washer reservoir with SFS breather hoses

Abbey Motorsport Pro Alloy large radiator

Tomei fuel pump, fuel regulator & 600cc injectors

A’PEXi Power Intake induction kit

A’PEXi GT Spec intercooler (237x610x136mm) & hard pipe kit

HKS GT-SS turbos

HKS twin AFM delete kit

Tomei turbo elbows

HKS downpipes

HKS Silent Hi-Power exhaust

Abbey Motorsport 80mm decat pipe

Mine’s VX-ROM

HKS F-Con V Pro

HKS EVC 6 boost controller (1.6 bar)

AEM wideband lambda sensor

Splitfire DI Super Direct Ignition System

HKS Circle Earth kit

HKS GD Max twin-plate clutch (with lightened flywheel)

Abbey Motorsport rebuilt transfer box

Abbey Motorsport rebuilt gearbox with cryogenically hardened gear set, modified Nissan synchromesh upgrade and OS Giken strengthening plate

Abbey Motorsport rebuilt rear diff

Nismo gearbox mounts

Nismo Solid Shift gear stick (10% short shift)

Omex Shift Light Sequential

Sunsei SE-135 solar panel trickle charger mounted on a custom aluminium riser between the rear parcel shelf speaker enclosures.

Team Dynamics Equinox alloys 19x9.5, ET+15 in silver with polished stainless steel rim.

Falken FK452 265/30/19 Y-rated tyres

Cusco brake master cylinder brace

Cusco rear steering delete kit

Cusco front & rear upper suspension links

AST Sport Line 1 full suspension kit with UK spring setup

Nismo stainless steel braided brake hoses

StopTech 355mm rotor 4 pot caliper front brake kit

StopTech 355mm rotor 2 pot caliper rear brake kit with Abbey Motorsport modified pad retainers

Ferodo DS2500 brake pads front & rear

Bomex AD-390 front splitter

Nismo R34 smoked front indicators in custom aluminium mounting plates finished in crackle black

Nissan Xenon headlamp units

Border Racing Aero Fenders (vented front wings) with silver GT emblems from a R32 Skyline

Nismo smoked side repeaters

Top Mix one-off FRP twin blade rear spoiler on custom aluminium mounting plates

Entire exterior resprayed in BMW black (code 086) base and lacquer

Nissan Motorsport International carbon fibre B-pillar plates

PIAA carbon effect silicon wipers, front pair with spoilers, rear without

Nismo white face dial sets (dashboard & centre console) in carbon fibre panels

AEM AFR gauge mount replaces the lighter socket

HKS EVC display mounted on custom carbon fibre plate replacing the ashtray

Lighter socket relocated to the fog light switch panel

Nissan Momo steering wheel (with airbag)

Dressycar Nismo harness pads

Redline Automotive leather gearstick & handbrake gaiters

Abbey Motorsport carbon fibre door sill trims

Carbon fibre boot sill trim

Inlet plenum and sundry induction pipework finished in powder grey

Trust clear cam pulley cover

HKS Kansai Service carbon fibre spark plug cover

Right hand cam cover finished in crackle black

Nismo radiator & washer reservoir caps

HKS Kansai Service front strut brace finished in high gloss black

GReddy aluminium slam panel finished in crackle black

Tein bonnet dampers with black sleeves

Custom made one-off Cobra Misano Lux front seats: [Alcantara (colour code 9189) outers/Alcantara (colour code 9182) centre panels/One-piece carbon fibre backs/Sidewinder bases on custom subframes adapted by Abbey Motorsport/Cobra logo in silver thread on the headpads/GT-R logo beneath the grommets on seat backs]

JVC KD-AVX2 multi-media DVD/CD receiver with built-in 3.5” widescreen monitor

2x JL Audio Evolution VR600-CXi 6” speakers (front)

2x JL Audio Evolution TR650-CXi 6.5” speakers (rear)

Multiple and interlaced Thatcham rated security systems.

500 bhp. 520 ft/lb.

Ludicrously, hilariously, unbelievably fast.

Hope you enjoyed this little trip down memory lane with me. Cheers! JM.

(Photo by N. Liassides.)

