#cnc prototyping made in china

Explore tagged Tumblr posts

Text

Everyone is afraid of China. And why shouldn’t they be? They have a large industrial base, paid for by American industrialists. They have a lot of money, given to them by American industrialists. And they have tiny, quirky cars, which I desire more than my next breath. It’s an unbeatable combo, and the only way to compete is to play a different game.

We are going to build mid-sized, boring sedans, and then sell them into the Chinese market in exchange for tiny quirky cars and exotic sports electrics. For our prototype, we have chosen to clone the Plymouth Volare. Panel gap is actually better than the original car by far, because we’ve used CNC machining (an old 3D printer we found in the dumpster, with a plasma cutter duct-taped to the end of it) to produce immaculate replicas of the original panel. And our welder is only high on modern synthetic drugs, not the impure and unpredictable strains of the 1960s. That means consistency, and a return on your investment.

Do we think that the Chinese market will buy these cars? There’s a pretty good chance. They sport a lot of features that every market wants. Four wheels. A steering wheel. A trunk. And if the doors are closed and the windows are rolled up, you probably won’t get wet in the rain.

Powertrain is a problem, we agree. It’s a lot of startup cost to open a factory that is capable of manufacturing to the precision tolerances required to produce an internal combustion engine. That’s why we picked the Volare. Those cars came with an un-killable slant-six engine. They’re so unkillable, actually, that we didn’t have to build new ones, just pull ‘em of the junkyard and spray-paint ‘em: they’re good to a few million kilometers, so there’s no need to actually do a rebuild. That’s recycling, which is environmentally friendly (if you don’t think too hard about what’s in the spray cans we’re using.)

Last, investors shouldn’t fret about trade secrets. While these cars haven’t been made for a half-century, there’s not enough of them left in existence to use as a reference to copy from. Any imitators will have to buy at least one of our cars, and maybe two or three, if our quality control doesn’t get better. That’s called guaranteed sales.

There’s been a lot of fear about American workers leaking secrets to China, as opposed to the more traditional format where American managers sell them in large chunks to China instead. Here at Switch Industries, we guarantee our investors that none of us know how to dial long distance. Half of our employees are too young to even have seen a phone, and they definitely don’t use email. Maybe a few of them might know how to switch to Pinyin on their computer keyboards, so we’ve pried the control key off of every keyboard in the office.

179 notes

·

View notes

Text

Using the Potential of CNC Machining

In the constantly changing field of product development, efficiency, accuracy, and innovation are always sought after. CNC Prototype Machining is the core of this endeavor; this revolutionary technology has completely changed the way prototypes are imagined, created, and executed.

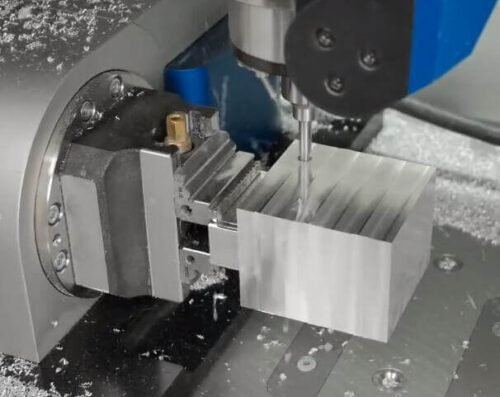

Redefining Precision: The Advantage of CNC

The unmatched accuracy of CNC prototype machining is its foundation. CNC machines are outfitted with the newest technology and are directed by exact CAD/CAM instructions to do jobs with minuscule accuracy. With CNC machining, every detail is painstakingly and precisely carved, whether it be for drilling precise holes or sculpting complex designs.

Innovation Acceleration: Accelerating the Development Cycle

Speed is crucial in the fast-paced environment we live in today. The days of protracted production schedules and never-ending revisions are over thanks to CNC prototype machining. CNC machines help engineers and designers to iterate quickly and bring things to market more quickly than ever before by optimizing the prototype process. This shortened development cycle encourages innovation and experimentation while simultaneously shortening time-to-market.

Unleashing Versatility: From Idea to Actuality

The adaptability of prototype CNC Machining China is among its most impressive features. CNC machines can easily mold a wide range of materials into working prototypes, whether they are made of metal, plastic, wood, or composite materials. The options are endless, ranging from sophisticated consumer electronics to delicate aircraft components.

Filling the Void: From Concept to Manufacturing

In addition to prototypes, CNC machining is essential for bridging the gap between production and design. CNC machines facilitate the process of moving from concept to mass manufacture by producing parts that are ready for production and of superior quality. Prototypes are guaranteed to be workable solutions prepared for practical implementation, not only functional mock-ups thanks to this smooth connection.

Promoting Innovation in All Sectors

Prototype CNC Machining has a significant influence that goes much beyond the boundaries of a particular sector. CNC machines are pushing innovation across a wide variety of sectors, from consumer products and medical devices to aerospace and automobiles. The future of manufacturing is being shaped by CNC prototype machining, which is at the forefront of innovations such as supply chain revolutions, improved product performance, and the ability to enable new design patterns.

#CNC Machining#CNC Machining process#CNC Machining process China#CNC Machining Techniques#CNC Prototype Machining#CNC Prototype Machining China#CNC Machining China

2 notes

·

View notes

Text

Manufacturability Design in Rapid Prototyping

Quickly producing physical models or prototypes with additive manufacturing technologies like 3D printing, CNC machining, or other sophisticated fabrication techniques is known as Rapid Prototyping China. With this method, designers may test their ideas, evaluate functionality, and spot problems in their designs early on, which cuts down on development expenses and time-to-market.

