#CNC Prototype Machining

Explore tagged Tumblr posts

Text

Using the Potential of CNC Machining

In the constantly changing field of product development, efficiency, accuracy, and innovation are always sought after. CNC Prototype Machining is the core of this endeavor; this revolutionary technology has completely changed the way prototypes are imagined, created, and executed.

Redefining Precision: The Advantage of CNC

The unmatched accuracy of CNC prototype machining is its foundation. CNC machines are outfitted with the newest technology and are directed by exact CAD/CAM instructions to do jobs with minuscule accuracy. With CNC machining, every detail is painstakingly and precisely carved, whether it be for drilling precise holes or sculpting complex designs.

Innovation Acceleration: Accelerating the Development Cycle

Speed is crucial in the fast-paced environment we live in today. The days of protracted production schedules and never-ending revisions are over thanks to CNC prototype machining. CNC machines help engineers and designers to iterate quickly and bring things to market more quickly than ever before by optimizing the prototype process. This shortened development cycle encourages innovation and experimentation while simultaneously shortening time-to-market.

Unleashing Versatility: From Idea to Actuality

The adaptability of prototype CNC Machining China is among its most impressive features. CNC machines can easily mold a wide range of materials into working prototypes, whether they are made of metal, plastic, wood, or composite materials. The options are endless, ranging from sophisticated consumer electronics to delicate aircraft components.

Filling the Void: From Concept to Manufacturing

In addition to prototypes, CNC machining is essential for bridging the gap between production and design. CNC machines facilitate the process of moving from concept to mass manufacture by producing parts that are ready for production and of superior quality. Prototypes are guaranteed to be workable solutions prepared for practical implementation, not only functional mock-ups thanks to this smooth connection.

Promoting Innovation in All Sectors

Prototype CNC Machining has a significant influence that goes much beyond the boundaries of a particular sector. CNC machines are pushing innovation across a wide variety of sectors, from consumer products and medical devices to aerospace and automobiles. The future of manufacturing is being shaped by CNC prototype machining, which is at the forefront of innovations such as supply chain revolutions, improved product performance, and the ability to enable new design patterns.

#CNC Machining#CNC Machining process#CNC Machining process China#CNC Machining Techniques#CNC Prototype Machining#CNC Prototype Machining China#CNC Machining China

2 notes

·

View notes

Text

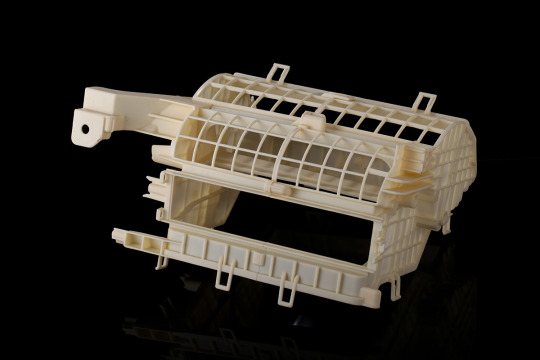

Rapid prototyping cnc machining center. __________________________________ Centro de mecanizado CNC de prototipado rápido. __________________________________ Centre d'usinage CNC de prototypage rapide.

#cnc machining#prototype#rapid prototyping#prototype machining#5axis#machining parts#cncMachinist#Manufacturingservice

3 notes

·

View notes

Text

5 notes

·

View notes

Text

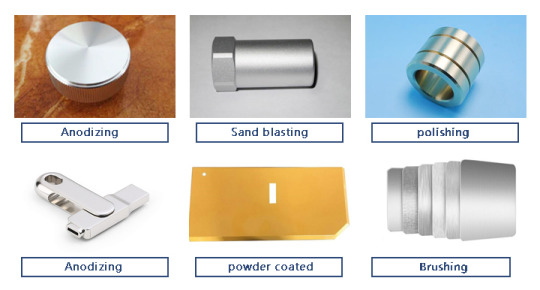

We provide precision CNC machining services, CNC Milling and Turning (3 axis, 4 axis, 5 axis), can manufacture complex and multi-structure plastic and metal parts.

#cncmachining#5 axis machining#cnc milling services#cnc machining parts#rapid prototyping#precision machining

2 notes

·

View notes

Text

Maintenance Tips for Your CNC Turning Machine by MechPlus China

As a leading CNC turning machine manufacturing, MechPlus China understands the importance of proper maintenance to ensure precision and efficiency. Regular upkeep not only extends the machine's lifespan but also maximizes productivity and quality. Here are essential maintenance tips from MechPlus China to keep your CNC turning machine running smoothly and efficiently.

