#construction hardware

Explore tagged Tumblr posts

Text

Hazardous Area Cable Glands: Ensuring Safety in Explosive Environments

What are Hazardous Area Cable Glands?

Hazardous Area Cable Glands are specialized fittings designed to protect electrical cables in environments where flammable gases or vapors are present. These areas, often referred to as "hazardous zones," pose a significant risk of explosion due to the potential ignition of these gases.

Key Features of Hazardous Area Cable Glands

Flameproof Design: These glands are engineered to withstand an explosion without igniting the surrounding atmosphere.

Certification: They must meet specific industry standards and certifications, such as ATEX or IECEx, to ensure their effectiveness.

Ingress Protection (IP) Ratings: Hazardous area cable glands typically have high IP ratings to protect against dust and water ingress.

Temperature Resistance: They are designed to withstand high temperatures to prevent the ignition of flammable gases.

Applications of Hazardous Area Cable Glands

Oil and Gas Industry: Offshore platforms, refineries, and petrochemical plants rely on these glands to protect electrical connections in areas where flammable gases are present.

Chemical Industry: Chemical processing plants often operate with hazardous materials, making hazardous area cable glands essential for safety.

Mining Industry: Underground mines can be prone to methane gas buildup, necessitating the use of these glands to prevent explosions.

Power Generation: Power plants, especially those using fossil fuels, may encounter hazardous areas where these glands are required.

Benefits of Using Hazardous Area Cable Glands

Enhanced Safety: By preventing the ignition of flammable gases, these glands significantly reduce the risk of explosions and fires.

Regulatory Compliance: Using certified hazardous area cable glands ensures compliance with industry standards and regulations, helping to avoid fines and penalties.

Protection of Electrical Equipment: These glands safeguard electrical cables and equipment from damage caused by explosions.

Increased Reliability: By maintaining the integrity of electrical connections, hazardous area cable glands contribute to the overall reliability of operations.

Selecting the Right Hazardous Area Cable Gland

When choosing hazardous area cable glands, consider the following factors:

Hazardous Area Classification: The gland's certification should match the specific hazardous area classification (e.g., Zone 0, Zone 1, Zone 2).

Cable Type and Size: The gland must be compatible with the cable being used.

Environmental Conditions: Factors like temperature, humidity, and corrosive substances may influence the gland's selection.

Ingress Protection Rating: Choose a gland with an appropriate IP rating based on the level of protection required.

Conclusion

Hazardous area cable glands are essential components in environments where flammable gases or vapors are present. By understanding their features, applications, and benefits, you can make informed decisions about their use in your specific industry.

0 notes

Text

Discover the perfect blend of strength and aesthetics with Clariannt’s Twisted Concrete Nails. Engineered for superior performance and durability, our concrete nails offer an unbreakable and unbendable fastening solution for all your construction needs. Learn how Clariannt’s precision-crafted nails can elevate your projects with their unique twisted design and exceptional resilience.

#Concrete Nails#Twisted Concrete Nails#Clariannt#construction nails#durable nails#twisted design nails#fastening solutions#unbreakable nails#construction hardware

0 notes

Text

Overcoming Water Damage Challenges: Nill Building Solutions' Waterproof Concrete Fasteners and Embed Anchors

Water damage is a common and costly challenge in construction, but with Nill Building Solutions' Waterproof Concrete Fasteners and Embed Anchors, builders can overcome these challenges and ensure the longevity of their projects. Let's explore how these innovative solutions are revolutionizing the construction industry.