Manufacturability-focused design (DFM)

DFM is a collection of best practices and standards for improving a product's design so that it can be manufactured more easily. DFM concepts are as important at the rapid prototyping stage, even though they are typically linked with mass production. Engineers may minimize problems and streamline the prototype process by taking manufacturing restrictions into account early in the design phase.

Essential DFM Takeaways for Quick Prototyping

Material Choice

Select materials that work well with the quick prototyping method you've chosen.

Depending on the planned use, take into account the material's strength, flexibility, and heat resistance.

Complexity of Geometry

Simplify designs to save money and time during manufacture.

Reduce overhangs and complex features, which might be difficult to create using some fast prototyping techniques.

Accuracy and Tolerance

Recognize the dimensional accuracy constraints of the fast Rapid Prototype technique that you have selected.

To guarantee the required precision in the finished prototype, design with the proper tolerances.

Assisting Frameworks

To avoid deformations during fabrication, especially in 3D printing, take into account the essential support structures in the design.

Reduce post-processing work and material waste by optimizing support structures.

Assembly Considerations

Create components that are simple to test and dismantle for adjustments.

When it's feasible, reduce the amount of components to expedite the prototype process.

Time Efficiency Gains from Using DFM in Rapid Prototyping

Designers may expedite the whole prototype phase by avoiding several revisions and delays by addressing manufacturability problems early on.

Lowering of Expenses

During the fast prototype stage, optimal design decisions result in cost savings through effective material consumption and less waste.

Better Cycles of Iterations

Faster design iterations are made possible by the prompt discovery and resolution of manufacturability difficulties, which enable more extensive testing and refinement.

Improved Prototyping Caliber

By keeping DFM principles in mind, you may minimize unforeseen difficulties during testing and validation by ensuring that the final Rapid prototyping manufacturer closely resembles the planned design.

#Rapid prototyping manufacturer#Rapid Prototype#Rapid Prototyping Services#Metal Rapid Prototyping Services#Rapid prototyping Supplier#Rapid Prototyping China#Chinese Rapid Prototyping Services

2 notes

·

View notes

Text

Custom CNC Machining Services Tailored in China

The China CNC custom machining services combine advanced equipment with skilled craftsmanship to deliver tailor-made components for diverse industries. Whether creating prototypes or high-volume parts, these services ensure precision, durability, and adherence to strict quality standards. Using a variety of materials like metals and plastics, manufacturers meet the unique needs of sectors such as aerospace, automotive, and electronics. With competitive pricing and cutting-edge technology, China has become a global hub for reliable and efficient CNC machining solutions.

#cnc machining services#cnc machining in china#china cnc machining#cnc machining china#cnc machining service china#china cnc machining service#cnc machining services china#custom cnc machining services#custom cnc machining china#china cnc custom machining

0 notes

Text

What You Need To Know About The Different Types Of CNC Milling Machines?

In factories and workshops, getting things done quickly and accurately is really important. CNC milling machines are like the superheroes of technology because they're super precise and can adapt to different tasks. Let's explore the different kinds of machines that are helping industries come up with cool new stuff, making CNC milling easier to understand.

1. Vertical Mills:

- An easily accessible workpiece from above is made possible by the vertical axis used on vertical milling machines. Flat surfaces, slots, and pockets are frequently created using them. For tasks like mould production and prototyping, where accessibility and precision are important, vertical mills are perfect.

2. Horizontal Mills:

- Horizontal milling machines have a spindle aligned horizontally, in contrast to vertical mills. These configurations are ideal for heavy-duty machining activities and batch production because they allow the cutting of numerous sides of a workpiece without requiring repositioning. Manufacturing sectors including aerospace, automotive, and marine are strongholds for horizontal mills.

3. Multi-Axis Mills:

- Advanced features of multi-axis milling machines include simultaneous movement along several axes. These devices have unmatched accuracy and productivity when it comes to carrying out intricate machining tasks. Multi-axis mills are essential in sectors like jewellery manufacture, medical, and aerospace because they can create complex geometries and shapes by adding extra axes of movement, such as rotational or tilting axes.

4. CNC Router Mills:

- To cut and shape wood, plastic, and other non-metallic materials, specialised milling machines known as CNC router mills are used. Signage, cabinetry, and woodworking businesses will find them perfect because of their big work envelopes and high-speed spindles. For small-scale producers, artists, and hobbyists, CNC router mills are great.

5. Benchtop Mills:

- Benchtop milling machines are compact and portable, making them ideal for small workshops, educational institutions, and prototype laboratories. Despite their diminutive size, these machines provide precision and adaptability that rival bigger industrial mills. Benchtop mills are popular among amateurs, DIY enthusiasts, and students learning the principles of machining.

CNC milling machines are available in a wide range of designs that satisfy a variety of industrial requirements, from vertical mills to multi-axis machining centres. Understanding the strengths and capabilities of each kind enables producers to pick the best machine for their individual applications, enabling innovation and efficiency in the ever-changing world of contemporary production.

Why choose HLH Rapid?

HLH Rapid is a remarkable team that combines the best of the West and East. It was founded by Vader Yu from China and Director James Murphy from the United Kingdom, both of whom have extensive industry expertise.

We help companies globally by promptly producing high-quality prototypes and parts. Our skills as well as expertise promote innovation, making it easier for businesses to develop new products swiftly.

We are pleased to provide a wide range of services, including rapid injection moulding, CNC machining, and numerous 3D printing technologies (such as SLA, SLS, and SLM), all in one stop.

To know more about cnc milling services, talk to our experts today by sending an email at [email protected] or visit our website: www./hlhrapid.com

0 notes

Text

Top Aluminum CNC Machining Service in China

Aluminum CNC machining is a procedure that uses computer numerical control (CNC) machines to produce accurate and complicated Aluminum components. With technological improvements, the demand for high-quality Aluminum parts has skyrocketed. As a result, several Chinese enterprises are providing aluminium CNC machining services to suit the expanding demand.