#r33#bcnr33#skyline#gt-r#nissan skyline#Abbey Motorsport#HKS#Bomex#Tomei#A'PEXi#GReddy#Nismo#RB26N1#Mocal#Team Dynamics

13 notes

·

View notes

Text

Hey everyone, time for a long overdue update!

Combustion Engines - Not Ready Just Yet

By this point, I was hoping to have combustion engines done. I tried a purely physics based approach, using separate cylinder, piston, con-rod, & crank rigidbodies, and applying a force to the piston based on the current angle of the crank. This worked reasonably well, but had problems with "phantom forces" whereby the engine got torque applied to it, sometimes flipping over the vehicle it's in. Also, using physics for all the parts like this has RPM limitations, and doesn't scale that well for sim performance.

So I've decided to change tack slightly, I still want to keep the appearance of the moving parts (i.e. pistons and con-rods), but my plan is now to procedurally animate these in code. There's not really any need to use physics as these parts can't collide with anything when inside an engine. To apply torque to the crankshaft, I'm working on something similar to the electric motors, but with a different torque curve.

Hopefully I'll be able to get this done soon, but in the meantime I thought it would be good to get a small update out. Here's what's in it…

Parts

There are now some slider versions of the 1-Hole and 2-Hole connectors, some new "angle axle" connectors, and a larger centrifugal clutch.

Also, the rounded beams can now be resized one unit smaller than before.

Part Behaviours

I've improved how the invert option works for parts with a single key bind (e.g. brakes), adding a separate invert option for the joystick axis.

You can now type in values for any part behaviour slider, by right clicking it. Even values beyond the normal slider range can be entered (but no guarantees the physics won't blow up with higher RPMs or torques!)

No Collide Tool

For those who want to bypass part collisions in their builds, I've added a new "PartCollision" script mod tool that can be used to disable part collisions. Parts with their collision disabled will still collide with the ground, but nothing else.

Here are the full release notes:-

New parts:-

"1-Hole Slider" and "2-Hole Slider" connectors.

Angle axle 90, 180, 3 x 90, & 4 x 90 connectors.

Centrifugal clutch x3.

Rounded and half rounded beams can now be resized one unit shorter.

Added "invert axis" option to part behaviour joystick axis settings.

In brake, clutch, and differential part behaviours, replaced "invert direction" option with "invert control", which properly inverts their control behaviour.

By right clicking a slider in the part behaviour settings, it's value can now be edited by typing in a number.

Shortcuts (Ctrl+C and Ctrl+V) for copy and paste in part behaviour settings.

A construction can now be unfrozen (via the construction UI) while the player is seated in it.

Lowered minimum mouse sensitivity values.

Added methods to IConstructionOperations to set whether parts are collidable (and added IsCollidable property to IPart interface).

Added new PartCollision script mod.

Bug fixes.

Upgraded to Unity 2021.3.34.

4 notes

·

View notes

Text

Mankoo Presses: Your Trusted Partner in Power Press Machinery

When it comes to precision engineering and high-performance machinery, Mankoo Presses stands as a name synonymous with excellence. Specializing in the manufacturing of top-quality power press machines, forging press machines, cross shaft press machines, H frame power press machines, and C frame power press machines, Mankoo Presses has established itself as a leader in the industry. With years of expertise, state-of-the-art technology, and a commitment to innovation, the company provides reliable solutions for various industrial applications.

Power Press Machines: The Backbone of Metal Forming

A power press machine is an indispensable tool in metalworking industries, responsible for shaping, cutting, and forming metal sheets with precision. These machines are widely used in industries such as automotive, aerospace, electrical, and heavy engineering. Mankoo Presses manufactures high-performance power press machines that deliver efficiency, durability, and consistency in operation.

With robust designs and advanced automation features, Mankoo’s power press machines offer seamless operation, enhancing productivity while reducing downtime. The company ensures that every press machine meets stringent quality standards and withstands the test of time.

Forging Press Machines: Strength and Precision Combined

Forging press machines play a crucial role in metal shaping by applying compressive force to mold metals into desired shapes. These machines are commonly used for manufacturing automotive components, industrial tools, and structural parts.

Mankoo’s forging press machines are designed to handle high-pressure applications with ease. Engineered for superior durability, these presses provide exceptional control over the forging process, ensuring precise and high-quality output. Their energy-efficient mechanisms and rugged construction make them ideal for heavy-duty industrial use.