Keeping your CNC turning machine in top condition is crucial for optimal performance. Regular maintenance not only extends the machine's lifespan but also ensures precision and efficiency in your operations. Here are essential maintenance tips to keep your CNC turning machine running smoothly.

Daily Inspection and Cleaning

Start each day with a thorough inspection of your CNC turning machine. Check for any signs of wear and tear, and ensure all components are in good working order. Clean the machine daily to remove any debris, chips, and coolant residue. This prevents buildup that can affect performance and accuracy.

Lubrication

Proper lubrication is vital for the smooth operation of your CNC turning machine. Lubricate all moving parts as recommended by the manufacturer. This includes the spindle, guideways, and ball screws. Regular lubrication reduces friction, prevents wear, and extends the machine’s life.

Coolant Maintenance

Maintaining the coolant system is essential for the longevity of your CNC machine. Regularly check the coolant level and concentration. Replace or refill the coolant as needed. Also, clean the coolant tank and filters to avoid contamination that can damage the machine and workpieces.

Alignment and Calibration

Ensure that your CNC turning machine is properly aligned and calibrated. Misalignment can lead to inaccuracies in your machining processes. Regularly check and adjust the machine’s alignment and calibration according to the manufacturer’s guidelines. This ensures precision in your operations.

Check Electrical Components

Inspect the electrical components of your CNC turning machine regularly. Look for any loose connections, worn-out wires, or faulty switches. Address any electrical issues immediately to prevent machine downtime and potential safety hazards.

Monitor Machine Vibration

Excessive vibration can lead to poor machining quality and damage to your CNC turning machine. Monitor the machine for any unusual vibrations or noises during operation. Identify and address the source of the vibration to maintain optimal performance.

Regular Software Updates

Keep your CNC machine’s software up to date. Manufacturers often release updates that improve functionality and fix bugs. Regularly updating the software ensures your machine operates efficiently and takes advantage of the latest technological advancements.

Tool Maintenance

Regularly inspect and maintain the cutting tools used in your CNC turning machine. Sharp and well-maintained tools are crucial for high-quality machining. Replace worn or damaged tools promptly to ensure precise and efficient operation.

Preventive Maintenance Schedule

Implement a preventive maintenance schedule for your quick response machining tool. Follow the manufacturer’s recommended maintenance intervals for all components. Regular preventive maintenance helps identify potential issues before they become major problems, reducing downtime and repair costs.

Training and Safety

Ensure that all operators are properly trained in the maintenance and operation of the CNC turning machine. Regular training updates and adherence to safety protocols are crucial for preventing accidents and ensuring smooth operations.

Document Maintenance Activities

Keep detailed records of all maintenance activities performed on your CNC turning machine. Documenting maintenance helps track the machine’s condition over time and provides valuable information for troubleshooting and repairs with all types of customized machining parts.

In conclusion, regular maintenance of your CNC turning machine is essential for its longevity and performance. By following these tips, you can ensure your machine operates efficiently, reducing downtime and improving the quality of your machining processes. Implement these maintenance practices to keep your CNC turning machine in optimal condition.

#Prototyping solutions#SLA Rapid Prototyping manufacturing#SLS Rapid machining manufacturing#5 Axis CNC machining manufacturing#3D metal printing manufacturing

2 notes

·

View notes

Text

The Importance of High-tech Rapid Prototyping

In the industrial industry, precision is not only desirable—it is essential. Consider a situation in which parts of a jet engine are even marginally machined incorrectly or misaligned. The repercussions can be disastrous and might cause the engine to fail in midair. Precision becomes the key to success in sectors like aerospace, automotive, and medical where safety and dependability are non-negotiable. Put simply, it's the capacity to manufacture parts or components that precisely conform to given dimensions, tolerances, and quality requirements. It takes state-of-the-art equipment, painstaking attention to detail, and highly competent operators to achieve this degree of accuracy. This is the sweet spot for Precision CNC Machining.

So how precisely can CNC machining accomplish such high precision levels?

Computerized Control: Advanced computer software is the brains of CNC machining, translating digital design requirements into exact motions and orders for the milling tools. This removes the possibility of human error and guarantees the highest level of precision in each cut, drill, and mill.

