#CNC Machining process China

Explore tagged Tumblr posts

Text

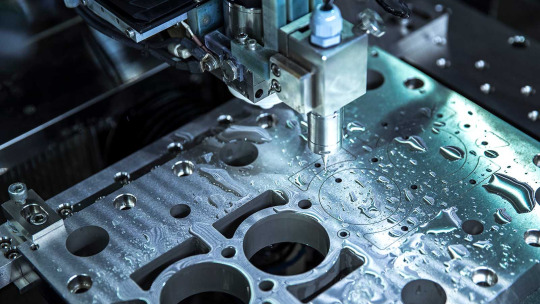

Using the Potential of CNC Machining

In the constantly changing field of product development, efficiency, accuracy, and innovation are always sought after. CNC Prototype Machining is the core of this endeavor; this revolutionary technology has completely changed the way prototypes are imagined, created, and executed.

Redefining Precision: The Advantage of CNC

The unmatched accuracy of CNC prototype machining is its foundation. CNC machines are outfitted with the newest technology and are directed by exact CAD/CAM instructions to do jobs with minuscule accuracy. With CNC machining, every detail is painstakingly and precisely carved, whether it be for drilling precise holes or sculpting complex designs.

Innovation Acceleration: Accelerating the Development Cycle

Speed is crucial in the fast-paced environment we live in today. The days of protracted production schedules and never-ending revisions are over thanks to CNC prototype machining. CNC machines help engineers and designers to iterate quickly and bring things to market more quickly than ever before by optimizing the prototype process. This shortened development cycle encourages innovation and experimentation while simultaneously shortening time-to-market.

Unleashing Versatility: From Idea to Actuality

The adaptability of prototype CNC Machining China is among its most impressive features. CNC machines can easily mold a wide range of materials into working prototypes, whether they are made of metal, plastic, wood, or composite materials. The options are endless, ranging from sophisticated consumer electronics to delicate aircraft components.

Filling the Void: From Concept to Manufacturing

In addition to prototypes, CNC machining is essential for bridging the gap between production and design. CNC machines facilitate the process of moving from concept to mass manufacture by producing parts that are ready for production and of superior quality. Prototypes are guaranteed to be workable solutions prepared for practical implementation, not only functional mock-ups thanks to this smooth connection.

Promoting Innovation in All Sectors

Prototype CNC Machining has a significant influence that goes much beyond the boundaries of a particular sector. CNC machines are pushing innovation across a wide variety of sectors, from consumer products and medical devices to aerospace and automobiles. The future of manufacturing is being shaped by CNC prototype machining, which is at the forefront of innovations such as supply chain revolutions, improved product performance, and the ability to enable new design patterns.

#CNC Machining#CNC Machining process#CNC Machining process China#CNC Machining Techniques#CNC Prototype Machining#CNC Prototype Machining China#CNC Machining China

2 notes

·

View notes

Text

Experience unparalleled innovation with our China Customized Graphite Special Machining Center, tailored to meet your unique machining needs and enhance production efficiency.

#China Customized Graphite Special Machining Center#Graphite Processing Machines#CNC precision engraving machine#Graphite Lathe#Graphite Milling

0 notes

Text

Revolutionizing Motorcycle Manufacturing with CNC Machining

Introduction In the world of motorcycle manufacturing, precision, efficiency, and innovation are key factors that drive the industry forward. Over the years, the advent of CNC machining has brought about a revolution in the manufacturing processes, allowing for the creation of high-quality motorcycles with intricate designs and superior performance. This blog post explores the intersection of CNC machining and motorcycle manufacturing, with a particular focus on China's prototype manufacturing prowess and the growing popularity of online CNC machining services, including sheet metal processing.

The Rise of CNC Motorcycle Manufacturing The integration of CNC machining technology in motorcycle manufacturing has significantly transformed the industry. CNC (Computer Numerical Control) machines offer unparalleled precision, repeatability, and speed in creating complex components, frames, and other motorcycle parts. These machines utilize computer-aided design (CAD) software to precisely control the movements of cutting tools, resulting in highly accurate and consistent production.

China Prototype Manufacturing Dominance China has emerged as a dominant player in the global motorcycle manufacturing industry, leveraging its expertise in prototype production. The country's prototype manufacturing capabilities, coupled with the widespread adoption of CNC machining, have fueled the growth of the motorcycle industry. Chinese manufacturers have harnessed the power of CNC machines to produce motorcycle prototypes quickly and cost-effectively, allowing for rapid design iterations and faster time-to-market.

Online CNC Machining Services In recent years, the rise of online CNC machining services has further revolutionized motorcycle manufacturing. These services provide a convenient platform for motorcycle manufacturers to access high-quality CNC machining capabilities without the need for significant upfront investments in expensive machinery. With just a few clicks, manufacturers can upload their design files and specifications to online platforms and experienced CNC machining service providers take care of the rest.