Key Features of Mankoo Forging Press Machines:

High Tonnage Capacity: Capable of handling heavy workloads with ease.

Precision Control: Advanced control systems for accurate shaping.

Energy Efficiency: Optimized power consumption for cost-effective operations.

Robust Design: Built to last, reducing maintenance requirements.

Cross Shaft Press Machines: High-Speed Performance with Accuracy

The cross shaft press machine is widely known for its ability to perform high-speed stamping and pressing operations. This type of press is ideal for mass production industries where speed and precision are of utmost importance.

Mankoo’s cross shaft press machines are built to meet the demands of modern manufacturing, ensuring minimal vibration and maximum stability. With a well-balanced crankshaft mechanism, these machines provide superior accuracy and efficiency, making them suitable for industries such as electronics, automotive, and precision component manufacturing.

Why Choose Mankoo’s Cross Shaft Press Machines?

Enhanced Stability: Reduced vibration for precise operations.

High-Speed Capabilities: Perfect for fast production lines.

User-Friendly Design: Easy to operate and maintain.

Durability: Long-lasting performance with minimal wear and tear.

H Frame Power Press Machines: Sturdy and Versatile

The H frame power press machine is one of the most popular choices for industries that require high-strength pressing applications. The ‘H’ frame design provides superior rigidity, ensuring uniform force distribution across the workpiece.

Mankoo’s H frame power press machines are engineered to deliver high efficiency and versatility. These machines are widely used in applications such as deep drawing, blanking, punching, and forming. The frame’s robust construction minimizes deflection, ensuring precision even under high load conditions.

Advantages of Mankoo’s H Frame Power Press Machines:

High Structural Rigidity: Ensures consistent performance under heavy loads.

Improved Safety Features: Equipped with safety mechanisms to prevent accidents.

High Load-Bearing Capacity: Ideal for industrial-grade operations.

Advanced Automation: Designed for ease of operation with automated controls.

C Frame Power Press Machines: Compact Yet Powerful

The C frame power press machine is another essential machine in metal forming industries. Recognized for its compact design and high accessibility, this machine is perfect for applications that require open-sided access.

Mankoo’s C frame power press machines are designed to handle a variety of punching, bending, and shearing tasks with ease. These machines offer superior flexibility, allowing for easy die changeovers and quick maintenance. Their small footprint makes them ideal for workshops with space constraints while still delivering powerful performance.

Features of Mankoo’s C Frame Power Press Machines:

Compact Design: Saves space while providing powerful performance.

Easy Accessibility: Open-sided design allows easy loading and unloading of materials.

Precision Engineering: High accuracy in metal forming operations.

Versatile Applications: Suitable for various pressing and stamping jobs.

Why Choose Mankoo Presses?

Mankoo Presses has earned a reputation for delivering high-quality and reliable power press solutions. The company focuses on integrating cutting-edge technology, precision engineering, and customer-centric designs to provide the best pressing solutions for industrial applications. Here are some reasons why Mankoo Presses stands out:

Expertise & Experience: Years of experience in manufacturing high-performance press machines.

Innovative Technology: Continuous research and development to improve efficiency and performance.

Customization Options: Tailored solutions to meet specific industrial needs.

Robust Quality Control: Stringent testing procedures to ensure durability and reliability.

Excellent After-Sales Support: Dedicated customer service for maintenance and troubleshooting.

Conclusion

Mankoo Presses is a leading manufacturer of power press machines, forging press machines, cross shaft press machines, H frame power press machines, and C frame power press machines. Their commitment to quality, innovation, and customer satisfaction has made them a trusted name in the industry.

Whether you need a heavy-duty forging press for industrial applications or a compact C frame press for precision tasks, Mankoo Presses has the right solution for you. With their expertise, advanced technology, and dedication to excellence, Mankoo Presses ensures that you get the best-in-class machinery for all your pressing needs.

For businesses looking to enhance their manufacturing capabilities, Mankoo Presses is the go-to choice. Contact them today to explore a range of high-quality power press solutions that can transform your production process!