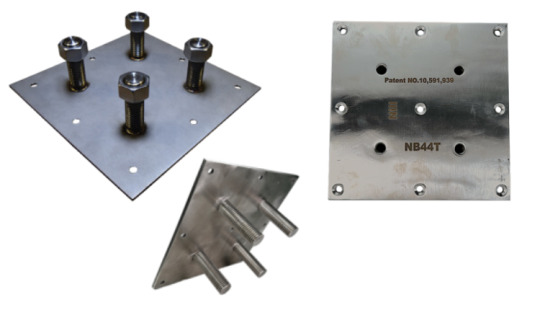

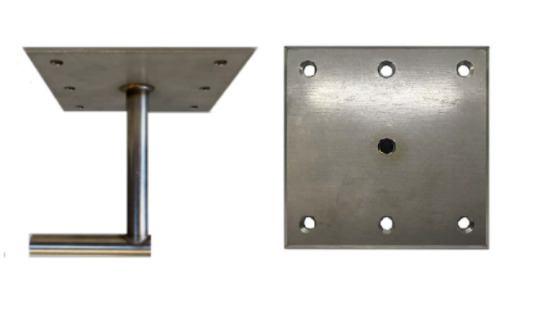

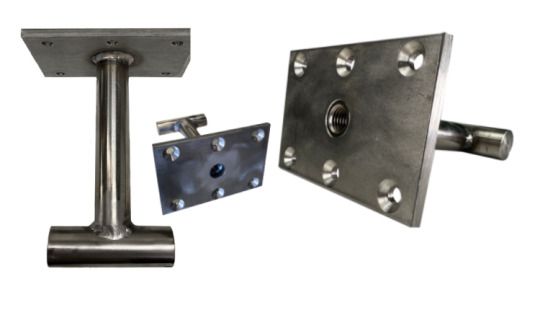

NBE.75 — (Nill Concrete Embed Anchor Mount) (PATENT NO. 10,501,939)

Understanding the Impact of Water Damage

Water damage can wreak havoc on construction projects, leading to structural weaknesses, mold growth, and costly repairs. Traditional concrete fasteners and embed anchors can create unsealed holes that allow water to penetrate the structure, resulting in leaks and deterioration over time. This not only compromises the integrity of the building but also poses safety risks for occupants.

NB3C1 Stainless Concrete Anchor (Patent Pending)

The Role of Waterproof Concrete Fasteners and Embed Anchors

Nill Building Solutions' Waterproof Concrete Fasteners and Embed Anchors offer a reliable solution to combat water damage. Unlike traditional hardware, Nill's innovative products are designed to create a watertight seal, preventing water from infiltrating the structure. This not only protects the building from leaks and moisture but also ensures its long-term durability and stability.

NB44T Stainless Nill Flange — 4 Ports Threaded (PATENT NO. 10,501,939)

Enhancing Structural Integrity

One of the primary benefits of Nill's Waterproof Concrete Fasteners and Embed Anchors is their ability to enhance structural integrity. By securely anchoring building components to concrete surfaces, these fasteners and anchors provide added strength and stability, even in harsh environmental conditions. This helps prevent structural damage caused by water infiltration and ensures the overall safety of the building.

NB1J Concrete Embedment Anchor (PATENT NO. 10,501,939)

Streamlining Installation Processes

In addition to providing superior waterproofing capabilities, Nill's Concrete Fasteners and Embed Anchors are designed for fast and easy installation. With user-friendly features and innovative designs, these products streamline the construction process, saving time and labor costs. This allows builders to complete projects more efficiently while maintaining high standards of quality and craftsmanship.

NB1T2 Concrete Embedment With T Anchor

Sustainable Construction Practices

Nill Building Solutions is committed to sustainability, and their Waterproof Concrete Fasteners and Embed Anchors are no exception. By preventing water damage and extending the lifespan of construction projects, these products contribute to reducing waste and promoting sustainable building practices. This not only benefits the environment but also helps builders minimize long-term maintenance and repair costs.

NB3C Stainless Concrete Anchor (Patent Pending)

Investing in Long-Term Solutions

In construction, prevention is always better than cure. By investing in Nill Building Solutions' Waterproof Concrete Fasteners and Embed Anchors, builders can proactively protect their projects from water damage and ensure their long-term success. With innovative technology and a commitment to excellence, Nill is revolutionizing the construction industry and helping builders overcome water damage challenges with confidence.

NB17BDAK Dual Extension Bolt (Patent Pending)

Conclusion

Water damage challenges are a significant concern in construction, but with Nill Building Solutions' Waterproof Concrete Fasteners and Embed Anchors, builders can overcome these obstacles and build structures that stand the test of time. From enhancing structural integrity to streamlining installation processes, Nill's innovative products offer a reliable solution to combat water damage and ensure the longevity and durability of construction projects. Choose Nill Building Solutions and protect your investments from water damage challenges today.