Superior Quality Equipment: Modern spindles, tools, and cutting implements that are designed to provide exact results are standard on CNC machines. These devices may operate at extremely tight tolerances, which are sometimes expressed in microns, guaranteeing an accurate reproduction of even the minutest features.

Consistency: The ability of CNC machining and High-tech Rapid Prototyping to manufacture similar components with little variance is one of its main advantages. A machine program that has been developed and tuned may be repeated endlessly with reliable outcomes. In fields where stability and dependability are critical, this degree of constancy is priceless.

Advanced Techniques: Multi-axis milling, turning, EDM (Electrical Discharge Machining), laser cutting, and other state-of-the-art methods are all included in CNC machining. With unmatched accuracy and efficiency, manufacturers can handle complicated geometries and materials thanks to these procedures.

Quality Assurance: CNC systems frequently include integrated quality control mechanisms including automated inspections, feedback loops, and real-time monitoring in addition to accurate machining. This reduces waste and rework by guaranteeing that any deviations from the intended standards are quickly identified and fixed. It is impossible to exaggerate the value of accuracy in production. Precision by Precision CNC Machining Manufacturer plays a crucial role in today's competitive economy, as it ensures everything from satisfying regulatory requirements and consumer expectations to assuring product performance and dependability.

Follow our Facebook and Twitter for more information about our product

#High-tech Rapid Prototyping#Precision CNC Machining#Precision CNC Machining Manufacturer#CNC Machining Manufacturer Company

2 notes

·

View notes

Text

0 notes

Text

CNC Machining for Rapid Prototyping | Fast & Accurate Prototypes

Transform your product ideas into real-world solutions with Rapid Prototyping CNC Machining services from Impel Concepts. Their precision and speed help bring your vision to life with accuracy and efficiency. Whether you’re developing a concept or refining a part, Impel Concepts delivers quality every step of the way. Trust them for fast turnarounds and professional-grade prototypes tailored to your specifications.

#rapid prototyping cnc machining#cnc production machining#FEA Analysis#Concept Rendering#cnc machining solutions#Prototype development

1 note

·

View note

Text

CNC Machining Prototyping For Efficient Product Testing

CNC Machining Prototyping entails growing precise, useful prototypes the usage of computer-controlled machines. This manner permits designers to quickly test and refine designs with excessive accuracy. Ideal for industries like aerospace, car, and medical, it ensures cost-powerful and speedy improvement of prototypes, facilitating faster selection-making and reducing manufacturing time.

0 notes

Text

Get the Finest Precision with CNC Machining

In a subtractive manufacturing technique known as CNC machining, materials are precisely shaped and cut into the necessary shapes. CNC machining automates the production process in contrast to conventional machining, which mainly depends on manual intervention, leading to improved precision, repeatability, and efficiency.

Using computer-aided design (CAD) software, a digital design is produced at the start of the process. The design acts as a guide for how the CNC machine should operate. The design is then transformed into a machine-readable format, often a G-code program, which gives instructions for the CNC machine after it is complete.

The ultimate product's needs are taken into consideration while selecting the material, which may be made of metals, polymers, or composites. By sawing the material into the required sizes, either manually or automatically, the material is prepared.

The prepared material is firmly secured to the work table of the CNC machine. The CNC program is entered into the machine's controller once the cutting tools, such as drills, mills, or lathes, are mounted during the CNC machining process.

After the machine is configured, the CNC controller reads the G-code program and gives precise instructions to the machine's motors to move the cutting tools. The cutting tools execute operations including drilling, milling, turning, and more to remove material in line with the design parameters.

Throughout the machining process, quality control procedures are used to make sure that the part's dimensions, tolerances, and surface finishes adhere to the necessary standards. To check accuracy, you could use measurement equipment like calipers, micrometers, or coordinate measuring machines (CMMs).

The advantages of CNC machining

The excellent precision and accuracy of CNC machining is well known. The process is computer-controlled, which guarantees consistent and dependable outcomes, making it perfect for applications that call for precise tolerances and complex geometries.

CNC machines can deal with a variety of materials, such as composites, metals, plastics, and wood. This adaptability makes it possible to produce a variety of components for different businesses.

Complex items may be produced fast and effectively using CNC machining. Once set up, the device can run alone with little assistance from a person. This shortens the production process and increases output in general.

It is possible to produce identical components with great repeatability using CNC prototype machining. Manufacturers can reliably make huge numbers of components because of the CNC program's ability to be stored and used again.