0 notes

Text

When Should You Opt For Timing Belt Replacement Adelaide? Consider These Signs

Introduction

Timing belts let your car’s engine function properly. They maintain the synchronization of the rotation system of the crankshaft as well as the camshaft. A perfect synchronization is important to open and close the engine valves. However, timing belts go through great forces and develop issues with time. Your timing belt may need a new timing belt replacement Adelaide at some point. But when should you replace your car’s timing belt? This is what you will explore here. Read on to find some common signs of a faulty timing belt.

Signs To Consider For Timing Belt Replacement or Repair

Misfire of Engine

A timing belt functions through multiple pulleys. These pulleys control the crankshaft as well as the camshaft. For this, they use teeth that are designed to grip and rotate the belt smoothly. However, it the belt wears out, you will find a ticking or clicking sound coming from the engine frequently. If you are experiencing the same issue, then its time to get your timing belt checked by an auto expert.

Oil Leaks Around the Cover of the Timing Belt

Timing belt and oil never mix. If you find oil pooling or seeping around the cover of the timing belt, it can be a sign of a faulty timing belt. Oil damages the belt’s rubber, affecting its integrity. This, in turn, can increase the chances of belt snapping. Such type of leak also suggests a faulty camshaft or crankshaft seal.

Visible Damage Signs on the Belt

Timing belts don’t last forever. It will wear down after some time. If you carefully check the belt, you may notice fraying, missing teeth or cracks on the belts. A damaged or worn belt can snap at times, leading to a costly engine repair. So, if you find any of these visible wear and tear, replace the belt as soon as possible.

Low Engine Performance

With a worn timing belt, your car’s engine may not be able to perform at its maximum level. Your car will become sluggish, and you will find it challenging to acceleration. As it wears and stretches over time, it will not offer the accurate timing required for an optimal performance. This, in turn, will lead to a visible decrease in acceleration and power. Remember that if you ignore such signs, it can worsen the situation and you may need to spend a lot of money on engine repair. So, take the necessary steps and get your timing belt repaired and replaced with the help of an experienced mechanic.

Conclusion

To make your car start properly, it is important to ensure that the timing belt is in perfect condition. If the timing belt has faults, you will hear strange noises, and your engine may not ignite. Such signs suggest that you need to go for a professional timing belt replacement Adelaide. However, this should be done by a professional mechanic and for that, you can always count on Adelaide CV Joints. We have been offering quick and reliable timing belt replacement service for years. When you are with us, you can find timing belts at the best prices and make your car run smoothly like before in no time. Contact us today to know more!

0 notes

Text

Automotive Battery Management System Market To Witness the Highest Growth Globally in Coming Years

The report begins with an overview of the Automotive Battery Management System Market 2025 Size and presents throughout its development. It provides a comprehensive analysis of all regional and key player segments providing closer insights into current market conditions and future market opportunities, along with drivers, trend segments, consumer behavior, price factors, and market performance and estimates. Forecast market information, SWOT analysis, Automotive Battery Management System Market scenario, and feasibility study are the important aspects analyzed in this report.

The Automotive Battery Management System Market is experiencing robust growth driven by the expanding globally. The Automotive Battery Management System Market is poised for substantial growth as manufacturers across various industries embrace automation to enhance productivity, quality, and agility in their production processes. Automotive Battery Management System Market leverage robotics, machine vision, and advanced control technologies to streamline assembly tasks, reduce labor costs, and minimize errors. With increasing demand for customized products, shorter product lifecycles, and labor shortages, there is a growing need for flexible and scalable automation solutions. As technology advances and automation becomes more accessible, the adoption of automated assembly systems is expected to accelerate, driving market growth and innovation in manufacturing. Automotive Battery Management System Market Size, Share & Industry Analysis, By Type (Lithium-ion, Lead Acid, Nickel-based), By Connection Topology (Centralized , Distributed , Modular), By Vehicle type (Electric Vehicles, E-bikes) And Regional Forecast 2021-2028

Get Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/105479

Key Strategies

Key strategies in the Automotive Battery Management System Market revolve around optimizing production efficiency, quality, and flexibility. Integration of advanced robotics and machine vision technologies streamlines assembly processes, reducing cycle times and error rates. Customization options cater to diverse product requirements and manufacturing environments, ensuring solution scalability and adaptability. Collaboration with industry partners and automation experts fosters innovation and addresses evolving customer needs and market trends. Moreover, investment in employee training and skill development facilitates seamless integration and operation of Automotive Battery Management System Market . By prioritizing these strategies, manufacturers can enhance competitiveness, accelerate time-to-market, and drive sustainable growth in the Automotive Battery Management System Market .