The advantages of online CNC machining services extend beyond cost savings. They offer a vast range of machining options, including 3-axis, 4-axis, and 5-axis CNC milling, turning, and sheet metal processing services. Motorcycle manufacturers can choose the most suitable machining processes for their specific needs, ensuring the highest precision and quality in the final products.

Sheet Metal Processing Services Sheet metal processing plays a vital role in motorcycle manufacturing, as it involves shaping and forming thin metal sheets to create various components and structures. CNC machines equipped with specialized sheet metal processing capabilities enable precise cutting, bending, and welding, resulting in components that fit together seamlessly. Online CNC machining services often provide comprehensive sheet metal processing services, offering manufacturers a one-stop solution for their motorcycle production needs.

Conclusion CNC machining has become an indispensable tool in the motorcycle manufacturing industry, enabling precise and efficient production processes. China's prototype manufacturing expertise, combined with the rise of online CNC machining services, has further accelerated the pace of innovation and cost-effective production. Motorcycle manufacturers can leverage these advancements to bring their designs to life with exceptional accuracy and quality. As the industry continues to evolve, the integration of CNC machining and sheet metal processing services will play a crucial role in shaping the motorcycles of the future.

By embracing CNC machining and taking advantage of the convenience and versatility offered by online CNC machining services, motorcycle manufacturers can stay at the forefront of the industry, delivering cutting-edge designs and superior performance to motorcycle enthusiasts worldwide.

#cnc motorcycle#china prototype manufacturing#Online CNC Machining Services#Sheet Metal Processing Services

0 notes

Text

Maintenance Tips for Your CNC Turning Machine by MechPlus China

As a leading CNC turning machine manufacturing, MechPlus China understands the importance of proper maintenance to ensure precision and efficiency. Regular upkeep not only extends the machine's lifespan but also maximizes productivity and quality. Here are essential maintenance tips from MechPlus China to keep your CNC turning machine running smoothly and efficiently.

Keeping your CNC turning machine in top condition is crucial for optimal performance. Regular maintenance not only extends the machine's lifespan but also ensures precision and efficiency in your operations. Here are essential maintenance tips to keep your CNC turning machine running smoothly.

Daily Inspection and Cleaning

Start each day with a thorough inspection of your CNC turning machine. Check for any signs of wear and tear, and ensure all components are in good working order. Clean the machine daily to remove any debris, chips, and coolant residue. This prevents buildup that can affect performance and accuracy.

Lubrication

Proper lubrication is vital for the smooth operation of your CNC turning machine. Lubricate all moving parts as recommended by the manufacturer. This includes the spindle, guideways, and ball screws. Regular lubrication reduces friction, prevents wear, and extends the machine’s life.

Coolant Maintenance

Maintaining the coolant system is essential for the longevity of your CNC machine. Regularly check the coolant level and concentration. Replace or refill the coolant as needed. Also, clean the coolant tank and filters to avoid contamination that can damage the machine and workpieces.

Alignment and Calibration

Ensure that your CNC turning machine is properly aligned and calibrated. Misalignment can lead to inaccuracies in your machining processes. Regularly check and adjust the machine’s alignment and calibration according to the manufacturer’s guidelines. This ensures precision in your operations.

Check Electrical Components

Inspect the electrical components of your CNC turning machine regularly. Look for any loose connections, worn-out wires, or faulty switches. Address any electrical issues immediately to prevent machine downtime and potential safety hazards.

Monitor Machine Vibration

Excessive vibration can lead to poor machining quality and damage to your CNC turning machine. Monitor the machine for any unusual vibrations or noises during operation. Identify and address the source of the vibration to maintain optimal performance.

Regular Software Updates

Keep your CNC machine’s software up to date. Manufacturers often release updates that improve functionality and fix bugs. Regularly updating the software ensures your machine operates efficiently and takes advantage of the latest technological advancements.

Tool Maintenance

Regularly inspect and maintain the cutting tools used in your CNC turning machine. Sharp and well-maintained tools are crucial for high-quality machining. Replace worn or damaged tools promptly to ensure precise and efficient operation.

Preventive Maintenance Schedule

Implement a preventive maintenance schedule for your quick response machining tool. Follow the manufacturer’s recommended maintenance intervals for all components. Regular preventive maintenance helps identify potential issues before they become major problems, reducing downtime and repair costs.

Training and Safety

Ensure that all operators are properly trained in the maintenance and operation of the CNC turning machine. Regular training updates and adherence to safety protocols are crucial for preventing accidents and ensuring smooth operations.

