#cnc aluminium cutting

Explore tagged Tumblr posts

Text

Looking for Best CNC Laser Cutting Service in Vadodara?

Searching for CNC Metal Cutting Service? Mahavir Enterprise is an trusted CNC design cutting in Vadodara. We provides various types of CNC laser cutting services such as, CNC aluminium cutting, CNC metal cutting service, brass CNC cutting service, brass CNC cutting service, etc. Call us today!

#cnc cutting in vadodara#cnc cutting vadodara#cnc design cutting vadodara#Best CNC Laser Cutting Service in vadodara#CNC Laser Cutting Service in vadodara#CNC Laser Cutting Service vadodara#CNC Laser Cutting Services in Vadodara#cnc laser cutting#cnc laser cutting services#cnc metal cutting service#cnc sheet metal cutting#cnc aluminium cutting#cnc for aluminium cutting#brass cnc cutting service#metal sheet cnc cutting

0 notes

Text

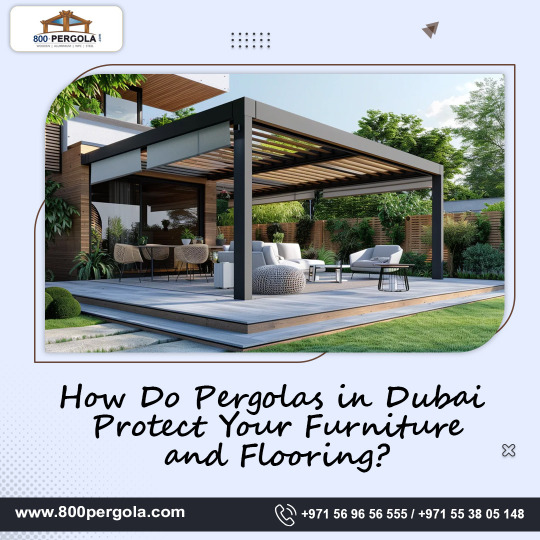

How Do Pergolas in Dubai Protect Your Furniture and Flooring?

The al fresco patio lifestyle in Dubai is flourishing with all residents making the most out of their exterior space at any time of the year. Be it a large backyard, a top roof, or a small corner in the garden, the right fitting outdoor structure can be of great use in the making and utility of the space. Though in the case of Dubai, its persistent sunshine, occasional sandstorms, and climatic conditions that are extreme, there is the issue of the safety of your outdoor furniture and flooring. Under such circumstances, adding a pergola is one such idea that is both decorative and practical. So how do pergolas in Dubai serve the purpose of shielding the outdoor furniture and flooring from damage? Let’s find out.

The Harsh Weather Conditions in Dubai

The climate of Dubai is characterized by extreme temperatures especially during summer season where the sun is so intense. Most outdoor furniture and flooring, and particularly those with wooden and other soft materials, may get impaired or damaged upon prolonged use in high temperatures and direct sunlight. In addition, outdoor investments are likely to get worn out with sandstorms as well as occasional rain.

Most importantly, pergolas also offer shelter and shade which helps in creating a favorable environment for different activities thus protecting the elements from outdoor patio furniture. Such structures do not only reduce the amount of direct sunlight getting into your space and protect you from extreme weather conditions, but they also help in preserving your outside deck and patio furniture for some longer period, thus making it possible to use the space in a decent manner.

How Pergolas Provide Shade and UV Protection ?

Pergolas primarily safeguard the outdoor furniture and flooring by means of shade. The pergola’s overhead slatted roof design allows light into the roofing while filtering sunlight penetrating underneath. There are high levels of Ultraviolet rays in the sun that can be harmful and are responsible for causing discoloration of the fabric, warping of wood, and deterioration of other material over time.

When installing a pergola in Dubai, it is advisable to consider some top quality materials such as aluminium and treated wood alongside the designer aspects. As the #1 pergola manufacturer company in Dubai, we appreciate the need to source for components that not only beautify the pergola but also have structural integrity to endure the unfriendly climatic conditions. There are also other types of pergolas such as those with retractable canopies and bioclimatic louvered roof which offer additional flexibility as the user can control the amount of sun or shade desired as per the climatic conditions.

Protection Against Rain and Sandstorms

Dubai is often touted as having sunny weather almost all through the year. Rain, however, has its own implications especially in the cooler months. There may not be much rain but when it does, it is strong enough to soak outdoor cushions, wet wooden furniture, and spoil even deck tiles and other composite surfaces. A pergola is able to offer only so much from the falling rain, at least in lessening the dampness of the outdoor area.

Moreover, due to its geographical conditions, sandstorms sweep across Dubai frequently, where the sand tends to be quite coarse, which destroys your simple furniture and floors. Wind and sand are mostly what outdoor furniture and fixtures will be exposed to thanks to the windbreak effect puddling of the. Furthermore, soft furnishings are again either side screens or curtains around the handrail which reduces the dust contact when the dust is blown.

Increasing the Longevity of Outdoor Flooring

Just like furniture, even outdoor flooring is not immune to external forces. If a wooden deck is kept in direct sunlight for longer periods of time it will begin to crack, discolor or warp and stone tiles on the other hand might get faded and overheated. This is where lying out a structure like a pergola becomes effective by blocking some rays of sunshine and easing the burden on the flooring materials.