#anchor#Usa#Waterproof anchors#Concrete fasteners#Embed anchors#Heavy-duty anchors#Construction hardware#Corrosion-resistant anchors#Industrial anchors#Structural fasteners#Masonry anchors

0 notes

Text

a group of old man borrowers who live together. they don’t interact with the giant much. except for every time the giant does some home repair or DIY, then the tiny old men line up on the nearest high surface to watch like this

#g/t#giant tiny#i worked at a hardware store for a bit and suddenly i Understood#watching construction and noting their supplies and techniques. it rules#old men are so right about this actually

423 notes

·

View notes

Text

i knowww the dog motif is a little overdone. it's passe. it's old hat. however i like it on account of the pup thing.

#fuck it puppyposting on main who cares! who care#who care! i like the dog motif on account of i am the dog#can we get a little more leather and jingly silver hardware with the dog motif. is my one piece of constructive criticism

10 notes

·

View notes

Text

Something something about Eddie trying to glue wood and plastic together but not having the right glue to make it work.

Two different materials that don’t bond well together and gluing them will never be as strong as proper joints when putting the same material together - not needing glue to hold them in a relationship because they can be dovetailed

#idk where I’m going with this does it make sense?#something something about having to return to a hardware store for the glue#something something about construction on sunset and how Marisol could locate the right glue but isn’t involved in construction#something something about Eddie still getting it wrong#and something something about this being like the gingerbread house all over again#911 spoilers#911 on fox#911 fox#911onfox#eddie diaz

64 notes

·

View notes

Text

Essential Power Tools to Boost Your Workshop Efficiency

Upgrade your workshop with essential power tools. From drills and saws to sanders and grinders, our top-quality tools are designed to enhance your productivity and precision. Whether you're a professional or a DIY enthusiast, find the perfect equipment to tackle any task easily. Boost efficiency with power tools from First Choice Industrial today!

#hardware#industrial equipment#hardware store#hardware tools#construction#building materials#power tools#drill machine

3 notes

·

View notes

Text

Fuck superglue. The devil’s precum. All my homies love High Strength Construction Adhesive

SHE HAS THE RANGE!!!

Wip: Clay sculpted koi pen holder with wooden base. construction adhesive was used to glue it down AND create wave effects. (Yes actual sculpture medium would be better but its 11pm im not running to the store again)

8 notes

·

View notes

Text

Al Abbasi Fasteners And Hardware

Welcome Al Abbasi Fasteners And Hardware on TradersFind!

Al Abbasi Fasteners And Hardware is one of the leading importers and dealers of building materials, hardware, tools, fasteners, consumables, and safety products. Discover their offerings and enhance your business with their trusted products. Explore Al Abbasi's wide range of solutions on TradersFind today! https://www.tradersfind.com/seller/al-abbasi-fasteners-and-hardware

#alabbasifastenersandhardware#buildingmaterials#hardware#fasteners#tools#construction#safetyproducts#importers#dealers#uae#businessnetworking#b2bplatform#tradersfind#businessgrowth#supplychain#industryleaders#qualityproducts#buildingsupplies#industrialsupplies#businesscommunity#buildingindustry#engineering#infrastructure#projectmanagement#commercialconstruction

2 notes

·

View notes

Text

Fixings and Fasteners: Essential Components for Secure and Durable Installations

In construction, manufacturing, and DIY projects, Fixings And Fasteners are essential components that ensure materials are securely attached, stable, and capable of withstanding stress over time. From securing heavy structural elements to holding smaller parts in place, the right choice of fixings and fasteners can make a significant difference in the safety, strength, and durability of an installation.

This guide will explore the different types of fixings and fasteners, their uses, and how to select the right ones for various applications.

What Are Fixings and Fasteners?

Fixings and fasteners are hardware devices used to join or secure materials together. They come in various forms, including screws, bolts, nails, rivets, anchors, and clips, each designed for specific tasks. These components can be used for permanent or temporary connections and are critical in ensuring that structures and assemblies hold up under mechanical forces such as tension, compression, and shear.