Document Maintenance Activities

Keep detailed records of all maintenance activities performed on your CNC turning machine. Documenting maintenance helps track the machine’s condition over time and provides valuable information for troubleshooting and repairs with all types of customized machining parts.

In conclusion, regular maintenance of your CNC turning machine is essential for its longevity and performance. By following these tips, you can ensure your machine operates efficiently, reducing downtime and improving the quality of your machining processes. Implement these maintenance practices to keep your CNC turning machine in optimal condition.

#Prototyping solutions#SLA Rapid Prototyping manufacturing#SLS Rapid machining manufacturing#5 Axis CNC machining manufacturing#3D metal printing manufacturing

2 notes

·

View notes

Text

Manufacturability Design in Rapid Prototyping

Quickly producing physical models or prototypes with additive manufacturing technologies like 3D printing, CNC machining, or other sophisticated fabrication techniques is known as Rapid Prototyping China. With this method, designers may test their ideas, evaluate functionality, and spot problems in their designs early on, which cuts down on development expenses and time-to-market.

Manufacturability-focused design (DFM)

DFM is a collection of best practices and standards for improving a product's design so that it can be manufactured more easily. DFM concepts are as important at the rapid prototyping stage, even though they are typically linked with mass production. Engineers may minimize problems and streamline the prototype process by taking manufacturing restrictions into account early in the design phase.

Essential DFM Takeaways for Quick Prototyping

Material Choice

Select materials that work well with the quick prototyping method you've chosen.

Depending on the planned use, take into account the material's strength, flexibility, and heat resistance.

Complexity of Geometry

Simplify designs to save money and time during manufacture.

Reduce overhangs and complex features, which might be difficult to create using some fast prototyping techniques.

Accuracy and Tolerance

Recognize the dimensional accuracy constraints of the fast Rapid Prototype technique that you have selected.

To guarantee the required precision in the finished prototype, design with the proper tolerances.

Assisting Frameworks

To avoid deformations during fabrication, especially in 3D printing, take into account the essential support structures in the design.

Reduce post-processing work and material waste by optimizing support structures.

Assembly Considerations

Create components that are simple to test and dismantle for adjustments.

When it's feasible, reduce the amount of components to expedite the prototype process.

Time Efficiency Gains from Using DFM in Rapid Prototyping

Designers may expedite the whole prototype phase by avoiding several revisions and delays by addressing manufacturability problems early on.

Lowering of Expenses

During the fast prototype stage, optimal design decisions result in cost savings through effective material consumption and less waste.

Better Cycles of Iterations

Faster design iterations are made possible by the prompt discovery and resolution of manufacturability difficulties, which enable more extensive testing and refinement.

Improved Prototyping Caliber

By keeping DFM principles in mind, you may minimize unforeseen difficulties during testing and validation by ensuring that the final Rapid prototyping manufacturer closely resembles the planned design.

#Rapid prototyping manufacturer#Rapid Prototype#Rapid Prototyping Services#Metal Rapid Prototyping Services#Rapid prototyping Supplier#Rapid Prototyping China#Chinese Rapid Prototyping Services

2 notes

·

View notes

Text

ACCURL Machines: Precision CNC Machinery for Cutting and Forming

ACCURL Machines specializes in advanced CNC machinery for metal fabrication, offering innovative solutions for cutting and forming processes. Their range includes precision equipment like laser cutters, press brakes, and the metal bending machine, designed for high-performance and efficient metalworking. With state-of-the-art technology and customization options, ACCURL provides solutions tailored to meet the needs of industries seeking accuracy, speed, and reliability in their metal fabrication processes. Whether for small-scale operations or large industrial applications, ACCURL Machines delivers top-quality tools to boost production and optimize workflow.

Our Mission 🚀

At ACCURL, our mission is clear: to lead the industry with energy-efficient, environmentally friendly, and technologically advanced solutions. We strive to empower manufacturers worldwide by providing them with state-of-the-art machinery that enhances productivity, precision, and profitability. Deliver High-Quality Machinery: Provide top-tier CNC press brake and metal bending machines tailored to industry standards.

Enhance Manufacturing Efficiency: Optimize production processes through precision-engineered solutions.

Commit to Innovation: Continuously invest in research and development to offer cutting-edge technology.

Support Diverse Needs: Address various types of pipe bending and metalworking requirements across industries.

Prioritize Customer Satisfaction: Build lasting relationships by offering expert advice and exceptional service.

Promote Sustainability: Implement environmentally friendly practices in our manufacturing processes.

Empower Our Clients: Equip businesses with the tools and knowledge to excel in their operations.

What Sets Us Apart 🌟

Innovation and Progress

Pioneering Spirit: From our early days as one of China's first manufacturers of CNC press brakes and fiber laser cutting machines, we've consistently pushed the boundaries of innovation.