In particular, the wear of the systems becomes much less if there are installed wooden, composite or even stony pavings under the pergola. As the best pergola construction company in UAE, we have designs that provide both shade and protection from the rains without restriction. This helps to protect your outdoor flooring without compromising on its appearance or the design of your garden or patio.

Customizable Pergolas for Ultimate Protection

It is interesting to note that not all pergolas are constructed in the same manner. Since design and materials can be flexible, you can easily design your pergola to best suit the needs of your outdoor setting. Depending on the space available and the needs at hand, it would be possible to go for a conventional slatted design or even an up to date bioclimatic model with adjustable blades.

Bioclimatic pergolas will give the perfect peace of mind as they enable you to dictate the amount of light, wind or even water that comes into your outdoor area. These designers use motorized roofs that can either tilt or retract depending on the weather in order to protect interior furnishings and wooden flooring.

Because of Dubai’s changing weather standards, it is important to invest in a pergola that suits your preferences. In cases where you want to keep a deck and elaborate outdoor dining set or lounge chairs, pergolas come with extra elements like enclosing curtains, retractable roofs or sun-proof materials that can help bring great preservation of outdoor investments.

Enhancing Your Outdoor Space’s Aesthetic Appeal

Though a pergola may primarily act as a safeguard for your furnishing and flooring, it equally plays the role of an enhancement to the outdoor space. A simple patio can be made more sophisticated and useful with the addition of a tasteful pergola which in turn brings out both warmth and elegance.

Moreover, pergolas can serve as a welcome feature for entertaining, lounging, or dining outside. You can also create an outdoor living area to enjoy the pleasant sunshine in Dubai without any fear of ruining the indoors by making the space shaded and cozy.

Conclusion

Given the love for outdoor spaces in a city like Dubai where the weather is extreme, the addition of a pergola is a smart choice. It beautifies the lawn or patio in addition to providing protection for the outdoor furnishings and their flooring. The features of pergolas are the covers that help block out the sun’s harmful rays, the showers, and even the sandstorm helping the outdoor features and furniture remain in good condition for many years.

If you want to put up a pergola, working with Top pergola contractors in Dubai, will guarantee you the best quality materials, design, and installation standards. At 800 Pergola, we design and build beautiful and functional pergolas that are suitable for the hot and windy weather of Dubai.

To find out more on how our pergolas can protect your outdoors and make your life better get in touch with 800Pergola on +971 56 96 56 555.

OFFICE Address –

Office #60, M. Floor, Al Fajer Building, Airport Road, Al Garhoud, Dubai- United Arab Emirates

Mobile: 056 96 56 555 / 055 380 5148

Email: [email protected]

Website - https://800pergola.com/

Our Social Media Presence –

Facebook - https://www.facebook.com/800pergola

Instagram - https://www.instagram.com/800pergola/

LinkedIn - https://www.linkedin.com/company/800pergola

#Top pergola suppliers in UAE#best pergola suppliers in Dubai#Trusted pergola contractor in AlZahia#Stylish pergola developers in Abu Dhabi#Leading pergola designers in Dubai#Top pergola manufacturers in Villa Nova#Affordable pergola builders in dubai#Commercial pergola professionals in Emirates Hills#Residential Pergola Sub contractors UAE#leading Retractable pergola manufacturers in Dubai#commercial Aluminium pergola professionals in Dubai#1 Wooden pergola contractor in Dubai#Residential Thermowood pergola pprofessionals UAE#top Bioclimatic pergola developers in Damac Hills#top smart pergola developers in UAE#Best CNC Cut pergola suppliers in Abu Dhabi#Best motorized pergola Builders in Sharjah#Premium Pergola developers in UAE#800 Pergola#Outdoor Shade#Outdoor pergola#Pergola#Best Pergola company in UAE#Reliable pergola professionals in UAE#Pergola Experts in Dubai#Pergola service providers in Dubai#Pergola services in Dubai marina#best Pergola providers in Alsafa

0 notes

Text

Custom Aluminum CNC Cutting Services

youtube

Want to hire top-notch aluminum CNC cutting services? Reach out to Createproto Rapid System Limited; they offer custom CNC cutting & machining services to meet your specific needs.

0 notes

Text

How to Choose the Best Aluminum Die Casting Supplier?

When selecting the best aluminum die casting supplier for your project, there are many factors that need to be taken into consideration.

As the aluminum die casting process is often used to produce parts with more intricate shapes and sizes, selecting the right supplier is essential for achieving the desired results.

Here are some tips to help you choose the best aluminum die casting supplier for your project. The first step in choosing an aluminum die casting supplier is to research their experience and qualifications.

Look for a supplier that is knowledgeable about the specific type of aluminum die casting that you need for your project.

It is also important to ensure that the supplier has the necessary certifications and accreditations, such as ISO 9001 and AS 9100.

The next step in selecting an aluminum die casting supplier is to evaluate their quality control processes. Quality control is essential in aluminum die casting, as it ensures that parts are produced to the highest standards and meet your specifications.

Make sure the supplier you choose has a robust quality control system in place to ensure that your parts are produced with the highest quality. It is also important to research the supplier’s customer service.

Ask for references from past customers and read customer reviews to get an idea of the quality of service you can expect from the supplier.

You should also ask the supplier about their turnaround times and delivery options.

Finally, consider the supplier’s pricing. Different suppliers may offer different prices, so make sure to compare quotes from multiple suppliers before making your decision.