Types of Fixings and Fasteners

Screws

Screws are one of the most commonly used fasteners. They are designed to be driven into materials like wood, metal, or plastic with a twisting motion. Screws come in a wide range of types, such as wood screws, machine screws, and self-tapping screws, each suited to different materials and applications.

Common Applications: Furniture assembly, decking, and general construction.

Bolts and Nuts

Bolts are threaded fasteners typically used with nuts to secure two or more parts together. They are ideal for applications where high strength and durability are required. Bolts and nuts come in different sizes, grades, and materials, including steel, stainless steel, and brass.

Common Applications: Heavy machinery, automotive, structural steelwork, and construction.

Nails

Nails are used to fasten materials by driving them through one or more layers using a hammer or nail gun. Unlike screws or bolts, nails do not have threads, making them suitable for applications where high shear strength is needed.

Common Applications: Framing, roofing, and carpentry.

Anchors

Anchors are used to secure fasteners to surfaces like concrete, brick, or drywall, where screws or bolts alone would not be effective. There are several types of anchors, including wall plugs (also known as rawl plugs), toggle bolts, and concrete anchors.

Common Applications: Hanging heavy objects like shelves, fixtures, and cabinets on walls.

Rivets

Rivets are permanent fasteners used to join two or more materials by deforming the head after insertion. They are commonly used in applications where access to both sides of the material is limited.

Common Applications: Aircraft assembly, shipbuilding, and metalworking.

Washers

Washers are thin plates with a hole in the middle, used to distribute the load of a threaded fastener, like a screw or bolt. They help prevent the fastener from loosening and can protect the material surface from damage.

Common Applications: With screws and bolts in mechanical and structural installations.

Clips and Clamps

Clips and clamps are fasteners that hold objects together or secure cables and pipes in place. They are often used in scenarios where frequent disassembly or adjustment is necessary.

Common Applications: Cable management, piping systems, and automotive assembly.

Staples

Staples are U-shaped fasteners driven into materials using a staple gun or hammer. They are commonly used for attaching thin materials like fabric, paper, or insulation to wood or other surfaces.

Common Applications: Upholstery, packaging, and light construction.

Choosing the Right Fixings and Fasteners

Selecting the appropriate fixing or fastener for a project depends on several factors:

Material Type: Different materials require specific types of fasteners. For example, wood screws are designed for timber, while machine screws are suitable for metal or plastic.

Load Requirements: The strength and load-bearing capacity of the fastener should match the weight and mechanical forces it will need to withstand. Bolts and anchors are often used in high-load applications, while screws and nails are better for lighter tasks.

Environmental Conditions: In outdoor or corrosive environments, such as marine or chemical industries, materials like stainless steel or galvanized fasteners are preferred for their resistance to rust and wear.

Installation Method: Consider how the fastener will be installed. Some fasteners, like nails and staples, are hammered in, while others, like screws and bolts, require tools like screwdrivers or wrenches.

Permanent vs. Temporary: If the assembly needs to be frequently disassembled and reassembled, choose fasteners like screws, bolts, or clamps. For permanent installations, rivets or nails might be more appropriate.

Common Applications of Fixings and Fasteners

Construction: Fasteners such as screws, bolts, and nails are used to assemble structures, secure frameworks, and attach components like doors and windows.

Manufacturing: In industries such as automotive and aerospace, fasteners like bolts, rivets, and clips ensure the secure attachment of parts that undergo mechanical stress.

Home Improvement: From hanging shelves to assembling furniture, various fixings and fasteners are used in everyday home projects.

Electrical Installations: Fasteners like anchors, clips, and clamps are essential for securing wiring and electrical components in place.

Conclusion

Fixings and fasteners are fundamental to nearly every construction, manufacturing, and DIY project. Selecting the right type based on material, load, and environmental factors ensures that your installation is secure, durable, and safe. With the vast range of options available, understanding the specific requirements of your project will guide you in choosing the most appropriate fixing or fastener for the job.