Main source: https://cneasteel.wordpress.com/

#CNC Machining#CNC Machining process#CNC Machining Techniques#CNC Prototype Machining#CNC Machining China

2 notes

·

View notes

Text

CNC Machining Service: Precision Manufacturing from Fuson Precision Machining

CNC Machining Service plays a pivotal role in various industries, providing the accuracy and precision required to meet exacting standards. One standout player in this field is Fuson Precision Machining, a leading CNC precision machining shop located in China. With a commitment to producing high-quality components and assemblies, Fuson has become a trusted partner for businesses across multiple sectors, including the Medical, Mechanical, Aviation, Packaging, Automation, and Electronics industries. For more information please visit : https://penzu.com/p/7f6dd23b3c894d34

0 notes

Text

Prototype Fabrication

Bring your ideas to life with Let's Escape Together's prototype fabrication services. Our expert team utilizes cutting-edge technology to transform concepts into precise, functional prototypes. From initial design to final production, we ensure top-quality craftsmanship and attention to detail. Trust us to deliver reliable, cost-effective solutions tailored to your specific needs, helping you innovate and succeed in your projects. Visit Us : : https://nagualmetal.en.alibaba.com/

#cnc machining service#progressive stamping die#sheet metal fabrication#plastic injection mold#prototype fabrication

0 notes

Text

GD prototyping five-axis machining of high-precision and complex parts, high machining accuracy, improved machining flexibility and efficiency, machining high-quality parts.

#cnc machining#prototyping#5 axis machining#cnc milling services#cnc machining parts#parts machining#cnc milling#precision machining

0 notes

Text

#rapid prototype# If you are looking for rapid prototype supplier, we are here for you. Please drop me an email at your convenience [email protected], we will be happy to help! For more information, please visit https://www.sgproto.com/

0 notes

Text

Why Vacuum Forming is Perfect for Low-Volume Manufacturing Needs

Vacuum forming is a cost-effective method for producing high-quality, custom plastic parts. Discover why it’s ideal for low-volume manufacturing.

#custom plastic parts#cnc rapid prototyping#3d printing companies in michigan#cnc precision machining

0 notes

Text

The Potential of High-Tech Rapid Prototyping

High-tech Rapid Prototyping has become a game-changer in the rapidly changing fields of innovation and technology, altering the way things are planned, developed, and introduced to the market. This dynamic process, which promotes creativity, shortens time-to-market, and ultimately drives unmatched innovation, has emerged as a key component for companies looking to maintain their leadership positions in their respective fields.

The Innovation-Promoting Technologies

The 3D Printing Process

3D printing is a key component of the fast prototyping revolution because it allows digital models to be layered into actual items. This technology has made it easier to produce intricate, personalized prototypes and greatly reduced design cycles.

Machining using computer numerical control (CNC)

Prototypes made of different materials may be accurately cut, shaped, and assembled with the help of computer-controlled gear thanks to CNC machining from CNC Machining Manufacturer. This adaptable technique works especially well for creating prototypes with intricate geometries and great accuracy.

Using Injection Molding

Rapid prototyping is greatly aided by injection molding, a process that is frequently employed in mass manufacturing. The appearance, feel, and functioning of the final product are accurately represented by injection-molded prototypes.

Benefits of Rapid High-Tech Prototyping

Quicker Iterations in Design

Design revisions may be completed quickly and affordably using rapid prototyping. Instead of weeks or months, designers may test several iterations of a product, improve functionality, and fix bugs in a matter of days.

Economy of Cost

High-tech fast prototyping decreases the upfront expenses associated with traditional manufacturing methods by eliminating the need for expensive equipment and molds. This makes it possible for companies to test concepts more affordably before committing to large-scale manufacturing.

Improved Cooperation

Improved cross-functional team communication is facilitated by prototyping. A prototype may be physically interacted with by stakeholders, who can offer insightful input and encourage cooperation between end users, engineers, and designers.

Sensitivity to the Market

Being able to react swiftly to customer input and industry developments is critical in businesses that move quickly. Businesses may maintain their agility, adjust to shifting customer needs, and obtain a competitive advantage in the market by using high-tech fast prototyping and Precision CNC Machining.

Follow our Facebook and Twitter for more information about our product.

#High-tech Rapid Prototyping#Precision CNC Machining#Precision CNC Machining Manufacturer#CNC Machining Manufacturer Company#Precision CNC Machining Manufacturer Company

2 notes

·

View notes