Also, ask if the supplier offers any discounts or special offers. Choosing the right aluminum die casting supplier is essential for achieving the desired results in your project.

By following these tips, you can ensure that you select the best supplier for your project.

Make sure to research the supplier’s experience and qualifications, evaluate their quality control processes, research their customer service, and compare quotes from multiple suppliers before making your decision.

With the right supplier, you can be sure that your aluminum die casting project will be a success.

#aluminum die casting#die casting#aluminum die casting design guide#CNC machining#aluminum machining#CNC aluminum#Precision Machining#aluminium machining china#CNC cutting#CNC milling#CNC grinding#CNC welding#CNC forming#CNC stamping#CNC punching#Casting Machining#Forging Machining

1 note

·

View note

Text

CNC-Cut Pergolas: The Ultimate in Precision and Customization

Introduction

Dubai is a city that is known for its luxurious outdoor spaces, and many homeowners in the area are looking for ways to enhance their yards.

Pergolas have been a staple in outdoor architecture for centuries. These structures, traditionally made of wood or other materials, provide a shaded outdoor space perfect for relaxing or entertaining guests. However, with the advent of computer numerical control (CNC) technology, pergolas have taken on a new level of precision and customization. In this blog, we will explore the benefits of CNC-cut pergolas and highlight reliable CNC-cut pergola developers and manufacturers in Dubai, including 800 PERGOLA, one of the top pergola suppliers in the region.

What is CNC technology?

CNC technology is a process that involves using a computer program to control the movement of machines. This technology has revolutionized the manufacturing industry, allowing for the precise and consistent production of complex designs. CNC machines can be used to cut, shape, and carve materials like wood, metal, and plastic, making them versatile solutions for many industries.

Where We Can Use CNC-Cut Pergolas?

CNC-cut pergolas can be used in a variety of settings, including residential backyards, commercial spaces, parks and public spaces, rooftops, and garden centers. They provide a versatile and functional outdoor structure that can be customized to fit the unique needs and style of any space.

Here are some examples of where you can use CNC-cut pergolas:

Residential Backyards: CNC-cut pergolas are a great addition to any residential backyard. They can provide shade, privacy, and comfortable outdoor living space for homeowners to enjoy.

Commercial Spaces: Many commercial spaces, such as hotels, restaurants, and cafes, use CNC-cut pergolas to create an inviting outdoor space for customers. These structures can be customized to fit the unique branding and style of the business.

Parks and Public Spaces: Parks and public spaces can benefit from the addition of CNC-cut pergolas. They can provide shade and seating for visitors, making these spaces more comfortable and enjoyable.

Rooftops: Rooftops can be transformed into beautiful outdoor spaces with the addition of CNC-cut pergolas. These structures can provide shade and privacy, as well as a stunning view of the city.

Garden Centers: Garden centers can use CNC-cut pergolas to showcase their plants and products in an outdoor setting. These structures can also provide a comfortable space for customers to relax and enjoy the scenery.

Benefits of CNC-Cut Pergolas

CNC-cut pergolas offer several benefits over traditional pergolas. Here are just a few of the benefits of choosing a CNC-cut pergola:

Precision: CNC machines can cut materials with incredible accuracy, which means that pergolas can be made to exact measurements.

Customization: With CNC-cut pergolas, homeowners can choose from a wide range of designs and customize their pergolas to fit their exact needs.

Durability: CNC-cut pergolas are made using high-quality materials, which means that they are built to last.

Low Maintenance: CNC-cut pergolas require little maintenance, which means that homeowners can enjoy their outdoor space without spending a lot of time on upkeep.

800 PERGOLA uses state-of-the-art CNC machines to ensure that your pergola is built to your exact specifications. They offer a variety of materials, including wood, metal, and polycarbonate, and their designs can be customized to fit any style. Whether you want a traditional wooden pergola or a sleek metal design, their team can make it happen.

In addition to their CNC-cut pergolas, 800 PERGOLA also offers a range of other outdoor structures, including gazebos, carports, and sunshades. They also provide installation services to ensure that your pergola is properly installed and structurally sound.

Why Choose 800 PERGOLA?

There are several reasons why 800 PERGOLA should be your first choice for CNC-cut pergolas in Dubai. Here are just a few:

Quality: 800 PERGOLA uses only the highest quality materials and CNC machines to ensure that your pergola is built to last. Their team of experts has years of experience in the industry, so you can trust that your project is in good hands.

Customization: 800 PERGOLA offers a range of customization options, including materials, designs, and colors. This means that you can create a pergola that fits your specific needs and style.

Affordability: Despite their high-quality products and services, 800 PERGOLA offers competitive pricing. They understand that a pergola is an investment, and they want to make it accessible to everyone.

Customer Service: 800 PERGOLA values its customers and strives to provide the best possible service. Their team is always available to answer any questions or concerns you may have, and they work closely with you throughout the entire process.

Conclusion

To sum up, if you’re looking for a precise and customized outdoor structure that offers durability and low maintenance, then CNC-cut pergolas are the ultimate solution for you. With their unparalleled precision and customization options, CNC-cut pergolas provide several advantages over traditional pergolas. Homeowners in Dubai can rely on the expertise of top-notch pergola suppliers such as 800 PERGOLA to help create the perfect outdoor space that meets their unique needs and style. Choose CNC-cut pergolas to elevate the beauty and functionality of your outdoor space.