Technological Advancements: We lead the charge in integrating the latest technologies to optimize machine performance and efficiency.

Quality and Customization

Tailored Solutions: We specialize in crafting machines that meet the unique requirements of our clients, ensuring maximum efficiency and ROI.

Precision Engineering: Our machines are renowned for their precision, reliability, and durability, setting industry standards worldwide.

Commitment to Sustainability

Energy Efficiency: ACCURL machines are designed with energy-saving features to reduce environmental impact without compromising performance.

Environmental Responsibility: We prioritize sustainability in our manufacturing processes and product designs.

Our Services 🛠️

ACCURL offers a comprehensive range of services designed to support our clients at every stage of their manufacturing journey:

Machine Sales: Explore our diverse portfolio of CNC press brakes, fiber laser cutting machines, and more.

Customization: Tailor machines to meet specific production requirements, ensuring optimal performance.

Installation and Training: Expert installation and comprehensive training programs to maximize operational efficiency.

Technical Support: Dedicated support teams to assist with maintenance, troubleshooting, and upgrades.

Why Choose ACCURL? 🌐

Global Reach: With a presence in over [number] countries, ACCURL provides localized support and expertise.

Industry Leadership: Ranked among the top 10 global manufacturers, we uphold rigorous standards of quality and innovation.

Customer-Centric Approach: Our commitment to customer satisfaction drives us to exceed expectations in every interaction.

Conclusion 🌍

In conclusion, Accurl Machines stands as a leader in providing high-quality CNC press brake and metal bending solutions designed to elevate your manufacturing capabilities. With our commitment to precision and efficiency, we cater to diverse needs, including various types of pipe bending. By choosing Accurl, you're not just investing in advanced machinery; you're partnering with a dedicated team of experts ready to support your business every step of the way. Discover the difference our innovative solutions can make in enhancing your production processes today.

0 notes

Text

Automatic Argon Arc Welding

ACE Valve located in Yancheng, Jiangsu Province is a customer-centric manufacturer of professional valve components used in oil and gas, chemical power generation, and mining. water treatment and general industrial systems. our main products are valve bodies. closures, seat rings bonnets, trunnion plates, stems, top flanges, and other accessories. Overlay Manufacturers and Overlay Company in China. our facilities allow us to manufacture valve assemblies from 1/2-56"it has a group of dedicated and professional staff with ten years of experience in the production line, factory management, and quality control marketing. etc. We are equipped with more than 50 sets of advanced processing equipment including CNC machine tools, and CNC machining centers. lathes, etc., and testing equipment.

E-mail [email protected]

Mobile / Whatsapp / Wechat: +86 - 15722580267

Address No. 1 Shenfeng Rd. Dafeng Economic Zone, Jiangsu, P.R.China.

0 notes

Text

An in-depth look at the role of furniture manufacturers in uae and their significance in various sectors

furniture manufacturers in uae play a crucial role in the global economy by designing, producing, and distributing a wide range of furniture products for residential, commercial, and institutional use. Their impact extends beyond aesthetics and functionality, influencing sustainability, economic growth, and consumer behavior. Here’s an in-depth look at the role of furniture manufacturers in uae and their significance in various sectors:

Design and Innovation furniture manufacturers in uae are at the forefront of design innovation, combining traditional craftsmanship with modern technology to create functional and aesthetically pleasing products. They work closely with designers, engineers, and materials scientists to develop new styles, ergonomic solutions, and sustainable materials.

Customization: Many manufacturers offer customizable options to meet specific client needs, from bespoke pieces for luxury homes to specialized furniture for commercial spaces.

Trendsetting: They drive design trends by introducing new styles, materials, and finishes that reflect contemporary tastes and cultural shifts.

Production and Supply Chain Management The manufacturing process involves sourcing raw materials, assembling components, and ensuring quality control. furniture manufacturers in uae must manage complex supply chains, often involving multiple suppliers, production facilities, and distribution channels.

Sustainability: Increasingly, manufacturers are focusing on sustainable practices, such as using eco-friendly materials, reducing waste, and implementing energy-efficient production methods.

Technology Integration: Advanced technologies like CNC machining, 3D printing, and robotics are being integrated into manufacturing processes to improve efficiency, precision, and scalability.

Economic Impact Furniture manufacturing is a significant contributor to the global economy, providing employment opportunities and driving economic growth in both developed and developing countries.

Employment: The industry employs millions of workers worldwide, from factory laborers to skilled artisans and designers.

Export and Trade: Furniture is a major export commodity, with countries like China, Italy, and the United States being leading exporters. This trade supports global economic interdependence and contributes to foreign exchange earnings.