China has quickly emerged as a top provider of CNC machining services because to its trained labor, superior technology, and cost-effective solutions. This has made it a popular choice for businesses wishing to outsource their CNC machining requirements. Aluminum CNC machining services provide a numerous benefits, including quick turnaround times, competitive pricing, and high-quality goods.

Our Aluminum CNC Machining Capabilities

We specialise in a variety of Aluminum CNC machining services, such as milling, turning, drilling, tapping, and more. Whether you need prototypes, small batches, or large-scale production runs, we can handle projects of any size or complexity. Our staff uses cutting-edge CNC machining equipment to enable quick turnarounds without sacrificing quality.

Benefits of Aluminum CNC Machining

Aluminum is regarded as being lightweight, sturdy, and corrosion-resistant, making it an excellent material for a variety of applications. Aluminium CNC machining allows you to make parts and components that are robust, reliable, and visually appealing. Additionally, aluminum is a cost-effective option that offers excellent thermal conductivity, making it suitable for various industries.

One of the primary benefits of choosing aluminium CNC machining services in China is the country's extensive network of suppliers and manufacturers. This provides organisations with access to a diverse choice of aluminium materials and machining techniques, guaranteeing that they can discover the optimum solution for their individual requirements. Furthermore, Chinese manufacturers are known for their meticulous attention to detail and precision, which ensures that the finished items satisfy the highest standards.

Another advantage of using Aluminum CNC machining Service is cost reduction. The country's competitive labor market and lower production costs result in lower prices for customers. China offers a cost-effective manufacturing choice without sacrificing quality.

In conclusion, Aluminum CNC Machining Service in China offers high-quality precision machining for aluminum parts. With state-of-the-art equipment and experienced technicians, we can produce custom aluminum components with tight tolerances and excellent surface finishes. Whether you need prototypes or large production runs, our CNC machining service can meet your specific requirements efficiently and cost-effectively. Trust us to deliver top-notch aluminum parts that meet your exact specifications and exceed your expectations.

0 notes

Text

Revolutionizing Innovation: China's Pioneering Role in Mockup Prototype Production

Introduction:

In the dynamic landscape of global manufacturing, China has emerged as a powerhouse, not only in mass production but also in the realm of mockup prototype production. As businesses worldwide seek to innovate and bring new products to market swiftly, the strategic utilization of China's expertise in mockup prototyping is playing a pivotal role in accelerating the product development lifecycle. Check their site to know more details 中国モックアップ #中国で試作品製作

The Rise of China in Mockup Prototype Production:

Traditionally, the term "Made in China" has been synonymous with mass production. However, the narrative is shifting as Chinese manufacturers increasingly specialize in the intricate and highly nuanced process of creating mockup prototypes. A mockup prototype is a three-dimensional model that represents a design concept, allowing engineers, designers, and stakeholders to visualize and evaluate the product before mass production.

China's prowess in this field is driven by a combination of factors. The country's robust infrastructure, skilled workforce, and cutting-edge technology have transformed it into a hub for prototype development. Chinese manufacturers are not only meeting global standards but are often exceeding them, fostering a reputation for precision and quality in mockup prototype production.

Cost Efficiency and Speed:

One of the primary reasons behind the surge in outsourcing mockup prototype production to China is cost efficiency. Chinese manufacturers offer competitive pricing without compromising on quality. This cost-effectiveness allows businesses, especially startups and small enterprises, to allocate resources more efficiently and invest in other critical areas of product development.

Moreover, China's production ecosystem is characterized by unparalleled speed. From conceptualization to the delivery of a high-fidelity mockup prototype, Chinese manufacturers exhibit remarkable agility. This rapid turnaround time is a game-changer for companies aiming to stay ahead in the fiercely competitive market by minimizing time-to-market and gaining a first-mover advantage.

Technological Advancements:

China's commitment to technological advancements has been a driving force behind its success in mockup prototype production. State-of-the-art manufacturing facilities equipped with the latest technologies, such as 3D printing, CNC machining, and laser scanning, enable Chinese manufacturers to create highly accurate and detailed prototypes.

The integration of artificial intelligence (AI) and automation further enhances the efficiency of the production process. This not only reduces the margin of error but also allows for customization at scale, accommodating the diverse needs of clients across various industries.

Collaboration and Customization:

Chinese manufacturers actively collaborate with businesses worldwide, fostering a culture of innovation and customization. By understanding the unique requirements of each client, they can tailor mockup prototypes to specific needs. This collaborative approach ensures that the final product aligns seamlessly with the client's vision, mitigating potential design flaws and streamlining the overall product development process.

Conclusion:

China's ascent in mockup prototype production signifies a paradigm shift in global manufacturing dynamics. Beyond the conventional image of mass production, Chinese manufacturers are now recognized for their agility, precision, and technological prowess in creating high-quality prototypes. As businesses continue to prioritize innovation and speed to market, the strategic outsourcing of mockup prototype production to China is poised to play a pivotal role in shaping the future of product development worldwide.

1 note

·

View note

Text

Injection Molding Redefining CNC Machining

Unleashing Personalization: Injection Molding Redefining CNC Machining

The Intricate Dance of Precision and Customization

In the dynamic landscape of manufacturing, where precision meets personalization, CNC machining has emerged as a cornerstone

technology. As the gears of global industries turn, customization has become not just a luxury but a necessity. The question that

echoes in the halls of innovation is, how does Injection Molding technology empower the creation of truly personalized products?