Read More :CNC Cut Pergola – The New Trending Pergola

#aluminium pergola uae;#CNC cut pergola developer in dubai#CNC Cut Pergola#cnc cut pergola suppliers in dubai#luxurious pergola developers;#pergola development company in dubai

0 notes

Text

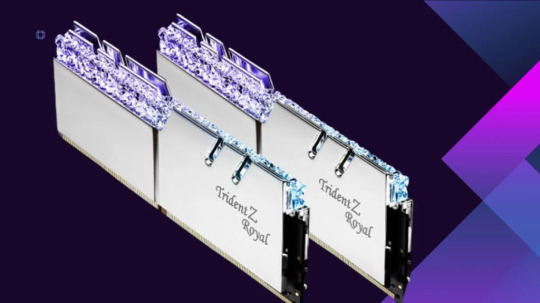

G.SKILL Trident Z5 Royal DDR5 RAM Brings Bling to Your PC

G.SKILL Trident Z5 Royal DDR5 RAM

The highly anticipated Trident Z5 Royal series of high-performance overclock DDR5 memory is now available from the world’s leading brand of performance overclock memory and PC components.

The Trident Z5 Royal is the pinnacle of the flagship Trident Z5 product family, showcasing a full-length crystalline light bar with a mirrored-finish heatspreader in gold or silver. The Royal Design is back.

The dazzling mirrored-finish heatspreader in gold or silver colour and the crystalline light bar design for an amazing RGB lighting display are traits passed down from its DDR4 predecessor. The Trident Z5 Royal brings luxury-class design to the new generation of DDR5 memory under the Trident Z5 design. Every heatspreader has an exquisite design worthy of its royal name because it is CNC-cut from aluminium and electroplated.

G.SKILL Trident Z5 Royal

Performance RGB Memory Overclocked

The Trident Z5 Royal, designed for overclocked performance, will be available in various configurations with kit capacities up to 96GB (2x48GB), as well as an extreme DDR5-8400 CL40 with 48GB (2x24GB) kit capacity. Additionally supported are third-party motherboard lighting programmes and the G.SKILL Trident Z Lighting Control software for customisable RGB lighting.

Intel XMP 3.0 Availability & Support

In late May 2024, G.SKILL’s global distribution partners will begin to receive the new Trident Z5 Royal series DDR5 memory kits, which support the most recent Intel XMP 3.0 memory overclocking profile enabling simple memory overclocking via the motherboard BIOS.

DDR5-8400 CL40

The memory can run at overclocked speeds up to DDR5-8400 CL40 thanks to its architecture. It also has capacities of up to 96 GB (two 48 GB capacities). The Trident Z5 Royal facilitates overclocking by supporting the AMD EXPO and Intel XMP 3.0 platforms.

The following are some of the Trident Z5 Royal Series DDR5 Memory’s salient characteristics:

Elegant style including heat spreaders in gold or silver with a mirrored finish

Long-lasting crystalline light bar with RGB lighting customisation

Designed to operate at overclocked speeds, reaching DDR5-8400 CL40

96 GB of capacity is possible (2×48 GB)

Compatible with AMD and Intel platforms

Supports AMD EXPO and Intel XMP 3.0 for simple overclocking

Trident Z5 Royal DDR5 RAM from G.SKILL is beautifully designed and overclocked.

Its qualities include:

Luxury Design: The Trident Z5 Royal has a full-length crystalline light bar and a gold or silver mirrored heat spreader for RGB lighting. High-frequency overclocking: The 48 GB memory kits (2 x 24 GB) can be adjusted to DDR5-8400 CL40. This allows RAM overclocking, enhancing computer performance. Configurable RGB Lighting: Third-party motherboard lighting software or G.SKILL’s Trident Z Lighting Control programme can change the crystalline light bar’s colours and effects. Built for heavy use: The Trident Z5 Royal can handle gaming and computing. Trident Z5 Royal Series DDR5 Memory is elegant and powerful. Trident Z5 Royal is a high-performance DDR5-compatible system.Trident Z5 Royal performs best with DDR5.

Overclockers and hobbyists use G.Skill’s Trident Z5 Royal Series DDR5. Luxury features include gold or silver mirrored heat spreaders and a full-length crystalline light bar for RGB lighting adjustment.

Trident Z5 Royal Series DDR5 Memory specs:

Memory type DDR5

DDR5-8400 CL40+ speeds

Up to 96GB (2x48GB)

RGB lighting can be customised using third-party motherboard lighting software or G.SKILL Trident Z Lighting Control.

Aluminium heatspreader with silver or gold mirror finish.

Gamers and hobbyists may consider the Trident Z5 Royal Series DDR5 for the best DDR5 memory performance. A luxurious memory package is another option.

High-performance DDR5-8400 CL40:

The technical terms are below. DDR5 (5th generation). This new memory standard is faster and less power-hungry than DDR4.

8400: Megahertz memory.

A 8400 MHz data transfer rate is 8400 million cycles per second.

Data transport speeds rise with MHz.

Column Address Strobe Latency (CAS) is CL40, which monitors RAM retrieval time.

Low CLs suggest faster latency.

CL latency affects RAM performance along with many other parameters.

Faster RAM with somewhat higher CL latency may outperform slower RAM with tighter CL timings.

DDR5-8400 CL40 is high-speed DDR5 with 40 CAS latency. This RAM is great for gamers, overclockers, and creatives who use 3D rendering and video editing tools.