Supporting Local and Global Markets furniture manufacturers in uae cater to diverse markets, ranging from local retailers to international chains. They play a crucial role in meeting the demands of various sectors:

Residential Furniture: Manufacturers produce a wide range of products for homes, including sofas, dining tables, beds, and storage solutions.

Commercial Furniture: They supply furniture for offices, hotels, restaurants, and educational institutions, often focusing on durability, ergonomics, and aesthetic appeal.

Institutional Furniture: Manufacturers also produce specialized furniture for healthcare facilities, government buildings, and public spaces.

Sustainability and Environmental Responsibility In response to growing environmental concerns, furniture manufacturers in uae are increasingly adopting sustainable practices:

Eco-friendly Materials: Many are using recycled materials, sustainably sourced wood, and non-toxic finishes to reduce their environmental footprint.

Circular Economy: Some manufacturers are embracing the circular economy model, designing furniture that can be easily disassembled, recycled, or repurposed at the end of its life cycle.

Consumer Engagement and Customization Modern furniture manufacturers in uae are focusing on consumer engagement through:

E-commerce: Many have expanded their reach through online platforms, offering consumers a wider selection and the convenience of shopping from home.

Personalization: They are increasingly offering customizable options, allowing consumers to tailor furniture to their specific needs and preferences.

Challenges and Future Trends The furniture manufacturing industry faces several challenges, including:

Global Competition: Intense competition from low-cost producers in emerging economies.

Changing Consumer Preferences: Shifting tastes and the rise of minimalism and multifunctional furniture.

Technological Disruption: The need to keep pace with advancements in materials science, automation, and digital design tools.

Conclusion furniture manufacturers in uae are essential players in the global economy, driving innovation, supporting employment, and meeting the diverse needs of consumers and businesses. As the industry evolves, manufacturers must adapt to changing market dynamics, embrace sustainability, and leverage technology to remain competitive. Their role in shaping the spaces where we live, work, and play underscores their importance in modern society.

0 notes

Text

TAIZHOU HUANGYAN SHINE MOULD CO. LTD. has invested more than 10M USD in the various plastic mould tooling and machining equipment. Now, we have CAD/CAM/CAE system and advanced processing equipment, such as CNC lathes(6000RPM), Japan Sodick electric discharge machining, and slow-feeding NC wire-cut machine.

0 notes

Text

Know About The CNC Machining In Details

Computer numerical control, or CNC, machines are becoming essential components of the manufacturing and production sectors, found in anything from small workshops to massive industrial complexes. The term numerical control was all that was used to describe CNC machining back then. This was an earlier system without computers that could be programmed. CNC, which stands for “computer numerical…

View On WordPress

1 note

·

View note

Text

Gate Valve Symbols and Pipeline Instrumentation Diagrams: from Design to Manufacturing in China

In industrial pipeline systems, valves are the core components that control fluid flow, and gate valves and check valves are one of the most common types. Whether it is design engineers, procurement personnel or maintenance teams, they need to understand the symbol representation of these valves in pipeline instrumentation diagrams, as well as how to choose high-quality gate valve manufacturers and suppliers. This article will deeply analyze the gate valve symbols, check valve symbols and their meanings in PID diagrams, and explore China’s advantages as an important gate valve manufacturer in the world.

Sample of Valve Symbols in Pipeline Instrumentation Diagrams

Gate Valve Symbols and Check Valve Symbols

1. Gate valve symbol analysis

In the PID diagram, the gate valve symbol is usually composed of the following elements: - Vertical lines: Represents the main structure of the valve body. - Horizontal wedge gate: Symbolizes the opening and closing components of the gate valve, which controls the flow of fluid through lifting and lowering movements. - Handwheel or actuator symbol: Marked on the top of the valve body, indicating manual or automatic operation mode. - Flow direction arrow (optional): Indicates the allowed direction of the fluid.

Example: - Manual gate valve: A horizontal wedge is added in the middle of the vertical line, and the handwheel symbol is marked on the top. - Electric gate valve: Add a motor icon next to the wedge symbol.

2. Check valve symbol analysis

Check valve‘s symbol design emphasizes its unidirectional flow characteristics: - Triangle or arrow: Points to the direction of allowed flow. - Vertical line or spring symbol: Indicates the mechanism of automatic closing of the valve.

Example: - Swing check valve: An arc line is added next to the arrow to indicate the swing of the valve disc. - Lift check valve: vertical line with lift disc symbol.

2. Importance of Piping and Instrumentation Diagram Symbols

PID diagram is the “blueprint” of industrial process design, which clearly expresses pipelines, valves, instruments and control logic through standard symbols. The significance of using symbols correctly is:

1. Improve communication efficiency: The globally common symbol system avoids language and technical misunderstandings. 2. Ensure safety: Clearly mark valve types and functions to prevent operating errors. 3. Optimize maintenance processes: Quickly locate equipment through symbols to reduce downtime.