Customization in the Era of Smart Manufacturing: Injection Molding Technology Empowering Personalized Products has become more

than a mere phrase; it's a paradigm shift that propels businesses like mine, CNC MACHINING, into the forefront of cutting-edge manufacturing.

The Powerhouse of Adaptability: Injection Molding Unveiled

In the bustling streets of technology, where every product screams for uniqueness, CNC machining, coupled with injection molding,

takes center stage. Injection molding, a technique that REGO, my B2B company based in China, specializes in, is not just a manufacturing

process; it's a dynamic force enabling the crafting of bespoke components.

Imagine a world where your products aren't just items on a shelf but reflections of individuality. Mark Sheng, our discerning client in Canada,

values quality above all. For him, each component isn't just a piece; it's a testament to the precision and care invested in its creation. Our 5

production lines and 55 dedicated employees ensure that every piece meets not just industry standards but exceeds the expectations of clients.

CNC machining, bolstered by injection molding, is the bridge between the generic and the tailored. It's not about mass production; it's about

the art of crafting products that seamlessly fit into the intricate tapestry of diverse industries—be it aerospace, automotive, medical, or electronics.

The Canvas of Customization: Who Holds the Brush?

In this era where everyone seeks a unique stroke in the canvas of manufacturing, the question arises—how does customization become

the hallmark of smart manufacturing? It's not merely about producing goods; it's about sculpting experiences. The answer lies in the ability

to mold not just plastic but ideas, dreams, and necessities.

Accessibility and affordability have transformed CNC machining from a specialized tool for industrial giants to a playground for small

businesses and individuals. The democratization of technology has made it possible for anyone, regardless of expertise, to wield the power

of CNC machines. The era of personal projects, prototypes, and custom parts is upon us, and CNC machining is the vehicle driving this revolution.

Navigating the Maze: Addressing Pain Points in Customization

As the path to personalization unfolds, challenges emerge. REGO understands the pain points of clients—the frustration of low efficiency,

the anxiety of delayed deliveries, and the fear of fraudulent certifications. It's not enough to offer customization; it's about delivering it

seamlessly, efficiently, and with unwavering reliability.

Our commitment extends beyond the production lines; it encompasses quality control, streamlined certifications, efficient logistics, and

transparent payment methods. Mark Sheng doesn't just receive a product; he receives an assurance—an assurance of quality, trust, and timely delivery.

The Symphony of Solutions: Exhibition Platforms and Online Avenues

How does one broadcast the symphony of customization to the world? The answer lies in the harmony of offline and online promotion.

REGO doesn't just showcase products in exhibitions; it extends its reach through online platforms like Alibaba and Google. It's about being

where the eyes of industries and individuals converge, offering a glimpse into the world where CNC machining and injection molding dance in unison.

Questions related to "Customization in the Era of Smart Manufacturing: Injection Molding Technology Empowering Personalized Products"

How does CNC machining redefine the boundaries of customization?

What role does injection molding play in the era of smart manufacturing?

How has the democratization of technology impacted the accessibility and affordability of CNC machines?

More related questions

What are the key factors influencing clients like Mark Sheng to prioritize quality over price?

How does REGO address the pain points of low efficiency, delayed deliveries, and fraudulent certifications?

Conclusion: Crafting Tomorrow, Today

In the symphony of manufacturing, where precision and personalization dance hand in hand, REGO stands not just as a supplier but as a maestro. The fusion of CNC machining and injection molding isn't just a process; it's a journey—a journey into the heart of smart manufacturing where products aren't just created; they are crafted.

As the sun sets on the horizon of traditional manufacturing, the dawn of customization rises. In this era, Our clients, discerning and demanding, the need for a reliable partner like REGO becomes paramount. The legacy of tomorrow is crafted today, in the hum of CNC machines and the precision of injection molding—a legacy that resonates with the heartbeat of every personalized product.

0 notes

Text

From Gallons to Greatness: The Innovation Behind Package Bucket Moulds

When it comes to packaging large quantities of liquids, such as paints, adhesives, or industrial chemicals, the humble bucket becomes an essential solution. These buckets, often made from plastic or metal, are designed to hold several gallons of liquid while keeping it safe and secure. However, have you ever wondered how these buckets are made and the innovation behind their design? In this article, we will explore the fascinating world of package bucket moulds and the technology that drives their production.

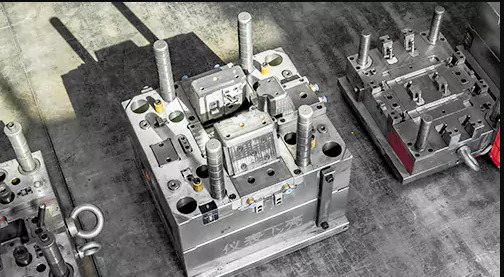

Package bucket moulds are custom-made tools used in the manufacturing process of plastic or metal buckets. These moulds play a crucial role in creating buckets of various sizes and shapes, accommodating different industries' needs. Whether it's a small 1-gallon bucket or a larger 5-gallon one, the moulds are engineered to ensure precise and consistent results.

The process of creating package bucket moulds involves several steps. First, the design and specifications of the bucket are determined, taking into account factors such as capacity, shape, handle design, and any special features required. Once the design is finalized, the mould-making process begins.

Mould making typically involves computer-aided design (CAD) software, which allows engineers to create a digital representation of the bucket mould. This digital model serves as a blueprint for the machining process, where the mould is carved out of a solid block of material, such as steel or aluminum. The level of precision required in the machining process is critical to ensure that the final product meets the desired specifications.