0 notes

Text

Discover the power of Clariannt’s Wall Plugs, also known as Rawl Plugs or Plastic Gitti, designed to enhance the stability and durability of your installations. Our wall plugs come in various sizes and colors, offering both functionality and aesthetic appeal for any project. Learn how Clariannt’s high-quality wall plugs can provide reliable support and a sleek finish to your electrical and construction needs.

https://clariannt.in/wall-plugs-rawl-plugs-plastic-gitti/

#Wall Plugs#Rawl Plugs#Plastic Gitti#Clariannt#wall anchors#screw anchors#construction hardware#durable wall plugs#installation solutions

0 notes

Text

Yite Offer The Good Quality And Competitive Price Stainless Steel Bathroom Accessories

To keep your bathroom neat and tidy, Stainless steel bathroom accessories are essential. yite produce items like stainless steel soap dispensers, stainless steel soap dishes, stainless steel toothbrush holders, stainless steel toilet paper tissue holders, stainless steel toilet brush holders,stainless steel towel bar & rail, stainless steel towel ring & holder,stainless steel towel shelf & rack,stainless steel grab rail & bar,stainless steel robe hooks& hangers,stainless steel shower caddies & basket,To get a uniform look, a bathroom accessories set is a great option.

Consider all sorts of useful modern stainless steel bathroom accessories to provide bathroom storage while matching your desired decor style. Explore a wide stainless steel bath accessories selection of vanity trays, cosmetics organizers, styling racks, modular organizers with drawers, freestanding storage shelves and bathroom canisters. You'll have plenty of choices when outfitting your new space with stylish bathroom decor sets.

Bath and shower caddies are another key consideration, which keep your showering and hygiene products organized and easy to reach in the tub or shower. Some bathroom organizers hang over the shower head or use suction cups, while others use tension rods for a floor-to-ceiling solution. No matter your decor or organization needs, our stainless steel bathroom sets with accessories will add style and function.

more info.please visit www.yite304.com china professional manufacturer for

stainless steel bathroom accessories

2 notes

·

View notes

Text

i wonder if anyone has ever made punk spikes using nuts and bolts and screws, like these

#i think it would be funny. hardware store punk#plucked them off from the floors of a construction site#oce pon a time

4 notes

·

View notes

Text

Save time and money by reclaiming used nails with a de-nailer 🔨

When you’re building in a remote location off the grid every nail counts. You can’t just hop in the car and run out to a local hardware store to pick up a bag. With a de-nailer you can straighten and remove used nails much easier than with a framing hammer.

We even created a special section covering all the tools we use when building and living off grid.

#diy #framing #reclaimedwood #construction #toolsofthetrade

1 note

·

View note

Text

Nah I worked at Home Depot for two years in Hardware and a year and a half in Tool Rental and if someone came in an hour before closing I got so mad cuz 90% of the customers I'd get at that time of night were people who had NO IDEA what they were looking for and would spend thirty minutes more than they needed to bothering me and keeping me from cleaning the department and causing me to go home late.

But that's just me.

Social anxiety has me thinking dumb stuff like “if I go in this store when they’re closing in an hour the employees will hate me and want to kill me” which is especially dumb to think bc I worked retail before, it’s only like the last 20 minute that they want to kill you

#I had a customer once say they needed to screw a shelf into a wall. they then said so I need a wrench#I said you need a screwdriver if you're screwing something in#it's in the name#but they absolutely insisted they knew what they needed and they needed a wrench to put the screws in (they were Phillips head screws)#so I said okay I'll get you that wrench.#an hour later the customer comes back all bashful and mutters I need a screwdriver#OH WOW IF ONLY SOMEONE HAD SUGGESTED THAT#I'm just very bitter because of how a lot of people treated me#they saw a young kid who they assumed knew nothing about tools when in reality I've been exposed to construction since I was five#and they'd treat me like an idiot#so I'm full of resentment#Home Depot#screw the musogynistic old men who look at girls in hardware and assume they know nothing

56K notes

·

View notes

Text

#design#interiordesign#architecture#building#homedecor#renovation#art#builder#artwork#carpenter#mechnical#construction#mechnicalengineering#mechnicalengineer#mechanicalengineering#ozstrut#hardware#civilengineering#ductworkproject#mechanicalplumbingworks#supplier#constructionhardware#mechnica#engineer#engineering#pipesupportsystems#jobs#civil#sydney#mechnicalpencil

0 notes