Common symbol standards: - ISO 10628: Internationally common flowchart symbol standard. - ANSI/ISA 5.1: Detailed symbol specifications developed by the American Instrument Association.

Global Competitiveness of Chinese Gate valve Manufacturers

As an important production base for industrial valves in the world, China’s gate valve factories and manufacturers dominate the market with the following advantages:

1. Technology and manufacturing capabilities

- Material innovation: Adopt corrosion-resistant materials such as high-strength alloy steel and stainless steel to adapt to high temperature and high pressure environments. - Precision machining: CNC machine tools and automated production lines ensure the sealing and durability of valves. - Complete certification: Meet international standards such as API 600 and ISO 9001 to meet the needs of global customers.

2. Cost advantage

- Scaled production: Reduce unit costs through mass production and provide **competitive prices**. - Supply chain integration: Localized raw material procurement and logistics networks further reduce costs.

3. Customized service

- Non-standard design: Support customers to customize valve size, pressure level and connection method. - Fast delivery: Perfect inventory management and efficient production cycle to meet urgent needs.

4. Global supply network

Chinese gate valve suppliers expand international markets through the following ways: - Cross-border e-commerce platforms: such as Alibaba International Station, directly connect with overseas customers. - Localized services: Set up warehousing and after-sales centers in North America, Europe, and the Middle East.

How to choose a high-quality Chinese Gate Valve Supplier

1. Verify qualifications and reputation - Check whether the company holds API, CE and other certifications. - Understand customer feedback through third-party platforms (such as Google Reviews).

2. Request sample testing - Test the sealing, pressure resistance and service life of the valve.

3. Pay attention to after-sales service - Ensure that the supplier provides technical support and fast repair services.

4. Compare prices and delivery dates - Avoid choosing suppliers whose quotations are far below the market level (there may be quality problems).

Application scenarios and selection recommendations for gate valves

1. Typical application areas

- Oil and gas: used for pipeline opening and closing and flow control. - Chemical industry: special gate valves that withstand corrosive media. - Water treatment system: large-diameter gate valves are used in reservoirs and water pipelines.

2. Key selection parameters

- Pressure level: such as Class 150, Class 300. - Connection method: flange, welding or threaded connection. - Operation method: manual, electric or pneumatic.

Conclusion

From the gate valve symbol in the PID diagram to the valve selection in actual application, each step directly affects the safety and efficiency of the industrial system. As the world’s leading gate valve manufacturer, China has become the first choice for international procurement with its technical strength and cost advantages. Whether you are an engineer, a purchaser or a project manager, choosing a reliable China gate valve supplier will be the key to ensuring the success of the project.

#ball valve manufacturers in india#ball valve suppliers#butterfly valve#esdv#ball valve#check valve#gate valve#gate valve manufacturers#globe valve#plug valve

0 notes

Text

🛠️ Aircraft Brackets: Market Expansion to $1.5B by 2034!

Aircraft Brackets Market is projected to expand from $0.9 billion in 2024 to $1.5 billion by 2034, growing at a CAGR of approximately 5.2%. This market is integral to the aerospace industry, encompassing the production and supply of structural components essential for securing various aircraft parts. These brackets play a critical role in ensuring structural integrity and safety, making them indispensable in aircraft assembly and maintenance.

To Request Sample Report: https://www.globalinsightservices.com/request-sample/?id=GIS31475 &utm_source=SnehaPatil&utm_medium=Article

Key Growth Drivers

The market’s growth is driven by:

Technological advancements in materials and manufacturing processes.

An increasing focus on lightweight and fuel-efficient aircraft.

Expanding commercial aviation fleets and defense modernization programs.

The commercial aviation segment leads the market, supported by the rising demand for lightweight, durable components. Military aviation follows as the second-highest performing sub-segment, driven by the acquisition of advanced aircraft and defense upgrades.

Regional Insights

North America dominates the market, benefiting from a strong aerospace industry and continuous innovation in aviation technology. The region is home to leading aircraft manufacturers and suppliers, driving demand for high-performance brackets.

Europe is the second-leading region, with significant contributions from Germany and France, known for their advanced aerospace manufacturing capabilities.

Asia-Pacific is rapidly gaining traction, fueled by increasing air traffic and investments in aviation infrastructure. Countries like China and India are emerging as major players due to growing commercial aviation demand.