One of the innovative aspects of package bucket moulds is the use of interchangeable inserts. These inserts allow manufacturers to create multiple bucket sizes using the same mould base. By simply swapping out the inserts, manufacturers can accommodate different volume requirements without the need for an entirely new mould. This interchangeability not only saves time and resources but also provides flexibility and cost-effectiveness in the production process.

To ensure optimal functionality and durability, package bucket moulds may undergo additional treatments. For instance, the mould surface can be heat-treated, coated, or polished to enhance its resistance to wear and tear. These treatments help prolong the mould's lifespan, ensuring that it can withstand the demands of high-volume production over an extended period.

The advancement in technology has also contributed to the innovation behind package bucket moulds. Through the use of computer numerical control (CNC) machines, the machining process has become more precise and efficient. CNC machines are capable of executing complex designs with minimal errors, resulting in higher-quality bucket moulds. Additionally, the use of 3D printing technology has gained traction in the mould-making industry. 3D printing allows for rapid prototyping and offers greater design flexibility, enabling manufacturers to explore new possibilities in bucket mould design.

Package bucket moulds are not limited to traditional plastic or metal buckets but can also be used for specialized applications. For example, food-grade buckets made from high-density polyethene (HDPE) are commonly used in the food industry to store ingredients or transport food products. These buckets need to meet specific hygiene and safety standards, and the moulds used to create them must adhere to those requirements.

In conclusion, Gallons package bucket moulds are an integral part of the manufacturing process for larger liquid containers. Their design and engineering ensure the creation of buckets that are durable, efficient, and fit for purpose. The use of interchangeable inserts, precision machining, and technological advancements contribute to the innovation behind these moulds. As industries continue to evolve, we can expect further advancements in package bucket moulds to meet the ever-changing needs and demands of packaging solutions.

#Gallons packge bucket mould Exporter#Gallons packge bucket mould Price#Gallons packge bucket mould Maker

0 notes

Text

Advancing Manufacturing Excellence: Aluminum Die Casting and Robot Prototyping in China

Introduction In the realm of manufacturing, China has emerged as a powerhouse, leading the way in aluminum die casting and robot prototyping. With a robust industry and a wealth of expertise, Chinese manufacturers have perfected the art of aluminum die casting, while their prototype makers are pushing the boundaries of innovation with advanced technologies like SLA (Stereolithography). Join us as we explore the dynamic landscape of aluminum die casting manufacturers and robot prototype makers in China and discover how they are transforming industries worldwide.

Aluminum Die Casting Manufacturers in China Aluminum die casting has become a cornerstone of modern manufacturing, offering precise and cost-effective solutions for a wide range of industries. In China, a multitude of reputable manufacturers have established a strong foothold in the industry. These manufacturers combine state-of-the-art technology with skilled craftsmanship to deliver high-quality aluminum castings.

Chinese aluminum die casting manufacturers have invested in advanced machinery and equipment, including CNC machines and automated production lines, to ensure efficiency and accuracy. With a focus on continuous improvement, they adhere to stringent quality control measures, ensuring that each casting meets the strictest standards.

Notably, China's aluminum die-casting manufacturers have a competitive edge in terms of cost-effectiveness. They possess the ability to scale production, leveraging economies of scale while maintaining superior quality. This advantage has made China a preferred outsourcing destination for companies seeking high-quality aluminum castings at competitive prices.

The Power of SLA Prototypes In the realm of product development, prototyping plays a vital role in transforming ideas into reality. SLA (Stereolithography) has revolutionized the prototyping process, enabling the creation of intricate and highly accurate models. Chinese manufacturers have harnessed the power of SLA prototypes to enhance product development cycles.

SLA prototypes offer numerous advantages. With their ability to produce detailed and complex geometries, SLA prototypes allow designers and engineers to evaluate form, fit, and functionality before moving forward with production. This technology enables rapid iteration and design optimization, significantly reducing time-to-market.

Chinese manufacturers specializing in SLA prototypes leverage cutting-edge 3D printing technologies and a vast selection of materials, including resins and polymers, to meet diverse project requirements. Their prototyping services are known for their precision, attention to detail, and commitment to delivering top-notch results.

Where Aluminum Die Casting Meets Robotics The convergence of aluminum die casting and robotics has opened up new frontiers in manufacturing. Chinese prototype makers are at the forefront of this fusion, offering expertise in both disciplines to create advanced robot prototypes.

Combining the strength and lightweight properties of aluminum die castings with the agility of robotics, these prototypes embody the future of automation. Chinese prototype makers collaborate closely with their clients, understanding their needs and translating them into functional and efficient robotic designs.

The synergy between aluminum die casting and robotics allows for the production of lightweight yet robust robot components. Aluminum castings offer excellent thermal conductivity, durability, and precision, making them ideal for creating components such as robot frames, joints, and housings.

Chinese prototype makers employ state-of-the-art technologies, including CNC machining, 3D printing, and automation, to manufacture robot prototypes with exceptional precision and reliability. They work hand-in-hand with clients throughout the design and iteration process, ensuring that the final prototype meets the desired performance criteria.

Conclusion China's aluminum die casting manufacturers and robot prototype makers are revolutionizing the manufacturing landscape with their expertise and advanced technologies. Their commitment to quality, cost-effectiveness, and innovation has propelled them to the forefront of the industry. From producing high-quality aluminum castings to creating intricate SLA prototypes and pushing the boundaries of robotics, Chinese manufacturers continue to shape the future of manufacturing. As industries worldwide embrace the potential of aluminum die casting and robot prototypes, the collaborative efforts of China's manufacturers and prototype makers will undoubtedly pave the way for groundbreaking advancements in manufacturing excellence.