Major Automotive Battery Management System Market Manufacturers covered in the market report include:

Some of the major companies that are present in the automotive battery management system market include Thyssenkrupp AG, Nippon Steel Integrated Battery Management LLC, Braynt Racing Inc., Arrow Precision Ltd., Maschinenfabrik Alfing Kessler GmbH, Mahindra CIE, Tianrun Battery Management Co., Ltd., among others.

Owing to this, many Battery Management manufacturers are developing advanced Battery Management with improved fatigue strength, reliability, and quality. Also, the crankshafts are manufactured with the latest trend of steelmaking processes by materials with high strength, and this factor is also expected to drive the automotive Battery Management market.

Trends Analysis

The Automotive Battery Management System Market is experiencing rapid expansion fueled by the manufacturing industry's pursuit of efficiency and productivity gains. Key trends include the adoption of collaborative robotics and advanced automation technologies to streamline assembly processes and reduce labor costs. With the rise of Industry 4.0 initiatives, manufacturers are investing in flexible and scalable Automotive Battery Management System Market capable of handling diverse product portfolios. Moreover, advancements in machine vision and AI-driven quality control are enhancing production throughput and ensuring product consistency. The emphasis on sustainability and lean manufacturing principles is driving innovation in energy-efficient and eco-friendly Automotive Battery Management System Market Solutions.

Regions Included in this Automotive Battery Management System Market Report are as follows:

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

Middle East & Africa [GCC, North Africa, South Africa, Rest of the Middle East and Africa]

Significant Features that are under offering and key highlights of the reports:

- Detailed overview of the Automotive Battery Management System Market .

- Changing the Automotive Battery Management System Market dynamics of the industry.

- In-depth market segmentation by Type, Application, etc.

- Historical, current, and projected Automotive Battery Management System Market size in terms of volume and value.

- Recent industry trends and developments.

- Competitive landscape of the Automotive Battery Management System Market .

- Strategies of key players and product offerings.

- Potential and niche segments/regions exhibiting promising growth.

Frequently Asked Questions (FAQs):

► What is the current market scenario?

► What was the historical demand scenario, and forecast outlook from 2025 to 2032?

► What are the key market dynamics influencing growth in the Global Automotive Battery Management System Market ?

► Who are the prominent players in the Global Automotive Battery Management System Market ?

► What is the consumer perspective in the Global Automotive Battery Management System Market ?

► What are the key demand-side and supply-side trends in the Global Automotive Battery Management System Market ?

► What are the largest and the fastest-growing geographies?

► Which segment dominated and which segment is expected to grow fastest?

► What was the COVID-19 impact on the Global Automotive Battery Management System Market ?

Table Of Contents:

1 Market Overview

1.1 Automotive Battery Management System Market Introduction

1.2 Market Analysis by Type

1.3 Market Analysis by Applications

1.4 Market Analysis by Regions

1.4.1 North America (United States, Canada and Mexico)

1.4.1.1 United States Market States and Outlook

1.4.1.2 Canada Market States and Outlook

1.4.1.3 Mexico Market States and Outlook

1.4.2 Europe (Germany, France, UK, Russia and Italy)

1.4.2.1 Germany Market States and Outlook

1.4.2.2 France Market States and Outlook

1.4.2.3 UK Market States and Outlook

1.4.2.4 Russia Market States and Outlook

1.4.2.5 Italy Market States and Outlook

1.4.3 Asia-Pacific (China, Japan, Korea, India and Southeast Asia)

1.4.3.1 China Market States and Outlook

1.4.3.2 Japan Market States and Outlook

1.4.3.3 Korea Market States and Outlook

1.4.3.4 India Market States and Outlook

1.4.3.5 Southeast Asia Market States and Outlook

1.4.4 South America, Middle East and Africa

1.4.4.1 Brazil Market States and Outlook

1.4.4.2 Egypt Market States and Outlook

1.4.4.3 Saudi Arabia Market States and Outlook

1.4.4.4 South Africa Market States and Outlook

1.5 Market Dynamics

1.5.1 Market Opportunities

1.5.2 Market Risk

1.5.3 Market Driving Force

2 Manufacturers Profiles

Continued…

About Us:

Fortune Business Insights™ delivers accurate data and innovative corporate analysis, helping organizations of all sizes make appropriate decisions. We tailor novel solutions for our clients, assisting them to address various challenges distinct to their businesses. Our aim is to empower them with holistic market intelligence, providing a granular overview of the market they are operating in.