Market Segmentation

The Aircraft Brackets Market is segmented by:

Type: Fixed Brackets, Adjustable Brackets, Hinged Brackets

Product: Engine Brackets, Fuselage Brackets, Wing Brackets, Tail Brackets, Landing Gear Brackets

Material Type: Aluminum, Titanium, Stainless Steel, Composite Materials

Technology: Additive Manufacturing, CNC Machining, Casting, Forging

End User: OEMs, Aftermarket, MRO (Maintenance, Repair, and Overhaul)

Competitive Landscape

Key players in this market include Arconic Inc., Precision Castparts Corp., and TriMas Corporation, each holding substantial market shares. Arconic Inc. leads with innovations in lightweight solutions, while Precision Castparts focuses on high-strength components. TriMas Corporation is recognized for its advanced manufacturing processes and extensive product range.

The Aircraft Brackets Market is poised for steady growth, driven by advancements in additive manufacturing, increasing adoption of composite materials, and a growing demand for fuel-efficient aircraft. As aviation technology evolves, the market offers lucrative opportunities for stakeholders, emphasizing innovation and sustainability.

#AircraftBrackets #AerospaceInnovation #AviationTechnology #LightweightComponents #FuelEfficiency #CommercialAviation #MilitaryAviation #AerospaceManufacturing #StructuralIntegrity #AircraftAssembly #AerospaceMaterials #CompositeBrackets #AdditiveManufacturing #CNCMachining #AerospaceComponents #AviationGrowth #AerospaceIndustry #AviationSafety #AerospaceEngineering #FlightEfficiency #AdvancedManufacturing #AerospaceInnovation #AirTrafficGrowth #AviationInfrastructure #AircraftMaintenance #AerospaceOEM #MROIndustry #DefenseAviation #AerospaceTrends #AviationSustainability #FutureOfFlight

0 notes

Text

Transforming Precision into Performance: The Future of Automotive Parts

High-precision CNC machining is shaping the future of automotive manufacturing. 🚗💡 In this post, we dive into how automating the production process is revolutionizing the industry, offering:

✅Unmatched precision for complex automotive components ✅Faster production with high-quality results every time ✅Customization for performance-driven parts at scale

Experience how automated CNC machining is driving innovation and efficiency in the automotive sector. From engine components to suspension parts, perfection is automated, one part at a time. 🔧⚙️

🔑 Pro Tip: Automation isn't just about speed—it's about achieving consistent quality across every part.

What automotive innovations are you excited about? Share your thoughts in the comments!

CNCmachining #AutomotiveParts #PrecisionEngineering #InnovationInMotion #TechDrivenManufacturing #FutureOfAutomotive #AutomatedManufacturing #EfficiencyInMotion #industry4_0

Contact Us Get More Info: GreatLight Metal Technology Co., Ltd

✅ Website: https://glcncmachining.com/ ✅ Website: https://cnc-5-axis.com/ ✅ #10, Xinrong Street, Chongtou Community, Chang'an Town, Dongguan City, Guangdong, China, 523845 ✅ + 86 180 2756 7310 ✅ + 86 180 2756 7310(whatsapp) ✅ [email protected]

0 notes

Text

API6D Valve Components

ACE Valve located in Yancheng, Jiangsu Province is a customer-centric manufacturer of professional valve components used in oil and gas, chemical power generation, and mining. water treatment and general industrial systems. our main products are valve bodies. closures, seat rings bonnets, trunnion plates, stems, top flanges, and other accessories. Machining Manufacturers and Machining Company in China. our facilities allow us to manufacture valve assemblies from 1/2-56"it has a group of dedicated and professional staff with ten years of experience in the production line, factory management, and quality control marketing. etc. We are equipped with more than 50 sets of advanced processing equipment including CNC machine tools, and CNC machining centers. lathes, etc., and testing equipment.

Information Mobile/Whatsapp/Wechat: +86 - 15722580267 Tel: +86 - 15722580267 Email: [email protected] Address: No. 1 Shenfeng Rd. Dafeng Economic Zone, Jiangsu, P.R.China.

0 notes

Text

Operational Technology Market Dynamics: Growth Drivers and Challenges

The global operational technology market size is expected to reach USD 364.74 billion by 2030, growing at a CAGR of 10% from 2024 to 2030, according to a new report by Grand View Research, Inc. The increased demand for operational technologies (OT) security solutions arises from the growing dependence on digital technologies within industrial systems, resulting in heightened vulnerability of OT systems to cyber threats. Furthermore, the imposition of strict government regulations, such as the cybersecurity framework aimed at enhancing industrial control systems (ICS), compels organizations to implement extensive OT security protocols. Moreover, the integration of IT and OT systems leads to increased interconnectedness, thereby exposing OT systems to cyber threats originating from IT networks. Consequently, there is an escalating need for resilient OT solutions to safeguard vital industrial processes against potential cyber risks.