#aluminium die casting manufacturers in china#sla prototypes#aluminum die casting china#robot prototype maker

0 notes

Text

As a professional metal stamping factory in China, Dongguan Orienson Hardware Electrical Co., Ltd. has complete supporting resources, which can provide customers with one-stop hardware products as well as the full set of processing services, we can independently develop and manufacture molds, and provide precision CNC machining services, plastic injection molding service, metal plating services, heat treatment, passivation, grinding, radium carvings and other surface treatment processing technology, besides, assembly services such as metal laser welding, resistance welding, automatic tapping, and automatic riveting is included, Orienson is equipped with a complete inspection and testing instruments to ensure quality from raw material production to delivery, thus reduce the loss and cost of the customer and also offer high-quality and cost-effective prototype metal stamping.

Types of Custom Service Stampings

Assembling ServiceAssembling Service

CNC MachiningCNC Machining

Plastic Injection MoldingPlastic Injection Molding

ElectroplatingElectroplating

Other Surface TreatmentOther Surface Treatment

Automatic TappingAutomatic Tapping

Automatic RivetingAutomatic Riveting

Advantages Of Metal Stamping Supporting ServicesAdvantages Of Metal Stamping Supporting Services

Assembly

Assembly refers to the process of assembing parts according to specifed technical requirements and making them qualifed products.

Products

As an excellent sheet metal stamping manufacturer, we provide highly consistent assembly services at every stage of your production process, from prototyping, proof of concept to mass production.

Professional Team

In addition, our professional automation engineering design team can provide comprehensive assembly.

How Do You Choose Metal Stamping Supporting Services

01

Rich Experience

Service from RED stage to mass production, Our technical team can design, manufacture and maintain.

02

Professional Technology

As an excellent sheet metal stamping manufacturer, we also have the support equipment for tapping machines, riveting machines, automatic assembly lines.

03

Automatic Assembly Line

Our production capability is more than 50 million pieces per month, mold developing and manufacturing capability.

04

R&D Capability

The in-house tool room has LS-WEDM, HS-WEDM, spark machines, grinding machines, milling machines, etc., which can meet all the demands.

05

Highest Cost Effectiveness

Including heat treating, plating, injection molding, CNC machining, etc., we work closely with our customers to ensure the most cost-effective material.

Why Choose Orienson Metal Stamping Supporting Services

Rapid open mold speed, high quality, mature bending process made Orienson widely welcomed by customers. Metal bending parts we produced has been widely used in automobiles, sensor electrical and electronic switches.

Mold speed, high quality, mature bending process

Automobiles, sensors, electrical and electronic switches

Under the guarantee of dimensional accuracy

Committed to providing smooth surface edge rolling parts

Custom Metal Stamping Supporting Services

Impact On Production To Meet Customers' need

Professional One-stop Whole Process CNC Service

Mold Opening, Material Selection

0 notes

Text

Cnc Turning Service

Aerospace CNC Machining - Prototool.com

Aluminium Turning We provide state-of-the-art CNC machining & Injection molding service. Our respective clients provide us with the product design idea along with the preferred material. The rest of the work is done by our experts. We buy quality material, refine the client’s designs, machining the product, and then deliver the finished product to the customer. We are also the market-leading CNC and injection molding material suppliers as well. We are an affiliate of First Part China Limited. Aluminum Cnc Machining

Machining Process of Injection Mold Parts Such as Core, Insert, Lifter and Slide

Aluminum Mold Making Part craftsmen typically provide mold design job books based on molded part task books. To assure the logic and consistency of the mold manufacturing process, optimize the processing process, and improve mold manufacturing progress, each mold factory normally develops a process standard fit for its factory, including using unique injection mold parts. Prototool.com

This article will discuss common injection mold parts, their applications, and things to consider when employing them throughout a factory’s machining process. Cnc Machining Services

The Most Suitable Metal Materials for your CNC Machined Parts

Material selection is essential to any manufacturing process, but engineers and CNC machining service providers must be extremely careful regarding CNC machined parts.

Because this procedure is suitable for a wide range of materials — from metal to fiberglass to wood — it’s easy to select an adequate material but not optimal for the job. However, you may want to select the best metal material for your CNC machining project. Cnc Milling Service

This blog will review several critical considerations to help you choose the best metal material for CNC machined parts.

Designing Top-Quality Plastic Molded Parts: 7 Proven Tips

Cnc Plastic Machining Thousands of designers create injection molded parts. However, a select group in this big community can create parts for injection molders. Before all parts are completely recorded and handed to molders for manufacturing, injection molded product design goes through many development stages. The last stage of development is essential since design adjustments or corrections can no longer be performed without dramatically raising expenses or project delays. So, how can you

ensure that your plastic molded parts are perfectly designed? Here’s a detailed guide on effectively designing the parts.

Material Selection and Its Implications:

Cnc Rapid Prototyping Materials are typically specified early in the design process, and both parties must agree. Molders can sometimes get large amounts of specialized resins at steep savings. Customers can benefit from these offers. For example, a designer can save tens of thousands of dollars if they select an ABS grade that matches the ABS grade that molders buy in bulk. Prototool.com

Due to viscosity, high glass content, or crystallinity, designers may discover that certain high-performance resins are not suited for molders. Resins can be chosen for certain physical or chemical resistance qualities. However, they can be difficult to mold and keep to specified tolerances. Molders must adhere to the prescribed resin and integral part specifications to mold the part. Cnc Turning Service

The Most Common Types of Machining Services and Processes

Consumer Electronics Manufacturers Machining services are crucial in manufacturing, as they shape and transform raw materials into finished products. Various machining services are available, each with its unique set of benefits and applications. From milling to drilling and turning, machining methods have revolutionized how products are made. This article will explore the seven most common types of machining methods, their advantages, and the industries that use them.