Contact Us:

Fortune Business Insights™ Pvt. Ltd.

US:+18339092966

UK: +448085020280

APAC: +91 744 740 1245

#Automotive Battery Management System Market#Automotive Battery Management System Market Share#Automotive Battery Management System Market Size#Automotive Battery Management System Market Trends

0 notes

Text

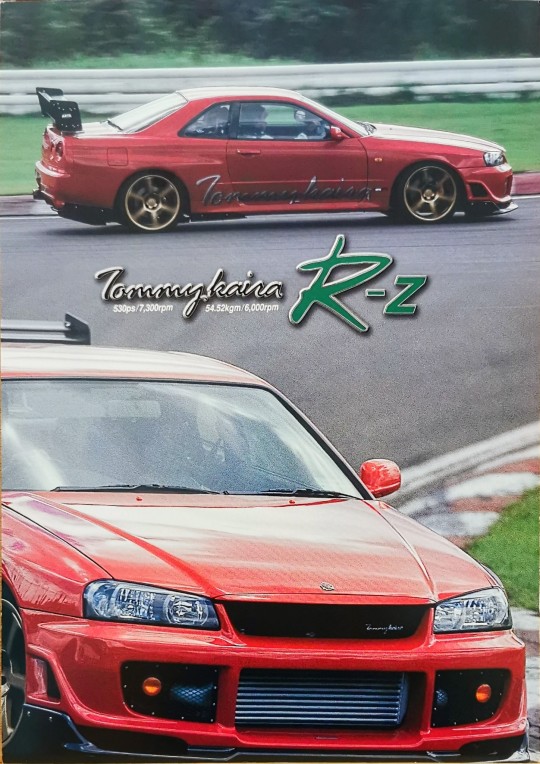

Tommykaira R-z brochure translation.

The wonders of Tommykaira Magic that you can experience while driving. R

Total balance with a high degree of perfection commensurate with 530ps.

The displacement has been increased to 2700cc, achieving a maximum output of 530 horsepower and a maximum torque of 54.52kgm. To achieve this, various types of tuning have been applied. For example, the crankshaft, which is the most important element for bringing out the best performance of the engine, is an original crankshaft manufactured by Fandon in the UK. Highly rigid full counter type provides excellent balance performance. Furthermore, the R-z uses an H-section connecting rod and forged aluminum piston, making it both highly rigid and lightweight. What's more, it achieves well-balanced tuning. In addition, the R-z uses metal head gaskets, high-lift camshafts, valve springs, and racing plugs to bring out the best in the pistons, connecting rods, and crankshafts that are the main moving parts. Composite Radiator Improves cooling effect by using NI water pump.

I got it.

Changes to the intake and exhaust system have resulted in a significant increase in efficiency through the use of a stainless steel exhaust system with suction from the front pipe and a racing type intercooler. By increasing the size of the fuel system parts and strengthening the drive system, you can enjoy ample torque even when driving at low rpm around town. What's more, the sense of power, extension, and revving at high rpm will captivate anyone sitting in the driver's seat.

suspension tuning is

"High ride comfort and handling"

Balance in Dimensions.” During normal driving

Passenger-friendly ride

While realizing the taste, wine day

It is sharp and has excellent turning performance when turning.

Tomita has achieved this goal and has received rave reviews from many quarters.

It's a magic called Kaira Magic.

The front brake has been strengthened to control the 530 horsepower. Uses AP 6-pot calipers, AP brake rotors, and PFC brake pads. This is a highly reliable braking system that responds precisely to the driver's wishes.