Operational technologies enable direct control and monitoring of devices, processes, and events within the physical environment. Examples include DCS, SCADA, PLCs, BMS, CNC systems, and more. These technologies operate critical infrastructure such as manufacturing plants, power plants, and water treatment facilities, ensuring efficient and secure management of industrial processes. They are integral components of various essential systems in modern society, playing crucial roles in maintaining functionality and reliability while safeguarding against potential disruptions and hazards.

In the dynamic operational technology market, the competitive environment is in constant flux, prompting companies to continually innovate and develop fresh growth strategies to uphold their market leadership. Key players prioritize research and development to craft advanced security solutions infused with AI and machine learning. For instance, Huawei Technologies Co., Ltd. is poised to transform manufacturing by spearheading the integration of Information and Communications Technologies (ICT) and Operational Technologies (OT) to enable smarter production processes. In alignment with global initiatives such as Germany's Industry 4.0, China's Made in China 2025, and the US's Industrial Internet, Huawei is at the forefront of driving digitalization across every manufacturing sector.

In North America, operational technology serves as a cornerstone of industrial operations, supporting sectors including manufacturing, transportation and logistics, and healthcare. With a focus on efficiency and reliability, OT systems in North America are integral for maintaining critical infrastructure and ensuring smooth production processes. Companies in sectors such as automotive, aerospace, and energy rely heavily on OT to streamline operations and minimize downtime. As technological advancements continue to reshape industries in North America, the integration of OT with emerging technologies such as AI and automation holds the promise of further optimizing performance and driving innovation. Meanwhile, in the Asia Pacific region, operational technology plays a central role in fueling the rapid industrialization and economic growth of emerging economies.

Operational Technology Market Report Highlights

Computer Numerical Control (CNC) technology stands out as a dominant force within the operational technology market. Its widespread adoption across various industries, including manufacturing, aerospace, and automotive, highlights its significance in driving precision, automation, and efficiency in industrial processes

The wired segment is experiencing significant growth in 2023. This preference for wired solutions highlighted the reliability, security, and consistent performance that wired technologies offer, particularly in critical industrial settings where uninterrupted connectivity is paramount

The large enterprises segment has gained dominance in the market, with a significant market share in 2023. Their ability to invest in and implement advanced OT solutions is greater than that of smaller businesses, allowing them to streamline operations and enhance efficiency on a larger scale

The discrete Industry segment secured dominance in the market, capturing a substantial market share by 2023. OT solutions customized for discrete manufacturing environments offer capabilities such as real-time monitoring, quality control, and production optimization, which are essential for maximizing efficiency and ensuring product quality

Advancements in AI and machine learning are driving growth in the market. These technologies enable OT systems to swiftly analyze extensive data sets and generate actionable insights in real time. As a result, businesses can make informed decisions more efficiently, leading to enhanced productivity and overall performance

With the increasing connectivity of industrial systems and the rise of IoT devices, the vulnerability to cyber threats has become a significant concern for businesses. As a result, there's an increased focus on integrating robust cybersecurity measures into OT solutions to protect critical infrastructure and sensitive data

Operational Technology Market Segmentation

Grand View Research has segmented the global operational technology market based on component, connectivity, deployment, enterprise size, industry, and region:

Operational Technology (OT) Component Outlook (Revenue, USD Billion, 2017 - 2030)

Supervisory Control and Data Acquisition (SCADA)

Programmable Logic Controller (PLC)

Remote Terminal Units (RTU)

Human-machine Interface (HMI)

Others

Distributed Control System (DCS)

Manufacturing Execution System (MES)

Functional Safety

Building Management System (BMS)

Plant Asset Management (PAM)

Variable Frequency Drives (VFD)

Computer Numerical Control (CNC)

Others

Operational Technology (OT) Connectivity Outlook (Revenue, USD Billion, 2017 - 2030)

Wired

Wireless

Operational Technology (OT) Deployment Outlook (Revenue, USD Billion, 2017 - 2030)

Cloud

On-premises

Operational Technology (OT) Enterprise Size Outlook (Revenue, USD Billion, 2017 - 2030)

SMEs

Large Enterprises

Operational Technology (OT) Industry Outlook (Revenue, USD Billion, 2017 - 2030)

Process Industry

Oil & Gas

Chemicals

Pulp & Paper

Pharmaceuticals

Mining & Metals

Energy & Power

Others

Discrete Industry

Automotive

Semiconductor & Electronics

Aerospace & Defense

Heavy Manufacturing

Others

Operational Technology (OT) Regional Outlook (Revenue, USD Billion, 2017 - 2030)

North America

US

Canada

Europe

UK

Germany

France

Asia Pacific

China

Japan

India

South Korea

Australia

Latin America

Brazil

Mexico

Middle East and Africa

Kingdom of Saudi Arabia (KSA)

UAE

South Africa

Order a free sample PDF of the Operational Technology Market Intelligence Study, published by Grand View Research.

0 notes