Understanding these services will help businesses determine the best machining processes for their manufacturing needs.

This article will discuss the seven different machining services and how they are conducted in the plastic injection molding/manufacturing industry. High Volume Manufacturing

Prior Materials Preparation and Pre-Molding Considerations for Effective Plastics Injection Molding

High-volume Production In plastics injection molding, the work done to prepare the mold before adding material to it and molding plastic to make a product is of critical importance. It includes evaluating and setting up for a wide variety of processes, such as material processing performance inspection (determination of plastic fluidity, moisture content, etc.); dyeing and granulating of raw materials before processing; preheating and drying of granules; cleaning and preheating of inserts; mold testing and cylinder cleaning, etc.; and so on. Prototool.com

Having a sound comprehension of all the procedures involved and commencing with the appropriate strategy to evaluate and prepare the material is crucial for ensuring the effectiveness of the plastic injection molding process. Now, in the event that you are uninformed of what occurs before the use of high-tech machinery, the phase of mold

inserting, and the phase of production form, let’s go ahead and investigate many aspects of preparing the production setup before formally beginning the production process.

Injection mold China

4-Axis CNC – The Various Features and Important Details about It

4-axis CNC machines are advanced versions of 3-axis CNC centers that have revolutionized the field of workpiece shaping. With the installation of the fourth axis, these machines have significantly enhanced the quality of machining. Injection Molding Manufacturers

A 4-axis CNC machine has four axes, which allows it to perform intricate operations such as milling, turning, drilling, and more. This multi-tasking capability allows the machines to perform multiple jobs simultaneously. In this comprehensive guide, we will explore the features and capabilities of 4-axis CNC machines to provide you with a complete understanding of their capabilities. Injection Molding Services

More Information - https://prototool.com/

0 notes

Text

Facing Process in CNC Machining

New Post has been published on http://www.cncmachinings.com/facing-process-in-cnc-machining/

Facing Process in CNC Machining

Frequently, the principal activity to be performed on a milled part is a confronting activity. This machines the top surface of the part level and smooth, while accomplishing an ideal thickness. This surface turns into the Z-zero plane that any remaining profundity measurements will be referred to from. After the face processing device is stacked in the shaft, quick cross moves the device to the starting X-and Y-position, fast navigate carries the apparatus to the Z-confronting position, and afterward direct insertion is utilized to play out the confronting cut. This confronting activity starts real machining tasks and is the material expulsion segment of the CNC program design appeared in china custom titanium machined parts.

Since program organizes are identified with the focal point of the instrument, the fringe of the face factory should be considered so when the device goes to the ideal Z-profundity, it is still clear of the part. The instrument ought to likewise be taken care of completely off the workpiece toward the finish of the cut. In the model, the 3″ width face factory has a span of 1.5″, so the beginning point and finishing point of the confronting pass should clear the work by at any rate 1.5″. It is a smart thought to permit some additional room for wellbeing. For this situation, permitting an extra 0.200″ toward the beginning and the finish of each pass will be adequate.

The components of the workpiece to be confronted are appeared in china precision aluminum milling parts suppliers. In this model, the molder is sufficiently enormous to cut the full width of the part in one pass.

The Y facilitate can be the focal point of the workpiece at Y 1.25. This will place the face plant in the part along the Y-hub. The beginning X-arrange is determined by adding the sweep of the face plant and the wellbeing sum, at that point taking away that answer from the inception. The beginning X-facilitate is X 5.7. This worth would be 1.5 + 0.2= 1.7.

The closure X-arrange is X-1.7. The closure X-organize is determined by adding the length of the part, the range of the face plant, and the security sum. This point would be 4+ 1.5+0.200= 5.7.

Since past models set Z-zero on the highest point of the stock, it could be hard to see how any material will be eliminated if the face plant cuts at Z-zero.

On most parts, the Z-zero position will be set beneath the outside of the unpleasant stock. Assume the objective thickness is 0.900″ and the stock is 1.0″ thick; 0.100″ should be taken out during looking to arrive at the last thickness (1.0一0.900 = 0.100). In the event that the situation of Z-zero is set 0.100″ underneath the top surface of the harsh stock, the part will be the right thickness and the top surface plane of Z-zero will be made by the face factory of precision cnc machining parts manufacturers.

This article is from http://www.cncmachinings.com/

#china 3 axis cnc machining service manufacturers#china cnc machining medical parts#china cnc machining shop#china cnc plastic milling parts and service suppliers#china cnc stainless steel turning service manufacturers#china cnc turning&milling service manufacturers#china custom titanium machined parts#china customized precision metal lathe#china high precision cnc bronze custom made parts manufacturers#china metal cnc machining parts suppliers#china milling machine parts suppliers#china precision aluminum milling parts suppliers#china precision parts factory#china steel cnc turned component suppliers#china titanium machine parts manufacturers#cnc cutting carbon fiber part suppliers#cnc machine for carbon fiber suppliers#cnc prototyping made in china#low price custom cnc parts precision milling other cnc parts#machining parts manufacturers#machining parts quotation#medical devices tooling made in china#precision alloy manufacturers china#precision cnc machining parts manufacturers#Featured Articles

0 notes

Text

Bar Pullers and Bar Feeders

Posted from 5 axis machining China blog

Bar Pullers and Bar Feeders

For china high precision cnc bronze custom made parts manufacturers exhausting, inward stringing, and inner scoring tasks utilize a bar to hold the cutting apparatus. The additions mounted in these bar-type holders are generally indistinguishable from those utilized for OD working. Numerous ID-working toolholders for CNC machines additionally have coolant entries penetrated through their shanks that exit at the supplement, so coolant streams straightforwardly into the cutting zone. This can be useful to flush chips from inside the drag during cutting.