[mechanism]

engine body

・Cylinder head/port polishing

・Cylinder block/boring, internal polishing

・Original crankshaft made in UK Fandon

・Special H section connecting rod

・Special forged piston

・Titanium coated piston ring

・Metal head gasket

・High lift camshaft

・Reinforced valve spring, valve guide

・Racing plug

computer unit

・R-z dedicated computer unit

cooling system

・Large capacity water-cooled oil cooler

Water pump for high speed N1

Intake and exhaust system

・All exhaust system

・Large capacity intercooler

・Special turbine

fuel system

Large capacity air flow meter

large capacity injector

・Large capacity fuel pump

drive system

・Twin plate clutch

Reinforcement parts

・Strut tower bar (with master cylinder stopper)

・Reinforced engine mount

・Enhanced mission mount

[Suspension]

Brake system

・AP 6-pot caliper & rotor (F)

・PFC brake pad

suspension

・Bilstein original shock absorber

・Original spring (F)

Original double spring (R)

tires/wheels

・Forged magnesium cut wheel “PRO R” 9.5×19+22

・DUNLOP FORMULA FM901 275/30ZR19

Reinforcement parts

・Stainless mesh brake hose

・Front tension rod (pillow ball)

* [Exterior] and [Interior] are the same specifications as R-s.

Tommykaira R-Z SPECIFICATION

PRICE ¥10,500,000-

PERFORMANCE

Max Output 530ps/7300rpm

Max Torque 54.52kgm/6000rpm

ENGINE

RB26DETT STRAIGHT-6 DOHC Turbo with multi-cup Intercooler

Piston Displacement: 2700cc

Bore x Stroke: 87.0mm x 75.7mm

BODY

Length: 4620mm

Width: 1785mm

Height: 1335mm

Wheelbase: 2665mm

Tread: Front 1496mm

Rear 1496mm

LAYOUT

4 Wheels Drive

Transmission: 6MT

Brakes:(F) 6 Piston Opposed Type Caliper + Ventilated Disc

Brakes:(R) 2 Piston Opposed Type Caliper + Ventilated Disc

Wheels: 9.5JJX 19 (Front&Rear)

Tire: 275/30ZR19 (Front&Rear)

Suspension : Original Shock absorber + Original Coil Spring

Steering: Rack & Pinion < SUPER HICAS >

*Price is vehicle price delivered at Kyoto store, registration fees and consumption tax not included US specifications, data, etc. are subject to change without notice. *Detailed options, equipment, body color, etc. are based on genuine Nissan. Catalog photos may look different from the actual products as they are printed materials. For inquiries and requests..

TOMITA

dream factory

http://www.tommykaira.com

18 notes

·

View notes

Text

Ductile Cast Iron Market Insights and Global Outlook 2025-2031

"Ductile Cast Iron" 2025 Breakdown, Data Source, Secondary Sources, Primary Sources, Research Report delivers leading competitors strategic analysis, with micro and macro-economic factors, market trends, future growth scenarios, with pricing analysis. This report provides a holistic overview on Market Current Situations, Key Collaborations, Merger & Acquisitions along with Trending Innovations and New Business Development Policies. A detailed professional report focusing on primary and secondary growth drivers, regional segments, growth share, and geographical analysis of top key players. Ductile Cast Iron trend analysis with historical data, estimates to 2025 and Compound Annual Growth Rate (CAGR) forecast to 2031.

According to our (Global Info Research) latest study, the global Ductile Cast Iron market size was valued at US$ 32100 million in 2024 and is forecast to a readjusted size of USD 40510 million by 2031 with a CAGR of 3.4% during review period.

Ductile Iron is a type of cast iron known for its impact and fatigue resistance, elongation, and wear resistance due to the spherical (round) graphite structures in the metal. Ductile Iron is also called ductile cast iron, spheroidal graphite cast iron, or nodular cast iron. Ductile iron castings are very strong compared to regular cast iron (gray iron). The tensile strength of cast iron is 20,000 – 60,000 psi while ductile iron starts at 60,000 psi and can go to 120,000 psi. The yield strength for ductile iron is generally 40,000 – 90,000 psi but the yield strength of cast iron is so low it is considered not measurable. Ductile iron is great for use where you need strong metal with wear resistance. Here is a sample list of things made from or contain ductile iron: Pipe and pipe fittings, Axles, Connecting rods (like in engines), Crankshafts, Cylinders, Disc brake calipers, Gears and Gear Boxes, etc. The major players in global Ductile Cast Iron market include Waupaca Foundry, American Axle & Manufacturing (AAM), Georg Fischer, etc. The top 3 players occupy about 35% shares of the global market. North America and China are main markets, they occupy about 70% of the global market. Vertical Molding is the main type, with a share about 65%. Automotive is the main application, which holds a share about 30%.