Additional DDR5-8400 CL40 RAM considerations:

Its high-end memory specification and recent availability may make it more expensive and scarce than other DDR5 choices.

The motherboard must support DDR5-8400 memory speeds and AMD EXPO or XMP settings for automated overclocking.

DDR5-8400 CL40 RAM costs more than DDR5.

For optimal DDR5 RAM performance, choose DDR5-8400 CL40. When buying, consider compatibility, price, and availability.

Features of DDR5-8400 CL40 memory:

The memory is DDR5.

Speed: DDR5-8400 This is memory data transmission rate. High speeds improve performance, especially in bandwidth-intensive applications.

CAS Latency:CL40: The number of clock cycles it takes memory to retrieve data after a request. Lower CLs indicate faster memory. Higher-speed DDR5 memory normally has higher CAS latency. Thus, DDR5-8400 CL40 may not be faster than DDR5-6400 CL38. When evaluating DDR5 memory, speed and CAS delay matter.

Depending on the model, DDR5-8400 CL40 memory may have these features:

Capacity: DDR5 modules hold 4GB to 128GB.

ECC memory fixes data transfer errors. ECC memory costs extra, but data-intensive servers and workstations need it.

DDR5 memory modules with RGB LEDs can show numerous colours and lighting effects.

Trident Z5 Royal Release date

The G.SKILL Trident Z5 Royal DDR5 memory’s official release date is yet unknown.

What is known as follows:

The first time it was displayed was at Computex 2023, a hardware event. A release in Q4 2023 was rumoured, but it never happened. As of May 2024, G.Skill appears to be finishing the product. Therefore, although a release date has not yet been announced, it may happen shortly. G.Skill’s announcements regarding the formal release can be followed.

Read more on Govindhtech.com

2 notes

·

View notes

Text

It is our Pleasure to introduce our company HITZE ENGINEERING PVT LTD., Which has been incorporated as manufacturing of sheet metal components Since 2019.

7 notes

·

View notes

Text

Know the Crucial Steps Involved in custom metal fabrication in Sydney?

From conception to finished product, every element of the whole process involved with custom metal fabrication in Sydney finds its essence on the basis of satisfying the requirements posed by a particular client. From initial consultation meetings to final tests, all points are equally integral to delivering good results on project completion. Hence, this article elaborates on the prime steps underlined for further emphasis.

Prime Steps To Fabricate Customised Metal:

1. Initial Consultation

The first step of custom metal fabrication is the preliminary consultation between the client and the fabrication team.

In this stage, clients discuss project requirements with the design specifications, materials, and budget constraints.

Such a dialogue is vital as it serves as the base for the whole project and provides an opportunity to set realistic expectations about timelines and costs.

2. Design Review

After completing the initial consultation, the subsequent step is design review. The client can prepare the drawings or may work with a fabricator to develop a design based on his or her requirements.

This step involves discussions about the dimension and tolerance as well as material choice. Design review ensures that everyone is on the same page before producing the product.

3. Material Selection

Choosing the correct material is the most important thing in custom metal fabrication. Among these factors are strength, resistance to corrosion, and cost.

Some of the common materials are stainless steel, aluminium, brass, and copper.

The application and environment where it is used will determine the correct material.

4. Fabrication Process

Fabrication is basically a series of operations:

Cutting: Raw materials are cut to size using techniques like laser cutting or CNC machining.

Shaping: The metal is then shaped through processes like bending or rolling to give it the required form.

Welding: The components are then joined together by welding techniques such as MIG or TIG welding.

Finishing: The finishing touches involve polishing, coating, or painting for aesthetic and durability purposes.

Each step here demands accuracy and experience to get the final output up to standard.

5. Quality Control

Quality control is not neglected during custom metal fabrication. At every production stage, a variety of checks are done to confirm that all the parts meet the industrial standards and specifications of the clients.

This may be in the form of inspection during different stages of fabrication to ascertain dimensions, finishes, and general quality.

6. Delivery and Installation

Once the fabrication is done and quality checks are passed, the finished products are delivered to the client.

Some fabrication companies also offer installation services to ensure that components are properly fitted and function as intended.

This added service can save clients time and effort while ensuring optimal performance.

Conclusion

Understanding the key steps in custom metal fabrication in Sydney is crucial for anyone looking to undertake a project requiring tailored metal solutions. From initial consultations through design reviews and quality assurance checks, each phase plays a vital role in delivering high-quality results that meet specific client needs. By following these steps diligently, businesses can ensure that their custom metal projects are executed efficiently and effectively. Custom metal fabrication enables functionality enhancement alongside creative design ability, thus remaining an important service for diverse industrial sectors in Sydney.

0 notes

Text

Summary Analysis of CNC Milling Process

In modern manufacturing, CNC milling technology is widely used for its high precision and flexibility. Whether it's a mechanical part, an automotive component, or a component for a medical device, CNC milling provides excellent machining results.

What is CNC Milling?

CNC milling is a computer-controlled machining process that utilises a rotating tool to cut a workpiece. CNC milling allows for greater accuracy and consistency than traditional manual milling. It is often combined with other machining methods (e.g. turning, drilling) to meet different and diverse manufacturing needs.