Bar pullers and bar feeders are frill used by machining parts manufacturers to make a given machine as robotized as could be expected under the circumstances and need as little administrator consideration as could reasonably be expected. A bar puller is an instrument that is mounted to the turret and, when modified, can move toward the excess bar material after a section has been cut off, grasp the bar, and after the workholding gadget is delivered, pull the bar to the ideal length. These capacities are programmable. Bar pullers are accessible in numerous structures, including grasping ring type, spring-jaw type, and coolant-controlled pressure driven.

Bar feeders mount outside of the machine headstock, in-accordance with the shaft centerline, and acknowledge whole lengths of bar stock. The bar pivots in the feeder tube and the feeder controls the bar from whipping out of equilibrium. As one workpieceis cut off of the bar toward the finish of the machining cycle, the workholding gadget will unclamp and the feeder will push enough material length through the axle bore with the goal that the following workpiece can be delivered.

The standard tasks performed by china precision machined components suppliers on a turning place are fundamentally the same as those performed on a manual machine. Commonplace activities include turning, confronting, stringing, holemaking, scoring, and cutoff. Every one of these particular assignments in itself is alluded to as an activity. The sum of all tasks needed in the machining of a section is known as an assembling cycle.

Before programming or setting up the machine, the designing drawing should be closely inspected and the creation of the part arranged beginning to end. The arranging of workholding gadgets, tooling, and the machining activities relies upon the part’s highlights, resiliences, and surface completions needed by the drawing.

When an intensive technique has been resolved to deliver a section, the means would then be able to be point by point on a record called a cycle plan.

This arrangement will incorporate a portrayal of every activity, the apparatuses required, speed and feed information, workholding data, different notes and remarks, and frequently a sketch portraying the part direction. This archive is significant not just for the underlying programming of the part, yet additionally as a source of perspective for any arrangement individual or administrator who will run this part later on. When the arranging has been done, the tooling is recorded on a tooling arrangement sheet.

This article is from http://www.5axismachiningchina.com/

#china 4 axis cnc machining#china aluminum cnc machining suppliers#china brass metal auto parts#china cnc machining metal component#china customized precision metal lathe#china high precision cnc bronze custom made parts manufacturers#china precision aluminum milling parts suppliers#china precision machined components suppliers#cnc machined part#cnc machined part factory#cnc machining suppliers china#cnc product suppliers china#cnc prototyping made in china#cnc stainless steel turned machining parts suppliers#custom machine parts china#customized cnc milling parts factory#machining parts manufacturers#precision cnc machined parts supplier#precision custom machining parts/service factory#precision machining parts suppliers china#shapeways cnc

0 notes

Text

A Dive into the Revolutionary CNC Technology in Manufacturing

Unleashing the Future: A Dive into the Revolutionary CNC Technology in Manufacturing

In the fast-evolving landscape of manufacturing, the gears of innovation never cease to turn. As we propel into the digital future,

the realm of CNC machining stands at the forefront of this technological revolution. How is the latest CNC technology reshaping

the manufacturing landscape? What groundbreaking features does it bring to the table? Let's embark on a journey through the

corridors of innovation to uncover the answers.

Digital Future: Exploring the Innovation of Our Latest CNC Technology in Manufacturing

In the heart of China, where precision meets prowess, CNC MACHINING at REGO takes center stage. With five production lines

humming in harmony and a dedicated team of 55 professionals, our commitment to delivering top-tier products resonates in

every meticulously crafted piece. But what sets us apart in this era of digital transformation?

Customization is the linchpin of our prowess. In a world where one size rarely fits all, our CNC machining capabilities extend

beyond the ordinary. We pride ourselves on tailoring solutions to the specific needs of our clients. Whether it's CNC machining,

injection molding, die casting mold, or 3D printing, REGO is not just a supplier; we are architects of precision.

The Technological Tapestry Unraveled

Now, let's delve into the core of our innovation. The latest CNC technology we employ seamlessly integrates with various

manufacturing processes, empowering industries ranging from aerospace to electronics. With precision at its zenith, this

technology has become the heartbeat of the manufacturing floor.

Our clients, a discerning executive in Canada, symbolizes our typical client. At 43, he understands the critical balance between

quality and cost. like many others, values the craftsmanship that comes with products made in China. His priority is not just a

transaction; it's a relationship built on trust and personalized service.

In a world where efficiency is a currency, REGO's CNC technology thrives. Our clients, have encountered the pain points of inefficiency,

delays, and the haunting specter of fraudulent certifications with other suppliers. At REGO, we understand these challenges,

and our commitment to quality control, certification, logistics, and transparent payment methods aims to alleviate these concerns.

Navigating the Digital Wave

As we ride the digital wave, accessibility and affordability have become the cornerstones of CNC machining. Small businesses

and individuals, not just industry giants, now harness the power of CNC machines for prototypes, custom parts, and personal projects.

The democratization of CNC technology transcends expertise levels, bringing manufacturing capabilities to anyone with a vision.

In the digital era, our online presence is as robust as our manufacturing lines. Platforms like Alibaba and Google serve as windows

to our world, showcasing not just products but a commitment to excellence. These platforms bridge the geographical gap,

connecting us with clients, who seek quality irrespective of borders.

Conclusion: A Glimpse into Tomorrow's Manufacturing Landscape

As we navigate the digital future, the innovation in CNC technology at REGO is not just about precision engineering; it's about forging

lasting partnerships. Our commitment to quality, customization, and transparency positions us as more than suppliers. We are enablers

of dreams, architects of progress, and custodians of trust in the evolving saga of manufacturing. Join us as we continue to redefine what's

possible in the relentless pursuit of excellence.

0 notes