Top Key Players Covered in Market Report 2025-2031:Proterial, Ltd. (Formerly Hitachi Metals)、Grede Foundry、Wescast Industries (Sichuan Bohong)、Grupo Industrial Saltillo、Tianjin New Wei San Industrial、Aludyne、Metal Technologies, Inc.、MAT Foundry、Castings PLC、Weichai Power (Weifang) Casting、Miracle Automation Engineering、Georg Fischer、Huaxiang Group、ACO Eurobar、INTAT Precision、Meide Group、Neenah Enterprises, Inc. (NEI)、Silbitz Group、Goldens’Foundry、Rochester Metal Products、Kutno Foundry (Luma Automation)、Denizciler、Aarrowcast, Inc.、Willman Industries、Chuo Malleable Iron Short Description of the Ductile Cast Iron 2025-2031: Market Overview of Global Ductile Cast Iron: According to our latest research, the global Ductile Cast Iron looks promising in the next 6 years. As of 2025, the global Ductile Cast Iron was estimated at USD Million, and it’s anticipated to reach USD Million in 2031, with a CAGR during the forecast years. This report covers a research time span from 2020 to 2031, and presents a deep and comprehensive analysis of the global Ductile Cast Iron, with a systematical description of the status quo and trends of the whole market, a close look into the competitive landscape of the major players, and a detailed elaboration on segment markets by type, by application and by region. Global and Regional Analysis: North America (United States, Canada and Mexico) Europe (Germany, France, United Kingdom, Russia, Italy, and Rest of Europe) Asia-Pacific (China, Japan, Korea, India, Southeast Asia, and Australia) South America (Brazil, Argentina, Colombia, and Rest of South America) Middle East & Africa (Saudi Arabia, UAE, Egypt, South Africa, and Rest of Middle East & Africa)

Market Segmentation Ductile Cast Iron report provides an exhaustive 360-degree analysis, by utilizing both primary and secondary research techniques. The research gained comprehensive insights into current market dynamics, pricing trends, developments, supply-demand and evolving consumer behaviors.

On the basis of product type, this report displays the production, revenue, price, market Vertical Molding、Horizontal Molding

On the basis of the end users/applications, this report focuses on the status and outlook for major applications/end users, consumption (sales), market share and growth rate for each Agriculture, Construction and Mining、Automotive、Energy and Power、Oil and Gas、Aerospace and Defense、Municipal、OthersOur method for estimating market size is holistic and multifaceted. We assess vital industry trends, regulatory landscapes, and segment-specific dynamics, evaluating their potential influence on demand projections. Key macroeconomic factors, including price fluctuations, demographic shifts, and changes in demand patterns, are integrated into our calculations. To discover market value, we not only delve deep into the profiles of prominent players and their global market shares but also rely on our frequently updated internal database, enriched with insights and announcements from pivotal market stakeholders.

Some of the Key Questions Answered in this Report:

What is the Ductile Cast Iron size at the regional and country level

What are the key drivers, restraints, opportunities, and challenges of the Ductile Cast Iron, and how they are expected to impact the market

What is the global (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa) sales value, production value, consumption value, import and export of Ductile Cast Iron

Who are the global key manufacturers of the Ductile Cast Iron? How is their operating situation (capacity, production, sales, price, cost, gross, and revenue)

What are the Ductile Cast Iron opportunities and threats faced by the vendors in the Ductile Cast Iron?

Which application/end-user or product type may seek incremental growth prospects? What is the market share of each type and application?

What focused approach and constraints are holding the Ductile Cast Iron?

What are the different sales, marketing, and distribution channels in the global industry?

What are the key market trends impacting the growth of the Ductile Cast Iron?

Economic Impact on the Ductile Cast Iron and development trend of the Ductile Cast Iron

What are the Ductile Cast Iron opportunities, market risk, and market overview of the Ductile Cast Iron