Workflow of CNC Milling

Design stage In the initial stages of CNC milling, designers use Computer-Aided Design (CAD) software to create a model of the product. Commonly used software includes SolidWorks and Autodesk, which are tools that help designers accurately draw the shape and dimensions of the desired part.

Programming stage Once the design is complete, the CAD file needs to be converted to G-code, a language that CNC machines can understand. With Computer-Aided Manufacturing (CAM) software, the design files are converted into machine-executable instructions that enable automated machining.

Machine setting During the machine set-up phase, the workpiece needs to be fixed to the table and a suitable tool selected. At the same time, the operator needs to set the initial co-ordinates to ensure accurate positioning during machining.

Advantages of CNC Milling

High precision and dimensional stability CNC milling allows for micron-level machining accuracy, ensuring consistency from part to part.

Complex shapes can be processed Whether it's a simple flat surface or a complex three-dimensional structure, CNC milling can handle it with ease.

Efficient production capacity Due to its high degree of automation, CNC milling can significantly increase productivity and shorten lead times.

Applications of CNC Milling

CNC milling technology is used in a wide range of industries, including:

Mechanical parts: Used in the manufacture of key components in a variety of mechanical equipment.

Automotive parts: High-precision parts for the automotive industry, such as engine components.

Medical device parts: Ensure the reliability and safety of medical devices.

Optical product parts: For the production of optical instruments and related products.

Frequently Asked Questions

What materials can be CNC milling machined? CNC milling is suitable for a wide range of materials, including metals (e.g. aluminium, steel), plastics, wood, and more. However, for some materials, such as ceramics or certain composites, the machining is more difficult and requires special handling.

What are the limitations of CNC milling? Despite its advanced technology, CNC milling has some limitations. For example, machining may be limited for internal vertical angles or very complex small structures.In addition, high hardness materials may lead to faster tool wear, which can affect productivity.

Comparison of CNC milling with other manufacturing technologies The advantages and disadvantages of each can be seen when comparing CNC milling with other manufacturing techniques such as 3D printing. CNC milling is generally superior to 3D printing in terms of accuracy and surface finish, but 3D printing has advantages in rapid prototyping and complex geometries. In terms of cost-effectiveness, the choice of technology depends on specific project needs and budget.

Summary

In summary, CNC milling is an indispensable manufacturing technology that plays an important role in several industries with its efficiency, precision and flexibility.

#prototyping#prototype#rapid prototyping#prototype machining#precision machining#cnc machining#cnc milling#machining parts#cnc milling 5 axis#cnc milling machining#cnc milling turning#precision cnc milling#cnc milling parts

1 note

·

View note

Text

Aluminium Welding and Fabrication: The Essential Guide

Aluminium welding is commonly used in many industries including auto manufacturing aerospace industries construction marine industries etc. This material is highly versatile because of its lightweight, high durability, and immunity to corrosion; it is a darling of manufacturers and engineers. In this article, we will analyze the possibility of welding and fabrication of aluminum materials, its advantages and disadvantages, anthe d necessary equipment and methods.

Key Characteristics of Aluminium:

Lightweight: Aluminium is about 1/3 of the density of steel.

Corrosion Resistance: To be more specific, it develops an oxide film to prevent the process of rusting.

High Thermal Conductivity: Aluminium conducts heat and hence it is not very suitable for welding procedures.

Oxide Layer: The surface oxide has a higher melting point than the base metal so exacting methods are necessary.

Common Aluminium Welding Methods:

TIG Welding (Gas Tungsten Arc Welding): Recommended for thin sections due to the accuracy and smoothness of the finish.

MIG Welding (Gas Metal Arc Welding): More appropriate for thicker materials to offer a faster rate of production.

Spot Welding: Primarily used in car manufacturing for fastening thin metals such as sheet metal.

Aluminium Fabrication Explained

Fabrication means the shaping of aluminum by processes such as cutting, bending as well as joining to produce particular parts or systems.

Fabrication Processes:

Cutting: Possible to utilize laser cutting, water jet cutting, or CNC machining if accuracy is necessary.

Bending: Aluminium sheets are bent through the use of press brakes/rollers.

Joining: This may be welding, riveting,g, or bonding together of the parts, that is, the use of adhesives to join the parts.

Finishing: Polishing anodizing, or powder coating of the outside view to improve its look and performance.

Industries Using Aluminium Fabrication:

Aerospace: Things like wings and segments of the fuselage as used in the construction of a plane.

Automotive: Fuel-efficient components for lighter cars.

Construction: Windows, doors, and roofing.

Marine: Items such as hulls of ships and structures of decks.

Benefits of Aluminium Welding and Fabrication

Aluminium is a versatile metal, which cannot be substituted in a multitude of industries and applications. Here are the key advantages:

Lightweight Yet Strong: Offers a high strength-to-weight ratio, reducing structural load.

Corrosion Resistance: Excellent for outdoor and marine applications.

Eco-Friendly: Aluminium is 100% recyclable, reducing environmental impact.

Cost-Effective: Despite higher initial costs, its durability and low maintenance make it economical in the long run.

Future Trends in Aluminium Welding and Fabrication

The industry is evolving with advancements in technology and sustainability efforts:

Automation: Robotic welding and CNC machining increase the accuracy and speed of steel production.

3D Printing: Modern manufacturing techniques such as AM are applied to highly complicated aluminum parts.

Sustainable Practices: Focus on reuse and usage of energy-saving practices and policies.

Advanced Alloys: Higher performance non-heat treatable aluminum alloy-based specific applications.

Essential Tools and Techniques

Aluminum welding and fabrication are as important as any other type of welding, but there is a stark difference in the way it has to be done.

Welding Machines: TIG and MIG welders with a pulse to enable control of the heat intensity.

Filler Materials: Base metal compatible aluminum alloy filler rods or wires.

Protective Equipment: Welding helmets gloves and clothing for safety.

Preparation Tools: Wires for brushing the oxide layer away and chemical products for washing the oxide layer off.

Clamping Systems: To keep the component in a fixed position and minimize its movement during the fabrication.

Challenges in Aluminium Welding and Fabrication

Nonetheless, aluminum holds some advantages, yet it needs expertise and tools to work because of its peculiar characteristics.

Warping and Distortion: A high ability to conduct heat can lead to parts distorting as welds are being made.

Porosity: Aluminium reacts with hydrogen and, therefore, porosity is often observed in welds.

Oxide Removal: The oxide layer has to be removed for better adhesion and this can be done through pre-weld cleaning.

Skill Requirements: Welding of aluminum requires skilled professionals and specific parameters to accomplish excellent work.

Final Thoughts

Aluminum welding and fabrication are integral to modern engineering and manufacturing. From selecting the right welding method to leveraging advanced fabrication techniques, working with aluminum requires expertise and precision. As industries push towards lighter, stronger, and more sustainable solutions, aaluminumcontinues to lead the way.For expert aaluminumwelding and fabrication services, trust DARMIS, a name synonymous with quality and innovation in the field. Visit their website to learn more about their offerings and how they can bring your projects to life.

0 notes

Text

Do you want to know about Mahavir Enterprise?

Mahavir Enterprise offer precision cutting services with CNC Laser Cutting, cnc aluminium cutting, cnc bending, cnc plasma cutting, metal fabrication Machines which can handle various materials and sizes. Ravi Industries is backbone of Mahavir Enterprise & with expertise & vast experience. Call us!

#laser cutting service provider vadodara#laser cutting service provider#cnc laser cutting#cnc aluminium cutting#cnc plasma cutting#cnc plasma service#metal fabrication vadodara#cnc bending#cnc bending in vadodara

0 notes

Text

How Do Pergolas in Dubai Protect Your Furniture and Flooring?

Discover how pergolas in Dubai protect your outdoor furniture and flooring from harsh weather conditions, UV rays, and sandstorms. Contact 800Pergola Today !

#Top pergola suppliers in UAE#best pergola suppliers in Dubai#Trusted pergola contractor in AlZahia#Stylish pergola developers in Abu Dhabi#Leading pergola designers in Dubai#Top pergola manufacturers in Villa Nova#Affordable pergola builders in dubai#Commercial pergola professionals in Emirates Hills#Residential Pergola Sub contractors UAE#leading Retractable pergola manufacturers in Dubai#commercial Aluminium pergola professionals in Dubai#1 Wooden pergola contractor in Dubai#Residential Thermowood pergola pprofessionals UAE#top Bioclimatic pergola developers in Damac Hills#top smart pergola developers in UAE#Best CNC Cut pergola suppliers in Abu Dhabi#Best motorized pergola Builders in Sharjah#Premium Pergola developers in UAE#800 Pergola#Outdoor Shade#Outdoor pergola#Pergola#Best Pergola company in UAE#Reliable pergola professionals in UAE#Pergola Experts in Dubai#Pergola service providers in Dubai#Pergola services in Dubai marina#best Pergola providers in Alsafa

0 notes

Text

As a purchasing manager responsible for acquiring sheet metal components, selecting the right supplier is crucial. Opting for bespoke sheet metal housings from V and F Sheet Metal offers numerous advantages that can significantly benefit your projects.

Tailored Precision and Design Flexibility

Bespoke sheet metal housings are custom-made to fit your product's exact dimensions and specifications. This precision ensures a perfect fit, eliminating the need for modifications that can compromise functionality or aesthetics. Unlike standard off-the-shelf options, bespoke designs provide enhanced flexibility, allowing for complex shapes, cutouts, and features tailored to your unique requirements. This adaptability is particularly beneficial in industries where precision is critical, such as lighting and electronics.

Advanced Manufacturing Capabilities

V and F Sheet Metal employs state-of-the-art equipment to deliver high-quality bespoke sheet metal housings. Their Trumpf 3030 3KW fibre laser cutting machine ensures precise and clean cuts, accommodating a wide range of sheet metal thicknesses. Additionally, their CNC bending machines, including the Safan e-Brake and Trumpf 7036, provide accurate and consistent bending to your exact specifications. These advanced technologies enable V and F to handle both low-volume prototypes and high-volume production runs efficiently.

Comprehensive Services and Expertise

With over 35 years of experience, V and F Sheet Metal offers a complete sub-contract sheet metal fabrication service. Their expertise extends to various industries, including electronics, lighting, heating, and audio. They provide services such as CNC punching, laser cutting, CNC bending, welding, and press work. Moreover, their in-house design and engineering team can assist in developing bespoke sheet metal housings that meet both functional and aesthetic requirements. This comprehensive approach ensures that all aspects of your project are handled with professionalism and expertise.

Material Versatility and Finishing Options

V and F Sheet Metal works with a wide variety of materials, including aluminium, steel, and stainless steel. This material versatility allows you to choose the most suitable option for your application, considering factors like weight, strength, and corrosion resistance. Additionally, they offer various finishing processes, such as powder coating, wet painting, and screen printing, to enhance the durability and appearance of your bespoke sheet metal housings.

Cost-Effective Solutions

While bespoke sheet metal housings may seem more expensive upfront, they can be cost-effective in the long run. By ensuring a perfect fit and reducing the need for modifications, you can minimize waste and assembly time. Furthermore, V and F Sheet Metal's advanced manufacturing processes and experienced team contribute to efficient production, potentially lowering overall costs.

Conclusion

Choosing bespoke sheet metal housings from V and F Sheet Metal provides tailored precision, design flexibility, advanced manufacturing capabilities, comprehensive services, material versatility, and cost-effective solutions. Their extensive experience and commitment to excellence make them an ideal partner for your sheet metal component needs. By collaborating with V and F, you can ensure that your projects meet the highest standards and achieve optimal performance.

0 notes

Text

A 6-KW machine is a fully automated multi-functional machine laced with CNC software. Metallic cutting thickness to upto 30mm for metallic surfaces. It includes numerous metallic materials like stainless steel, brass, aluminium, galvanised steel, etc.

#lasercuttingmachineforsale#6kwlasercuttingmachine#lasercuttingmachinemetal#lasercuttingandengraving#sslasercutting#mslasercutting

1 note

·

View note

Text

Channel Letter Bending Machine in Maharashtra

Success Technologies is a Manufacturer, and Supplier of Channel Letter Bending Machine in Maharashtra, India. Our Registered Office and Manufacturing Unit are located in Ahmedabad, Gujarat, India. A Channel Letter Bending Machine is a specialized tool used in the production of channel letters for signage. These machines precisely bend metal strips (usually aluminum or steel) to create the "C," "U," or "L" shapes that form the framework of channel letters. The process involves using hydraulic, pneumatic, or motorized systems to bend the metal into specific forms, ensuring accuracy and efficiency. Businesses can use channel letters for both illuminated and non-illuminated signs, offering flexibility to create custom signage solutions for various applications. How the Channel Letter Bending Machine Works: The working process of a Channel Letter Bending Machine is relatively simple but highly efficient: Material Loading: The operator loads the metal sheet (usually aluminum) onto the machine, which is then fed into the machine for bending. Customization: The operator configures the machine according to the specific dimensions and shape of the desired letter or number. Bending: The machine uses a combination of hydraulic or motorized bending to precisely shape the metal into the correct channel letter form. Cutting and Trimming: After the bending process, the machine cuts the metal at the desired length and trims any excess for a clean and professional finish. Assembly: The manufacturer assembles the channel letters and adds optional illumination components for enhanced visibility. Types of Channel Letter Bending Machine: CNC Aluminium Bending Machine Channel Letter Bending Machine Applications: Architectural Design Automotive Industry Aerospace Sector Retail and Display Fixtures Prototyping and R&D What materials can be bent with a Channel Letter Bending Machine? Manufacturers design Channel Letter Bending Machines to bend aluminum, stainless steel, and galvanized steel. Some models may also be suitable for other materials like brass and copper. How do I choose the right Channel Letter Bending Machine? The choice of machine depends on factors such as the volume of production, the types of signs you need to create, your budget, and the size of your operation. We recommend discussing your specific requirements with our team for personalized advice. Success Technologies is a Supplier of Channel Letter Bending Machine in Maharashtra, india Including Mumbai, Pune, Nagpur, Thane, Pimpri-Chinchwad, Nashik, Kalyan-Dombivli, Vasai-Virar, Aurangabad, Navi Mumbai, Solapur, Mira-Bhayandar, Bhiwandi-Nizampur, Jalgaon, Amravati, Nanded-Waghala, Kolhapur, Ulhasnagar, Sangli, Malegaon, Akola, Latur, Dhule, Ahmednagar, Chandrapur, Parbhani, Ichalkaranji, Jalna, Ambarnath, Bhusawal, Panvel, Badlapur, Beed, Gondia, Satara, Barshi, Yavatmal, Achalpur, Osmanabad, Nandurbar, Wardha, Udgir, Hinganghat. For more information and inquiries, feel free to contact us. View Product: Click Here Read the full article

#Achalpur#Ahmedabad#Ahmednagar#Akola#Ambarnath#Amravati#Aurangabad#Badlapur#Barshi#Beed#Bhiwandi-Nizampur#Bhusawal#Chandrapur#ChannelLetterBendingMachine#ChannelLetterBendingMachineinAhmedabad#ChannelLetterBendingMachineinGujarat#ChannelLetterBendingMachineinIndia#ChannelLetterBendingMachineinMaharashtra#Dhule#Exporter#ExporterofChannelLetterBendingMachine#Gondia#Gujarat#Hinganghat#Ichalkaranji#India#Jalgaon#Jalna#Kalyan-Dombivli#Kolhapur

0 notes

Text

Laser Cut Personalized Office aluminium cnc machine Filescnc 2024 For Free

Imagine turning your workspace into a work of art. You can design your own office accessories, just the way you like them. And you don’t have to spend a lot of money. The future of making your office your own is here, thanks to laser-cut aluminum and free vector files from Filescnc. But are you ready to make your workspace the best it can be? Laser Cut Personalized Office aluminium cnc machine

0 notes